Reactor for synthesizing methyl tert-butyl ether and application thereof

A methyl tert-butyl ether and etherification reactor technology, which is applied in the preparation of ether by addition of unsaturated compounds, ether preparation, organic chemistry, etc., can solve the problem of uneven distribution of liquid materials along the cross-section, high temperature of the catalytic bed, The problems such as the shutdown of the reaction system can avoid the shortening of the catalyst life, the small pressure drop of the bed and the uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

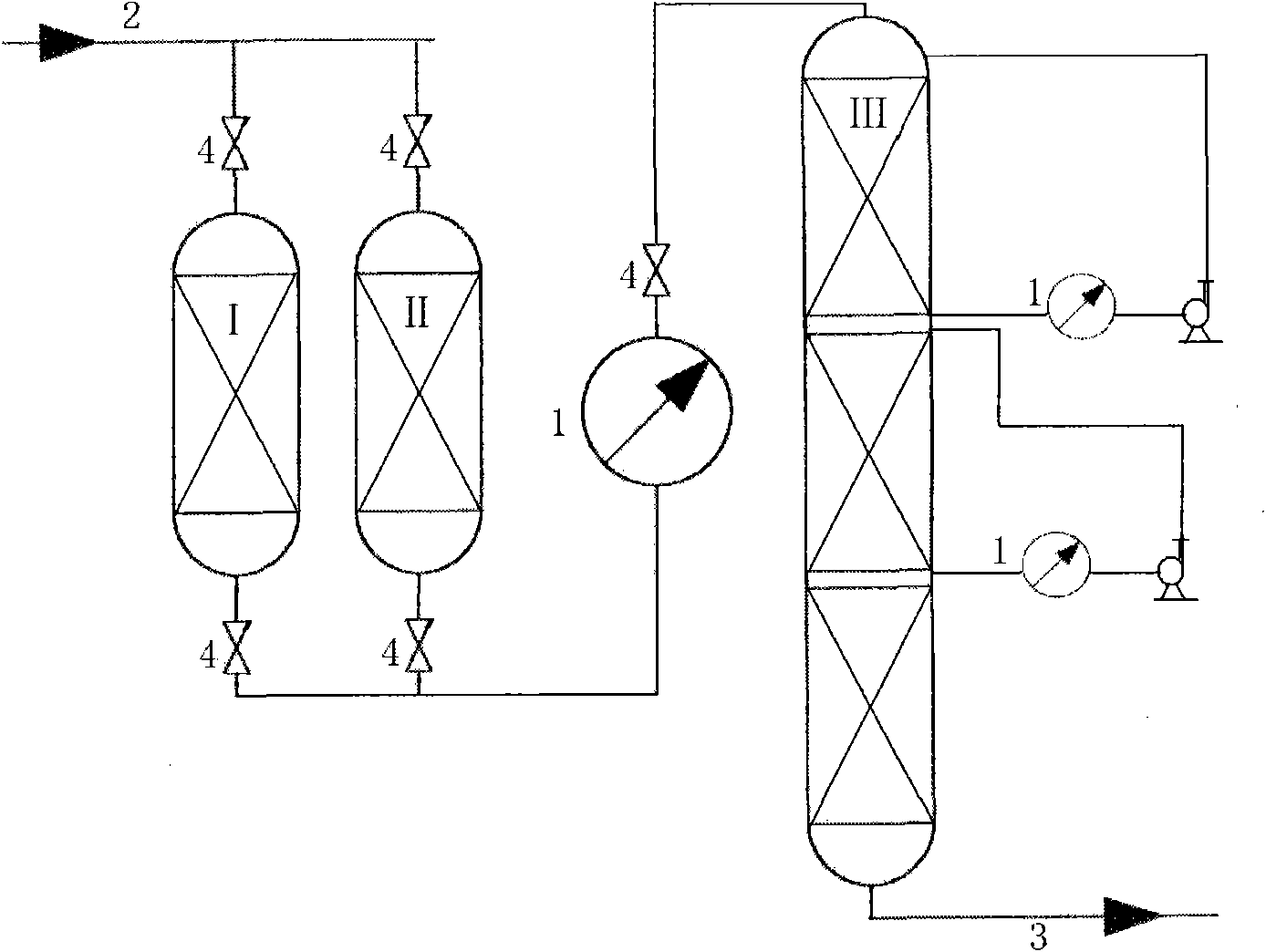

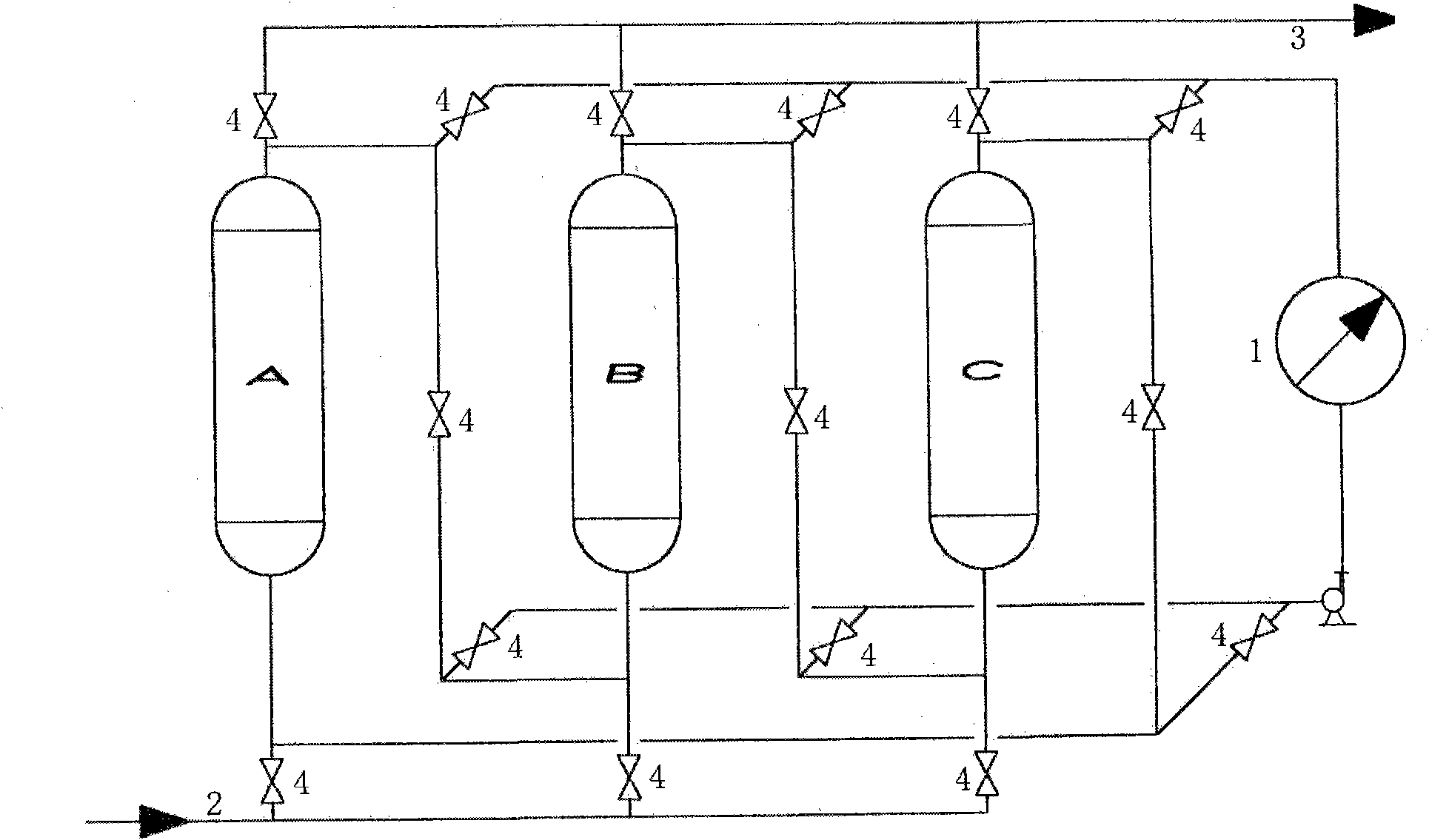

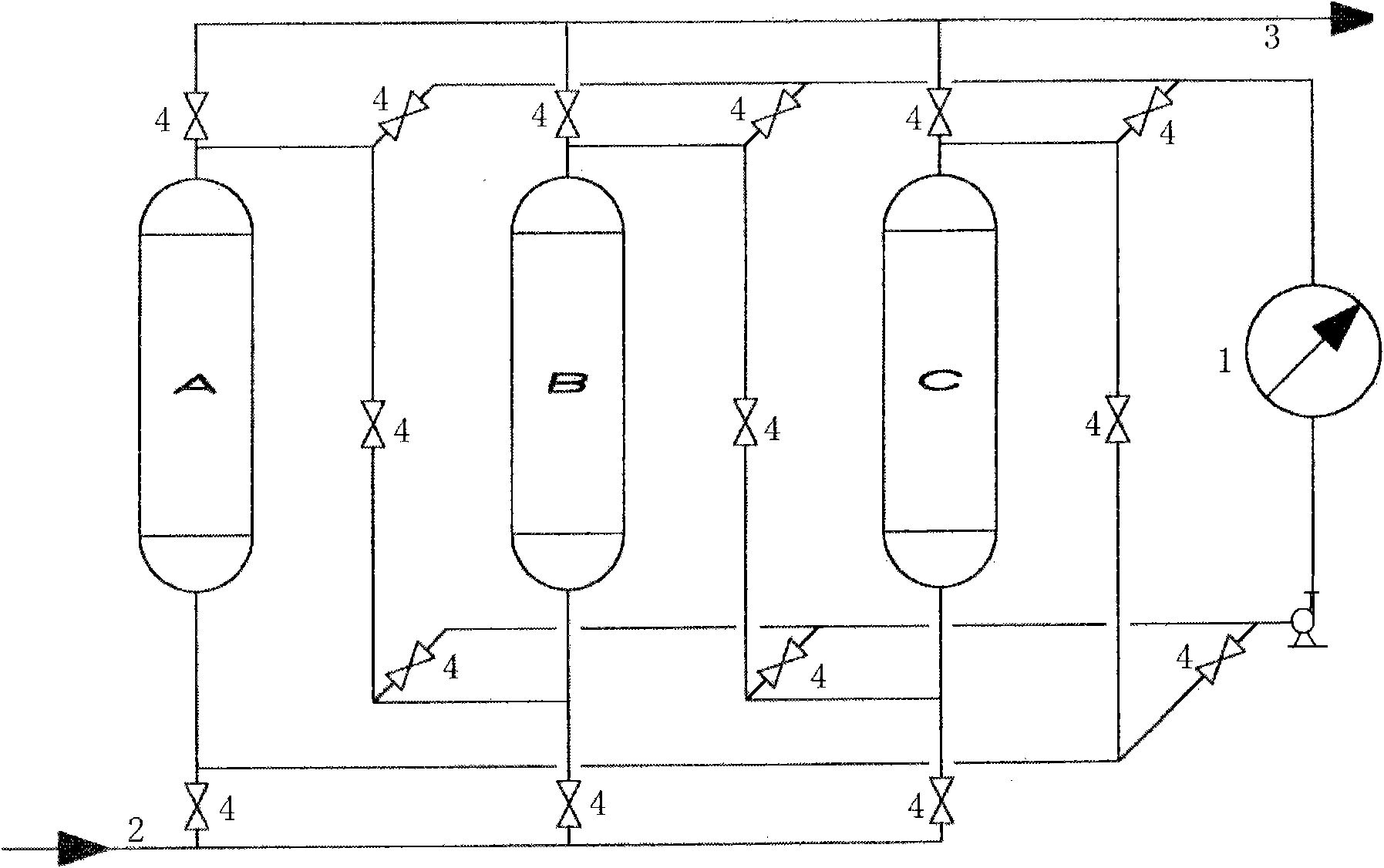

[0033] A reactor for synthesizing MTBE, including an etherification reactor, a heat exchanger 1, a reaction raw material inlet pipe 2 and a product outlet pipe 3,

[0034] The etherification reactor has a split structure of three etherification reaction sections. The split structure means that each etherification reaction section has its own independent tank filled with etherification catalyst. The three tanks are respectively Denoted by A, B, C; a feed port is provided at the lower end of the tank body, and a discharge port is provided at the upper end of the tank body;

[0035] The raw material inlet pipeline 2 is connected to the tank body inlet through the valve 4, and the product outlet pipeline 3 is connected to the tank body outlet through the valve 4;

[0036] The outlet of tank A is connected to the inlet of tank B through a pipeline via valve 4, and the outlet of tank B is connected to the inlet of tank C via valve 4 through a pipeline. The discharge ports are all connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com