Hard carbon material for anode of sodium-ion battery, preparation method of hard carbon material and related sodium-ion battery

A technology of sodium ion battery and negative electrode material, applied in the fields of energy storage materials and electrochemistry, can solve the problems of poor performance and high cost, and achieve the effects of less difficulty in industrialization, high specific capacity and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Step 1: Take 10g of rape stalks, put them into 1mol / L potassium hydroxide solution, stir and wash for 1 hour, filter and separate, then put them into 1mol / L hydrochloric acid solution, stir and wash for 1 hour, filter and separate, put them in an oven, Dry at 80°C for 12 hours to remove moisture;

[0039] Step 2: Put the dried sample in step 1 into a tube furnace, raise the temperature to 400°C at a rate of 5°C / min in an inert gas atmosphere, and keep it warm for 1 hour. After completion, naturally cool to room temperature with the furnace and take it out;

[0040] Step 3: Put the sample treated in step 2 into a tube furnace, raise the temperature from room temperature to 1000°C at a rate of 5°C / min under an inert gas atmosphere, and keep it warm for 2 hours. After the pyrolysis reaction is completed, cool it with the furnace to room temperature, take out;

[0041] Step 4: The sample taken out in step 3 was stirred and washed in 1 mol / L hydrochloric acid solution for 1 ...

Embodiment 2

[0044] Step 1: Take 10g of rape stalks, put them into 1mol / L sodium hydroxide solution, stir and wash for 1 hour, filter and separate, then put them into 1mol / L hydrochloric acid solution, stir and wash for 1 hour, filter and separate, put them in an oven, Dry at 80°C for 8 hours to remove moisture;

[0045] Step 2: Put the dried sample in step 1 into a tube furnace, raise the temperature to 400°C at a rate of 5°C / min in an inert gas atmosphere, and keep it warm for 1 hour. After completion, naturally cool to room temperature with the furnace and take it out;

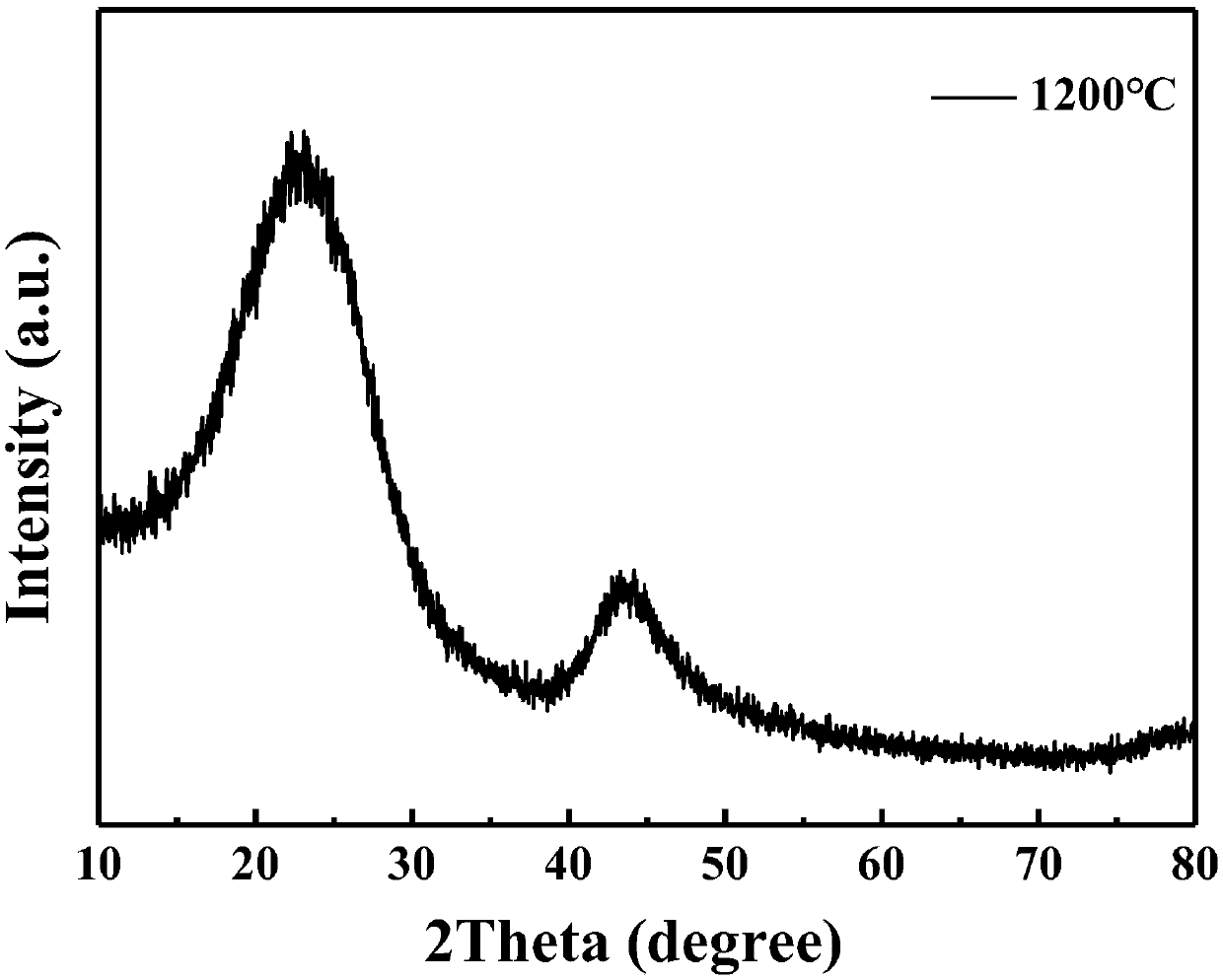

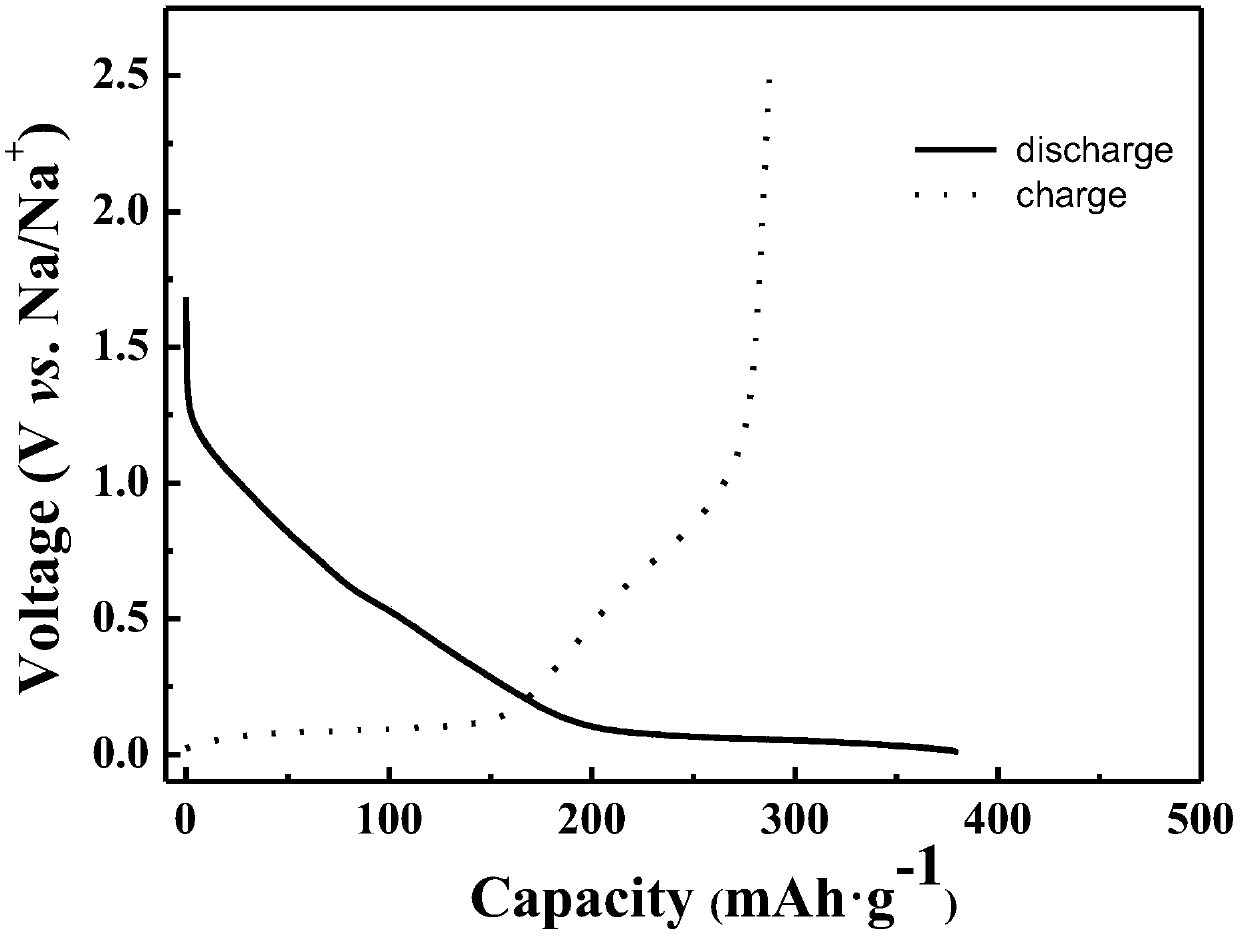

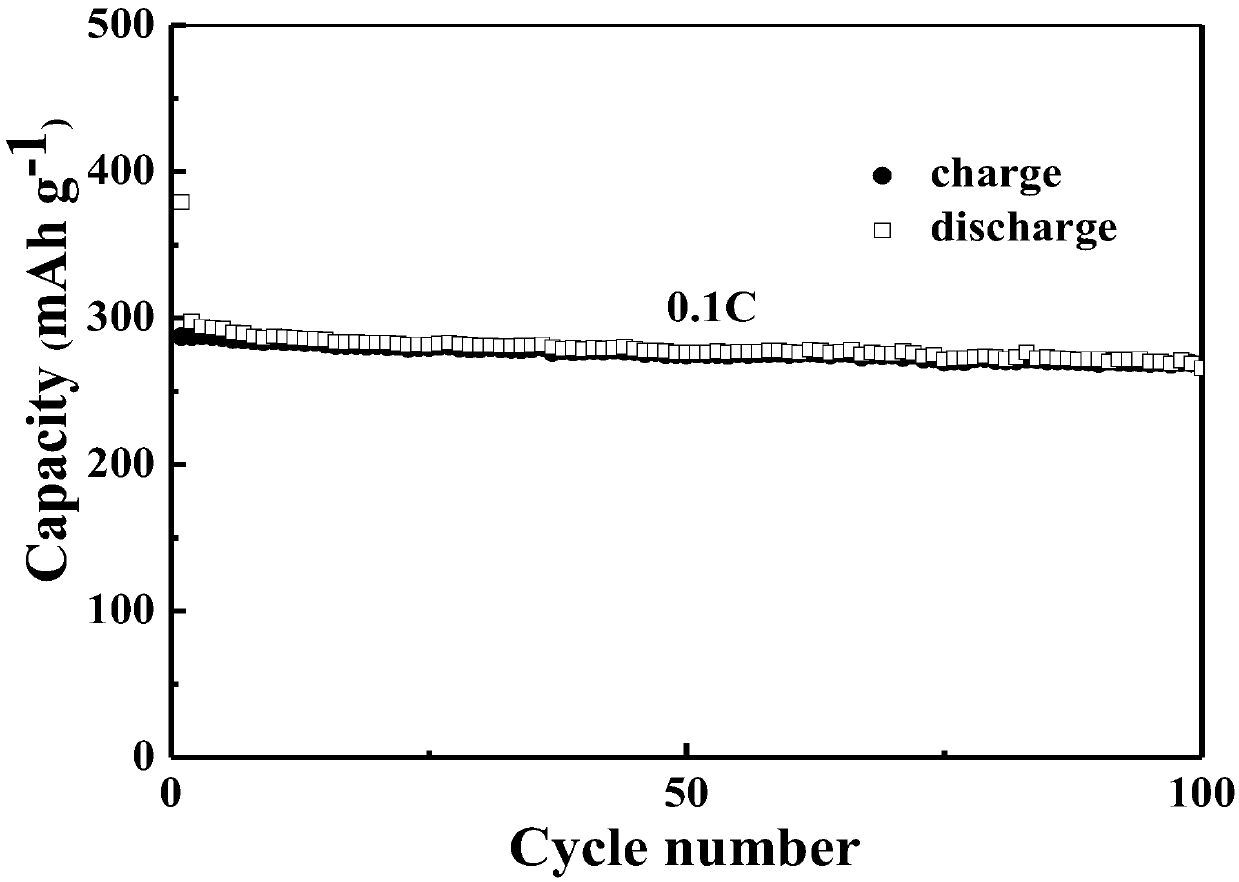

[0046] Step 3: Put the sample treated in step 2 into a tube furnace, raise the temperature from room temperature to 1200°C at a rate of 5°C / min under an inert gas atmosphere, and keep it warm for 2 hours. After the pyrolysis reaction is completed, cool down with the furnace to room temperature, take out;

[0047] Step 4: The sample taken out in step 3 was stirred and washed in 1 mol / L hydrochloric acid solution for 1 h...

Embodiment 3

[0054] Step 1: Take 10g of rape stalks, put them into 2mol / L sodium hydroxide solution, stir and wash for 1 hour, filter and separate, then put them into 1mol / L hydrochloric acid solution, stir and wash for 1 hour, filter and separate, put them in an oven, Dry at 80°C for 8 hours to remove moisture;

[0055] Step 2: Put the dried sample in step 1 into a tube furnace, raise the temperature to 400°C at a rate of 5°C / min in an inert gas atmosphere, and keep it warm for 2 hours. After completion, naturally cool to room temperature with the furnace and take it out;

[0056] Step 3: Put the sample treated in step 2 into a tube furnace, raise the temperature from room temperature to 1400°C at a rate of 5°C / min under an inert gas atmosphere, and keep it warm for 3 hours. After the pyrolysis reaction is completed, cool down with the furnace to room temperature, take out;

[0057] Step 4: The sample taken out in step 3 was stirred and washed in 1 mol / L hydrochloric acid solution for 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com