Metal Element Lattice Doped Silicon Carbide Reactor and Its Application in Ethane Dehydrogenation to Ethylene

A metal element, silicon carbide technology, applied in the field of new reactors, to achieve good ethane conversion rate and ethylene selectivity, reduced energy consumption, and excellent heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

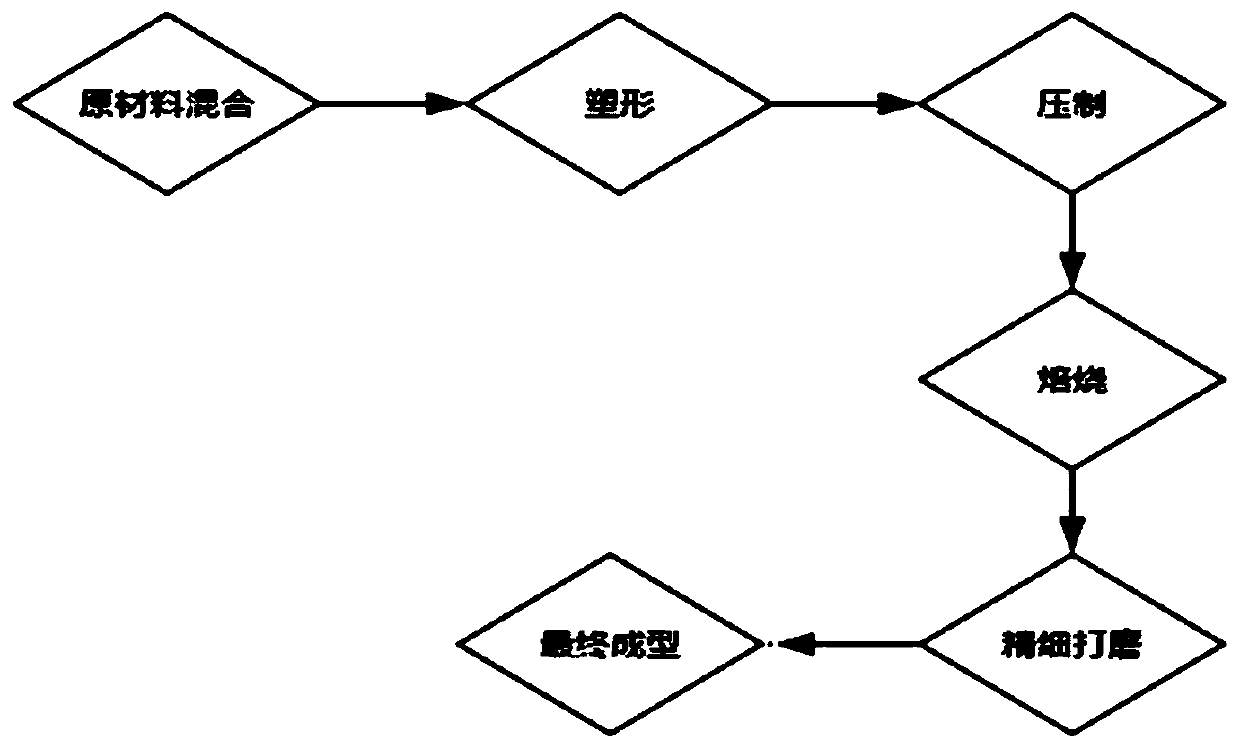

Method used

Image

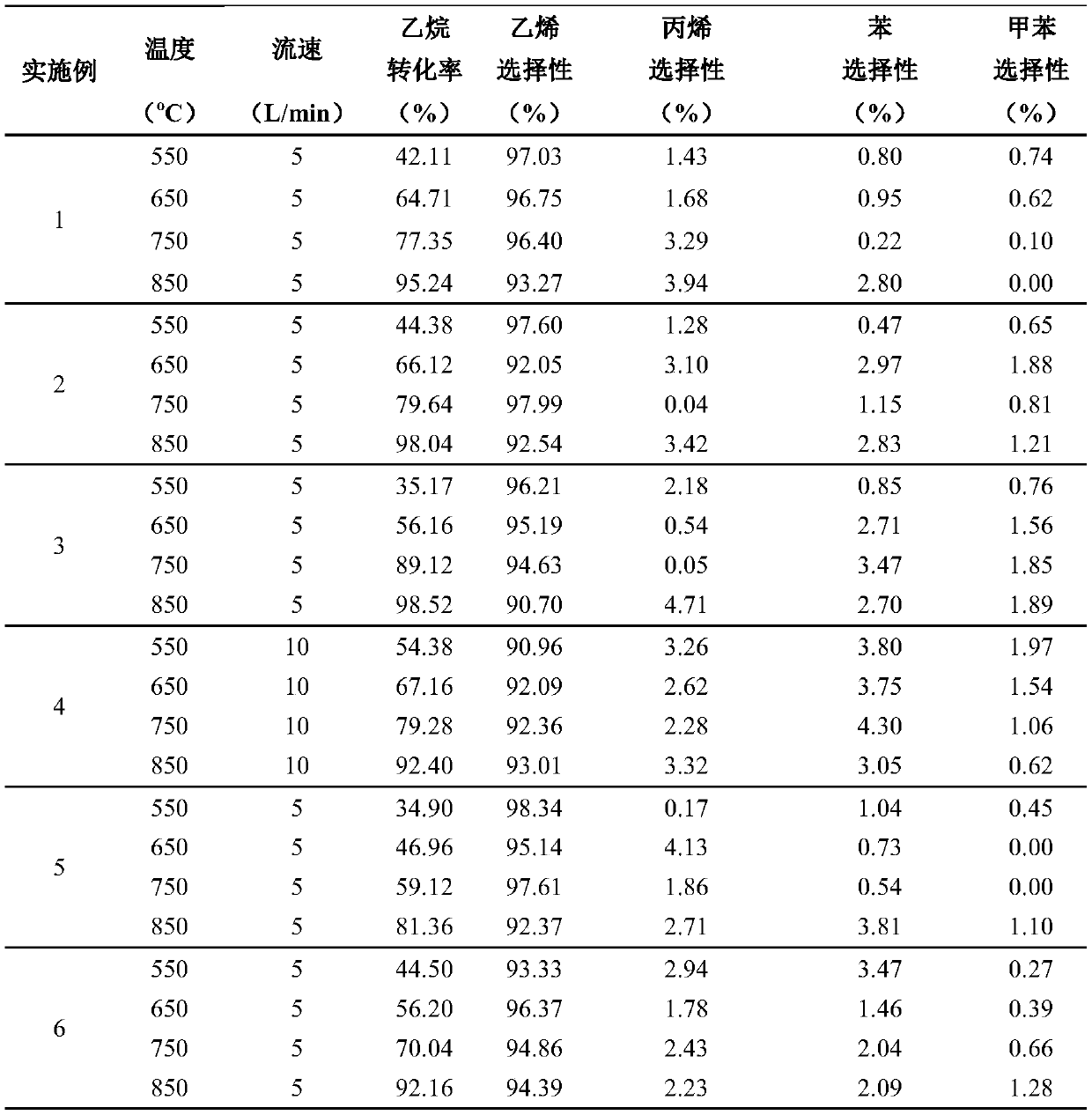

Examples

Embodiment 1

[0028] Mix 1kg SiC powder, 300g high-purity graphite powder, 300g silicon powder, 20g ferric nitrate, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 100-400nm and silicon powder with a particle size of 100μm. , sent to the extruder for extruded molding, the molding reactor is a straight tube type, 2 meters in length, 35mm in outer diameter, 25mm in inner diameter, after 4 days of natural drying, it is sent into a 50v muffle furnace to continue drying and dehumidification, and continue to dry and dehumidify in N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 2 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R1.

Embodiment 2

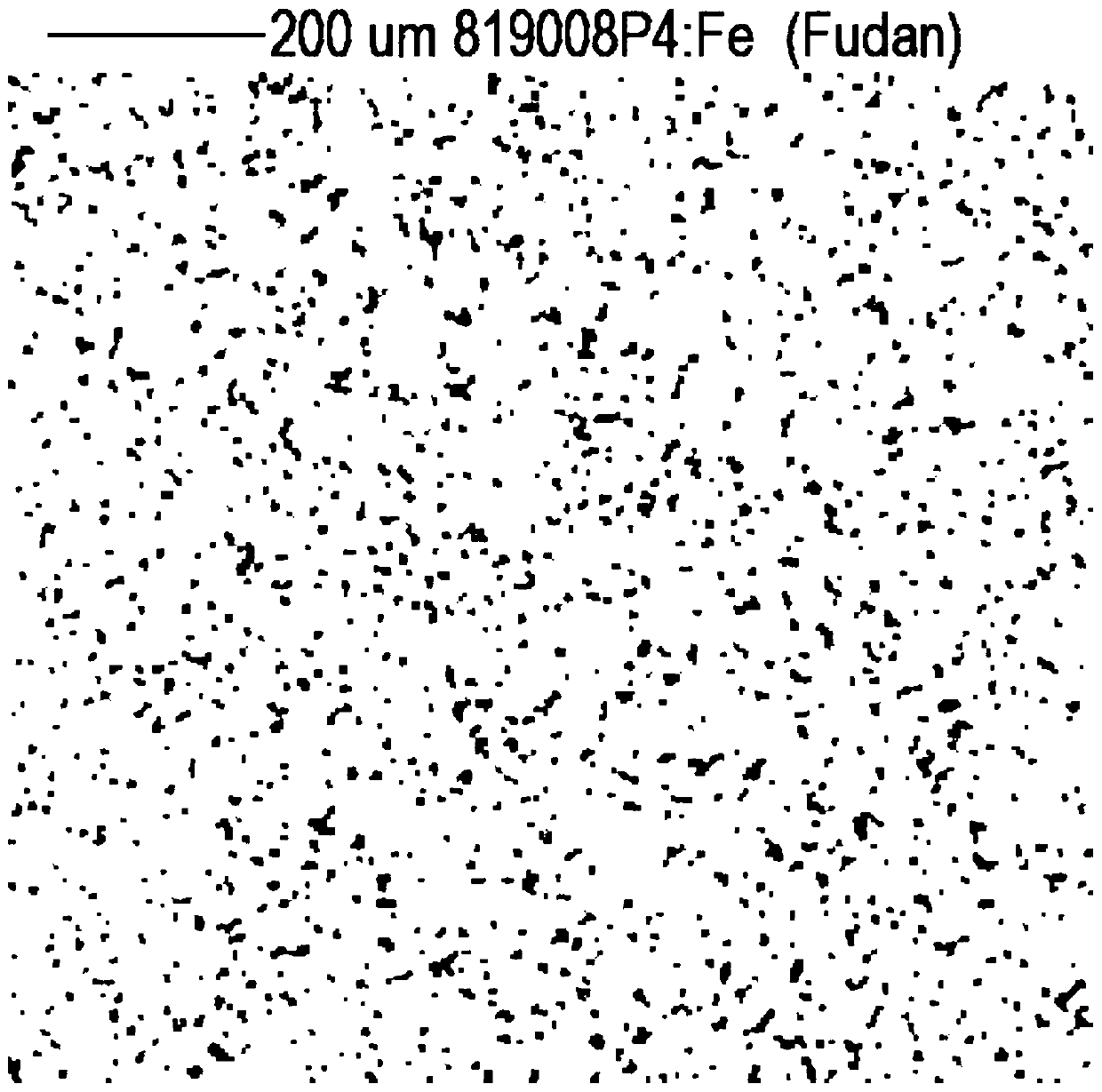

[0030] Mix 1kg SiC powder, 200g high-purity graphite powder, 200g silicon powder, 20g ferric chloride, 100mL epoxy resin, and 100mL water. The SiC powder is α-SiC with a particle size of 300-1000nm. 100 μm, sent to the extruder for extruded molding, the forming reactor is a straight tube type, 2 meters in length, 15mm in outer diameter, 5mm in inner diameter, after 4 days of natural drying, it is sent to a muffle furnace at 50°C to continue drying and dehumidification, and then Carry out pressing treatment, pressing pressure is 100Mpa, and pressing time is 30 minutes. continue at N 2 Under the protection of , it was treated in a high-temperature furnace at 2000°C for 3 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R2. figure 2 It is the proton fluorescence spectrogram of the inner wall of the reactor, and the bright spots are Fe atoms, indicating that the distribution of Fe is very uniform.

Embodiment 3

[0032] Mix 1kg SiC powder, 100g carbon black powder, 100g silica powder, 40g nickel chloride, 200mL epoxy resin, and 200mL water evenly. The SiC powder is α-SiC with a particle size of 300-500μm, and the silica The particle size of the powder is 200μm, and it is sent to the extruder for extrusion molding. The forming reactor is a straight tube type, with a length of 2 meters, an outer diameter of 25mm, and an inner diameter of 15mm. After natural drying for 4 days, it is sent to a muffle furnace at 50°C for further drying. Dehumidification continues at N 2 Under the protection of the reactor, it was treated in a high-temperature furnace at 2000°C for 4 days, taken out after cooling down, and the surface of the reactor was finely polished to obtain reactor R3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com