Binary mixed pressure intake duct applied to supersonic solid ramjet

A technology of solid impingement engine and air inlet, which is applied in the direction of engine components, air inlet of turbine/propulsion device, combustion air/combustion-air treatment, etc. It can solve the problems not mentioned and achieve easy processing, expansion and stability Working range, the effect of reducing the starting Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

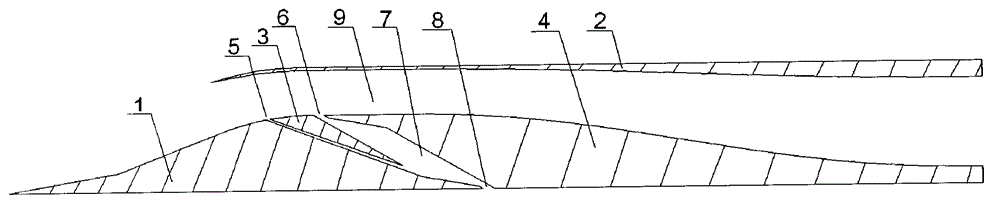

[0027] Supersonic solid impulse engine binary mixed pressure inlet, two wedges and three waves system. The starting Mach number is 2.5, and the design Mach number is 3.0. According to the inlet channel structure of the present invention, the positions and widths of the entrance 5 of the boundary layer auxiliary absorption channel and the entrance 6 of the boundary layer absorption chamber are determined through numerical simulation and engineering calculation. Among them, the inlet 5 of the boundary layer auxiliary suction channel is located at a horizontal distance of about 42 mm backward from the front edge lip of the outer cover 2, and the inlet 6 of the boundary layer suction chamber is located at a horizontal distance of about 81 mm backward from the front edge lip of the outer cover 2.

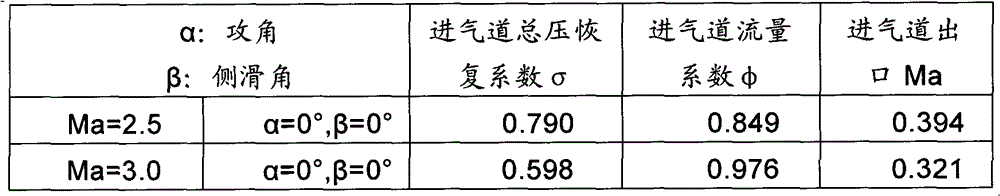

[0028] The above structure was subjected to wind tunnel test. The performance results are shown in the table below. Under the design Mach number 3.0, zero angle of attack and zero side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com