A grid-type shock-reducing flow equalizer

A grille and flow plate technology, applied in the field of reactor internals, can solve problems affecting the effect of hydrogenation reactor distributors, uneven depth of liquid layer on the distribution plate, weak ability to resist plate tilting, etc., to achieve fine The effect of optimized adjustment, smooth and uniform inlet conditions, and low requirements for installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

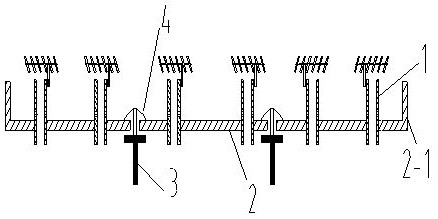

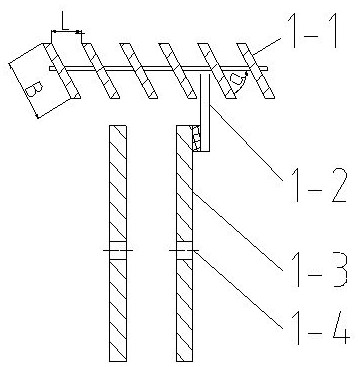

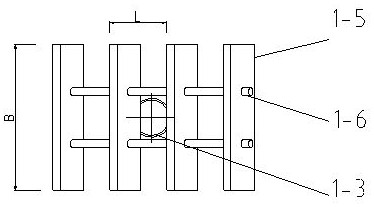

[0044] Compared with Comparative Example 1, in Example 1 of the present invention, the grid-type shock-reducing flow equalizer of the present invention is arranged in the upper head of the hydrogenation reactor, using such as figure 1 The grid-type shock-reducing equalizer shown is used in combination with a common ERI-type bubble-cap gas-liquid distributor. The parameters of the grid-type impact-reducing flow-distributor are as follows: the number of the grids and the descending pipes are the same, and the grids and the descending pipes are arranged in a vertical structure. There is a space between the lower surface of the grid and the uppermost edge of the downcomer, and the height of the space is 50mm. The grid includes a grid plate and a grid plate connecting rod, and 6 grid plates are connected together by a grid plate connecting rod to form a grid, and the 6 grid plates are arranged in parallel in the horizontal direction, And the grid plate is arranged obliquely, and t...

Embodiment 2

[0046] Same as Example 1, the difference is that the conventional ERI gas-liquid distributor in the field in the original hydrogenation reactor is canceled, and only the grid-type anti-flush equalizer provided in the present invention is retained, and the bed diameter is The temperature and temperature difference are shown in Table 1.

[0047] Table 1 Application Results

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com