A vertical axis wind turbine

A technology of wind power generators and vertical axes, applied in wind power generators, wind power generators at right angles to the wind direction, control of wind power generators, etc. The problems such as small flow angle of attack can achieve the effect of broadening the range of effective working conditions, reducing the drag coefficient and increasing the lift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

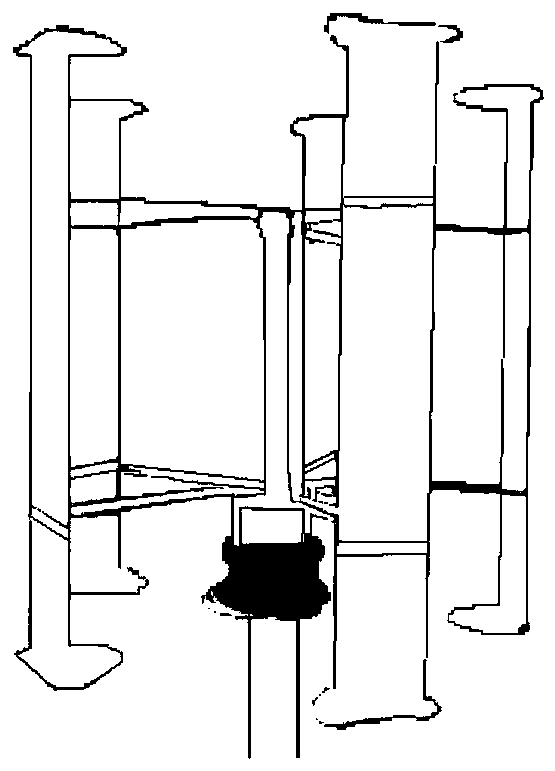

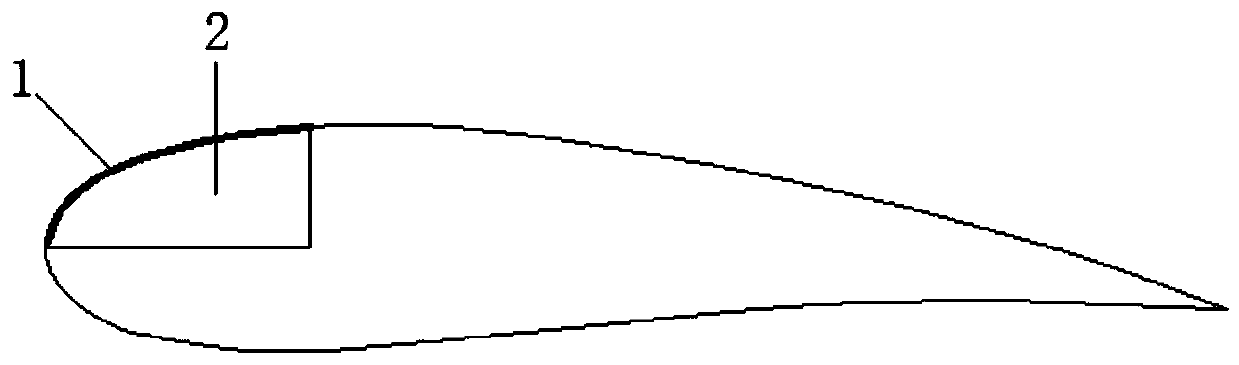

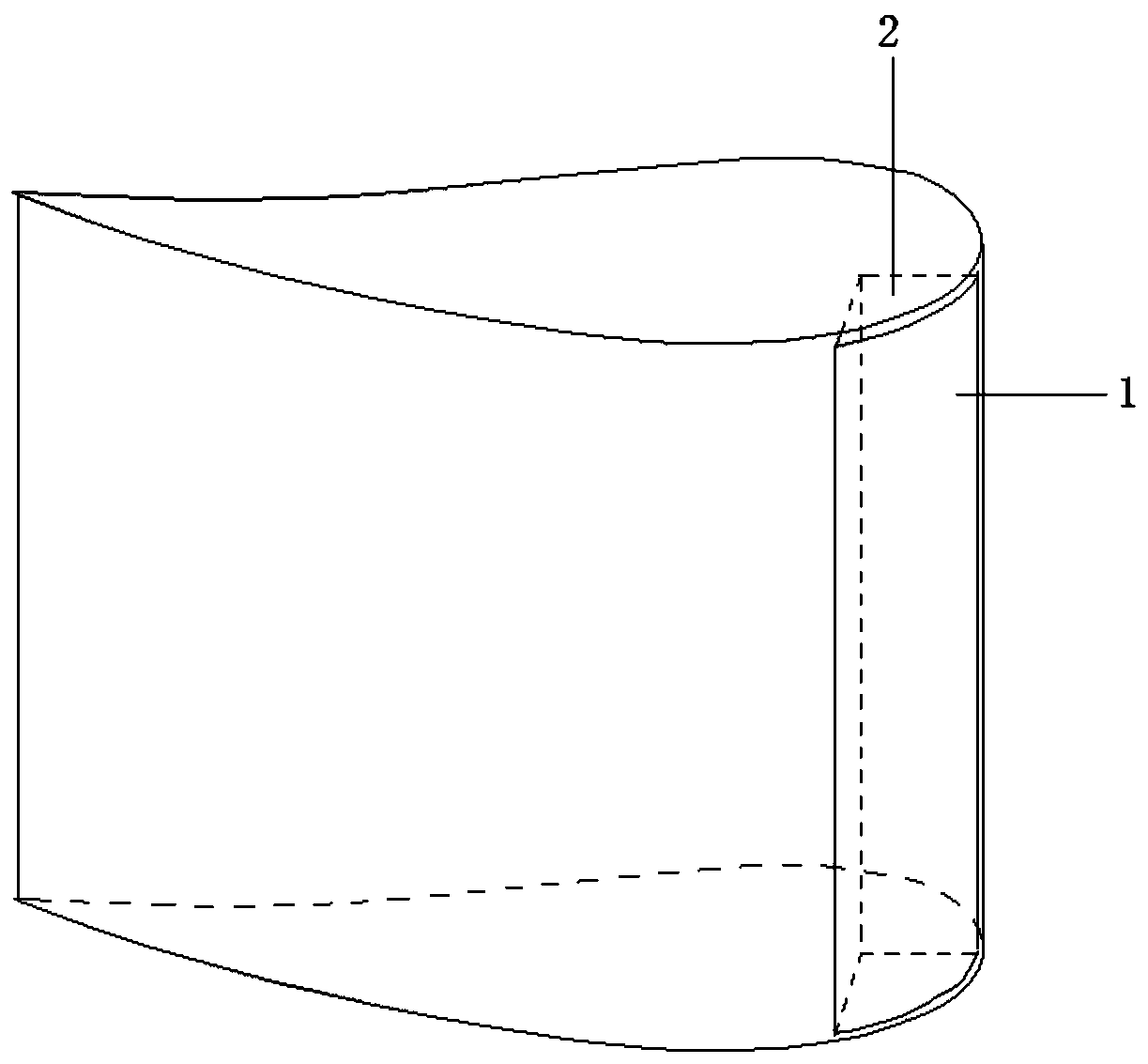

[0034] Such as figure 1 As shown, the vertical wind generator includes a generator, a vertical shaft and 5 blades. The blades of the wind turbine are equal-section airfoil blades. Facing the vertical axis of rotation, the pressure surface of the leading edge of the blade is provided with a cavity almost as long as the blade, figure 2 is a cross-sectional view of a wind turbine blade with a cavity, image 3 It is a schematic diagram of a wind turbine blade with a structure of a cavity 2 and a flexible membrane 1. The opening of the cavity 2 is covered with a flexible membrane 1 having the same shape as the opening of the cavity 2, and the edge of the flexible membrane 1 is tightly fixed to the edge of the opening of the cavity 2.

[0035] Studies have shown that the lift generated by wind turbine blades mainly comes from the front section of the blade profile, especially near the leading edge 1 / 3 of the blade profile, and the shearing of the leading edge of wind turbine blade...

Embodiment 2

[0038] Such as Figure 4 As shown, it is basically the same as Embodiment 1, the difference is that an exciter 3 is also fixed inside the cavity, and the fixing device 5 (crankshaft) on the exciter 3 is connected with one end of the spring 4, and the other end of the spring 4 is fixed. Connected to the flexible membrane 1, the spring 4 is stretched and compressed at a certain frequency through the exciter 3, and then the flexible membrane 1 is also vibrated at the frequency. The frequency of the exciter 3 is adjustable from 0 Hz to 200 Hz, so that the frequency of the flexible membrane can also be adjusted to adapt to the flow field and further optimize the flow field structure. Numerical simulation using the CFD software Fluent shows that for an incoming flow with a wind speed of 2m / s and an angle of attack of 10°, the lift coefficient of the wind turbine blade with this structural blade shape is increased by 16% compared with the rigid structure blade shape, and the drag coe...

Embodiment 3

[0040] Such as Figure 5 As shown, it is basically the same as Embodiment 1, except that an airbag 6 with a volume adapted to the cavity is also provided inside the cavity 2. On the one hand, the airbag 6 can play the role of supporting the flexible membrane 1 flexibly. On the one hand, the vibration performance of the flexible membrane 1 can be improved. Further, the airbag 6 can be inflated and deflated, and the vibration effect of the flexible membrane 1 can be changed by inflating and deflated the airbag 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com