Catalyst-silicon carbide reactor and application thereof in reaction of directly preparing olefin from methane

A technology of silicon carbide and reactor, applied in the field of new catalyst-reactor, which can solve the problems of high cost, inability to promote industrialization, and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

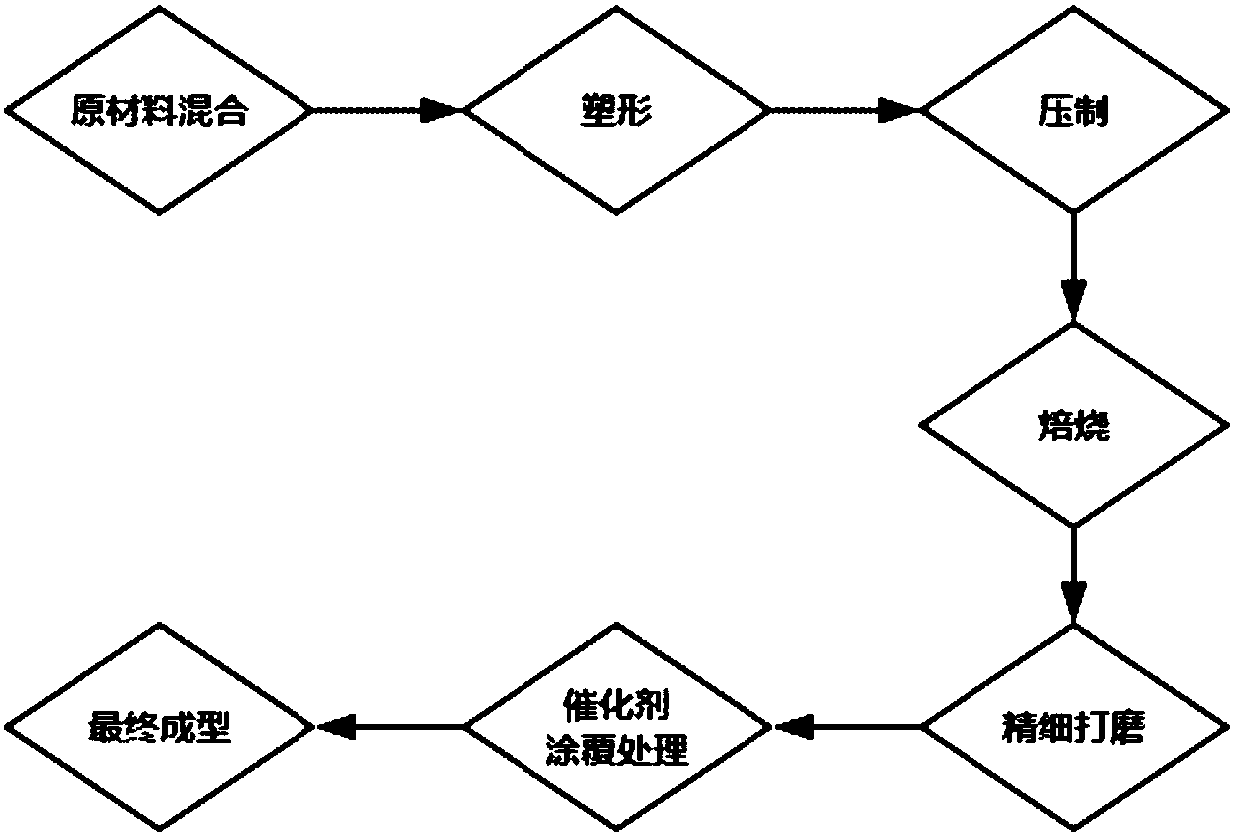

Method used

Image

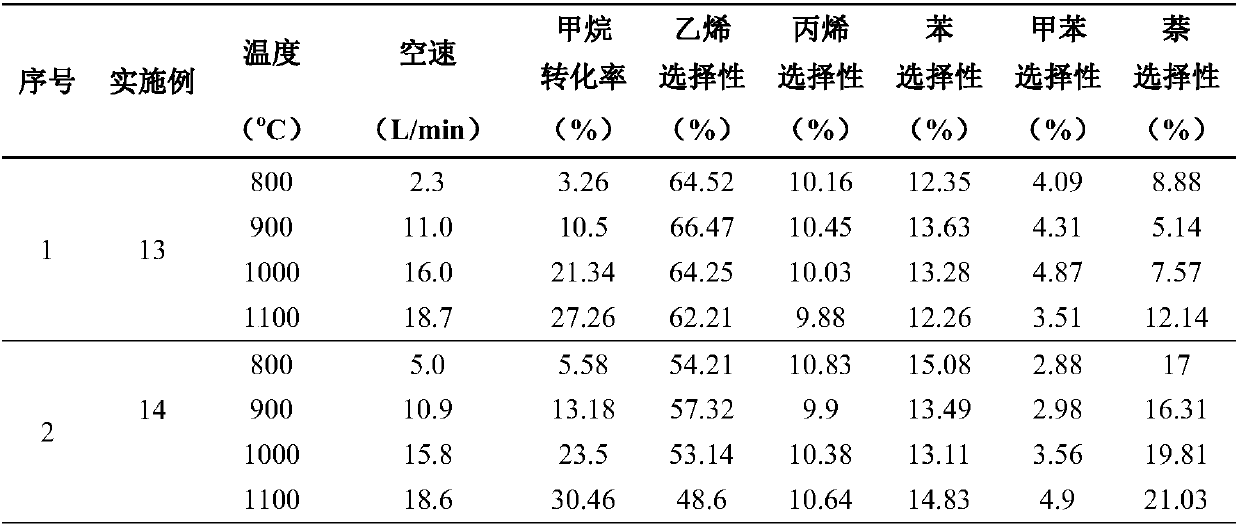

Examples

preparation example Construction

[0040] Embodiment 1-12 is the preparation of lattice doping reactor; Embodiment 13-22 is impregnation method supported catalyst; Embodiment 23-32 is gas phase CVD method supported catalyst; Embodiment 33-38 is sol-gel Combined with the high temperature melting method to support the catalyst.

[0041] Catalyst loading methods include impregnation, chemical vapor deposition (MCVD) or sol-gel combined with high-temperature melting coating technology:

[0042] Impregnation method: at 1-3 atmospheric pressure, immerse the shaped silicon carbide reactor in the doped metal salt solution for 0.1-48 hours at a temperature of 20-80°C; then melt it at 1600-2200°C to obtain Corresponding inner wall metal lattice-doped reactor, then cooled immediately to obtain catalyst-reactor after solidification;

[0043] Chemical vapor deposition method: under 1-3 atmospheric pressure, silicon tetrachloride liquid is doped with volatile doped metal salt or non-metallic chlorine gas-doped at 50-500°C w...

Embodiment 1

[0055]Mix 1kg SiC powder, 300g high-purity graphite powder, 300g silicon powder, 20g ferric nitrate, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 100-400nm and silicon powder with a particle size of 100μm. , sent to the extruder for extruded molding, the forming reactor is a straight tube, 2 meters in length, 35mm in outer diameter, 25mm in inner diameter, after 4 days of natural drying, it is sent to a 50°C muffle furnace to continue drying and dehumidification, and continue to dry in the N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 2 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R1.

Embodiment 2

[0057] Mix 1kg SiC powder, 200g high-purity graphite powder, 200g silicon powder, 20g ferric chloride, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 300-1000nm. 100 μm, sent to the extruder for extruded molding, the forming reactor is a straight tube type, 2 meters in length, 15mm in outer diameter, 5mm in inner diameter, after 4 days of natural drying, it is sent to a muffle furnace at 50°C to continue drying and dehumidification, and then Carry out pressing treatment, pressing pressure is 100Mpa, and pressing time is 30 minutes. continue at N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 3 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com