Patents

Literature

39results about How to "Industrialization is less difficult" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard carbon material for anode of sodium-ion battery, preparation method of hard carbon material and related sodium-ion battery

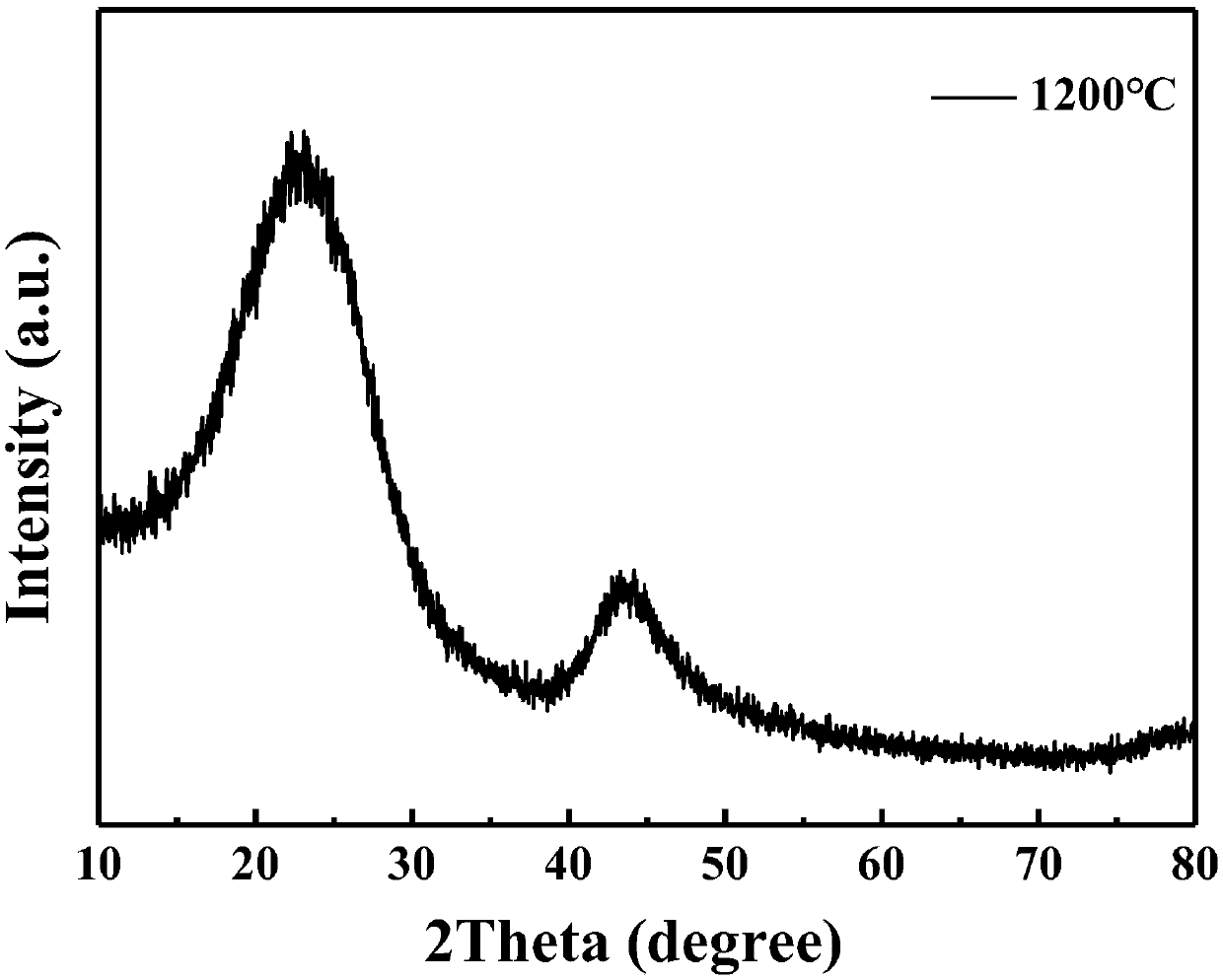

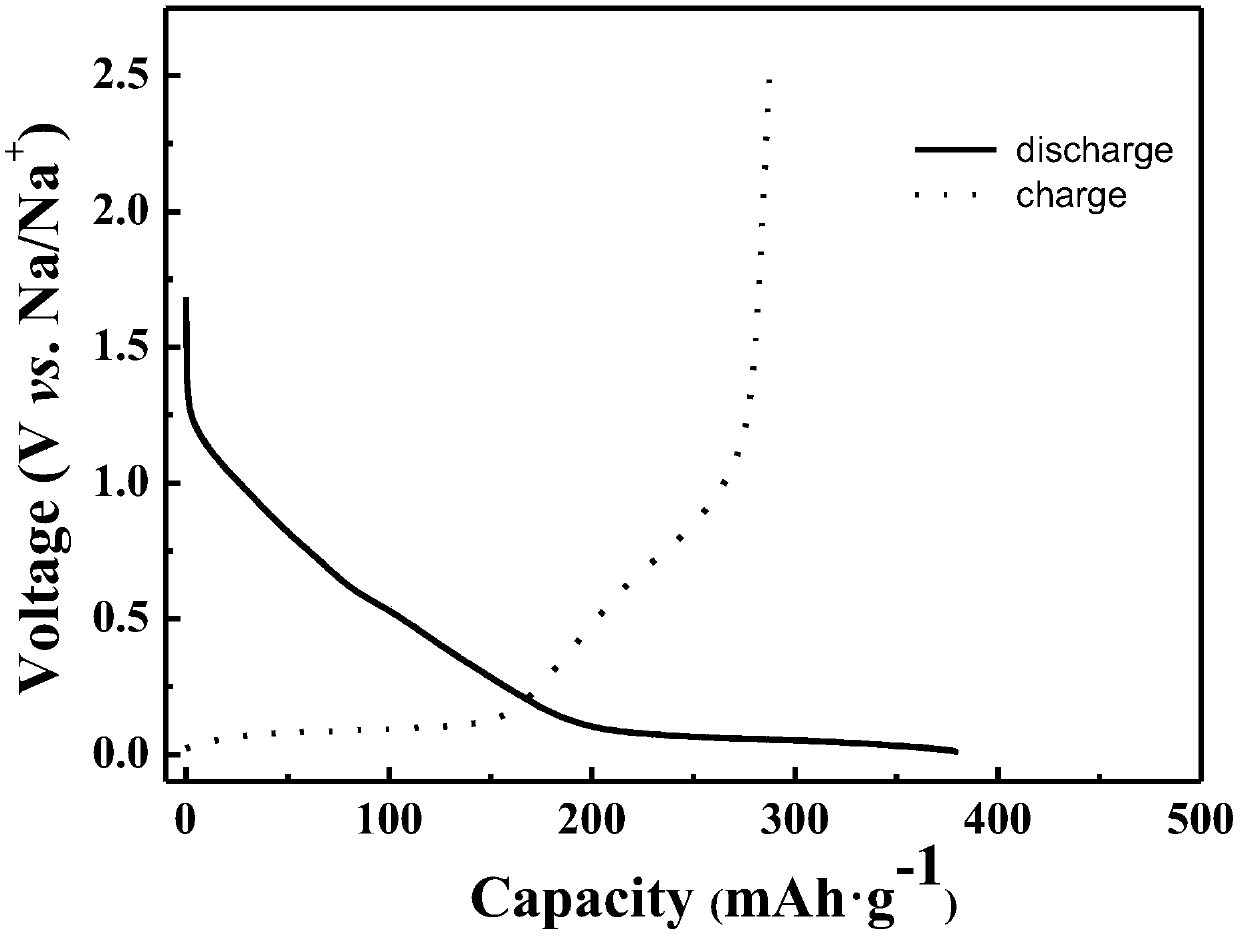

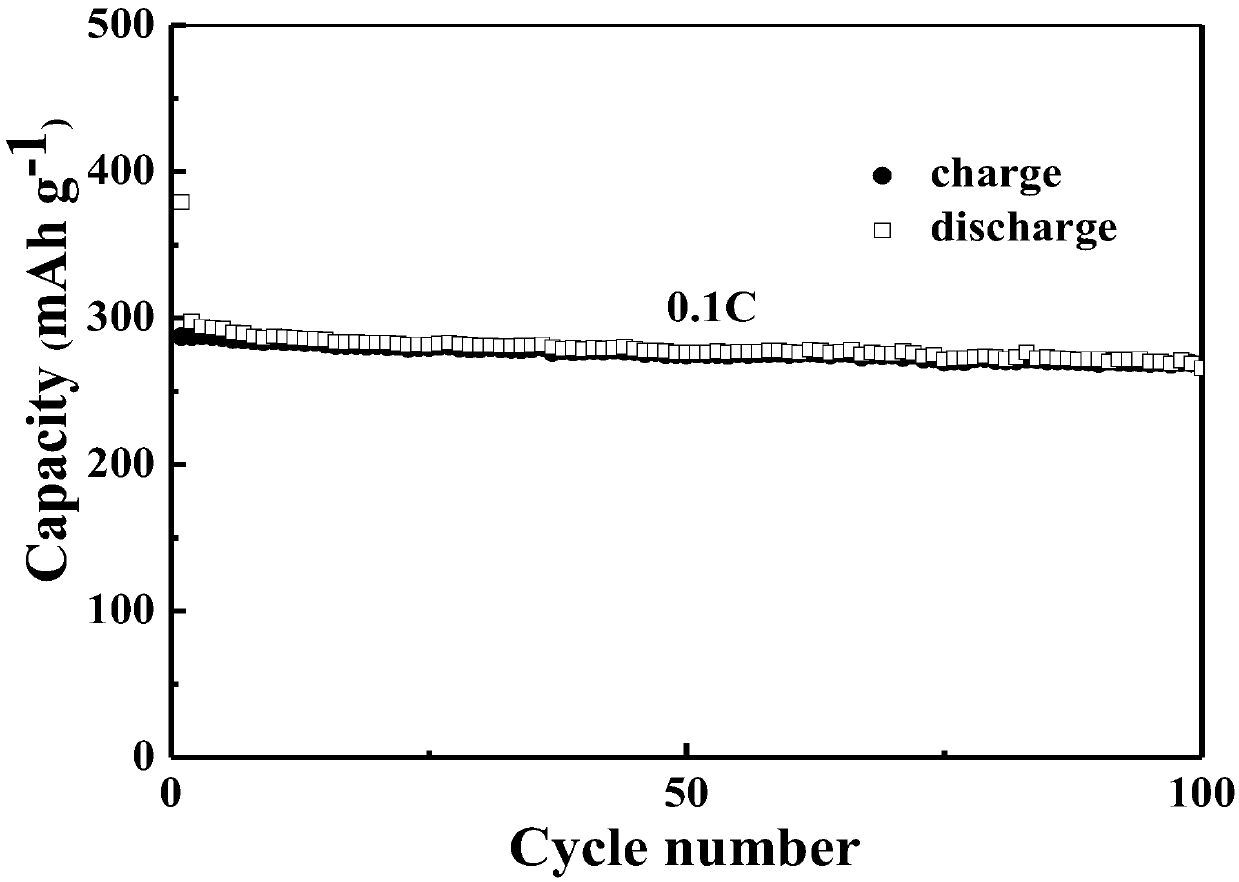

InactiveCN109678130ARich in microporesRich in mesoporesCell electrodesSecondary cellsElectrical batteryCarbonization

The invention provides a hard carbon material for an anode of a sodium-ion battery, a preparation method of the hard carbon material and the related sodium-ion battery, and belongs to the technical field of energy storage materials and electrochemistry. The hard carbon material is synthesized from a biomass material as a precursor, compared with the traditional high-temperature carbonization process, the preparation method adopts process steps of alkaline washing, acid pickling, drying, pre-carbonization and pyrolysis, and the hard carbon material having larger interlayer spacing (not smallerthan 0.37 nm), smaller specific surface area (about 100 cm<3> / g) and rich micropores and mesopores is prepared by adjusting process parameters. By means of a special microstructure, the hard carbon material serving as the anode of the sodium-ion battery shows excellent electrochemical performance, high specific capacity, high coulombic efficiency and good cyclic stability. A novel concept is provided for preparing a sodium-ion anode material, and the preparation method is simple and has low preparation cost, high repeatability and small industrialization difficulty, and the hard carbon material is expected to be applied to sodium-ion batteries for realizing large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

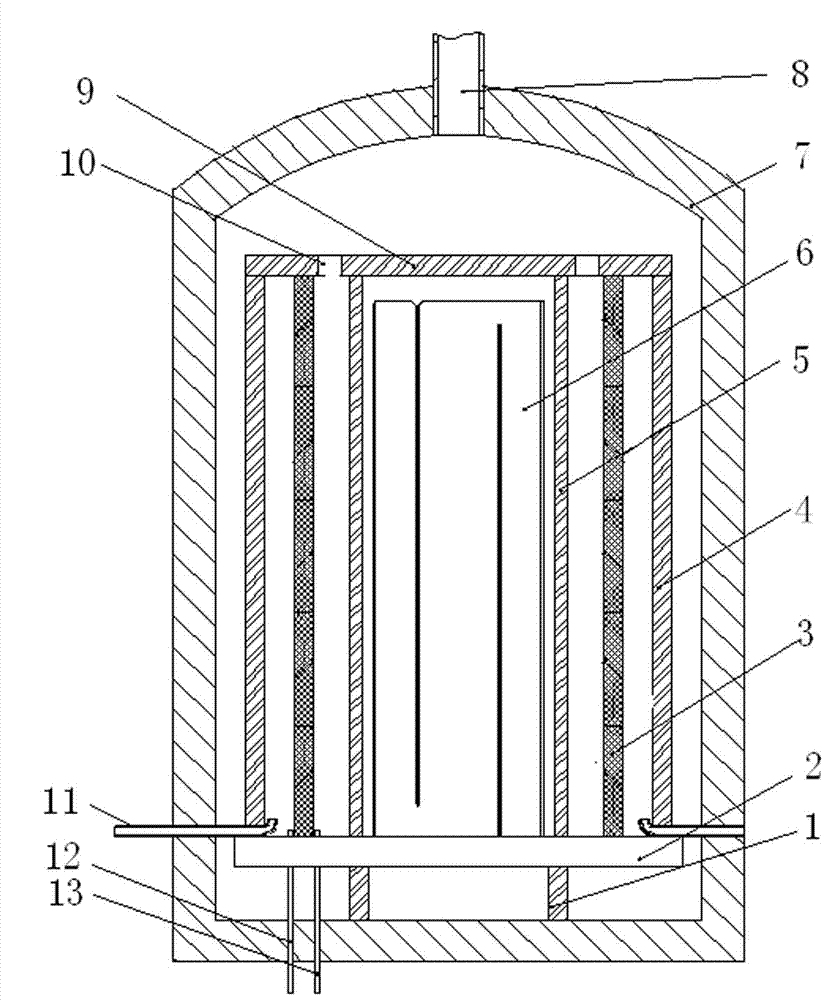

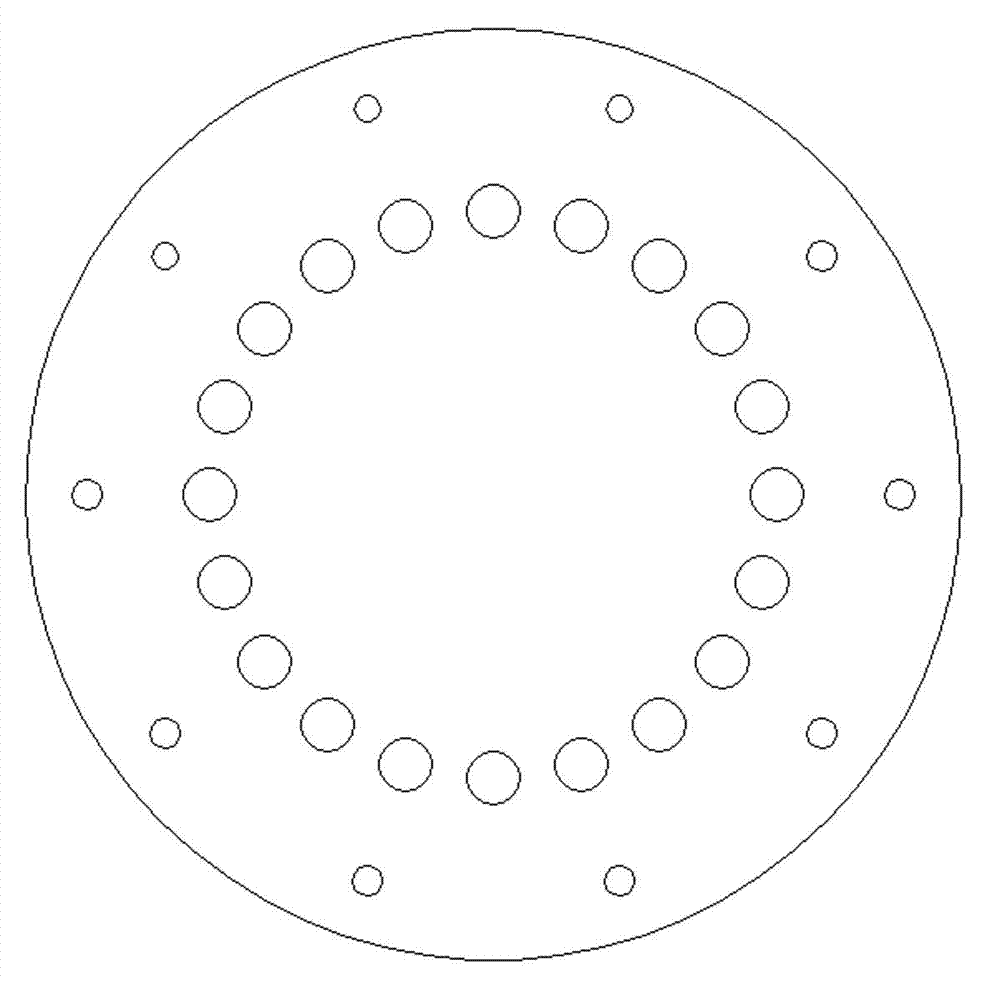

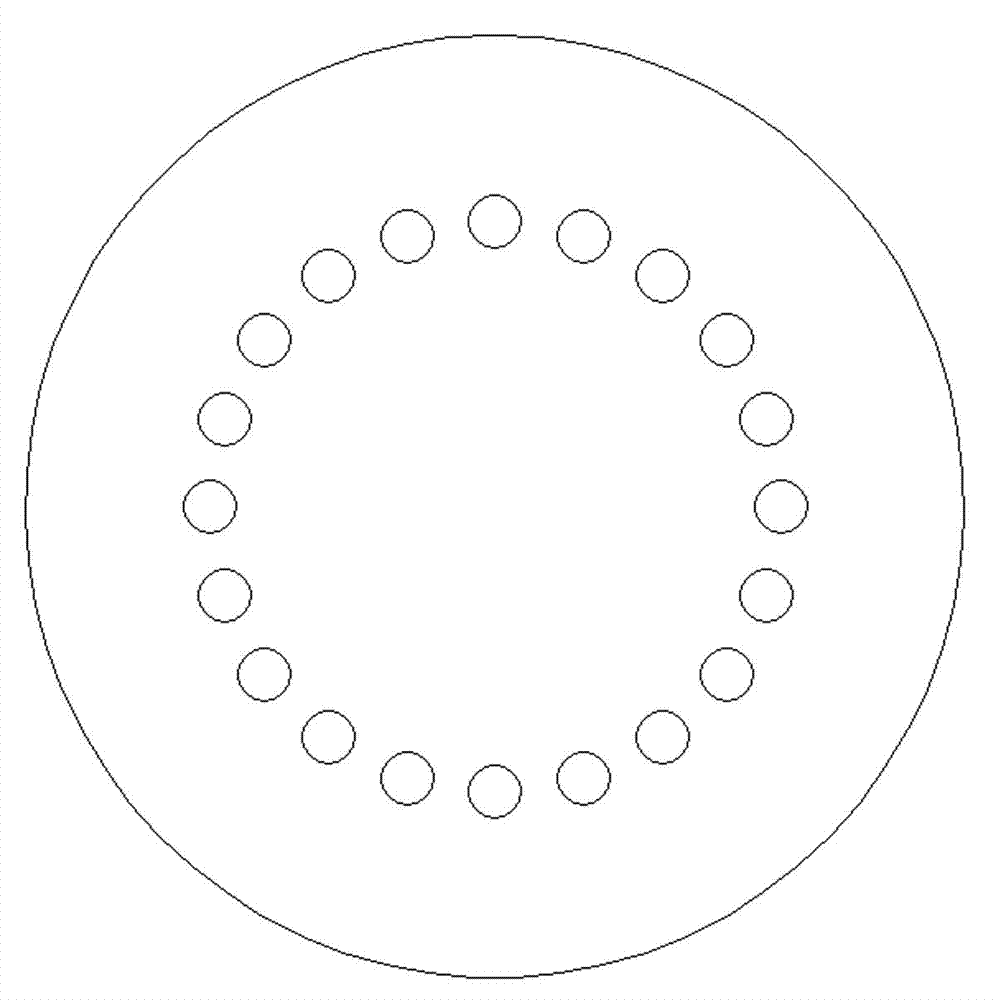

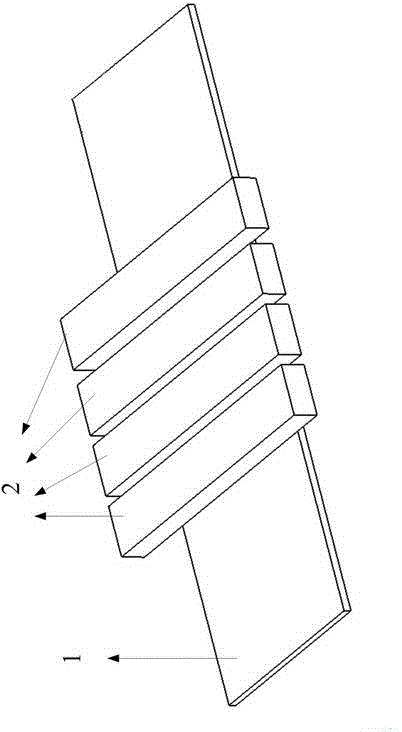

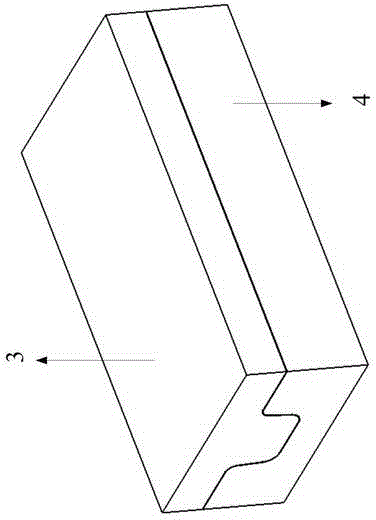

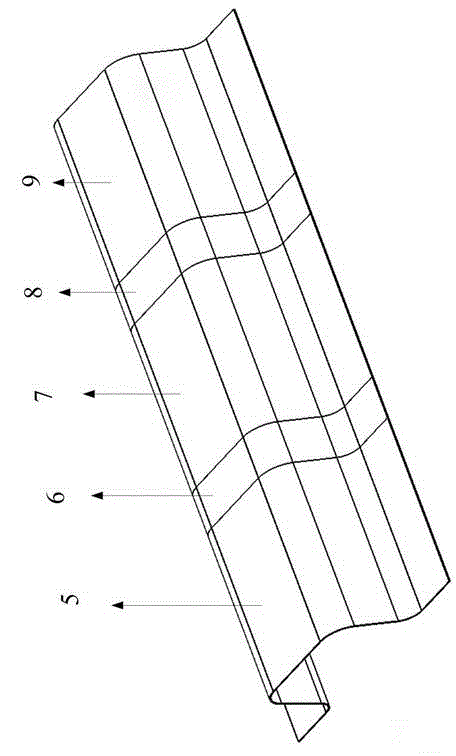

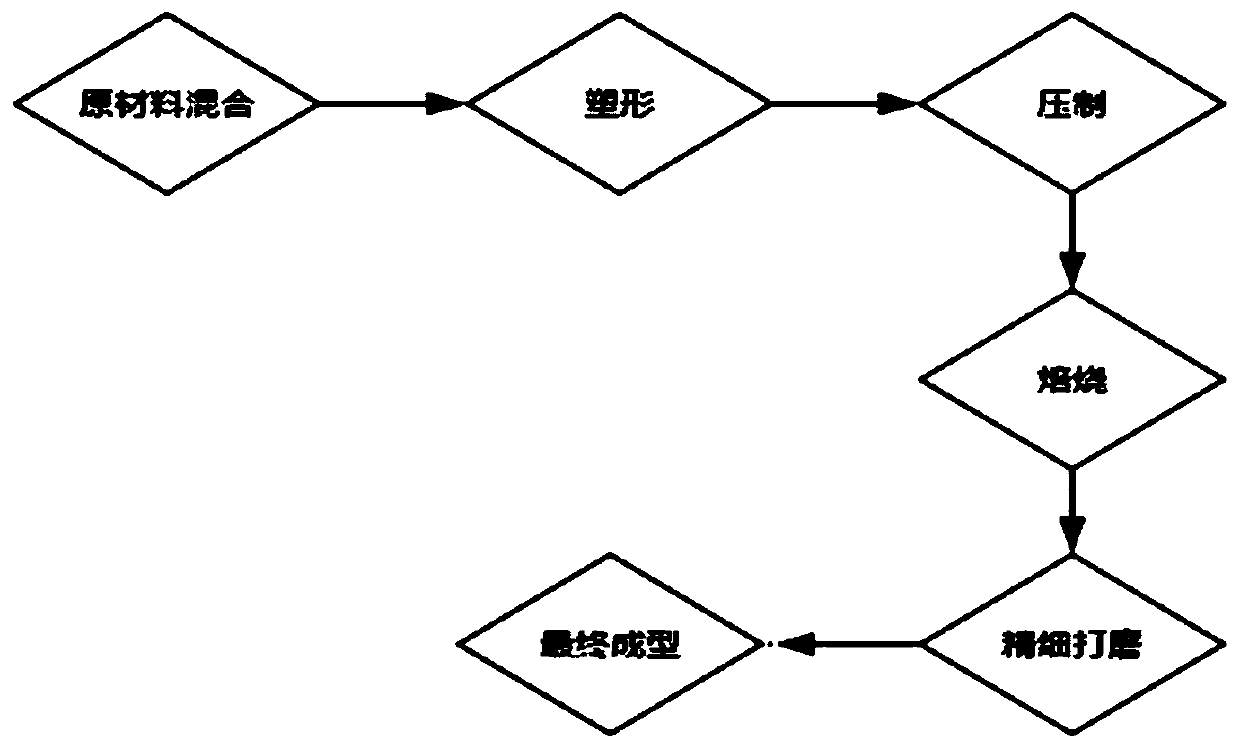

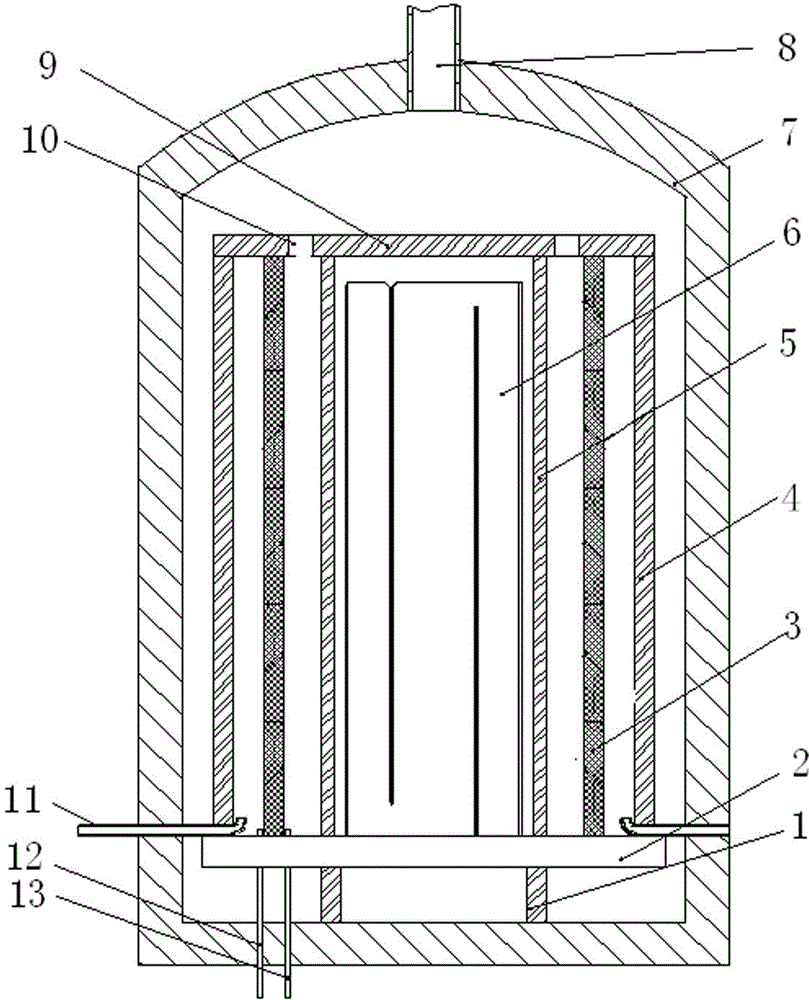

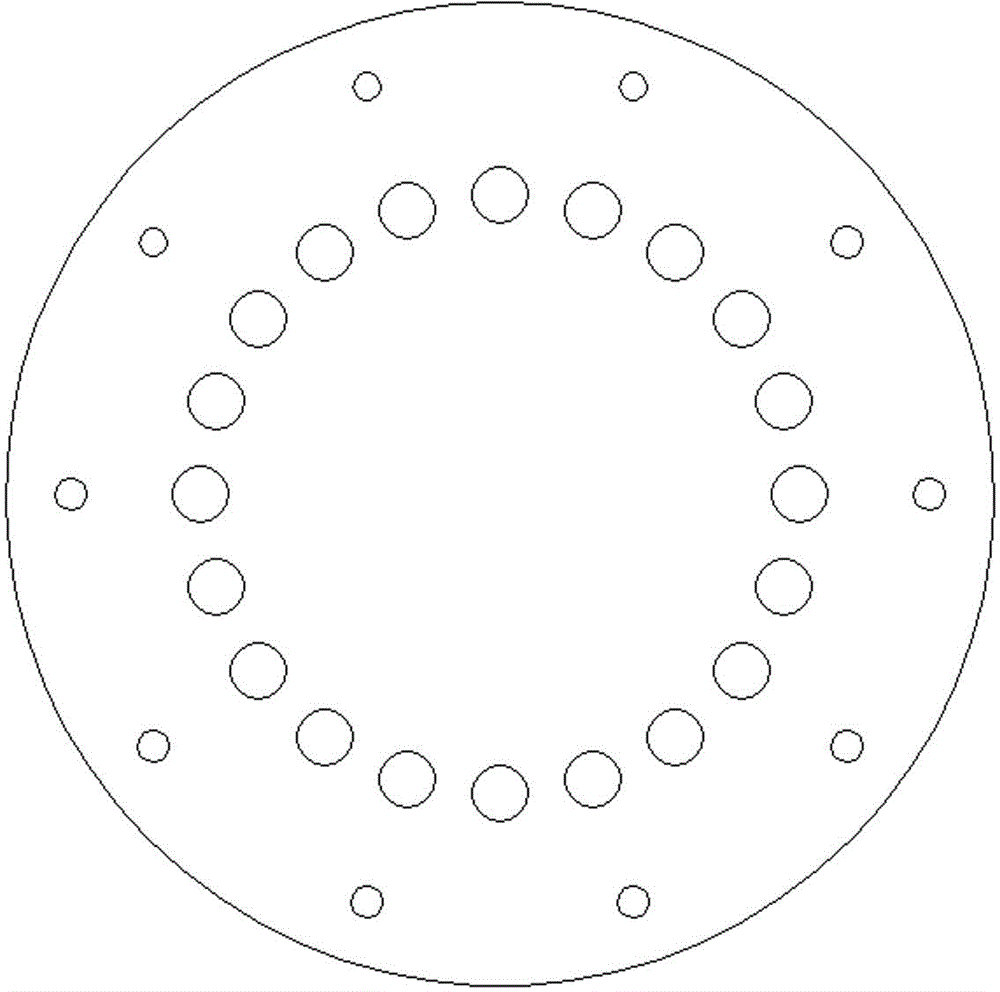

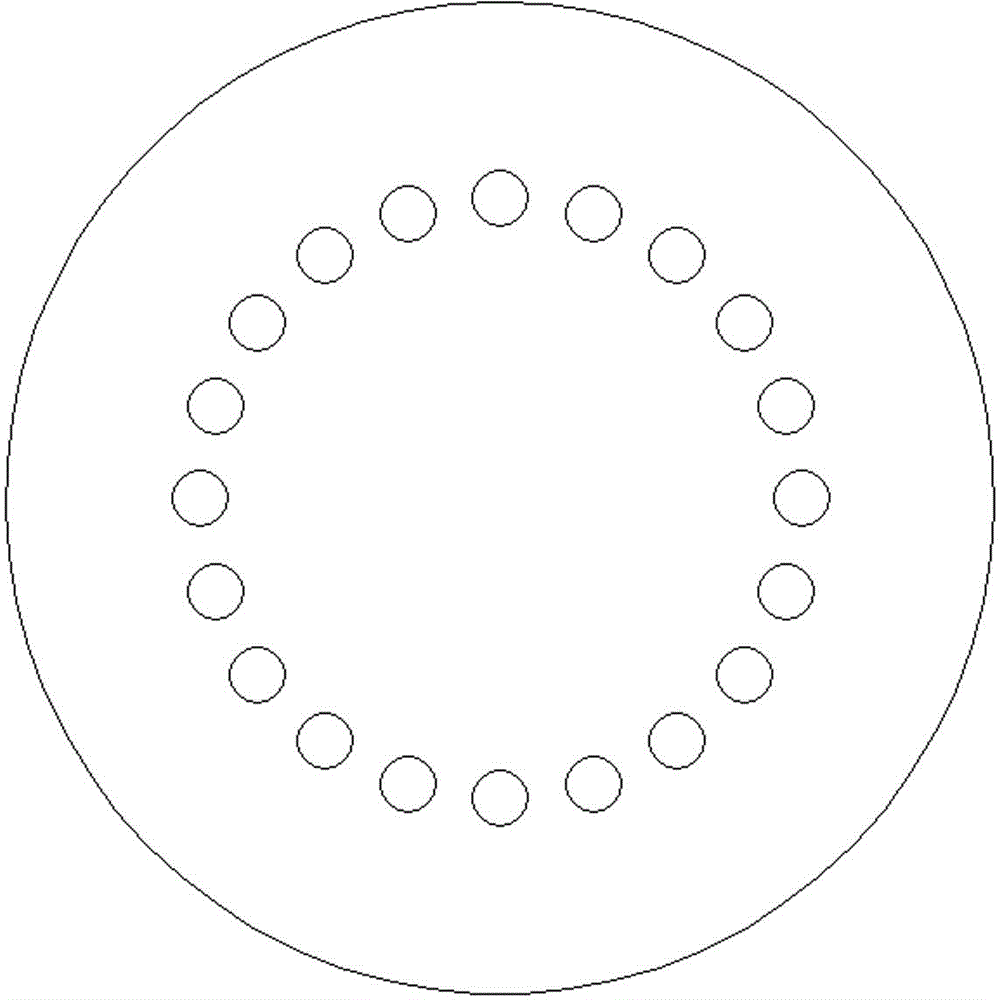

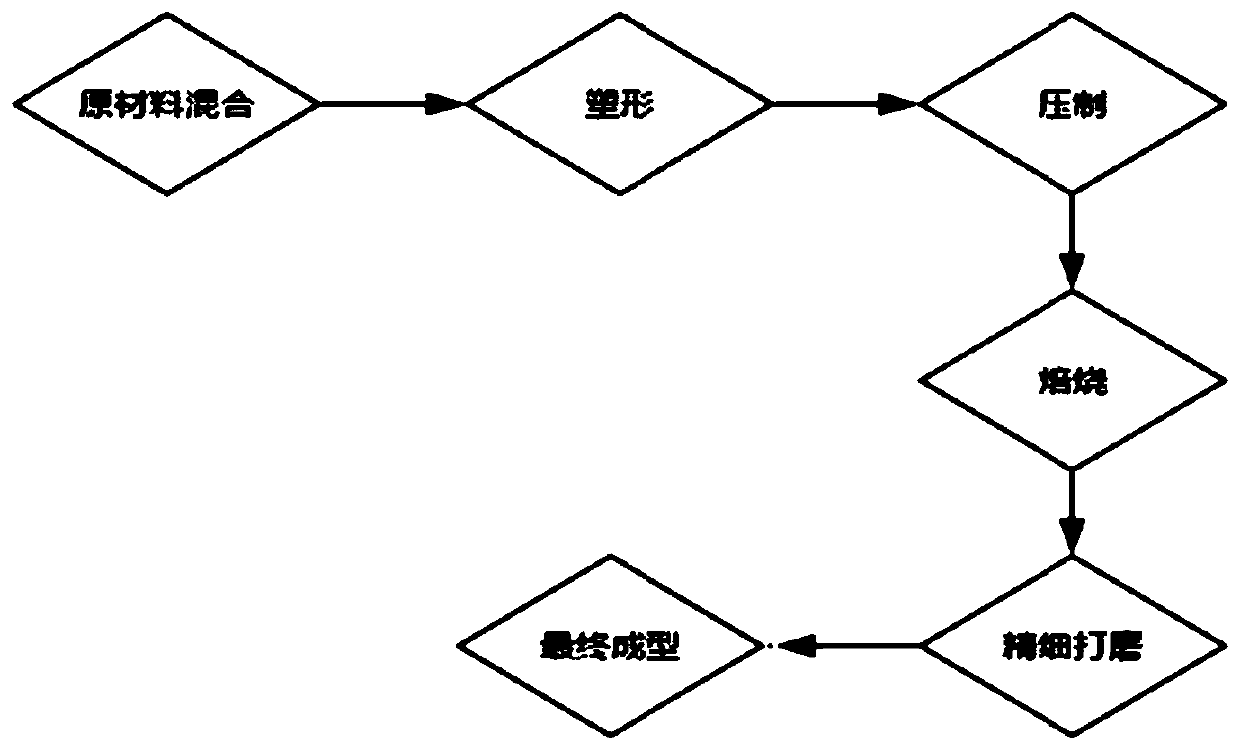

Technology and equipment for preparing C/C composite

The invention discloses a technology and equipment for preparing a C / C (carbon / carbon) composite. The technology for rapidly preparing the C / C composite comprises the following steps that (1) a preform is pretreated; (2) tools are prepared; (3) furnace loading is conducted; (4) temperature gradient differential CVI (chemical vapor infiltration) treatment is conducted; (5) heating of a heating element and input of mixed gas are stopped sequentially after 100-300h; and (6) a cover plate, the outer tool, the preform and the inner tool are taken out to form the C / C composite with density of 1.4-1.7g / cm<3>. The invention further discloses the equipment for preparing the C / C composite. According to the technology and the equipment, the operation is simple; the densification period is short; the industrial difficulty is small; the densification rate is high; ineffective reaction can be avoided; the carbon yield can be increased; and pollution of a vacuum system can be prevented.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Forming method for achieving different-area performance stable transition of high-strength steel hot-forming part

ActiveCN104475527AReduce manufacturing costGuaranteed forming effectShaping toolsVehicle componentsHot stampingPower flow

The invention relates to the technical field of hot stamping forming, in particular to a forming method for achieving different-area performance stable transition of a high-strength steel hot-forming part. The forming method utilizes induction heating to control electromagnetic fields and vortex fields of different areas, accordingly controls the heating temperatures in different areas of a plate and obtains different strengths after stamping is completed. The heating temperature ranges from 850 DEG C to 1000 DEG C and is kept for 0-10 min, a steel plate is heated to be in a complete austenitizing state, and the strength of the hot-formed steel plate is higher than1500 MPa. The heating temperature ranges from 25 DEG C to 850 DEG C and is kept for 0-10 min, the steel plate is heated to be in an incomplete austenitizing state, and the strength of the hot-formed steel plate ranges from 500 MPa to 900 MPa. The shape of an induction heating coil, the distance between the coil and the plate, current and frequency are designed according to the demand for different area strengths of the part, and the part has best collision performance matched with strength and plasticity after being subjected to hot stamping forming.

Owner:东莞市豪斯特热冲压技术有限公司 +1

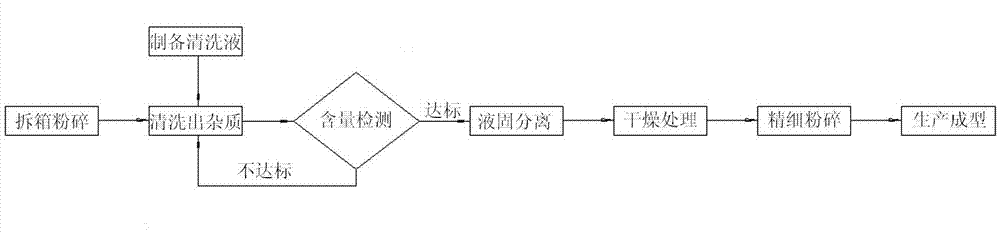

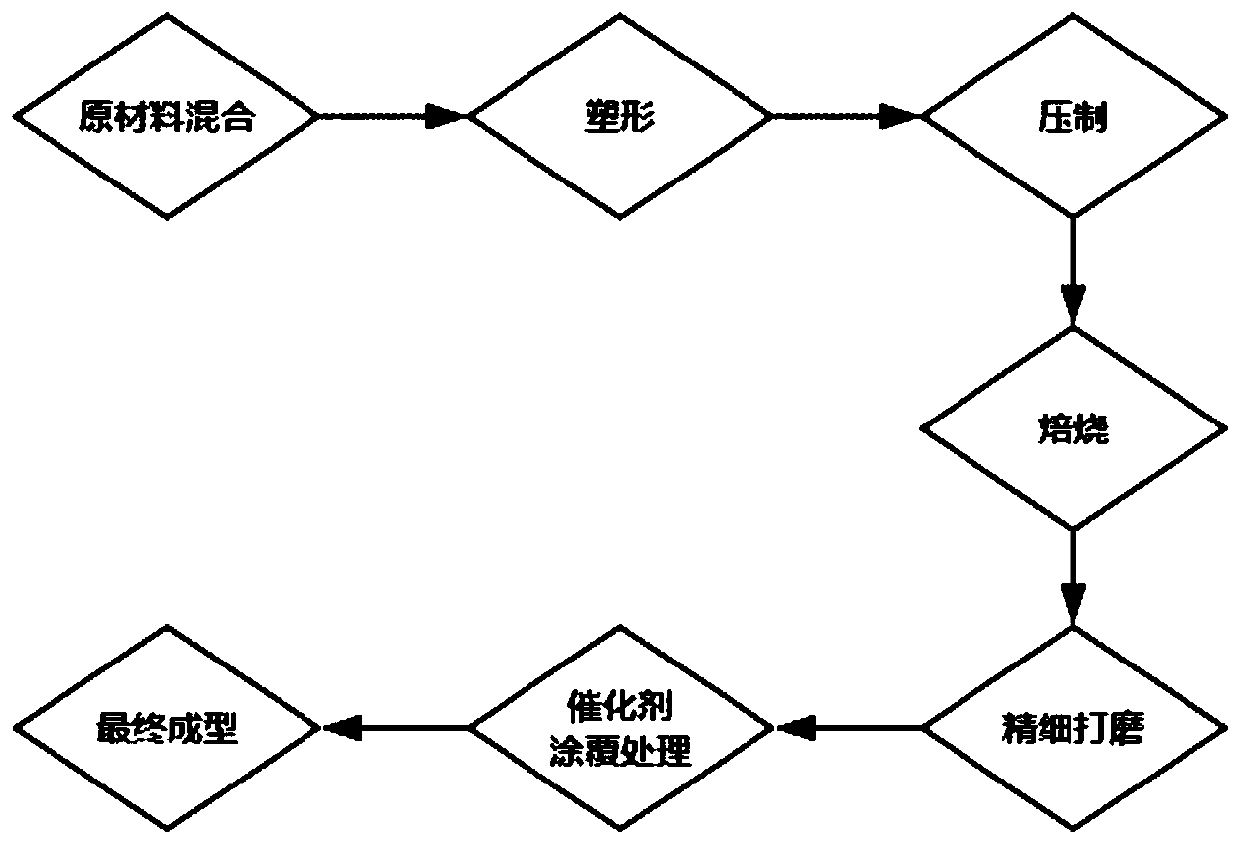

Recovering treatment method of waste-flue-gas denitration catalyst

The invention relates to a recovering treatment method of a waste-flue-gas denitration catalyst. The recovering treatment method comprises the following processes: (1) crushing; (2) preparing cleaning liquid; (3) cleaning and removing impurities; (4) separating solid from the liquid; and (5) drying and treating. The recovering treatment method has the beneficial effects that a great amount of waste-flue-gas denitration catalyst can be treated in a concentrated manner, and the reutilization of the waste-flue-gas denitration catalyst can be realized after the waste-flue-gas denitration catalyst is treated by the processes of crushing, preparing cleaning liquid, cleaning and removing impurities, separating solid from the liquid, drying and treating; and the waste-flue-gas denitration catalyst has the advantages of high recovering treatment and utilization rate, low industrialization difficulty, large concentrated treatment amount and the like; the waste-flue-gas denitration catalyst is recovered and treated, and can be used for producing a denitration catalyst as a production material, so that the pollution of solid wastes can be reduced, and simultaneously the benefits of recycling resources, reducing the cost, saving the energy, enhancing environmental-protection control and improving the comprehensive benefit also can be achieved.

Owner:无锡华光新动力环保科技股份有限公司

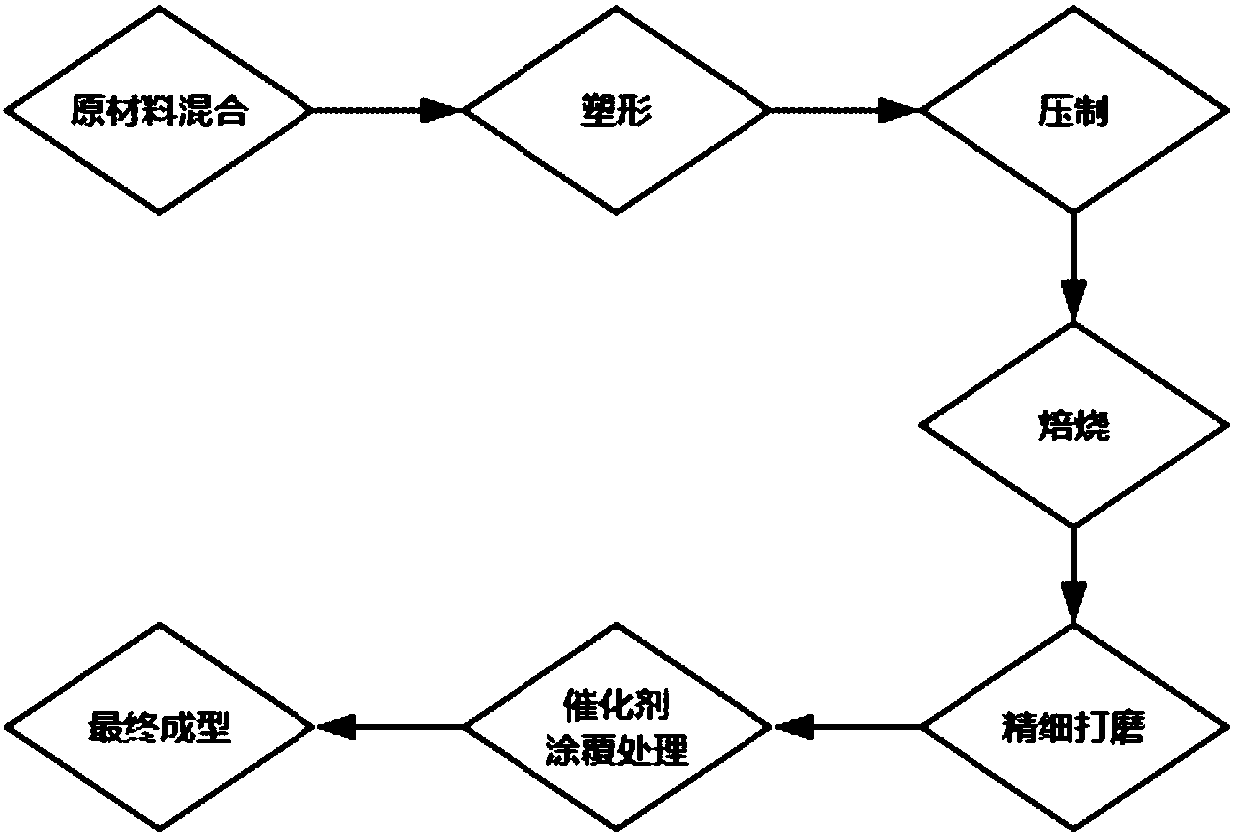

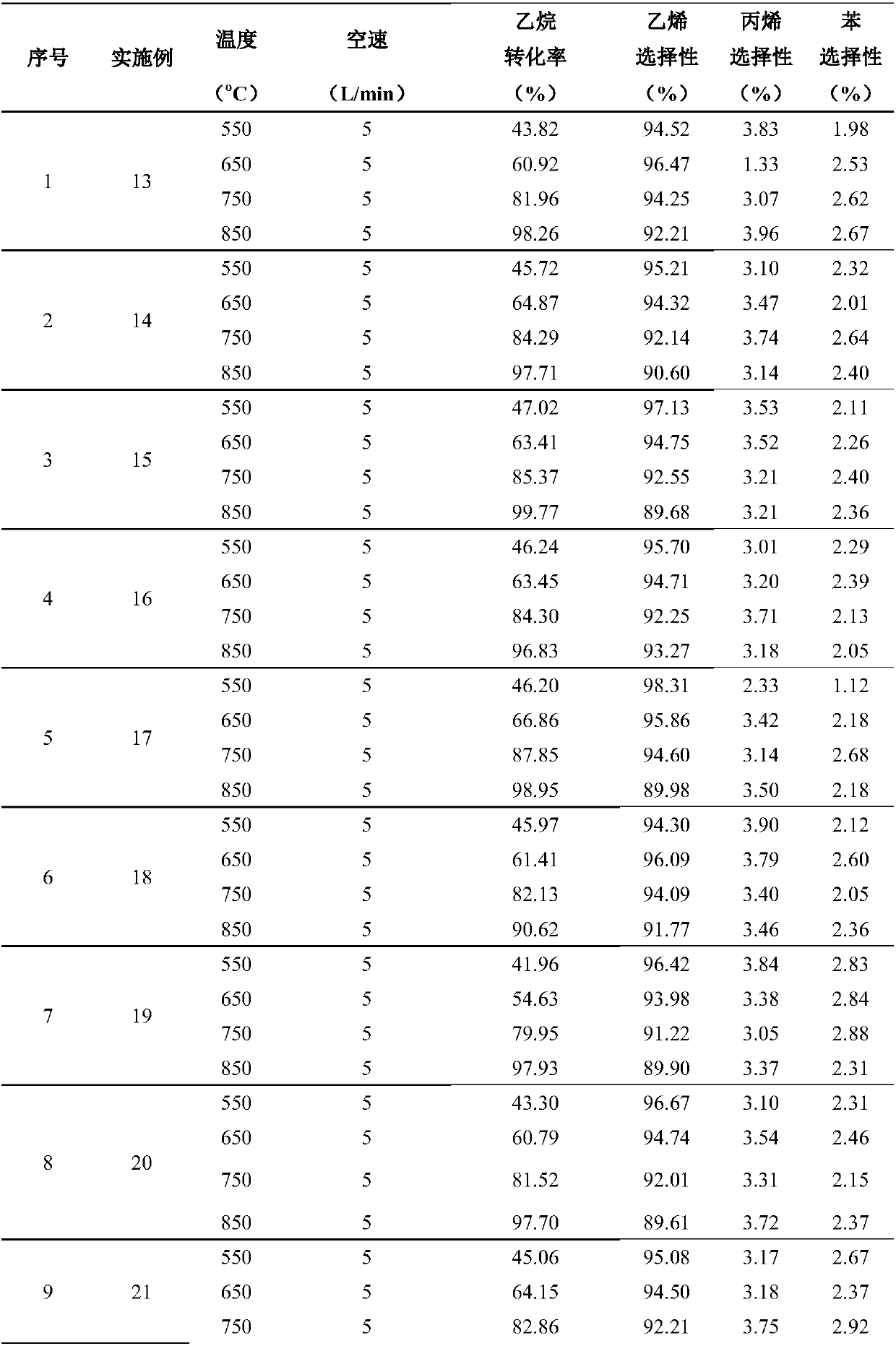

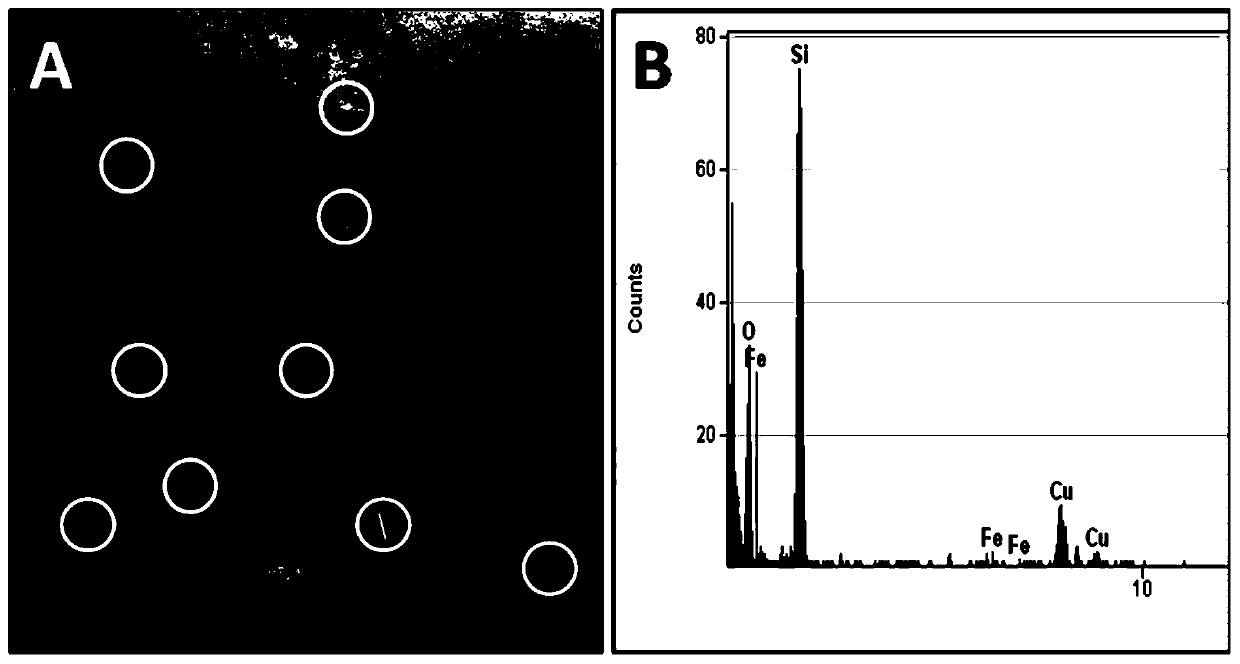

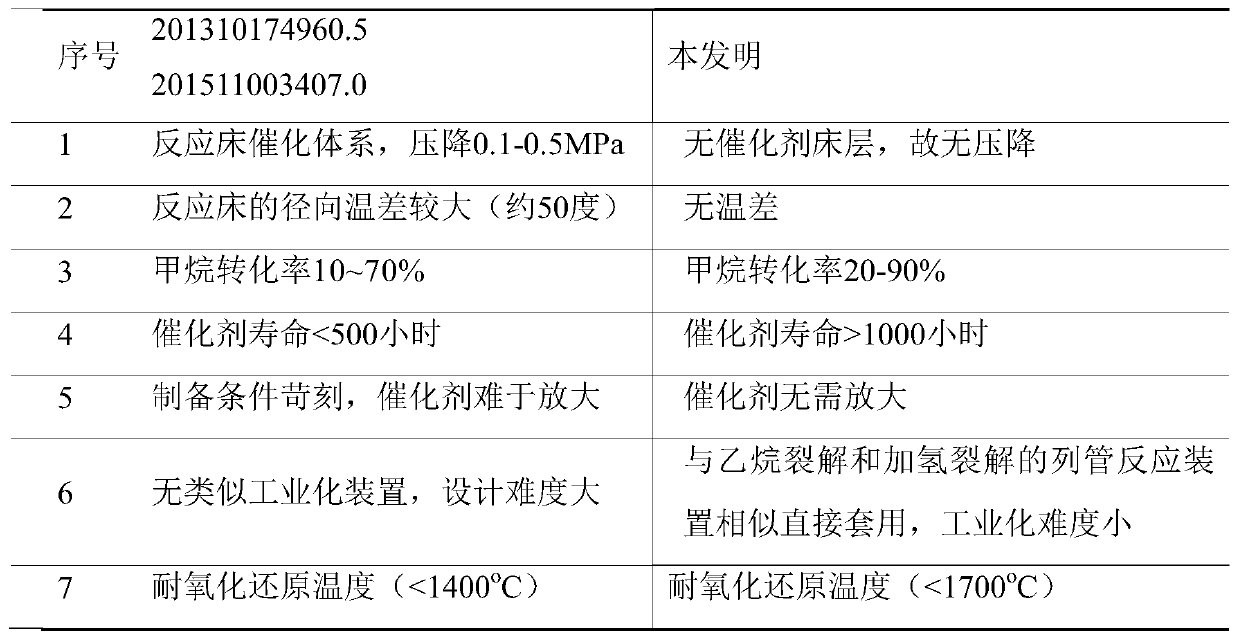

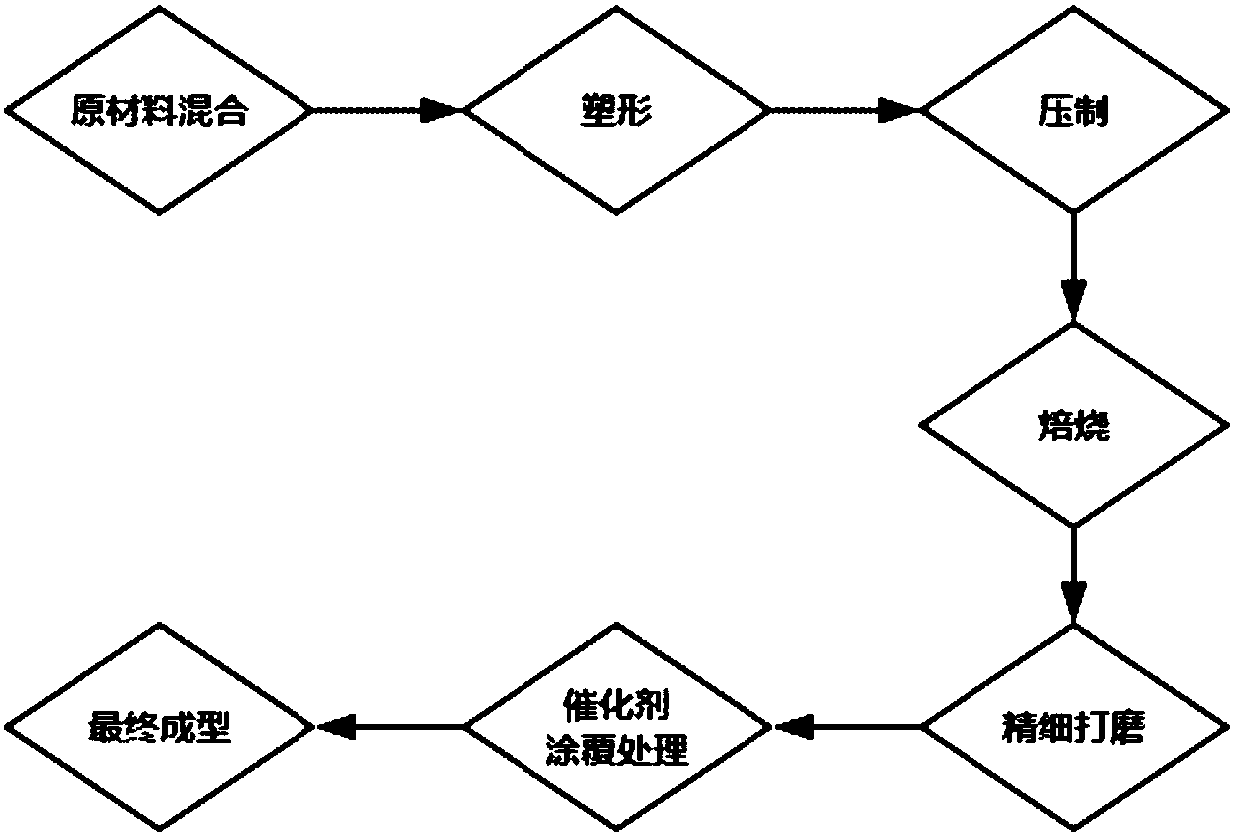

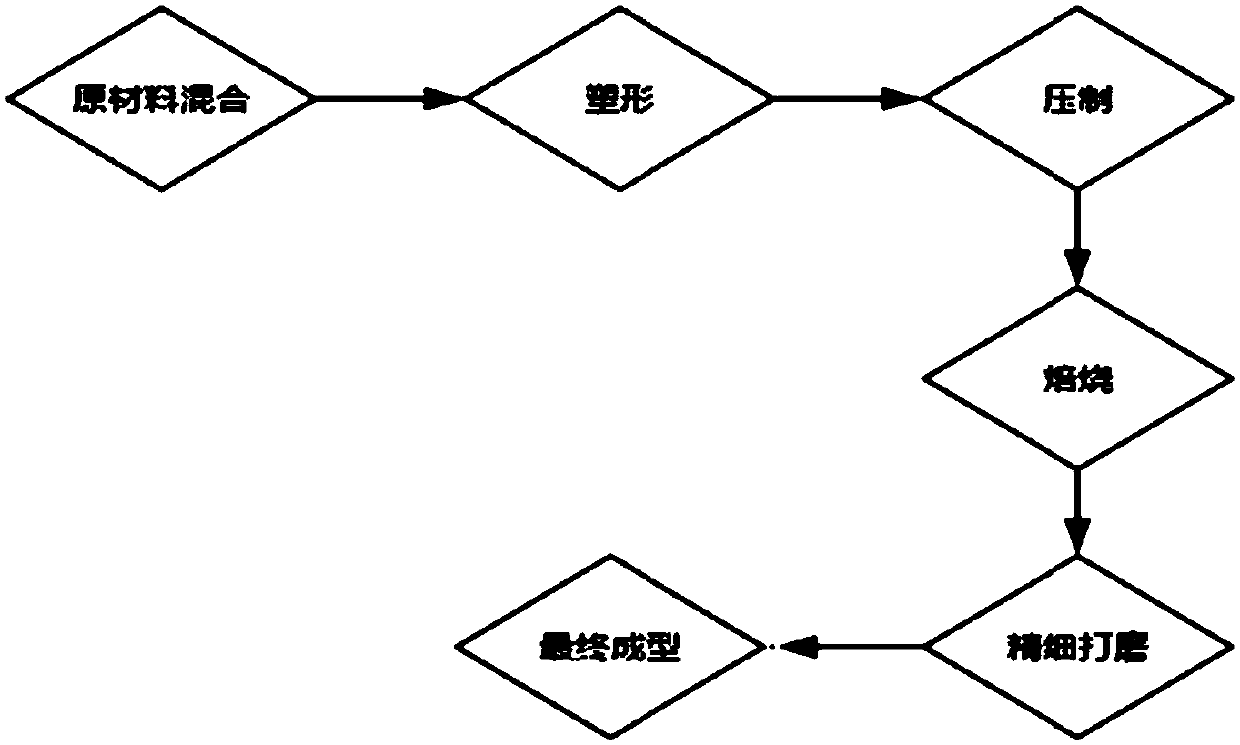

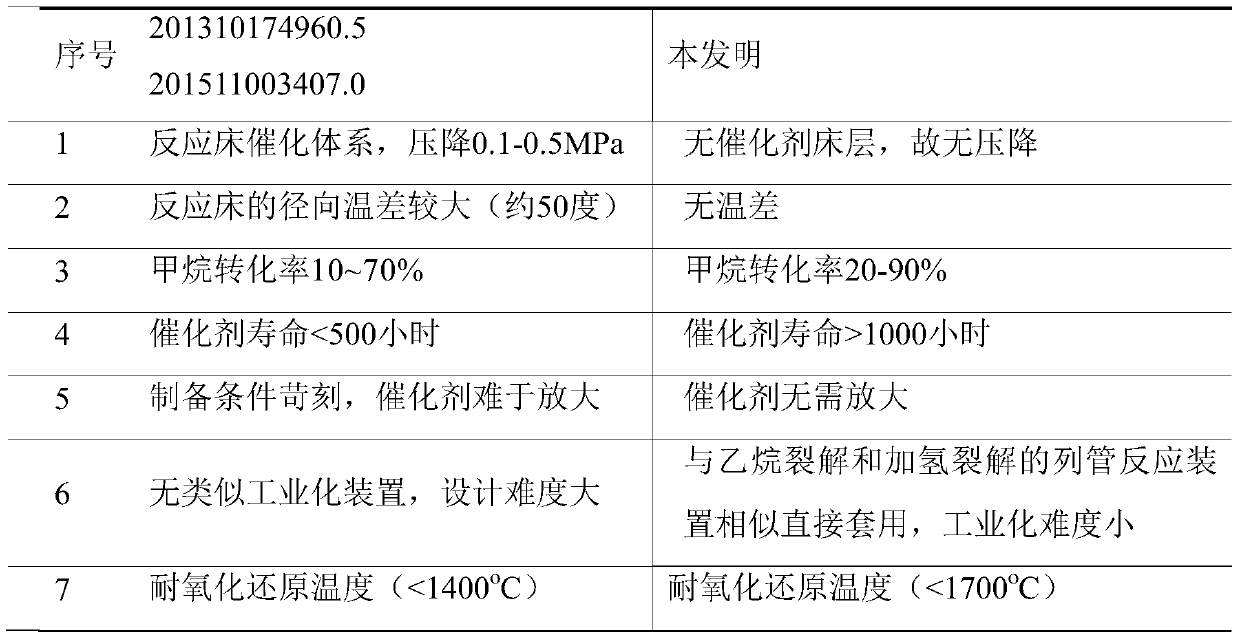

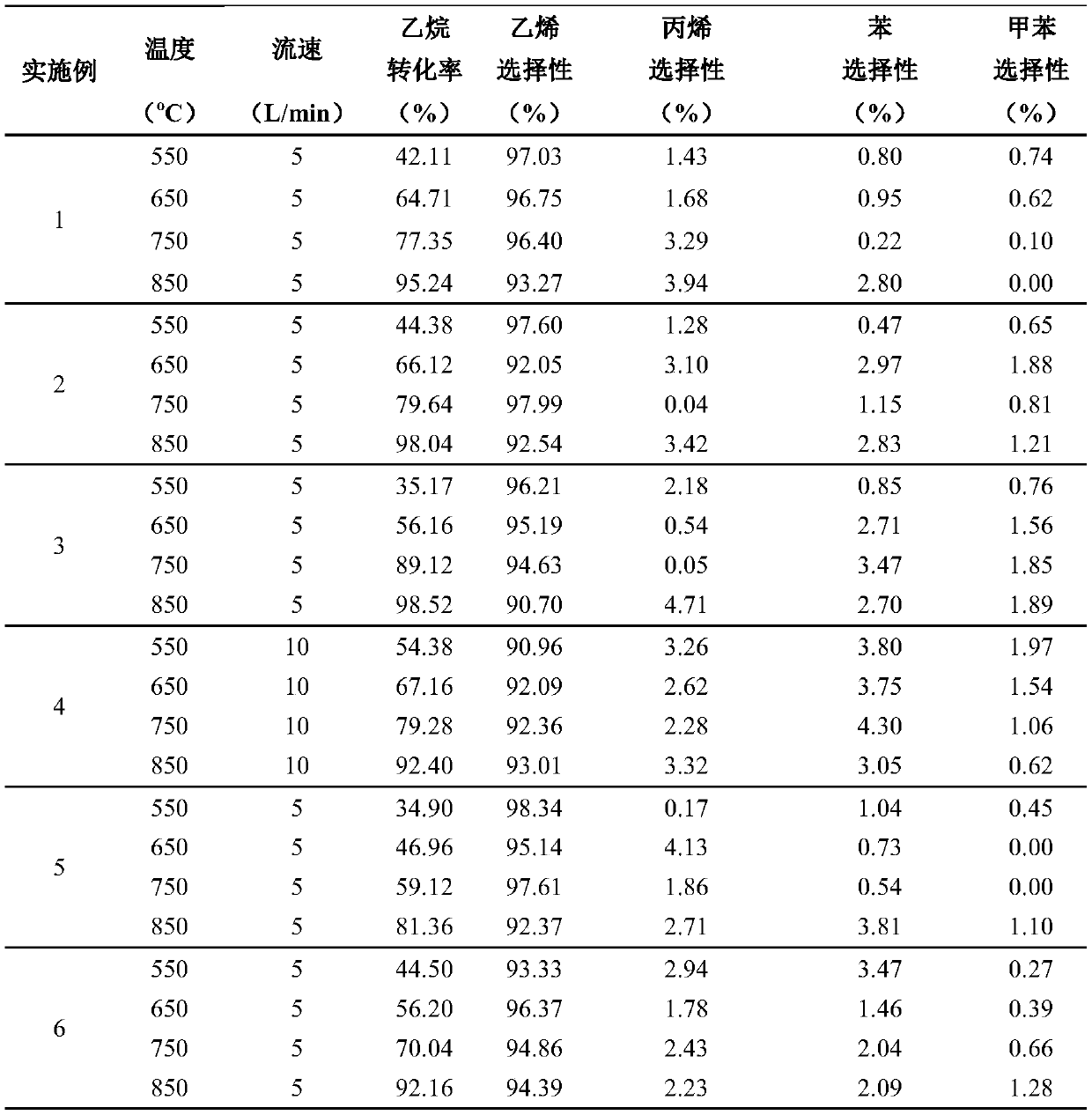

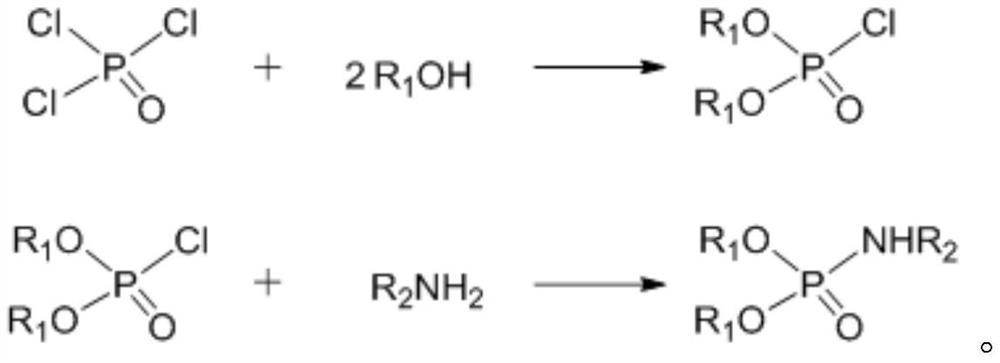

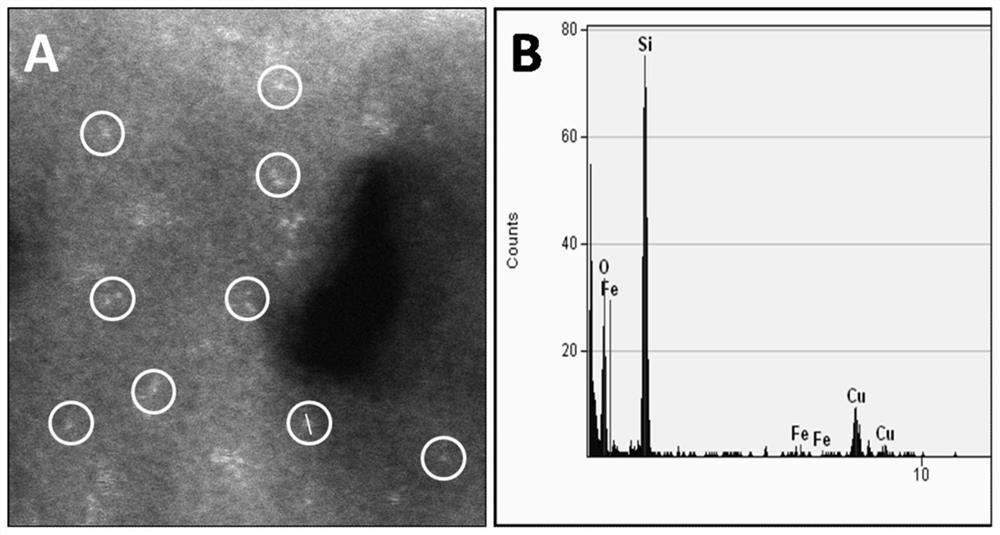

Preparation for catalyst-silicon carbide reactor for preparing ethylene through ethane dehydrogenation

ActiveCN109847671AImprove thermal conductivityImprove energy efficiencyPhysical/chemical process catalystsHydrocarbonsPhotochemistryHeat conducting

The invention relates to preparation for a catalyst-silicon carbide reactor for preparing ethylene through ethane dehydrogenation and a method for catalyzing the ethane dehydrogenation to prepare theethylene under an oxygen-free condition. According to the reactor provided by the invention, a novel prepared silicon carbide material is used and good heat-conducting performance and chemical reaction inertia properties of the material are utilized; and based on the catalyst-reactor and reaction conditions, high-yield synthesis of the ethylene is realized through the process. According to the preparation and the method provided by the invention, the conversion rate of ethane is 70 to 100 percent, the selectivity of ethylene is 80 to 99.99 percent, the selectivity of propylene is 0 to 5 percent and the selectivity of aromatic hydrocarbons is 0 to 5 percent. The preparation and method provided by the invention have the characteristics of long catalyst service life (longer than 1000 h), goodstability of the catalyst at high temperature (lower than 1700 DEG C), high ethylene conversion rate and product selectivity, low energy consumption, good process repeatability, safety and reliability in operation and the like, and have wide industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

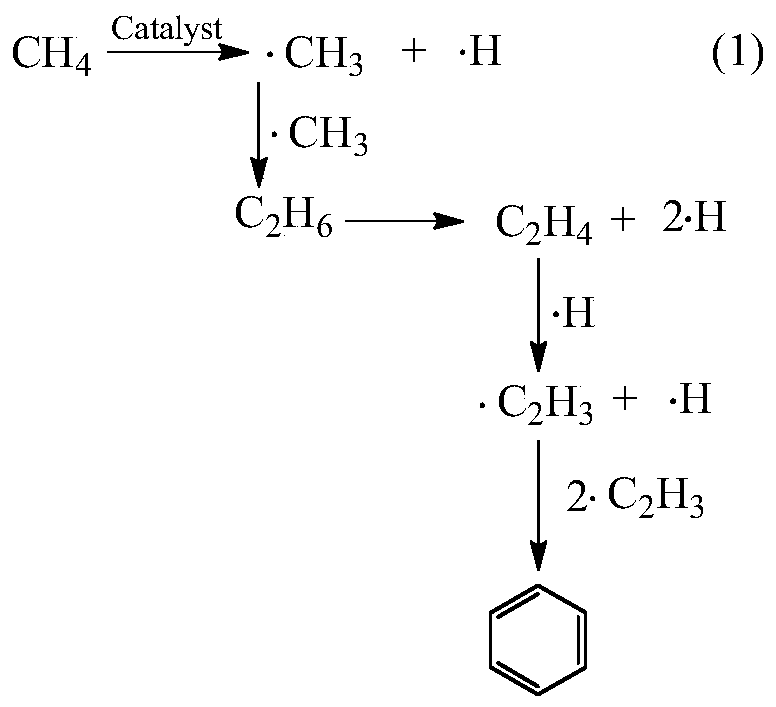

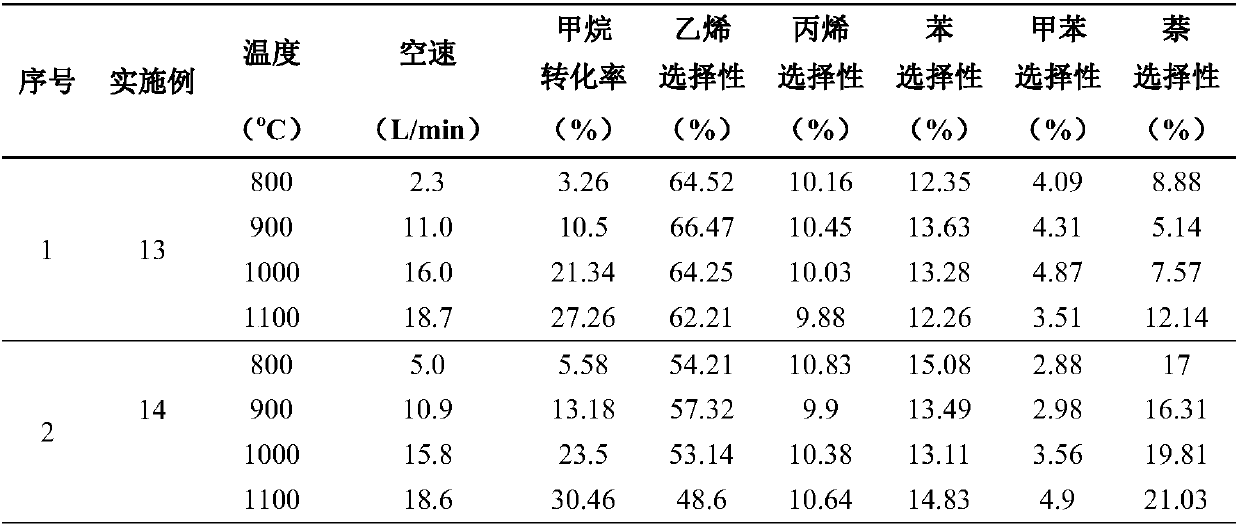

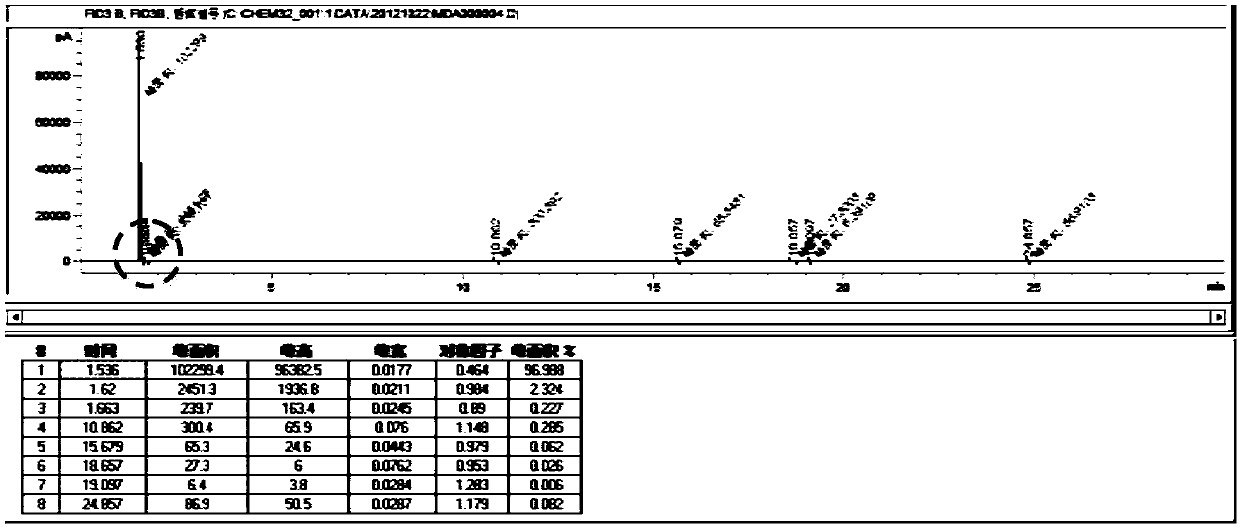

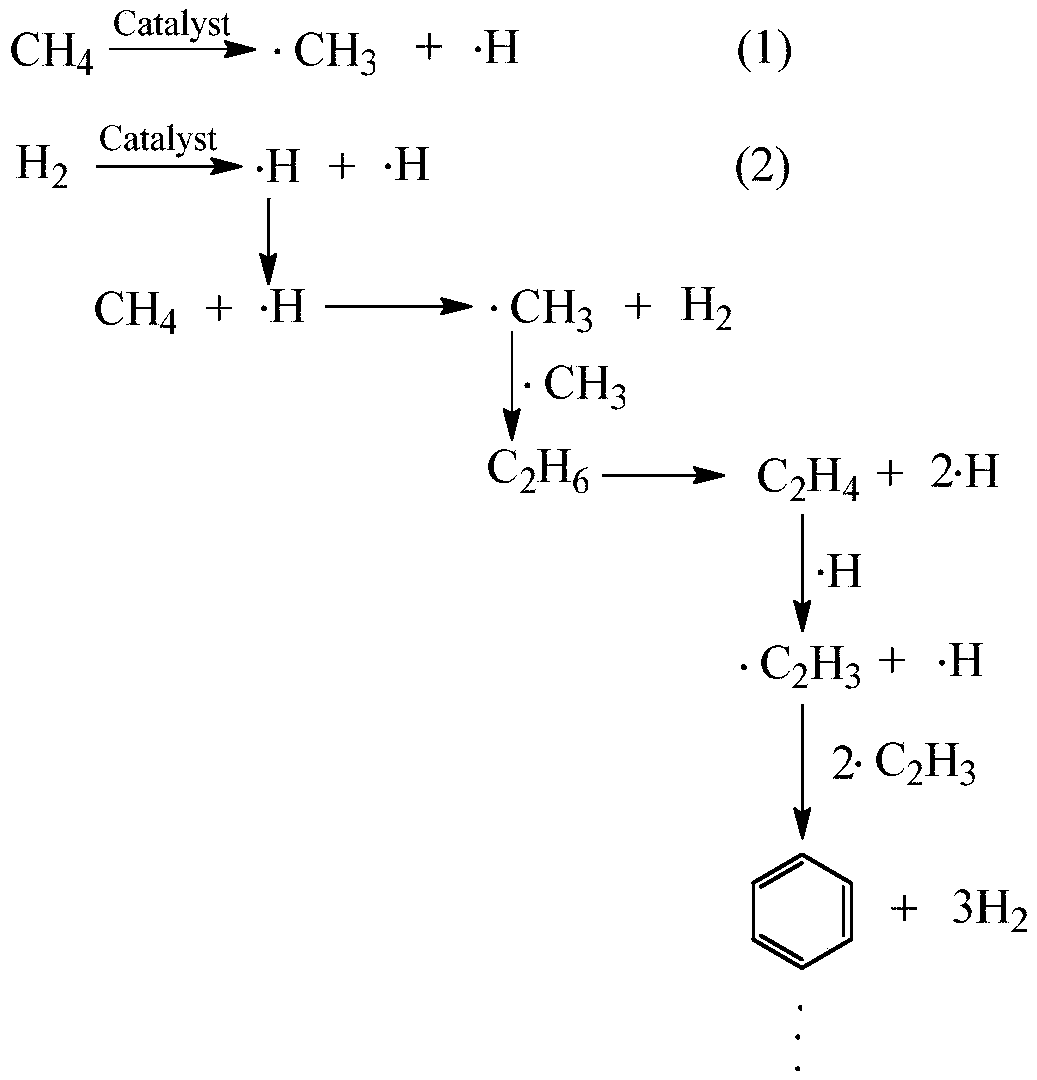

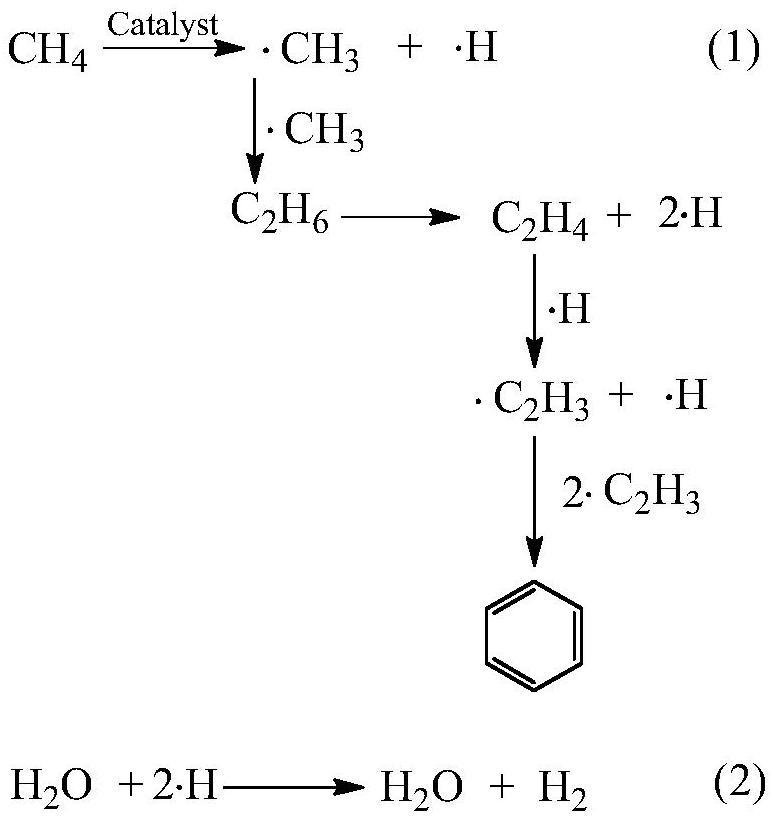

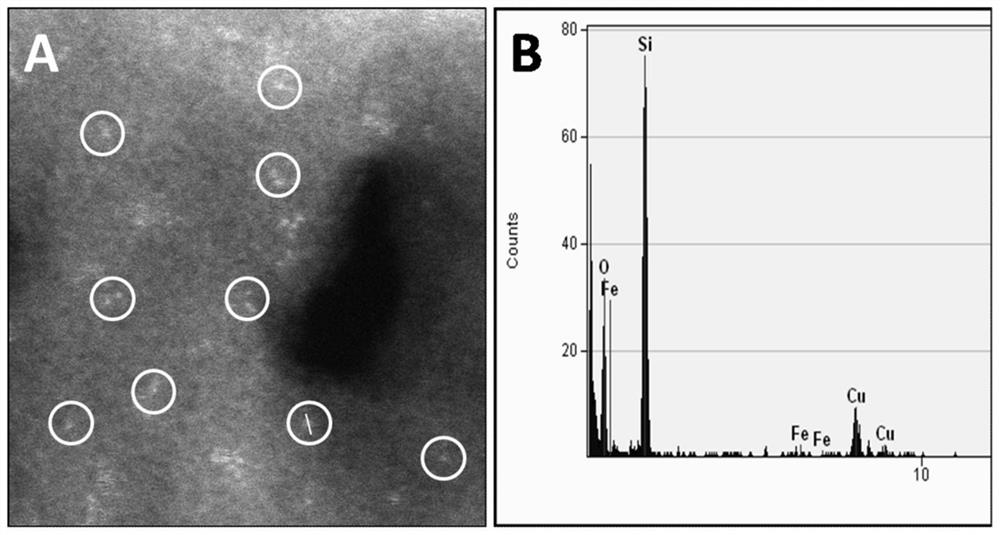

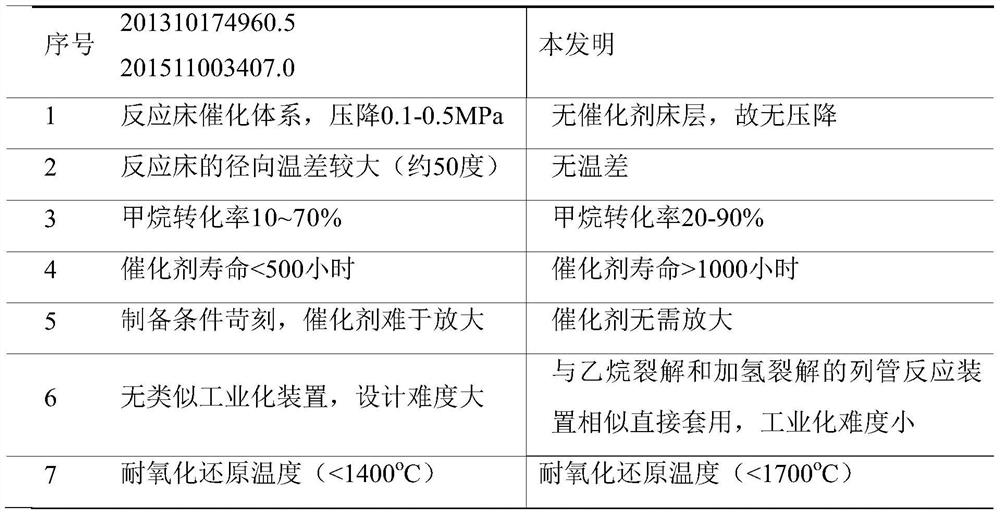

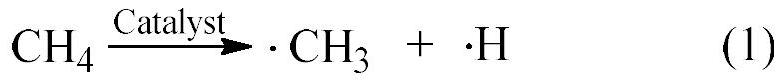

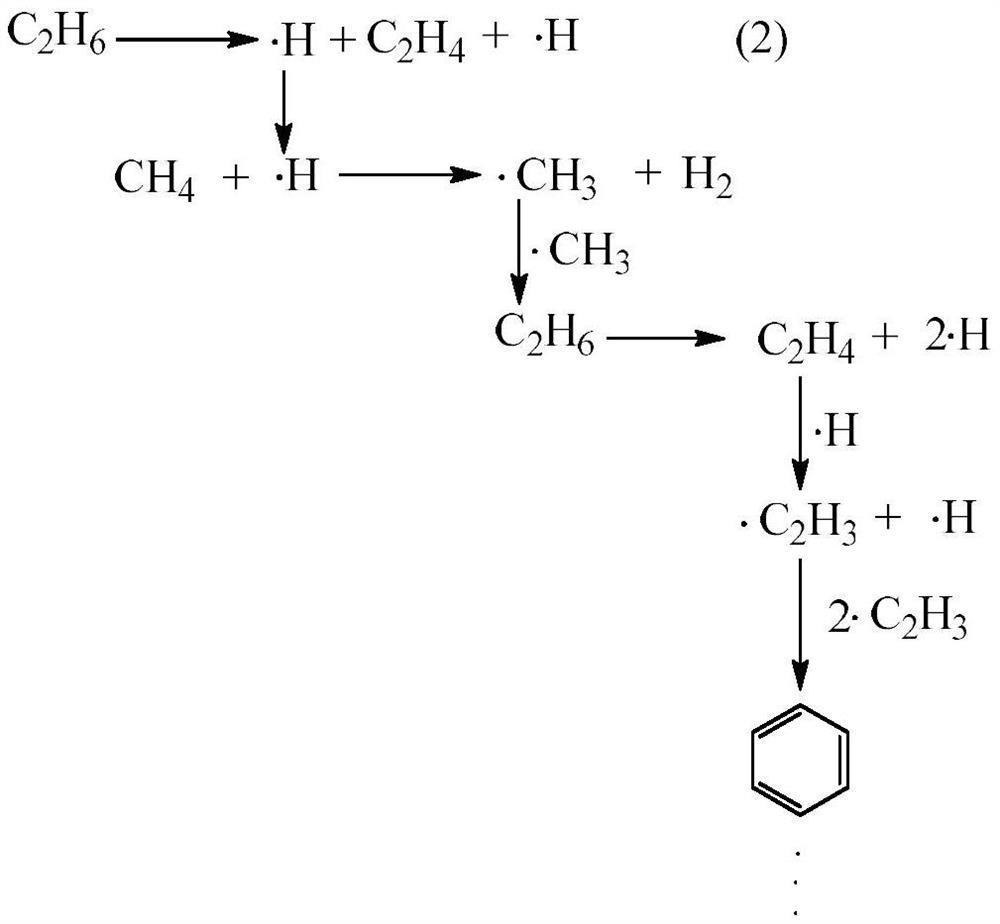

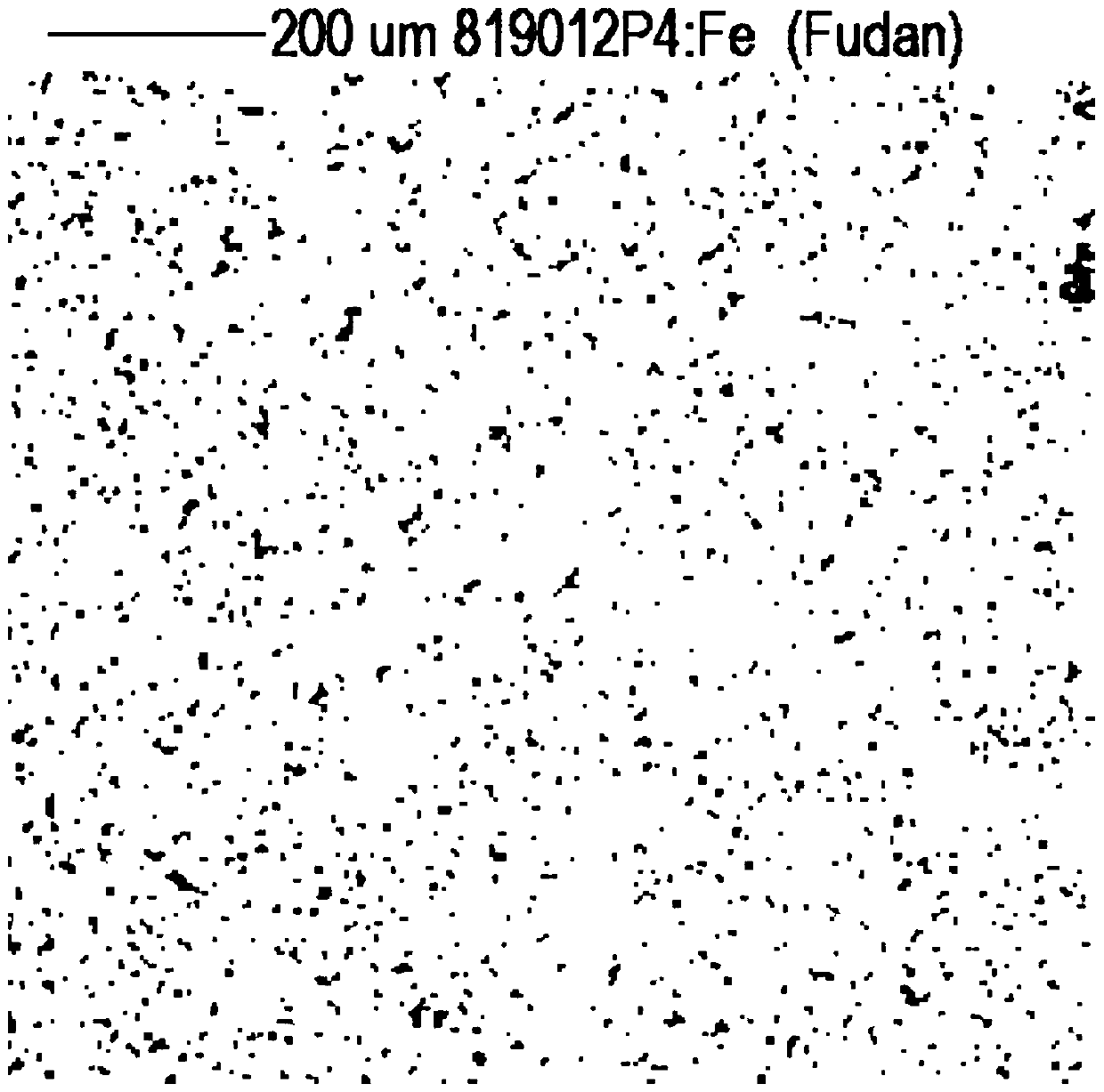

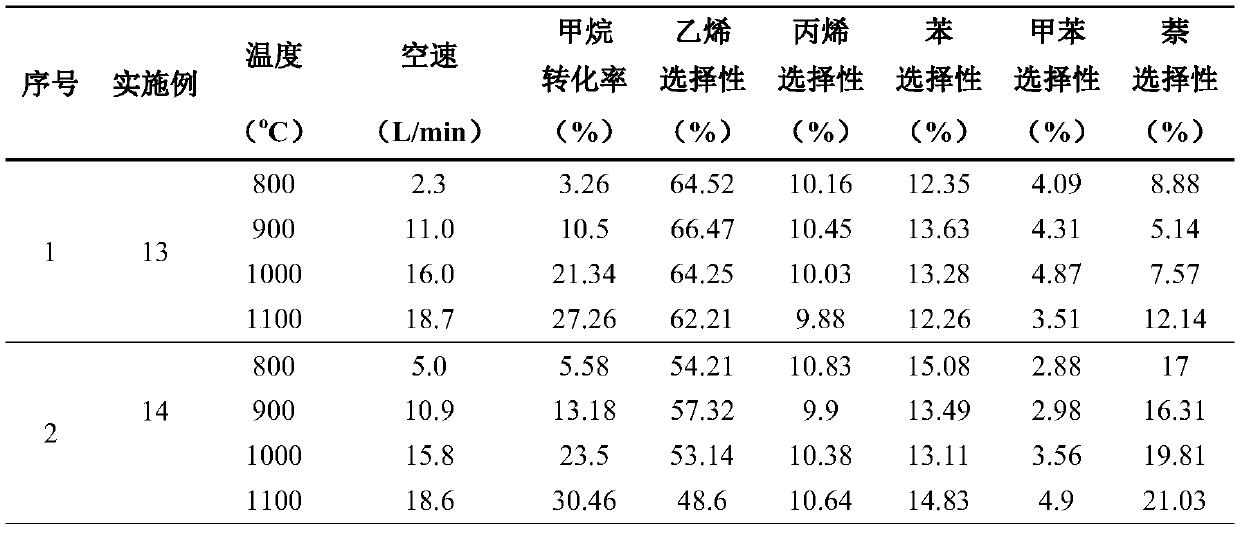

Method for preparing olefin, aromatic hydrocarbon and hydrogen through steam catalytic conversion of methane

ActiveCN111333478AImprove conversion rateIncrease conversion rateCatalystsHydrocarbon preparation catalystsPolycyclic aromatic hydrocarbonCatalytic transformation

The invention relates to a method for preparing olefin, aromatic hydrocarbon and hydrogen by steam catalytic cracking of methane by utilizing a quartz catalytic reactor. The process realizes high-efficiency conversion of methane, and generation of gas-phase polycyclic aromatic hydrocarbon and secondary carbon deposit under steam pressing, steam hardly participates in the reaction, only a trace amount of CO is generated, the steam improves the heat transfer efficiency, and the catalyst stability is high. The conversion rate of methane is 20-70%; the olefin selectivity is 85 to 95 percent; the benzene selectivity is 4.5 to 13 percent; the selectivity of CO is 0.5-2%; carbon deposition is zero. The method has the characteristics of long service lifetime of the catalyst, good oxidation reduction and hydrothermal stability of the catalyst at high temperature, high methane conversion rate and product selectivity, zero carbon deposition, no need of amplification of the catalyst, low industrialization difficulty, easiness in separation of the product, good process repeatability, safety and reliability in operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

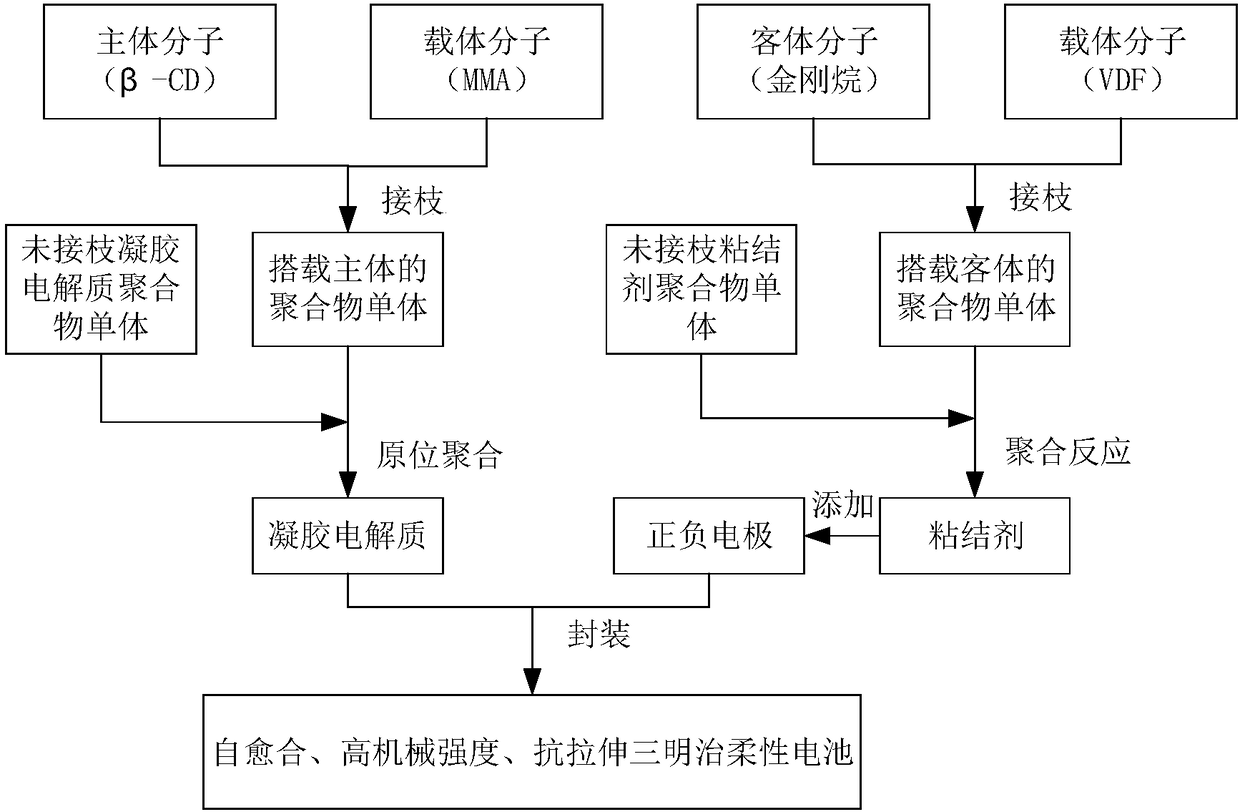

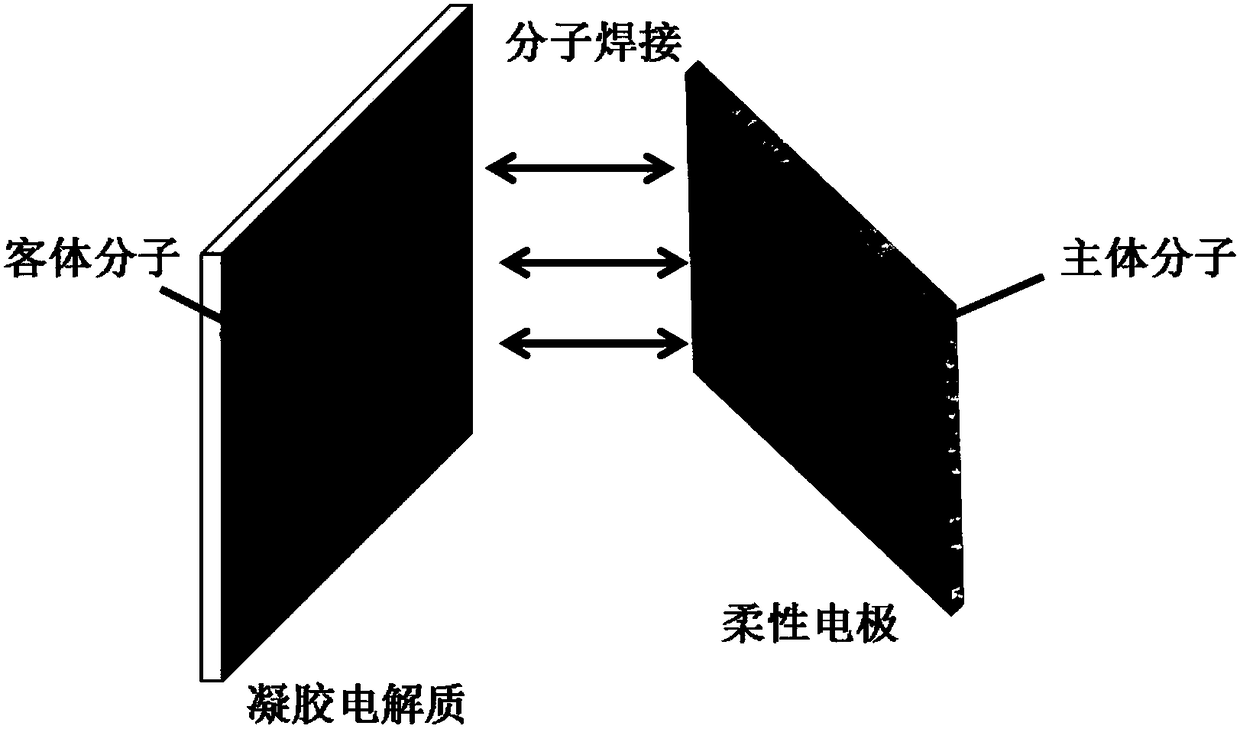

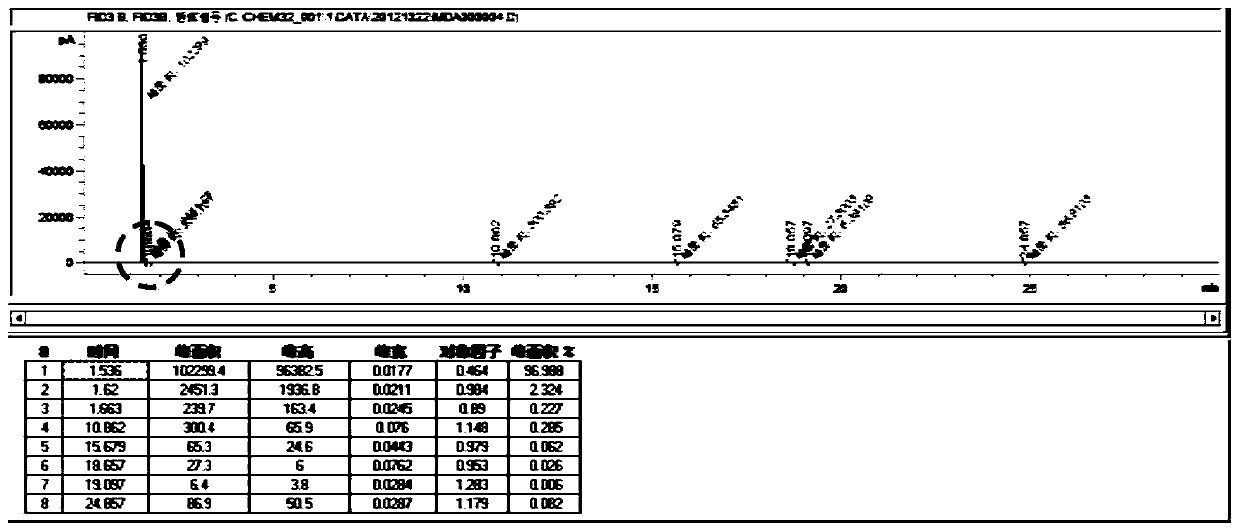

Self-adsorption flexible battery and preparation method thereof

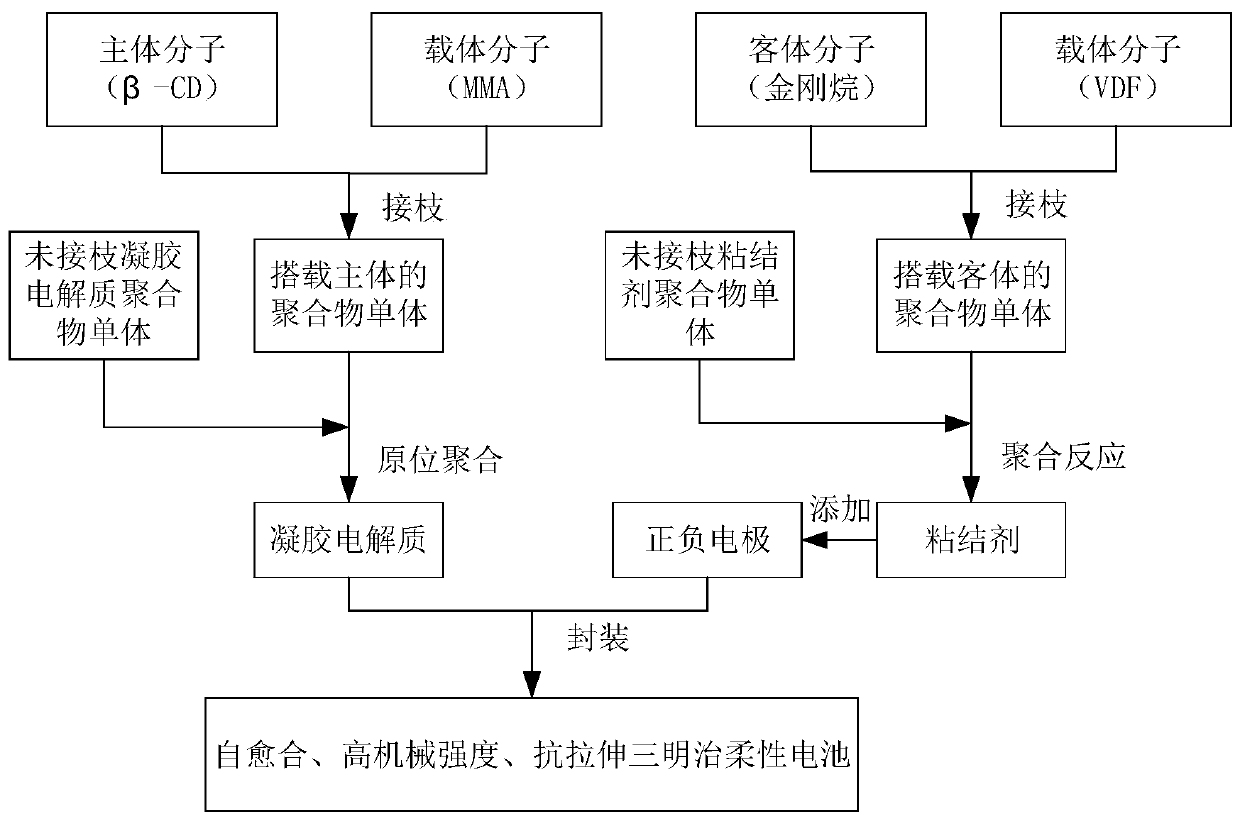

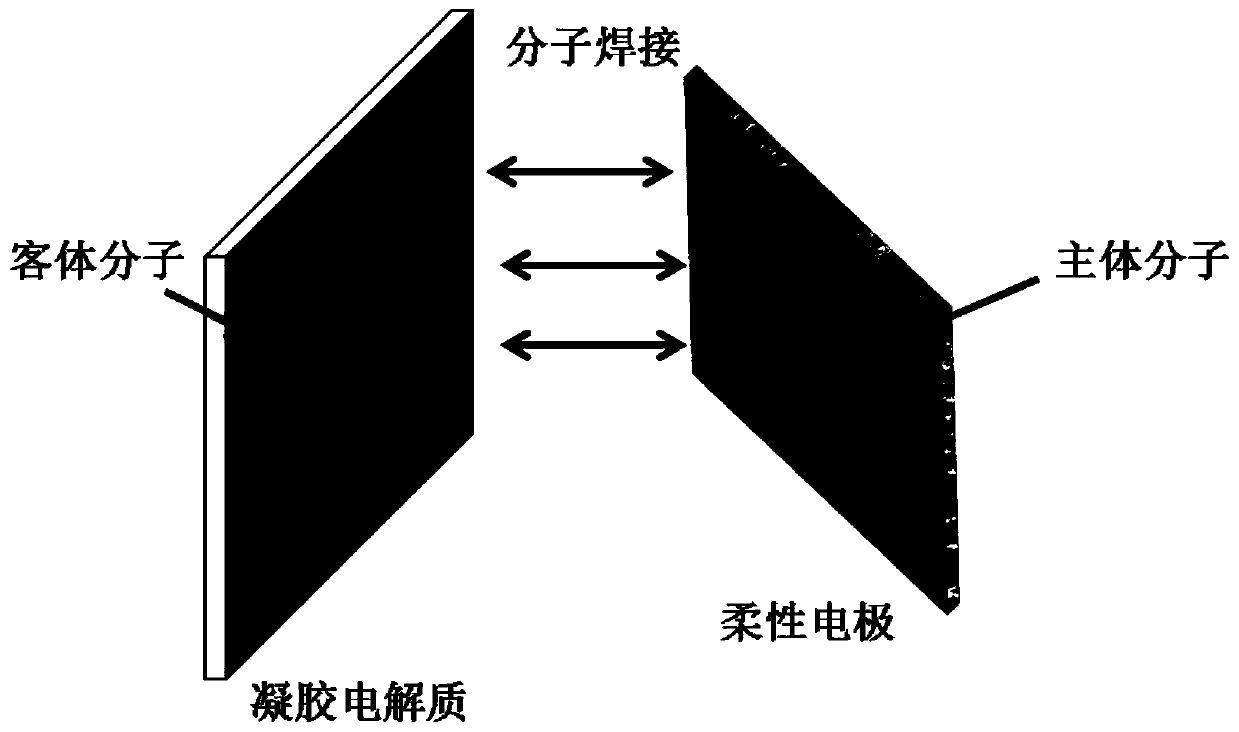

ActiveCN108242555AGood effectReduce energy densityFinal product manufactureSmall-sized flat cells/batteriesPolymer scienceAdhesive

The invention provides a self-adsorption flexible battery and a preparation method thereof. The preparation method comprises the following steps: grafting cyclodextrin, as a host, to a gel electrolytepolymer monomer, to form a host molecule carrying polymer monomer matrix; performing in-situ polymerization reaction of the host molecule carrying polymer monomer matrix and the un-grafted gel electrolyte polymer monomer, to generate a host molecule doped gel electrolyte; grafting adamantane or ferrocene, as an object, to an adhesive polymer monomer, to form an object molecule carrying polymer monomer matrix; performing polymerization reaction of the prepared object molecule carrying polymer monomer matrix and the un-grafted adhesive polymer monomer, to generate an object molecule doped adhesive; adding the object molecule doped adhesive into positive and negative electrodes, and encapsulating with the host molecule doped gel electrolyte, to obtain a self-adsorption sandwich flexible battery. Compared with existing flexible battery, the flexible battery has the advantages that the service life of the battery is prolonged while the flexibility is improved, and the shortcomings of existing flexible battery technology are overcome.

Owner:SINOCAT ENVIRONMENTAL TECH

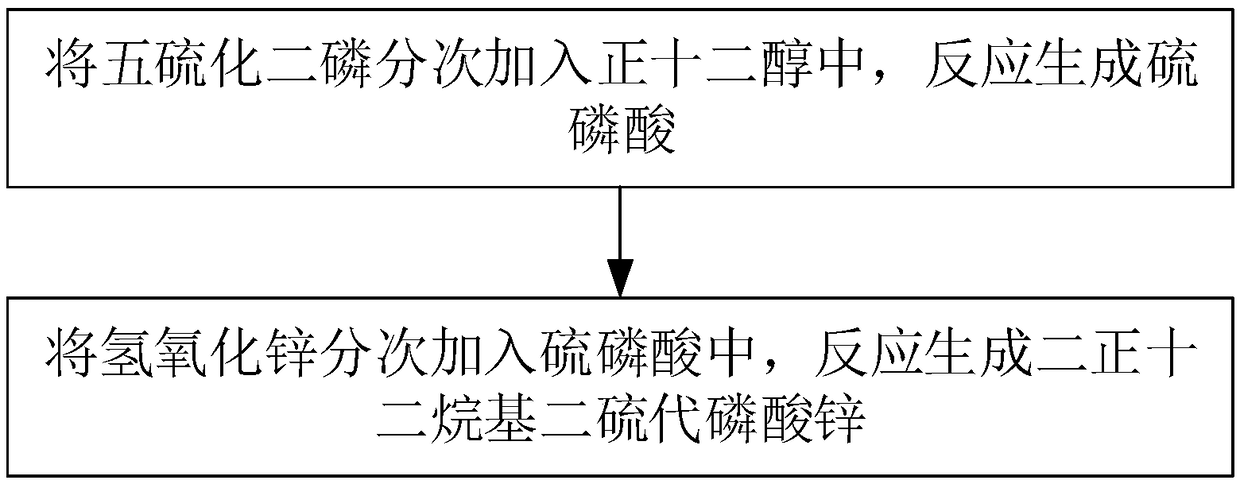

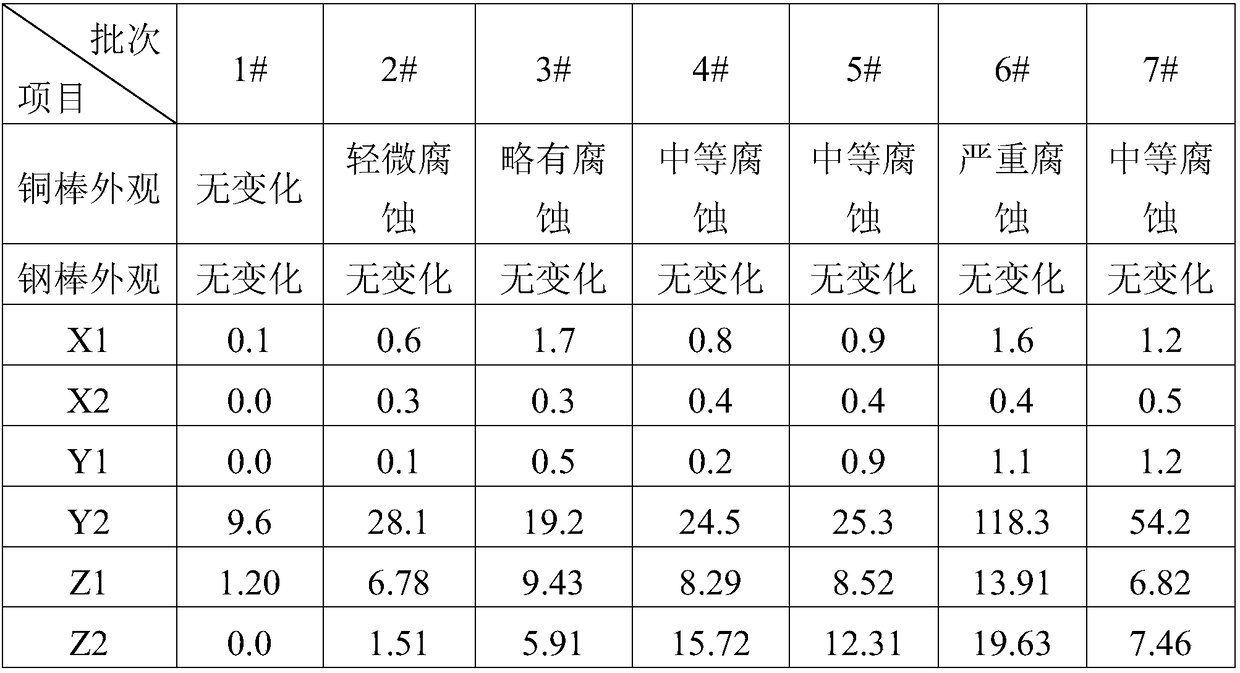

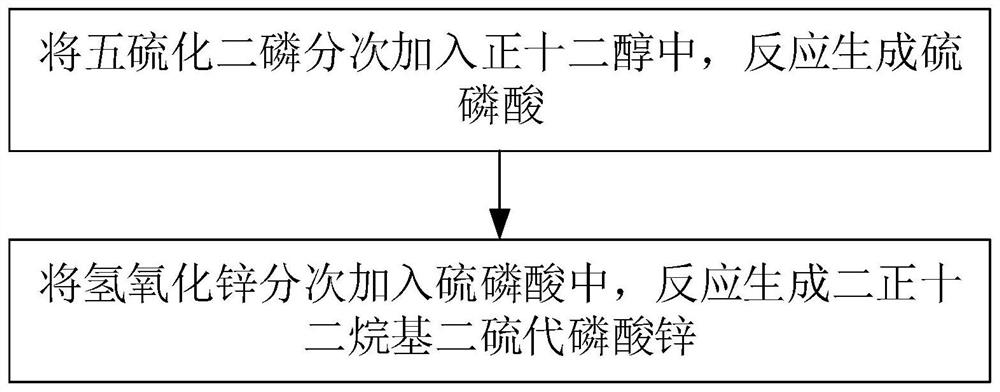

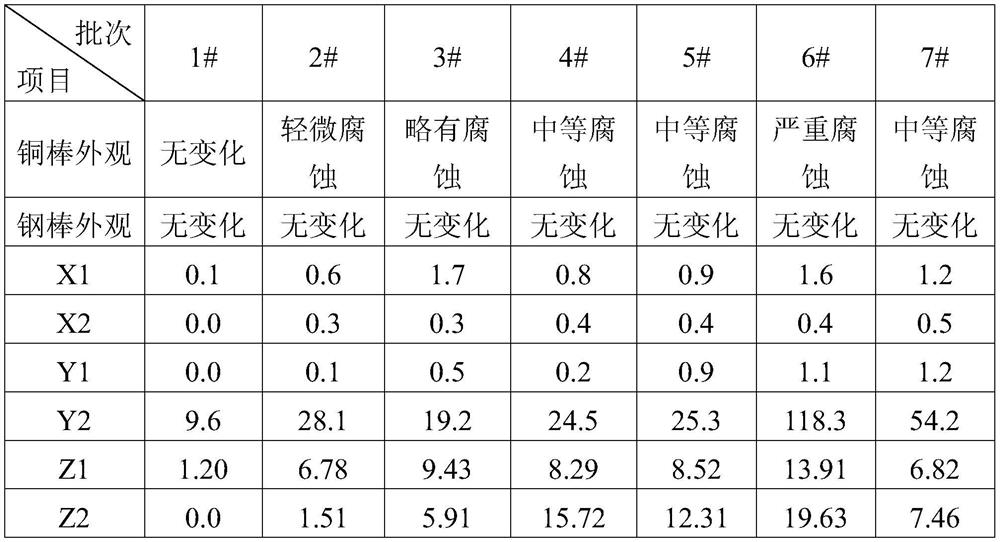

Special additive for wear-resistant hydraulic oil with excellent thermal stability and preparation method thereof

ActiveCN109160925AReduce processingImprove thermal stabilityGroup 5/15 element organic compoundsAdditivesPhosphorus pentasulfideWear resistant

The invention discloses a special additive for wear-resistant hydraulic oil with excellent thermal stability and a preparation method thereof. The special additive for the wear-resistant hydraulic oilwith excellent thermal stability is zinc di-dodecyl dithiophosphate, and the zinc di-dodecyl dithiophosphate is added in the wear-resistant hydraulic oil to improve the thermal stability of the wear-resistant hydraulic oil. The preparation method comprises the following steps: adding phosphorus pentasulfide in N-dodecanol time by time and reacting to generate thiophosphoric acids; and adding zinchydroxide in the thiophosphoric acids time by time and reacting to generate the zinc di-dodecyl dithiophosphate. The special additive for the wear-resistant hydraulic oil with excellent thermal stability and the preparation method thereof disclosed by the invention have the benefits that the zinc di-dodecyl dithiophosphate is used on the hydraulic oil to obviously improve the thermal stability ofthe hydraulic oil; and the production process is simpler, the industrialization difficulty is low, the application of a catalyst is also eliminated, the later waste treatment is reduced, and the production cost is obviously reduced.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

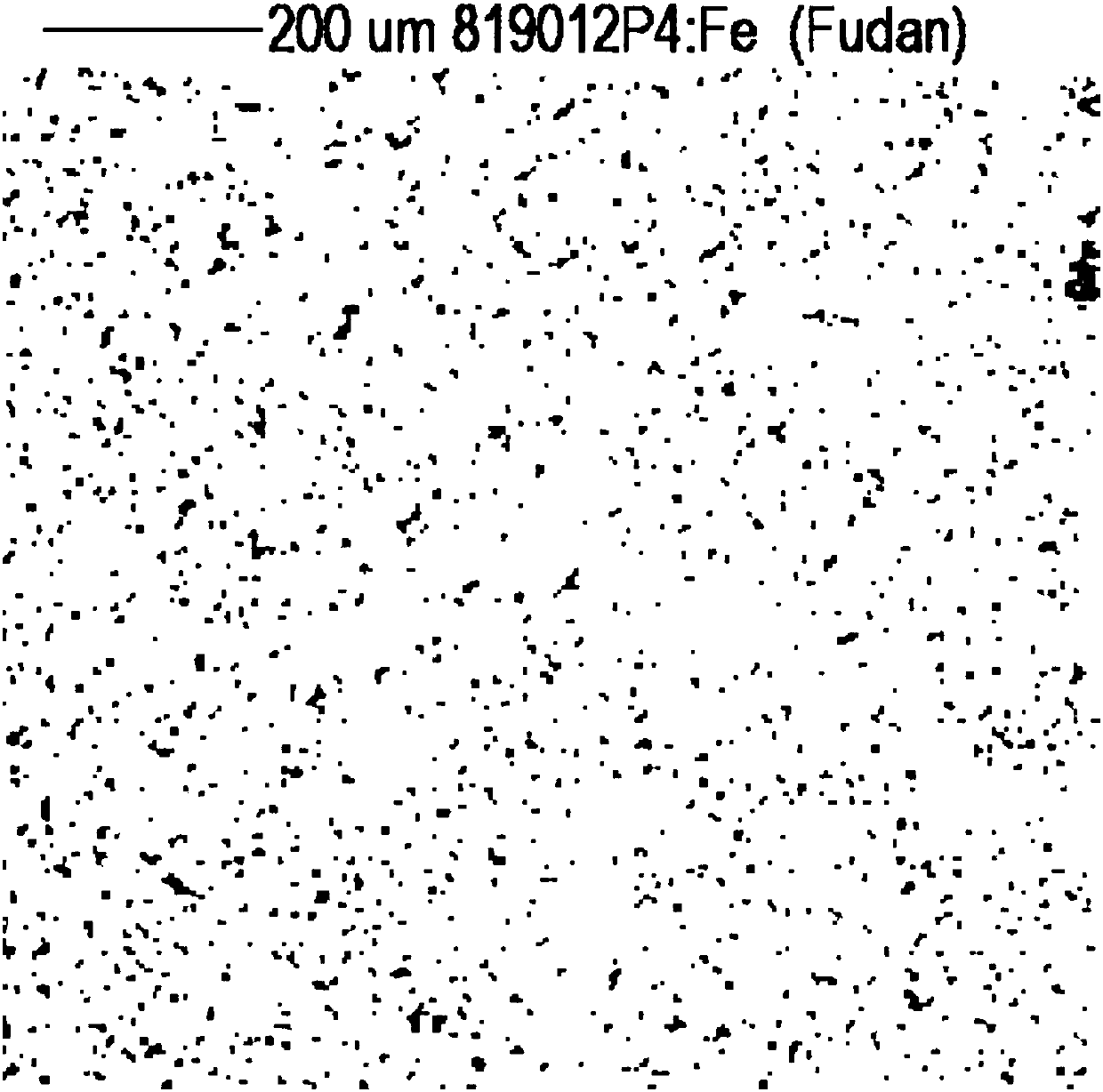

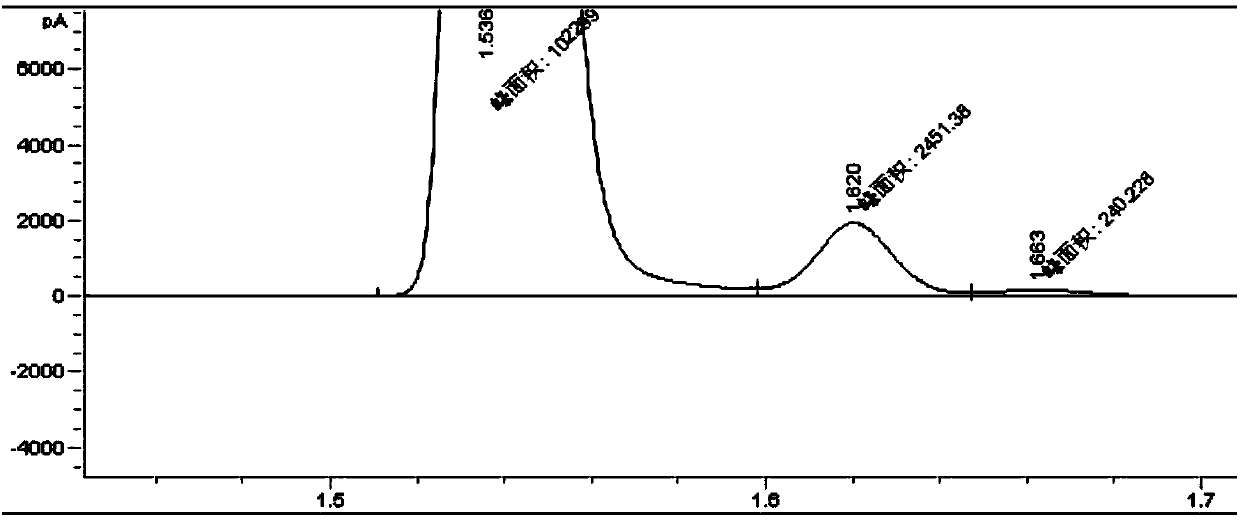

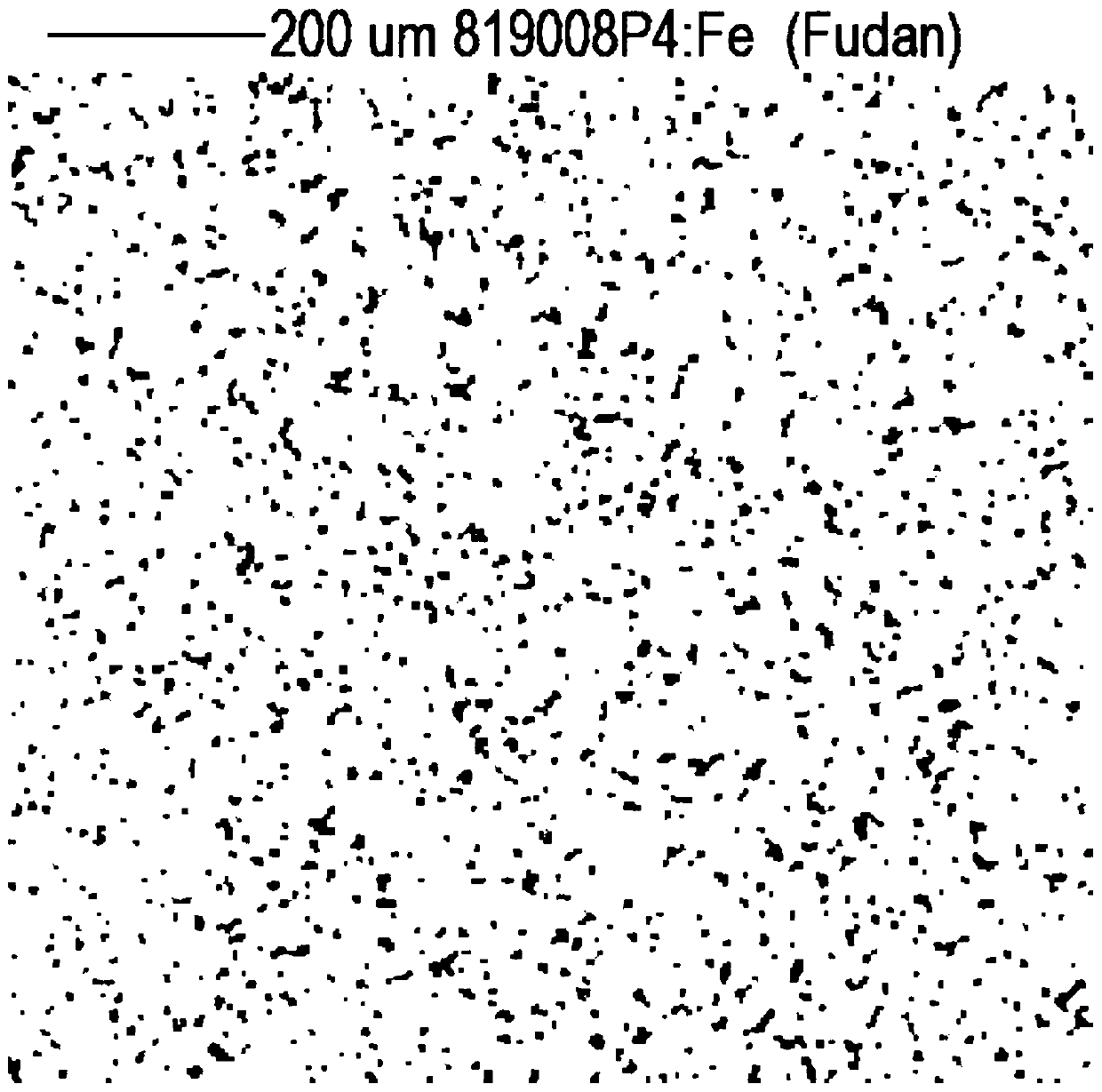

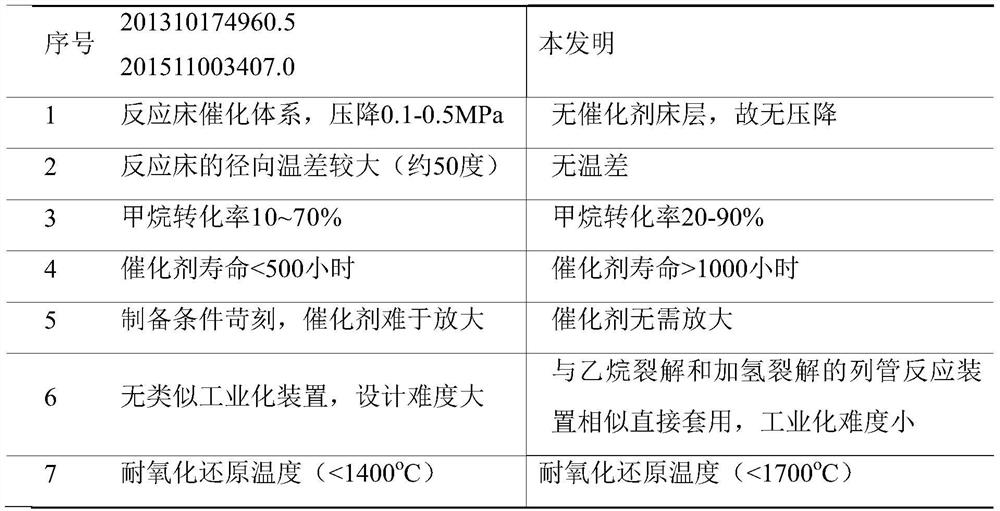

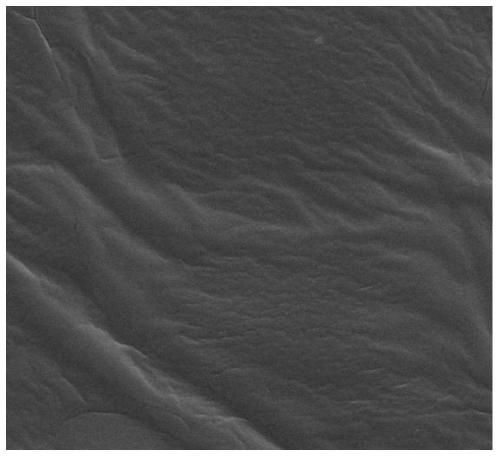

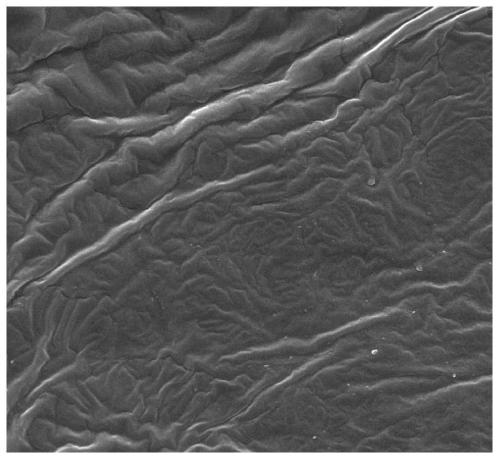

Catalyst-silicon carbide reactor and application thereof in reaction of directly preparing olefin from methane

ActiveCN109847665AGood choiceSolution to short lifeHydrocarbon by hydrocarbon condensationChemical/physical/physico-chemical processesChemical reactionOxygen

The invention relates to a preparation method of a catalyst-silicon carbide reactor and a method for catalyzing methane to directly synthesize ethylene under an oxygen-free condition. The catalyst-silicon carbide reactor is prepared on basis of a novel prepared silicon carbide material, and good thermal conductivity and chemical reaction inert characteristic of the material are utilized. Based onthe catalyst-silicon carbide reactor and reaction conditions, zero carbon deposition and high-selectivity synthesis of ethylene are realized. According to the invention, the conversion rate of methaneis 10-70%, the selectivity of olefin is 40-95%, the selectivity of propylene is 5-15%, the selectivity of aromatic hydrocarbon is 0-40%, and zero carbon deposition is achieved. The method provided bythe invention has the characteristics of long catalyst service life (1000 hours), good stability at a high temperature (1700 DEG C), high methane conversion rate and product selectivity, zero carbondeposition, low industrial difficulty, good process repeatability, safe and reliable operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

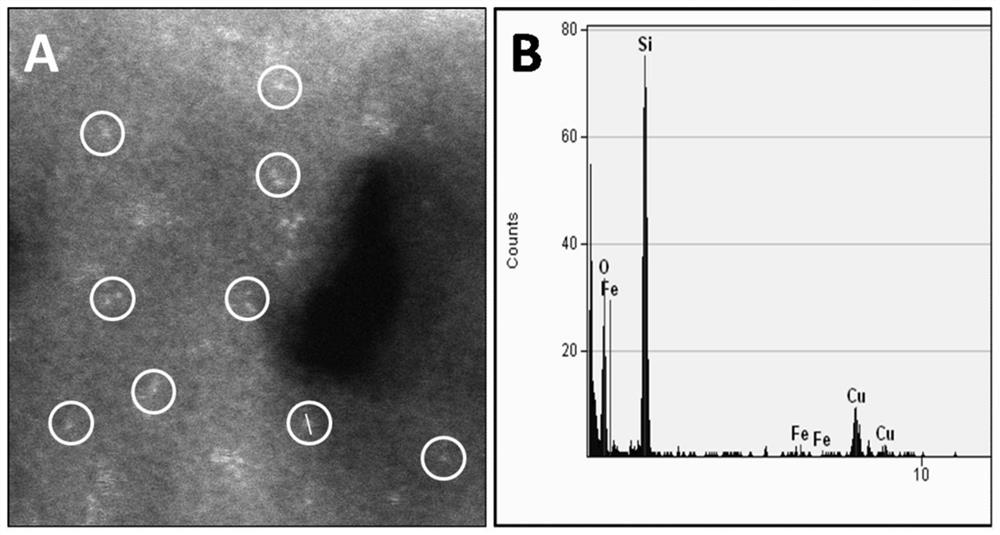

Preparation of silicon carbide reactor and application thereof in direct preparation process of olefins from methane

ActiveCN109847654ASolution to short lifeHigh selectivityHydrocarbon by hydrocarbon condensationInert gas productionChemical reactionOxygen

The invention discloses a silicon carbide reactor, the material of the reactor is metal element lattice doped silicon carbide. The characteristics of the material with good thermal conductivity and chemical reaction inertness are utilized, ethylene is directly synthesized from methane through catalysis based on oxygen-free conditions in the reactor, thus zero carbon deposition of methane and highselectivity synthesis of ethylene are achieved, the convension rate of methane is 10-70%, the selectivity of ethylene is 40-75%, the selectivity of propylene is 5-15%, the selectivity of arenes is 0-40%, and zero carbon is deposited. The silicon carbide reactor has the characteristics of long catalyst lifetime(>1000 h), good stability of the catalyst under high temperature(<1700 DEG C), high conversion rate of methane and product selectivity, zero carbon deposition, small difficulty of industrialization, good process repeatability, and safe and reliable operation, and has broad industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing olefin, aromatic hydrocarbon and hydrogen through catalytic conversion of methane under hydrogen condition

ActiveCN111333479ASolution to short lifeImprove conversion rateCatalystsHydrocarbon preparation catalystsCatalytic transformationAlkene

The invention relates to a preparation method for preparing olefin, aromatic hydrocarbon and hydrogen by converting methane in a quartz catalytic reactor under a hydrogen condition. In the process, efficient conversion of methane is realized, efficient dissociation of methane is promoted by hydrogen, heavy hydrocarbon generation is inhibited by hydrogen, and high catalyst stability and zero-carbon-deposition generation are realized. The conversion rate of methane is 20-70%; the olefin selectivity is 70 to 95 percent; the benzene selectivity is 5-30%, and zero carbon deposition is achieved. Themethod has the characteristics of long service lifetime of the catalyst, good oxidation reduction and hydrothermal stability of the catalyst at high temperature, high methane conversion rate and product selectivity, zero carbon deposition, no need of amplification of the catalyst, low industrialization difficulty, easiness in separation of the product, good process repeatability, safety and reliability in operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

Special additive for anti-wear hydraulic oil and preparation method thereof

ActiveCN109160925BReduce processingImprove thermal stabilityGroup 5/15 element organic compoundsAdditivesZinc hydroxidePhosphorus pentasulfide

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

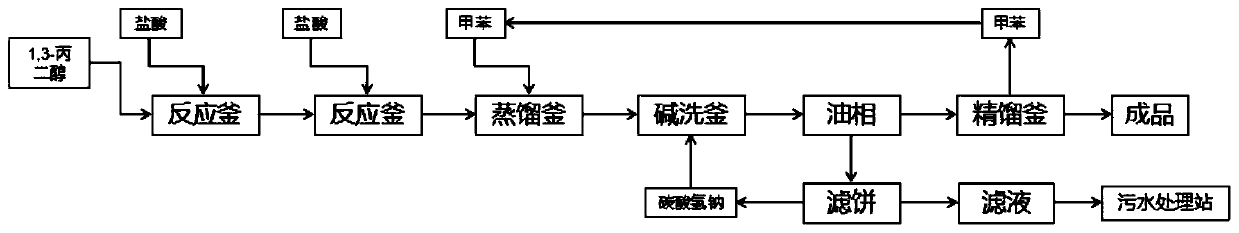

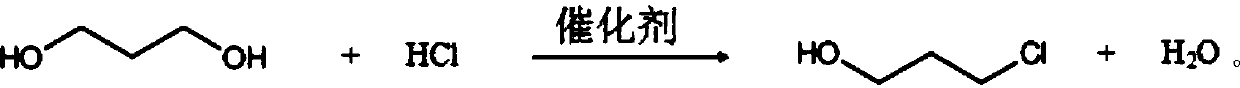

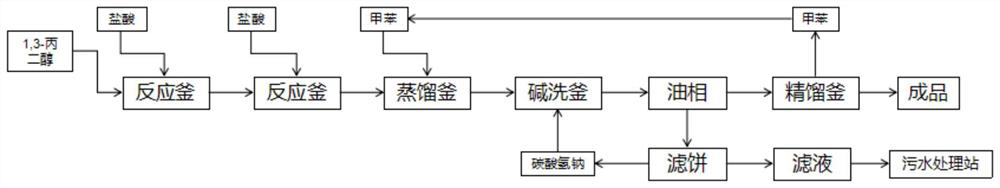

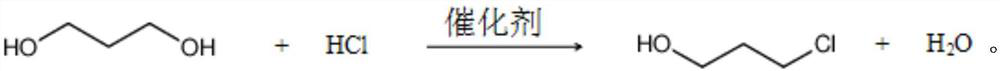

Chemical synthesis method of 3-chloro-1-propanol

ActiveCN110668918AAvoid generatingMild reaction conditionsOrganic compound preparationPreparation by halogen introductionChemical synthesisPtru catalyst

The invention belongs to the technical field of chemical synthesis, and concretely relates to a chemical synthesis method of 3-chloro-1-propanol. 1,3-propylene glycol reacts with hydrochloric acid with benzenesulfonic acid as a catalyst to synthesize 3-chloro-1-propanol. The method comprises the following steps: 1,3-propylene glycol, a part of hydrochloric acid and benzenesulfonic acid are added into a reaction kettle and are reacted, the remaining hydrochloric acid is added into the reaction kettle, the obtained mixture is continuously reacted until the sampling analysis result shows that thesample is qualified, toluene is added, a heating reflux water-carrying reaction is carried out, the kettle is cooled to room temperature after the water-carrying reaction is completed, an oil phase in the kettle is neutralized to be neutral, the oil phase is pumped into a rectifying kettle, and is rectified until the sampling analysis result shows that the sample is qualified, and the finished product is separated out. The method which adopts the benzenesulfonic acid as the catalyst has the advantages of increase of the reaction efficiency, prevention of excessive chlorination, no generationof high-toxicity and high-pollution three wastes in the reaction, recyclability of byproducts, realization of the comprehensive yield of 95% or above, high conversion rate, high operability, low riskand low industrialization difficulty.

Owner:邹平铭兴化工有限公司

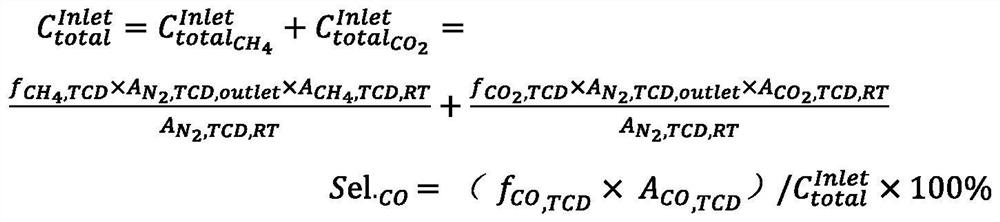

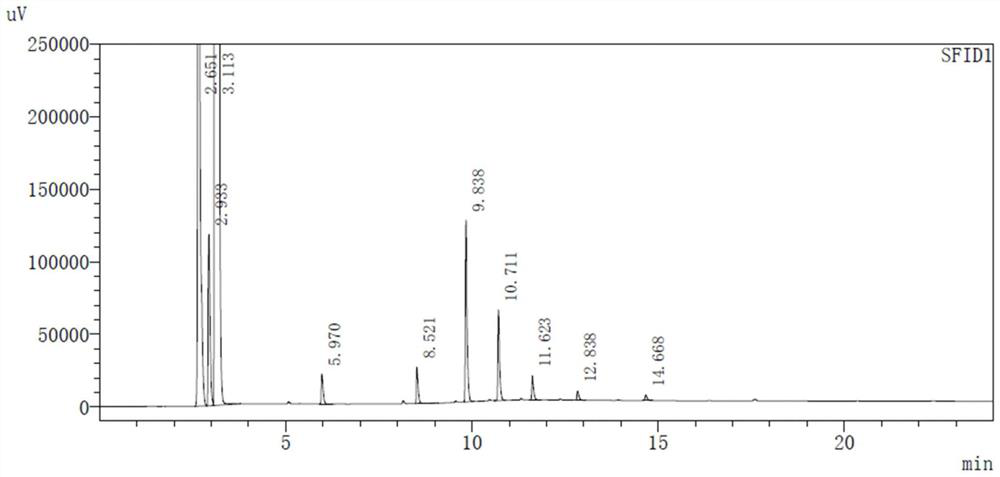

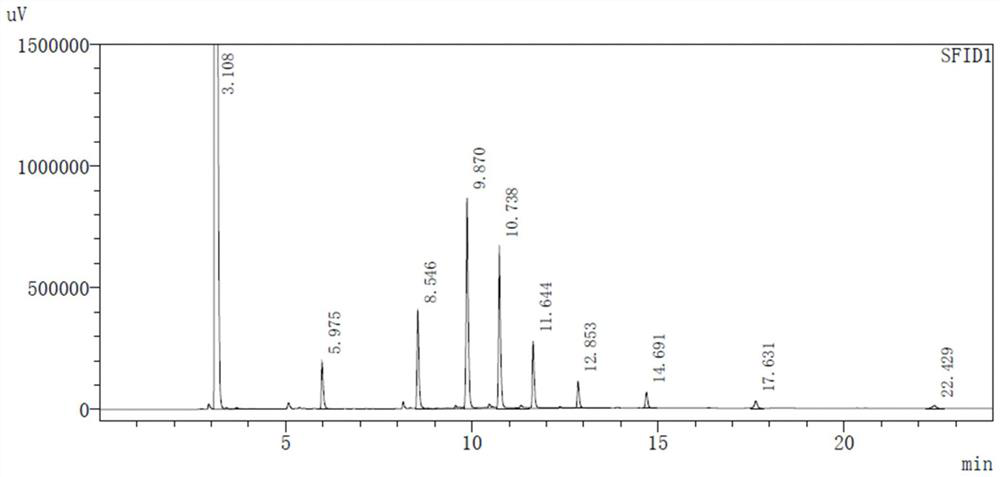

Metal catalytic reactor, preparation of metal catalytic reactor and application of metal catalytic reactor in preparation of synthesis gas by reforming natural gas and CO2 dry gas

PendingCN114768746ASimple processMild conditionsHydrogenHydrogen/synthetic gas productionSyngasNatural gas

The invention relates to a metal catalytic reactor as well as preparation and application thereof in preparation of synthesis gas by reforming natural gas and CO2 dry gas, a contact surface of a metal tube and a reaction raw material is coated and doped with a catalyst active component, a catalytic dopant thin layer is formed on the contact surface of the metal tube and the reaction raw material, and the metal catalytic reactor is obtained. The metal reactor is used for reforming reaction of natural gas and CO2 dry gas, and can realize efficient conversion of methane and carbon dioxide, high catalyst stability and low carbon deposition generation. According to the invention, the conversion rate of methane is 80-96%; the conversion rate of carbon dioxide is 80-98%; the selectivity of carbon monoxide is greater than 99%; cO / H2 = 1; and carbon deposition is low. The method has the characteristics of long catalyst service life, high methane conversion rate and product selectivity, low carbon deposition, no need of catalyst amplification, small industrialization difficulty, easy product separation, good process repeatability, safe and reliable operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

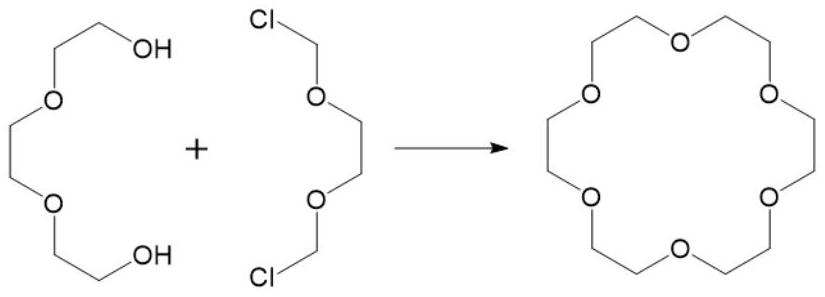

Method for preparing aliphatic crown ether from ethylene oxide through oligomerization

PendingCN114702472AReduce usageAvoiding Recycling ConundrumsOrganic chemistryChemical recyclingPolymer sciencePtru catalyst

The invention relates to a preparation method, in particular to a preparation method for preparing aliphatic crown ether from ethylene oxide through oligomerization. The method comprises the following steps: monomer solution preparation, catalyst solution preparation, polymerization reaction, reaction termination and product treatment. The synthesis method provided by the invention has the advantages of low raw material cost, continuous synthesis, easy product separation and the like, and is especially suitable for large-scale continuous production.

Owner:浙江肯特催化材料科技有限公司

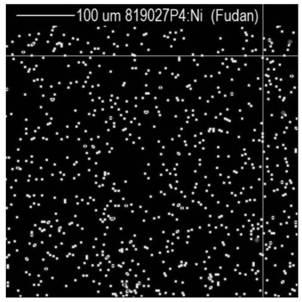

Metal Element Lattice Doped Silicon Carbide Reactor and Its Application in Ethane Dehydrogenation to Ethylene

ActiveCN109847670BSolution to short lifeImprove thermal conductivityHydrocarbonsChemical/physical/physico-chemical processesPtru catalystChemical reaction

The invention relates to a metallic element lattice doped silicon carbide reactor, and applications thereof in preparation of ethene through ethane dehydrogenation. The metallic element lattice dopedsilicon carbide reactor is invented base on a novel silicon carbide material which possesses excellent heat conductivity and chemical reactionlessness; based on the metallic element lattice doped silicon carbide reactor, and reaction conditions, the process is capable of realizing ethene high yield synthesis. The ethane conversion rate ranges from 70 to 100%; ethene selectivity ranges from 80 to 99.99%; propylene selectivity ranges from 0 to 5%; and aromatic hydrocarbons selectivity ranges from 0 to 5%. The metallic element lattice doped silicon carbide reactor possesses following characteristics: catalyst service life is long (>1000h), catalyst high temperature (<1700 DEG C) stability is excellent, ethane conversion rate and product selectivity are high, energy consumption is low, processrepeatability is excellent, and operation is safe and reliable; and the industrialized application prospect is promising.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method for steam catalytic conversion of methane to olefins, aromatics and hydrogen

ActiveCN111333478BImprove conversion rateIncrease conversion rateCatalystsHydrocarbon preparation catalystsPtru catalystCarbon deposit

The invention relates to a preparation method of a quartz catalytic reactor in steam catalytic cracking methane to olefins, aromatics and hydrogen. The process realizes efficient conversion of methane, generation of steam-compressed gas-phase condensed ring aromatics and secondary carbon deposits, and almost no participation of steam. Reaction, only a small amount of CO is generated, steam improves heat transfer efficiency, and high catalyst stability. The conversion rate of methane is 20-70%; the selectivity of olefins is 85-95%; the selectivity of benzene is 4.5-13%; the selectivity of CO is 0.5-2%; zero carbon deposition. The invention has the advantages of long catalyst life, good oxidation-reduction and hydrothermal stability at high temperature of the catalyst, high methane conversion rate and product selectivity, zero carbon deposition, no need for catalyst amplification, low industrialization difficulty, easy separation of products, good process repeatability, and easy operation. It has the characteristics of safety and reliability, and has broad industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

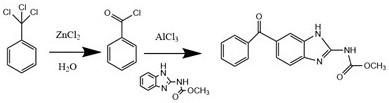

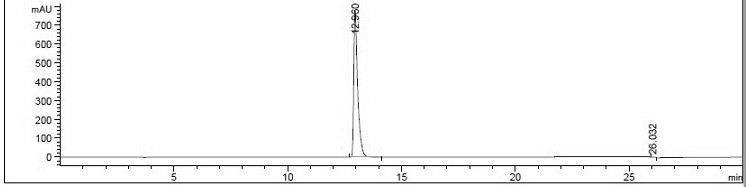

A kind of preparation method of mebendazole

The invention discloses a method for preparing mebendazole, which belongs to the technical field of drug synthesis. The preparation method includes an acylation reaction and a Friedel-Crafts reaction; wherein, in the acylation reaction, trichlorotoluene is heated to 50-90° C. and then chlorinated Zinc aqueous solution, after the dropwise addition, carry out insulation reaction. After the reaction is completed, benzoyl chloride is obtained by distillation under reduced pressure; the Friedel-Crafts reaction is to cool down after mixing and stirring carbendazim, solvent, and anhydrous aluminum chloride, and then add benzoyl chloride dropwise. After the dropwise addition, continue to stir and insulate the reaction, then distill under reduced pressure to obtain the product mebendazole; the present invention abandons the traditional method of first Friedel-Crafts and then forming a ring, and uses carbendazim as a reactant to directly synthesize mebendazole. The yield is high, and compared with the traditional process, it has the characteristics of simple process, mild conditions and high atom utilization rate.

Owner:SHANDONG GUOBANG PHARMA +1

Technology and equipment for preparing C/C composite

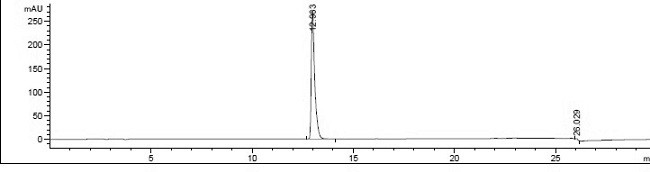

InactiveCN103044056BEffective "purgeHigh yieldFurnace typesVolumetric Mass DensityChemical vapor infiltration

The invention discloses a technology and equipment for preparing a C / C (carbon / carbon) composite. The technology for rapidly preparing the C / C composite comprises the following steps that (1) a preform is pretreated; (2) tools are prepared; (3) furnace loading is conducted; (4) temperature gradient differential CVI (chemical vapor infiltration) treatment is conducted; (5) heating of a heating element and input of mixed gas are stopped sequentially after 100-300h; and (6) a cover plate, the outer tool, the preform and the inner tool are taken out to form the C / C composite with density of 1.4-1.7g / cm<3>. The invention further discloses the equipment for preparing the C / C composite. According to the technology and the equipment, the operation is simple; the densification period is short; the industrial difficulty is small; the densification rate is high; ineffective reaction can be avoided; the carbon yield can be increased; and pollution of a vacuum system can be prevented.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Method for preparing synthesis gas by reforming natural gas and CO2 dry gas through thermal plasma coupling catalysis

PendingCN114733477AIncrease added valueIncrease energy densityHydrogenGas treatmentSyngasPtru catalyst

The invention relates to a method for preparing synthesis gas by reforming natural gas and CO2 dry gas through thermal plasma coupling catalysis. The process is coupled with thermal plasma heat supply to realize efficient co-conversion of methane and carbon dioxide to generate a mixed gas of CO and H2, namely synthesis gas. According to the invention, the methane conversion rate is 80-96%; the conversion rate of carbon dioxide is 80-98%; carbon monoxide selectivity gt; 99%; cO / H2 is approximately equal to 1; and carbon deposition is low. The device has the electrothermal conversion efficiency gt; and the catalyst has the characteristics of long electrode life, long catalyst life, high methane conversion rate and product selectivity, low carbon deposition, small industrialization difficulty, good process repeatability, safe and reliable operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

An additive for improving the extreme pressure anti-wear performance of lubricating grease and its preparation method

ActiveCN110257131BGood extreme pressure and anti-wear propertiesEasy to prepareAdditivesIsooctyl alcoholPhosphorus pentasulfide

The invention discloses an additive and a preparation method for improving the extreme pressure anti-wear performance of lubricating grease. The additive is n-butyl and isooctyl dithiophosphate; the preparation method is: phosphorus pentasulfide, n-butanol and isooctyl alcohol Mixed alcohols react to generate sulfuric acid; sulfuric acid reacts with the mixture of zinc oxide and antimony trioxide to generate n-butyl, isooctyl dithiophosphate; the additive of the present invention is used in grease, and its more It is easy to form an anti-wear and extreme-pressure oil film due to thermal decomposition, so the extreme-pressure and anti-wear properties of grease can be improved by controlling a single additive.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

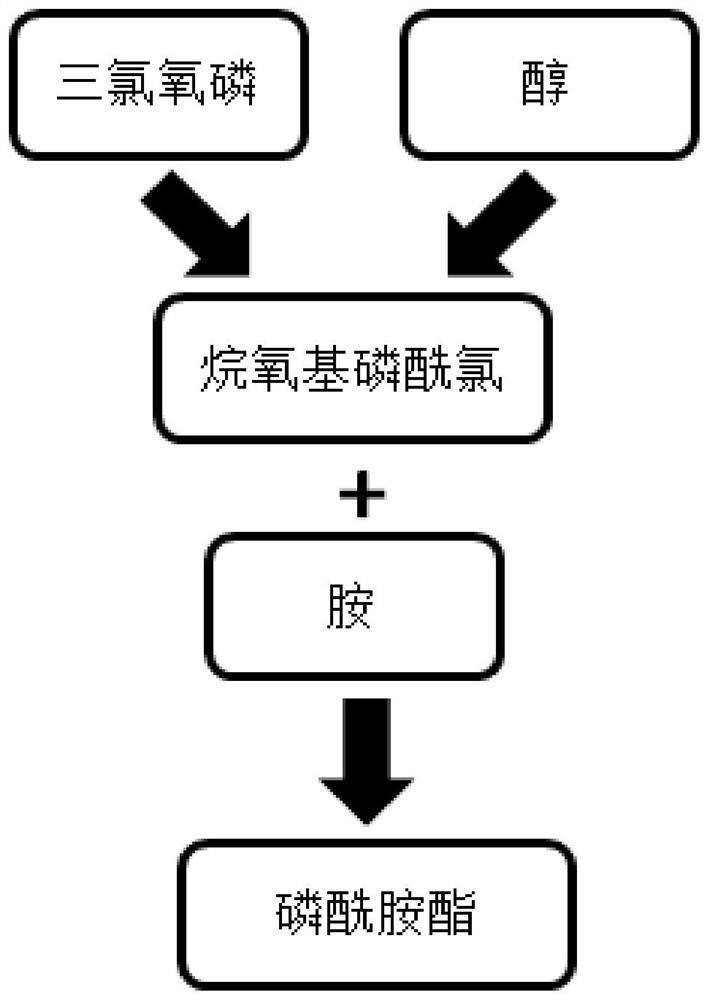

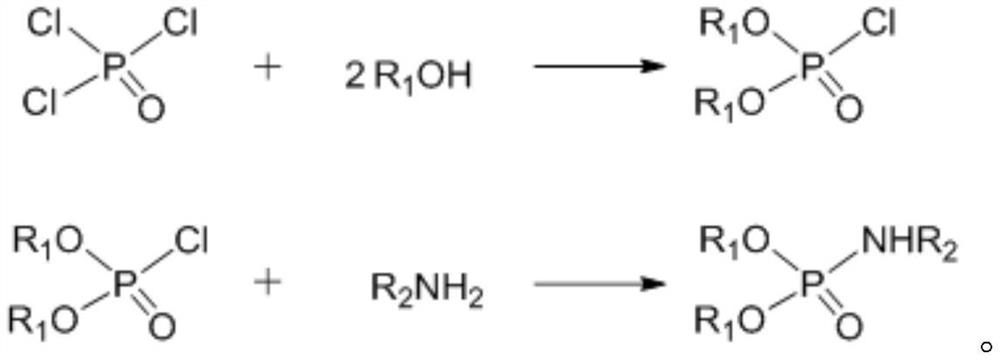

Preparation method of phosphorus-nitrogen type ash-free extreme pressure anti-wear agent and extreme pressure anti-wear lubricating oil

PendingCN113480572AGood extreme pressure and anti-wear propertiesGood demulsibilityGroup 5/15 element organic compoundsAdditivesNitrogen gasChemical engineering

The invention discloses a preparation method of a phosphorus-nitrogen type ash-free extreme pressure anti-wear agent and extreme pressure anti-wear lubricating oil. The preparation method comprises the following steps: respectively diluting phosphorus oxychloride and an alcohol compound in a molar ratio of 1:1.2-1:2.2 by using normal hexane, dropwise adding into a reaction container, introducing nitrogen as a protective gas, and removing generated hydrogen chloride; and heating to 30-50 DEG C after dropwise adding, keeping the temperature for 0.5-2 hours to obtain an intermediate alkoxy phosphoryl chloride, adding an organic amine compound in a molar ratio of the organic amine compound to the phosphorus oxychloride of (0.8:1)-(1.8:1), and keeping at the temperature of 50-80 DEG C for 1-3 hours to obtain phosphamide ester serving as an anti-wear agent. According to the technical scheme, the prepared extreme pressure anti-wear agent has excellent extreme pressure anti-wear performance and good demulsibility, does not contain sulfur, is simple in preparation process, low in industrialization difficulty and free of generation of waste pollution byproducts, the yield can reach 99% or above, and the production cost is reduced.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

A method for catalytic conversion of methane to olefins, aromatics and hydrogen under the condition of hydrogen

ActiveCN111333479BSolution to short lifeImprove conversion rateCatalystsHydrocarbon preparation catalystsBenzeneCatalytic transformation

The invention relates to a preparation method for converting methane to olefins, aromatics and hydrogen in a quartz catalytic reactor under hydrogen-facing conditions. The process realizes efficient conversion of methane, hydrogen promotes efficient dissociation of methane, hydrogen inhibits the formation of heavy hydrocarbons, and high Catalyst stability and zero carbon buildup. The conversion rate of methane is 20-70%, the selectivity of olefins is 70-95%, the selectivity of benzene is 5-30%, and there is no carbon deposition. The invention has the advantages of long catalyst life, good oxidation-reduction and hydrothermal stability at high temperature of the catalyst, high methane conversion rate and product selectivity, zero carbon deposition, no need for catalyst amplification, low industrialization difficulty, easy separation of products, good process repeatability, and easy operation. It has the characteristics of safety and reliability, and has broad industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

A method for the co-catalytic conversion of methane and ethane into olefins, aromatics and hydrogen

ActiveCN111333477BHigh selectivitySolution to short lifeHydrogenCatalyst activation/preparationCatalytic transformationPtru catalyst

The invention relates to a method for the co-catalytic conversion of methane and ethane into olefins, aromatics and hydrogen in a quartz catalytic reactor. Carbon deposits are formed. The conversion rate of methane in the invention is 20-70%, the selectivity of olefins is 60-90%, the selectivity of aromatics is 10-40%, and zero carbon deposit. The invention has the advantages of long catalyst life, good oxidation-reduction and hydrothermal stability at high temperature (<1700°C), high methane conversion rate and product selectivity, zero carbon deposition, no need for catalyst amplification, low industrialization difficulty, easy separation of products, and process It has the characteristics of good repeatability, safe and reliable operation, etc., and has broad industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

Self-adsorbable flexible battery and preparation method thereof

ActiveCN108242555BGood effectReduce energy densityFinal product manufactureSmall-sized flat cells/batteriesPolymer scienceElectrical battery

The invention provides a self-adsorbable flexible battery and a preparation method thereof. Cyclodextrin is grafted as a main body to a gel electrolyte polymer monomer to form a polymer monomer matrix carrying main molecules; The monomer matrix is in-situ polymerized with the ungrafted gel electrolyte polymer monomer to generate a gel electrolyte incorporating host molecules; adamantane or ferrocene is grafted as a guest to the binder polymer monomer The polymer monomer matrix carrying the guest molecules is formed on the polymer monomer matrix; the prepared polymer monomer matrix carrying the guest molecules is polymerized with the ungrafted binder polymer monomer to generate a binder incorporating the guest molecules. ; Add the binder doped with guest molecules into the positive and negative electrodes, and encapsulate it with the gel electrolyte doped with host molecules to form a self-adsorbing sandwich flexible battery. Compared with the existing flexible batteries, the flexibility is improved while extending the The service life of the battery makes up for the shortcomings of the existing flexible battery technology.

Owner:SINOCAT ENVIRONMENTAL TECH

Preparation of a silicon carbide reactor and its application in the process of direct methane to olefins

ActiveCN109847654BSolution to short lifeHigh selectivityHydrocarbon by hydrocarbon condensationInert gas productionPtru catalystChemical reaction

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

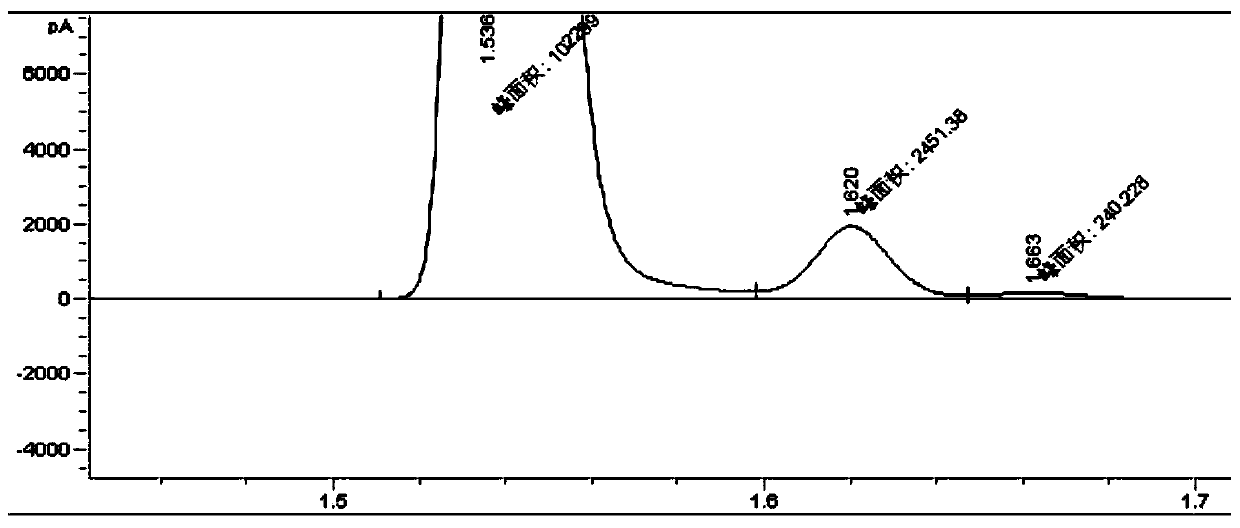

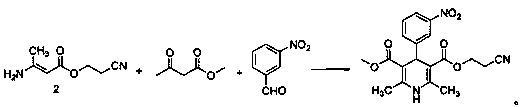

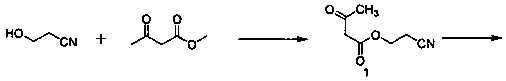

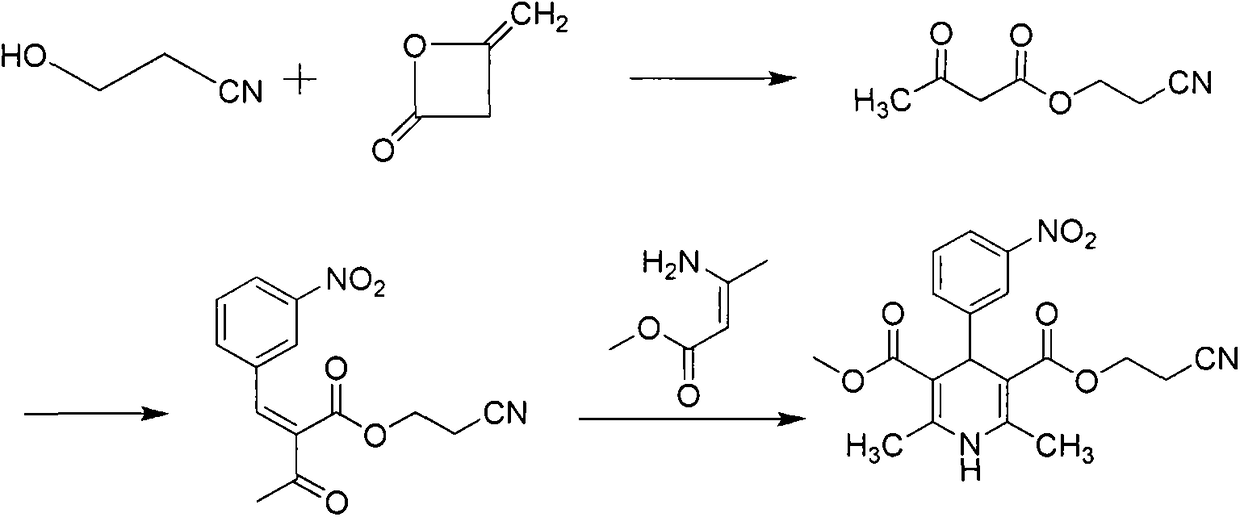

3-(2-Nitroethyl)-5-methyl-2,6-dimethyl-4-(3-nitrophenyl)-1,4-dihydropyridine-3,5-dicarboxylate preparation method

ActiveCN103739542BHigh reaction yieldSimple purification processOrganic chemistryPropionitrileEthylic acid

Owner:迪嘉药业集团股份有限公司

The chemical synthesis method of 3-chloro-1-propanol

ActiveCN110668918BAvoid generatingMild reaction conditionsOrganic compound preparationPreparation by halogen introductionChemical synthesisPropanol

The invention belongs to the technical field of chemical synthesis, and in particular relates to a method for chemical synthesis of 3-chloro-1-propanol, wherein benzenesulfonic acid is used as a catalyst, and 1,3-propanediol is reacted with hydrochloric acid to synthesize 3-chloro-1-propanol, The method includes the following steps: firstly put 1,3-propanediol, part of hydrochloric acid and benzenesulfonic acid into the reaction kettle for reaction, then put the remaining hydrochloric acid into the reaction kettle, continue to react until the sampling and analysis are qualified, then put into toluene for heating and refluxing with water After the reaction with water, the temperature of the kettle is lowered to room temperature, the oil phase in the kettle is neutralized to neutrality, the oil phase is pumped into the rectification kettle, and the finished product is separated after rectification until the sampling is qualified. By using benzenesulfonic acid as the catalyst, the present invention improves the reaction efficiency and prevents excessive chlorination, no three wastes with high toxicity and high pollution are generated in the reaction, the by-products can still be recovered and reused, and the comprehensive yield can reach more than 95%. The conversion rate is high, the operability is high, the risk is small, and the difficulty of industrialization is low.

Owner:邹平铭兴化工有限公司

Catalyst-Silicon Carbide Reactor and Its Application in Direct Methane to Olefins

ActiveCN109847665BGood choiceSolution to short lifeHydrocarbon by hydrocarbon condensationChemical/physical/physico-chemical processesPtru catalystChemical reaction

The invention relates to a preparation method of a catalyst-silicon carbide reactor and a method for catalyzing methane to directly synthesize ethylene under an oxygen-free condition. The catalyst-silicon carbide reactor is prepared on basis of a novel prepared silicon carbide material, and good thermal conductivity and chemical reaction inert characteristic of the material are utilized. Based onthe catalyst-silicon carbide reactor and reaction conditions, zero carbon deposition and high-selectivity synthesis of ethylene are realized. According to the invention, the conversion rate of methaneis 10-70%, the selectivity of olefin is 40-95%, the selectivity of propylene is 5-15%, the selectivity of aromatic hydrocarbon is 0-40%, and zero carbon deposition is achieved. The method provided bythe invention has the characteristics of long catalyst service life (1000 hours), good stability at a high temperature (1700 DEG C), high methane conversion rate and product selectivity, zero carbondeposition, low industrial difficulty, good process repeatability, safe and reliable operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com