Evaporation device and evaporation method

A technology for vapor deposition and vapor deposition materials, which is applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of uneven heating of vapor deposition materials, waste of vapor deposition materials, and blockage of openings, etc. Achieve the effect of reducing radial temperature difference, improving utilization rate, and improving heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

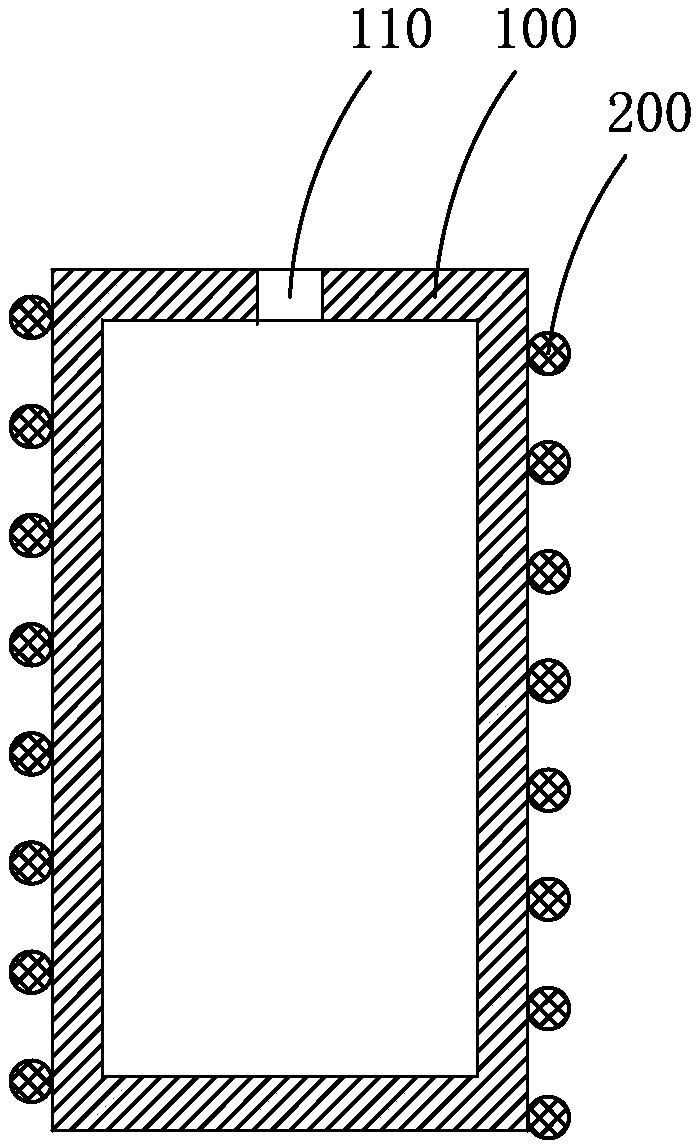

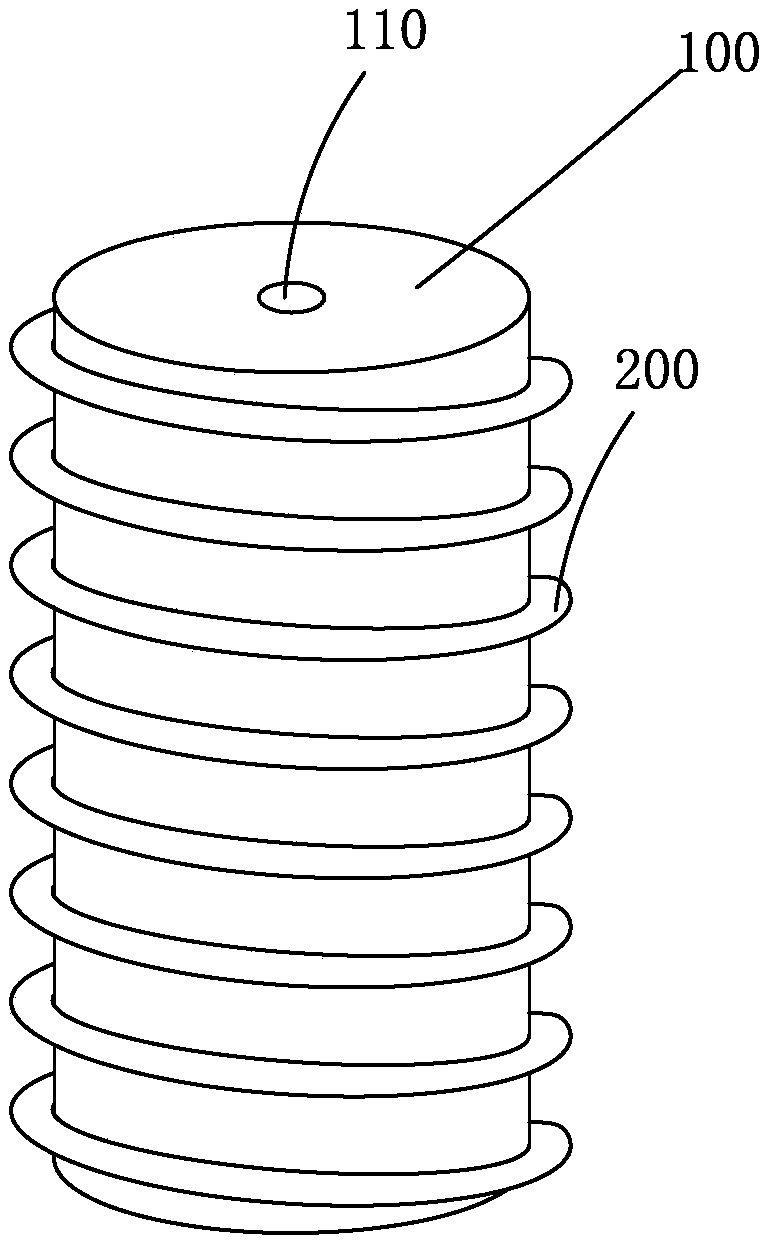

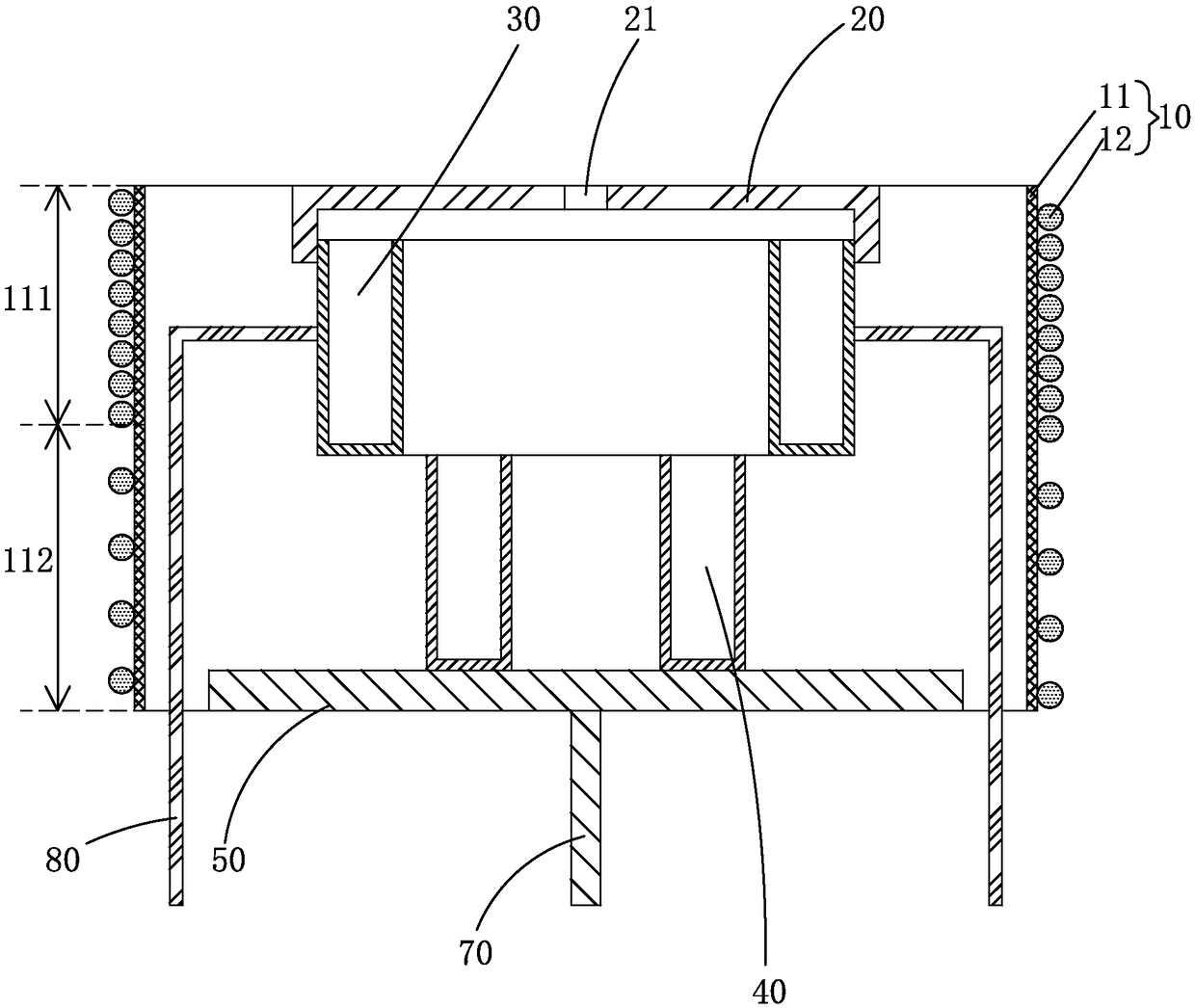

[0068] see Figure 13 , and combined with Figure 14 and Figure 15 , the first embodiment of the evaporation method of the present invention is applied to the first embodiment of the above-mentioned evaporation device, including the following steps:

[0069] Step S1, please refer to Figure 14 , the evaporation material 1 is placed in the first crucible 30 and the second crucible 40 , and the moving part 50 is moved by the rod part 70 so that the second crucible 40 is located under the first crucible 30 .

[0070] Step S2, energize the heating wire 12, the heating wire 12 heats the evaporation material 1 in the first crucible 30 to evaporate and discharge it through the opening 21, and at the same time, the heating wire 12 heats the evaporation material 1 in the second crucible 40 warm up.

[0071] Specifically, since the density of the heating wire 12 in the first region 111 is greater than that in the second region 112, when the same amount of electricity is supplied, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com