Patents

Literature

155results about How to "Structure is not destroyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/copper composite and preparation method thereof

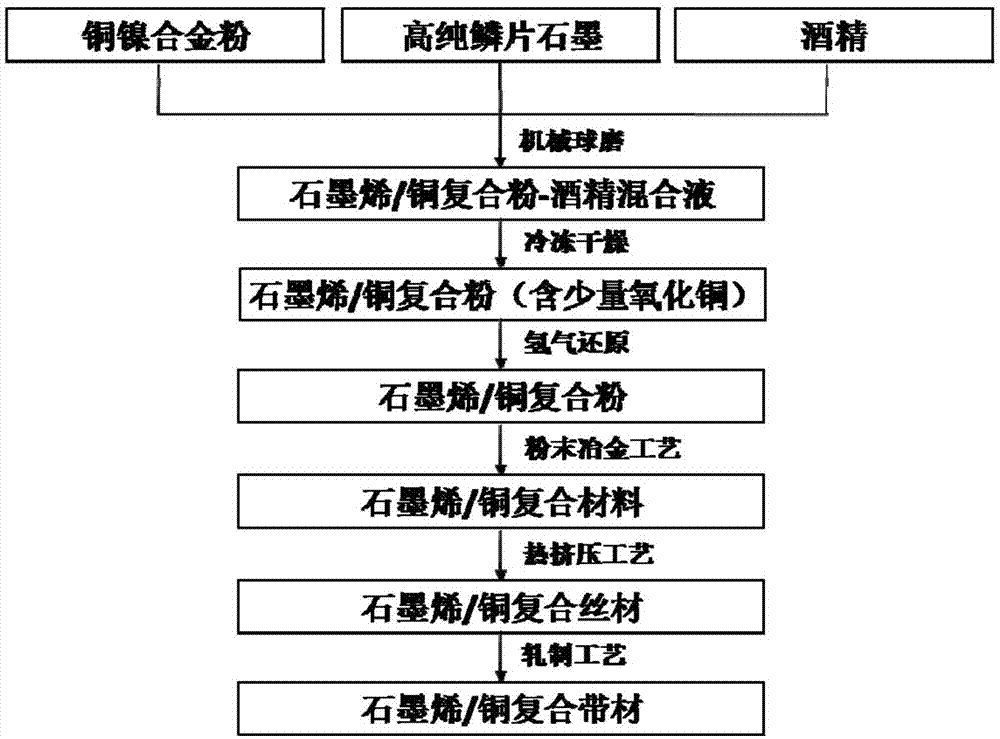

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Graphene/silver composite material and preparation method thereof

ActiveCN104700961AEvenly distributedTo achieve the effect of continuous productionMetal/alloy conductorsCarbon-silicon compound conductorsReducing agentGraphite oxide

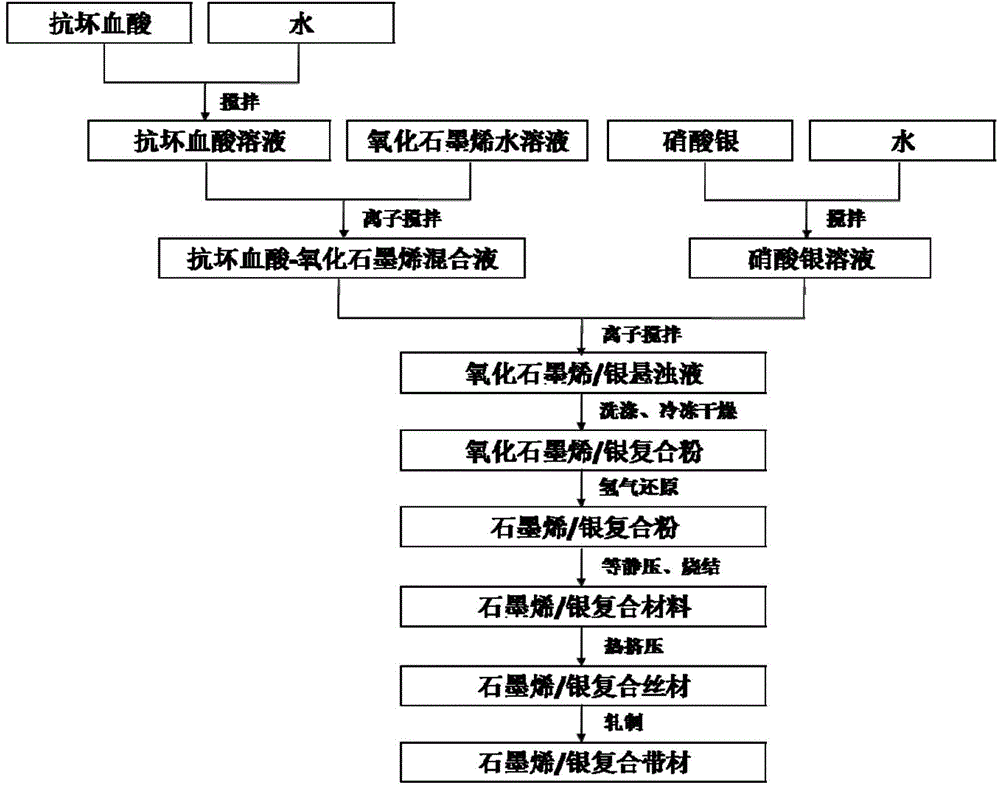

The invention provides a graphene / silver composite material and a preparation method thereof. The preparation method comprises the steps of adding a reducing agent and silver nitrate successively into a graphene oxide solution, combining silver powder obtained by reduction and graphene oxide in the solution, so as to obtain graphene oxide / silver composite powder; drying the graphene oxide / silver composite powder to obtain graphene / silver composite powder; and obtaining graphene / silver composite blocks, composite wires and composite strips through powder metallurgy, hot extrusion and rolling techniques. According to the graphene / silver composite material and the preparation method provided by the invention, the graphene is dispersed uniformly in the composite material, the interface bonding between a substrate and an enhanced body is good, and the composite materials is excellent in physical performance; meanwhile, the preparation method is simple in process, is likely to control the process and likely to realize large-scale production and application.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

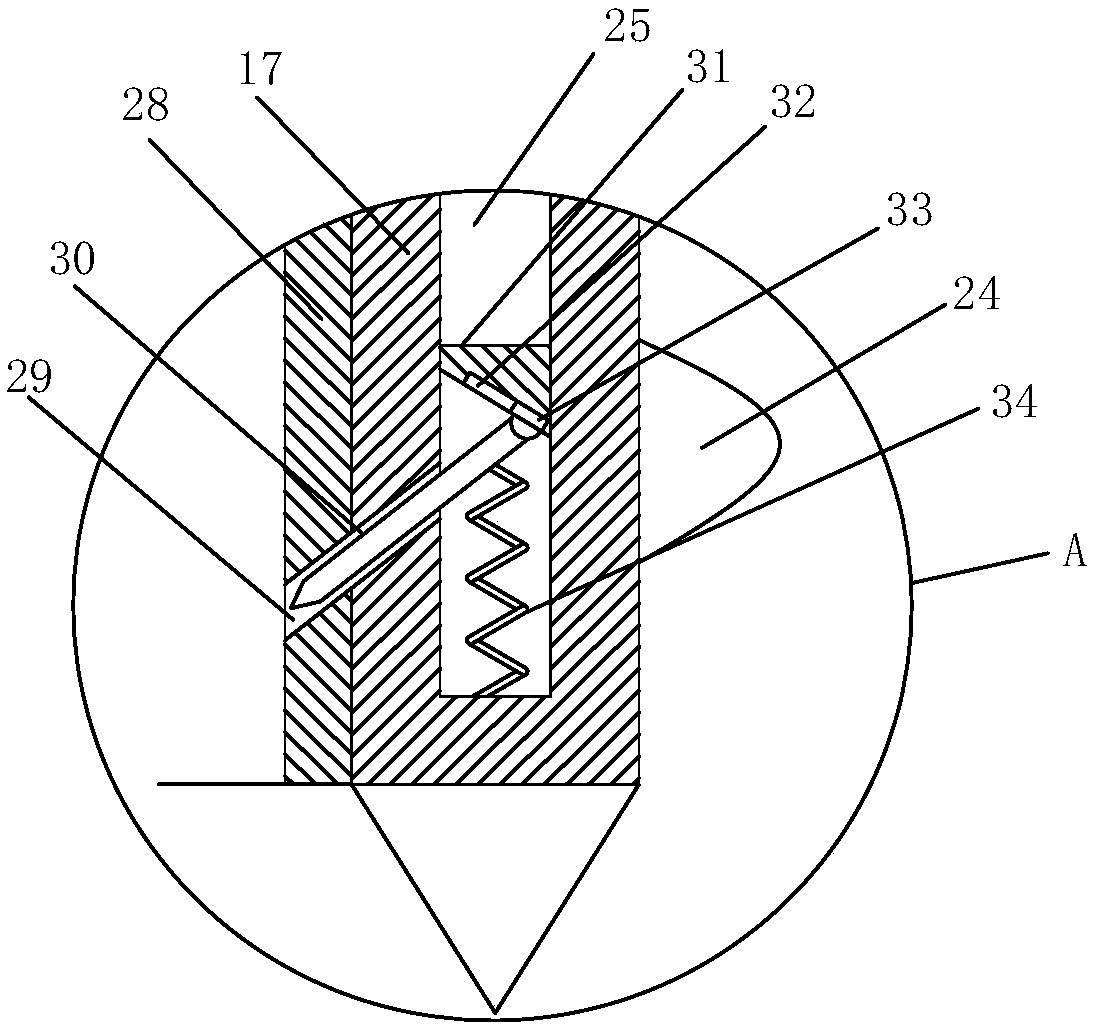

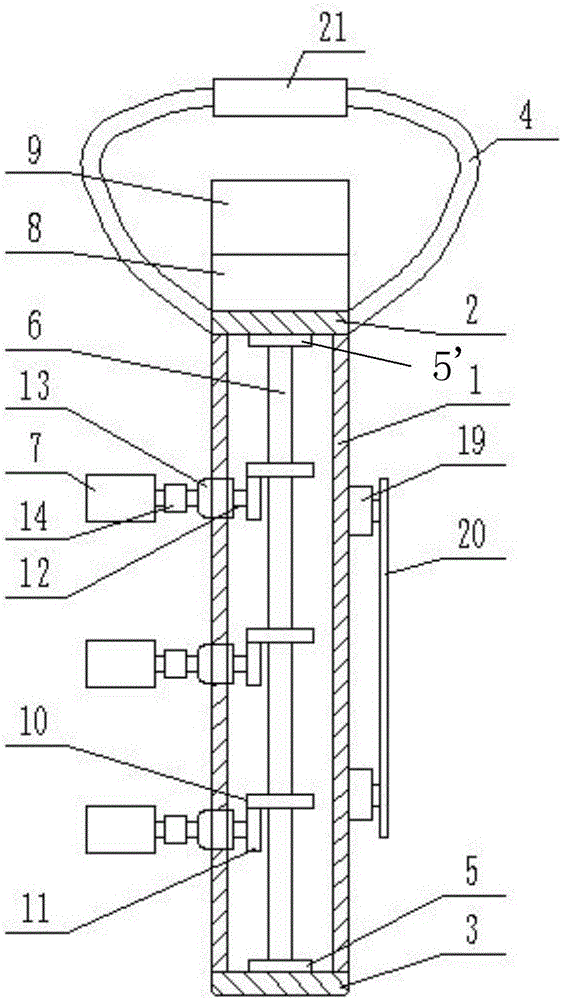

Cylinder type soil sampling device for detection

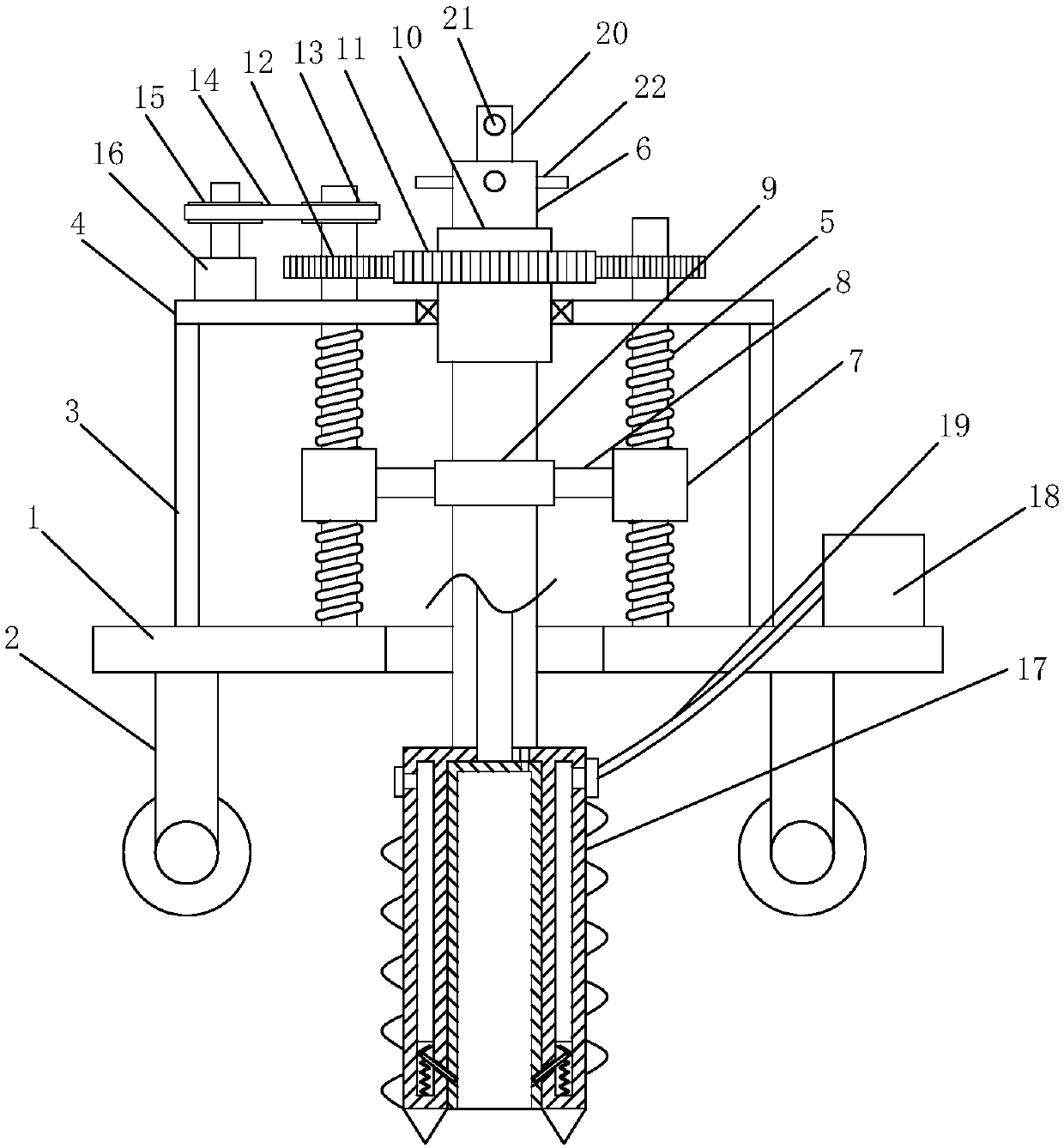

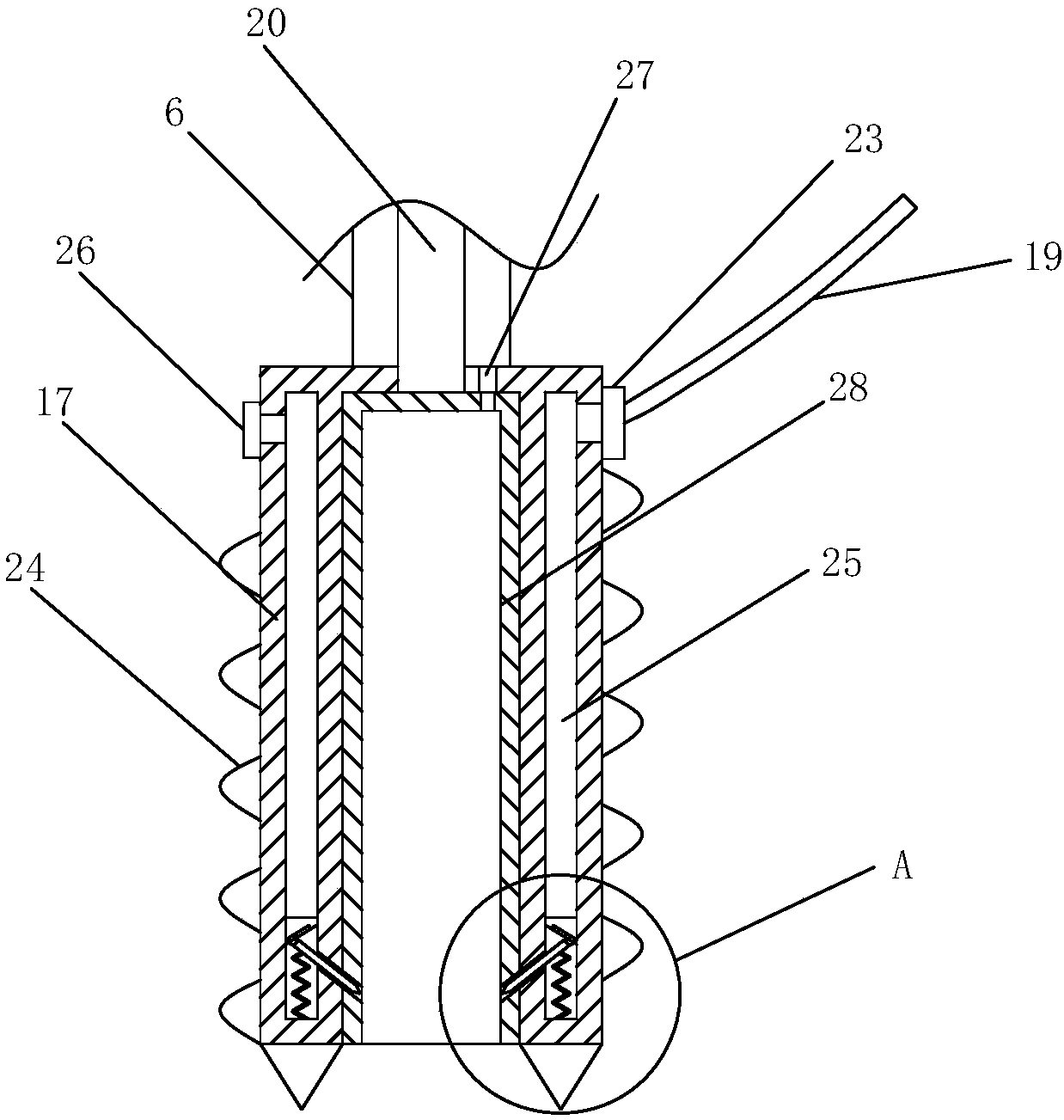

The invention discloses a cylinder type soil sampling device for detection. The cylinder type soil sampling device comprises a transverse plate and a sampling cylinder, wherein a spiral shaft is arranged between a top plate and the transverse plate; a bearing is arranged at the side wall of a lifting rod; a slide sleeve is arranged on the spiral shaft, and is connected with the spiral shaft in a thread matching way; the outside wall of the slide lifting rod is connected with the inner wall of a rotary sleeve pipe through a spline; the interior of the side wall of the sampling cylinder is provided with an annular cavity which is coaxial with the sampling cylinder; an annular press plate is arranged at the bottom part of the annular cavity; a plurality of inclined through holes are formed inthe inside wall of the annular cavity; a guide rod is arranged in each inclined through hole, the upper end of each guide rod is connected with the inclined surface of an annular press plate througha slide mechanism, and the lower side of the annular press plate is connected with the bottom wall of the annular cavity through a reset spring. The cylinder type soil sampling device has the advantages that the structure is simple, the sampling efficiency is higher, the bending and breaking of the sampling cylinder are avoided, the disengaging from the sampling cylinder due to moving-up of sampling soil is avoided, the labor intensity is lower, the operation is simple and convenient, and the practicality is stronger.

Owner:杨海建

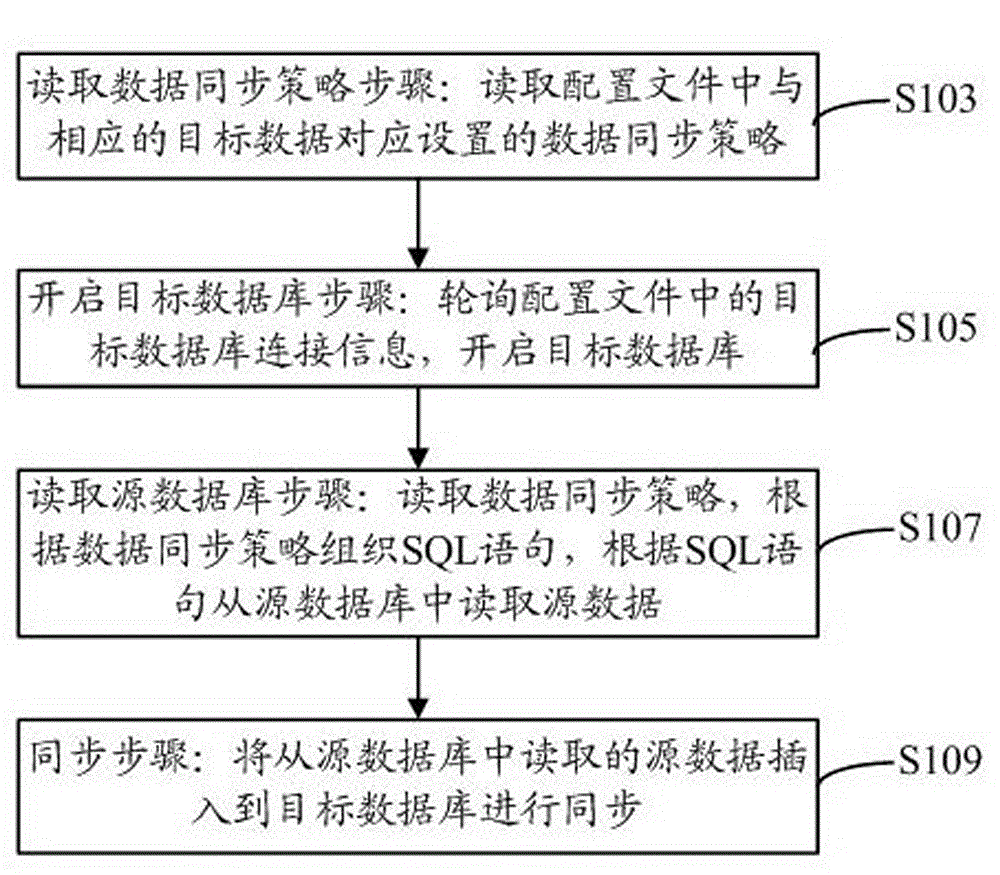

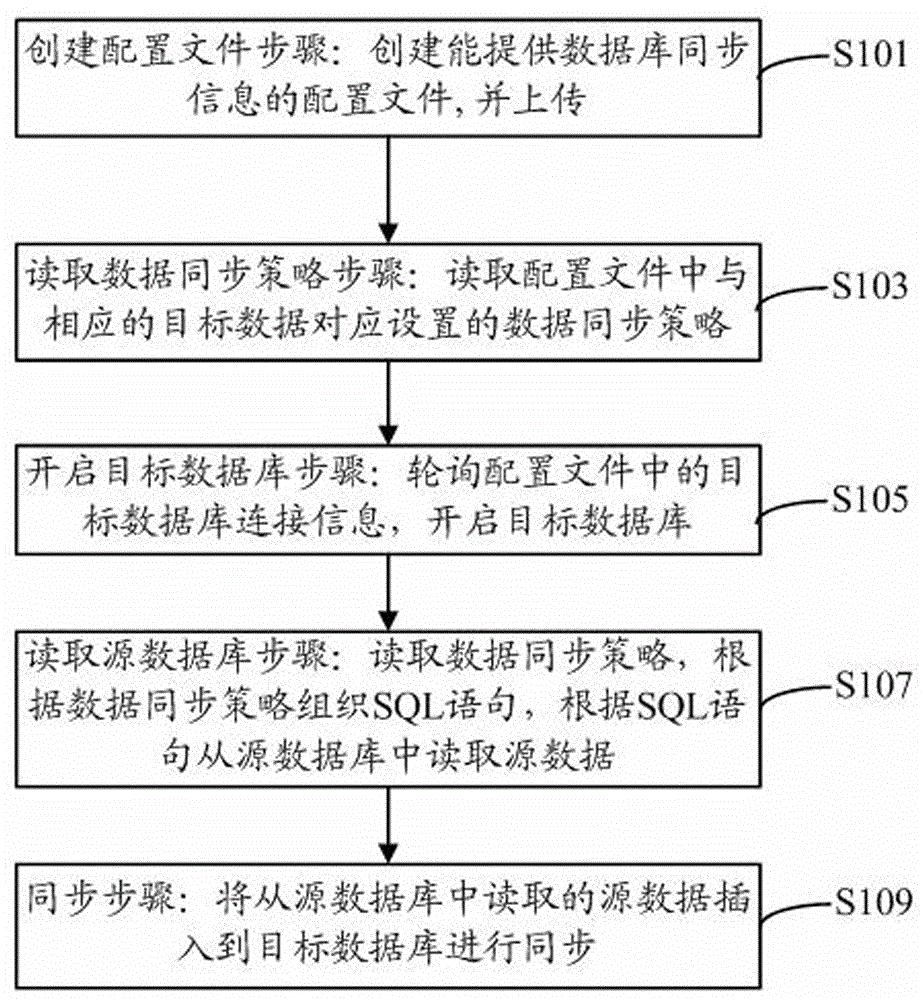

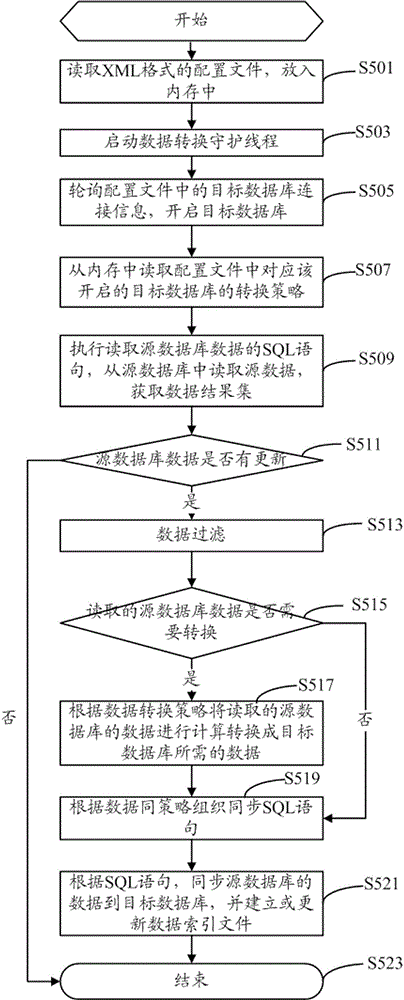

Method and system for converting or synchronizing databases

ActiveCN102915377AImprove synchronization efficiencyStructure is not destroyedSpecial data processing applicationsQuery languageData storing

The invention discloses a method and system for converting or synchronizing databases. The method comprises the following steps of: reading a data conversion and synchronization strategy set corresponding to a target database from a configuration file; polling target database connection information in the configuration file, and opening the target database; reading the synchronization strategy, reading SQL (structured query language) statements in a source database according to the organization of the synchronous strategy, and reading source data from the source database according to the SQL statements; and inserting the data read from the source database into the target database to carry out synchronization. According to the method and system for converting or synchronizing databases, disclosed by the invention, a mode of actively inserting the data stored in the source database and subjected to reading or conversion into the target database is adopted, so that the method and system disclosed by the invention can be applied to a multi-source heterogeneous situation and a situation that the structure of the source database is inconsistent with the structure of the target database, and also can be used under the condition that the source data is in a weak trend status but the target database is in a strong trend status, thereby adapting to different conversion modes; and based on the method or system for synchronizing databases, the structures of the source database and the target database are not destroyed.

Owner:SHENZHEN HONGDIAN TECH CORP

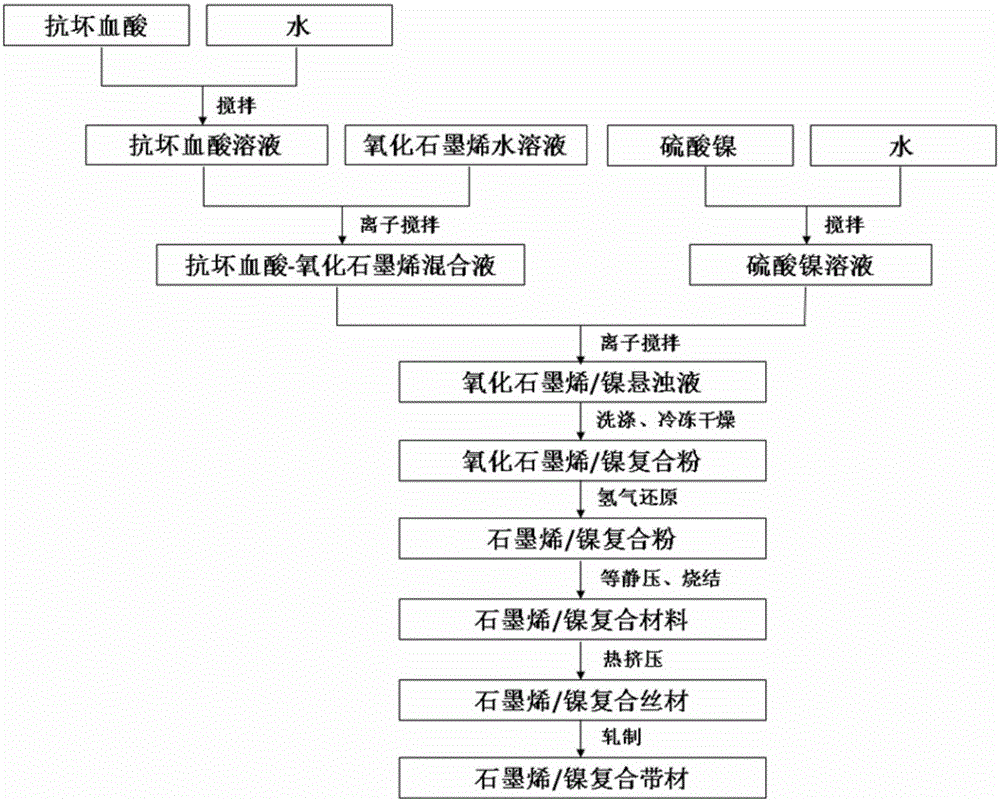

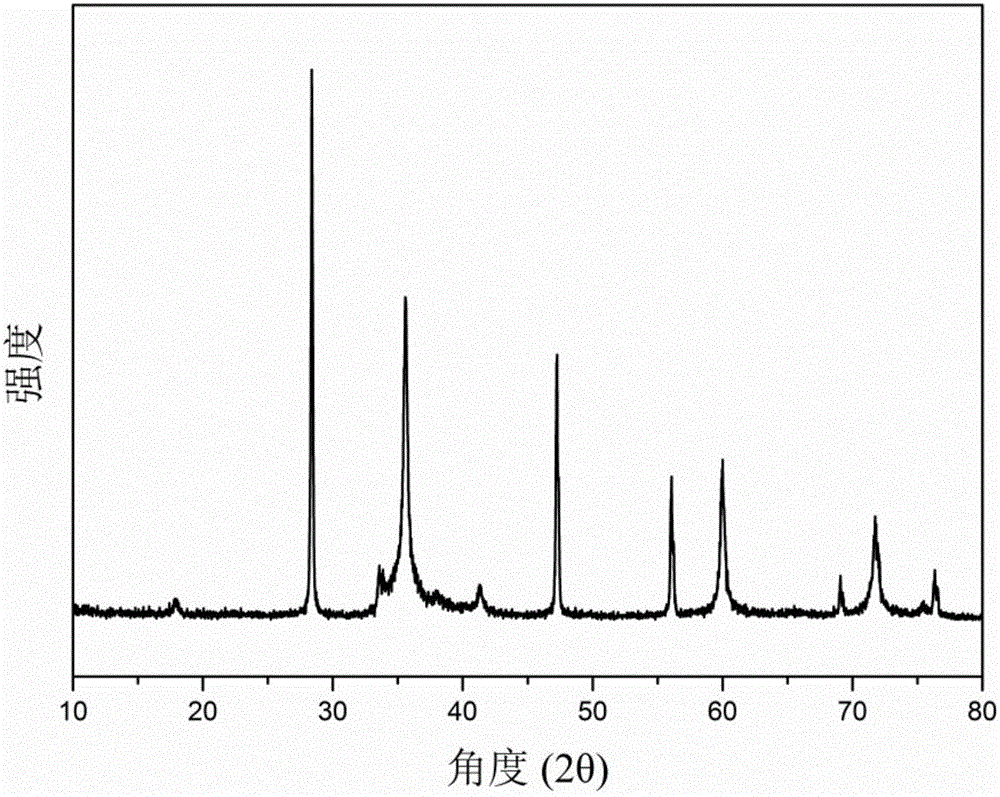

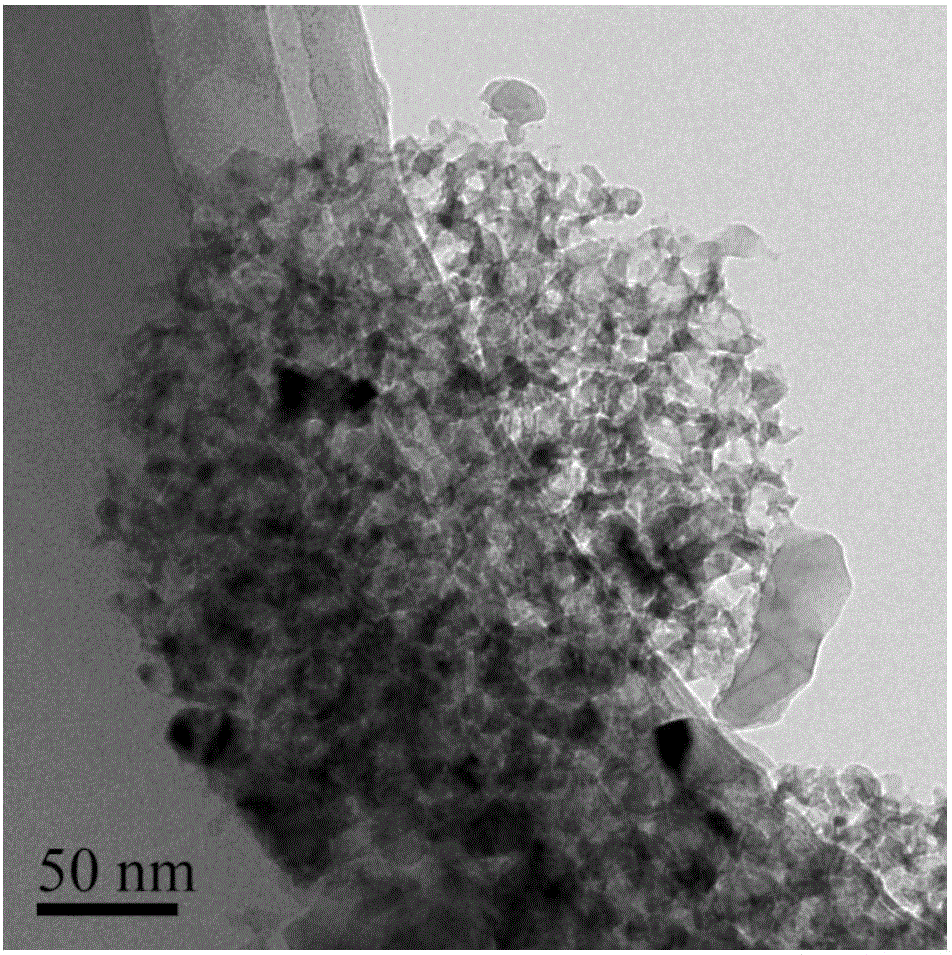

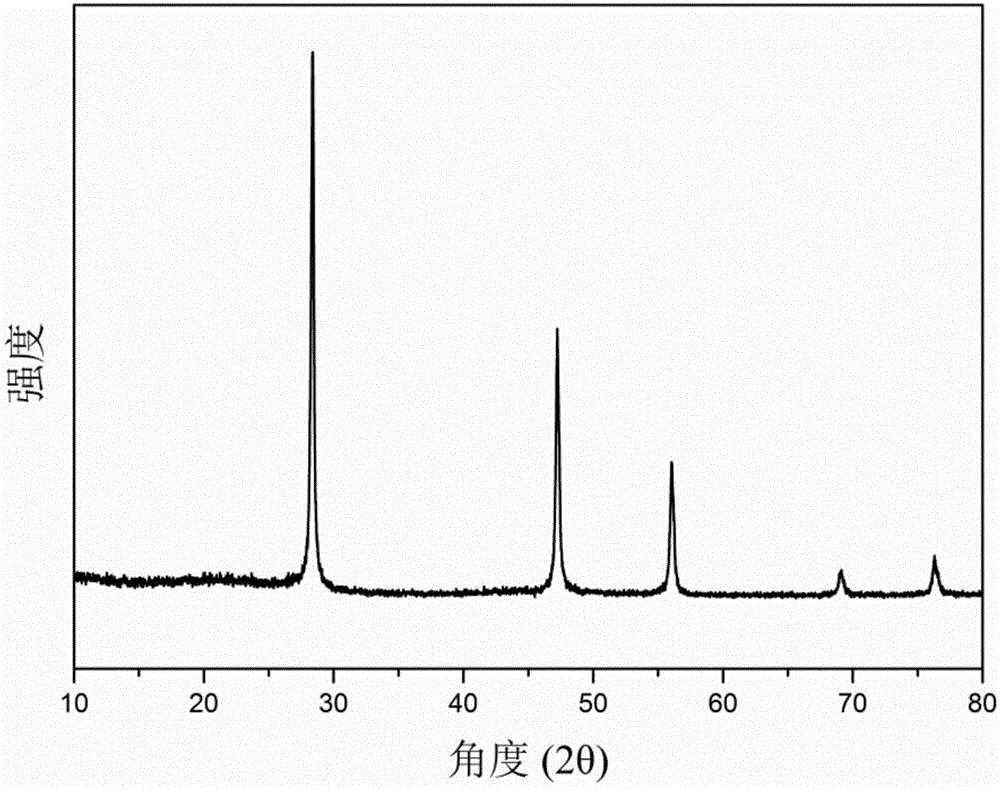

Graphene strengthening nickel base composite material and preparing method thereof

The invention discloses a graphene strengthening nickel base composite material and a preparing method thereof. The method includes the steps that a reducing agent and nickel sulfate are sequentially added into an oxidized graphene solution; nickel powder prepared through reduction is directly compounded with oxidized graphene in the solution, and oxidized graphene / nickel composite powder is initially obtained; the oxidized graphene / nickel composite powder is dried and restored to obtain graphene / nickel composite powder; and composite blocks, composite wires and composite strips of graphene / nickel are obtained through powder metallurgy, hot extrusion and rolling technologies. Graphene in the composite material is evenly scattered, base and strengthening body interface bonding is good, and the composite material has the excellent physical performance. Meanwhile, the process of the graphene strengthening nickel base composite material and the preparing method is simple, the procedure is easy to control, and large-scale application and production are easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Core-shell structure silicon carbon composite material and preparation method thereof

ActiveCN106099113AGuaranteed stabilityAvoid cracking and shatteringCell electrodesCarbon layerCarbon composites

The invention discloses a core-shell structure silicon carbon composite material and a preparation method thereof. The composite material is of a core-shell structure. The core-shell structure includes a shell composed of a carbon layer and a core composed of porous nano silicon. An air gap layer is arranged between the shell and the core. The preparation method comprises the steps that silicon dioxide particles perform magnesiothermic reduction reaction through magnesium powder, a reduction product is subjected to in-situ coating through an organic macromolecular carbon source, then carbonization is performed, and a carbonization product is corroded with hydrofluoric acid to obtain the silicon carbon composite material. The silicon carbon composite material has good stability, can well buffer silicon volume expansion and improve material conductivity, and thus ensures the cycle stability of electrodes. The silicon carbon composite material preparation process is simple and is suitable for industrial production, and the raw materials are wide in source.

Owner:湖南宸宇富基新能源科技有限公司

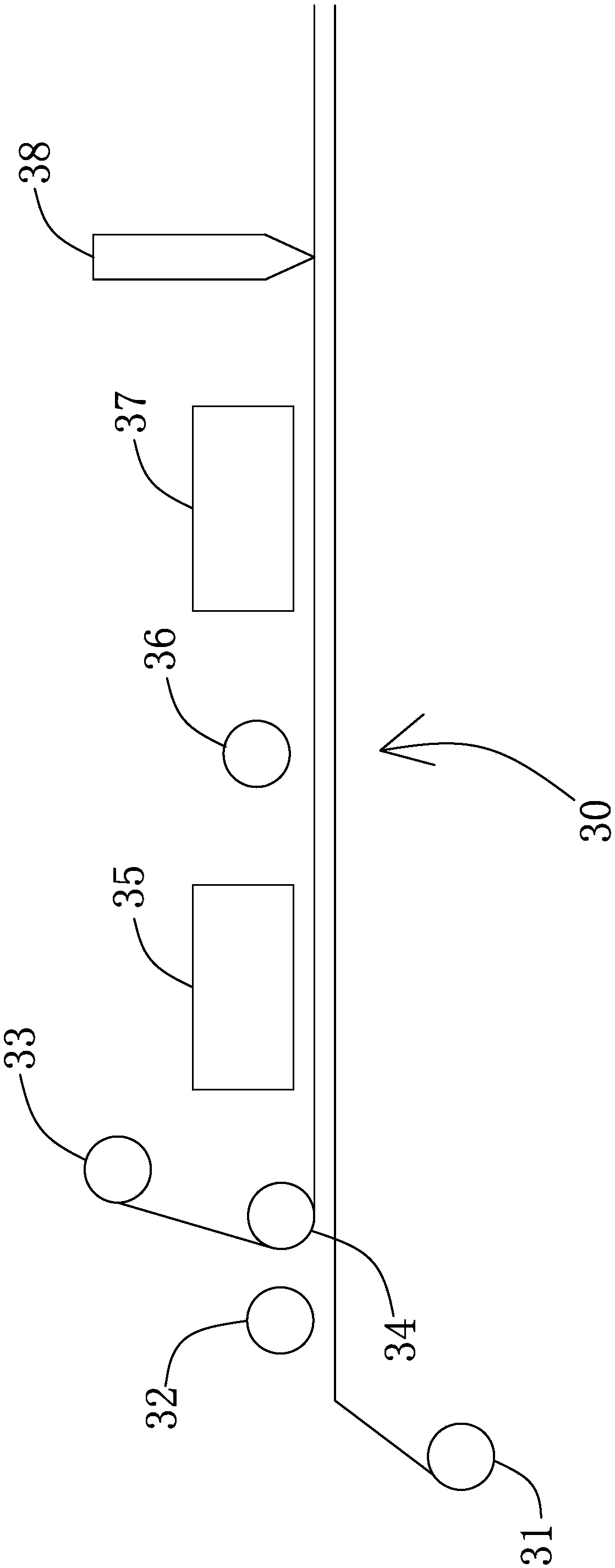

Soil cutting-ring layering synchronous sampling device

ActiveCN106092642AAccurate analysisSimple structureWithdrawing sample devicesEngineeringSoil horizon

The invention relates to a soil cutting-ring layering synchronous sampling device, and belongs to the technical field of soil detection devices. The soil cutting-ring layering synchronous sampling device comprises a cylinder which is provided with a top plate at the top and provided with a bottom plate at the bottom, a secure hand is disposed on the top plate, and the top plate and the bottom plate are respectively provided with a first rolling bearing and a second rolling bearing; and the cylinder is inside provided with a rotation shaft which is installed on the first and the second rolling bearing, the top end of the rotation shaft is connected with a driving mechanism, the rotation shaft is provided with a plurality of transmission mechanisms from top to bottom, the cylinder is provided with a plurality of beating blades from top to bottom, and the transmission mechanisms are connected with the beating blades. The provided soil cutting-ring layering synchronous sampling device is applicable to layering synchronous sampling of reclamation soil at mine lots, is simple in structure, convenient to operate, capable of rapidly sampling from soil, and is time-saving, labor-saving, efficient and small in disturbance to soil layer structure.

Owner:SHANXI UNIV

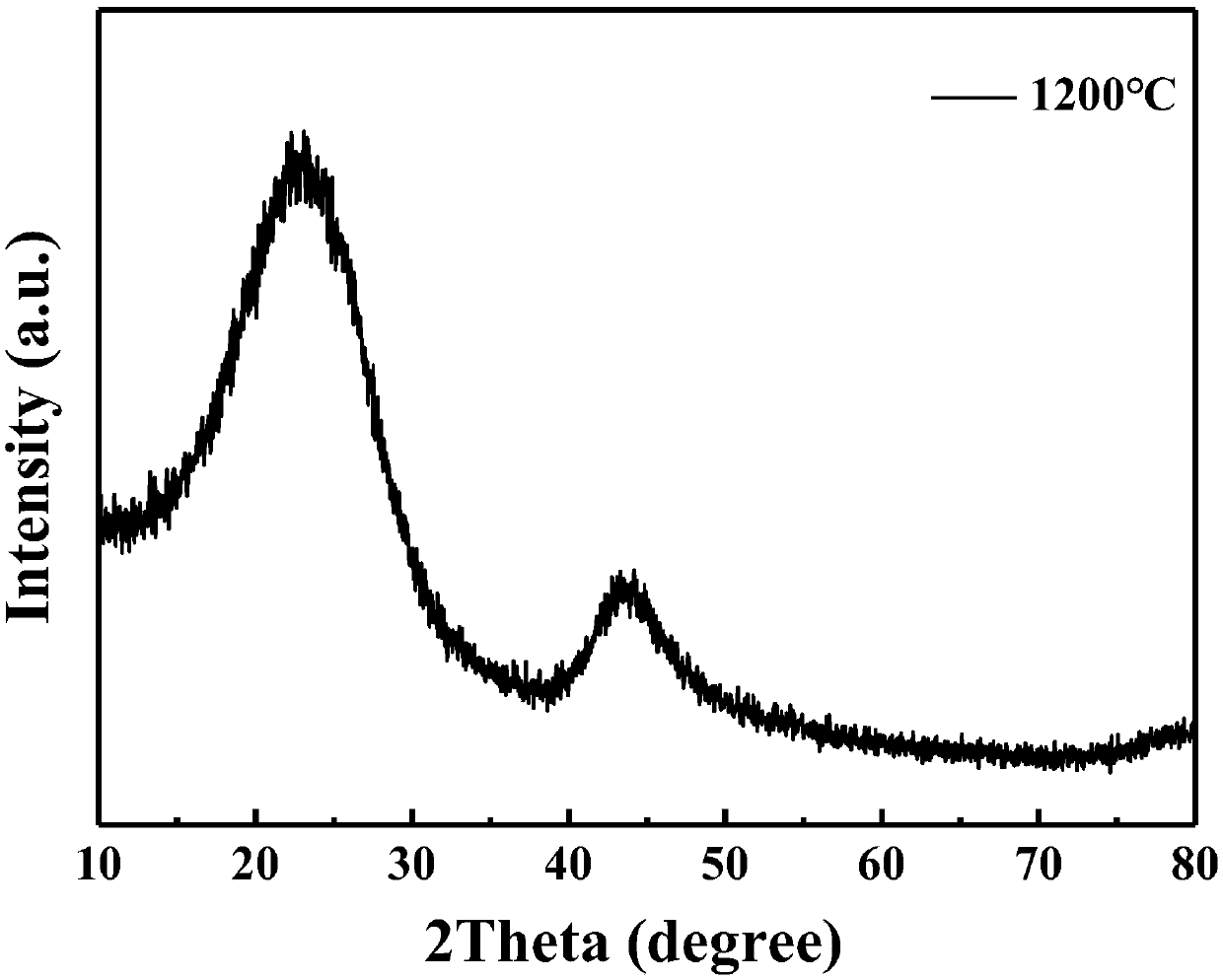

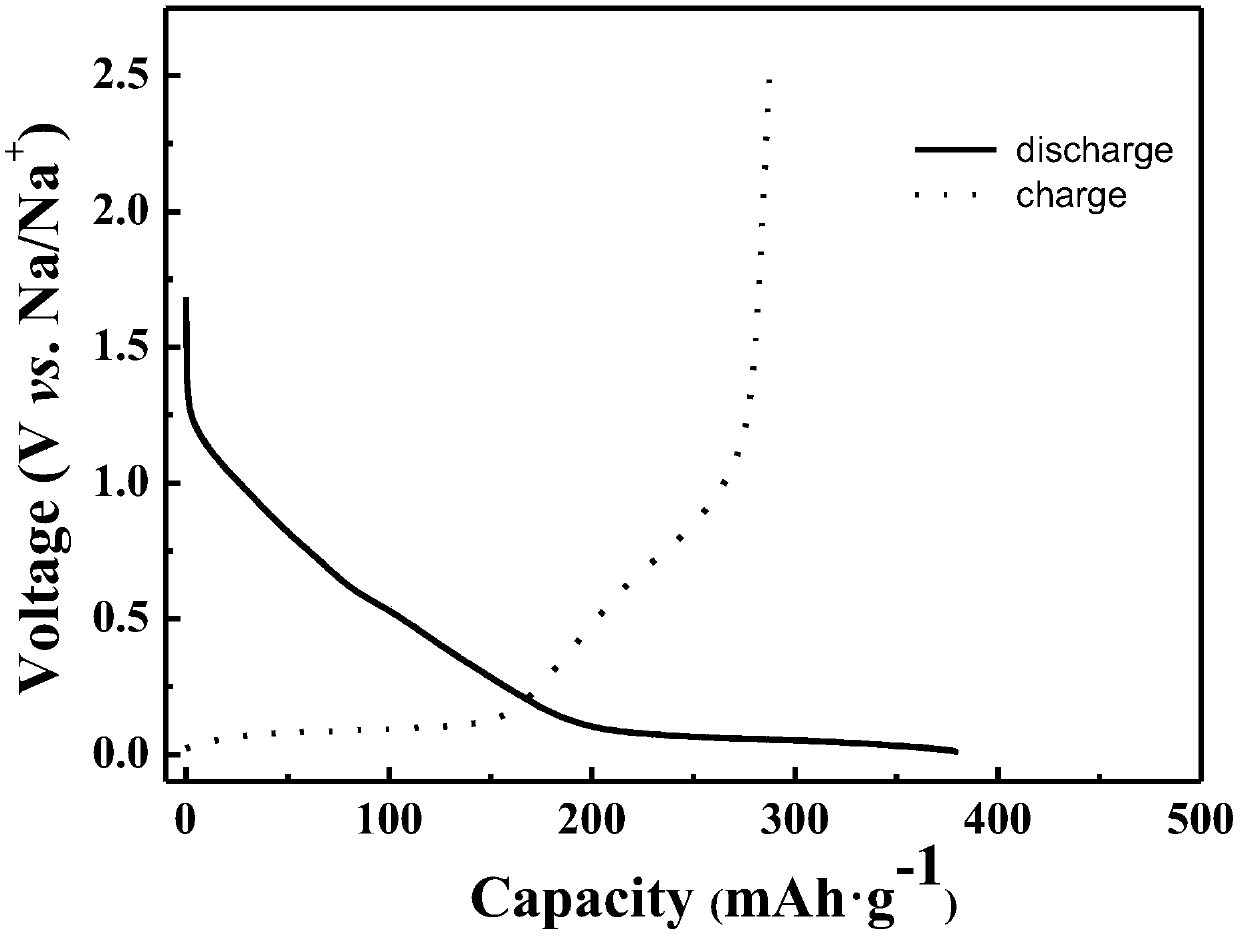

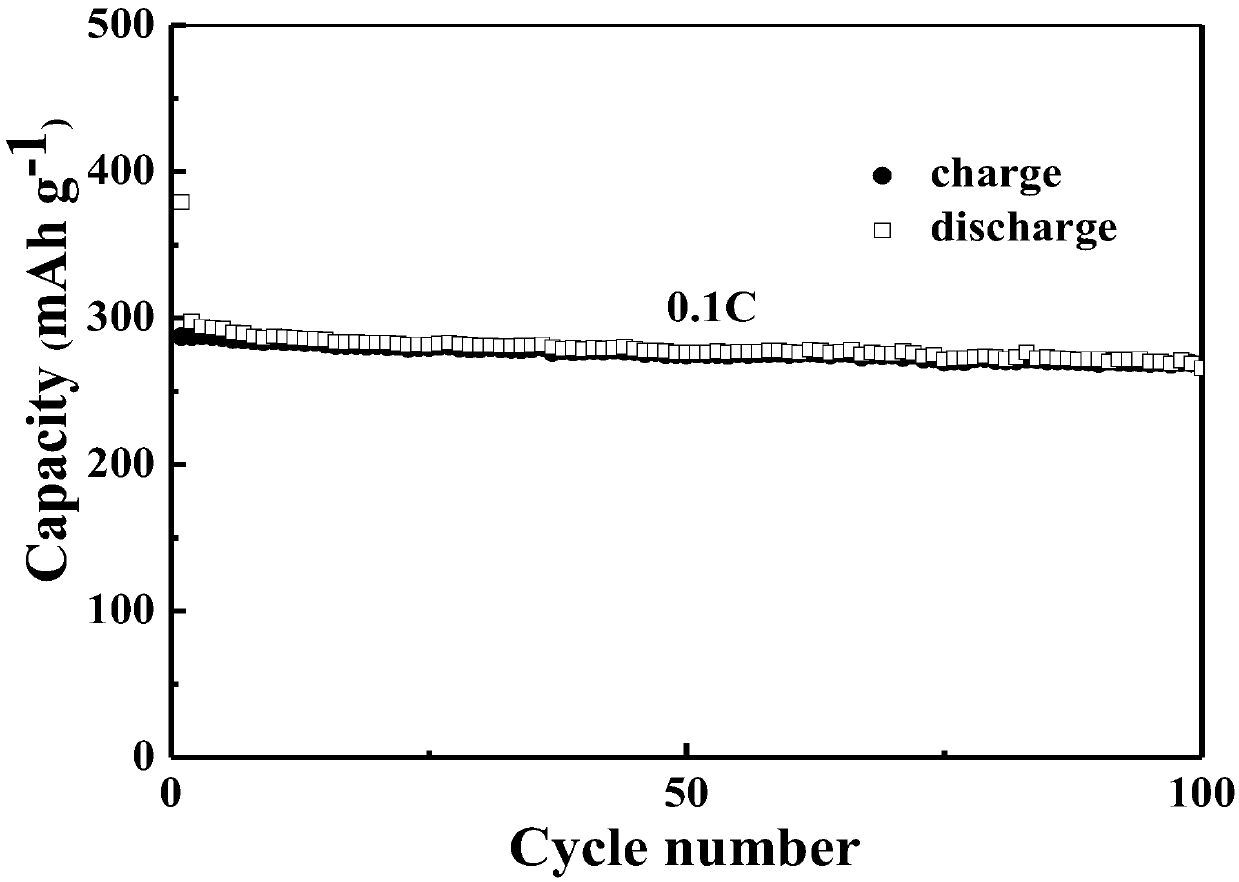

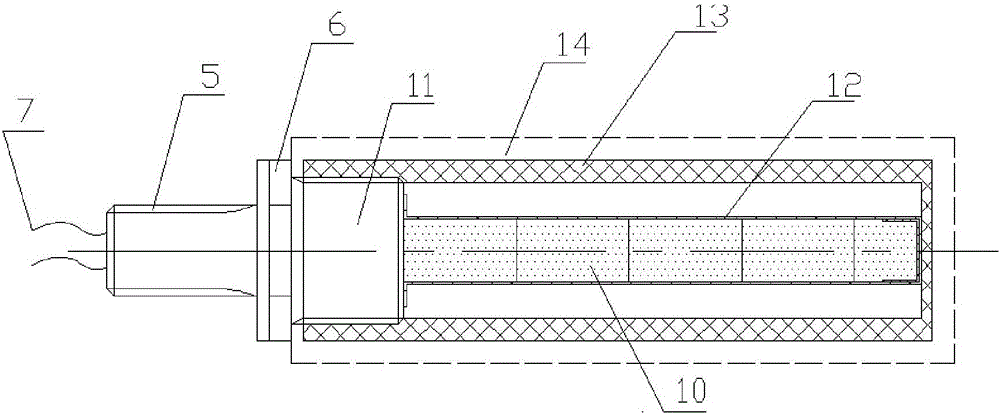

Hard carbon material for anode of sodium-ion battery, preparation method of hard carbon material and related sodium-ion battery

InactiveCN109678130ARich in microporesRich in mesoporesCell electrodesSecondary cellsElectrical batteryCarbonization

The invention provides a hard carbon material for an anode of a sodium-ion battery, a preparation method of the hard carbon material and the related sodium-ion battery, and belongs to the technical field of energy storage materials and electrochemistry. The hard carbon material is synthesized from a biomass material as a precursor, compared with the traditional high-temperature carbonization process, the preparation method adopts process steps of alkaline washing, acid pickling, drying, pre-carbonization and pyrolysis, and the hard carbon material having larger interlayer spacing (not smallerthan 0.37 nm), smaller specific surface area (about 100 cm<3> / g) and rich micropores and mesopores is prepared by adjusting process parameters. By means of a special microstructure, the hard carbon material serving as the anode of the sodium-ion battery shows excellent electrochemical performance, high specific capacity, high coulombic efficiency and good cyclic stability. A novel concept is provided for preparing a sodium-ion anode material, and the preparation method is simple and has low preparation cost, high repeatability and small industrialization difficulty, and the hard carbon material is expected to be applied to sodium-ion batteries for realizing large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Preparation method of water-soluble ferrocene supramolecular inclusion compound

The invention relates to a preparation method of a water-soluble ferrocene supramolecular inclusion compound, belonging to the field of preparation processes of water-soluble metal organic materials in the technical field of supramolecular materials. The preparation method comprises the following steps of: firstly crosslinking beta-cyclodextrin as a raw material with epoxy chloropropane to generate a beta-cyclodextrin polymer under a strong alkaline condition; and then carrying out homogeneous supramolecular reaction on the beta-cyclodextrin polymer as a subject molecule, ferrocene as an object molecule and glycol as a reaction solvent to generate the water-soluble ferrocene supramolecular inclusion compound. The preparation method has the advantages of easy and convenient operation, easy control of conditions, little environmental pollution and easy industrialization; the material not only has high water solubility, but also has stable structure without damaging the self structure of the ferrocene; and in addition, the water-soluble ferrocene supramolecular inclusion compound can be used in the fields of aqueous-phase electroanalytical chemistry, biological sensors, aqueous-phase organic synthesis, biological medicine, and the like because of good water solubility.

Owner:YANGZHOU UNIV

Method for extracting and separating bacitracin

InactiveCN102153633AHigh yieldStructure is not destroyedDepsipeptidesPeptide preparation methodsSeparation factorUltrafiltration

The invention relates to a method for extracting and separating bacitracin. The method is characterized by comprising the following steps of: (1) extracting and separating bacitracin concentrated liquor by ultrafiltration, namely acidizing bacitracin fermentation liquor, filtering or centrifuging by a vibrating screen to remove thalli, removing the thalli and macromolecular impurities by the ultrafiltration, removing an inorganic salt by resin adsorption and performing evaporation concentration under vacuum to obtain the bacitracin concentrated liquor; and (2) preparing a bacitracin crystalline solid by using the bacitracin concentrated liquor, namely performing production steps of extracting, decolorizing, nanofiltration, crystallizing and separating, drying, crushing, sieving, checking, the packaging of a finished product and the like on the bacitracin concentrated liquor to obtain the qualified bacitracin product. The method has the characteristics of high efficiency, simple equipment, high economy, large separation factor, high selectivity, low energy consumption, no secondary pollution, and the like, and is particularly suitable for the large-scale industrial production of the bacitracin; and operation can be performed continuously at the room temperature.

Owner:JIANGSU JIUYANG BIOLOGICAL PHARMA

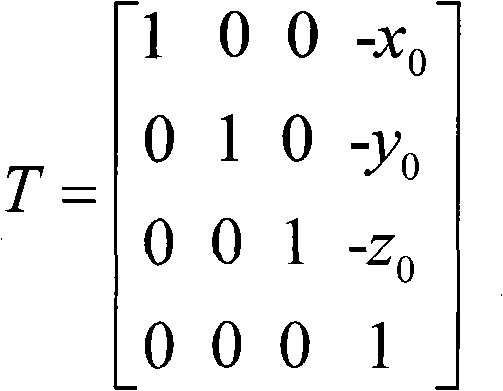

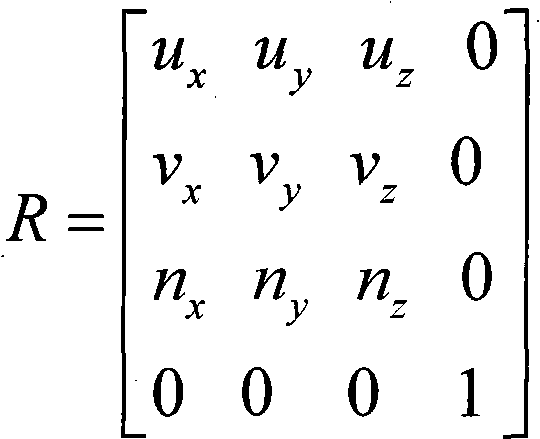

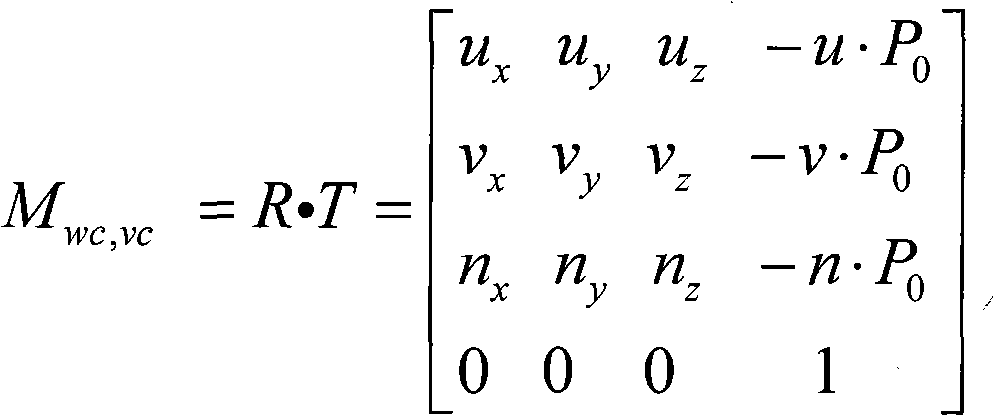

Real-time volume rendering method of three-dimensional heart data based on GPU (Graphic Processing Unit) acceleration

The invention relates to a real-time volume rendering method of three-dimensional heart data based on GPU (Graphic Processing Unit) acceleration, belonging to the field of graph and image processing and solving the problems of low speed and high requirement on computer performance of the traditional volume rendering the three-dimensional heart data. The real-time volume rendering method of the three-dimensional heart data based on the GPU acceleration is realized based on a PC (Personal Computer) with a graphics card supporting Cg language. The volume rendering method concretely comprises the following steps of: firstly, reading and preprocessing data: organizing data of a plurality of slices of the heart to be drawn into a volume data file, packing the volume data file into a three-dimensional grain data packet and storing the three-dimensional grain data packet into the memory of the graphics card; secondly, converting data coordinates: converting the data coordinates in the there-dimensional grain packet obtained in the data preprocessing step into screen coordinates; and thirdly, outputting the volume data after the coordinate standardization by adopting a volume rendering method. The invention is also suitable for the volume rendering of other three-dimensional organs with complex structures.

Owner:HARBIN INST OF TECH

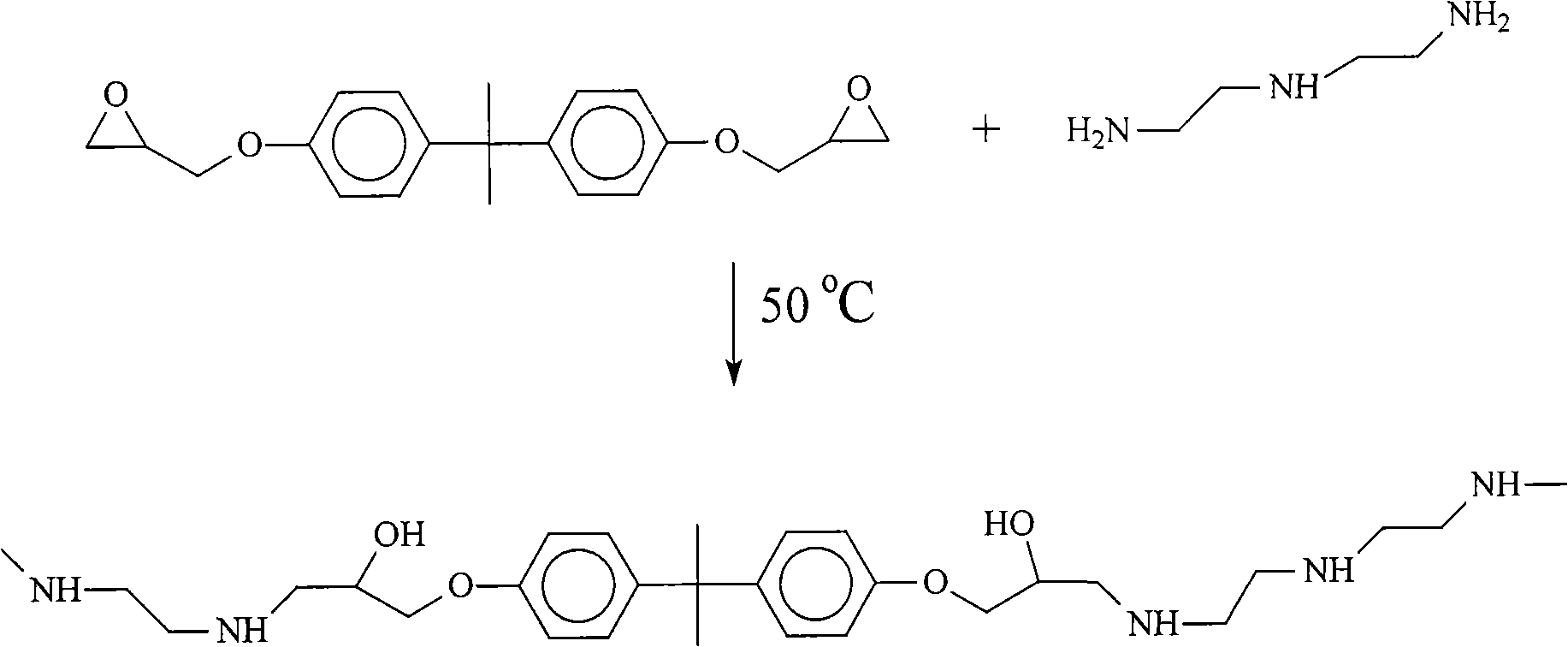

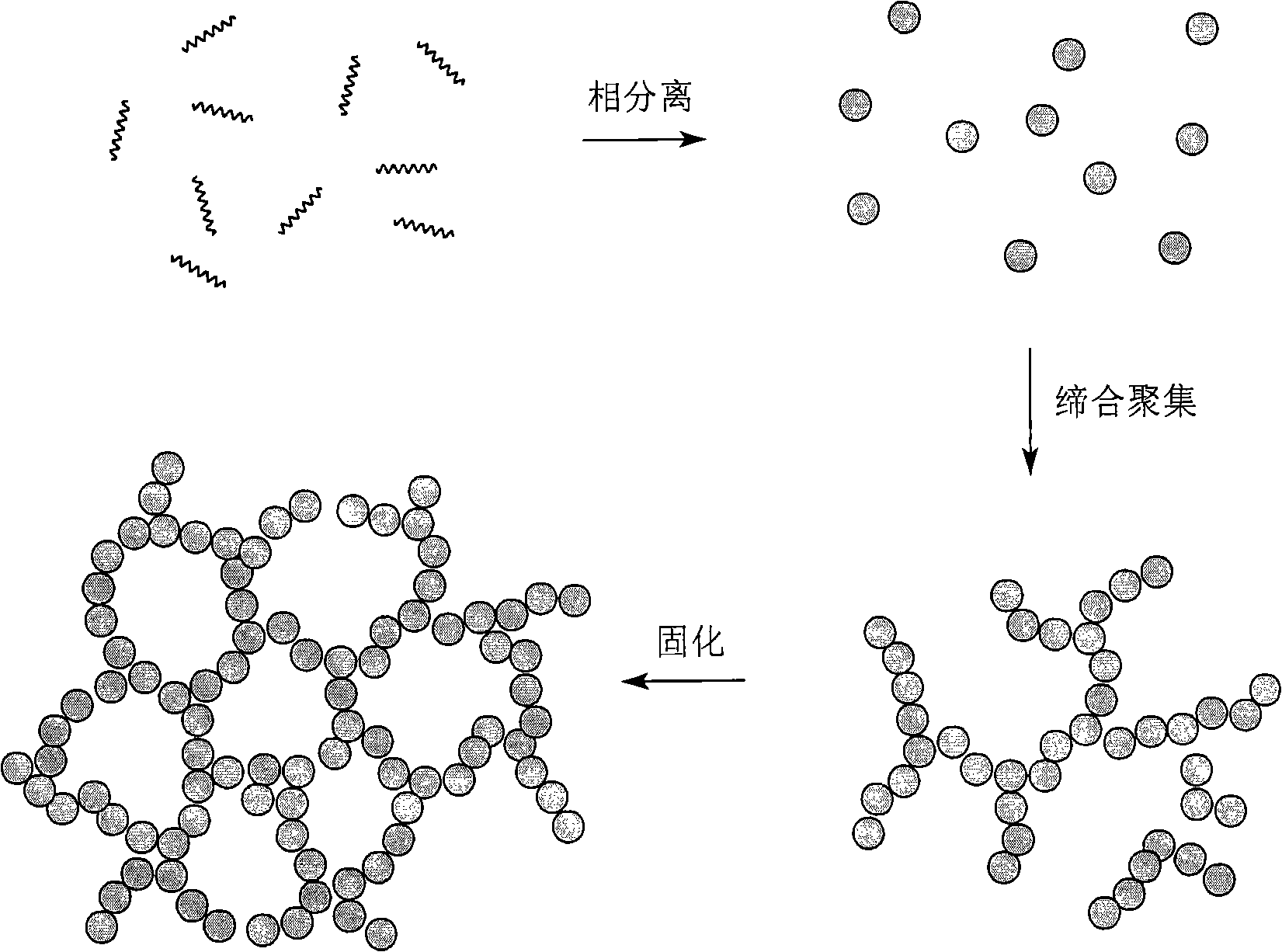

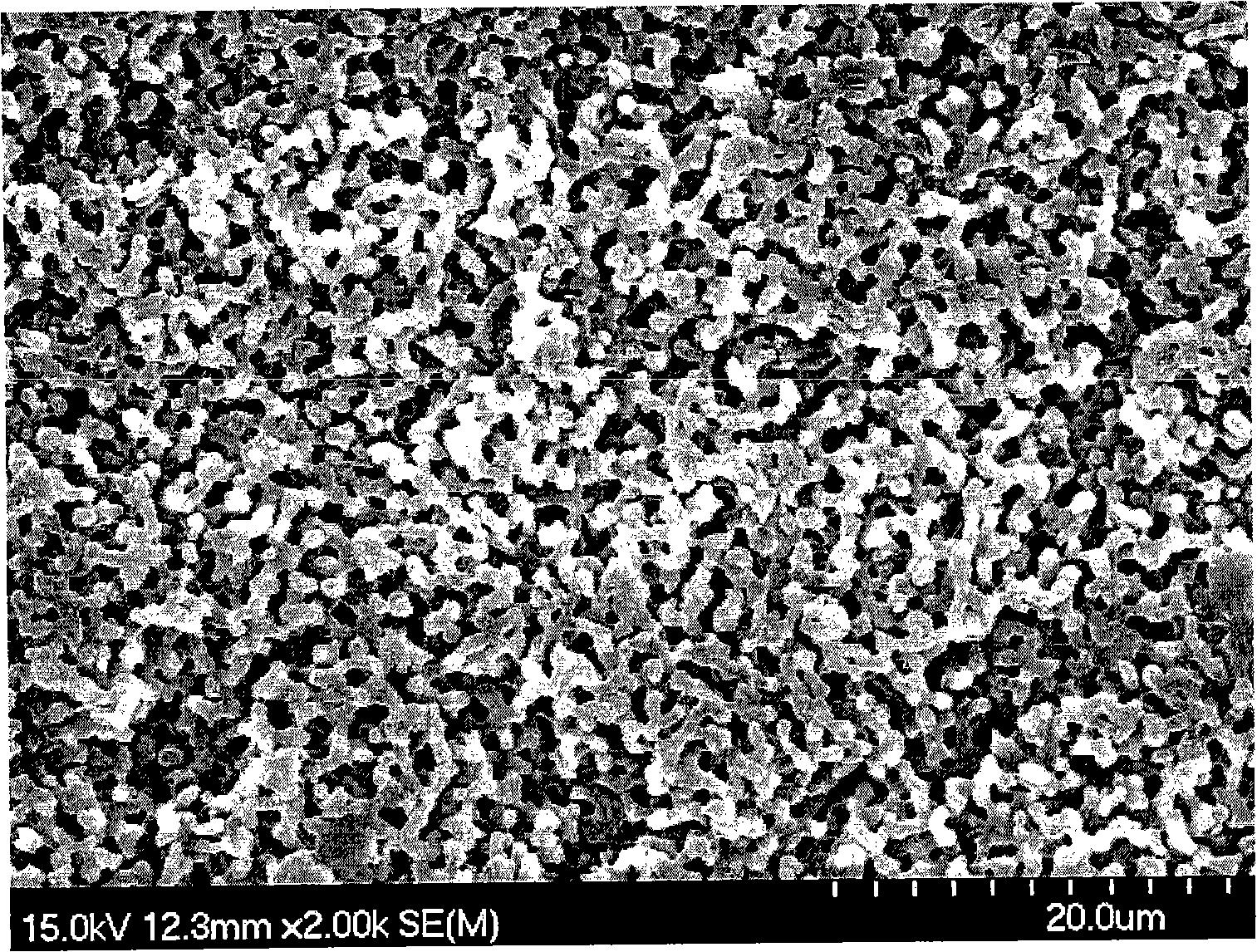

Method for preparing polymer micro-filter membrane

The invention relates to a preparation method of an epoxy resin-based micro-filtration film. Firstly, under a certain temperature, the epoxy resin and amines such as diethylene triamine or triethylenetetramine is completely dissolved in polyethyleneglycol medium by a certain weight ratio, and the air bubble is then removed; the solution is cast or flow-cast on supporting material such as metal or plastic tape, and suitable temperature is kept. After a certain time, monomer solution generates polymerization and phase separation at the same time; gel is solidified as white epoxy resin-based nascent state film; the nascent state film is finally dipped in water, and the medium polyethyleneglycol is removed to obtain the micro-filtration film. Other organic solvents are not required to be added in the preparation process, with green environmental protection. The prepared micro-filtration film has good mechanical strength, uniform distribution of aperture, adjustable size, strong hydrophilicity, acid resistance, alkali resistance and solvent resistance; furthermore, the structure of the film is not damaged by high-temperature germicidal treatment under the temperature of 120 DEG C; the film has excellent performance and the method of the invention can be widely applied to the separation and filtration in the industries such as instrument analysis, water disposal and biological medicine, etc.

Owner:NINGBO UNIV

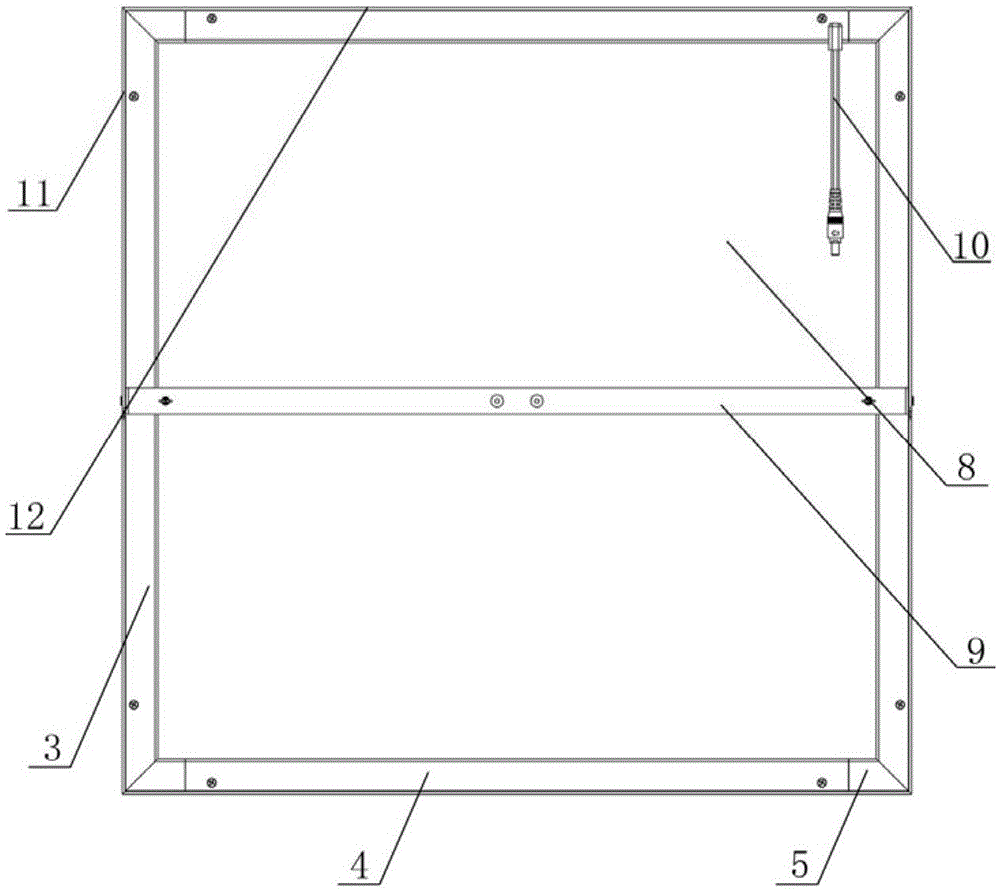

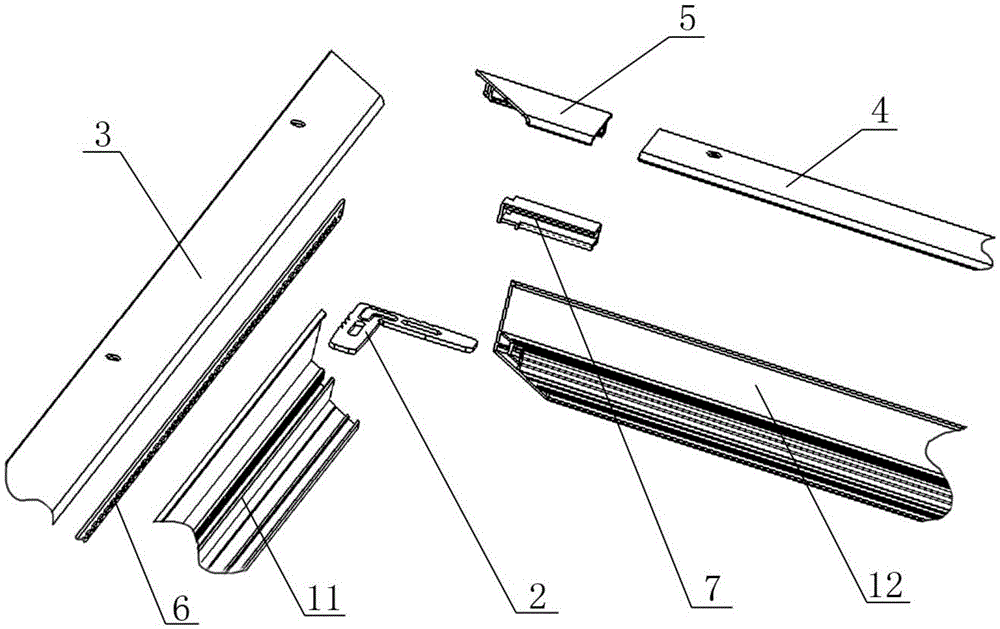

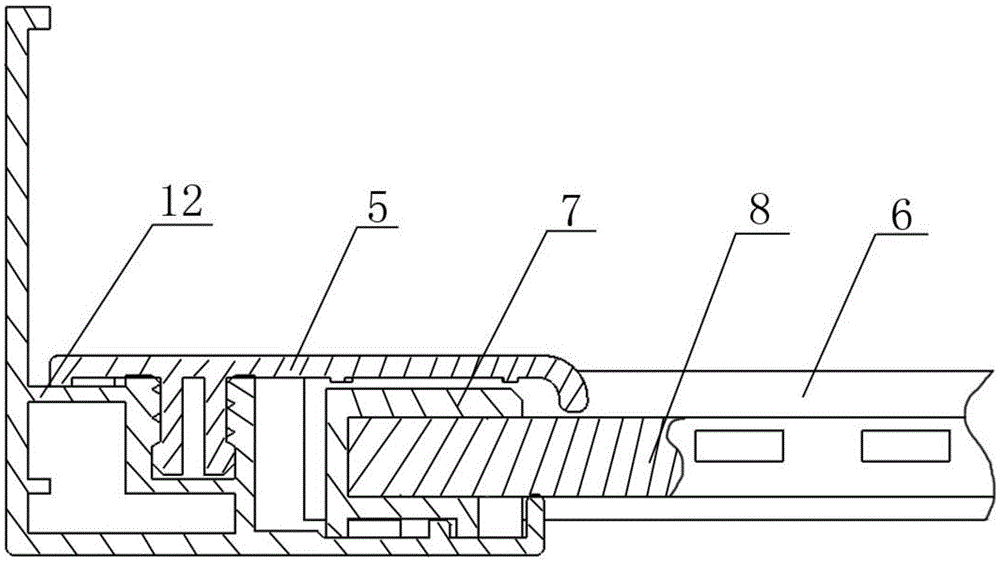

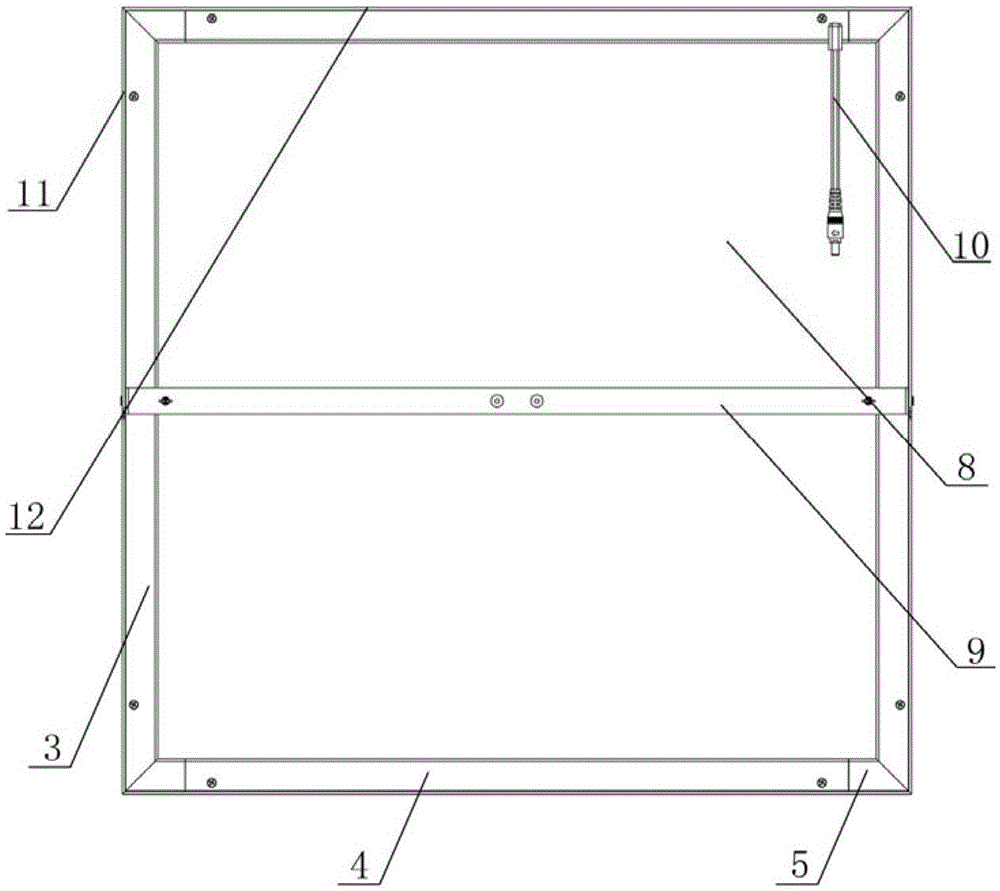

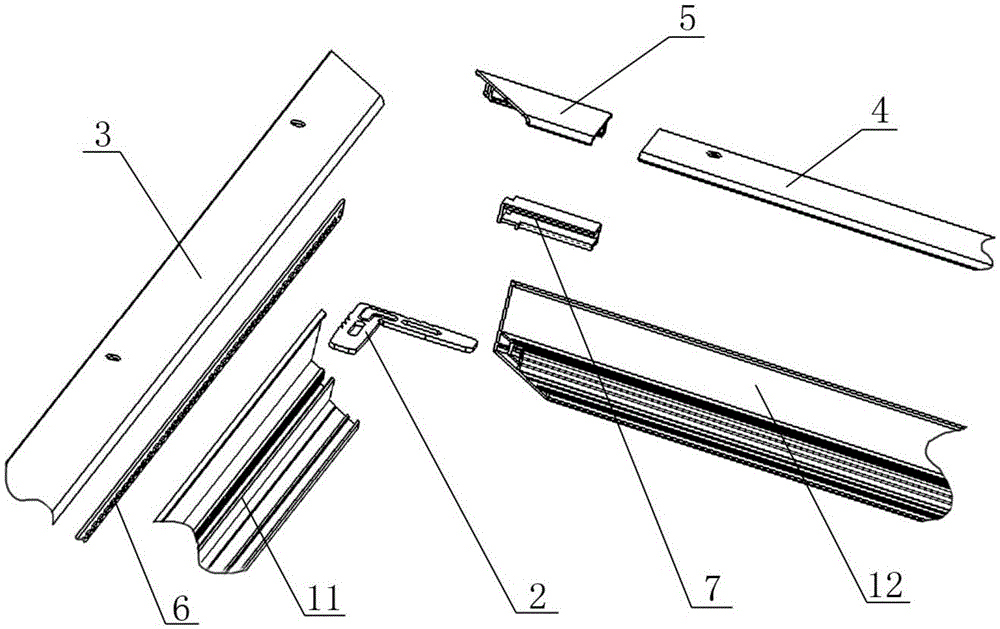

LED panel lamp

ActiveCN105650549AImprove structural strengthFirmly connectedPlanar light sourcesMechanical apparatusLight guideLED lamp

The invention relates to an LED panel lamp which comprises a frame, an LED lamp bar, positioning blocks and a light guide plate assembly, wherein the frame is formed by connection of two first frame profile bars and two second frame profile bars through four corner connection pieces, the two first frame profile bars are arranged oppositely, four corners of the light guide plate assembly are limited in clamping spaces of the four positioning blocks respectively, the four positioning blocks are fixed at the four corners of the frame, first profile bar cover plates are arranged on the first frame profile bars and mounted on the first frame profile bars in a detachable connection manner, the middles of the first profile bar cover plates extend downwards to form positioning bars, and the LED lamp bar is limited among the positioning bars and the positioning blocks; second profile bar cover plates are arranged on the second frame profile bars. The LED lamp bar is easy and convenient to replace, maintain and operate and is time-saving and labor-saving.

Owner:ANHUI ZERUN OPTOELECTRONICS

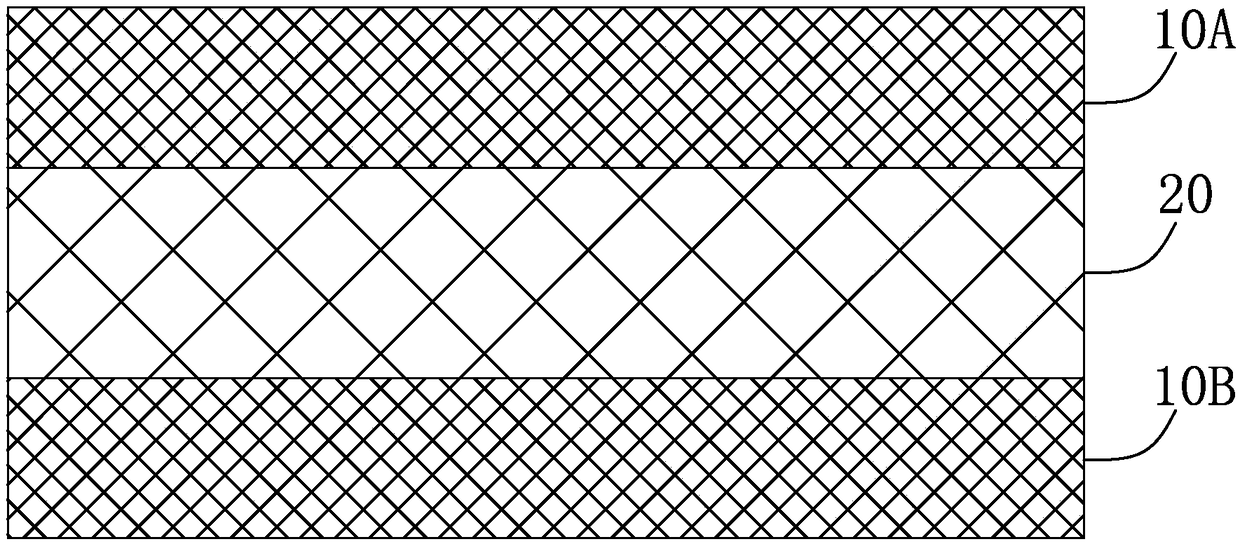

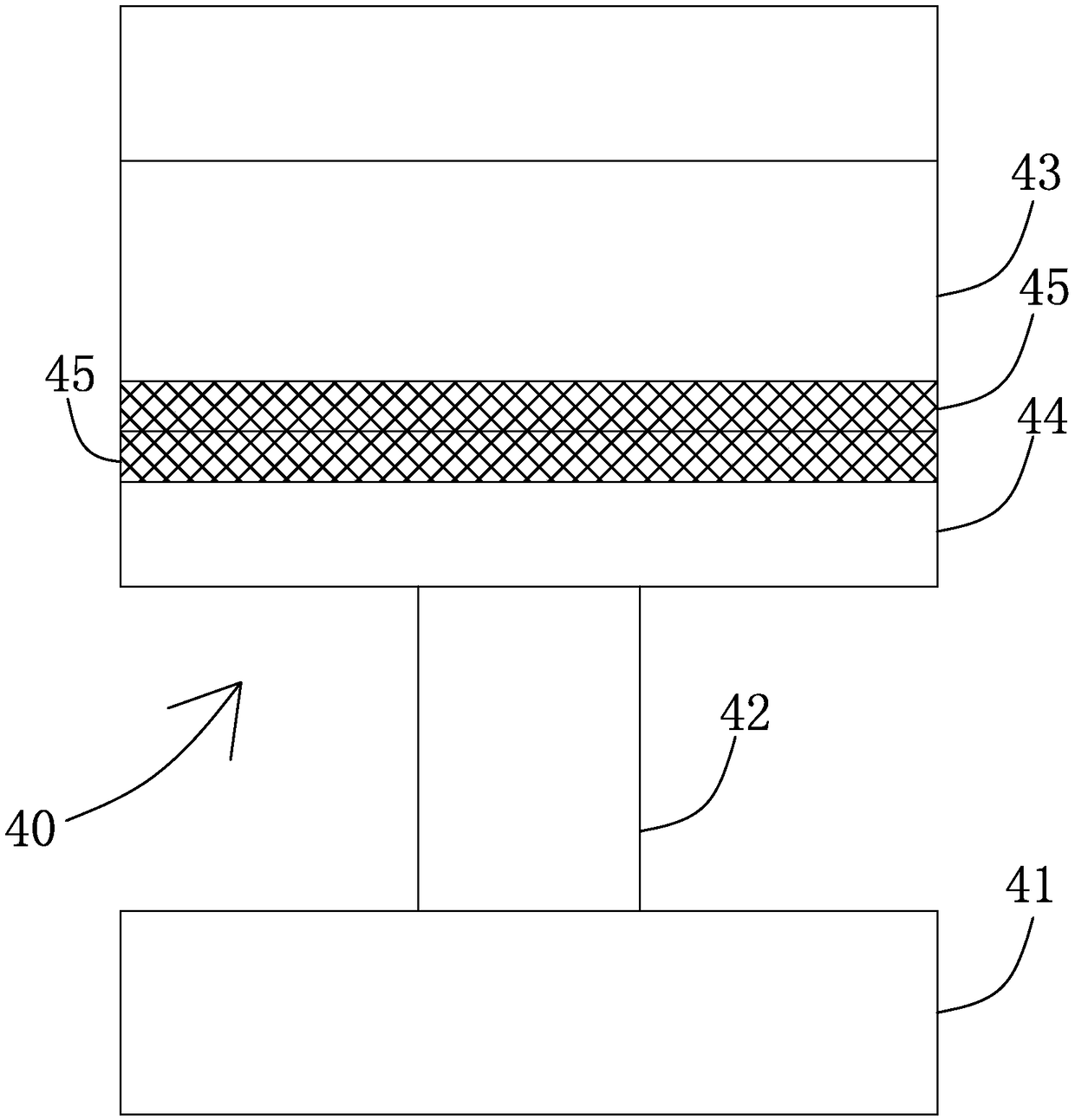

Insulating silicone gasket and preparation method and equipment thereof

PendingCN108859324AGood thermal conductivityImprove cooling efficiencyLamination ancillary operationsSynthetic resin layered productsDouble coatingThermal compression

The invention discloses an insulating silicone gasket. The insulating silicone gasket is composed of an upper thermal conductive adhesive layer, an intermediate alkali-free glass fiber cloth layer anda lower thermal conductive adhesive layer, wherein the upper and lower thermal conductive adhesive layers are composed of silicone rubber, boron nitride and an auxiliary agent, the thickness of the upper and lower thermal conductive adhesive layers is 0.02-0.4 mm respectively, and the thickness of the intermediate alkali-free glass fiber cloth layer is 0.01-0.2 mm. The invention also discloses apreparation method and equipment of the insulating silicone gasket. The insulating silicone gasket disclosed by the invention uses the boron nitride as a main filler, has an intermediate composite alkali-free glass fiber cloth layer and has a thickness of 0.1-0.5 mm; and when the breakdown voltage is greater than or equal to 3KV, the insulating silicone gasket has good heat conduction effect, highheat dissipation efficiency and no need of addition of a large amount of high heat conductive filler, the polymer structure of organosilicon cannot be damaged, so the insulating silicone gasket is convenient to process and mold. In addition, the insulating silicone gasket can be directly prepared by a two-stage double coating head coating device, is hot pressed by a molding machine, and has a simple structure and high production efficiency.

Owner:东莞市博恩复合材料有限公司

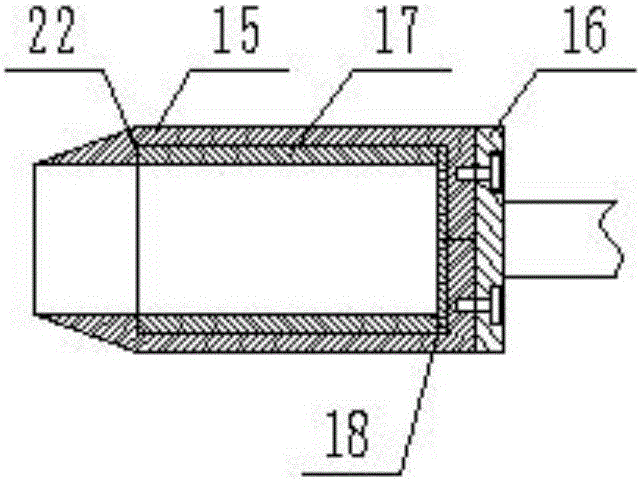

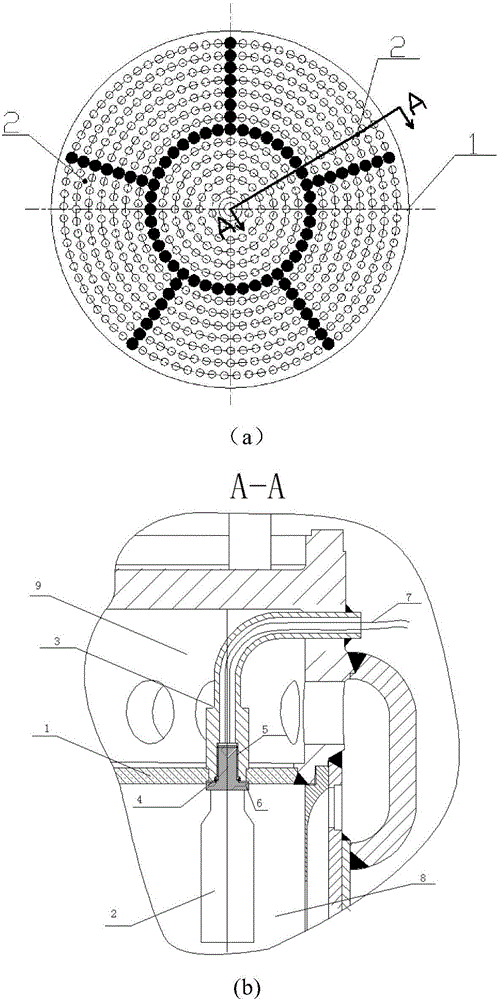

Disturbance device used for combustion stability qualification tests

ActiveCN106337759ASolve the problem of difficult installationMeet the requirements of high and low temperature extreme working environment temperatureRocket engine plantsDetonationCombustion

A disturbance device used for combustion stability qualification tests is suitable for the dynamic combustion stability qualification of a cryogenic liquid rocket engine. The disturbance device is of a combined structure composed of a composite heat insulation outer shell, a non-metal middle layer and a metal inner shell. The disturbance device can meet the temperature requirements of high-low temperature extreme work environment and achieve reliable detonation in the range of 35K-3600K; before detonation, the disturbance device needs to endure the low temperature and low pressure environment (35K, 0.5MPa) for 3s and then endure the high temperature environment (3600k, 10MPa) for 5s, and the total work time is about 10s. The disturbance device can further meet the requirements of vibration environment, and the structure is not damaged under the comprehensive vibration acceleration of about 200g; and it is guaranteed that explosion debris does not cause damage to the copper alloy inner wall of a test article.

Owner:BEIJING AEROSPACE PROPULSION INST

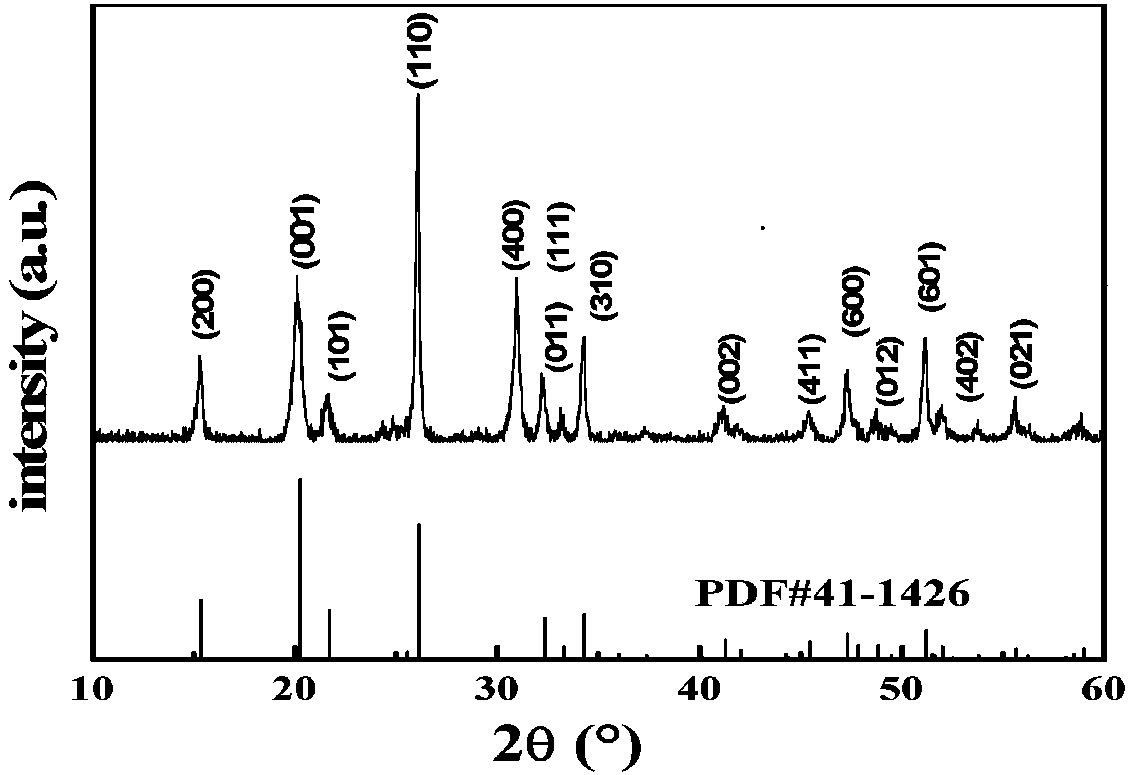

Tremelliform hollow core-shell structure vanadic anhydride positive electrode plate and its button lithium ion battery preparation method

InactiveCN108039486AQuality improvementLow costCell electrodesSecondary cellsDischarge efficiencyLithium-ion battery

The invention relates to the technical field of a lithium ion cathode material, and discloses a tremelliform hollow core-shell structure vanadic anhydride positive electrode plate and its button lithium ion battery preparation method. The synthesized tremelliform hollow core-shell structure C-coated V2O5 cathode material has advantages of high reversible capacity, good cycle performance, and highcharge and discharge efficiency, and also has the advantages of low collecting cost and environmental protection. The preparation method of the tremelliform hollow core-shell structure C-coated V2O5 cathode material has the advantages of simple process and easy operation.

Owner:HUNAN UNIV OF TECH

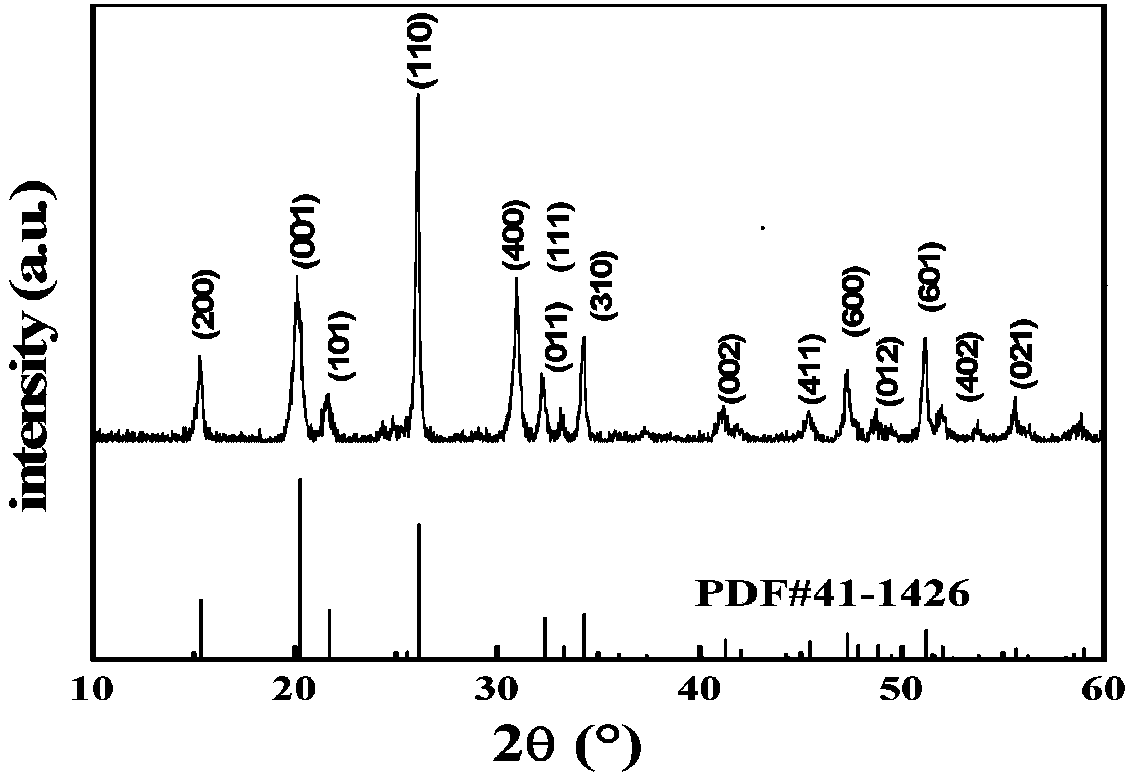

Tremella-like V2O5 lithium ion battery cathode material adopting hollow core-shell structure and preparation method of cathode material

InactiveCN108110244AHigh reversible capacityGood cycle performanceMaterial nanotechnologyCell electrodesHollow coreTremella

The invention relates to the technical field of lithium ion cathode materials and discloses a tremella-like V2O5 lithium ion battery cathode material adopting a hollow core-shell structure and a preparation method of the cathode material. The tremella-like V2O5 lithium ion battery cathode material adopting the hollow core-shell structure is prepared from raw materials including ethyl orthosilicate, m-dihydroxybenzene, formaldehyde, ammonium metavanadate and the like with a simple hydrothermal method. The electrical conductivity and stability of the existing V2O5 cathode material are greatly improved by the tremella-like hollow core-shell structure C@V2O5 with the special morphology, so that the electrochemical performance of the cathode material is significantly improved. The specific surface area is enlarged and the electrochemical performance is improved due to the tremella-like morphology. The electrical conductivity of the material is improved due to existence of hollow carbon spheres. The stability of the material is greatly improved by the hollow structure.

Owner:HUNAN UNIV OF TECH

Biological magnesium alloy with corrosion resistant function and preparation method thereof

InactiveCN107739940AImprove corrosion resistancePlay a role in corrosion resistanceSelective laser meltingAlcohol

The invention discloses biological magnesium alloy with a corrosion resistant function. The biological magnesium alloy is prepared from a biological magnesium alloy matrix and graphene oxide, whereinthe graphene oxide is distributed on the grain boundary of the biological magnesium alloy matrix, and the graphene oxide wraps biological magnesium alloy grains so as to form a second phase of a nanohoneycomb structure. The invention further discloses a preparation method. The preparation method comprises the following steps of (1) respectively putting GO powder and biological magnesium alloy powder in absolute ethyl alcohol according to the design proportion for ultrasonic agitation so as to obtain a GO suspension and a biological magnesium alloy suspension; (2) slowly adding the GO suspension to the biological magnesium alloy suspension, continuing to perform ultrasonic agitation so as to obtain a mixed suspension, and performing vacuum filtration and drying treatment on the mixed suspension so as to obtain mixed powder with uniform dispersion; and (3) performing selective laser melting on the mixed powder in the protective atmosphere so as to prepare the biological magnesium alloywith the corrosion resistant function. According to the biological magnesium alloy with the corrosion resistant function, the second phase of the nano honeycomb structure constructed by utilizing GO can be used as a shield so as to isolate the biological magnesium alloy from body fluid, so that a galvanic corrosion effect of a conventional second phase is avoided, and the corrosion resistance is improved.

Owner:CENT SOUTH UNIV

Modification method for activated carbon fiber

InactiveCN103623778ALarge adsorption capacityFast adsorptionOther chemical processesAlkali metal oxides/hydroxidesActivated carbonFiber

The invention relates to a modification method for an activated carbon fiber, and belongs to the technical field of material manufacture, particularly to a modification technology of the activated carbon material. The activated carbon fiber is boiled in boiling water under the ordinary pressure, taken out, cleaned with deionized water, dried at the constant temperature of 70 DEG C, and taken out; then the preprocessed activated carbon fiber is treated with microwave radiation of 800W and 150V. The modification method is simple in operation, and easy to control and industrialize, and economical and pollution-free when compared with a chemical modification method; the modified activated carbon fiber is larger in specific surface area, larger in low-pressure adsorption capability and specific pore volume, higher in adsorption capability and stable in structure, and adopts an un-destroyed structure of the original activated carbon fiber, compared with the original activated carbon fiber.

Owner:YANGZHOU UNIV

Preparation method of heteropoly acid / alumina mesoporous composite material

InactiveCN102247875AStructure is not destroyedHigh activityRefining with oxygen compoundsMetal/metal-oxides/metal-hydroxide catalystsChemical industryHeteropoly acid

The invention relates to a preparation method of a heteropoly acid / alumina mesoporous composite material, which is characterized in that the method comprises the following steps: dissolving aluminum isopropoxide in anhydrous alcohol, adjusting the pH value by nitric acid, adding heteropoly acid; stirring at room temperature for 4-8 hours to obtain a solution (1); dissolving a polyoxyethylene- polyoxypropylene-polyoxyethylene triblock copolymer (P123) into anhydrous alcohol to obtain a solution (2); slowly adding the solution (2) into the solution (1), stirring for 4-8 hours to obtain a uniform sol; pouring the sol into a culture dish, preserving the culture dish at 60 DEG C for 36-58 hours to obtain a light yellow film sample, grinding the sample, calcining at 400-420 DEG C for 2-3 days to obtain the heteropoly acid / alumina mesoporous composite material. The invention can effectively protect the heteropoly acid structure from being destroyed, and the material prepared by the invention has the characteristics of high activity, good selectivity, easy separation and recovery, and recyclability, and can be used as a catalyst for fuel oil deep oxidation and desulphurization in the petroleum chemical industry field.

Owner:YANGTZE UNIVERSITY

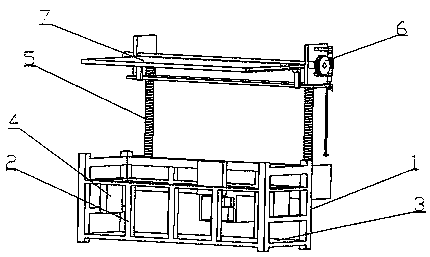

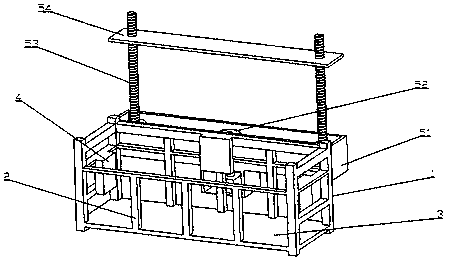

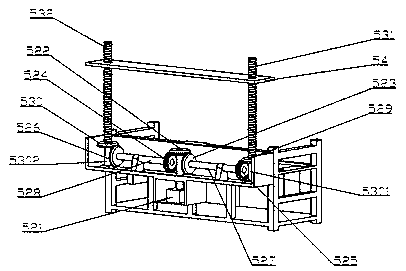

Hanging platform for hanging basket

PendingCN108678358ASimple structureStructure is not destroyedScaffold accessoriesBuilding support scaffoldsWorking environmentEngineering

The invention discloses a hanging platform for a hanging basket, and belongs to the technical field of construction engineering. The hanging platform for the hanging basket comprises a high handrail,a low handrail, a basket bottom and an elevator mounting frame which are connected and combined by bolts, and is characterized in that a lifting mechanism is arranged on the high handrail, wherein a telescopic mechanism is arranged at the top end of the lifting mechanism; the telescopic mechanism drives sunshading cloth to spread or fold. The hanging platform disclosed by the invention has the following beneficial effects: the hanging platform has the advantages of simple structure, high practicability and convenience in use; the overall structure of original hanging platform of hanging basketis not damaged, thus the transformation cost is low, and the operation is easy; moreover, the constructors can be effectively protected from some sunlight so as to provide a more humanized and more comfortable working environment.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

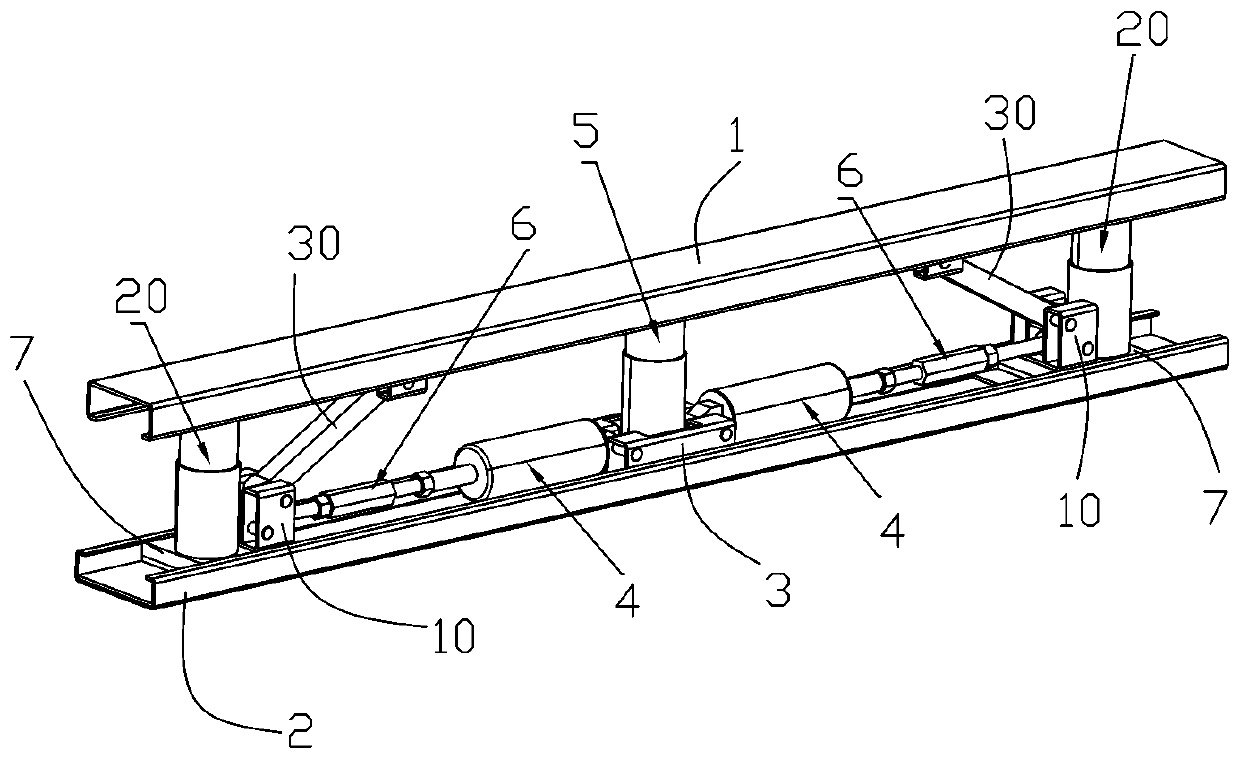

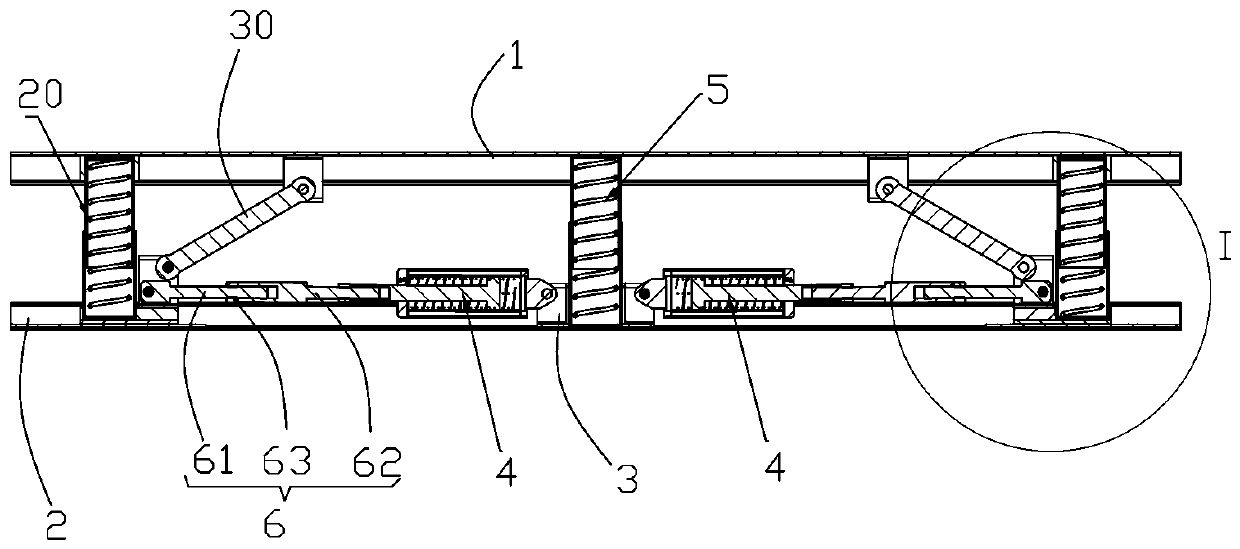

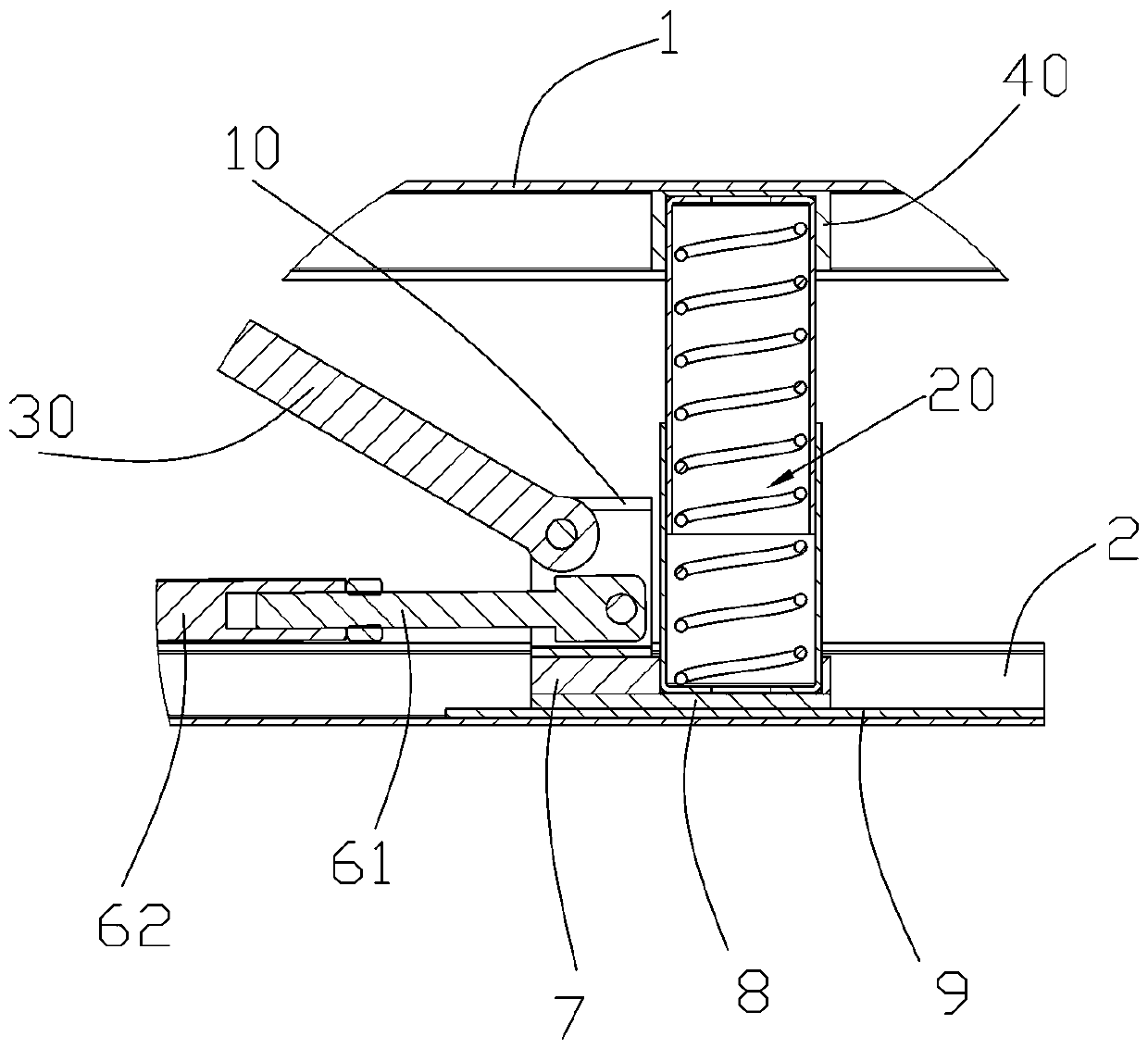

LED panel lamp and lamp bar installation structure thereof

ActiveCN105650554AImprove structural strengthAccurate and stable positionMechanical apparatusLight guides detailsLight guideEngineering

The invention belongs to the field of lighting lamps and particularly relates to a detachable LED panel lamp and a lamp bar installation structure thereof. The lamp bar installation structure comprises a frame, an LED lamp bar, positioning blocks and a light guide plate assembly, wherein the frame is formed by connection of two first frame profile bars and two second frame profile bars through four corner connection pieces, first profile bar cover plates are mounted on the first frame profile bars in a detachable connection manner, the middles of the first profile bar cover plates extend downwards to form positioning bars, the cross sections of the positioning bars of the first profile bar cover plates are in L shapes, the tail ends of the L shapes are folded to form second limit flanges, first limit flanges are further arranged in the positions, corresponding to the second limit flanges, of the first profile bar cover plates, the positioning bars of the first profile bar cover plates, the first limit flanges and the second limit flanges form an accommodating space, and the LED lamp bar is located in the accommodating space. The LED lamp bar is easy and convenient to replace and is time-saving and labor-saving.

Owner:ANHUI ZERUN OPTOELECTRONICS

Ultraviolet curing degradable cross-linking monomer and preparation method thereof

InactiveCN102408332AEasy to manufactureSimple structureOrganic compound preparationCarboxylic acid esters preparationCross-linkResist

The invention discloses an ultraviolet cured degradable cross-linking monomer which is used for ultraviolet light curing nanoimprint lithography. The cross-linking agent is formed through a reaction between a hydroxyl compound containing vinyl or (methyl) acrylate and ketone under the existence of a catalyst or a polymerization inhibitor, and nanoimprint resist can be cured through ultraviolet light into a three-dimensional net structure under the action of a photo initiating agent. The cross-linking bond of the cured substance can be opened under the existence of an acid and water to form a linear structure to be dissolved in a solvent. The ultraviolet cured degradable cross-linking monomer provided by the invention is convenient to prepare, has simple structure and is degradable. During the nanoimprint process, the ultraviolet cured degradable cross-linking monomer can be easily removed by using the solvent without damaging the structure of a template and has good application prospect in the ultraviolet light curing nanoimprint lithography.

Owner:WUXI IMPRINT NANO TECH

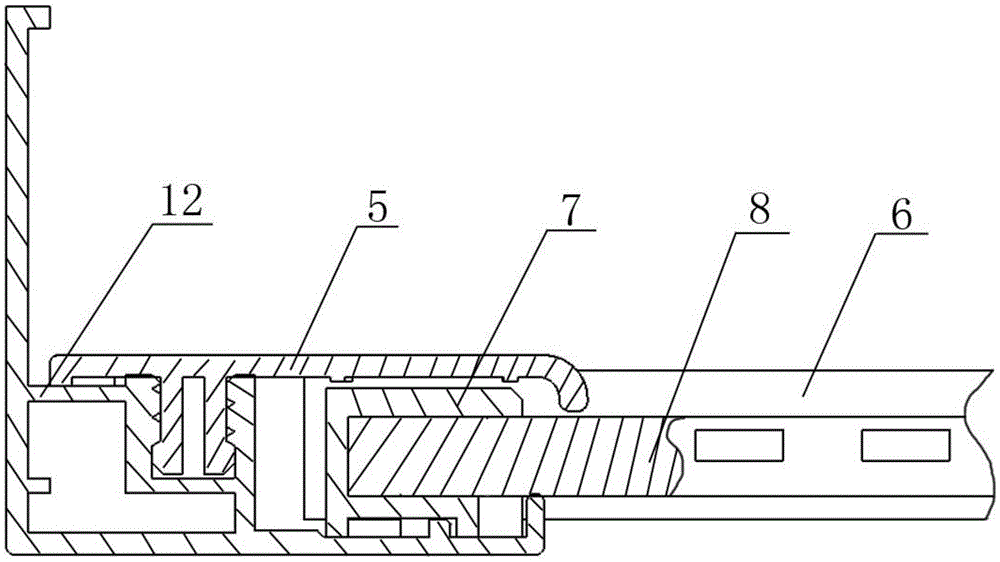

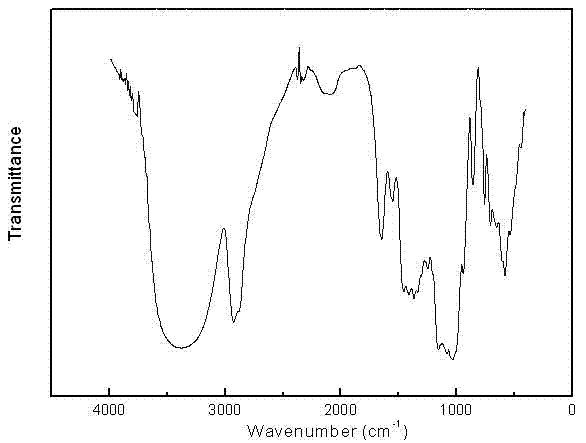

Llex A-cyclodextrin polymer medicine composition for preventing and curing atherosclerosis and preparation method thereof

InactiveCN102813938ASuppress inflammatory cellsInhibit its cytokine actionOrganic active ingredientsMacromolecular non-active ingredientsSolubilityDyslipidemia

The invention provides a novel llex A-cyclodextrin polymer (llex A-CDP) medicine composition for preventing and curing atherosclerosis (AS) and in particular relates to a preparation method of the novel water-soluble llex A-CDP medicine composition which takes CDP as the host molecule and llex A as the guest molecule. The invention obviously enhance the water-solubility of llex A and has regulating effect for dyslipidemia related to AS and inbibitional effect for inflammatory cell factor in vessel atheromatous plaque. The preparation method comprises the following steps: cyclodextrin polymer is taken as the raw material and is crosslinked with epoxy chloropropane under the condition of strong basicity to generate cyclodextrin polymer; the cyclodextrin polymer is taken as the host molecule, the llex A is taken as the guest molecule and water is taken as the reaction solvent to prepare the water-soluble llex A-CDP medicine composition by supermolecular reaction.

Owner:YANGZHOU UNIV

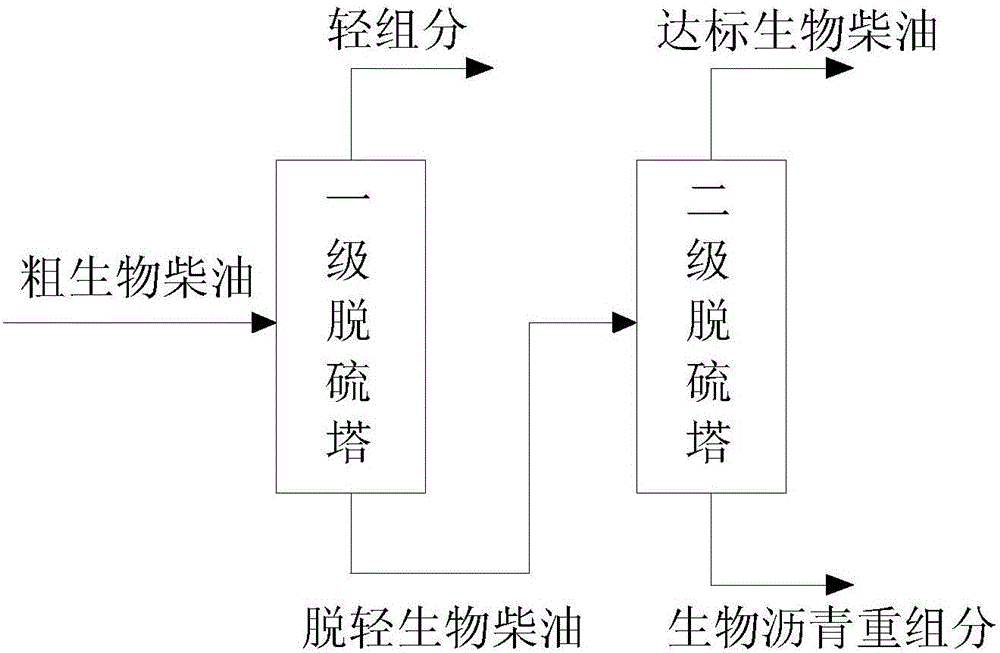

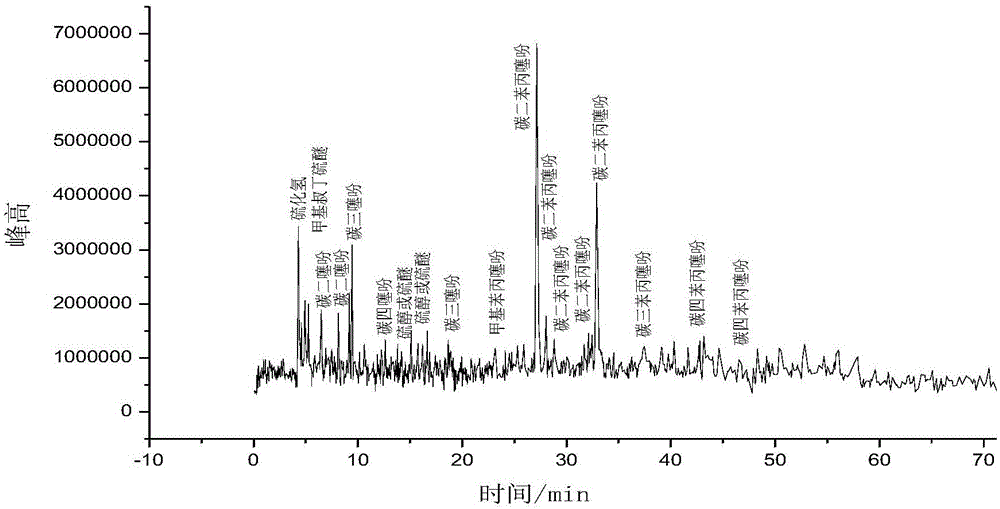

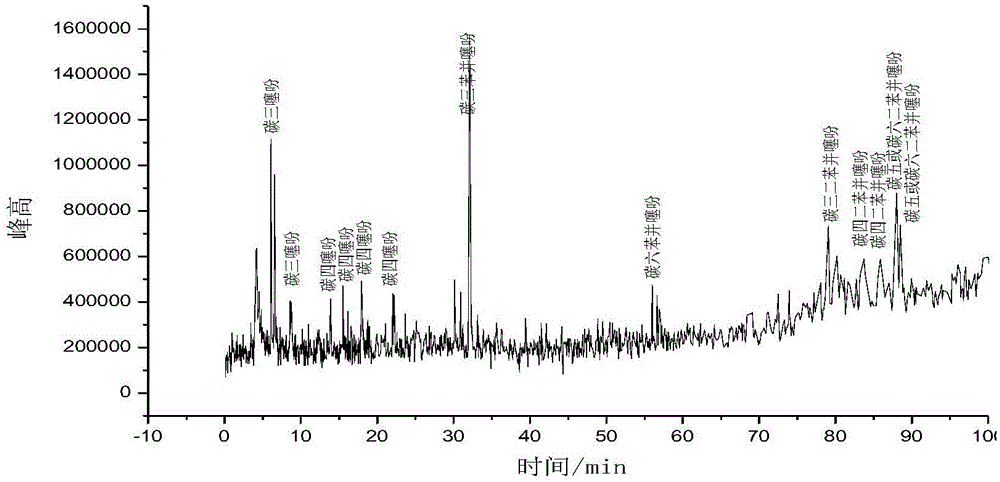

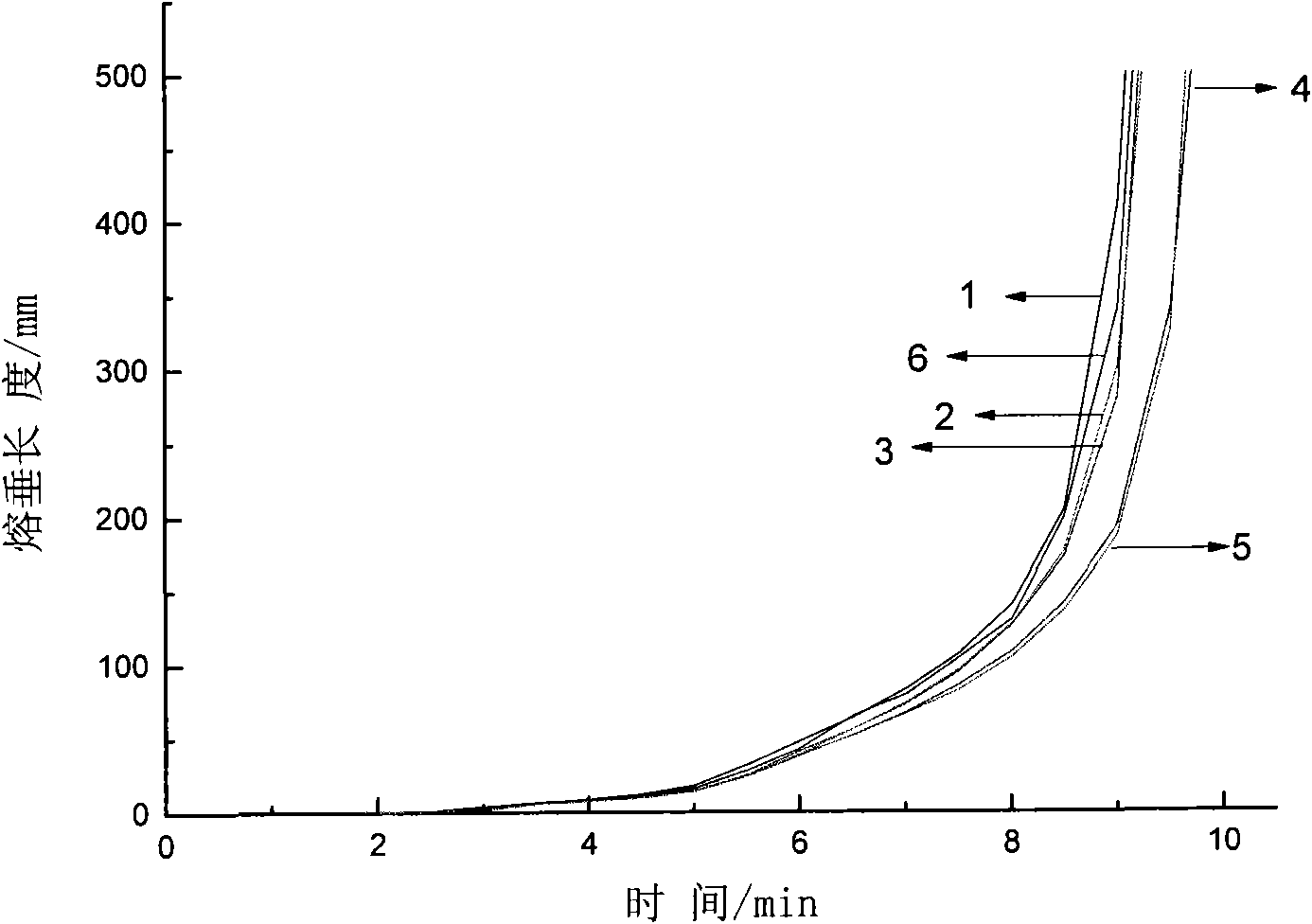

Novel desulfurization method of biodiesel

InactiveCN106336919AReduce sulfur contentQuality improvementFatty acids production/refiningLiquid carbonaceous fuelsBiodieselEngineering

The invention relates to a novel desulfurization method of biodiesel. The method comprises the steps that sulfur-containing compounds in the biodiesel are removed through two stages of high vacuum distillation, crude biodiesel is pumped into a first-stage desulfurization tower for first-stage high vacuum distillation, the tower top of the first-stage desulfurization tower is rich in light components of the sulfur-containing compounds; desulfurized biodiesel at the kettle bottom of the first-stage desulfurization tower is pumped into a second-stage desulfurization tower through a pump for second-stage high vacuum distillation, biodiesel reaching the standard is steamed out from the tower top of the second-stage desulfurization tower, the content of sulfur in the biodiesel reaching the standard is lower than 10 ppm, biological asphalt heavy components are obtained in a tower kettle of the second-stage desulfurization tower, the absolute operation pressure of the desulfurization towers ranges from 10 Pa to 1,000 Pa, and the tower kettle heating temperature ranges from 200 DEG C to 300 DEG C. The method is simple in technological process, low in equipment investment cost and capable of obtaining the biodiesel meeting the standard stably; compared with a traditional petrochemical oil product desulfurization method, a high-temperature catalytic reaction is not related, new substances are not introduced, therefore, the process is safer, the oil product structure is not destroyed, and it is guaranteed that the oil quality is stable.

Owner:ZHEJIANG UNIV OF TECH

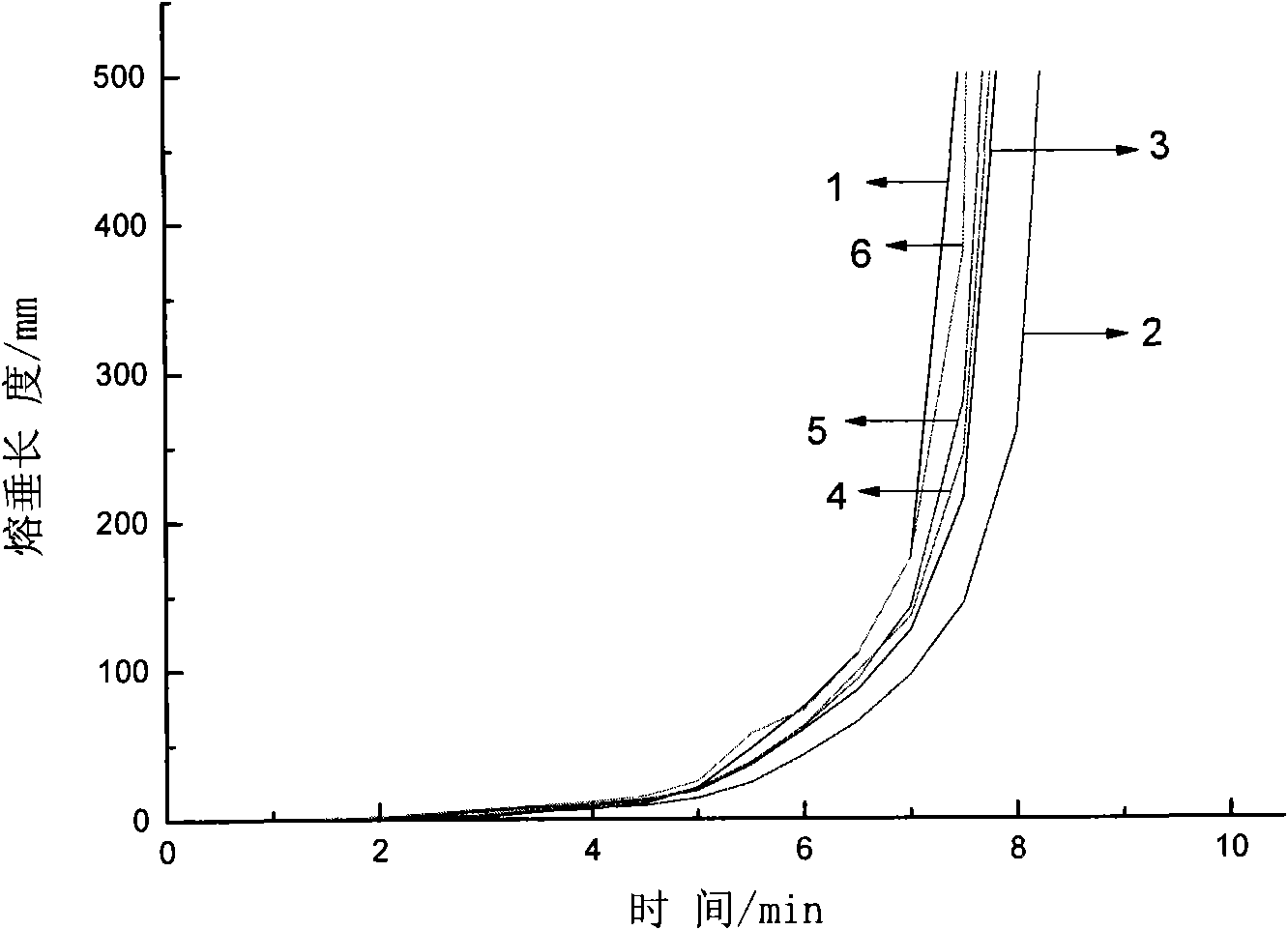

Sag resistant polypropylene and preparation method thereof

The invention relates to sag resistant polypropylene and a preparation method thereof, wherein the raw materials thereof are as follows in parts by weight: 100 parts of linear polypropylene, 0.5-5 parts of compatilizer, 1-5 parts of nano-clay and 0.5-1 part of antioxidant; and the product is obtained by extruding the raw materials in an extruder at the temperature of 175-205 DEG C. The preparation method comprises the following steps: mixing the linear polypropylene and compatilizer; adding the nano-clay and antioxidant, mixing to obtain a mixed material; adding the mixed material in a dual-screw extruder; extruding and pelletizing at the temperature of 175-205 DEG C; and drying. The invention intercalates the polymer large-molecular chain between sheets of a stack structure of the nano-clay so as to generate a polypropylene / nano-clay composite material with an intercalated structure, and the intercalated stack structure assembly services as a physical linking point in the polypropylene melt, thus improving elasticity of the polypropylene melt, and enhancing the slag-resistance performance of the polypropylene melt.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

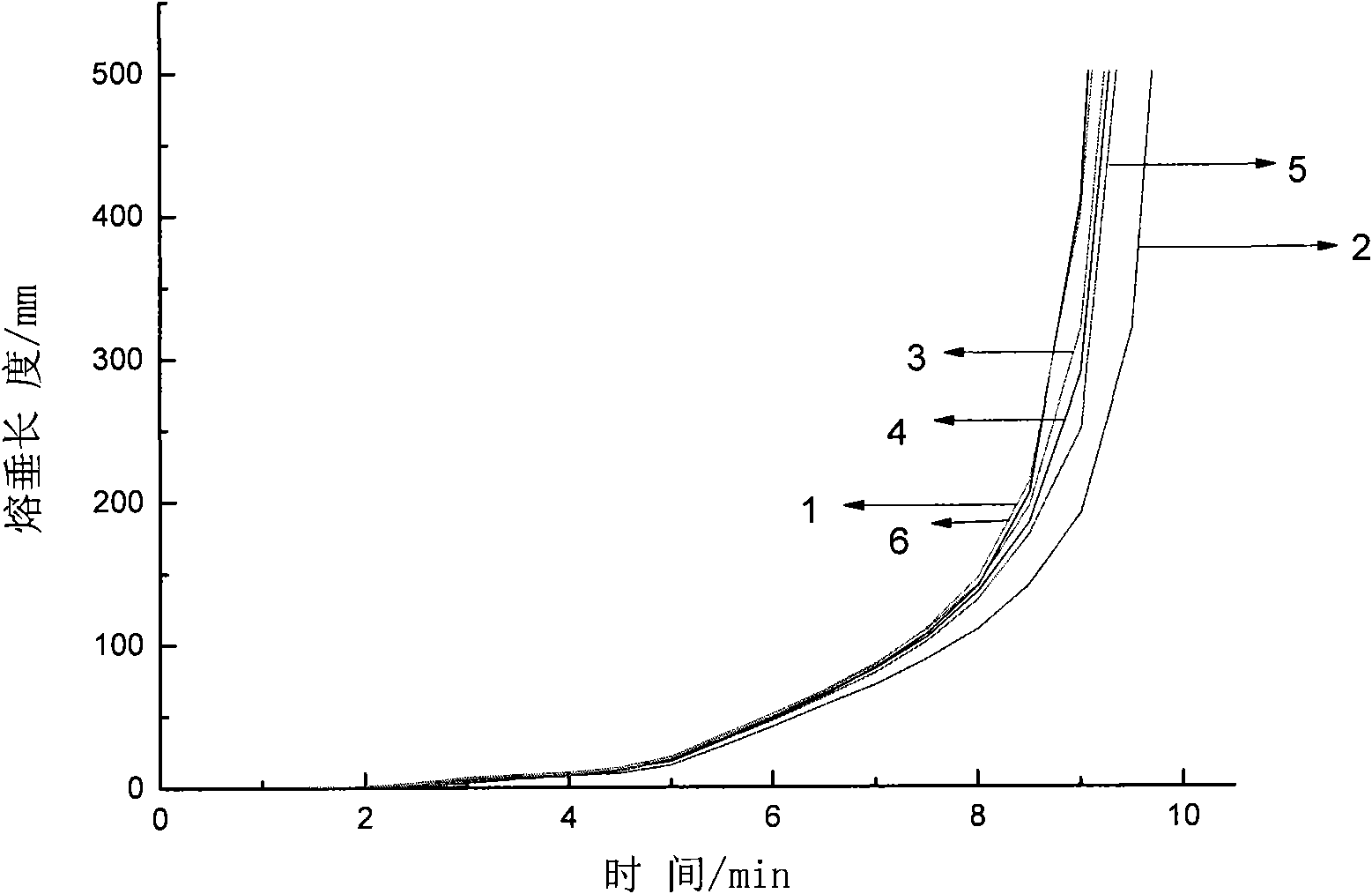

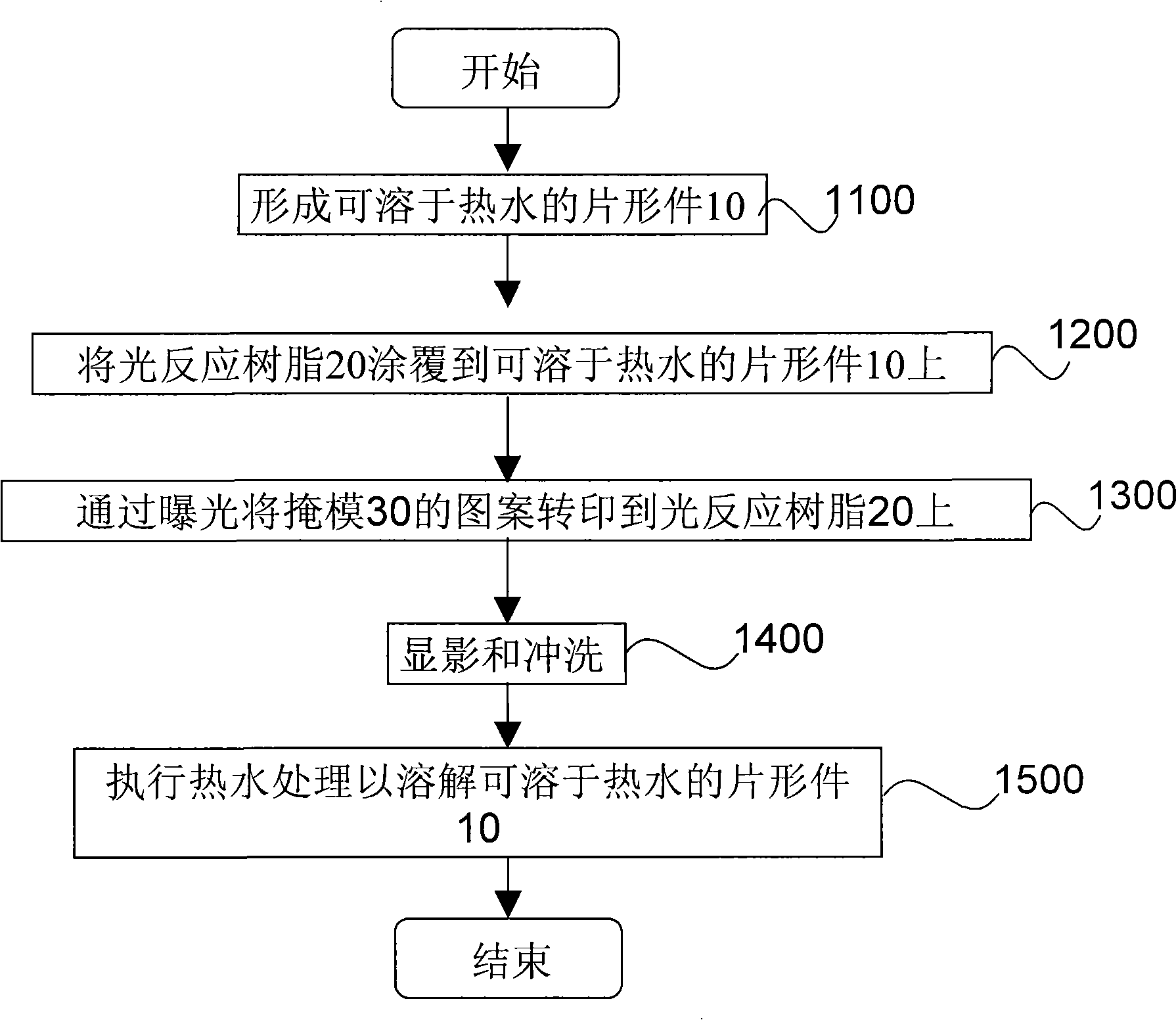

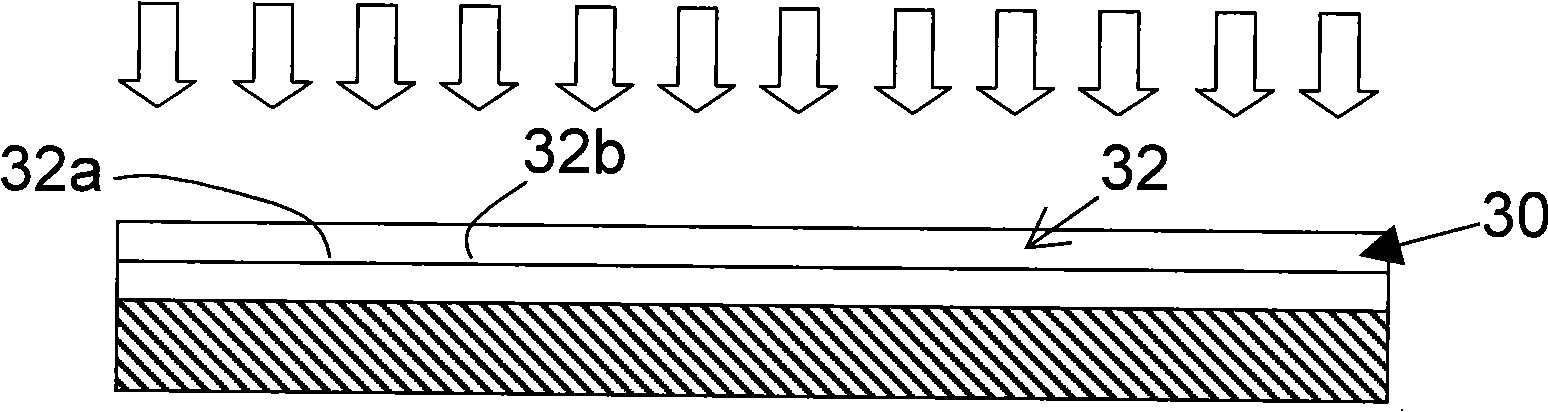

Method for producing structure

InactiveCN101266404AEasy to makeStructure is not destroyedPhotomechanical exposure apparatusPhotosensitive material processingChemistryRadiation

According to the present invention, a method is provided for manufacturing a structure composed of a photoreactive resin comprising the steps of: forming the photoreactive resin on a sheet member soluble in water; exposing the photoreactive resin selectively to a radiation activating the photoreactivity to produce the structure; and dissolving the sheet member in water after the exposing step.

Owner:FUJITSU LTD

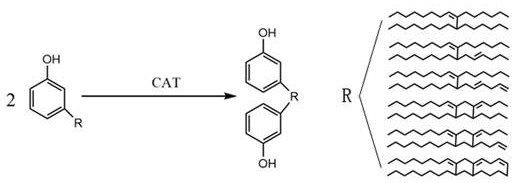

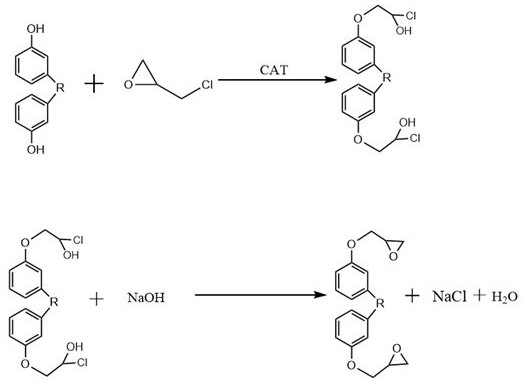

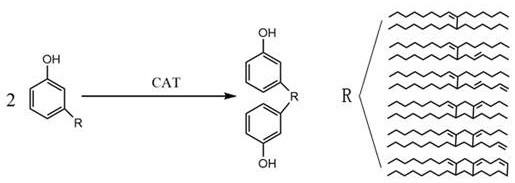

Preparation method of novel cardanol modified epoxy resin

PendingCN112250645AStrong responsivenessImproved solvent resistanceOrganic chemistryCardanolEthyl ester

The invention discloses a preparation method of novel cardanol modified epoxy resin, which belongs to the technical field of preparation of epoxy resin, and particularly comprises the steps of addinga mixture of cardanol and azobisisobutyronitrile or azobisisoheptonitrile into a reactor, heating to react, then adding a diethyl sulfate-phosphoric acid system (DES-H3PO4) or a diethyl sulfate-sulfuric acid system (DES-H2SO4), heating for reaction to obtain an intermediate product cardanol oligomer, after the temperature of the intermediate product is reduced to room temperature, adding epoxy chloropropane and tetraethylammonium bromide, uniformly mixing, heating for reaction, slowly dropwise adding a 48% NaOH solution, carrying out reduced pressure distillation, and filtering to obtain a final product. The novel epoxy resin prepared by the method is good in toughness, low in viscosity and good in chemical resistance and heat resistance, the performance of the novel epoxy resin is superior to that of a common epoxy resin product, and the novel epoxy resin utilizes the renewable resource cardanol and is green, environmentally friendly, low in cost and multipurpose.

Owner:ZHEJIANG WANSHENG

Low-smoke-density PC/ABS composition and preparation method thereof

The invention provides a PC / ABS (polycarbonate / acrylonitrile butadiene styrene) composition with low smoke density and a preparation method thereof. The composition comprises the following components in parts by weight: 50 to 80 parts of PC resin; 10 to 40 parts of ABS resin; 5 to 10 parts of porous ceramic; 0.1 to 1 part of an antioxidant; and 0.1 to 1 part of a lubricant. Due to the fact that the carbon density of PC is very high, PC / ABS can generate some unsaturated carbides and form dense smoke during combustion, compared with the prior art, according to the low-smoke-density PC / ABS composition; due to the fact that the porous ceramic component is added, the obvious smoke suppression effect is achieved, the porous structure can adsorb most dense smoke released during PC / ABS combustion, wherein the smoke density is reduced, and the effect is remarkable.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Adjustable car crash energy absorption device

InactiveCN110816452AThe size of energy absorption is adjustableSafe and reliable structureBumpersEnergy absorptionDamper

The invention discloses an adjustable car crash energy absorbing device. The adjustable car crash energy absorbing device comprises an anti-corrosion beam, a car body cross beam, a center hinged seat,hydraulic dampers and a first elastic energy absorbing mechanism. The output ends of the two hydraulic dampers are fixedly connected with adjusting connecting rod assemblies correspondingly. The other ends of the two adjusting connecting rod assemblies are both fixedly connected with lower sliding blocks. The two lower sliding blocks are symmetric about the center hinged seat. The two lower sliding blocks are slidably connected to the car body cross beam. First friction plates are fixed to the bottom surfaces of the lower sliding blocks. Second friction plates are fixed to the positions, corresponding to the first friction plates, of the car body cross beam. A hinge support and a second elastic energy absorbing mechanism are fixed to each lower sliding block. A supporting arm is hinged toeach hinge support. The other ends of the supporting arms are fixedly hinged to the anti-corrosion beam. The free end of each second elastic energy absorbing mechanism is fixed to an upper sliding block. The upper sliding blocks are slidably connected to the anti-corrosion beam. The adjustable car crash energy absorbing device can achieve the three-grade energy absorbing effect, does not damage the self-structure in the energy absorbing process and is lower in maintenance cost, applicable to different car types and high in universality.

Owner:荆门禾硕精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com