Single-ingot power frequency heating furnace

A heating furnace and single ingot technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of performance differences, elongation and surface quality, different profile outlet temperatures, and the ability to reduce presses, etc., to achieve accurate temperature gradient curves , Heating temperature is uniform, satisfying the effect of isothermal extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

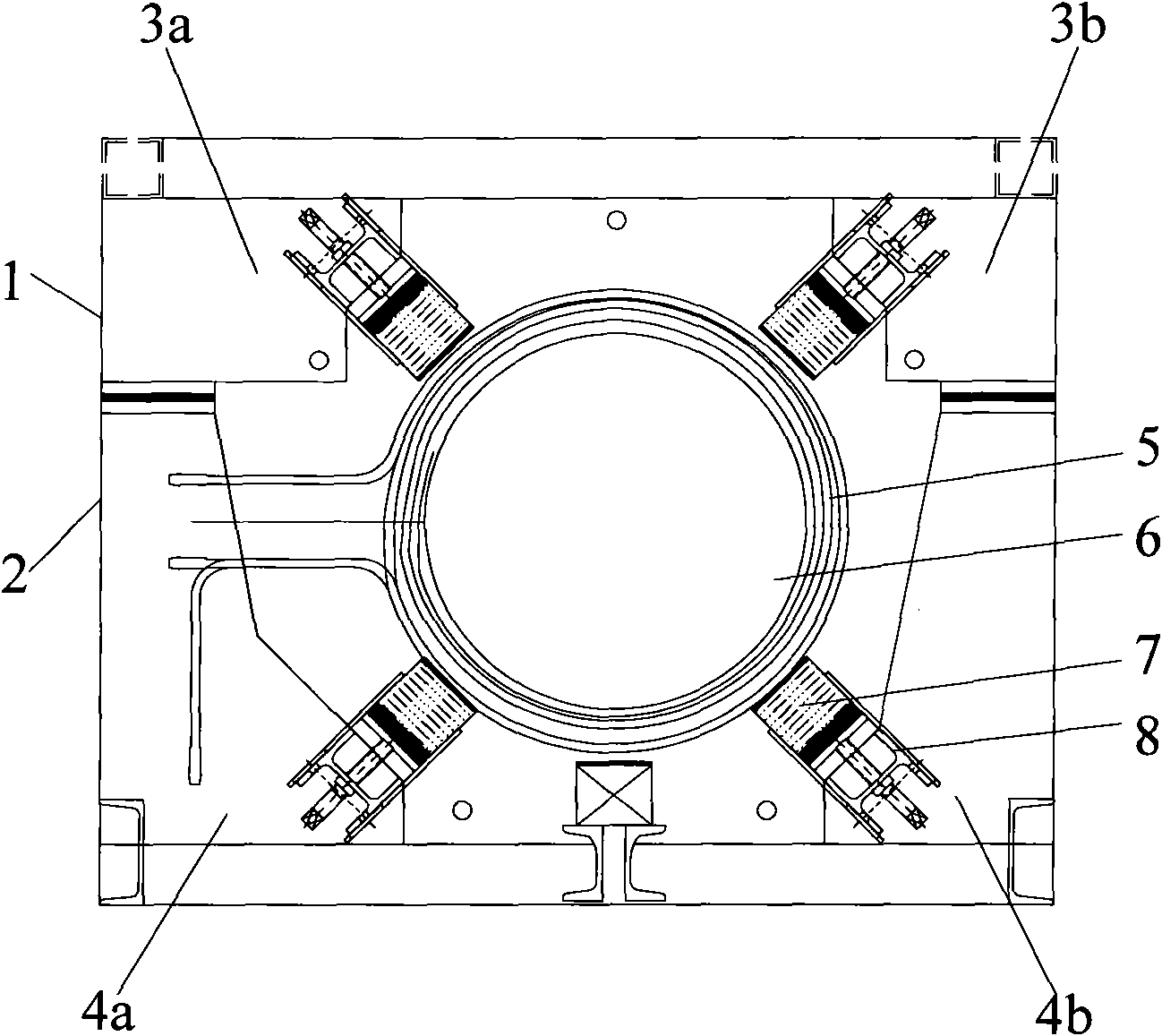

[0029] Induction heating is a direct electric heating method that uses the electromagnetic alternating magnetic field of the coil for energy conversion. The coil with circular flow direction will be concentrated and encapsulated by the heated workpiece, which is equivalent to the principle of transformer. That is to say, a secondary coil is penetrated by the bundle of force lines (magnetic field lines) of the primary coil which varies over time. The primary coil is the induction coil connected on a suitable power source, while the secondary coil is represented by the workpiece being heated itself.

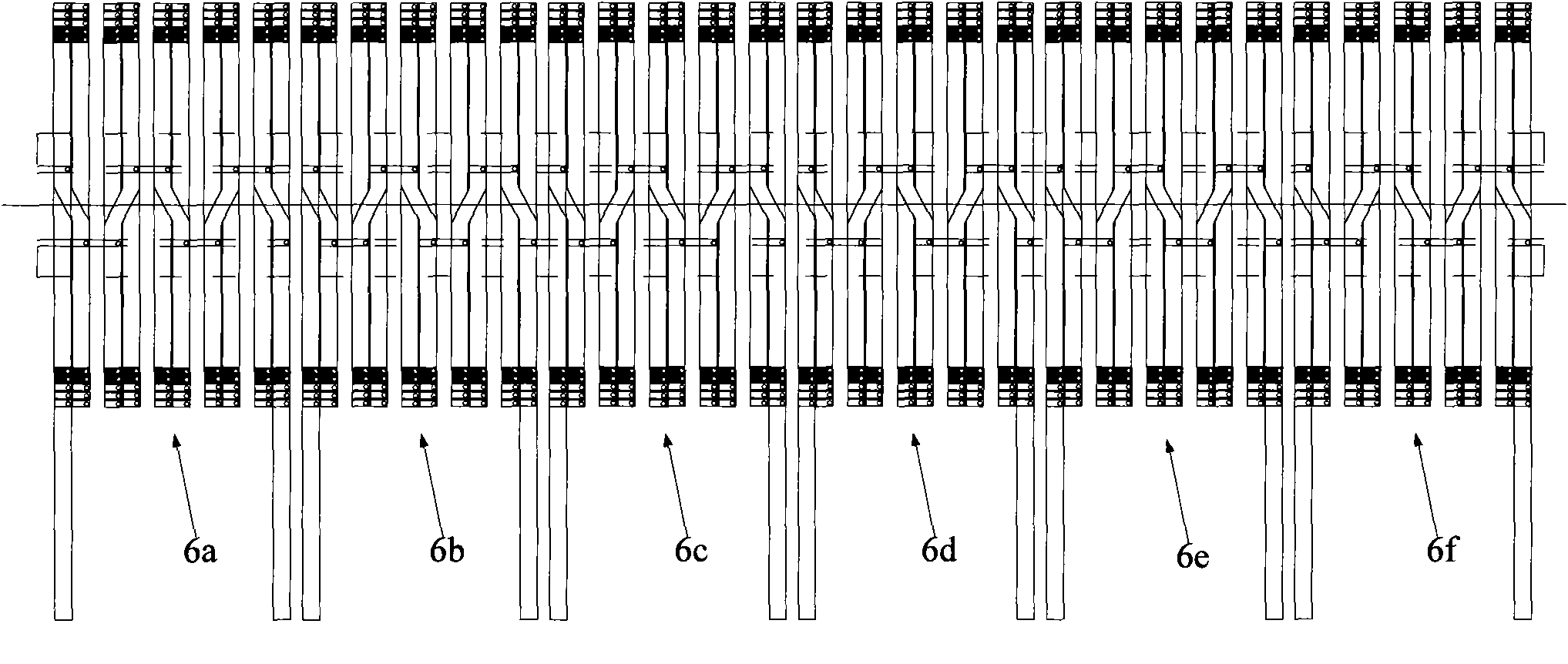

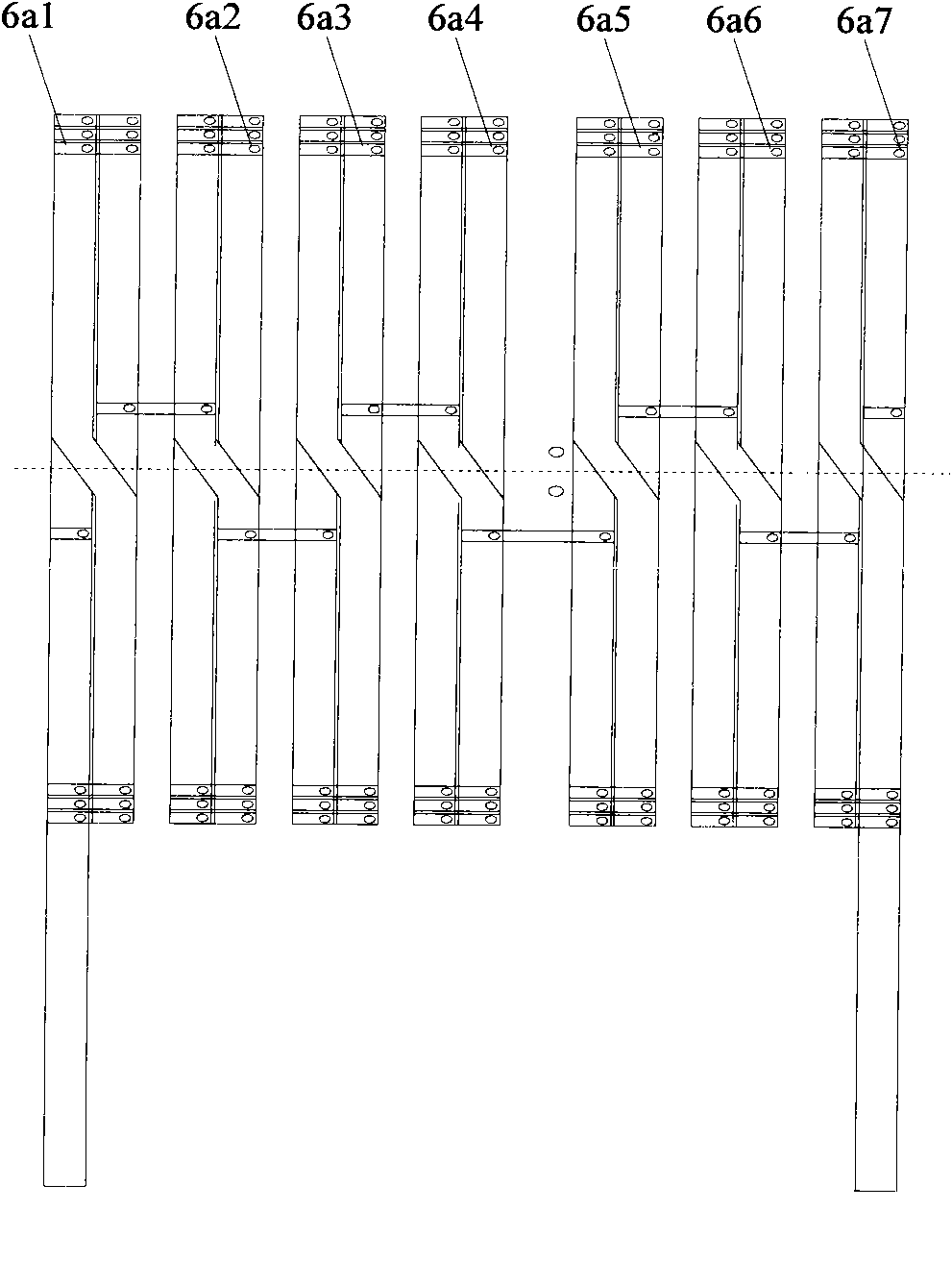

[0030] In order to meet the increasingly higher requirements of the extrusion industry for billet heating equipment, a single billet billet gradient heating system is designed. The new heating furnace is equipped with multiple induction coil sections, and each induction coil section is connected to the power supply separately. It can be controlled separately according to the bille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com