Variable geometry turbine with vortex elimination hole structures in front of movable blades

A technology of variable geometry turbine and moving blades, which is applied in the direction of blade support elements, engine components, machines/engines, etc., can solve the problem of increasing gas turbine compressor surge margin, gas generator residual power, variable geometry turbine efficiency decrease, Problems such as the separation and flow of the pressure surface of the moving blade, to achieve good working characteristics in all working conditions, reduce aerodynamic loss, and reduce the effect of lateral pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

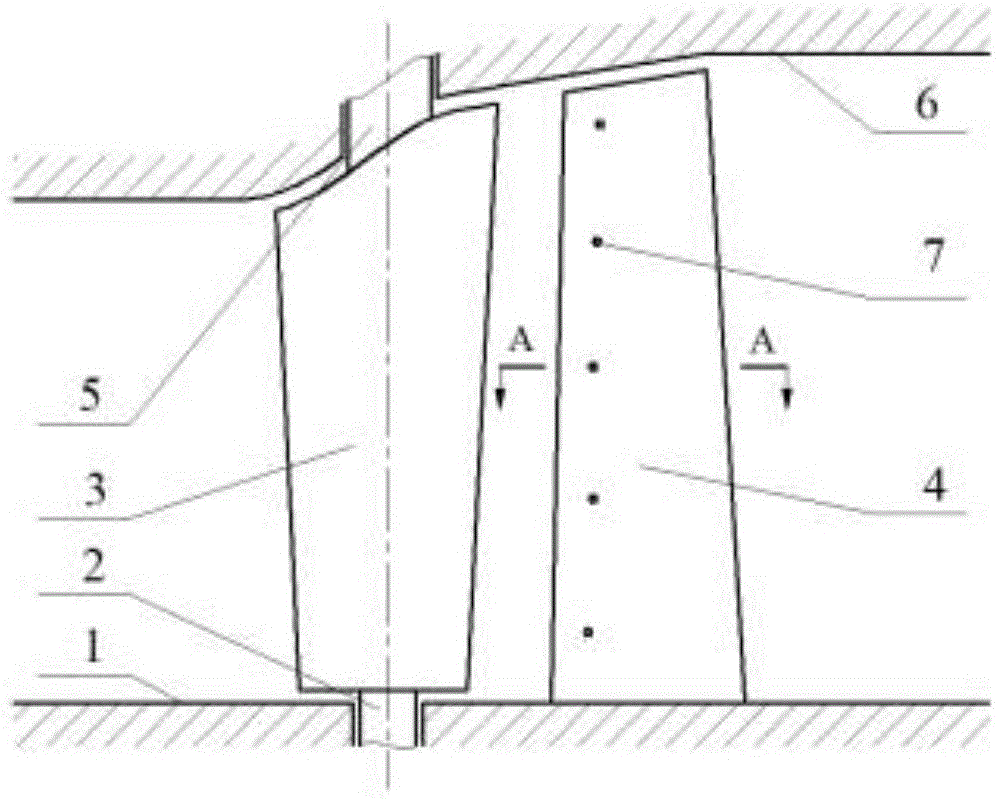

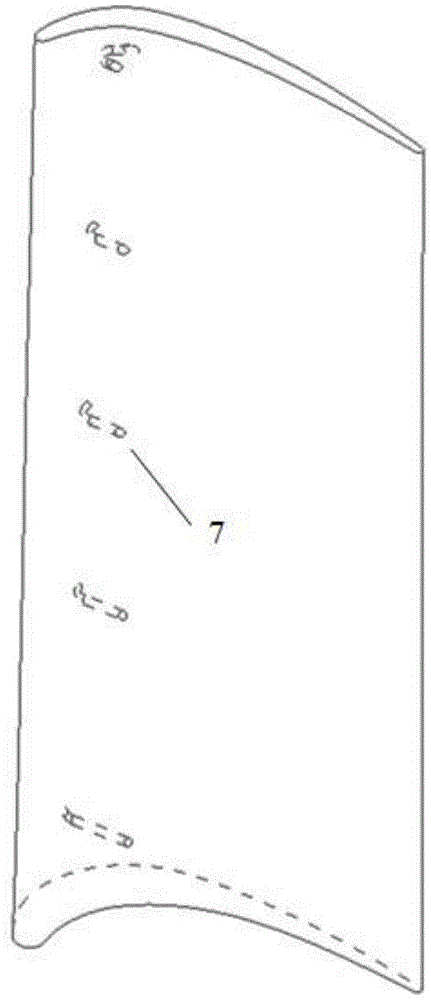

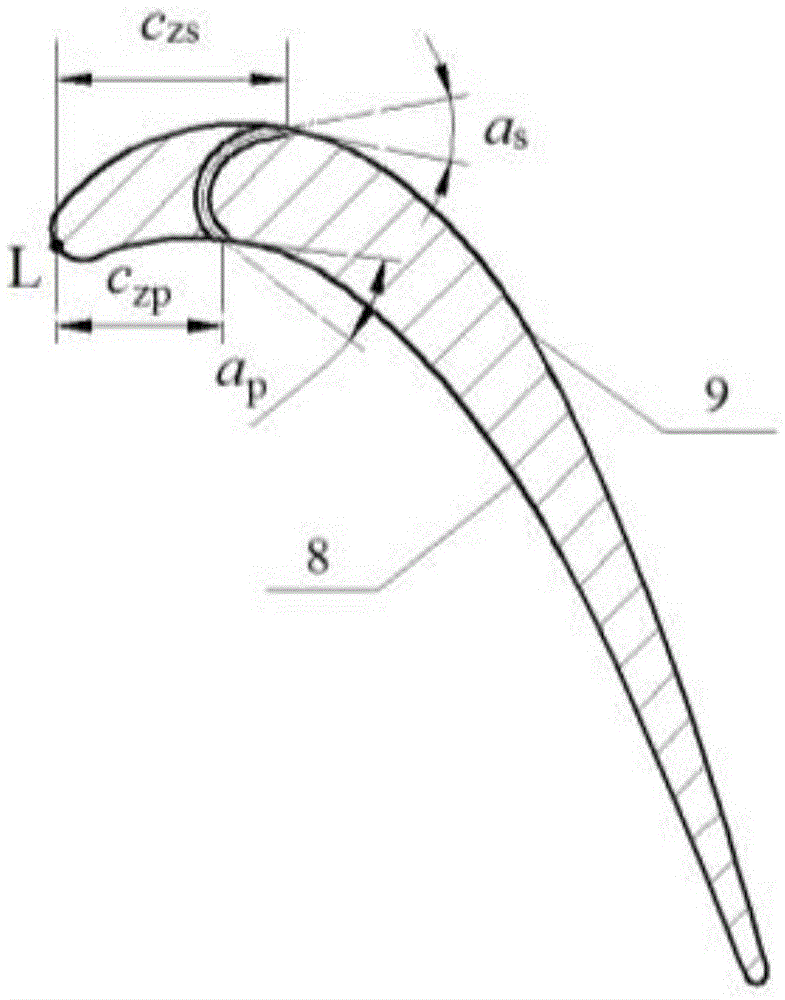

[0020] combine Figure 1~2 , the present invention is made up of wheel hub 1 (comprising stationary blade hub and moving blade hub), adjustable stationary blade 3, moving blade 4 and casing 6, and adjustable stationary blade is evenly installed along the circumferential direction between wheel hub 1 and casing 6 3 and the moving blade 4, the adjustable static blade 3 is in front, and the moving blade 4 is behind. The upper and lower end surfaces of the adjustable stationary blade are respectively provided with an upper rotating shaft 5 and a lower rotating shaft 2, and their axes are on the same rotation axis so that Because the adjustable vane rotates, and the shaft diameter of the upper rotating shaft is larger than that of the lower rotating shaft, the lower rotating shaft only serves as a positioning function, the upper rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com