Method for producing special marine heavy fuel oil with coal tar as raw material

A technology for heavy fuel oil and special ships, which is used in chemical extraction of tar, processing of hydrocarbon oil, petroleum industry, etc., can solve the problems of unreachable viscosity and density, complex process, high energy consumption, and maintain activity. Stabilizing and enhancing the effect of energy security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

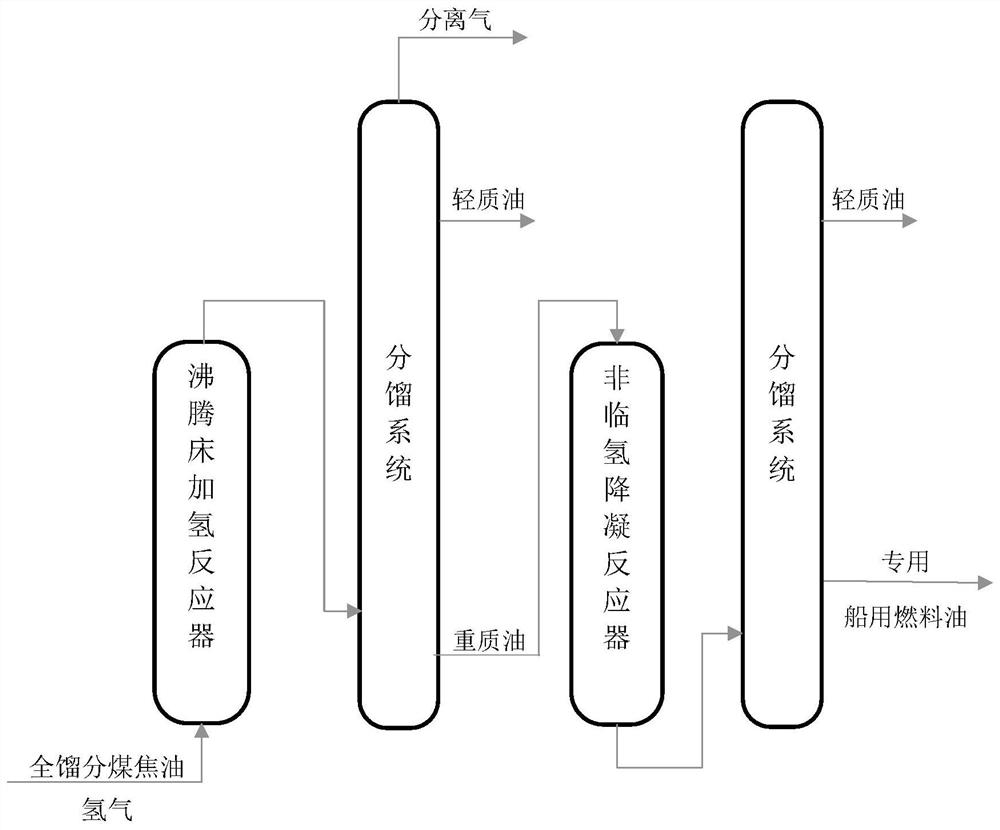

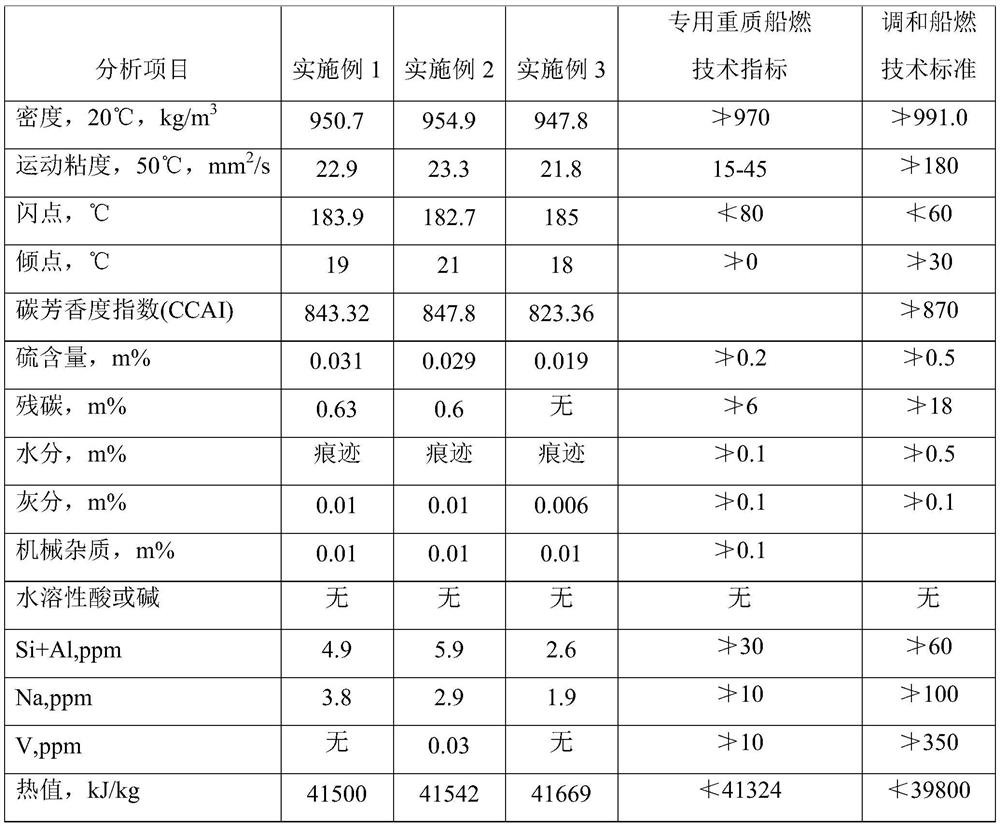

[0046] The method for producing special marine heavy fuel oil with coal tar as raw material, the concrete steps are as follows:

[0047] (1) Spherical ebullating bed hydrotreating catalyst after the vulcanization treatment is loaded into the ebullating bed reactor; Coal tar after the pretreatment and hydrogen heating are pumped into the ebullating bed reactor, and the process conditions listed in Table 2 Example 1 Next, the coal tar is hydrorefined to remove the colloid, asphaltenes, sulfur, nitrogen, oxygen, and metal impurities in the coal tar. After continuous oil feeding for 100 hours, the mixed oil samples from the reactor began to be collected continuously.

[0048] (2) The collected mixed oil samples were put into an atmospheric fractionation still, and the fractionation still was evenly heated to 320°C at a heating rate of 20°C / hour and maintained for 2 hours to fractionate light distillates. The remaining distillate oil is put into a vacuum fractionation kettle, and ...

Embodiment 2

[0066] The method for producing special marine heavy fuel oil with coal tar as raw material, the concrete steps are as follows:

[0067] (1) The pretreated coal tar and hydrogen heating are pumped into the ebullating bed reactor, and the feed oil is hydrorefined according to the process operating conditions listed in Table 2, Example 2. Operation steps and examples 1 Step (1) is exactly the same.

[0068] (2) Atmospheric and vacuum fractionation is carried out to the miscella collected in step (1), fractionation temperature and operation steps are exactly the same as embodiment 1 step (2), and the analysis data of the heavy distillate oil that fractionation goes out is listed in Table 3.

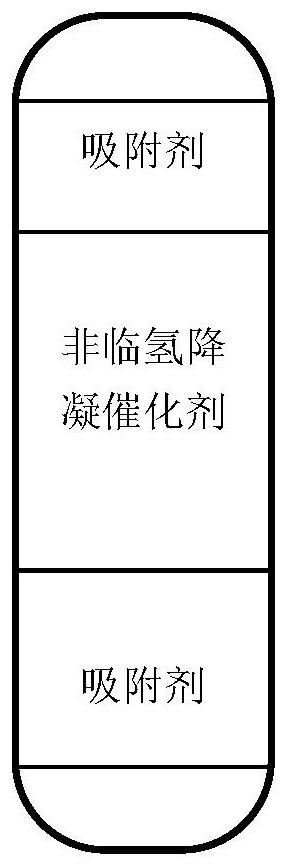

[0069] (3) The heavy distillate oil that step (2) is fractionated is pumped into the non-hydrogen decondensation reactor, and the process operation conditions listed in the embodiment 2 of Table 4 are used to purify the feed oil and depreciate. The operation steps are the same as Embodiment...

Embodiment 3

[0072] The method for producing special marine heavy fuel oil with coal tar as raw material, the concrete steps are as follows:

[0073] (1) The pretreated coal tar and hydrogen heating are pumped into the ebullating bed reactor, and the feed oil is hydrorefined according to the process operating conditions listed in Table 2, Example 3. Operation steps and examples 1 Step (1) is exactly the same.

[0074] (2) Atmospheric and vacuum fractionation is carried out to the miscella collected in step (1), fractionation temperature and operation steps are exactly the same as embodiment 1 step (2), and the analysis data of the heavy distillate oil that fractionation goes out is listed in Table 3.

[0075] (3) The heavy distillate oil that step (2) is fractionated is pumped into the non-hydrogen decondensation reactor, and the process operation conditions listed in the embodiment 3 of Table 4 are used to purify the feed oil and depreciate. The operation steps are the same as Embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com