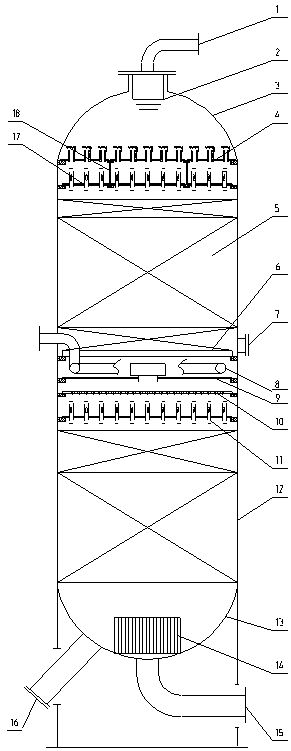

Hydrogenation reactor with impact reduction assembly

A hydrogenation reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of different reaction degrees, radial temperature difference, damage to catalyst performance, etc., and achieve good distribution effect and installation accuracy requirements. Low, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

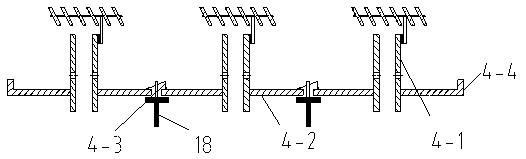

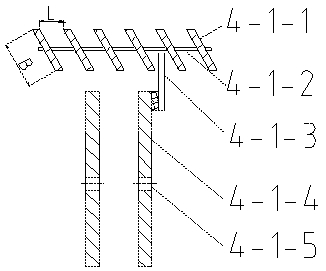

Embodiment 1

[0043] Compared with Comparative Example 1, the embodiment 1 of the present invention adopts the hydrogenation reactor of the present invention, and in the upper head of the hydrogenation reactor, the shock-reducing equalizer plate of the present invention is arranged, and adopts such as figure 2 The surge reducing equalizer disc shown is used in combination with a common ERI type bubble cap gas-liquid distributor. The parameters of the shock-reducing and equalizing plate are: the distance between adjacent grid plates is 100mm; the inclination angle of the grid plate is 30°; the width of the grid plate is 100mm; Two circular overflow holes are arranged horizontally on the top, and the total cross-sectional area of the overflow holes is 30% of the cross-sectional area of the downcomer; the center line of the overflow hole is 50mm away from the upper surface of the tray; The height of the space between the uppermost edges of the tubes is 50mm. The tray is assembled from 9 ...

Embodiment 2

[0045] Same as Example 1, the difference is that the conventional ERI gas-liquid distributor in the field in the original hydrogenation reactor is canceled, and only the buffering and equalizing plate provided in the present invention is retained, the bed radial temperature and See Table 1 for the temperature difference.

[0046] Table 1 Application Results

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com