Collector layer structure

A technology for collecting layers and conductive substrates, applied in structural parts, electrode carriers/collectors, circuits, etc., can solve problems such as explosion, loss of lithium ions, deposition reaction obstruction, etc., and achieve the effect of solving internal short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

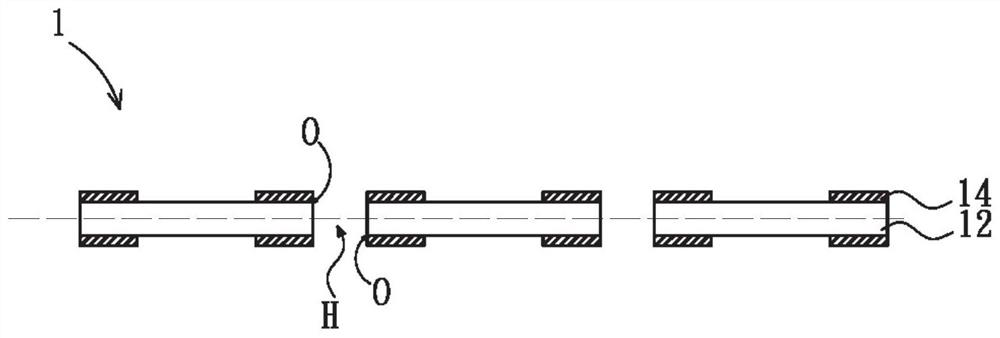

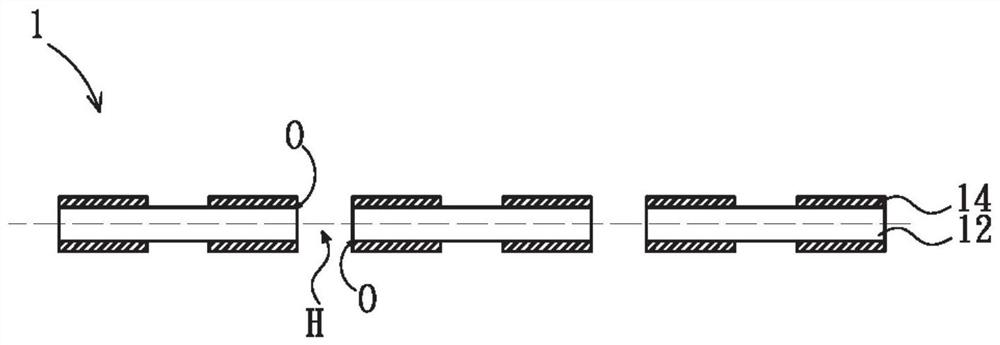

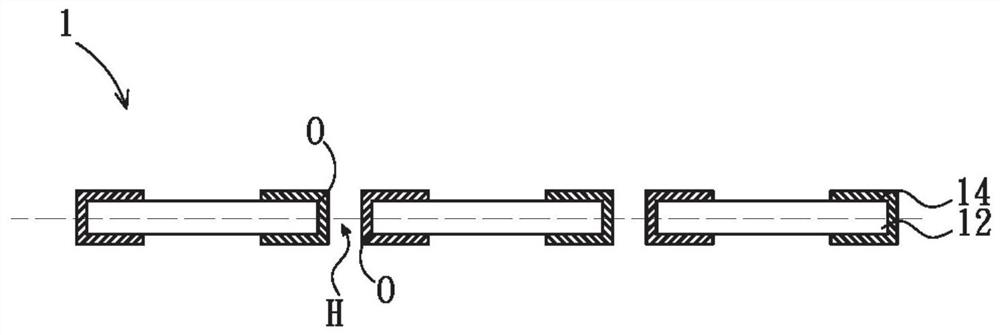

[0042] The spirit of the present invention is to provide a collector layer structure. The collector layer disclosed utilizes the insulating region therein to prevent electrons from contacting the surface close to the opening, so that lithium ions can be avoided during the electrochemical reaction. Deposition, reducing the penetration of lithium synapses through pores to puncture the isolation layer. The collector layer structure includes a conductive substrate and a plurality of insulating regions, wherein the conductive substrate has a plurality of holes, and each hole has two openings, and the insulating region is formed at least covering the periphery of the opening, and can also extend to the edge of the opening. Outside the periphery, and can also extend to at least part of the surface inside the hole, but at least part of the surface of the conductive substrate is exposed, which means that at least part of the surface of the conductive substrate is not covered by the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com