Patents

Literature

58results about How to "Radial temperature difference is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

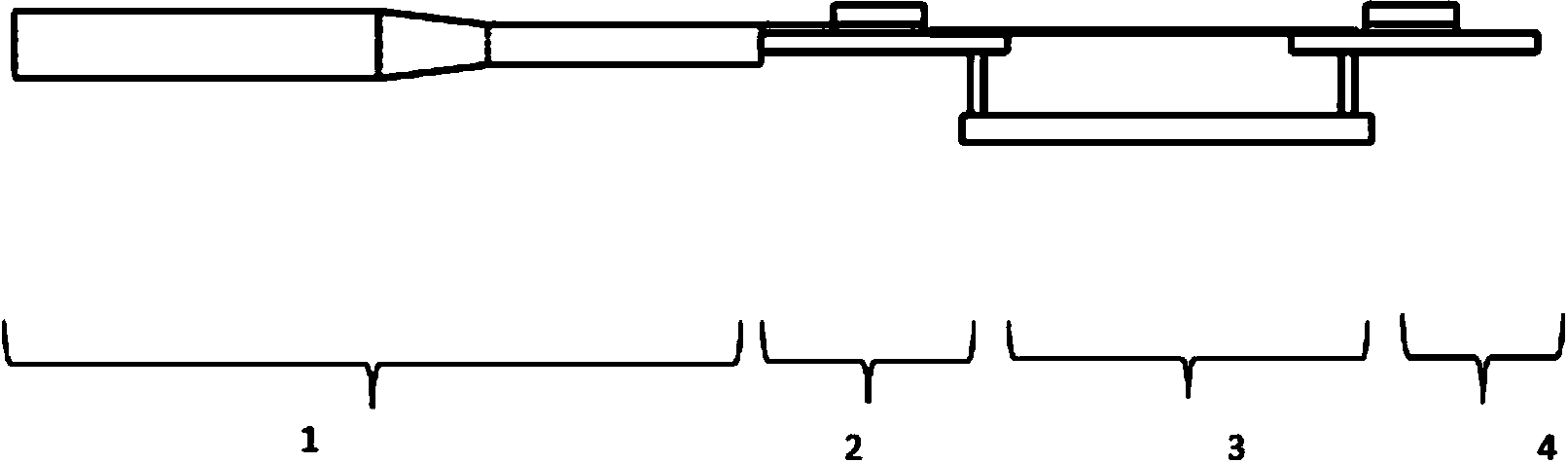

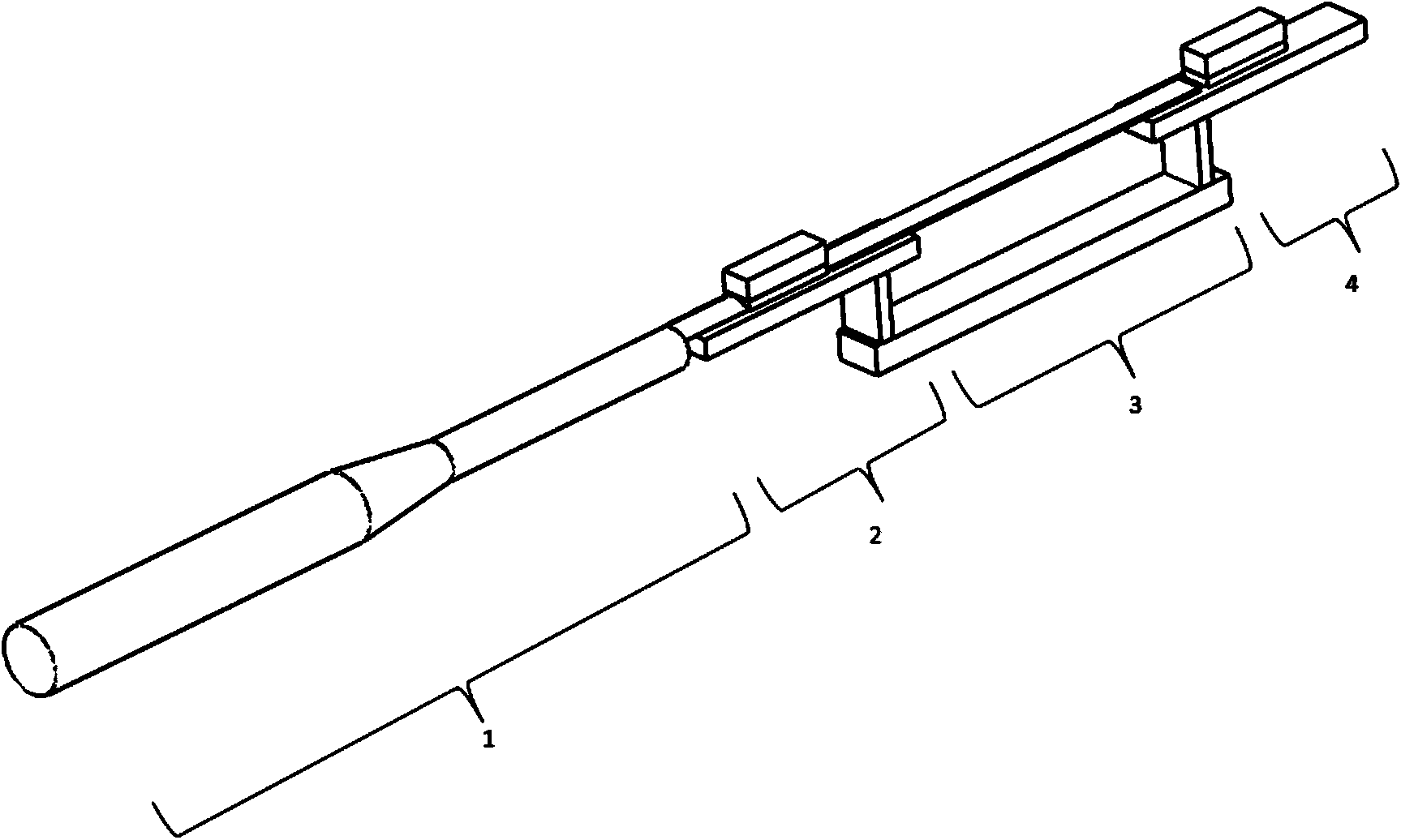

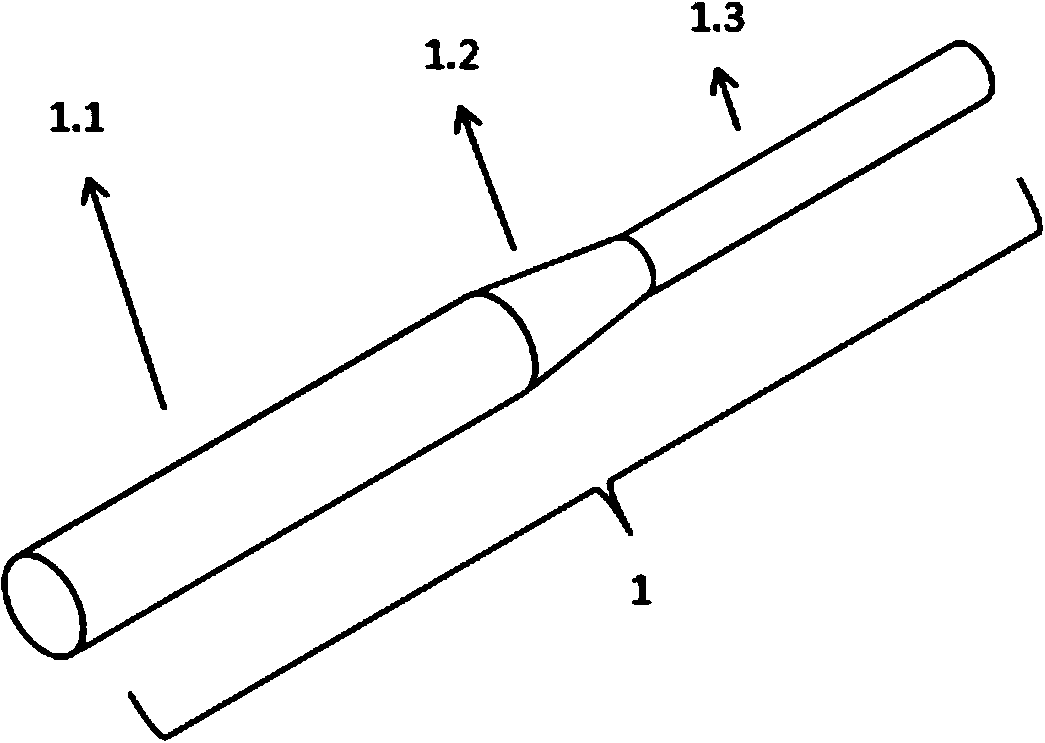

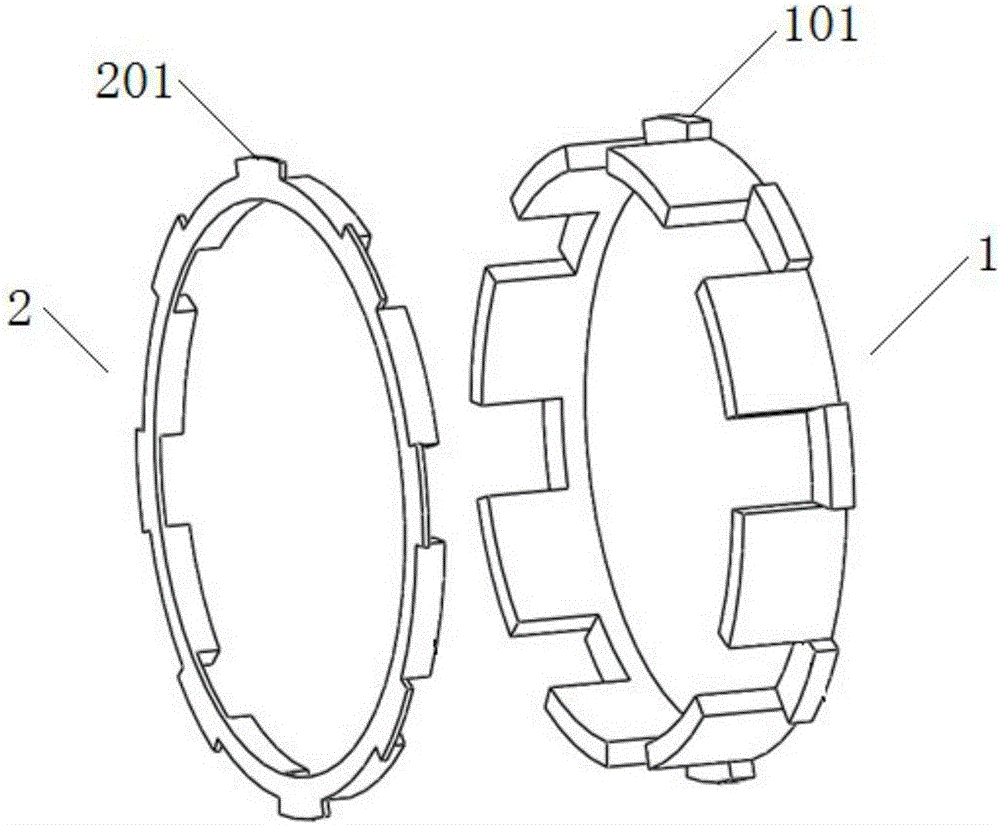

Binary current lead structure in conduction cooling mode

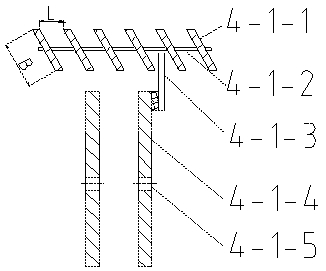

InactiveCN103839649ARadial temperature difference is smallGuaranteed low temperatureSuperconducting magnets/coilsEpoxyConduction cooling

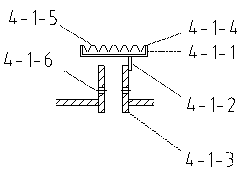

The invention discloses a sectional binary current lead structure on the basis of conduction cooling. The sectional binary current lead structure is characterized in that a copper lead portion of a current lead is of a sectional variable-cross-section structure, a constant-temperature connecting portion of the copper lead portion is thick, a high-temperature superconductor connecting lead end of the copper lead portion is thin, a connecting portion of the copper lead portion is in conical transition, and a superconductor lead portion of the current lead is of an epoxy resin fixed assembly structure. The sectional binary current lead structure has the advantages that heat leakage of the current lead can be greatly reduced owing to the sectional variable-cross-section structure, and the sectional binary current lead structure is favorable for machining; a joint of a common conductor and a superconductor is optimally designed and is refrigerated by a primary cold head of a refrigerator, aluminum nitride (AlN) is used as an insulating heat-conduction material, the cross section of the aluminum nitride is maximized, only the section side of a part, which is close to the cold head, of a copper lead keeps connected with a superconductor lead, accordingly, contact heat resistance of the joint is low, heat leakage can be reduced, a good cold-conduction effect can be realized, and quench at the joint can be effectively prevented.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

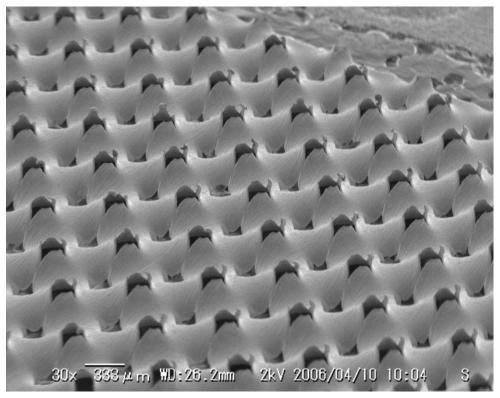

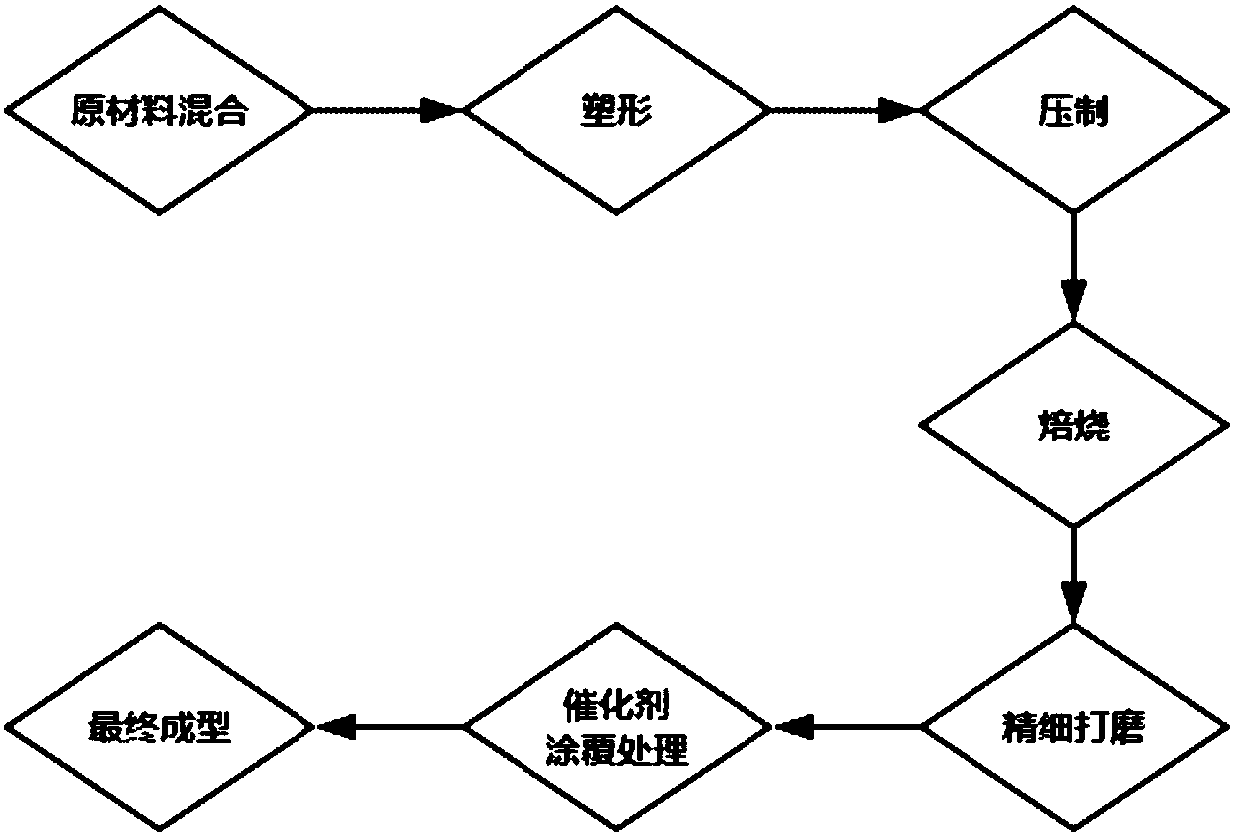

Catalyst for synthesizing oxalate by CO coupling reaction and preparation method thereof

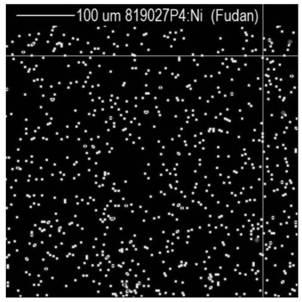

ActiveCN102784640AIncreased external specific areaSmall pressure dropPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsOxalateActive component

The invention relates to a catalyst for synthesizing oxalate by a CO coupling reaction and a preparation method thereof; the catalyst adopts metal wire mesh as a skeleton; a carrier coating is coated on the surface of the metal wire mesh; the carrier coating is loaded with active components and additives on the surface. Compared with the prior art, with the proviso that the catalytic activity is maintained to be the same, the catalyst of the invention greatly reduces the precious metals active component using amount per unit volume of the catalyst, significantly reduces the pressure drop of a catalyst bed layer, effectively decreases the radial temperature difference of the catalyst bed layer, improves the heat shift problem during the reaction process, and solves the problem of easy temperature jump when a traditional honeycomb catalyst is used in the reaction system.

Owner:PUJING CHEM IND SHA +1

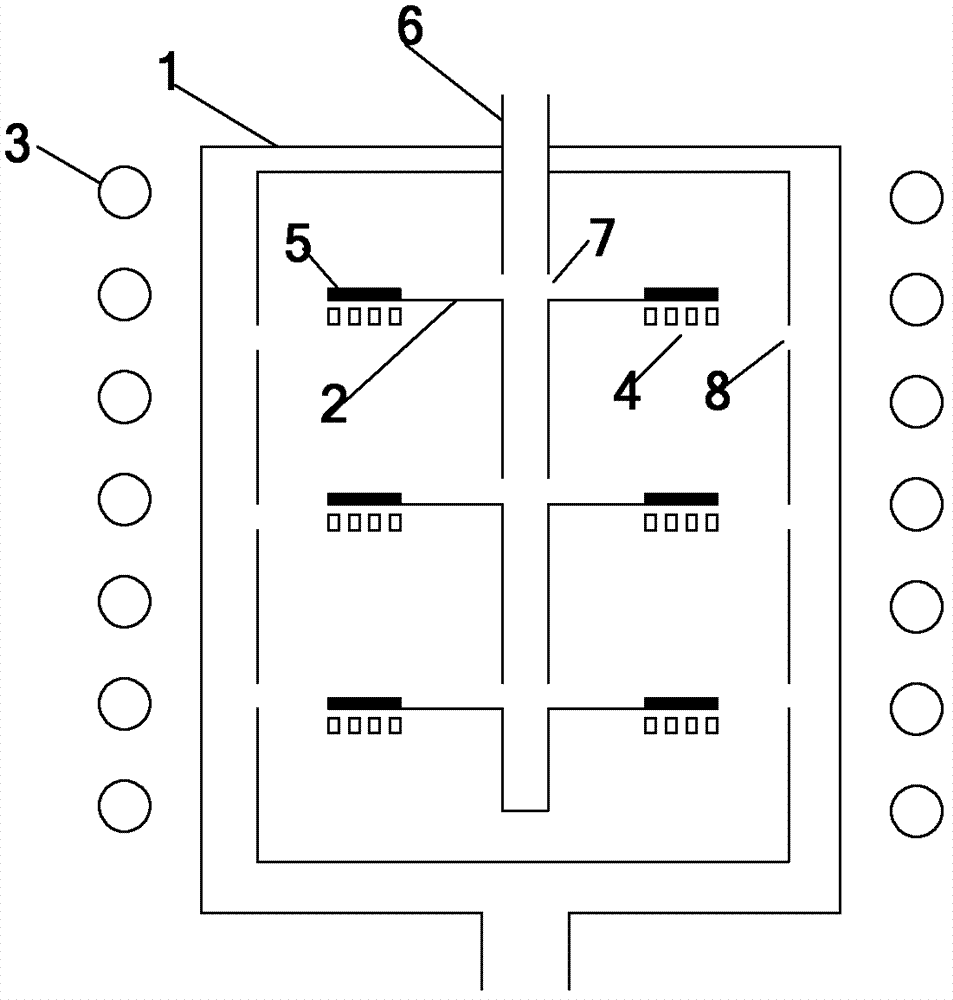

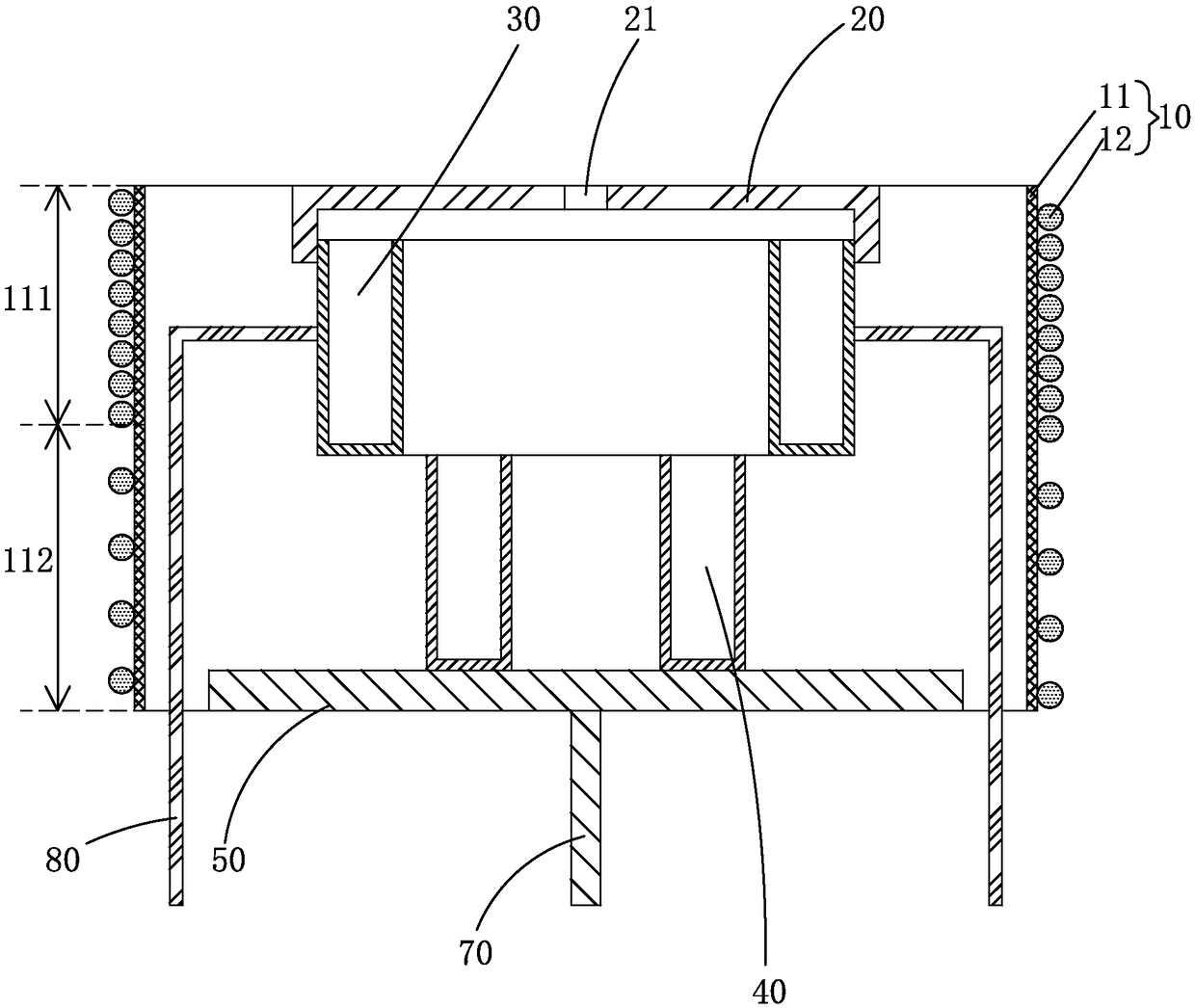

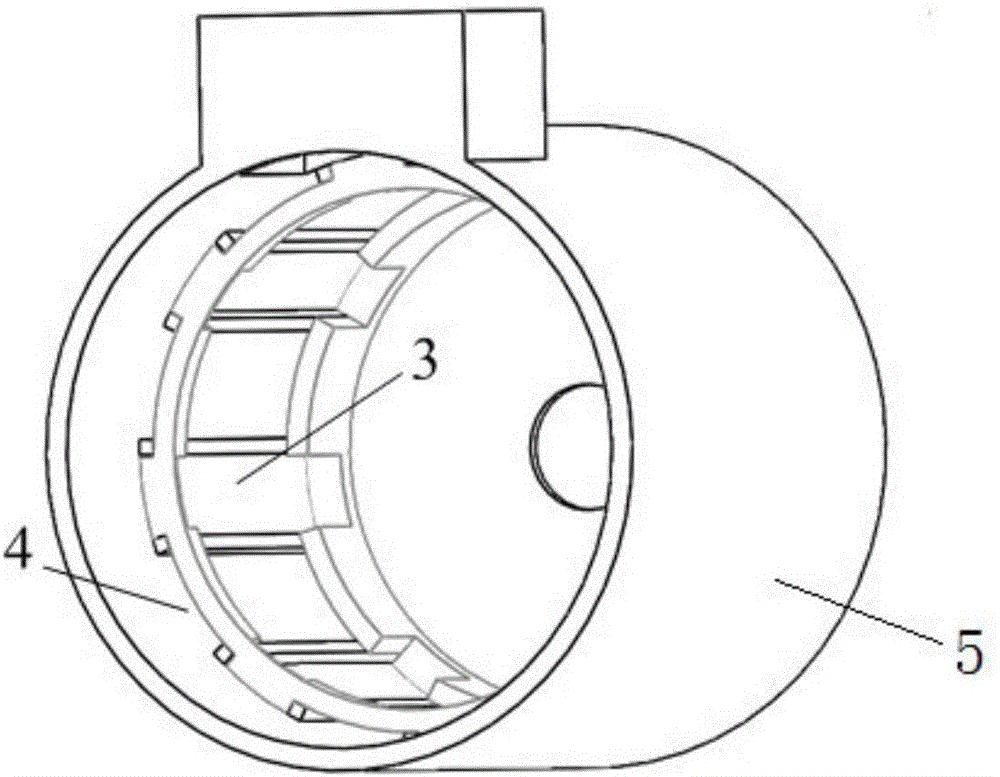

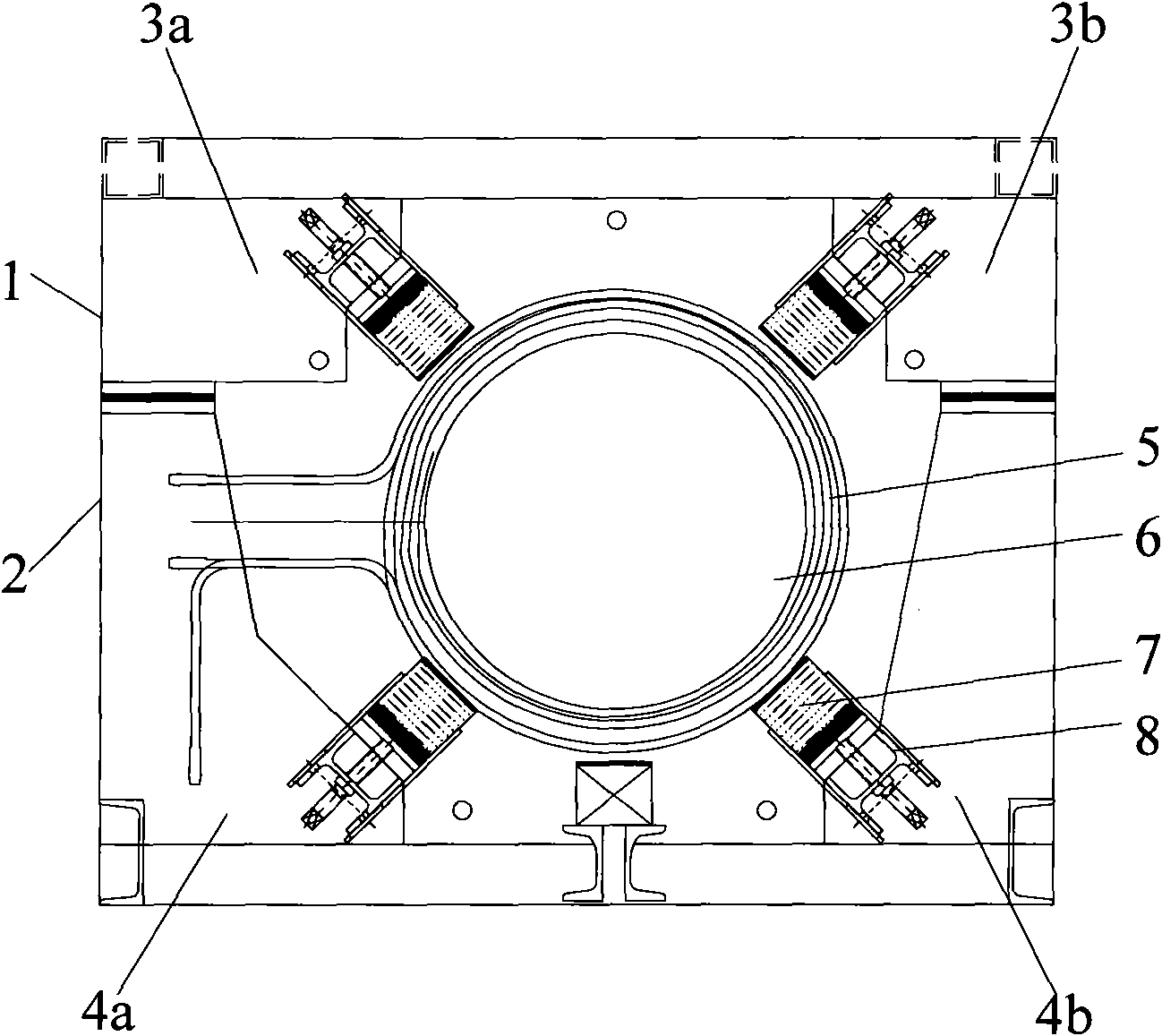

Chamber device and substrate treating plant with same

InactiveCN102953051ARadial temperature difference is smallGuaranteed uniformityChemical vapor deposition coatingEngineeringAuxiliary heating

The invention discloses a chamber device which comprises a chamber body, a tray, an external heating source and an auxiliary heating source, wherein a chamber is defined in the chamber body; the tray is arranged in the chamber and used for carrying a substrate; the external heating source is arranged around the periphery of the chamber body; and the auxiliary heating source is arranged on the tray and used for heating the tray. The chamber device disclosed by the embodiment of the invention adopts the external heating source and the auxiliary heating source for common heating, and can compensate uneven temperature distribution on the tray to reduce the radial temperature difference on the tray, thereby ensuring the evenness of the temperature field; and thus, the invention has the advantages of even substrate heating and high treatment efficiency. The invention also discloses a substrate treating plant with the chamber device.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

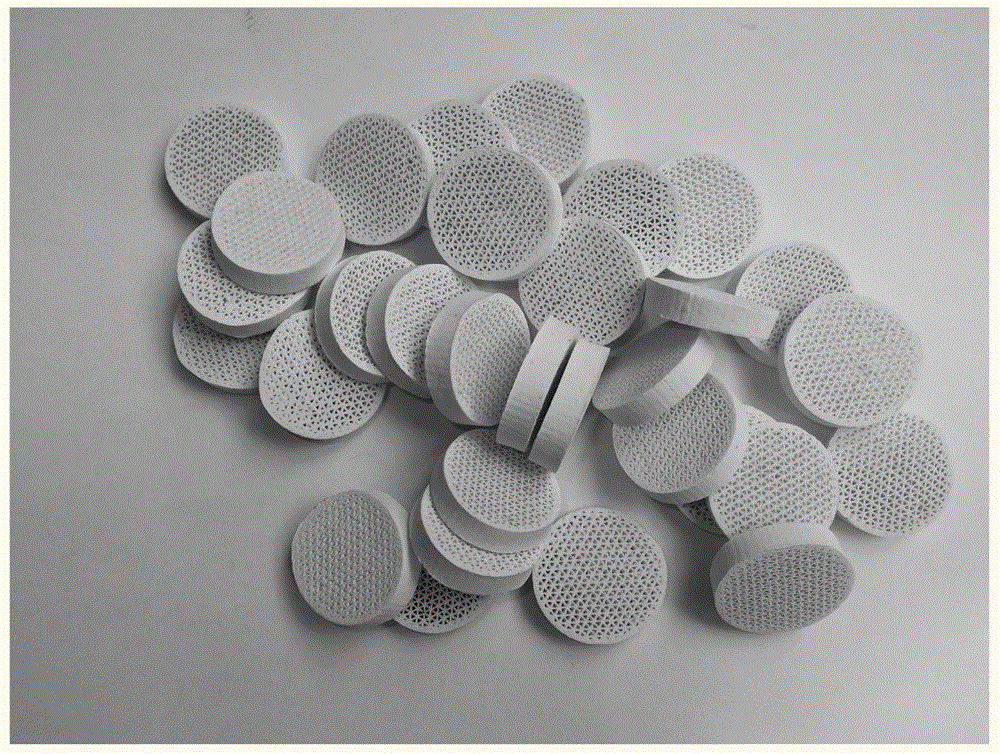

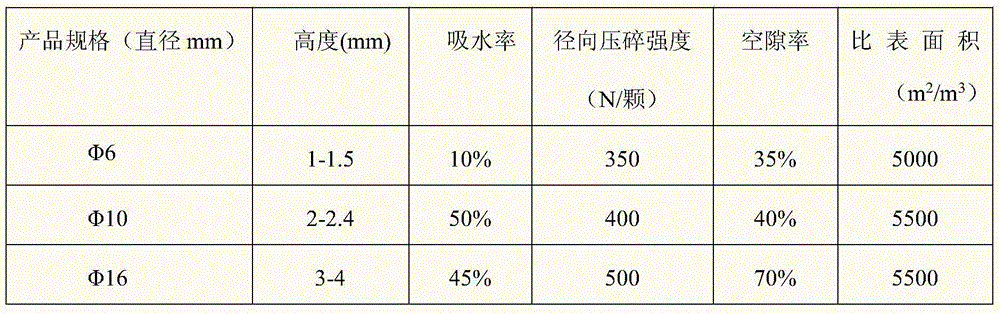

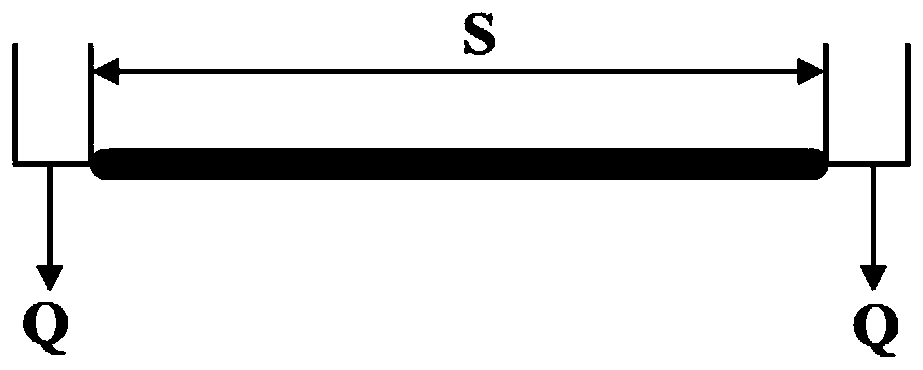

Honeycomb nest hydrogenation protecting agent

ActiveCN104888864AImprove firing pass rateExcellent extrusion formabilityCatalyst carriersHoneycombSolvent

A honeycomb nest hydrogenation protecting agent is prepared from 1-60% of alumina powder, 5-50% of kaolin, 0.1-15% of talcum powder, 5-60% of clay, 0.5-10% of an alkaline solvent, and 0.1-5% of an auxiliary material. The unit cross section area of the above product has more and denser through holes, so the external specific surface area of the product is greatly increased and reaches above 5000m<2> / m<3>, so a reaction raw material and the protecting agent have a larger contact and reaction area. The void fraction of the product reaches 30-70%, the water absorption rate reaches 10-50%, and the appropriate water absorption rate makes the protecting agent adsorb more active substances, so the absorption rate of adsorbed impurities is improved, and the catalysis effect is improved; and the radial crushing strength of the product is 50-500N / granule of the product, the product cannot be fragmented when 50-500N is applied to the two axial ends of the product, and maintains integrity, so the strength is improved, and the service life is prolonged.

Owner:JIANGXI ACICHEMSHUN IND

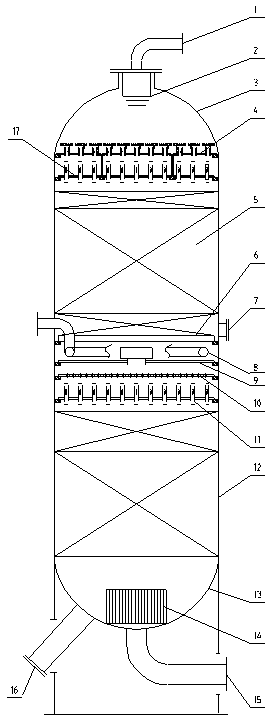

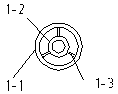

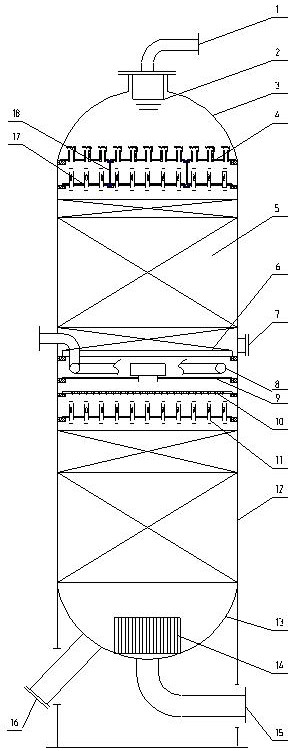

A hydrogenation reactor having an impact reducing element

ActiveCN109985570AIt has the function of reducing flushing and current sharingImprove distributionChemical/physical processesRefining to eliminate hetero atomsProcess engineeringDistributor

The invention discloses a hydrogenation reactor with an impact reducing element. The fixed bed hydrogenation reactor comprises a material inlet pipe, an inlet diffuser, a reactor upper head, an impactreducing flow equalizing disc, a catalyst bed layer, a catalyst support grid, a reactor cylinder, a reactor lower head, an outlet collector, a material outlet pipe and a catalyst discharge pipe. Theimpact reducing flow equalizing disc is arranged in an idle space of the reactor upper head or above the top end of the reactor cylinder and a top distribution disc; the impact reducing flow equalizing disc is provided with a plurality of distributors and each distributor comprises a flow equalizing disc, a downcomer and a connecting rod, and the flow equalizing discs are connected with the downcomers through the connecting rods. The hydrogenation reactor disclosed by the invention is suitable for hydrofining or hydrocracking treatment processes of oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

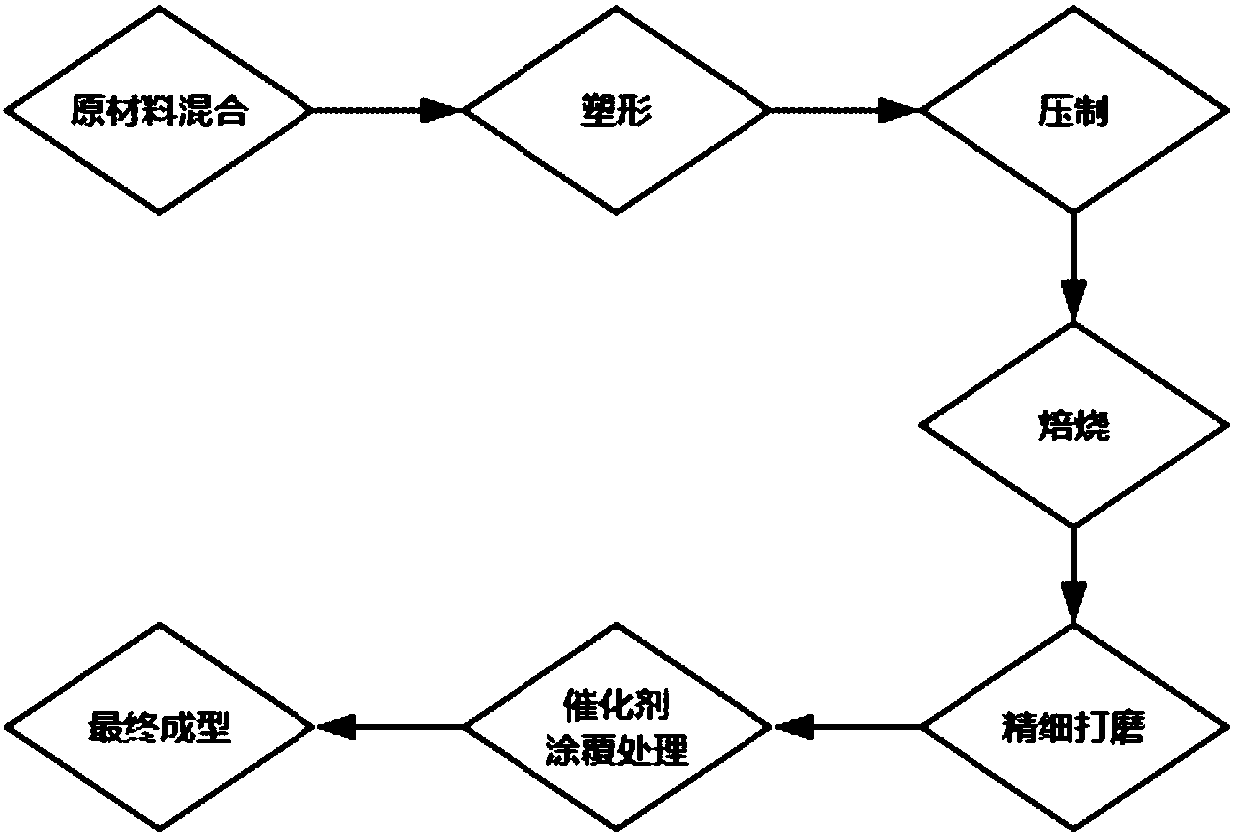

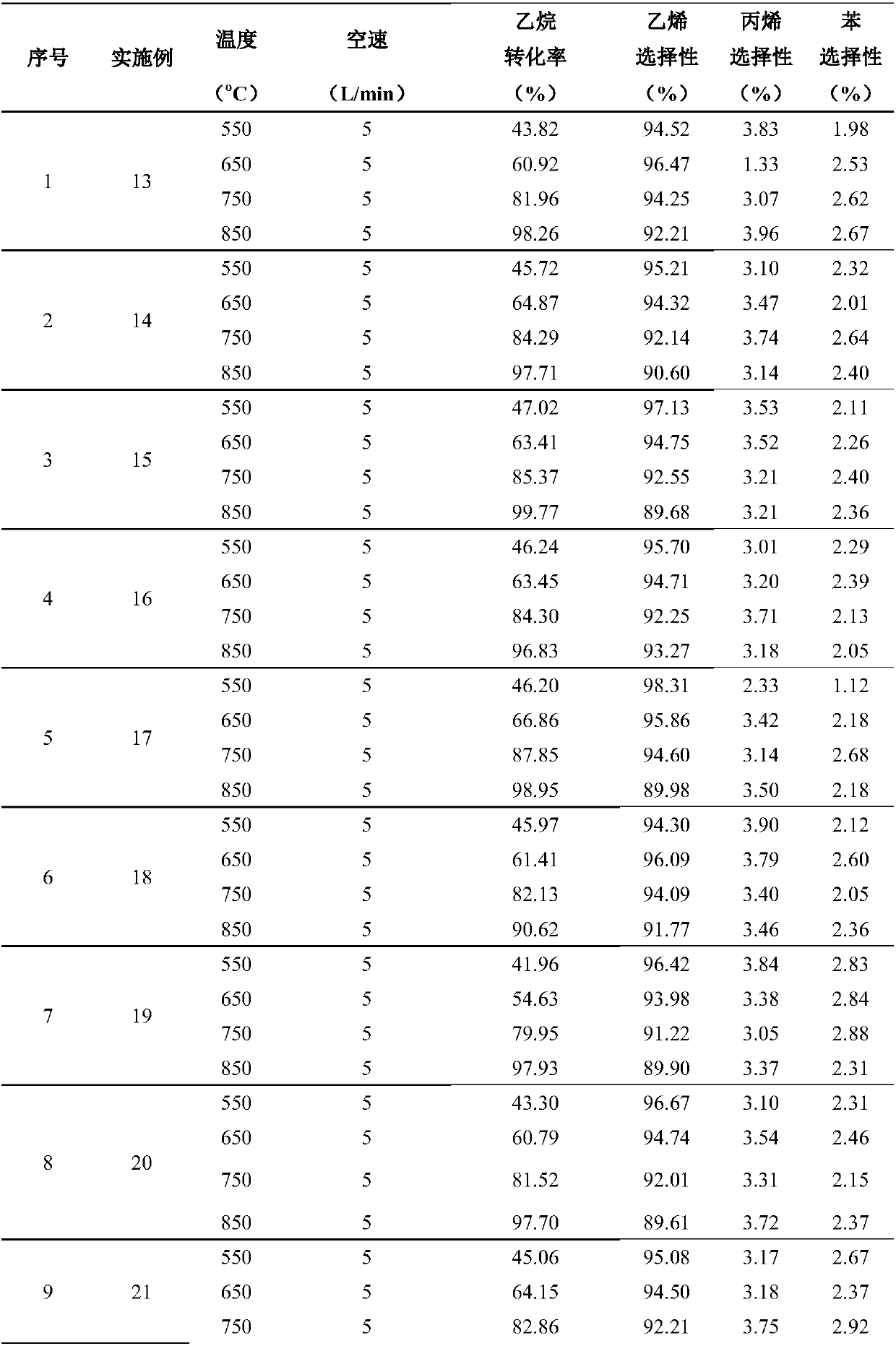

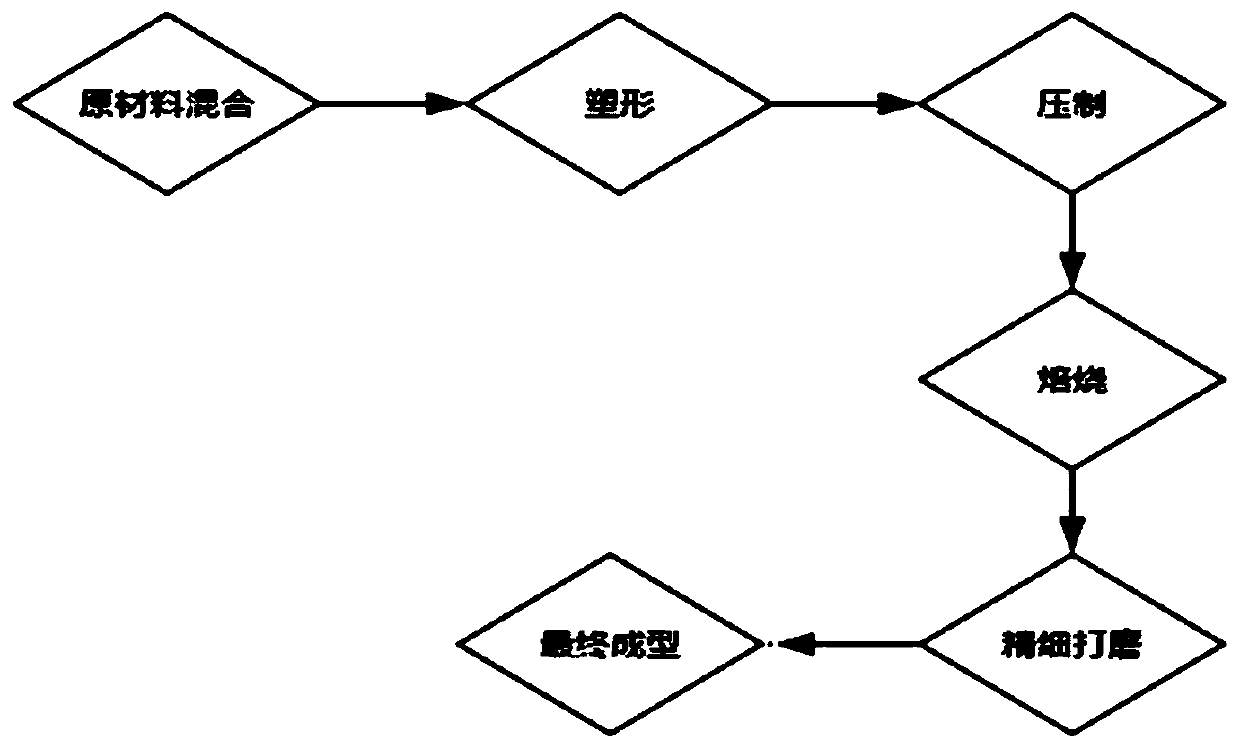

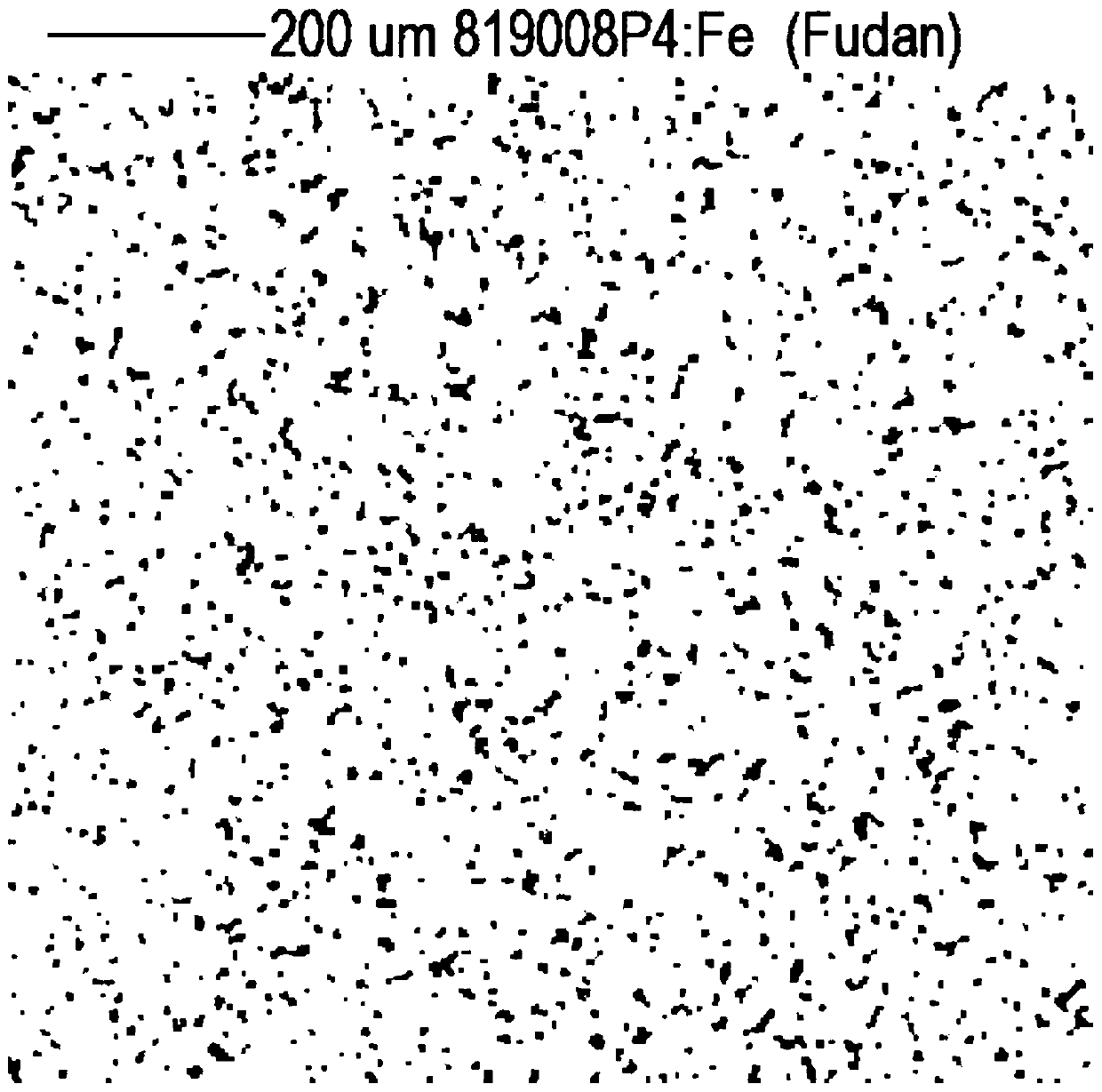

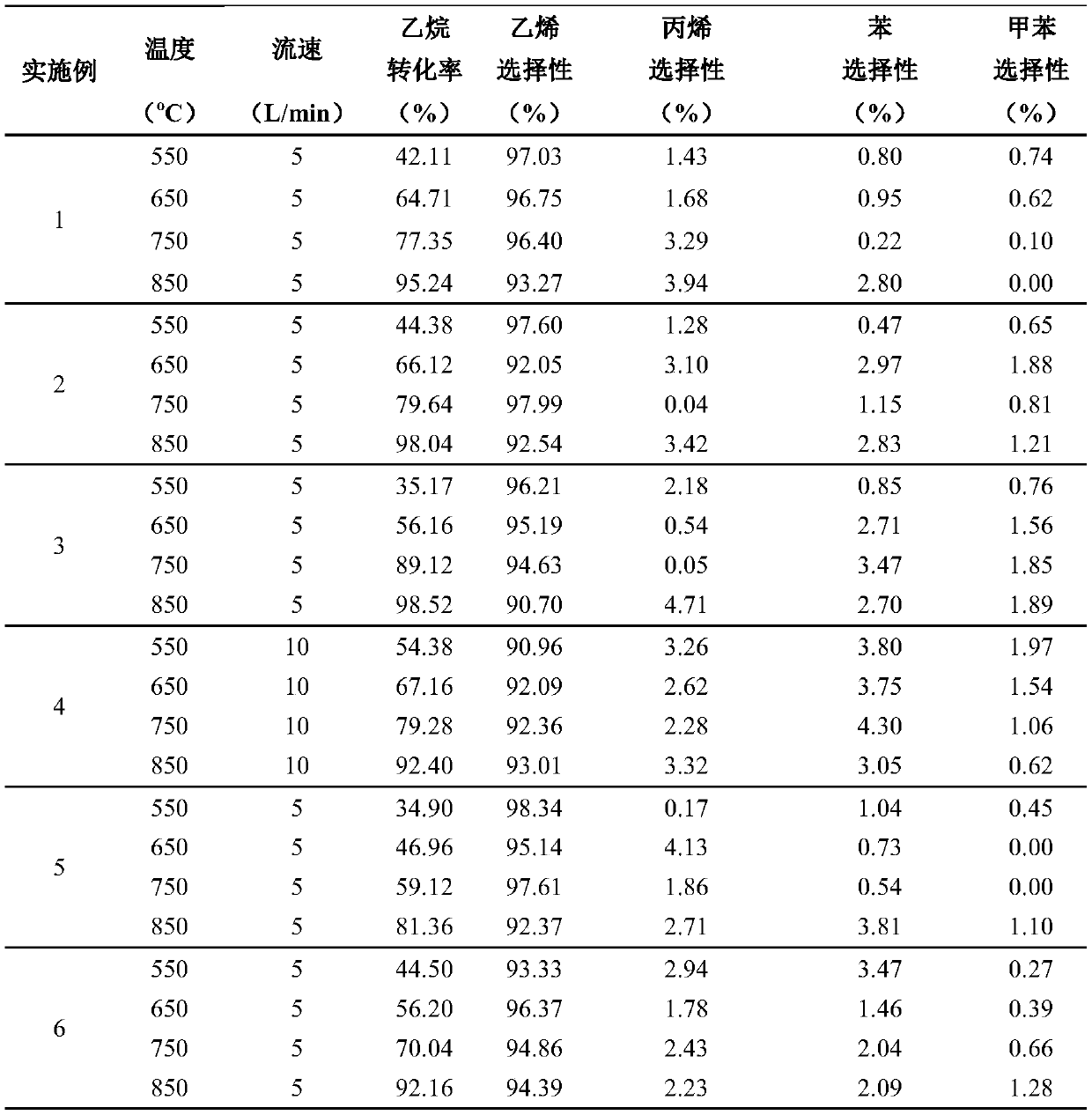

Preparation for catalyst-silicon carbide reactor for preparing ethylene through ethane dehydrogenation

ActiveCN109847671AImprove thermal conductivityImprove energy efficiencyPhysical/chemical process catalystsHydrocarbonsPhotochemistryHeat conducting

The invention relates to preparation for a catalyst-silicon carbide reactor for preparing ethylene through ethane dehydrogenation and a method for catalyzing the ethane dehydrogenation to prepare theethylene under an oxygen-free condition. According to the reactor provided by the invention, a novel prepared silicon carbide material is used and good heat-conducting performance and chemical reaction inertia properties of the material are utilized; and based on the catalyst-reactor and reaction conditions, high-yield synthesis of the ethylene is realized through the process. According to the preparation and the method provided by the invention, the conversion rate of ethane is 70 to 100 percent, the selectivity of ethylene is 80 to 99.99 percent, the selectivity of propylene is 0 to 5 percent and the selectivity of aromatic hydrocarbons is 0 to 5 percent. The preparation and method provided by the invention have the characteristics of long catalyst service life (longer than 1000 h), goodstability of the catalyst at high temperature (lower than 1700 DEG C), high ethylene conversion rate and product selectivity, low energy consumption, good process repeatability, safety and reliability in operation and the like, and have wide industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Evaporation device and evaporation method

ActiveCN108728801AIncrease profitImprove heating uniformitySolid-state devicesVacuum evaporation coatingCrucibleEvaporation

The invention provides an evaporation device and an evaporation method. The evaporation device comprises a heating source, a crucible cover, a first crucible, a second crucible, a moving part and a support, wherein the first crucible, the second crucible and the moving part are arranged below the crucible cover, and the first crucible is fixed on the support; the first crucible and the second crucible each comprise an inner side wall, an outer side wall and a bottom surface, the outer side walls are arranged outside the inner side walls, the bottom surfaces are connected with the inner side walls and the outer side walls, far away from one end of the crucible cover, the crucible cover is arranged on the outer side wall of the first crucible, the second crucible is fixed to the top surfaceof the moving part, the projection of the inner side wall of the first crucible in the vertical direction is located outside the outer side wall of the second crucible, and the density of an electricheating wire of a heating source in a first area corresponding to the position where the crucible cover and the first crucible are located is larger than the density of a second area below the first area. According to the evaporation device, the utilization rate of evaporation materials can be effectively improved, the radial temperature difference in the evaporation device can be effectively reduced, and the heating uniformity of the evaporation materials in the evaporation device is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

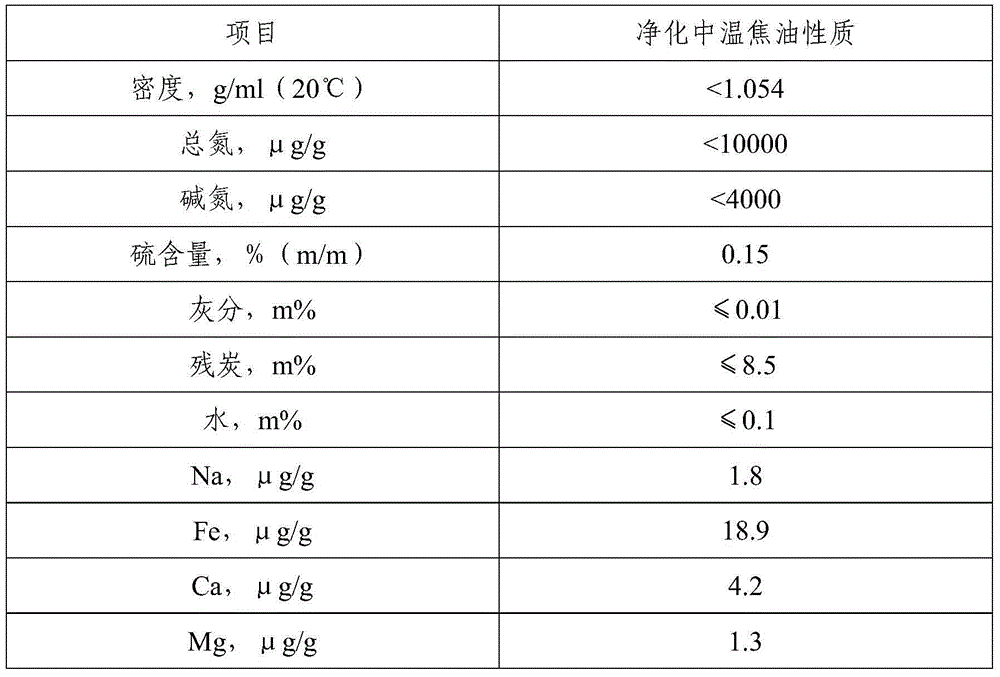

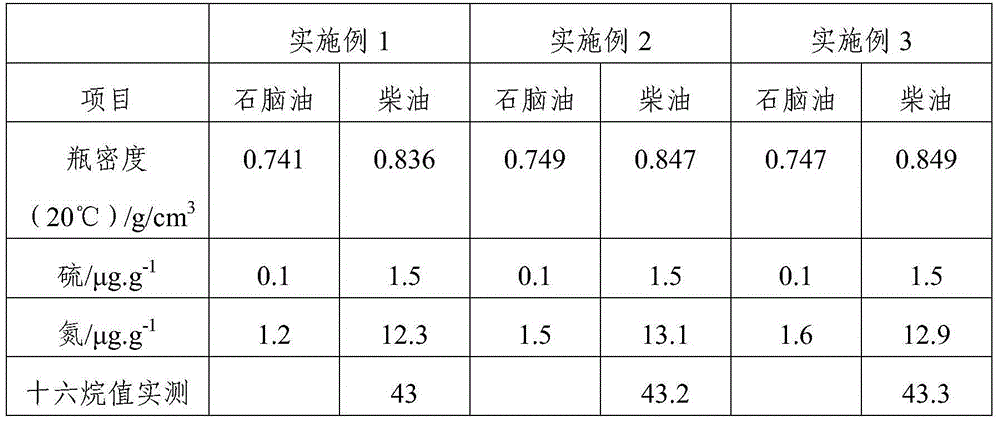

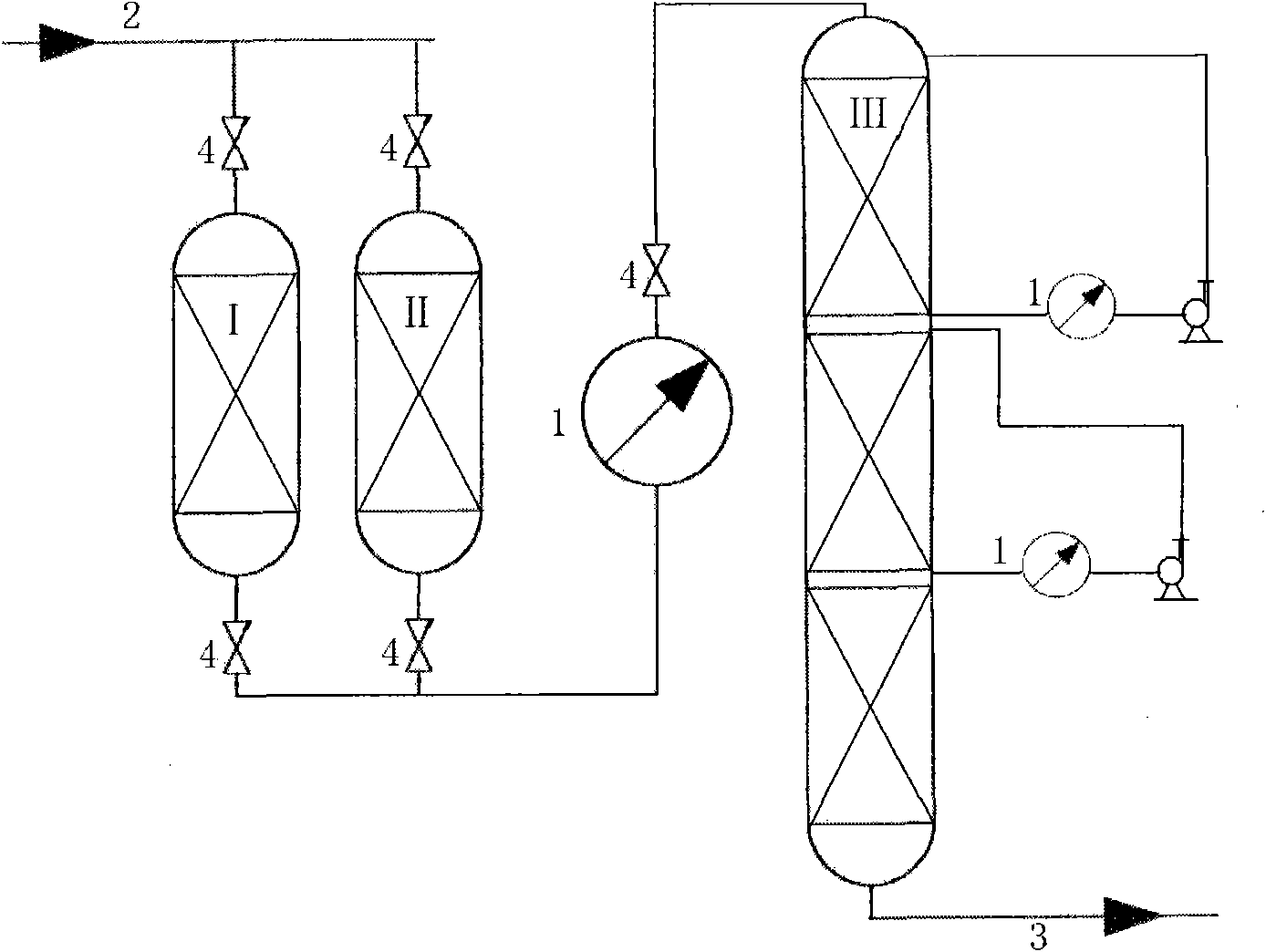

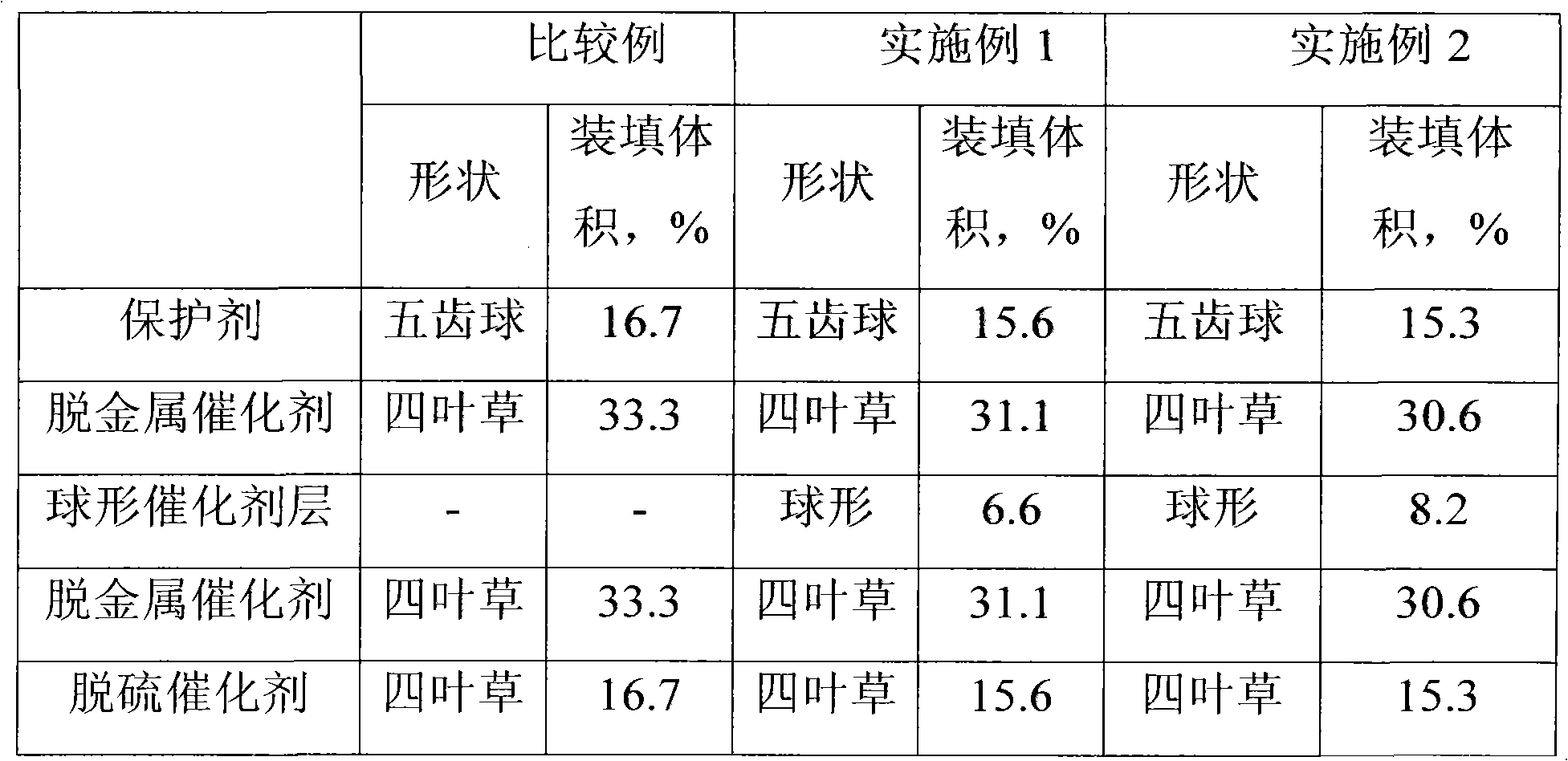

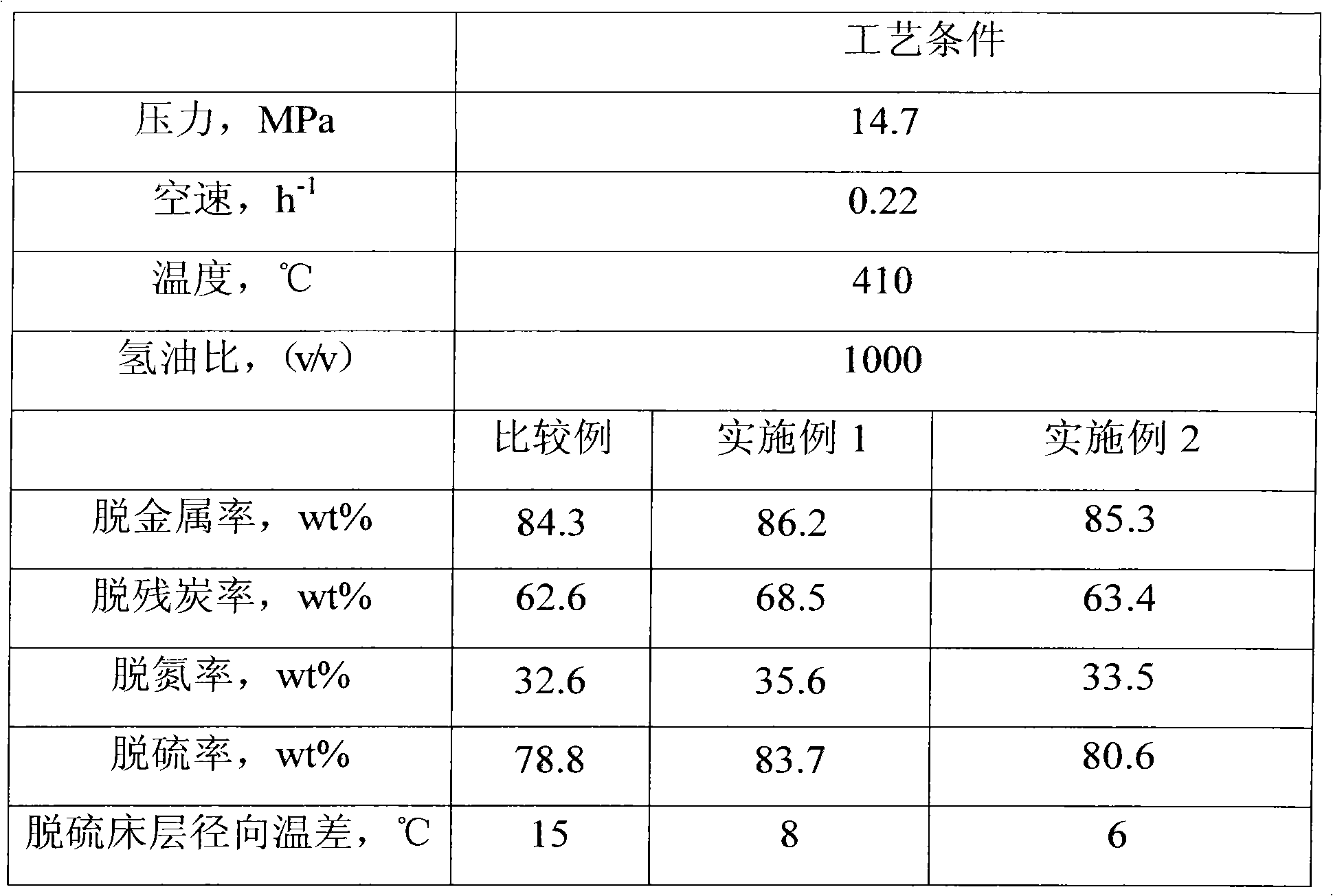

Method for grading catalysts during hydrogenation of medium-low-temperature coal tar

InactiveCN104974793ASlow down price hikesAvoid concentrated depositionTreatment with hydrotreatment processesLighter fuelHydrogenation process

The invention relates to a method for grading catalysts during hydrogenation of medium-low-temperature coal tar. A hydrogenation process comprises the following steps: mixing raw coal tar and hydrogen, and allowing the mixture to enter a No.1 protection reactor, a No.2 refining reactor, a No.3 modification reactor and a high-low separation system in sequence to finish a hydrogenation refining stage; allowing the separated liquid to enter a fractionating system, and allowing the obtained tail coal tar to enter a No.4 refining reactor, a No.5 cracking reactor and the high-low separation system to finish a hydrogenation and cracking stage and obtain a light fuel. Through optimization of a combination mode of the catalysts, the activity of the catalysts is further improved, and the service life of the catalysts and the operation cycle of devices are prolonged on the premise of ensuring the quality of the fuel product.

Owner:JIANGSU HUDA CHEM TECH CO LTD +1

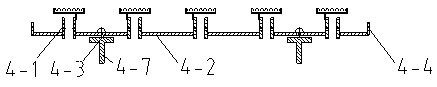

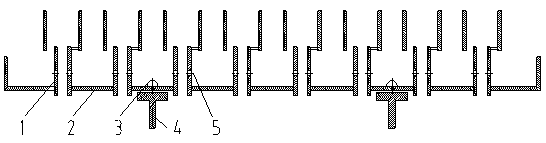

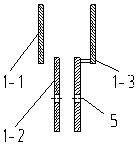

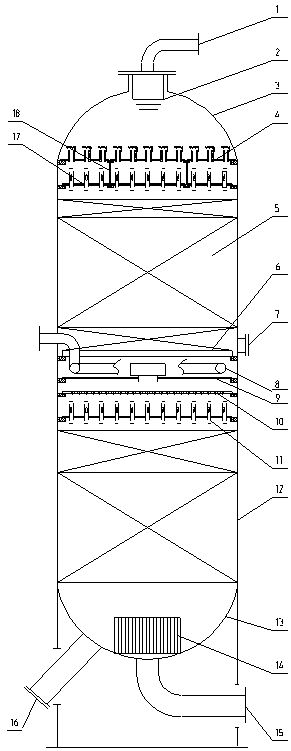

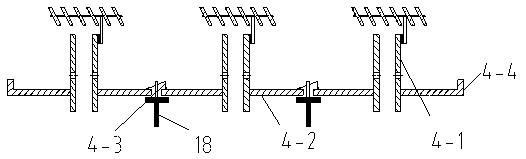

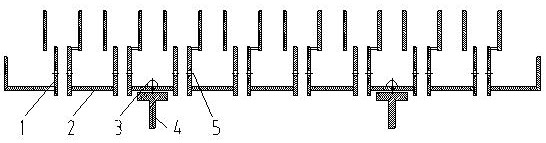

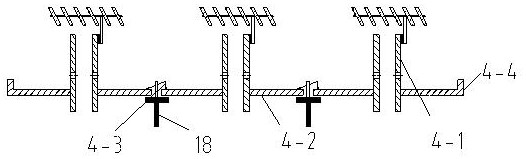

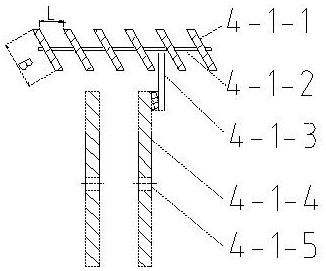

Toothed weir type impact reducing and uniform fluid distributing plate

ActiveCN108097178AReduce impactEliminate shockChemical/physical processesHydrocarbon oils treatmentEngineeringDistributor

The invention discloses a toothed weir type impact reducing and uniform fluid distributing plate and belongs to the field of chemical equipment. The toothed weir type impact reducing and uniform fluiddistributing plate comprises a tray and distributors arranged on the tray, wherein each distributor comprises a uniform fluid distributing plate, a material lowering pipe and connecting rods, and theuniform fluid distributing plate is arranged above the material lowering pipe and connected with the material lowering pipe through the connecting rods. The toothed weir type impact reducing and uniform fluid distributing plate has the characteristics of impact reducing and uniform fluid distributing functions, good distribution effect, small size, low mounting precision requirement and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

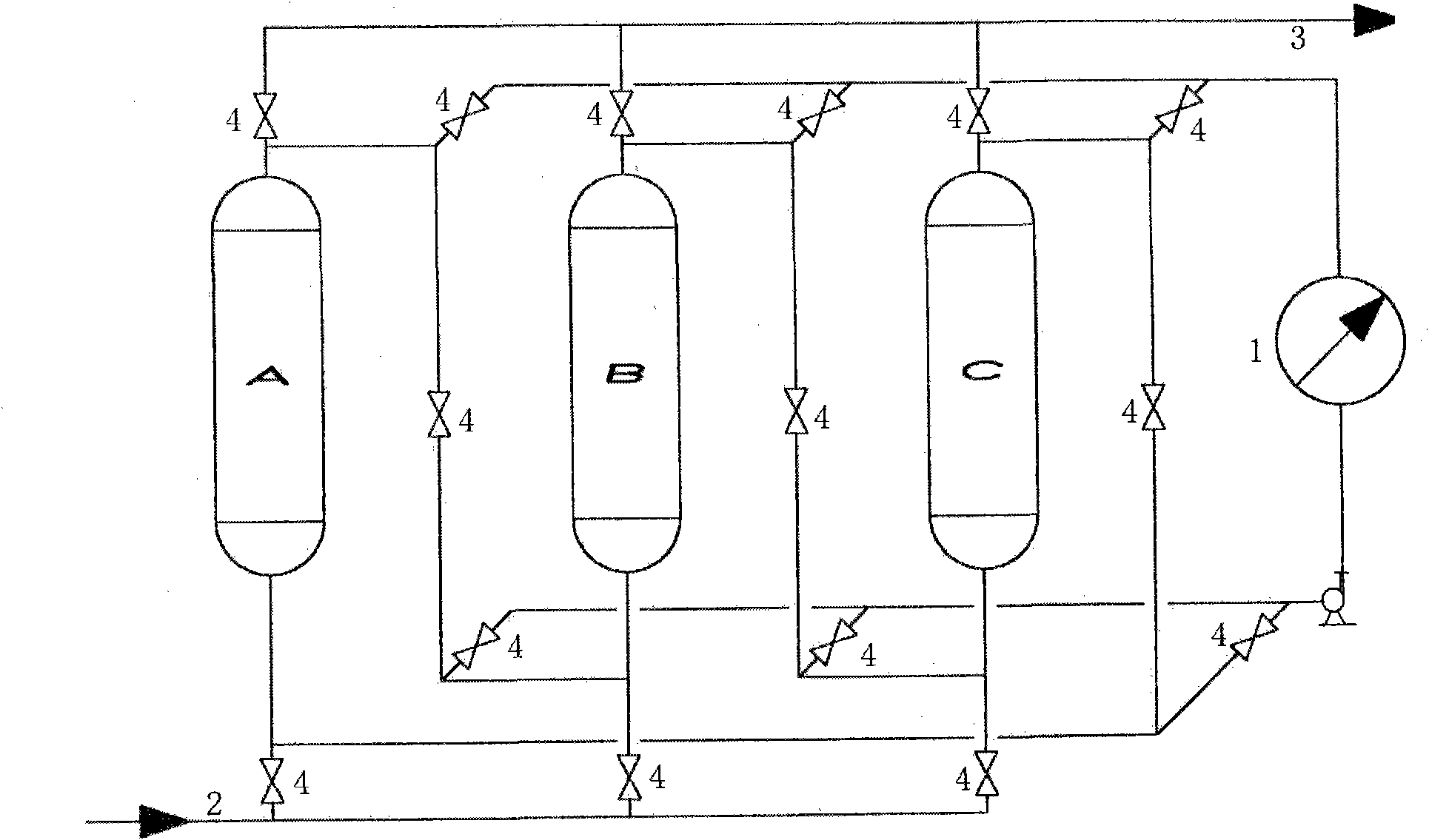

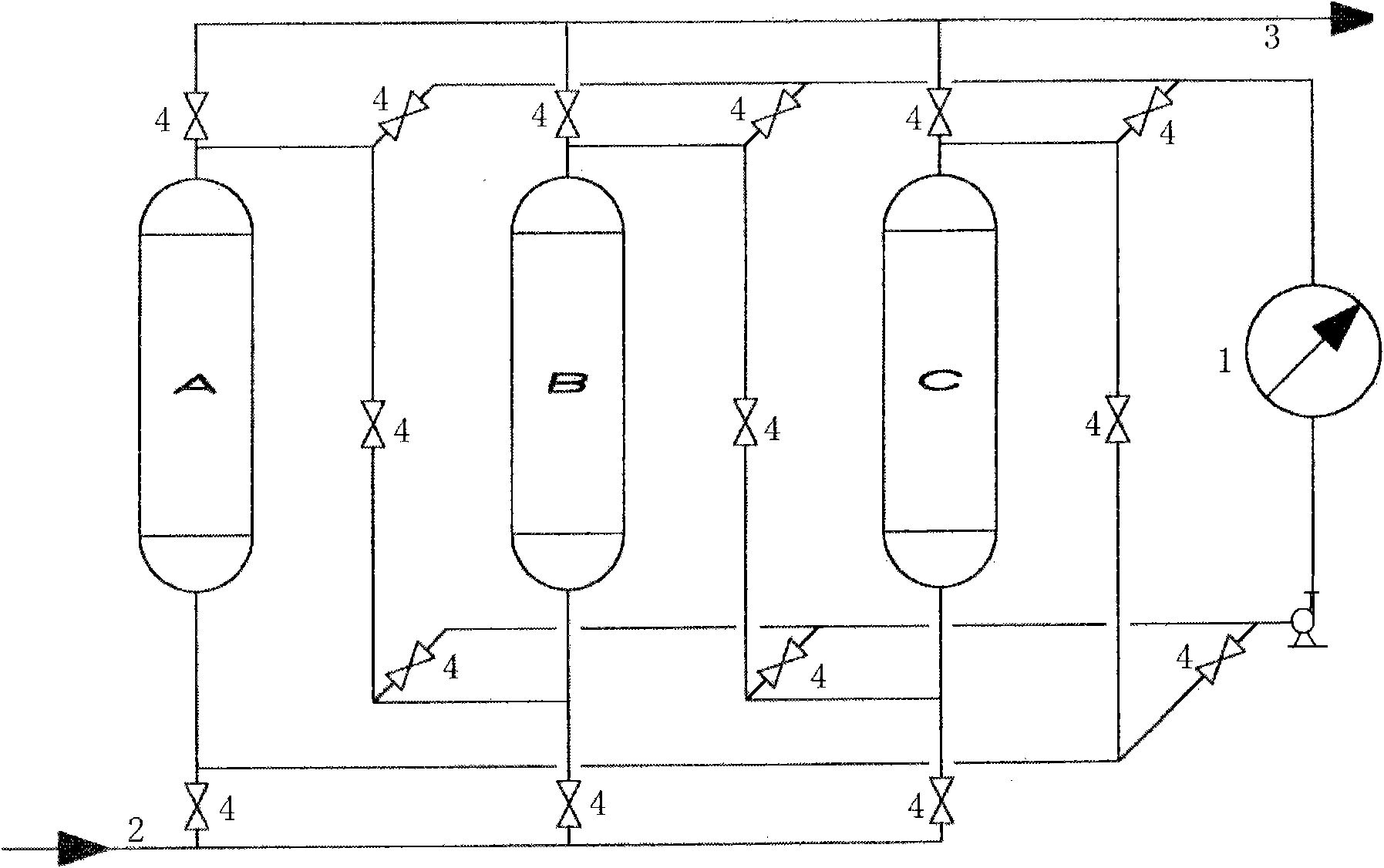

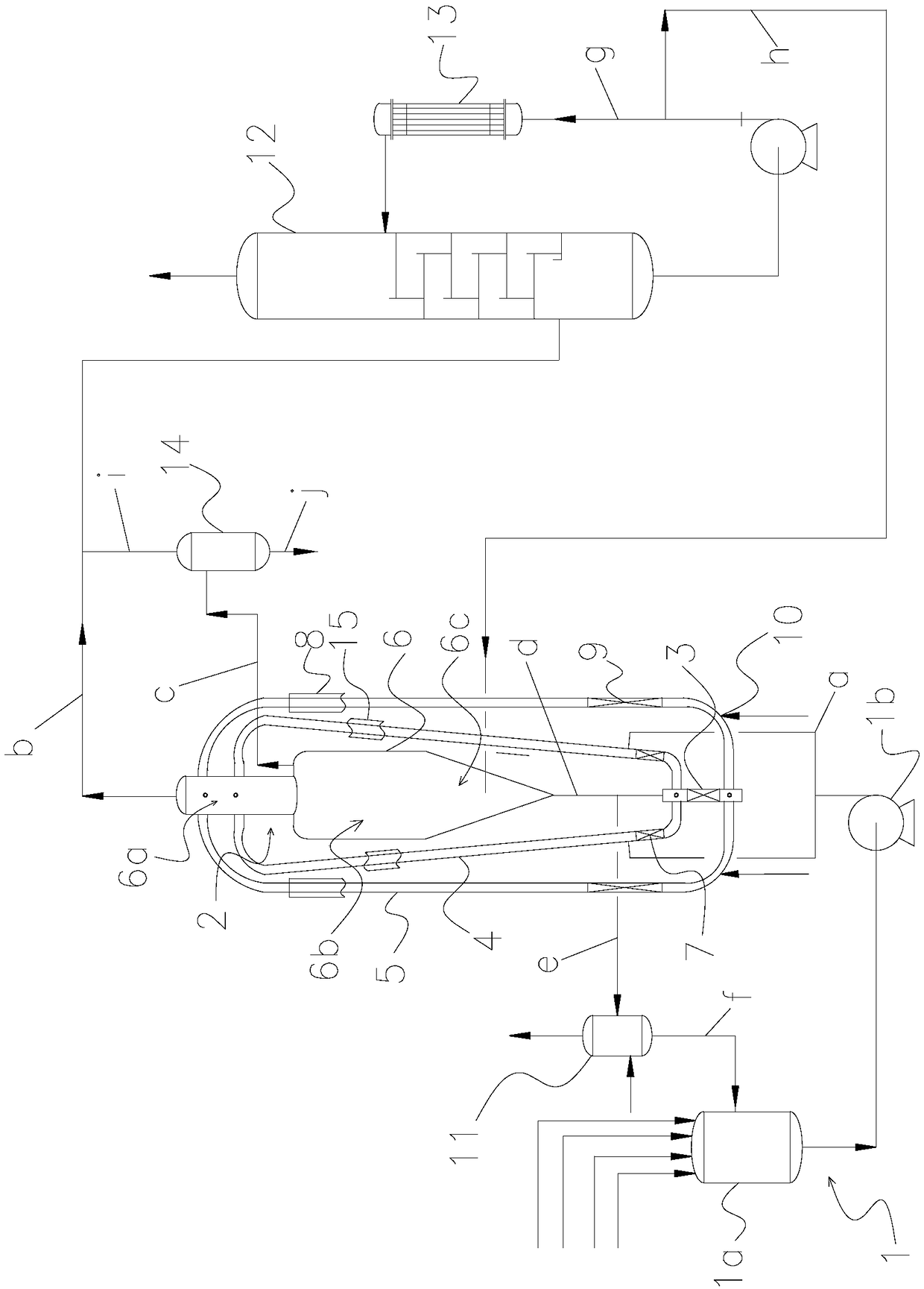

Reactor for synthesizing methyl tert-butyl ether and application thereof

ActiveCN101768053AUniform temperature distributionRadial temperature difference is smallEther preparation by compound additionChemistryHeat exchanger

The invention relates to organic catalytic reaction, in particular to a reactor for synthesizing MTBE. The reactor is characterized in that an etherification reactor is of split structure with not less than 3 etherification reaction sections. The split structure refers to that each etherification reaction section is provided with respectively independent pot bodies filled with catalyst therein, both ends of each pot body are provided with a feed inlet and a feed outlet and other auxiliary pipeline interfaces; a raw material inlet pipeline is connected with the feed inlets of the pot bodies respectively through valves, and a product outlet pipeline is connected with the feed outlets of the pot bodies respectively through valves; the feed outlet of the pot body of each etherification reaction section is connected with the feed inlet of another pot body via a pipeline through valves, and different pot bodies are connected in series sequentially to compose a continuous annular serial system; the inlet of a heat exchanger is connected with the feed outlet of the pot body of each etherification reaction section by a pipeline through valves, and the outlet of the heat exchanger is connected with the feed inlet of the pot body of each etherification reaction section by a pipeline through valves. The invention can improve production efficiency and reduce production cost.

Owner:丹东明珠特种树脂有限公司

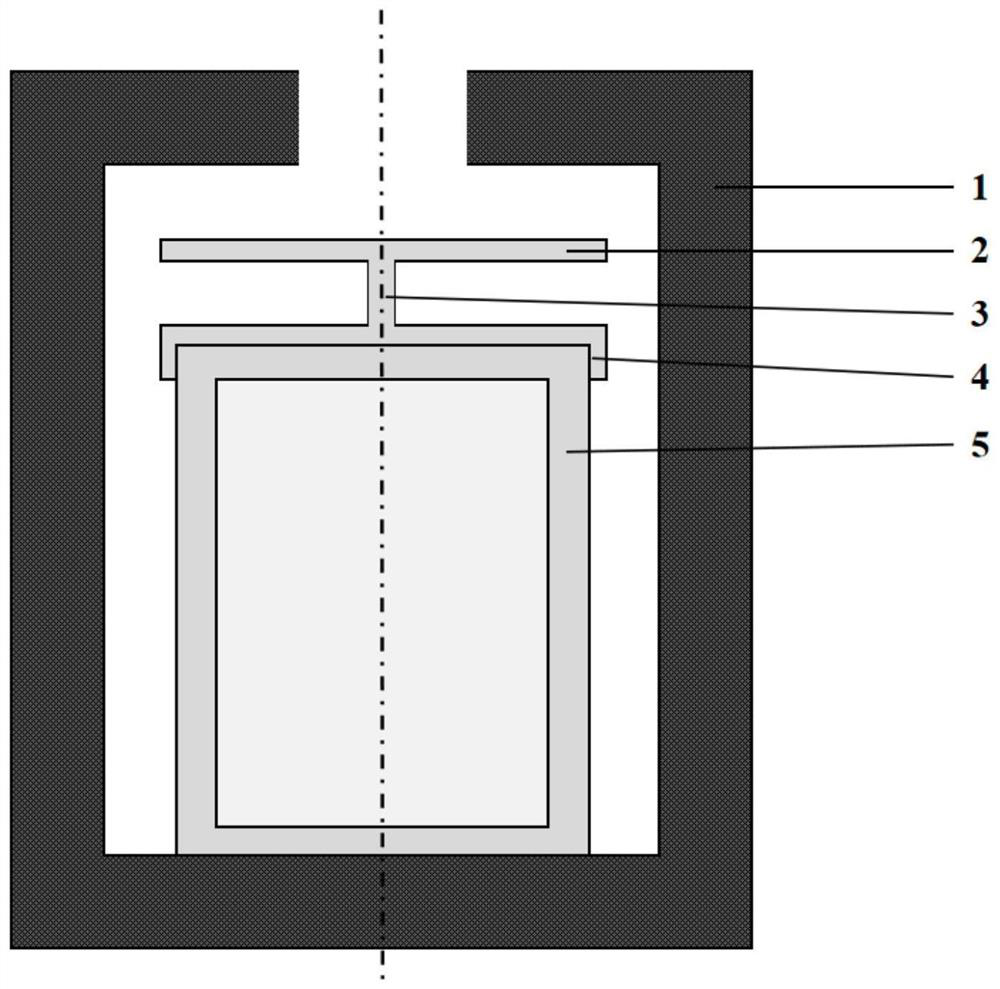

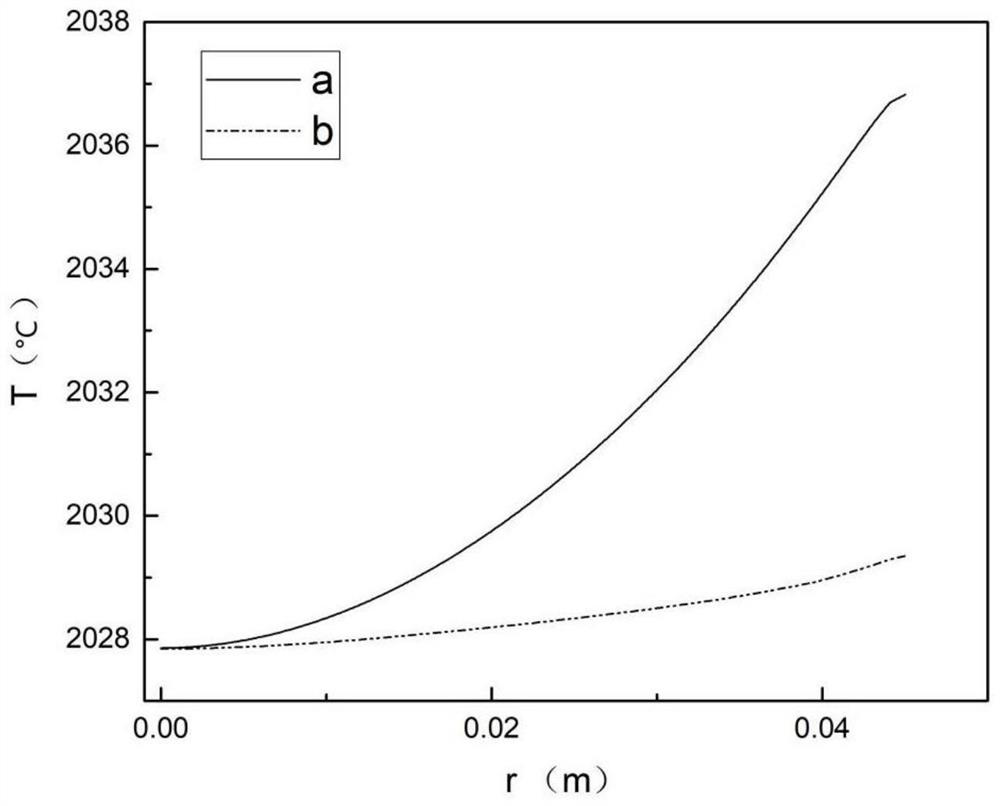

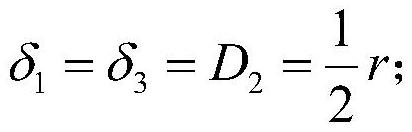

Crucible device for growing aluminum nitride crystals

ActiveCN112011825ASimple designRadial temperature difference is smallPolycrystalline material growthFrom condensed vaporsInsulation layerCrucible

The invention provides a crucible device for growing aluminum nitride crystals. The crucible device comprises: a thermal insulation layer, wherein a cavity is formed in the thermal insulation layer, and the thermal insulation layer is provided with an opening communicated with the cavity; a crucible arranged in the cavity, wheren the top of the crucible is covered with a crucible cover, and the opening is formed corresponding to the crucible cover; and a temperature uniformizing device which coats the top surface of the crucible cover, wherein the temperature homogenizing device is also positioned in the cavity. The temperature uniformizing device can greatly reduce the radial temperature difference of crystals grown at the bottom of the crucible cover, so that the thermal stress in the crystals is reduced, the dislocation in the crystals is reduced, and the growth of large-size crystals is particularly facilitated.

Owner:WUHAN UNIV

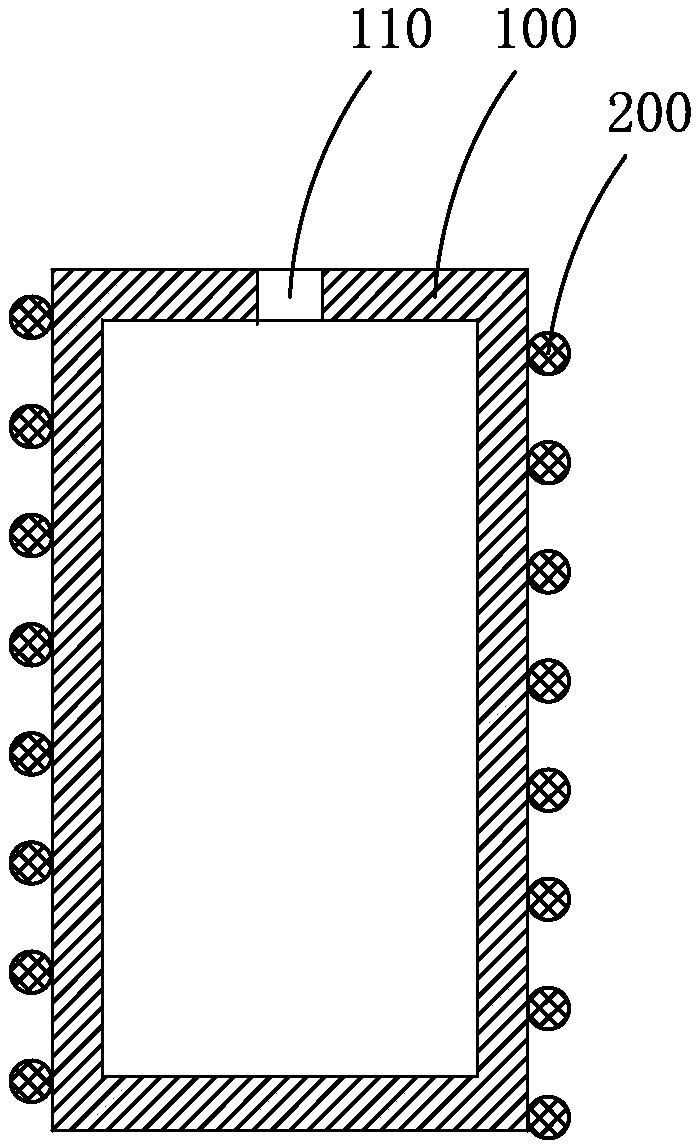

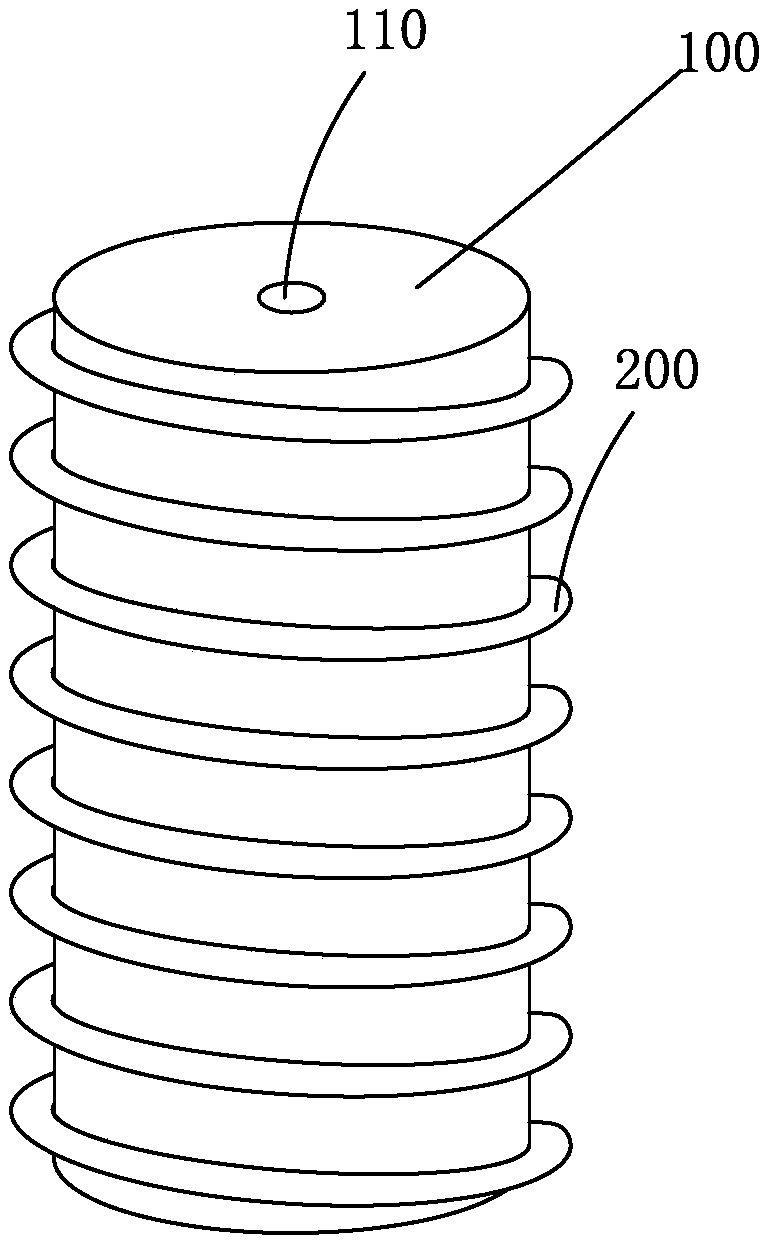

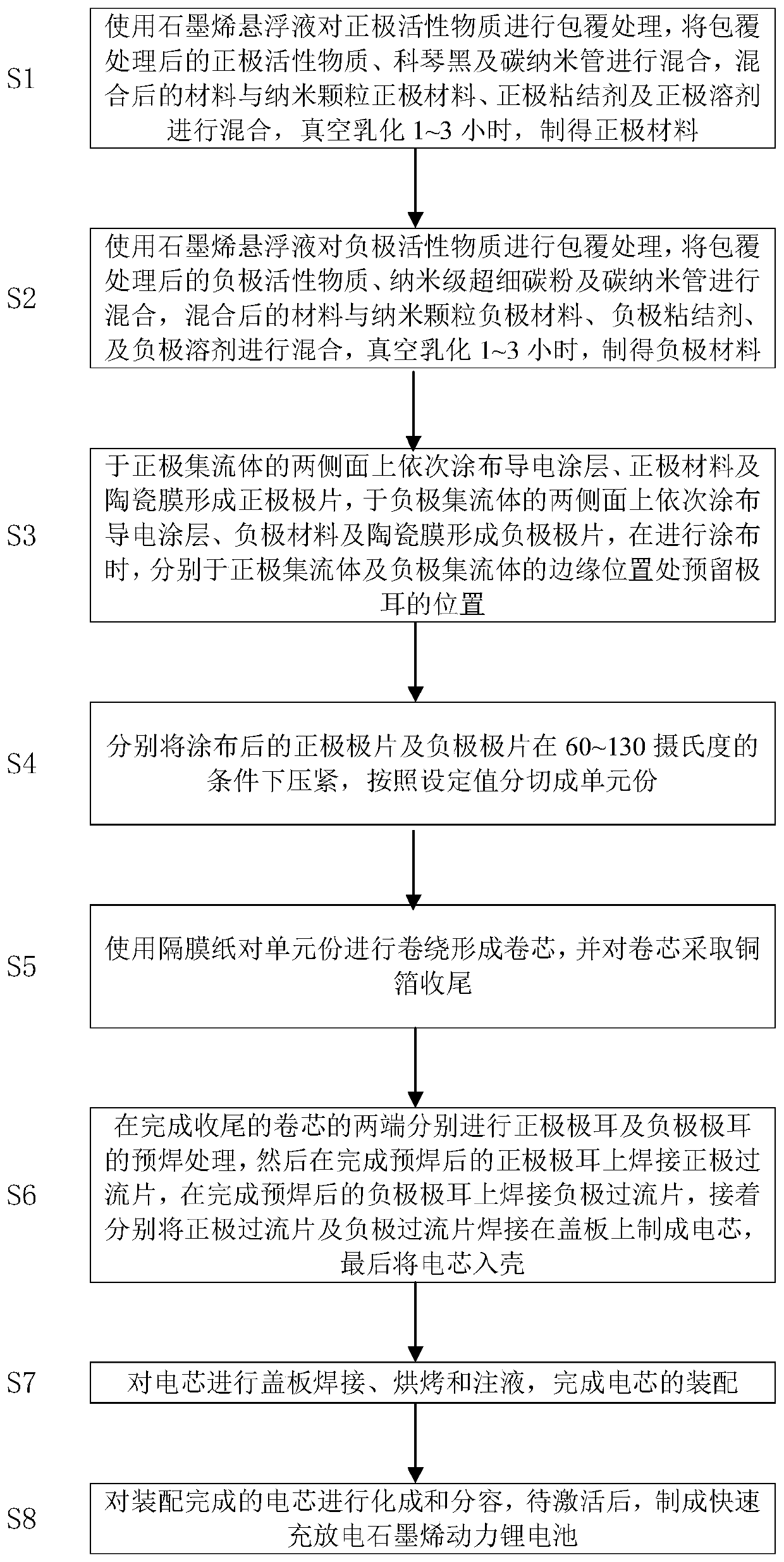

Rapid charging and discharging graphene power lithium battery and preparation method thereof

PendingCN111180730AImprove conductivityHigh resistivityFinal product manufactureElectrode carriers/collectorsGraphene coatingConductive coating

The invention discloses a rapid charging and discharging graphene power lithium battery and a preparation method thereof. The battery comprises a battery housing and a battery core accommodated in thebattery housing. The battery core comprises a positive pole piece, a negative pole piece and a diaphragm; the positive pole piece comprises a positive pole current collector and positive pole material coatings respectively coated on two side surfaces of the positive pole current collector; the negative pole piece comprises a negative pole current collector and negative pole material coatings respectively coated on two side surfaces of the negative pole current collector; a conductive coating and a ceramic membrane are coated between the positive pole current collector and the positive pole material coating, a conductive coating and a ceramic membrane are coated between the negative pole current collector and the negative pole material coating, and the conductive coating is a CNT / graphenecoating; a positive pole active substance in a positive pole conductive agent in the positive pole material coating and a negative pole active substance in a negative pole conductive agent in the negative pole material coating are respectively subjected to coating treatment by graphene suspension liquid; and the positive and negative pole current collectors comprise a plurality of through holes which are arranged in a matrix and penetrate through the upper and lower surfaces of the substrate.

Owner:王立军

Production process of high viscosity phenylmethylvinyl silicone rubber

ActiveCN101381459AImprove removal effectSolving Heat and Mass Transfer ProblemsPolymer scienceTemperature difference

The invention discloses a manufacturing process for preparing a high-viscosity phenyl methyl vinyl silicone rubber. The manufacturing technique comprises three steps: polymerization, catalyst deactivation and low boiling, and all the steps are finished in a high-power high shear vacuum stirring device. Compared with the prior art, the process has the advantages of remarkably improved heat transfer effect, small reaction kettle radial temperature difference, and greatly improved product quality, and can be used for large-scale production. For the high-viscosity phenyl methyl vinyl silicone rubber prepared by the process, the volatile compositions are less than 3 percent, the molar mass is larger than 700,000, the polydispersity index representing the molecular weight distribution is less than 3, and the production capacity of a single set of equipment is large. The indexes are better than that of the similar products manufactured by a static method on the market.

Owner:SHANGHAI RESIN FACTORY

Hexamethylenediamine synthesis system

ActiveCN109261085AGuaranteed mixing effectRadial temperature difference is smallAmino compound purification/separationOrganic compound preparationHydrogenHexamethylenediamine

A hexamethylenediamine synthesis system comprises a feeder, a reactor and a distributor, wherein the reactor comprises a plurality of material mixing pipelines, a plurality of material synthesis pipelines and a separator, an inner cavity of the separator comprises a gas-liquid separation zone, a liquid-solid separation zone and a conical sedimentation zone, a material mixing device is arranged ineach material mixing pipeline, and the feeder is connected with the material mixing pipelines. The upper end of each material mixing pipeline is communicated with the gas-liquid separation zone, the lower end of each material mixing pipeline is communicated with the feeding end of the distributor, and each material synthesis pipeline is wrapped with a cooling medium jacket. A spiral mixing deviceis arranged in each material synthesis pipeline, the upper end of each material synthesis pipeline is communicated with the gas-liquid separation zone and located above the corresponding material mixing pipeline, and the lower end of each material synthesis pipeline is communicated with the discharging end of the distributor. A hydrogen inlet is formed in each material synthesis pipeline, an exhaust pipeline is arranged at the top of the gas-liquid separation zone, the liquid-solid separation zone is provided with a hexamethylenediamine discharge pipeline, and the conical sedimentation zone iscommunicated with the feeding end of the distributor through a return pipeline.

Owner:CHONGQING HUAFON CHEM +2

Catalyst-silicon carbide reactor and application thereof in reaction of directly preparing olefin from methane

ActiveCN109847665AGood choiceSolution to short lifeHydrocarbon by hydrocarbon condensationChemical/physical/physico-chemical processesChemical reactionOxygen

The invention relates to a preparation method of a catalyst-silicon carbide reactor and a method for catalyzing methane to directly synthesize ethylene under an oxygen-free condition. The catalyst-silicon carbide reactor is prepared on basis of a novel prepared silicon carbide material, and good thermal conductivity and chemical reaction inert characteristic of the material are utilized. Based onthe catalyst-silicon carbide reactor and reaction conditions, zero carbon deposition and high-selectivity synthesis of ethylene are realized. According to the invention, the conversion rate of methaneis 10-70%, the selectivity of olefin is 40-95%, the selectivity of propylene is 5-15%, the selectivity of aromatic hydrocarbon is 0-40%, and zero carbon deposition is achieved. The method provided bythe invention has the characteristics of long catalyst service life (1000 hours), good stability at a high temperature (1700 DEG C), high methane conversion rate and product selectivity, zero carbondeposition, low industrial difficulty, good process repeatability, safe and reliable operation and the like, and has a wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

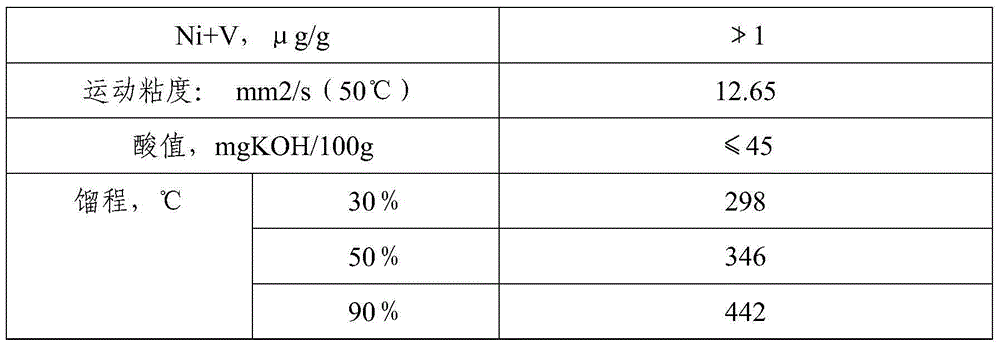

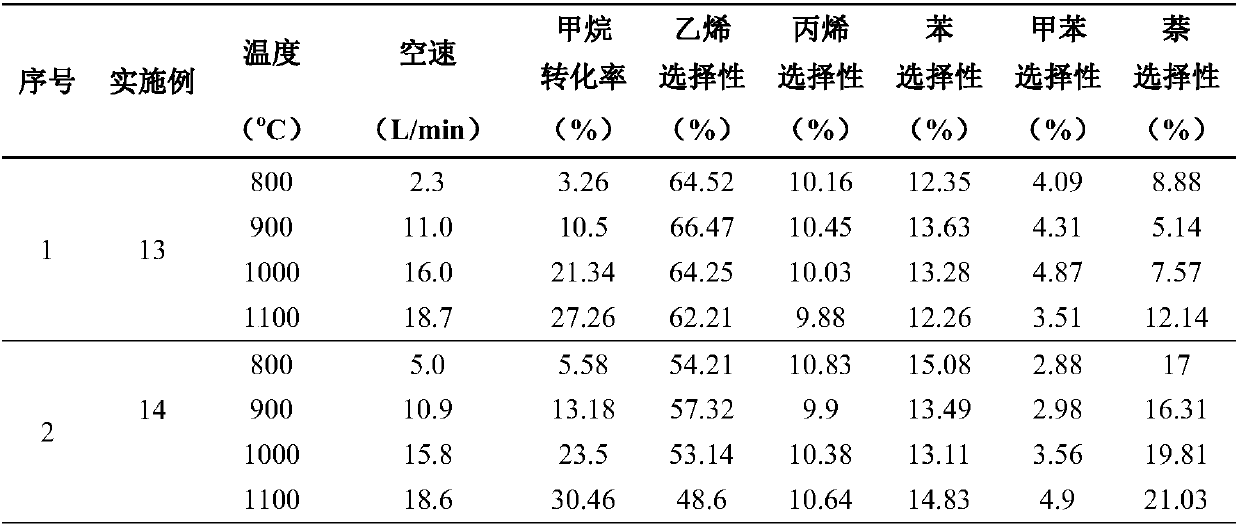

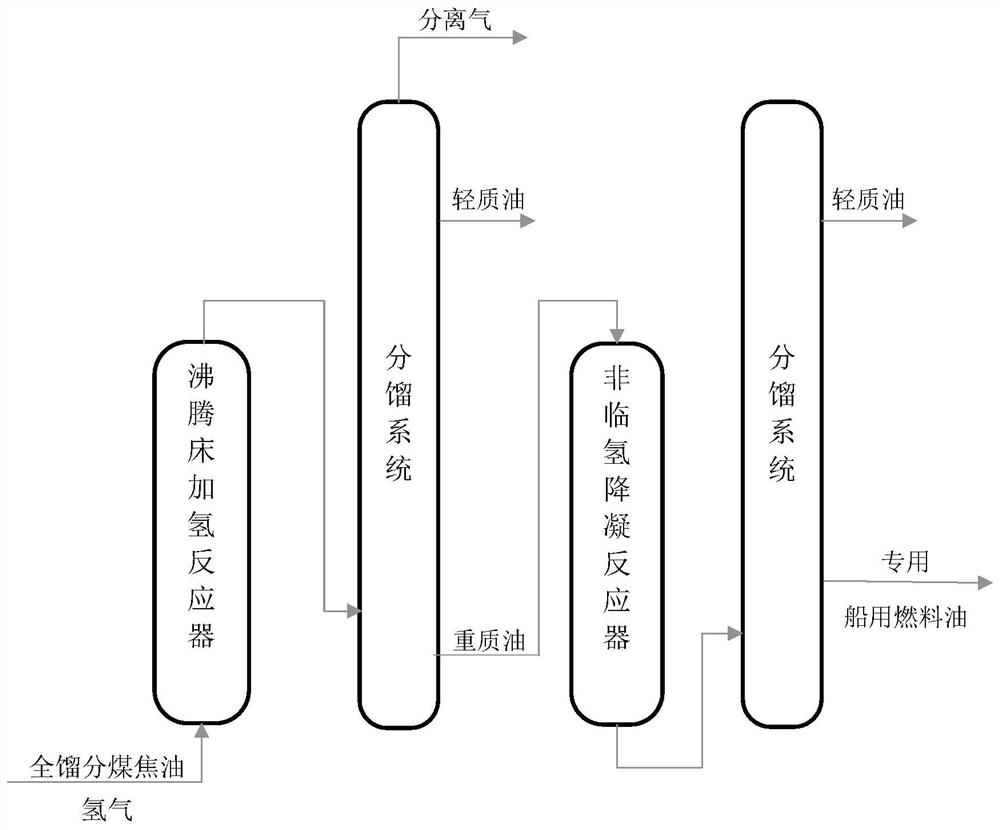

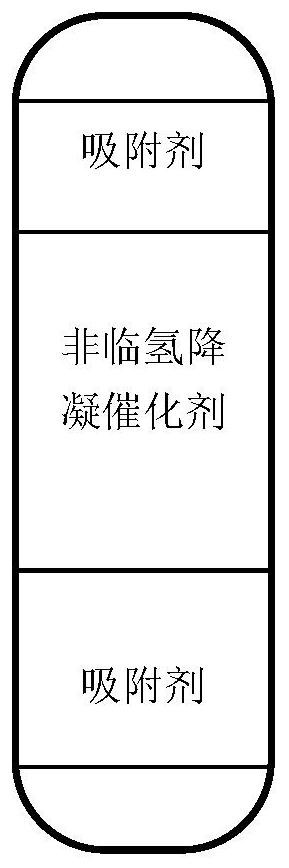

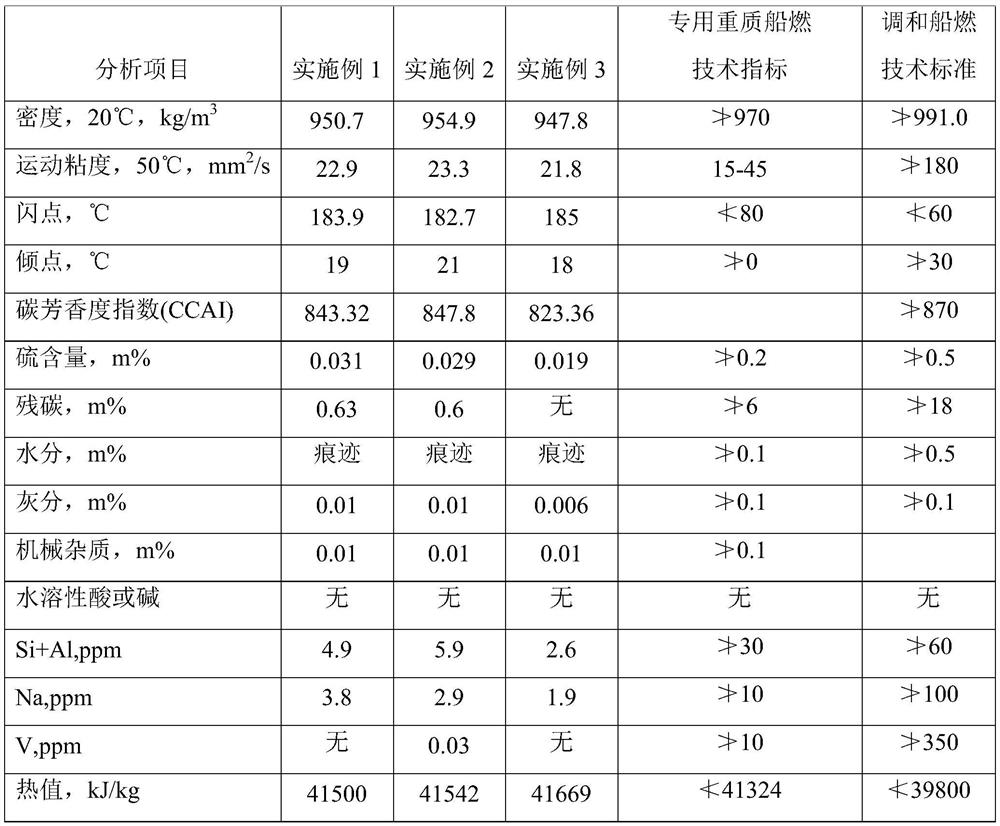

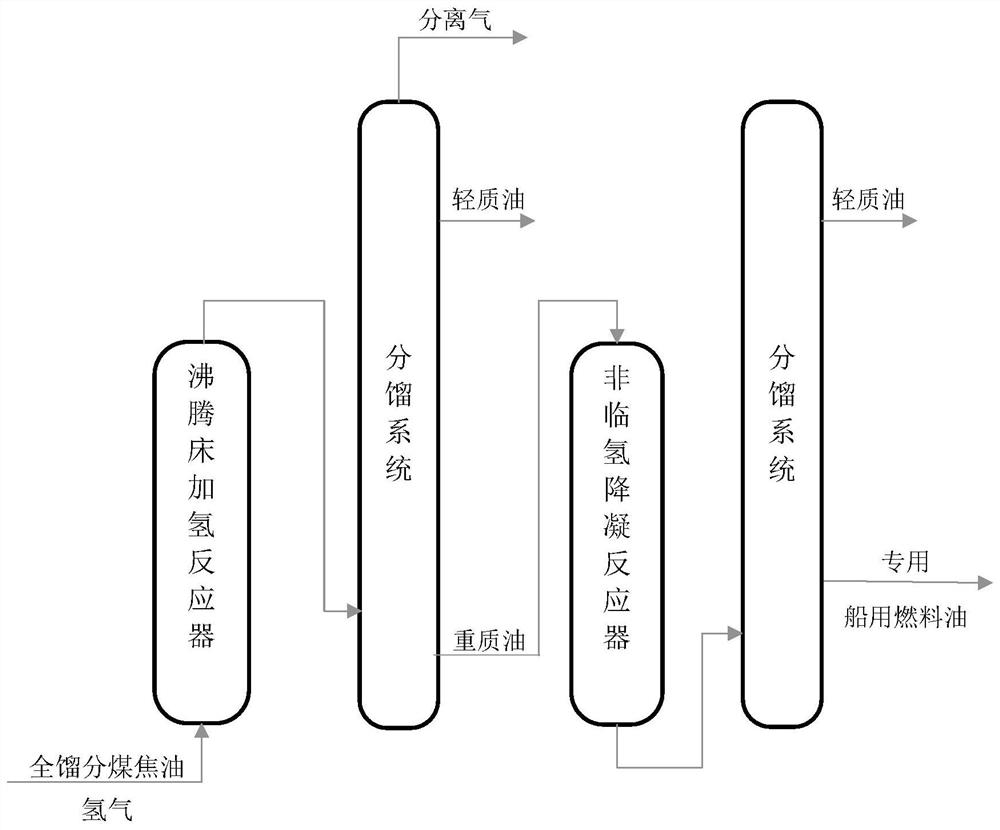

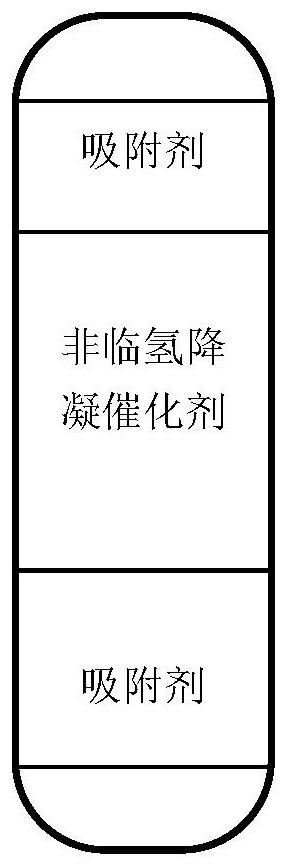

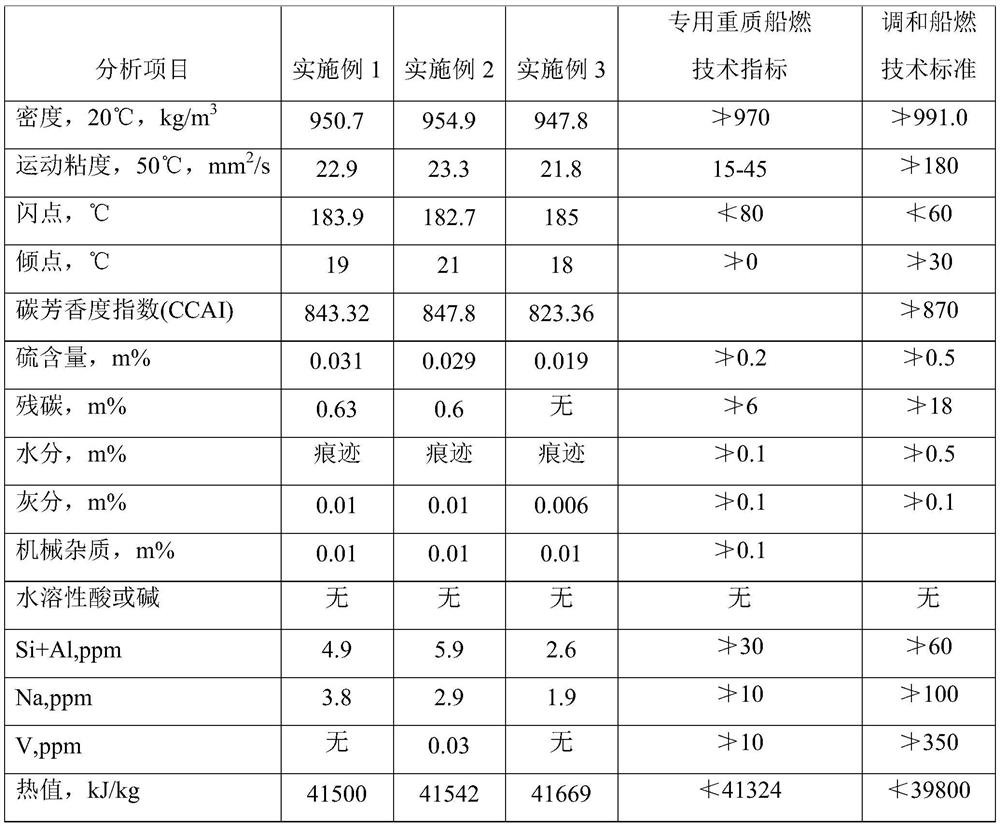

Method for producing special marine heavy fuel oil by using coal tar as raw material

ActiveCN112980484ANot manyIncrease production costTar working-up by chemical refiningPtru catalystFluidized bed

The invention relates to the technical field of production of marine heavy fuel oil, in particular to a method for producing special marine heavy fuel oil by taking coal tar as a raw material. The method comprises the following steps: (1) dehydrating full-fraction coal tar, removing mechanical impurities, feeding the full-fraction coal tar and hydrogen into a fluidized bed reactor, and carrying out hydrofining reaction under the action of a fluidized bed hydrotreating catalyst under selected process conditions; (2) sequentially carrying out high-low pressure separation and normal-pressure and vacuum fractionation on the reaction product in the step (1) to obtain light distillate oil and heavy distillate oil; (3) introducing the heavy distillate oil obtained in the step (2) into a non-hydrodewaxing fixed bed reactor, and carrying out dewaxing treatment through a non-hydrodewaxing catalyst and an active adsorbent under selected process conditions; and (4) carrying out normal-pressure fractionation treatment on the reaction product in the step (3) to obtain light distillate oil and special marine heavy fuel oil. According to the invention, the technical blank of producing the special marine heavy fuel oil by using the coal tar as the raw material is filled.

Owner:INNER MONGOLIA SHENGYUAN TECH CO LTD +1

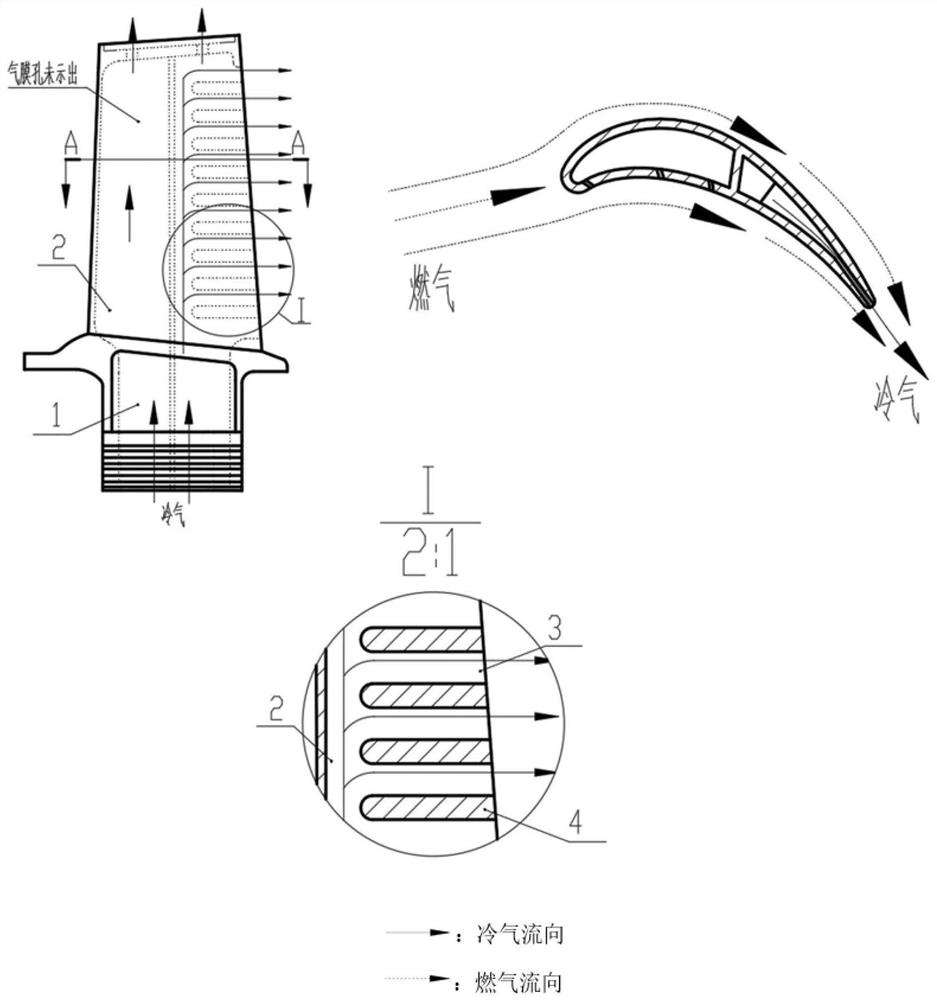

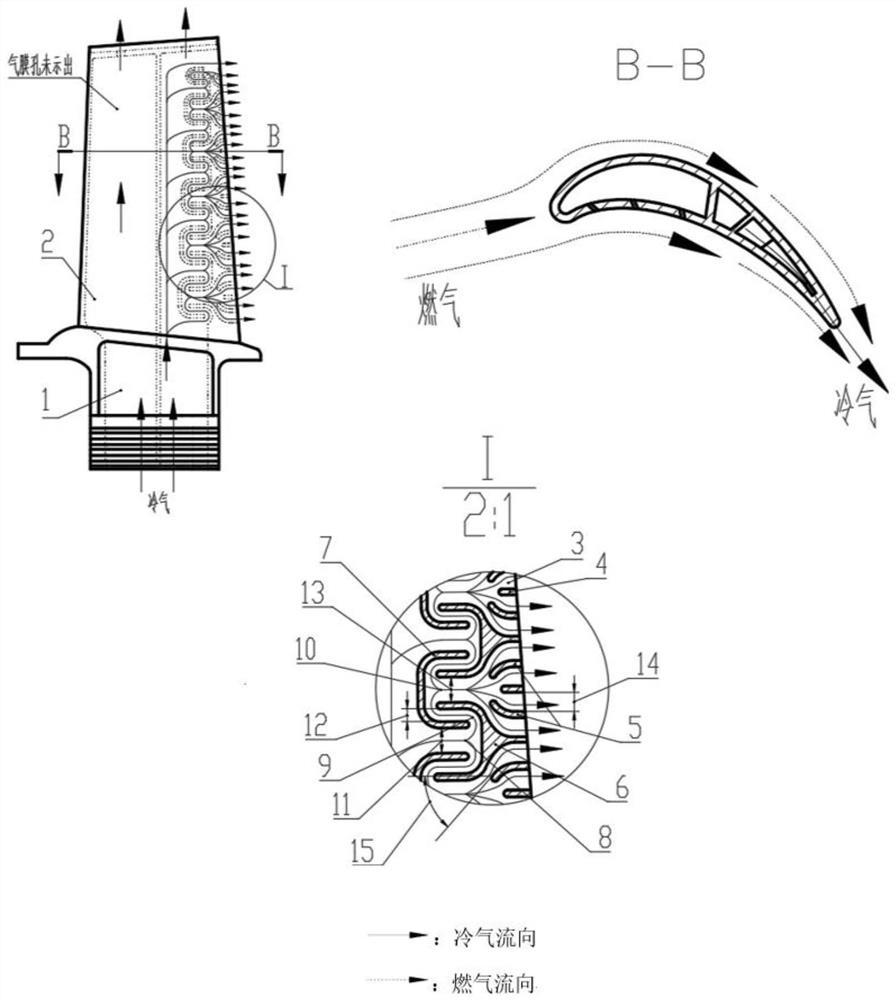

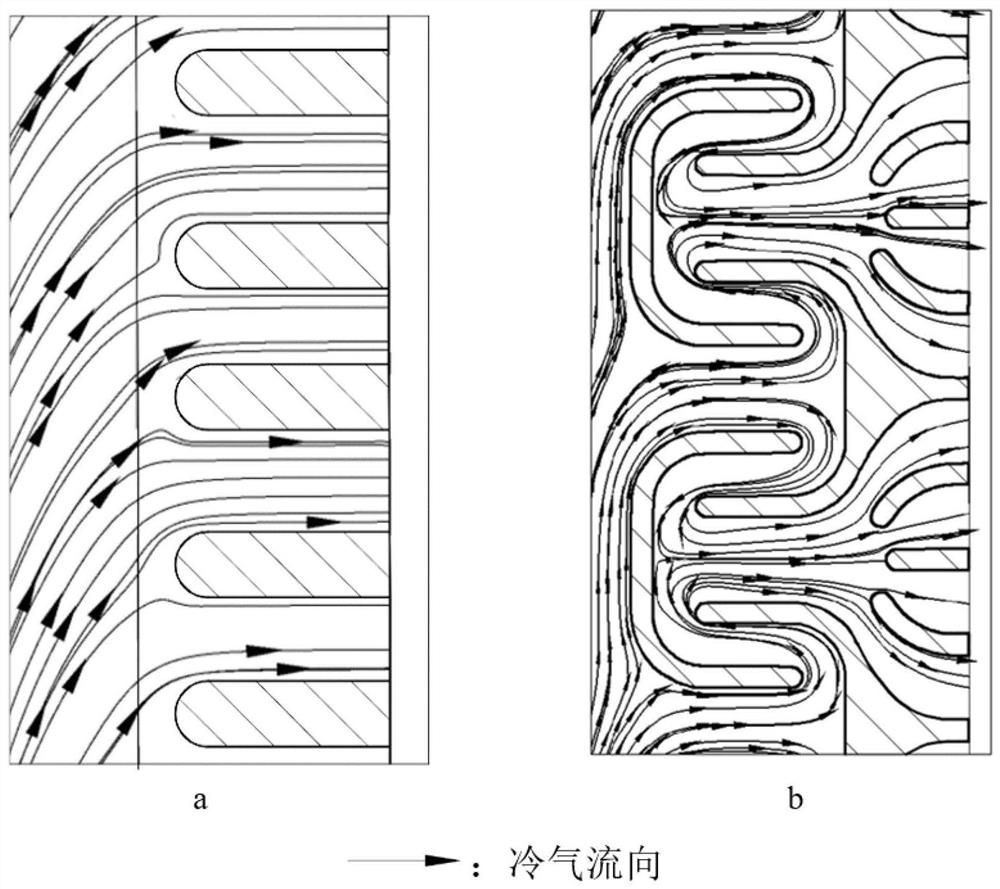

Turbine blade separation transverse rotation re-intersection type cooling structure

ActiveCN112943379AIncrease the heat exchange areaImprove cooling effectBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade separation transverse rotation re-intersection type cooling structure. An inner cavity cold air channel is arranged in a hollow turbine blade of the cooling structure, and low-temperature cooling gas flows in the blade to cool the blade. Herringbone partition ribs and C-shaped partition ribs are evenly distributed on the tail edge of the blade in the radial direction and are combined in a staggered mode to guide airflow to be separated, transversely rotate and then intersect. A cold air separation channel is formed between every two adjacent C-shaped ribs, the width of the cold air separation channel is D1, cold air flows downstream in the channel and then is separated into two air flows flowing towards the blade root and the blade tip correspondingly, and the two air flows rotate by 180 degrees for the first time in two cold air rotation channels correspondingly and flow reversely in the incoming flow direction. Each strand of cold air can flow out after passing through a trailing edge crack after being turned for multiple times, and the flowing distance is increased by about 40% compared with a conventional structure, so that the utilization rate of the cold air is increased, and the temperature of the blade is reduced.

Owner:DALIAN UNIV OF TECH

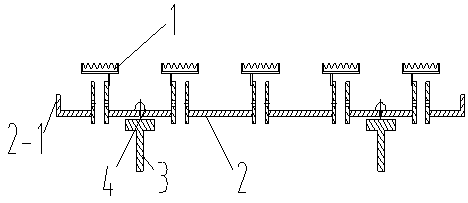

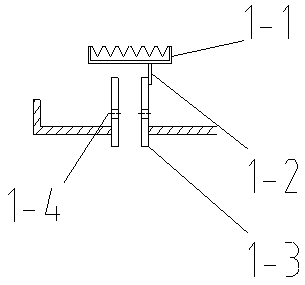

Sleeve type flushing reduction flow equalization disc

ActiveCN108114670ASmall installation sizeSaves reactor spaceChemical/physical processesLiquid layerEngineering

The invention discloses a sleeve type flushing reduction flow equalization disc which comprises a tower disc and a plurality of chimney distributors, wherein the chimney distributors are arranged on the tower disc; the chimney distributors comprise downcomers and flushing reduction cylinders arranged at the upper ends of the downcomers; both the flushing cylinders and the downcomers are of cylindrical structures of which two ends are opened; the flushing reduction cylinders and the downcomers are arranged up and down; and the diameters of the flushing reduction cylinders are greater than thoseof the downcomers. The flushing reduction flow equalization disc disclosed by the invention is a new internal component and is arranged inside an idle space inside an upper sealing head of a hydrogenation reactor or at the upper end of the cylinder of the hydrogenation reactor. By adopting the flushing reduction flow equalization disc disclosed by the invention, intense impact of residual kineticenergy of a fluid entering the reactor can be reduced, and the phenomenon of 'push waves'caused by inclined flowing lines to the liquid layer of a distribution disc when the fluid enters a central point can be eliminated. The sleeve type flushing reduction flow equalization disc disclosed by the invention is applicable to all hydrogenation reactors and particularly applicable to hydrogenation reactors which are relatively large in liquid-gas ratio and relatively large in scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of high viscosity phenylmethylvinyl silicone rubber

ActiveCN101381459BRadial temperature difference is smallIncrease production capacityPolymer scienceTemperature difference

The invention discloses a manufacturing process for preparing a high-viscosity phenyl methyl vinyl silicone rubber. The manufacturing technique comprises three steps: polymerization, catalyst deactivation and low boiling, and all the steps are finished in a high-power high shear vacuum stirring device. Compared with the prior art, the process has the advantages of remarkably improved heat transfer effect, small reaction kettle radial temperature difference, and greatly improved product quality, and can be used for large-scale production. For the high-viscosity phenyl methyl vinyl silicone rubber prepared by the process, the volatile compositions are less than 3 percent, the molar mass is larger than 700,000, the polydispersity index representing the molecular weight distribution is less than 3, and the production capacity of a single set of equipment is large. The indexes are better than that of the similar products manufactured by a static method on the market.

Owner:SHANGHAI RESIN FACTORY

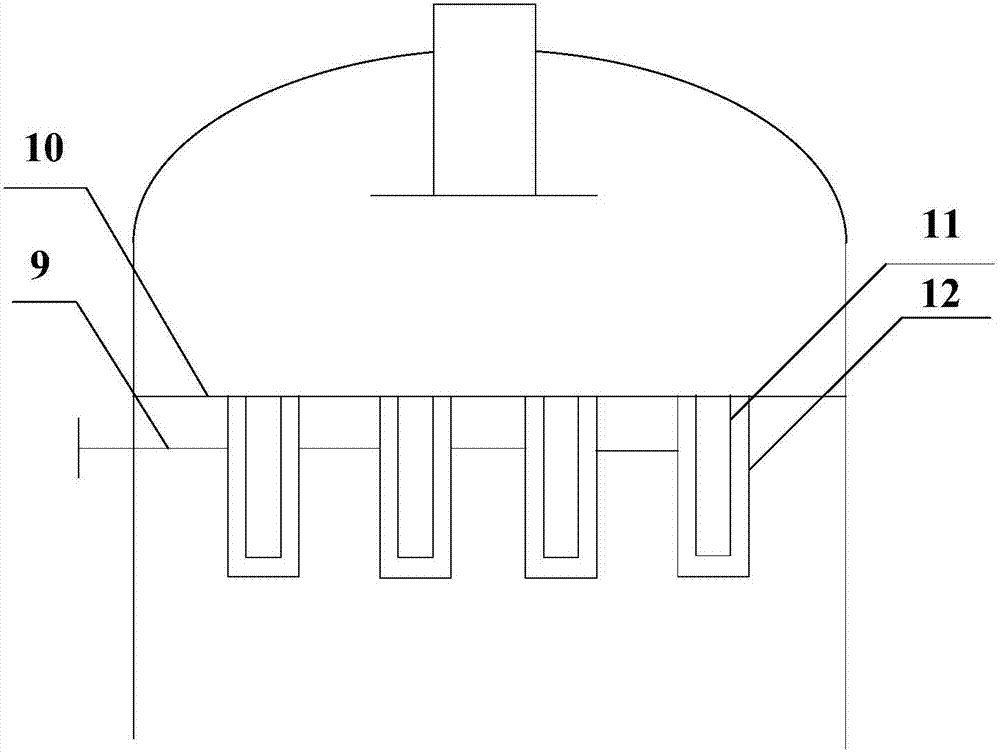

A hydrogenation reactor having an impact reducing assembly

ActiveCN109985571AIt has the function of reducing flushing and current sharingImprove distributionChemical/physical processesHydrogenation reactionProcess engineering

The invention discloses a hydrogenation reactor with an impact reducing assembly. The hydrogenation reactor comprises a material inlet pipe, an inlet diffuser, a reactor upper head, an annular plate type impact reducing and flow equalizing tray, a catalyst bed layer, a catalyst support grid, a reactor barrel, a reactor lower head, an outlet collector, a material outlet pipe and a catalyst discharging pipe. The annular plate type impact reducing and flow equalizing tray comprises a column tray and a distributor arranged on the column tray, the distributor is formed by arranging a plurality of layers of impact reducing annular plates on the column tray in a concentric circle mode, and a plurality of downcomers used for collecting and discharging materials are arranged between every two adjacent layers of the impact reducing annular plates. The hydrogenation reactor provided by the invention is suitable for a hydrogenation reaction process, especially for a hydrofining or hydrocracking process used for a raw material containing scale and utilizing a large-scale reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

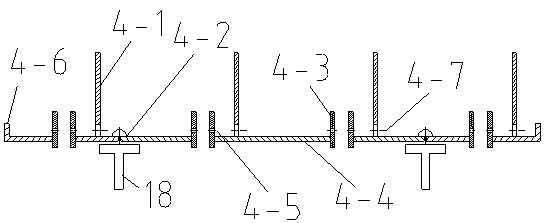

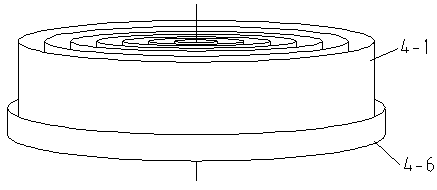

Method for grading catalyst for hydrogenation treatment

ActiveCN102311764AReduce cokingExtended service lifeHydrocarbon oil crackingHydrocarbon oils refiningTemperature differenceOrganic chemistry

The invention discloses a method for grading a catalyst for hydrogenation treatment. In the method, a spherical catalyst layer is arranged in a catalyst bed layer, and one or more than one spherical catalyst layer is arranged. The method disclosed by the invention can improve the distribution of a material flow in the reactor, lower the radial temperature difference in the reactor, and the operation period of the device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

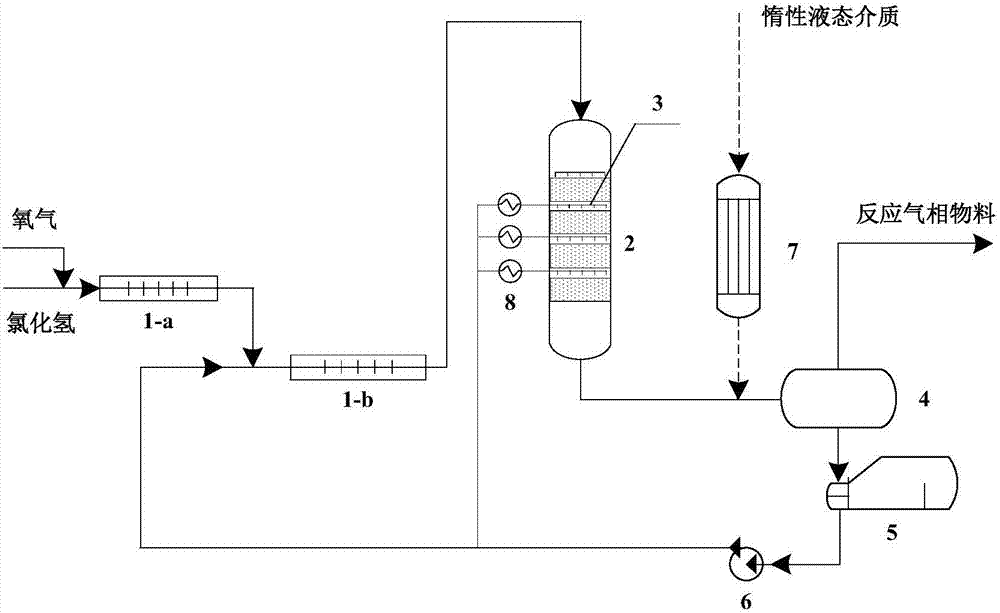

Method for preparing chlorine by performing hydrogen chloride oxidation by trickle bed reactor

ActiveCN107117580AReduce backmixingModerate responseCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsLiquid mediumGas phase

The invention discloses a method for preparing chlorine by performing hydrogen chloride oxidation by a trickle bed reactor. The method comprises the following steps: mixing airflow containing molecular oxygen and airflow gaseous phase containing hydrogen chloride, mixing the mixture and a high-temperature inert liquid medium, introducing the preheated mixed materials into the trickle bed reactor, and performing oxychlorination reaction under the action of a catalyst to prepare chlorine. Meanwhile, the inert liquid mediums are injected into different positions of the axial direction of the trickle bed reactor, and axial temperature gradient is formed in the reactor, so that the conversion rate is increased. By the method, the mass transfer and heat transfer effects of the catalytic reaction process can be effectively enhanced, the controllability of temperature distribution in the reactor is guaranteed, the axial temperature gradient is formed in the reactor, the reaction heat utilization efficiency is improved, the reaction conversion rate is increased, and use of reactor materials is reduced.

Owner:WANHUA CHEM GRP CO LTD

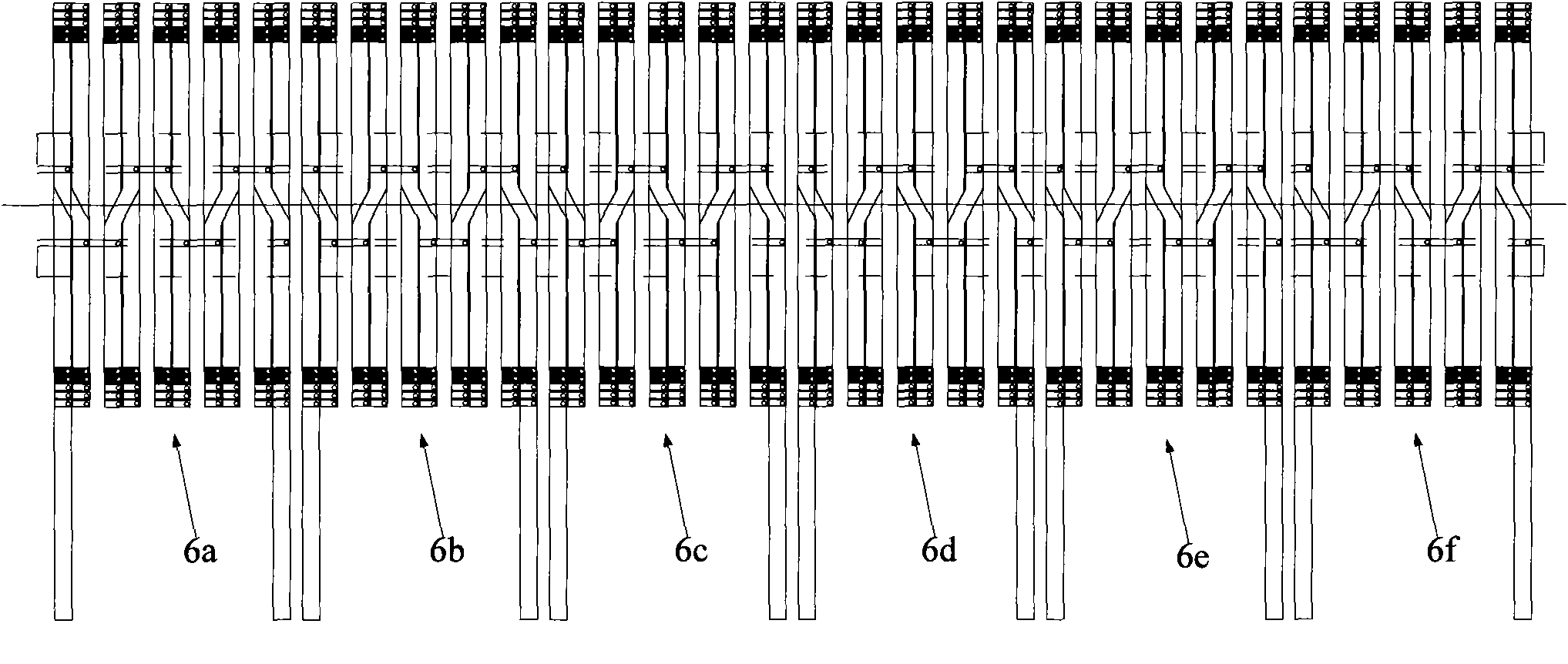

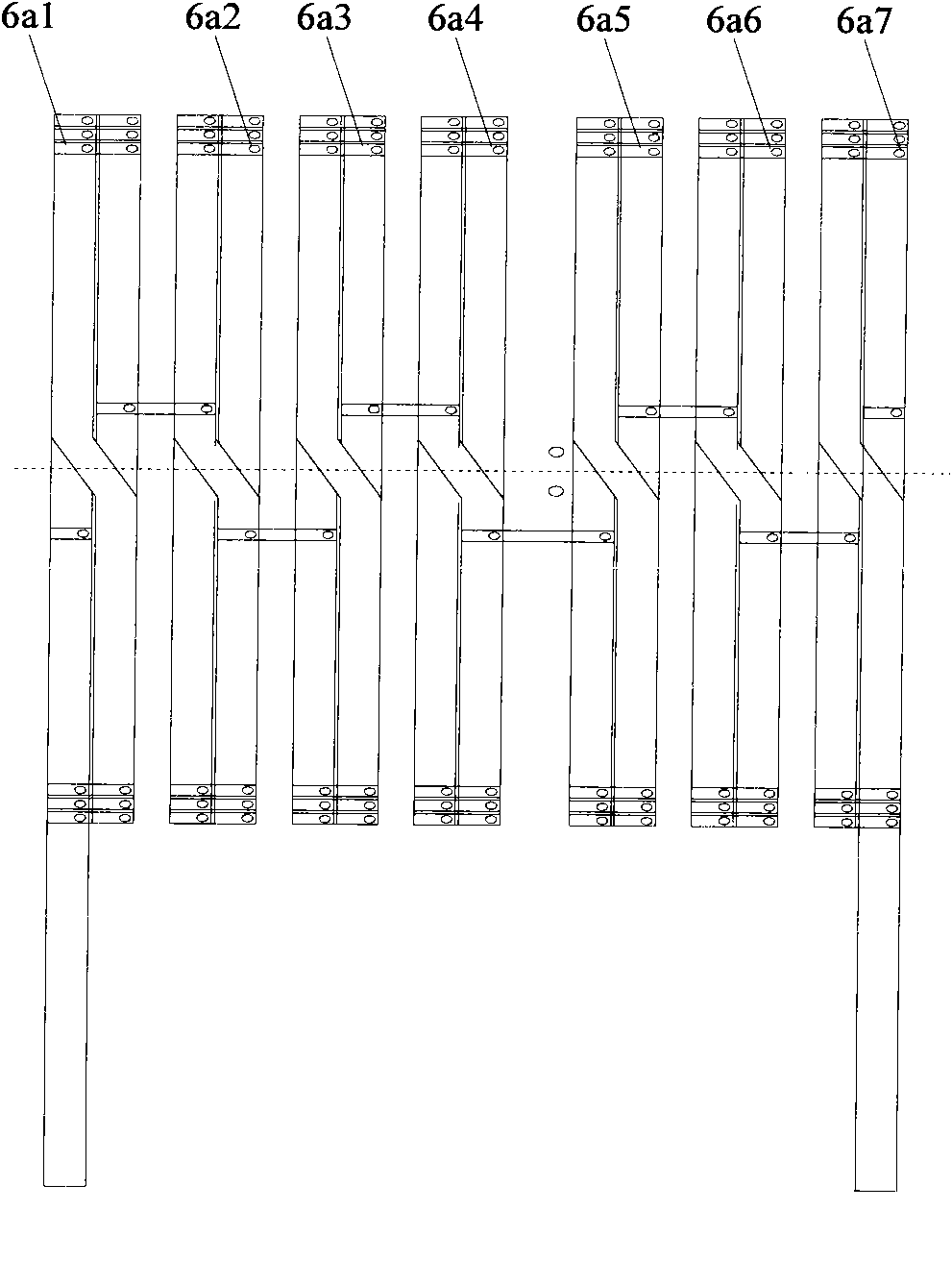

Ventilating structure and method for distributing flow of internal and external cooling medium based on loss ratio

InactiveCN105743268AImprove cooling effectMeet the cooling effectSupports/enclosures/casingsElectric machineCooling effect

The invention discloses a ventilating structure and a method for distributing flow of internal and external cooling medium based on loss ratio. A novel flowing path for a motor internal cooling medium is designed. The problem of relatively high temperature rise distribution difference of a stator and a rotor caused by unbalanced air ventilation distribution of the original ventilating structure is solved by the ventilating structure provided by the invention; the duty cycle of the internal and external ventilating ducts can be determined according to the ratio of the stator loss in the total loss; on the basis of a common ventilating baffle structure, a baffle is improved; a part of the original external ventilating duct is adopted as the flowing path for the internal cooling medium; the ventilating ducts filled by different cooling mediums are distributed at intervals, so that the internal air can be cooled by the external air; the matching between the baffle and a machine case along the width is adjusted only according to the stator and rotor loss ratio, and the effective heat exchange between a primary circuit and a secondary circuit is realized; balanced cooling effect distribution for the stator part and the rotor part can be realized as well; and therefore, the overall temperature rise distribution condition of the motor is perfected.

Owner:HARBIN UNIV OF SCI & TECH

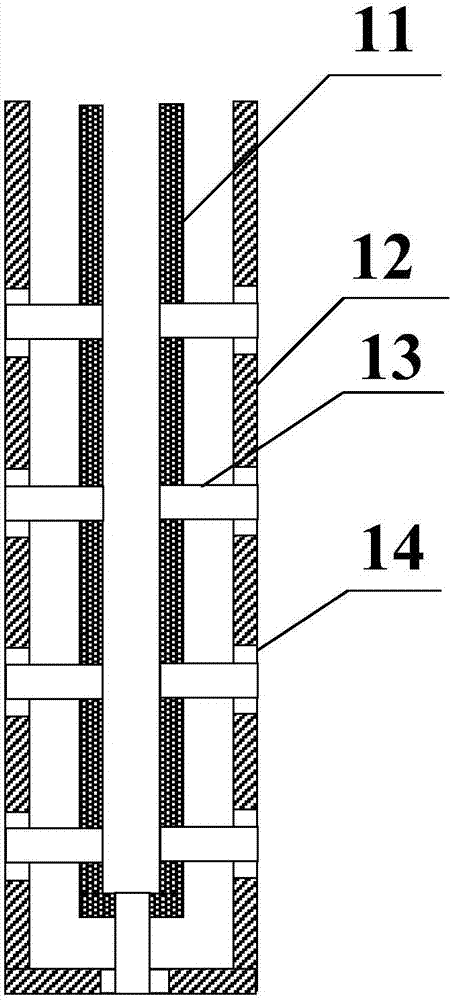

Hydrogenation reactor with impact reduction assembly

ActiveCN109985575AIt has the function of reducing flushing and current sharingImprove distributionChemical/physical processesGratingNuclear engineering

The invention discloses a hydrogenation reactor with an impact reduction assembly. The hydrogenation reactor comprises a material inlet pipe, an inlet diffuser, a reactor upper end socket, an impact-reducing flow-equalizing disc, a catalyst bed layer, a catalyst supporting grid, a reactor barrel, a reactor lower end socket, an outlet collector, a material outlet pipe and an unloading pipe. The impact-reducing flow-equalizing disc is arranged in the idle space of the upper end socket of the reactor or at the upper end of the reactor barrel; and the impact-reducing flow-equalizing disc comprisesan impact-reducing tower disc and a plurality of distributors arranged on the impact-reducing tower disc, each distributor comprises a grating, a material falling pipe and a connecting rod, the gratings are arranged above the material falling pipes, and the gratings are connected with the material falling pipes through the connecting rods. The hydrogenation reactor provided by the invention is suitable for a hydrogenation reaction process, especially a hydrogenation refining or hydrocracking process with a large reactor scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Single-ingot power frequency heating furnace

InactiveCN101948952AInnovative designEvenly distributedFurnace typesIncreasing energy efficiencyIngotHeating furnace

The invention relates to a single-ingot power frequency heating furnace which comprises a furnace rack, a furnace lining, an induction body and a magnet yoke, wherein the furnace rack comprises an upper supporting body and a lower supporting body; the induction body wound by a hollow copper tube surrounds the excircle of the furnace lining into a whole; the upper supporting body and the lower supporting body are combined and locked to ensure that the magnet yoke in the upper supporting body and the magnet yoke in the lower supporting body form opposite clamping to the induction body; the induction body consists of a plurality of independent inducing coil sections which are arrayed along the axial direction, and each inducing coil section is singly connected with a power supply; and each inducing coil section consists of a plurality of inducing coil units which are connected in series along the axial direction. Each inducing coil section can be applied with different power densities to generate an axial temperature gradient on an aluminum bar so as to realize stepless power regulation (the heating temperature can be arbitrarily set), achieve dynamic and static heating and meet the requirement of isothermal extrusion.

Owner:苏州工业园区华福科技有限公司

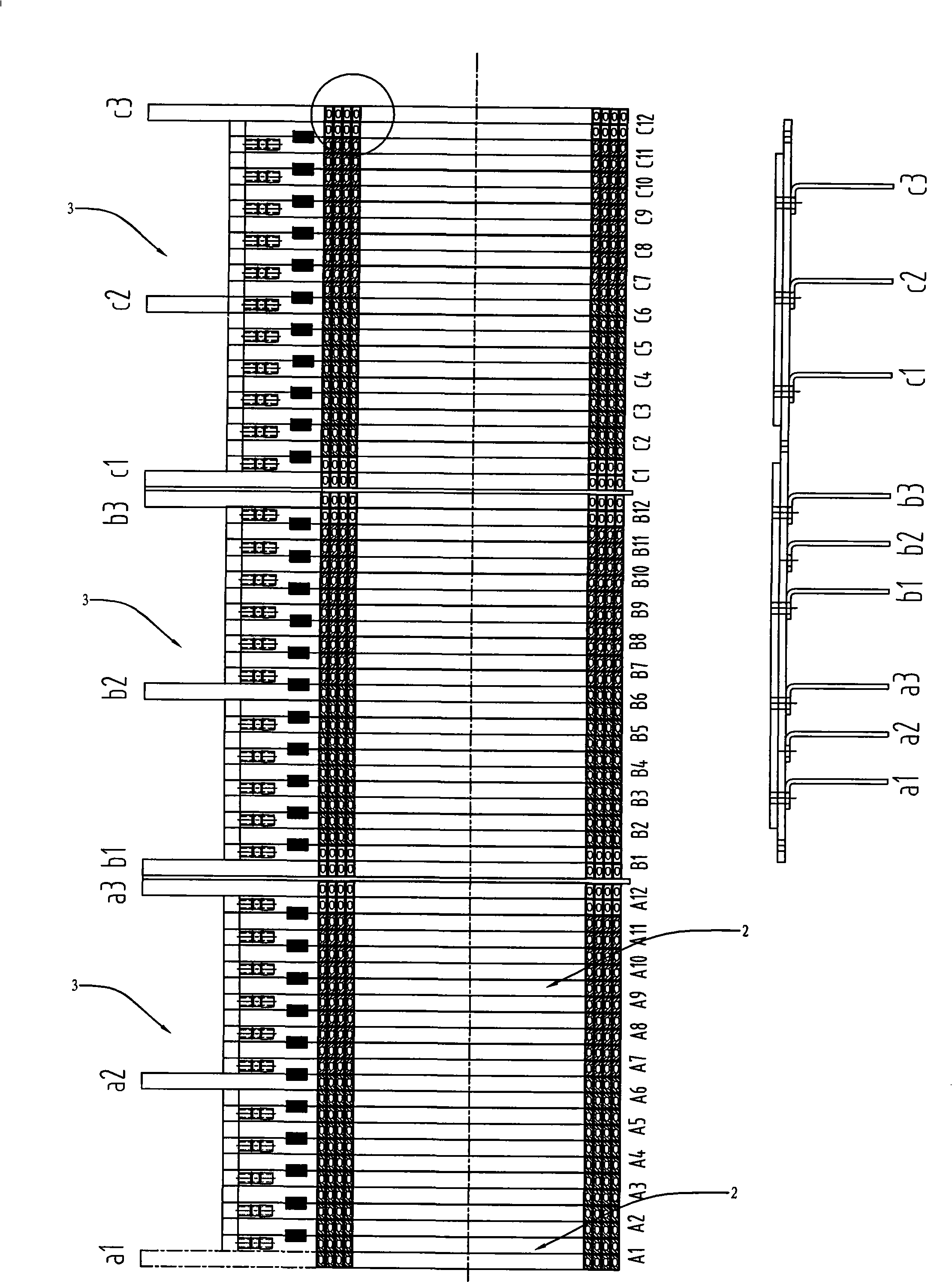

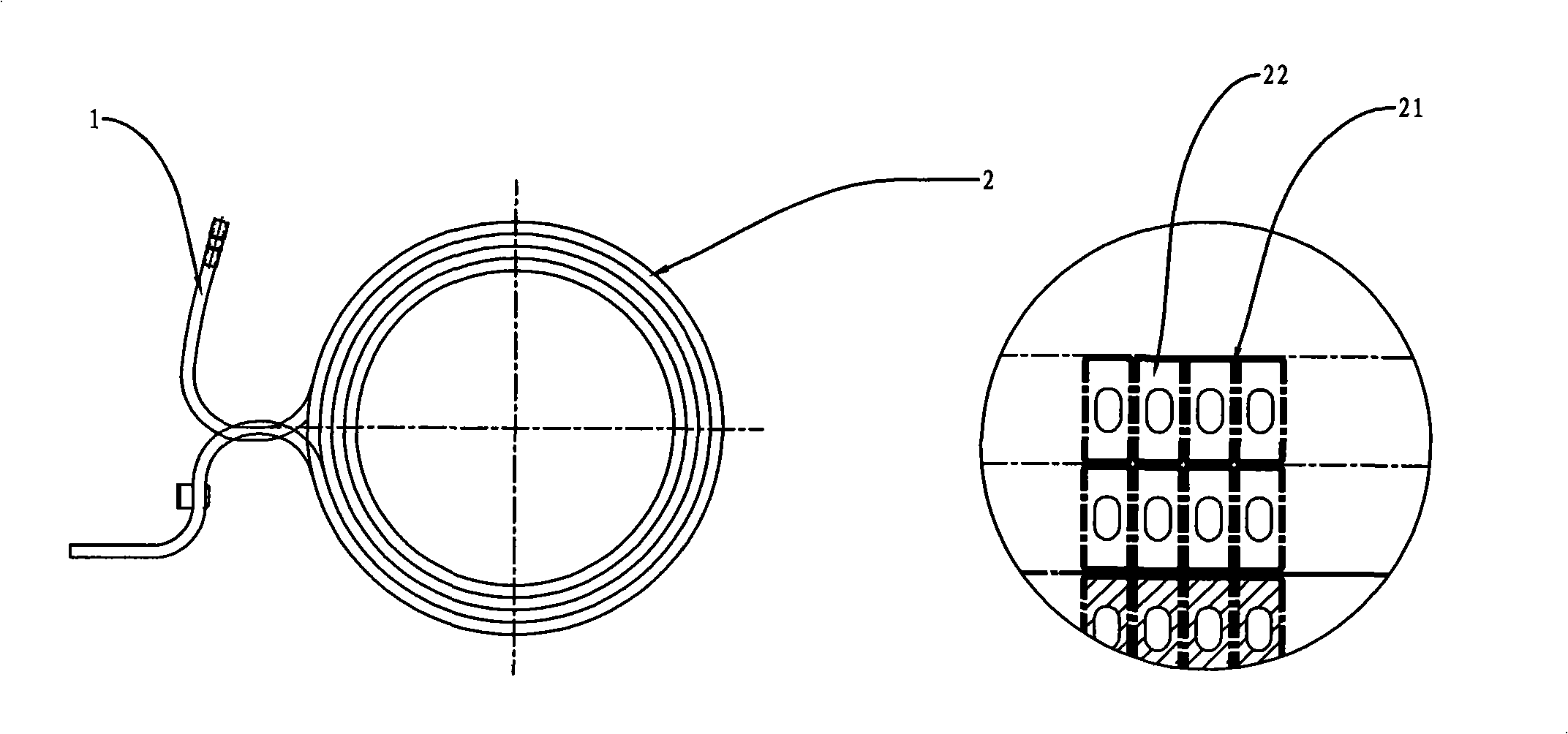

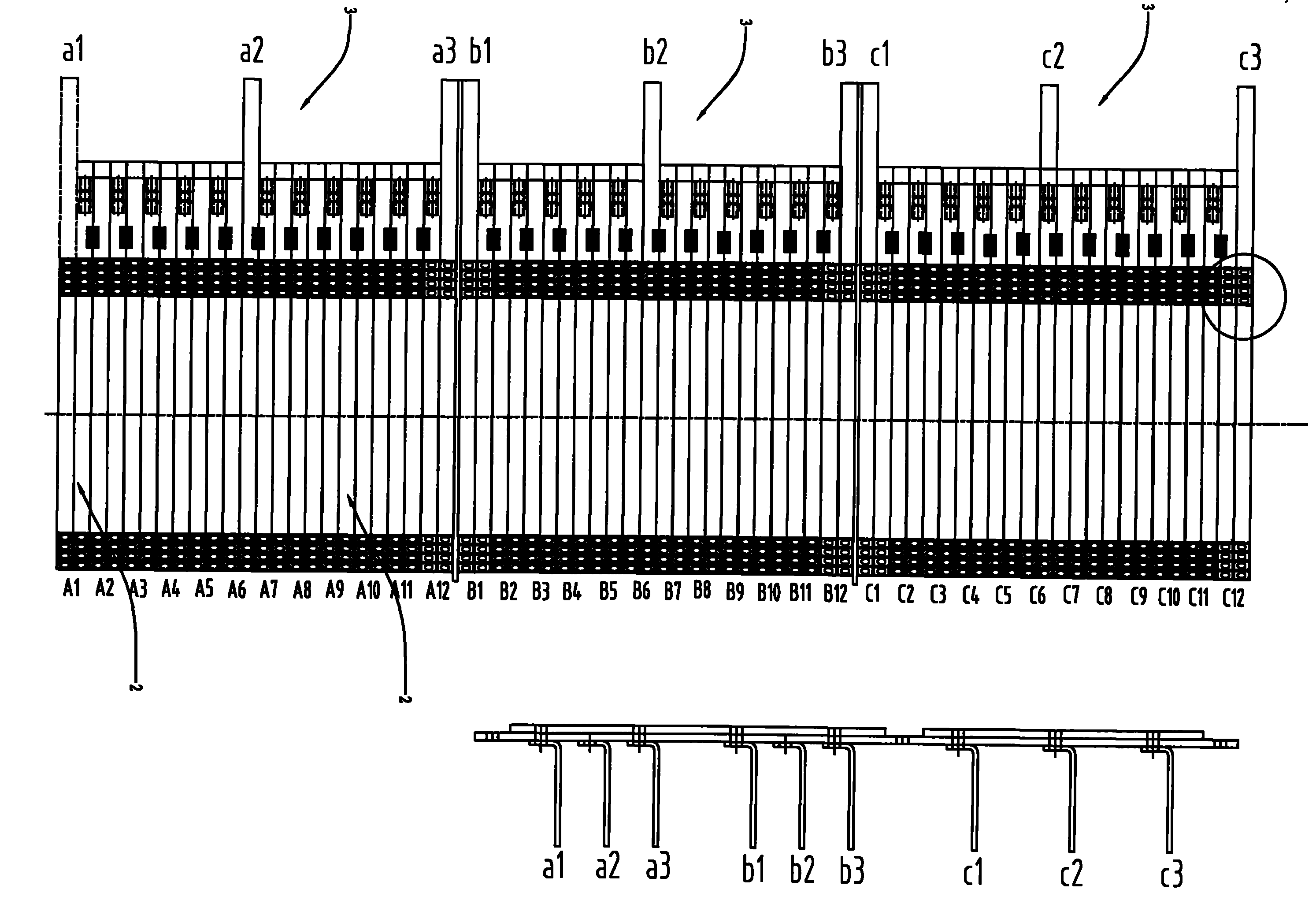

Heating coil, induction heating equipment and manufacturing method for heating coil

InactiveCN101505556BIncrease the lengthRadial temperature difference is smallCoil arrangementsIncreasing energy efficiencyFrequency changerTransformer

Owner:深圳市恒拓科技有限公司

A sleeve-type shock-reducing flow equalizer

ActiveCN108114670BSmall installation sizeSmall scaleChemical/physical processesLiquid layerThermodynamics

The invention discloses a sleeve type shock reducing and equalizing plate. The sleeve-type flush-reducing equalizer includes a tray and several chimney-type distributors arranged on the tray; the chimney-type distributor includes a downcomer and a shock-reducing barrel arranged at the upper end of the downcomer; Both the flushing barrel and the downcomer are cylindrical structures with openings at both ends, the flushing reducing barrel and the downcomer are arranged up and down, and the diameter of the flushing reducing barrel is larger than that of the downcomer. The shock reducing and equalizing plate of the present invention is a newly added internal member of the reactor, which is arranged in the idle space of the upper head of the hydrogenation reactor, or the upper end of the cylinder body of the hydrogenation reactor. The shock reducing and equalizing plate of the present invention can reduce the strong impact force formed by the residual kinetic energy when the fluid enters the reactor, and eliminate the "wave pushing" phenomenon of the inclined streamline formed when the central point enters the liquid layer of the distribution plate. The sleeve-type shock-reducing flow equalizer of the present invention is suitable for all hydrogenation reactors, and is especially suitable for hydrogenation reactors with large liquid-gas ratio and large scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing special marine heavy fuel oil with coal tar as raw material

ActiveCN112980484BNot manyIncrease production costTreatment with hydrotreatment processesTar working-up by chemical refiningPtru catalystFixed bed

The invention relates to the technical field of producing marine heavy fuel oil, in particular to a method for producing special marine heavy fuel oil using coal tar as a raw material. The method comprises the following steps: (1) after dehydration and removal of mechanical impurities, the whole distillate coal tar enters an ebullating bed reactor with hydrogen, and under selected process conditions, carries out a hydrofining reaction under the action of an ebullating bed hydrotreating catalyst; (2) Carry out high and low pressure separation successively to the reaction product of step (1), normal and vacuum fractionation, obtain light distillate oil and heavy distillate oil; (3) introduce the heavy distillate oil that step (2) obtains into non- Hydrodecondensation fixed bed reactor, under the selected process conditions, through the non-hydrodecondensation catalyst and active adsorbent to carry out the depointation treatment; (4) the reaction product of step (3) is subjected to atmospheric pressure fractionation treatment, Light distillates and specialty marine heavy fuel oil are obtained. The invention fills up the technical blank of producing special marine heavy fuel oil with coal tar as raw material.

Owner:INNER MONGOLIA SHENGYUAN TECH CO LTD +1

Hydrogenation Reactor with Surge Assemblies

ActiveCN109985575BIt has the function of reducing flushing and current sharingImprove distributionChemical/physical processesThermodynamicsPtru catalyst

The invention discloses a hydrogenation reactor with a buffer component. The hydrogenation reactor of the present invention includes a material inlet pipe, an inlet diffuser, an upper head of the reactor, a flow-reducing equalizer plate, a catalyst bed, a catalyst support grid, a reactor cylinder, a lower head of the reactor, and an outlet collecting device, material outlet pipe and unloading pipe. The impact reduction and equalizing plate is set in the idle space of the upper head of the reactor or at the upper end of the reactor cylinder; the impact reducing and equalizing plate includes the impact reducing tray and several impact reducing trays. Distributor, the distributor includes a grid, a material drop tube and a connecting rod, the grid is arranged above the material drop tube, and the grid and the material drop tube are connected through a connecting rod. The hydrogenation reactor of the present invention is suitable for the hydrogenation reaction process, especially the hydrofinishing or hydrocracking process with relatively large reactor scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal Element Lattice Doped Silicon Carbide Reactor and Its Application in Ethane Dehydrogenation to Ethylene

ActiveCN109847670BSolution to short lifeImprove thermal conductivityHydrocarbonsChemical/physical/physico-chemical processesPtru catalystChemical reaction

The invention relates to a metallic element lattice doped silicon carbide reactor, and applications thereof in preparation of ethene through ethane dehydrogenation. The metallic element lattice dopedsilicon carbide reactor is invented base on a novel silicon carbide material which possesses excellent heat conductivity and chemical reactionlessness; based on the metallic element lattice doped silicon carbide reactor, and reaction conditions, the process is capable of realizing ethene high yield synthesis. The ethane conversion rate ranges from 70 to 100%; ethene selectivity ranges from 80 to 99.99%; propylene selectivity ranges from 0 to 5%; and aromatic hydrocarbons selectivity ranges from 0 to 5%. The metallic element lattice doped silicon carbide reactor possesses following characteristics: catalyst service life is long (>1000h), catalyst high temperature (<1700 DEG C) stability is excellent, ethane conversion rate and product selectivity are high, energy consumption is low, processrepeatability is excellent, and operation is safe and reliable; and the industrialized application prospect is promising.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com