Method for grading catalysts during hydrogenation of medium-low-temperature coal tar

A hydrogenation process and catalyst technology, which is applied in the field of coal chemical industry, can solve the problems of unsatisfactory catalyst strength, heavy maintenance workload, and poor activity effect, and achieve the problems of increasing the active specific surface, solving back-mixing, and weakening the interaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

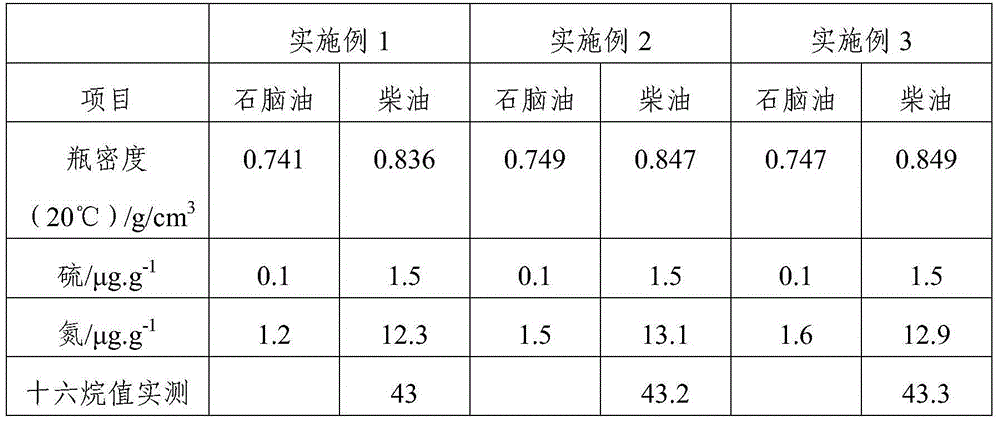

Embodiment 1

[0041] Embodiment 1 Catalyst gradation specific scheme in the middle and low temperature coal tar hydrogenation process

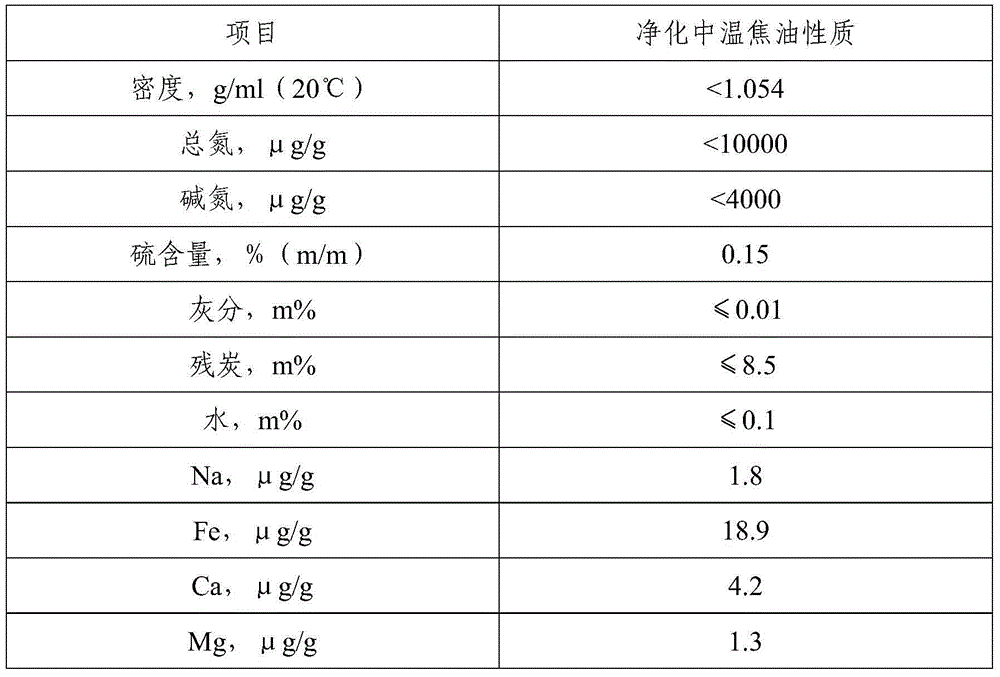

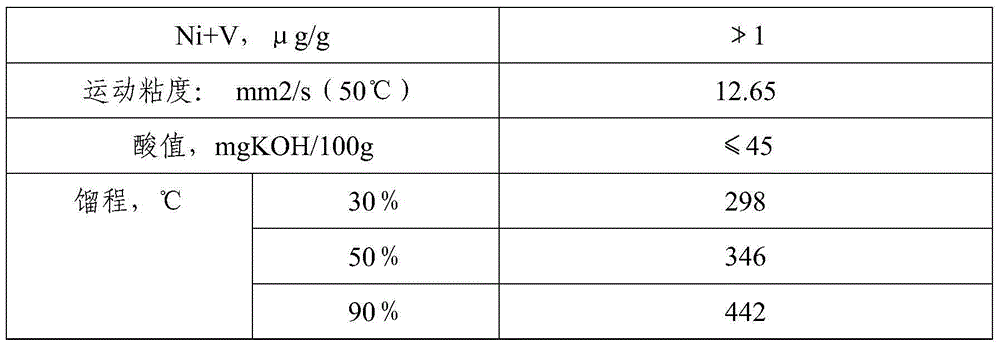

[0042] Mix medium-temperature coal tar, low-temperature coal tar, medium-low temperature coal tar, and shale oil at a weight ratio of 5:7:3:2, and the performance indicators of the raw material oil after mixing are shown in Table 1.

[0043] Table 1

[0044]

[0045]

[0046] The hydrogenation process is as follows: the raw oil and hydrogen are mixed and then enter the No. 1 protection reactor, the No. 2 refining reactor, the No. 3 upgrading reactor, and the high-low separation system to complete the hydrofining stage; the separated liquid enters the fractionation system, The resulting tail oil then enters No. 4 refining reactor, No. 5 cracking reactor, and high-low separation system to complete the hydrocracking stage to obtain light fuel oil;

[0047] Wherein, the loading ratios of the beds and catalysts in the No. 1 protection reactor are as follo...

experiment example 2

[0065] According to the method loading catalyst of embodiment 1, difference is:

[0066] The loading ratios of the beds and catalysts in the No. 1 protection reactor are as follows: the first bed is filled with 55V% demetallization agent, the second bed is filled with 25V% ZDL-T1 agent, and the third bed is filled with 20V% ZDL - T2 agent;

[0067] Each bed of described No. 2 refining reactor and the catalyst loading ratio are: the first bed is filled with 18V% ZDL-J1 agent, the second bed is filled with 17V% ZDL-J1 agent and 19V% ZDL-J2 agent, The third bed layer is filled with 46V% ZDL-J2 agent;

[0068] The loading ratios of the beds and catalysts in the No. 3 reforming reactor are as follows: the first bed is filled with 22V% of the ZDL-G1 agent, the second bed is filled with 19V% of the ZDL-G1 agent and 23V% of the ZDL-G2 agent , the third bed layer is filled with 36V% ZDL-G2 agent;

[0069] The loading ratios of the beds and catalysts in the No. 4 refining reactor are...

experiment example 3

[0075] According to the method loading catalyst of embodiment 1, difference is:

[0076] The loading ratios of the beds and catalysts in the No. 1 protection reactor are as follows: the first bed is filled with 65V% demetallization agent, the second bed is filled with 20V% ZDL-T1 agent, and the third bed is filled with 15V% ZDL - T2 agent;

[0077] The loading ratios of the beds and catalysts in the No. 2 refining reactor are as follows: the first bed is filled with 15V% ZDL-J1 agent, the second bed is filled with 20V% ZDL-J1 agent and 21V% ZDL-J2 agent, The third bed layer is filled with 44V% ZDL-J2 agent;

[0078] The loading ratios of the beds and catalysts in the No. 3 upgrading reactor are as follows: the first bed is filled with 20V% of the ZDL-G1 agent, the second bed is filled with 21V% of the ZDL-G1 agent and 18V% of the ZDL-G2 agent , the third bed layer is filled with 41V% ZDL-G2 agent;

[0079] The loading ratios of the beds and catalysts in the No. 4 refining r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com