Patents

Literature

49results about How to "Excellent extrusion formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

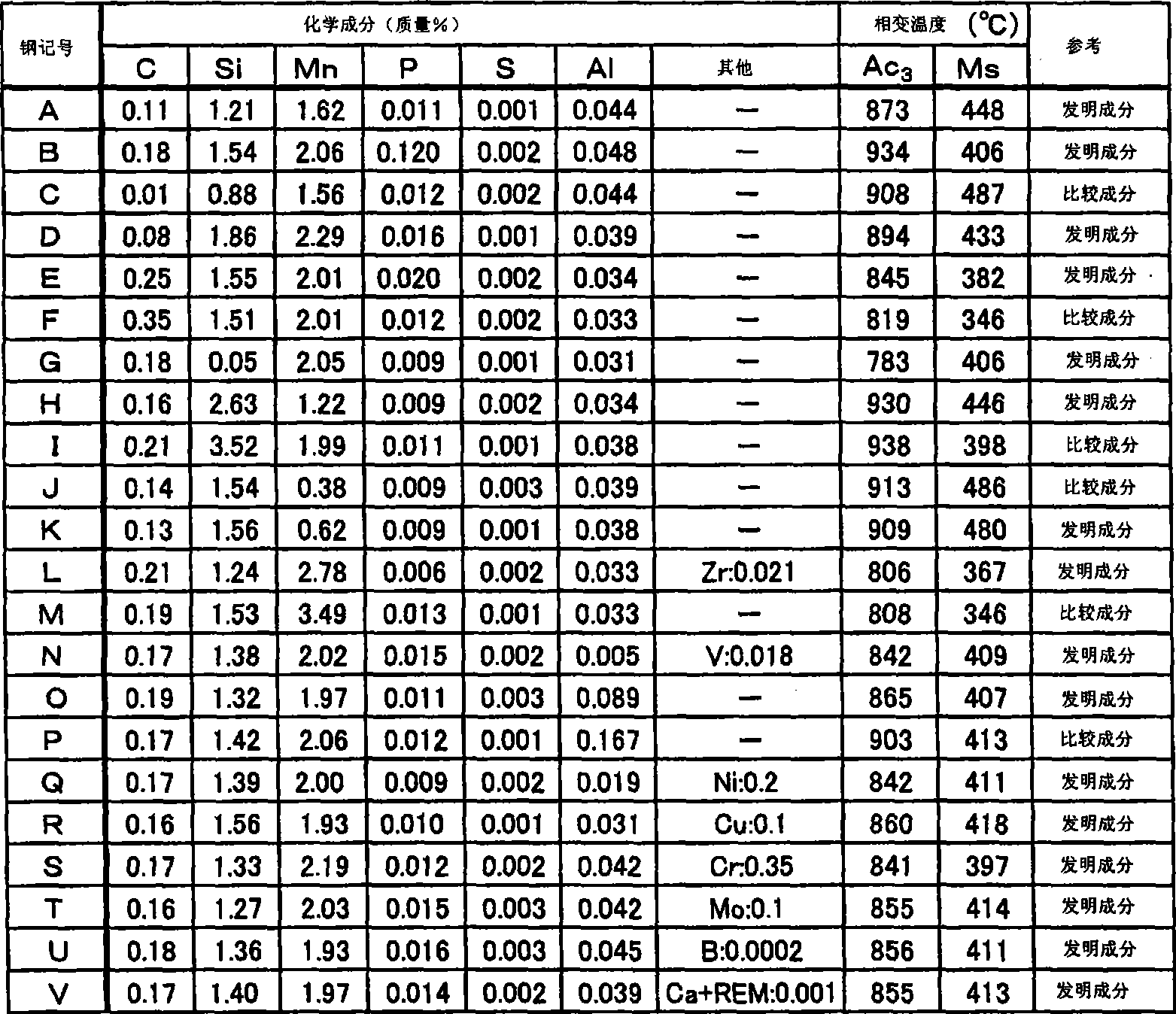

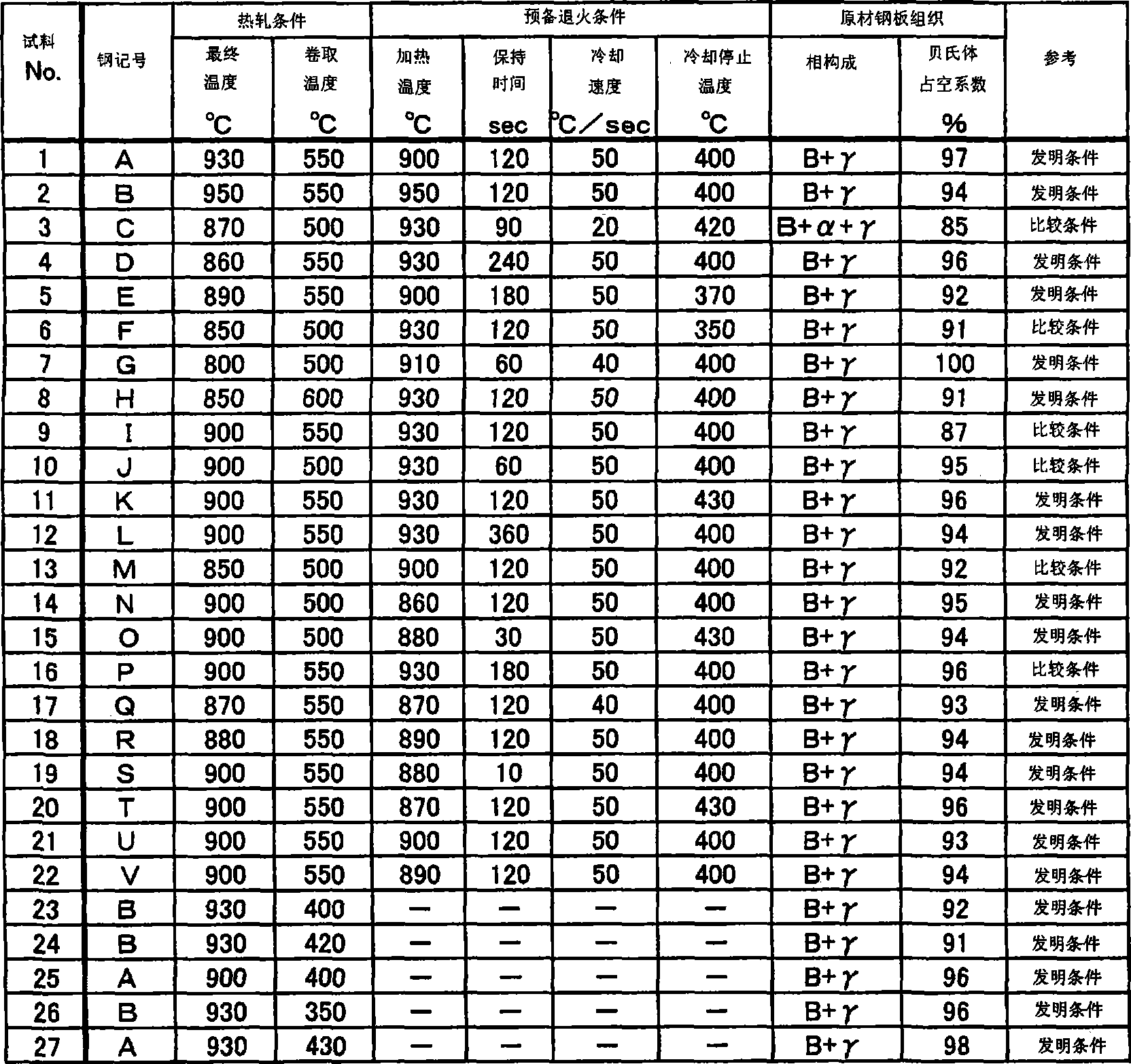

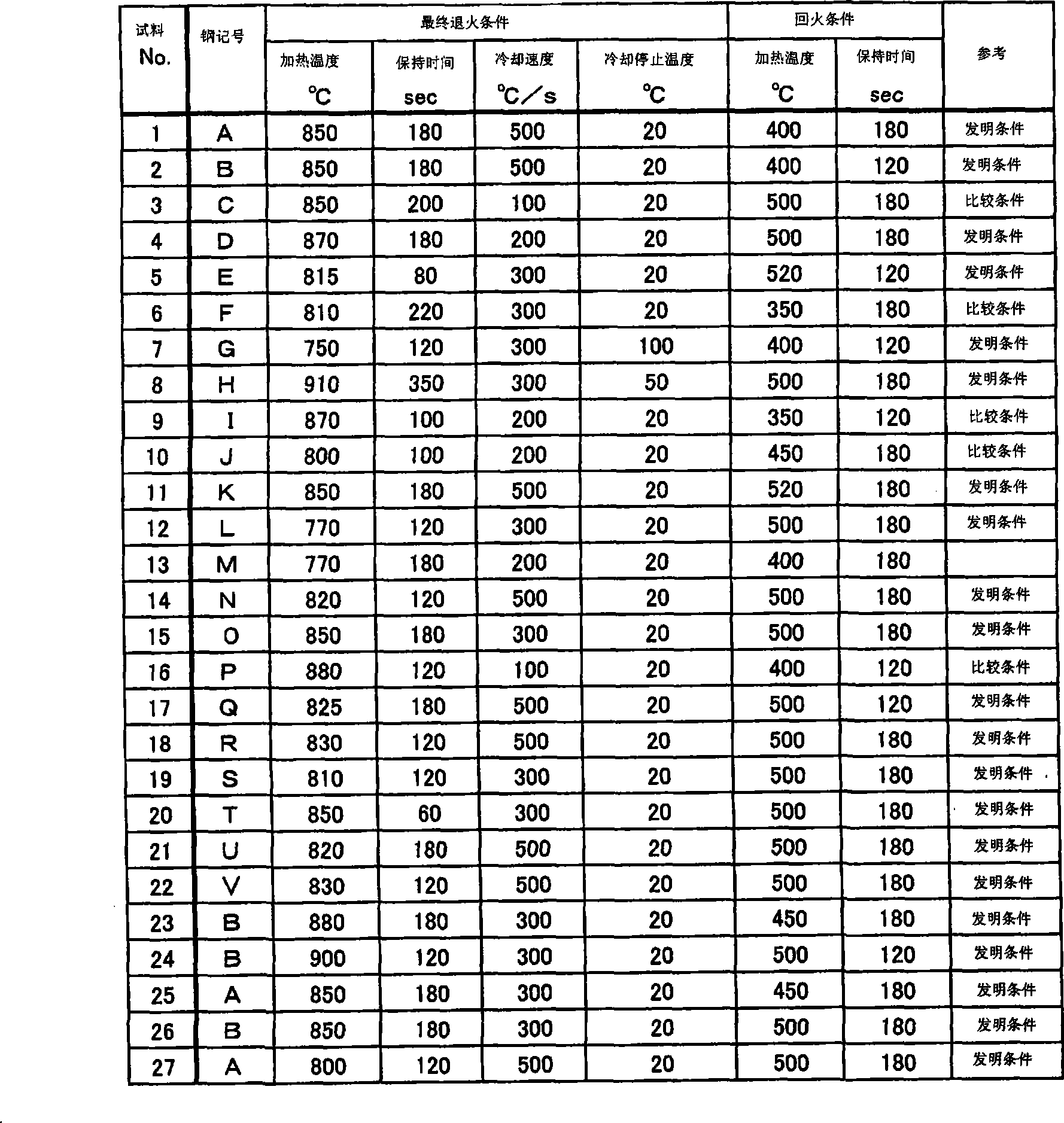

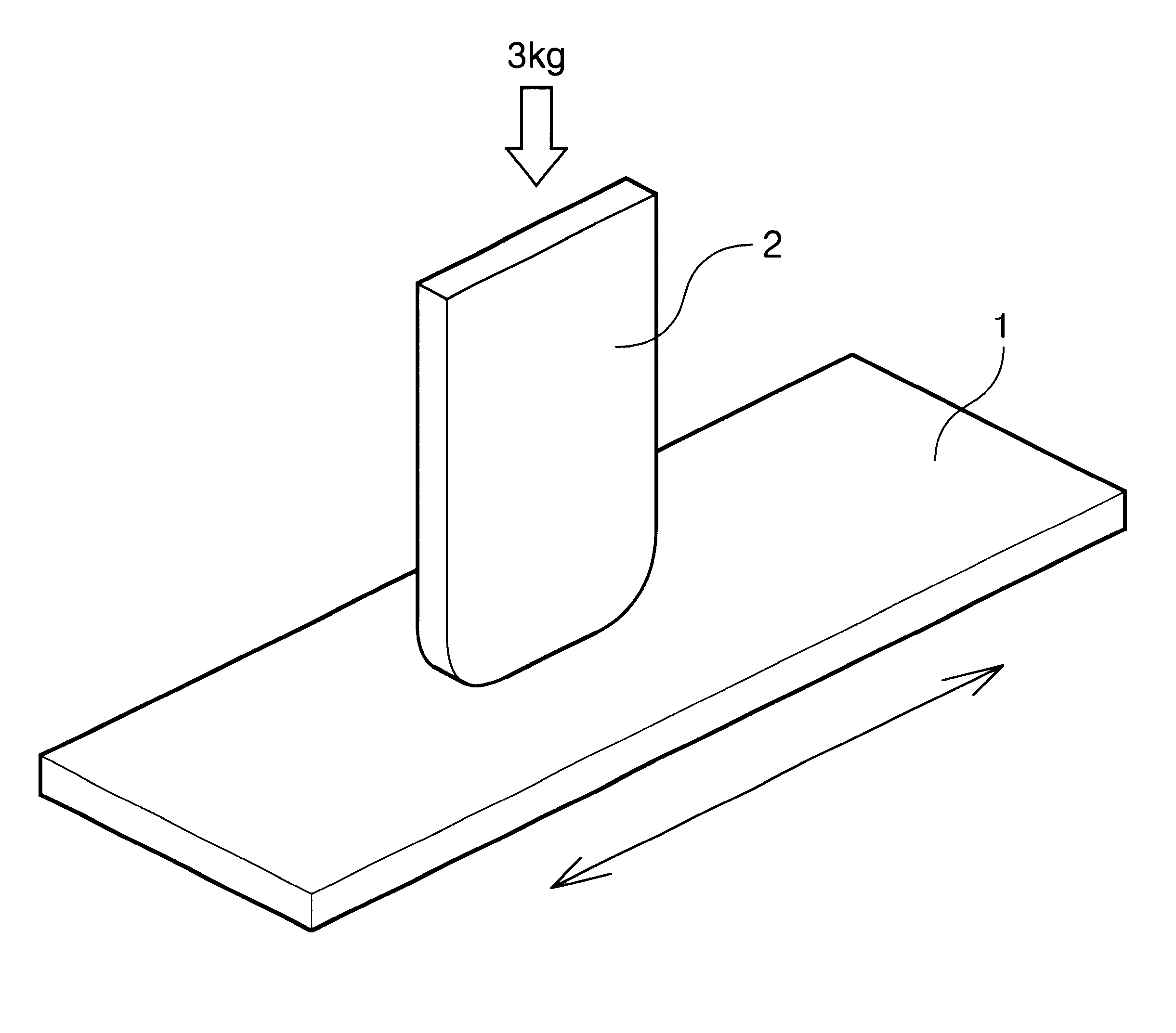

High-strength steel sheets and processes for production of the same

InactiveCN101460647AHigh strengthHigh elongationFurnace typesHeat treatment furnacesUltimate tensile strengthAustenite

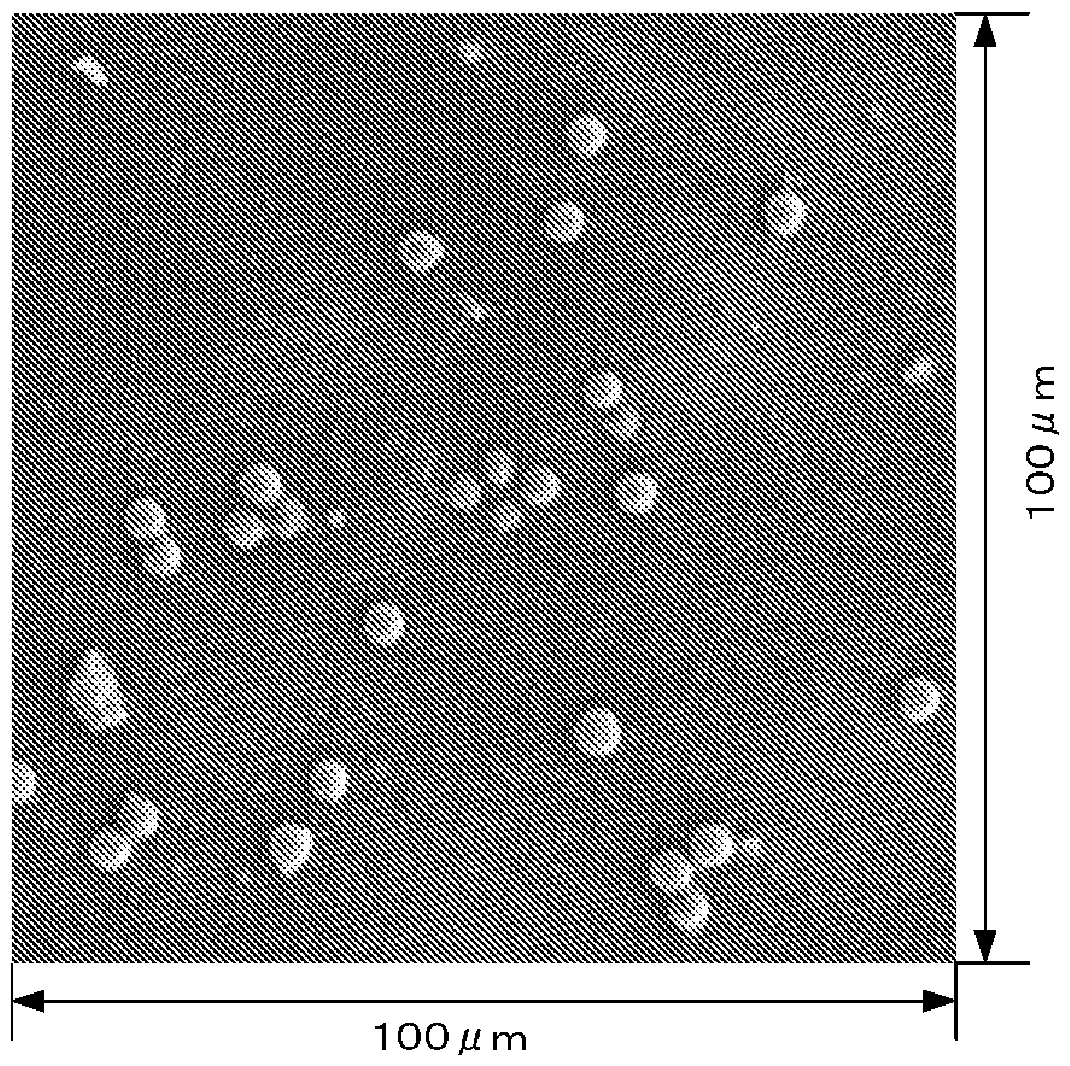

A high strength steel sheet with both excellent elongation and stretch-flanging performance is provided. The high strength steel sheet of the present invention comprises, in percent by mass, C: 0.05 to 0.3%, Si: 0.01 to 3.0%, Mn: 0.5 to 3.0%, Al: 0.01 to 0.1%, and Fe and inevitable impurities as the remainder, and has a structure mainly composed of tempered martensite and annealed bainite. The space factor of the tempered martensite is 50 to 95%, the space factor of the annealed bainite is 5 to 30%, and the mean grain size of the tempered martensite is 10 [mu]m or smaller in terms of the equivalent of a circle diameter. The steel sheet has a tensile strength of 590 MPa or higher. The high strength steel sheet of the present invention has a space factor of the martensite phase which is a main component of the metal structure is 80% or higher; the mean grain size of the martensite phase is 10 [mu]m or smaller in terms of the equivalent of a circle diameter; in the martensite phase, the space factor of the martensite phase having a grain size of 10 [mu]m or larger in terms of the equivalent of a circle diameter is 15% or lower; and the space factor of the retained austenite phase in the metal structure is 3% or lower. The high strength steel sheet of the present invention is a dual phase steel sheet mainly composed of a ferrite phase and martensite, and the space factor of the ferrite phase is 5 to 30%, and the space factor of the martensite phase is 50 to 95%. Moreover, the ferrite phase is annealed martensite.

Owner:KOBE STEEL LTD

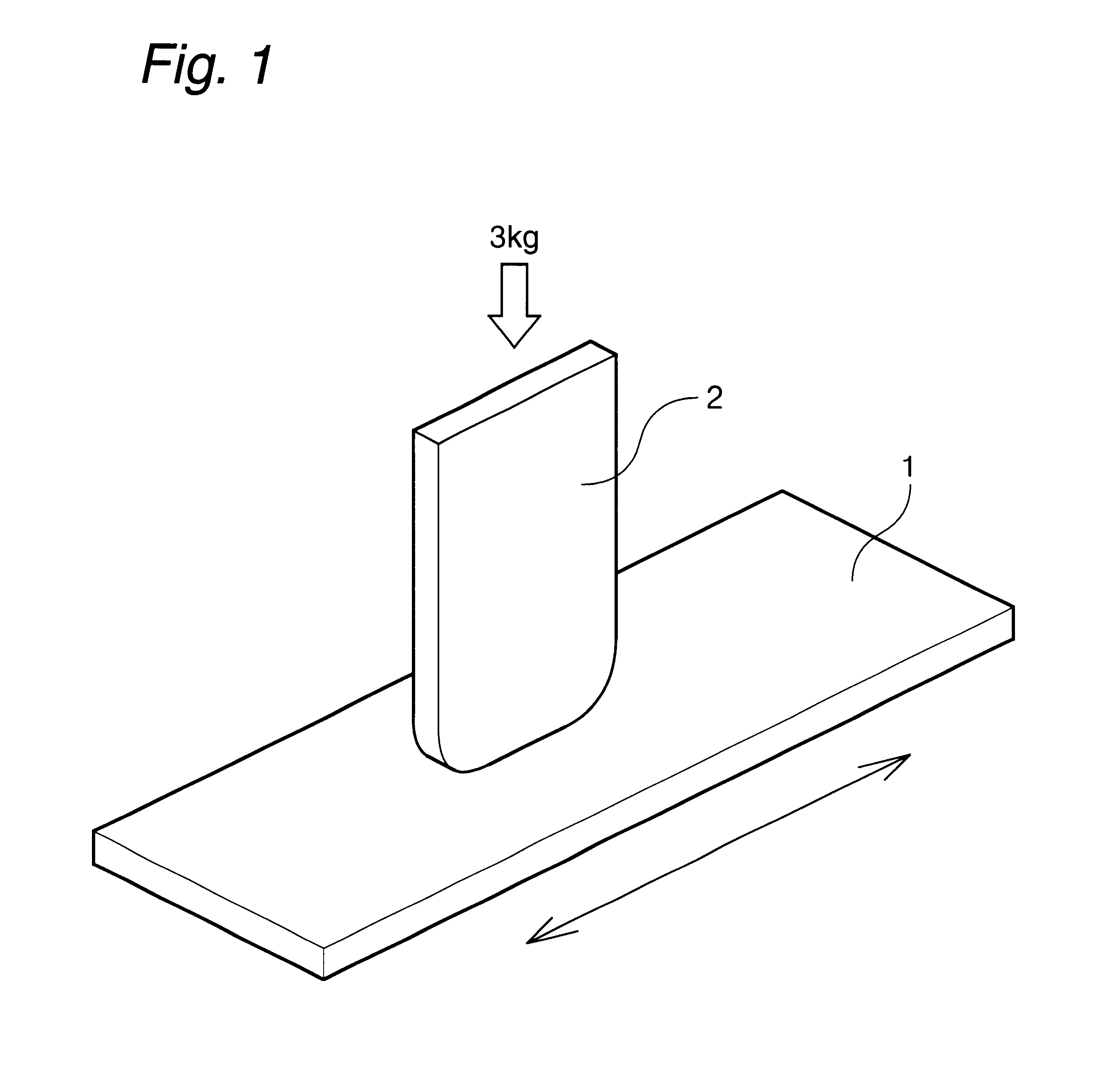

High lubricity, multi-layer polyolefin laminate

InactiveUS6706385B1Easy to slideImprove wear resistanceEngine sealsSynthetic resin layered productsPolymer sciencePolyolefin

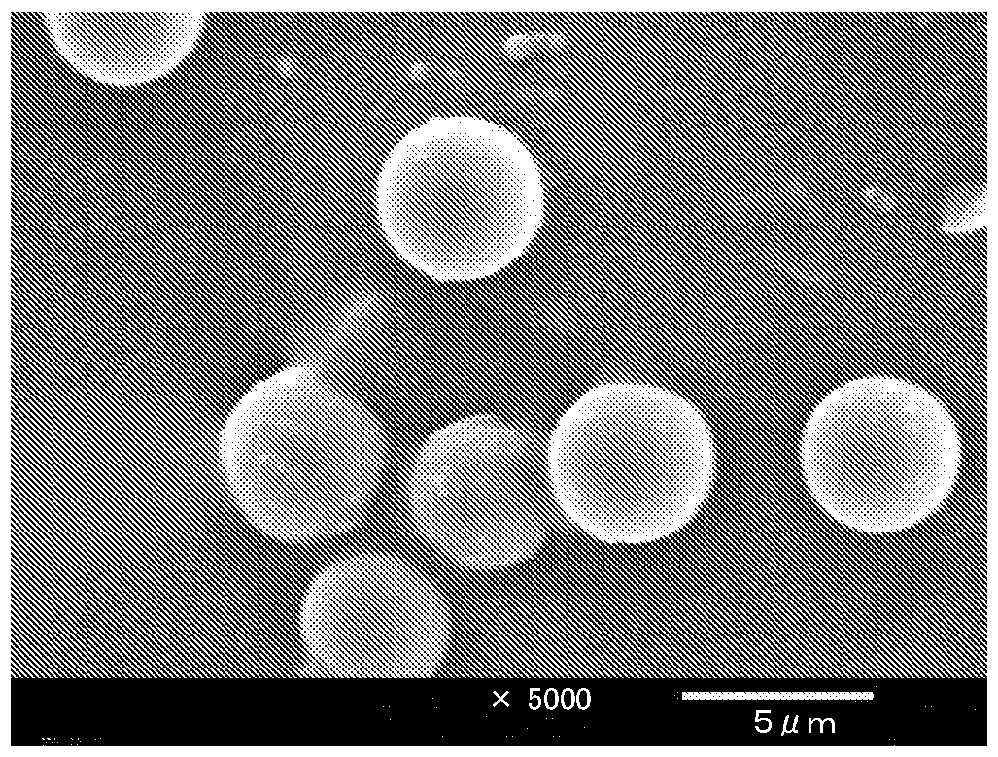

The laminate of the invention comprises a sliding member of a resin composition and a Substrate layer of a thermoplastic olefin elastomer (A), and is obtained by co-extruding: the resin composition which is obtained by melt kneading a thermoplastic olefin elastomer (A), an ultra-high-molecular weight polyolefin (except a powder thereof having a particle diameter of 1 to 100 mum) having an intrinsic viscosity, as measured in a decalin solvent at 135° C., of 1 to 40 dl / g, an inorganic or organic filler powder, and optionally, a polyolefin resin, an organopolysiloxane, a fatty acid amide and a fluororubber in a twin-screw extruder, and the thermoplastic olefin elastomer (A). The laminate has excellent sliding properties with window glass and excellent abrasion resistance. Moreover, the laminate can be produced by a simple process because it requires no adhesive, and the laminate has great bonding strength between the substrate layer and the sliding member layer.

Owner:MITSUI CHEM INC

Ethylene-based polymer resin

An ethylene-based polymer resin which is obtained by copolymerizing ethylene with an α-olefin having 5 to 20 carbon atoms, and has a melt flow rate (MFR) measured at 190° C. under a load of 21.18 N according to JIS K7210-1995, of not less than 0.01 g / 10 min. and less than 1 g / 10 min., wherein the melt flow rate and a melt tension(MT) at 190° C. (unit: cN) of the resin satisfy a relation of the following expression (1) and an intrinsic viscosity [η] (unit: dL / g) and the melt flow rate of the resin satisfy a relation of the following expression (2):2×MFR−0.59<MT<3.6×MFR−0.66 (1)1.02×MFR−0.094<[η]<1.50×MFR−0.156 (2).

Owner:SUMITOMO CHEM CO LTD

Nylon 12, nylon composition, method for producing nylon 12, and tubular molded product using nylon 12

InactiveUS6294644B1Excellent characteristicsIncrease flexibilitySemiconductor/solid-state device manufacturingThin material handlingNylon materialNylon 12

Disclosed is a member of nylon 12 having a relative viscosity of from 1.9 to 3.5 when measured in 98% sulfuric acid at a concentration of 10 g / dm.sup.3 and at 25.degree. C. and a melt flow rate of 0.1 g / 10 min. or more when measured at 235.degree. C. under a load of 2,160 g, wherein said relative viscosity and said melt flow rate have a relationship of the following formula (I): wherein .eta..sub.r is relative viscosity and MFR is melt flow rate. The nylon 12 has excellent extrusion moldability and creep characteristics, fatigue characteristics and the like mechanical properties and is suited for tubular molds. A nylon 12 composition comprising the nylon 12 having the above-described specific relationship between .eta..sub.r and MFR and a plasticizer is also disclosed.

Owner:UBE IND LTD

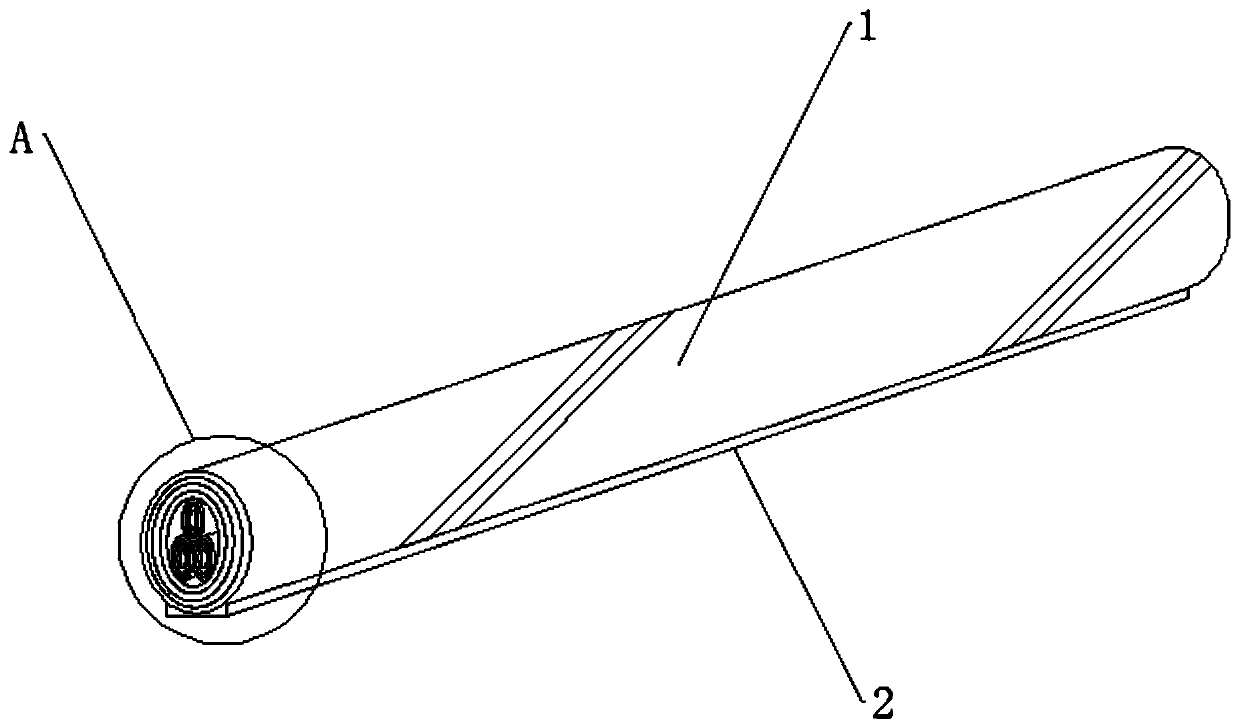

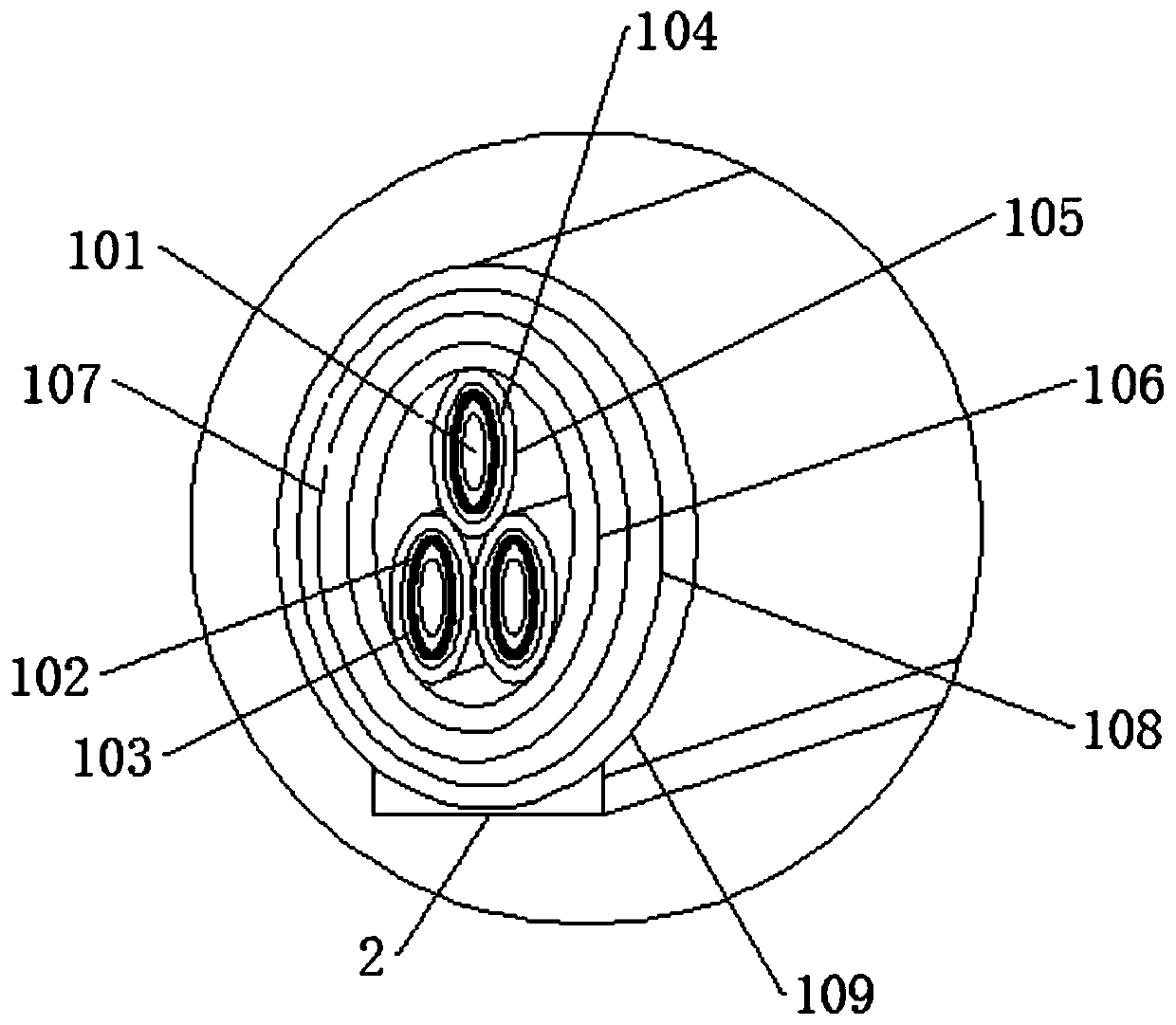

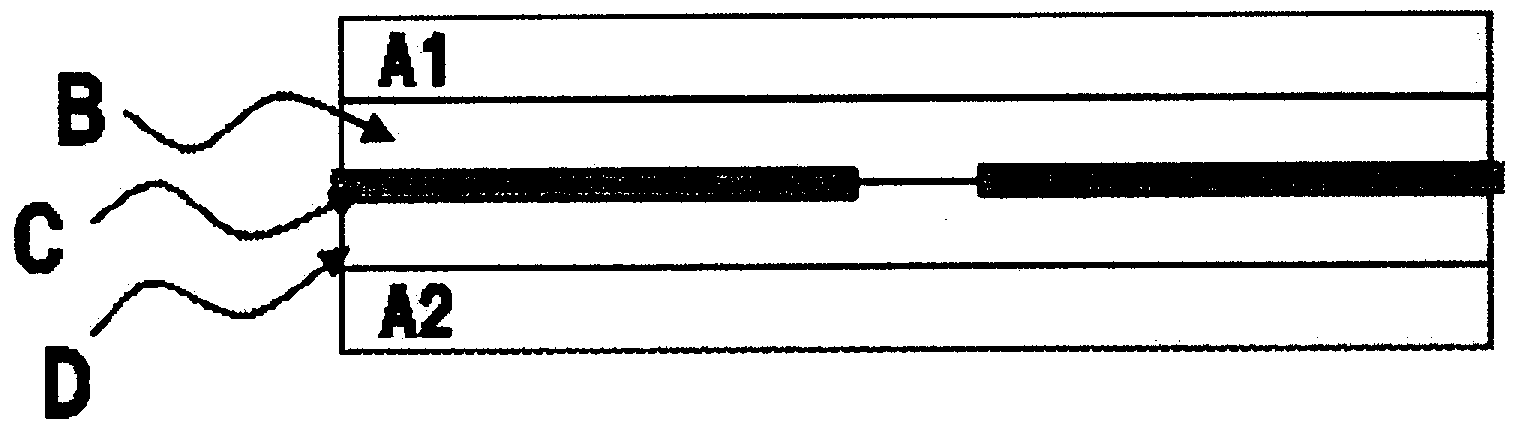

Wall-laminated self-setting type strong-power cable

ActiveCN109767870AEasy to layImprove insulation performanceClimate change adaptationPower cables with screens/conductive layersViscous liquidPower cable

The invention discloses a wall-laminated self-setting type strong-power cable and belongs to the technical field of cables. A wall-laminated self-setting type strong-power cable can be laid on the surface of a wall conveniently, the adsorption characteristic of a nanometer sucker is utilized, the cable is indirectly fixed for a long time under the action of the atmospheric pressure, effective fixing is realized under the condition of not damaging the cable, under the auxiliary action of liquid water and high-viscosity viscous liquid, the sealing performance of the nanometer sucker is improvedand the adsorption strength is further improved, a damping energy dissipation function is provided to counteract external force, meanwhile, the memory characteristic of shape memory alloy is used forhelping the cable to achieve self-setting, the laying mode is simple and fast, the lines laminated to the wall are straight, the aesthetic degree is remarkably improved, the cable is excellent in electrical insulation performance, high-temperature resistance and mechanical strength, and the service life of the cable is prolonged.

Owner:桂昌线缆集团有限公司

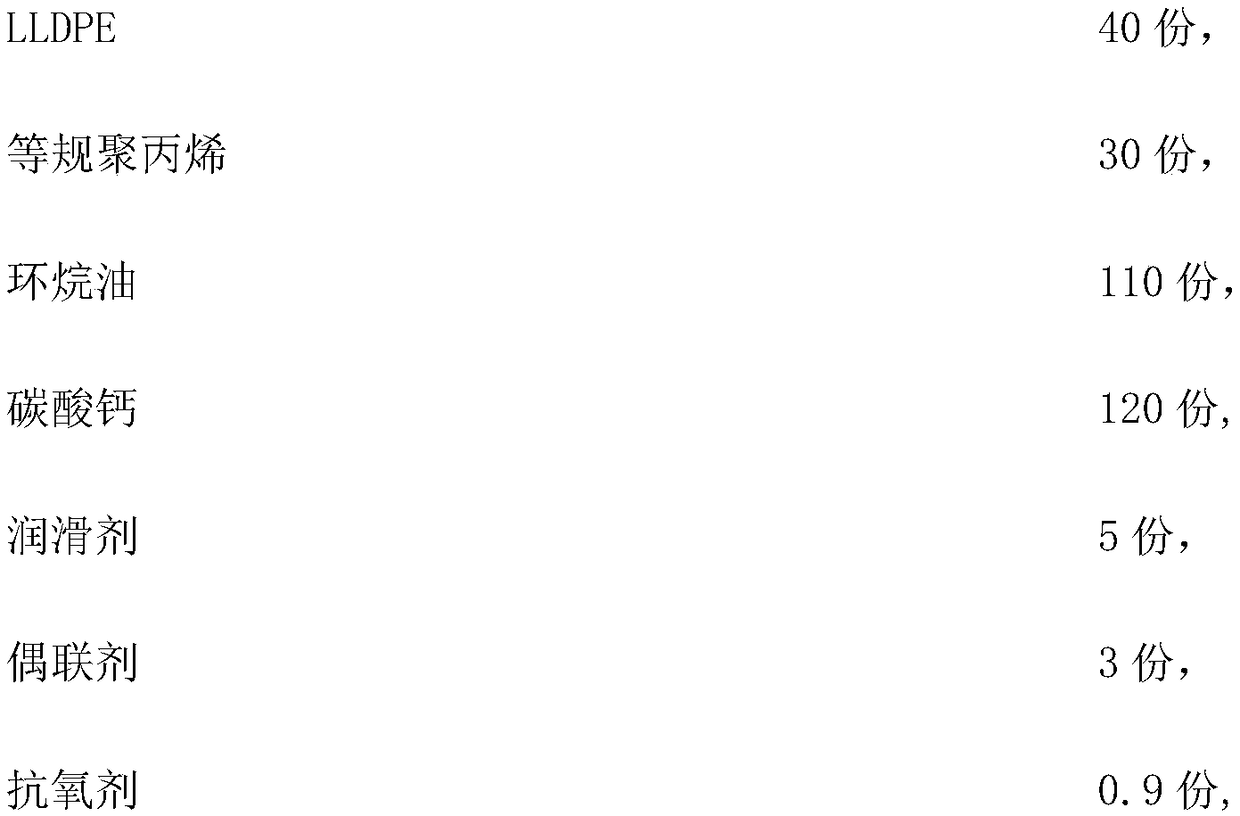

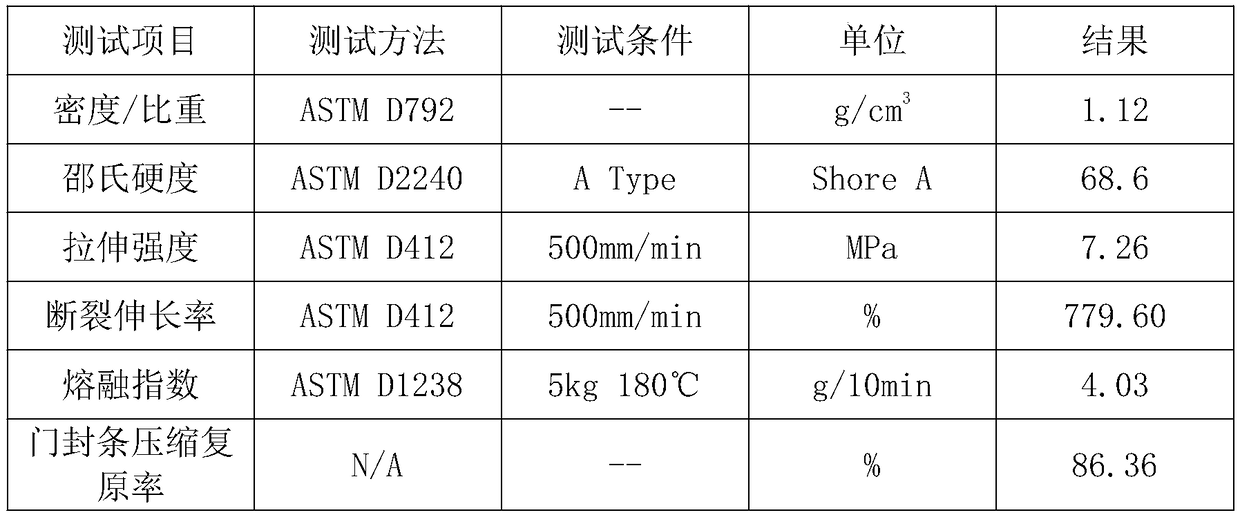

Thermoplastic elastomer refrigerator door sealing strip material and preparation method

The invention discloses a thermoplastic elastomer refrigerator door sealing strip material and a preparation method. The thermoplastic elastomer refrigerator door sealing strip material is prepared from the following materials of SEPS (hydrogenated styrene-isoprene) and / or SBS (styrene-butadiene-styrene), LLDPE (linear low density polyethylene), regular polypropylene, filling oil, mineral filler,a lubricant, a coupling agent and an antioxidant. The preparation method of the thermoplastic elastomer refrigerator door sealing strip comprises the following steps of weighing, uniformly mixing, granulating, extruding and forming. The thermoplastic elastomer refrigerator door sealing strip has the advantages that the problem in the refrigerator door sealing strip material using PVC (polyvinyl chloride), TPV (thermoplastic vulcanizate) and the like as the substrates on market is solved; the cold-resistant property is good, the elasticity is good, the deformation recovery ability is strong, the sealing effect is good, the non-toxic and environment-friendly effects are realized, and the recycling effect is realized; the hardness range is broad, the anti-crease effect is good, the dry and fresh effects are realized, the hand feel is comfortable, and any foreign odor is avoided.

Owner:ANHUI HIGASKET PLASTICS CO LTD

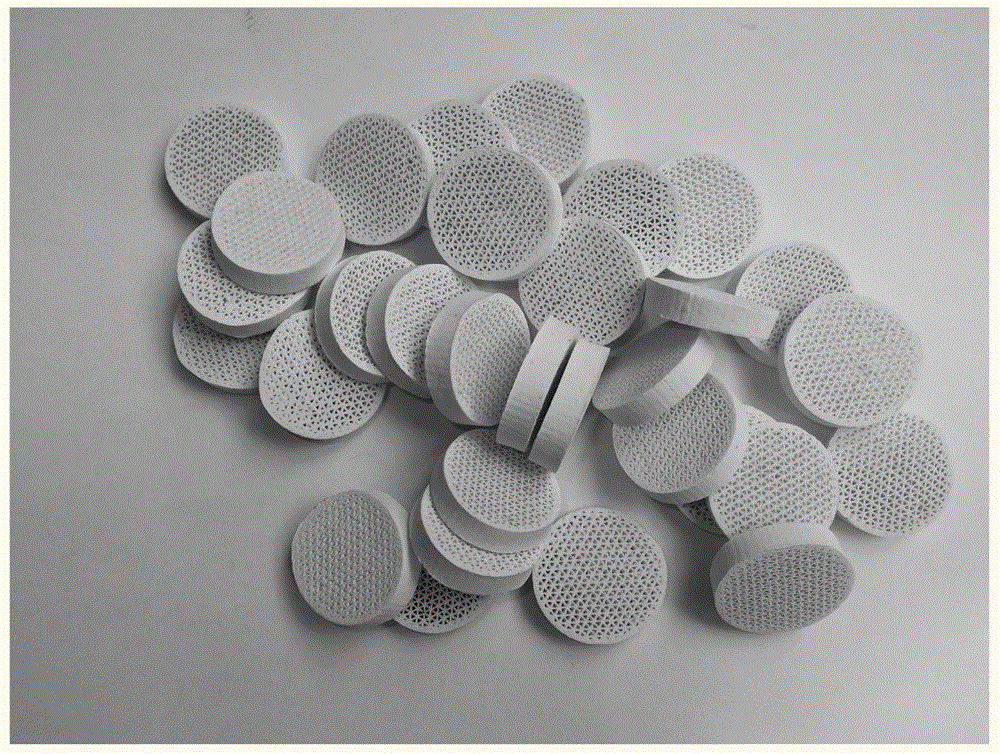

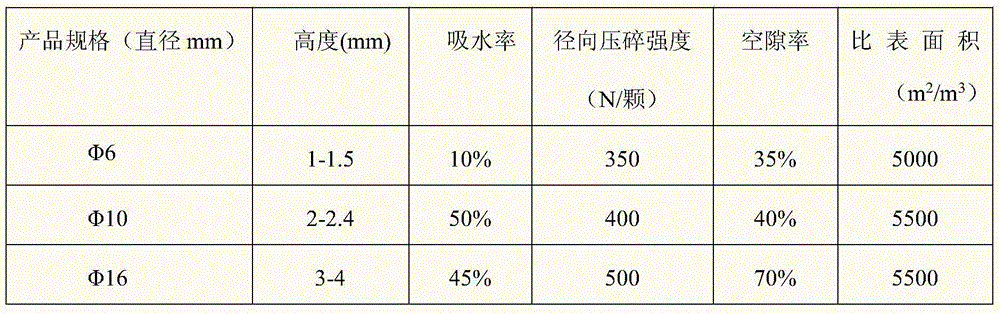

Honeycomb nest hydrogenation protecting agent

ActiveCN104888864AImprove firing pass rateExcellent extrusion formabilityCatalyst carriersHoneycombSolvent

A honeycomb nest hydrogenation protecting agent is prepared from 1-60% of alumina powder, 5-50% of kaolin, 0.1-15% of talcum powder, 5-60% of clay, 0.5-10% of an alkaline solvent, and 0.1-5% of an auxiliary material. The unit cross section area of the above product has more and denser through holes, so the external specific surface area of the product is greatly increased and reaches above 5000m<2> / m<3>, so a reaction raw material and the protecting agent have a larger contact and reaction area. The void fraction of the product reaches 30-70%, the water absorption rate reaches 10-50%, and the appropriate water absorption rate makes the protecting agent adsorb more active substances, so the absorption rate of adsorbed impurities is improved, and the catalysis effect is improved; and the radial crushing strength of the product is 50-500N / granule of the product, the product cannot be fragmented when 50-500N is applied to the two axial ends of the product, and maintains integrity, so the strength is improved, and the service life is prolonged.

Owner:JIANGXI ACICHEMSHUN IND

Automatic dough kneading equipment

ActiveCN107251926AEasy to operateExcellent extrusion formabilityMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringUltimate tensile strength

The invention discloses automatic dough kneading equipment. The equipment comprises a circular base; the upper surface of the circular base is fixedly connected with a circular uncovered dough kneading case; an automatic dough kneading mechanism is disposed in the circular uncovered dough kneading case; the upper surface of the circular base is fixedly connected with a group of tensile round rods which are oppositely disposed outside the circular uncovered dough kneading case; an automatic mixing mechanism is disposed between the group of tensile round rods; and the lateral surface of the circular uncovered dough kneading case is equipped with lifting mechanisms. The beneficial effects of the invention are that the equipment is a device relatively convenient to operate, and flour and water are uniformly stirred, and direct hand contact is avoided, and automatic extrusion molding of dough is carried out with a good effect, and labor intensity is alleviated, and the equipment is suitable for large-scale usage.

Owner:NANTONG WEALTH MASCH TECH CO LTD

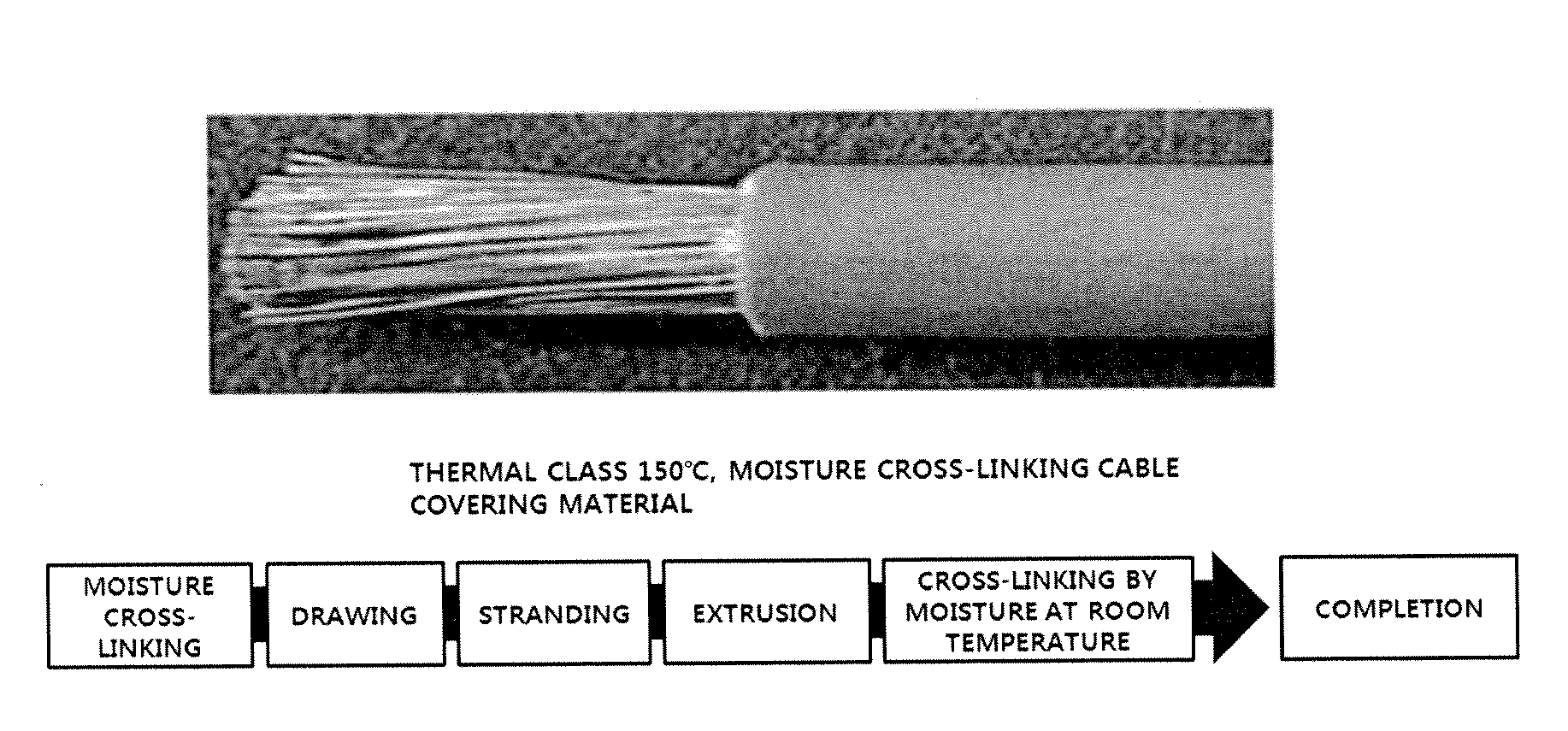

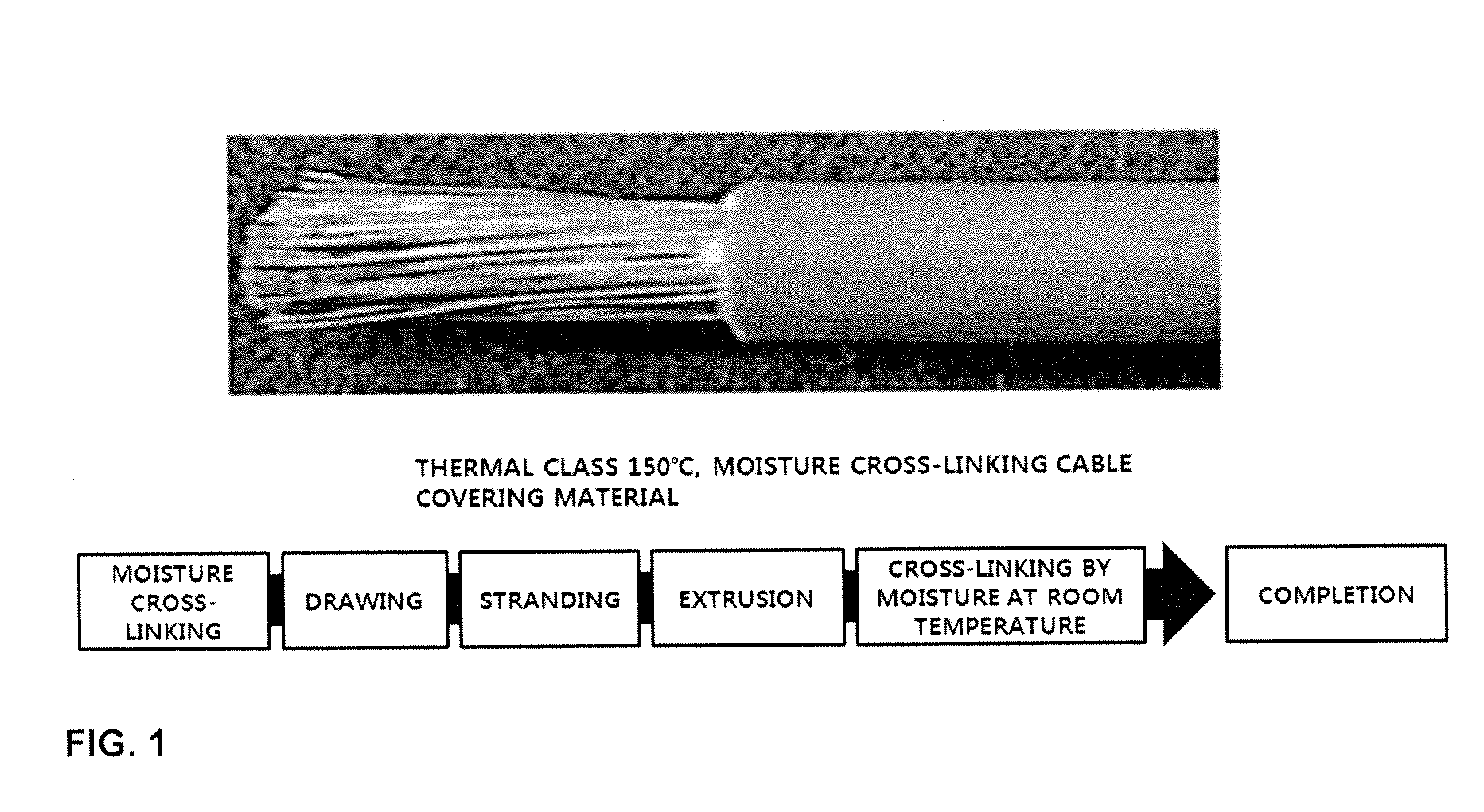

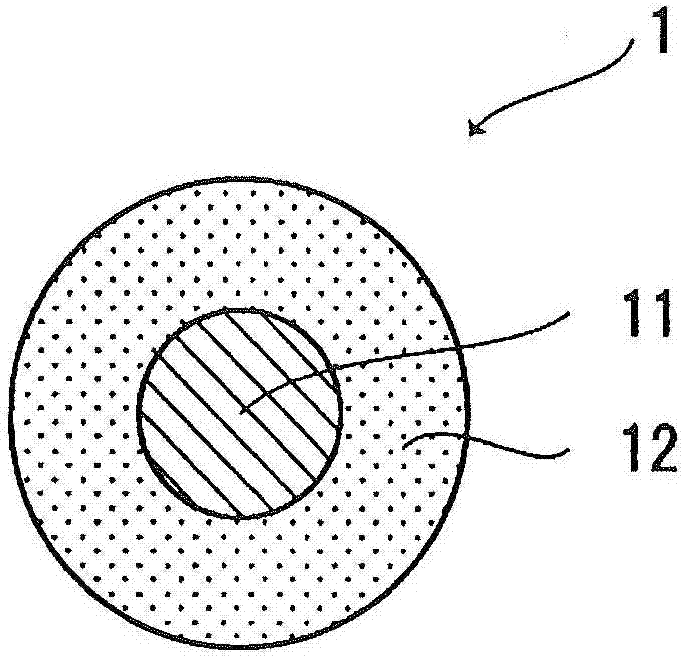

Wire, cable, and composition

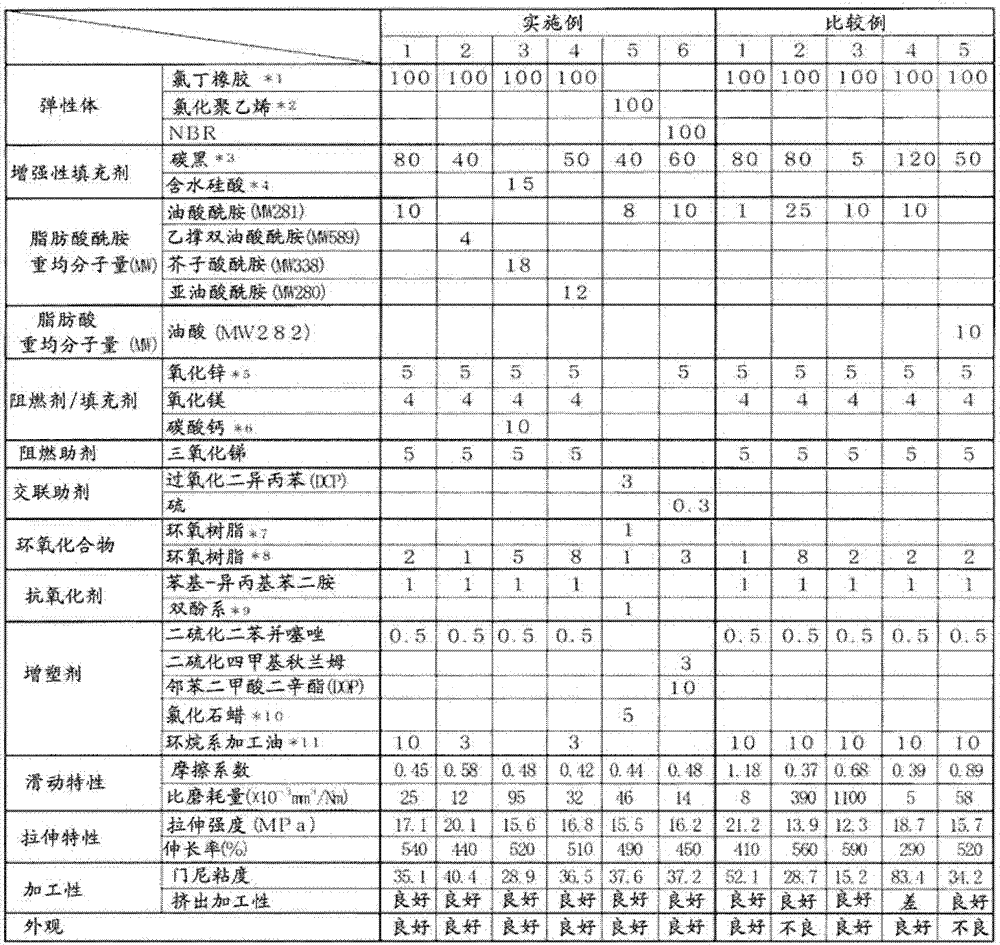

ActiveCN102956310AIncrease the scope of applicationExcellent abrasion resistanceInsulated cablesInsulated conductorsElastomerElectrical conductor

The invention discloses a wire, a cable, and a composition which feature excellent wearing resistance performance, low friction, and good mechanical strength. The wire and cable are formed by wrapping the composition to the periphery of the conductors or wire core, wherein the composition is formed by dispersing the reinforced type filler within the scope of above 10 parts by mass and below 100 parts by mass relative to the elastomer of 100 parts by mass and further dispersing the fatty acid amide within the scope of above 3 parts by mass and below 200 parts by mass.

Owner:HITACHI METALS LTD

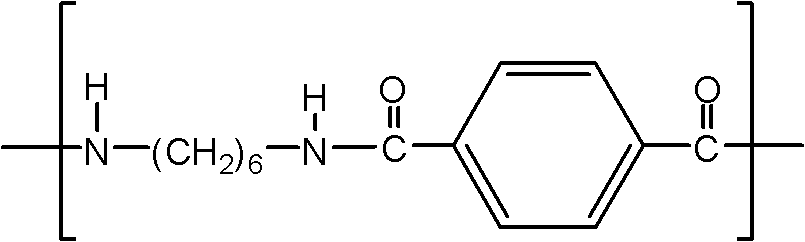

Polyamide thermoplastic elastomer composition and molded article thereof

ActiveCN105899586AGood flexibilityIncrease elasticityEngine sealsYielding couplingThermoplastic elastomerPolyamide

The present invention relates to: a rubber composition [X] containing a polyamide [I] of 30-100 mol% terephthalic acid structural units having a melting point of 220-290DEG C, an ethylene-alpha-olefin-unconjugated polyene copolymer rubber [II] containing ethylene, alpha-olefin having 3-20 carbon atoms, and unconjugated polyene structural units, and an olefin polymer [III] containing 0.3-5.0 mass% functional group structural units; and a polyamide thermoplastic elastomer composition [Y] dynamically crosslinked by a phenolic resin crosslinking agent [IV] ([I]-[IV] are a total of 100 mass%).

Owner:MITSUI CHEM INC

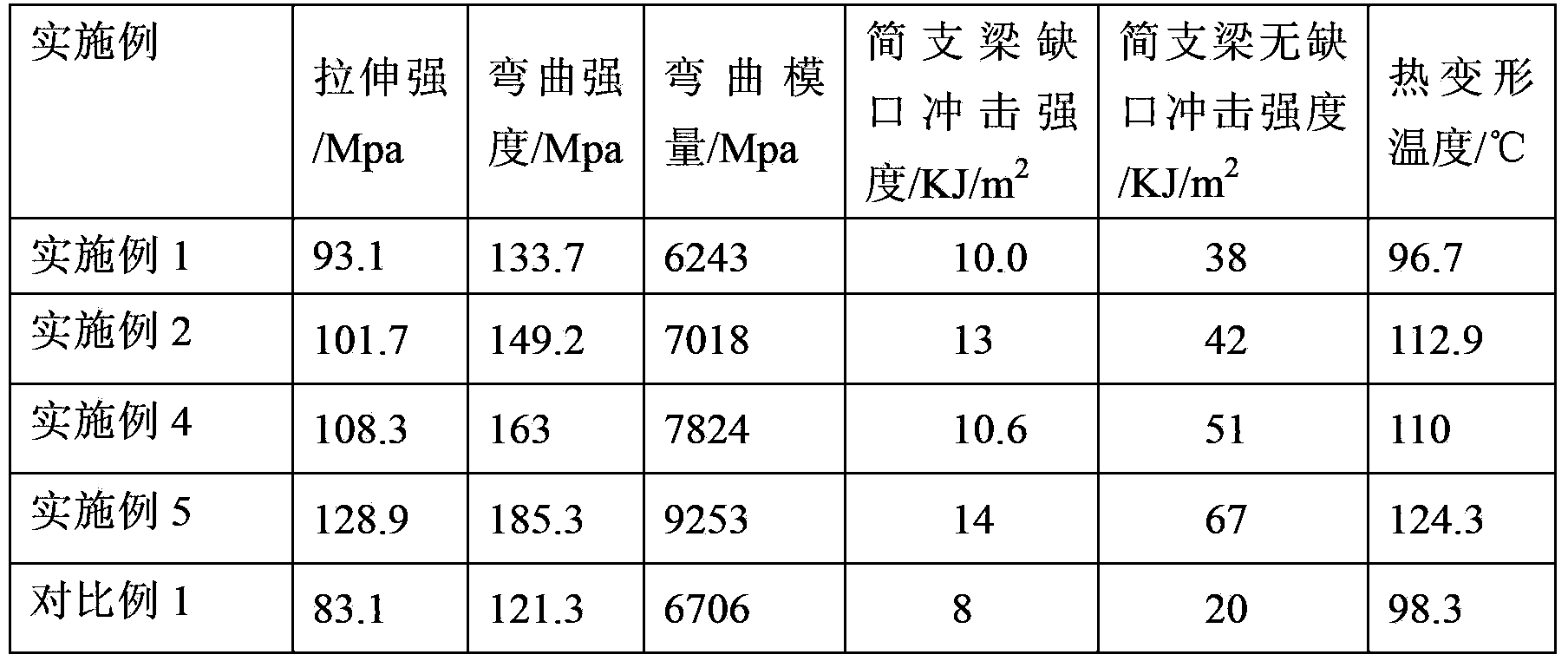

Polyamide based resin composition having excellent whiteness, thermal conductivity, and extruding moldability, and preparation method and product thereof

The present invention provides a polyamide resin composition having whiteness, thermal conductivity and extrusion molding property, which includes (A) polyamide resin; (B) heat conductive filler; (C) filler; and (D) thermoplastic resin which has miscibility with the polyamide and weight average molecular weight of 500,000 to 5,000,000. The above polyamide resin composition includes about 10 to about 80 % by weight of the (A) polyamide resin, about 5 to about 55 % by weight of the (B) heat conductive filler, about 5 to about 30 % by weight of the (C) filler, and about 5 to about 80 % by weight of the (D) thermoplastic resin which has miscibility with the polyamide and weight average molecular weight of 500,000 to 5,000,000. The present invention provides a method for preparing the polyamide resin composition. The invention also provides a product prepared from the polyamide resin composition.

Owner:CHEIL IND INC

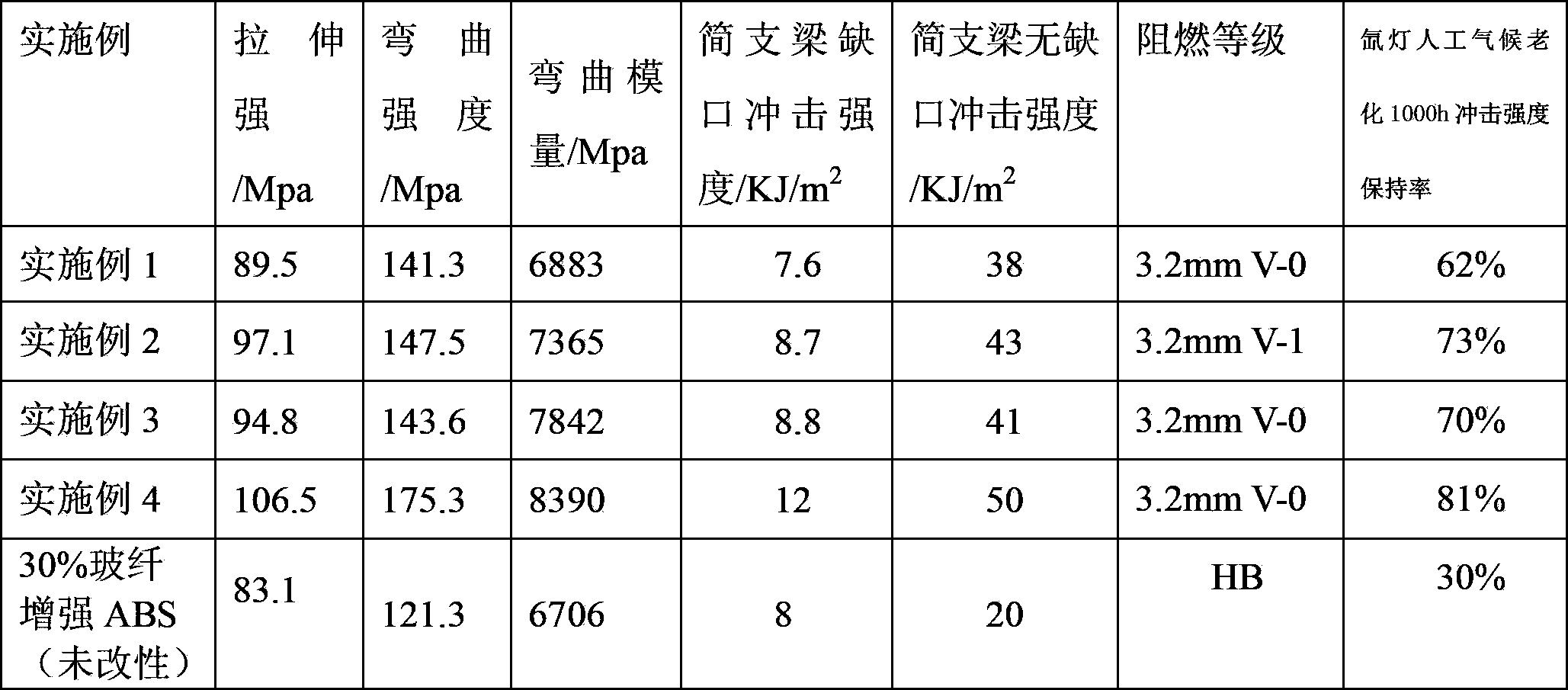

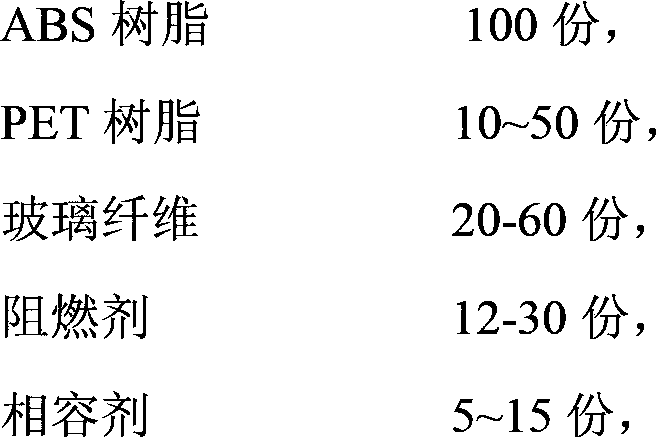

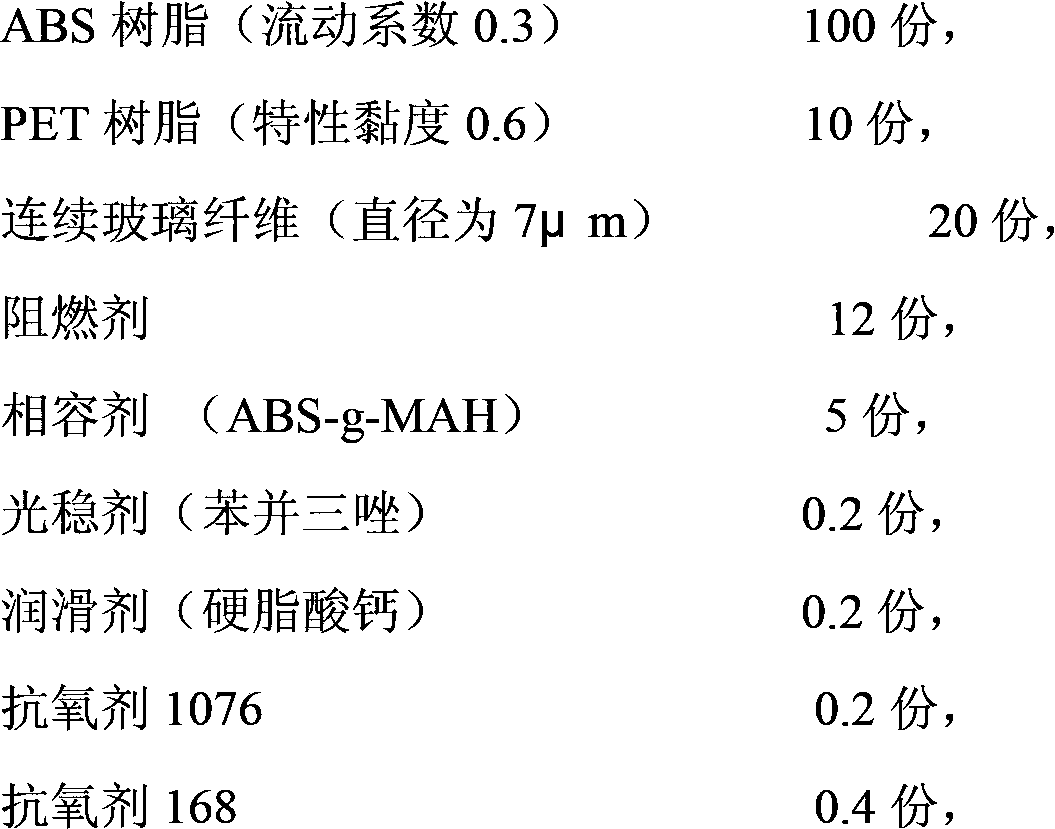

Weather-proof flame retardant ABS/PET material for extrusion process and preparation method of ABS/PET material

The invention belongs to the technical field of high polymer materials, and relates to an ABS / PET material and a preparation method thereof. The ABS / PET material comprises the following components by weight: 100 parts of ABS resin, 10-50 parts of PBT resin, 20-80 parts of glass fiber, 12-24 parts of a flame retardant, 5-15 parts of a compatilizer, 0.2-1.0 part of a light stabilizer, 0.2-1.5 parts of a lubricant, and 0.4-1.2 parts of an antioxidant. The ABS / PET material has excellent extrusion moldability, and outstanding flame retardance and weather resistance, can meet the requirement of outdoor use, and greatly extends the application range of the ABS material, the oil resistance, the solvent resistance and the physical and mechanical properties of the ABS / PET material are remarkably superior to those of an unmodified ABS material, the extruded product is high in performance, and an extrusion-grade plastic material with an excellent combination property is prepared.

Owner:HEFEI GENIUS NEW MATERIALS

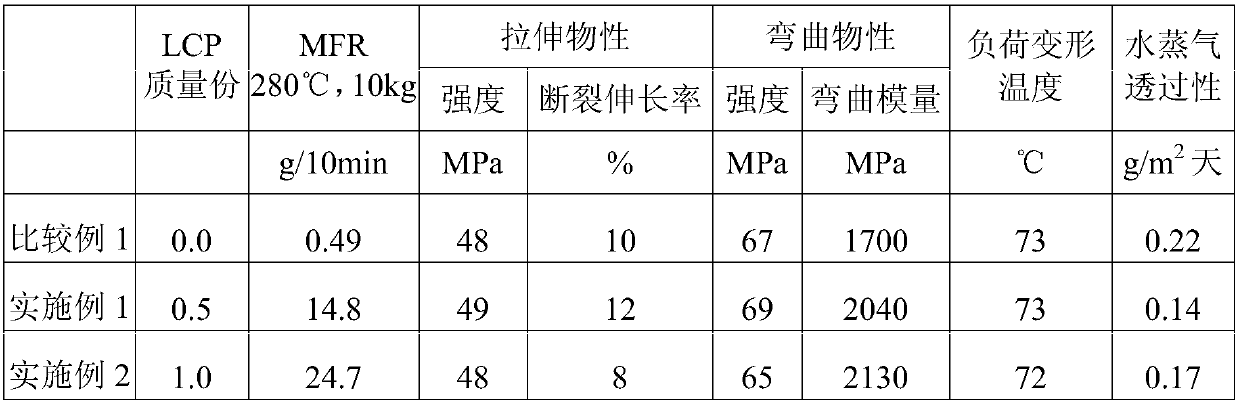

Fluorine-containing resin composition and producing method thereof

The invention provides a fluorine-containing resin composition and a producing method thereof, wherein the fluidity of the composition is greatly improved. The present invention relates to a fluorine-containing resin composition, which contains 99.99-97% by mass of a fluorine resin having a melting point of 205-225 DEG C and 0.01-3% by mass of a thermotropic liquid crystal polymer. The present invention further relates to a fluorine-containing resin composition production method, which comprises: mixing polytrifluorochloroethylene and a thermotropic liquid crystal polymer at a temperature of 285-320 DEG C.

Owner:TSINGHUA UNIV +1

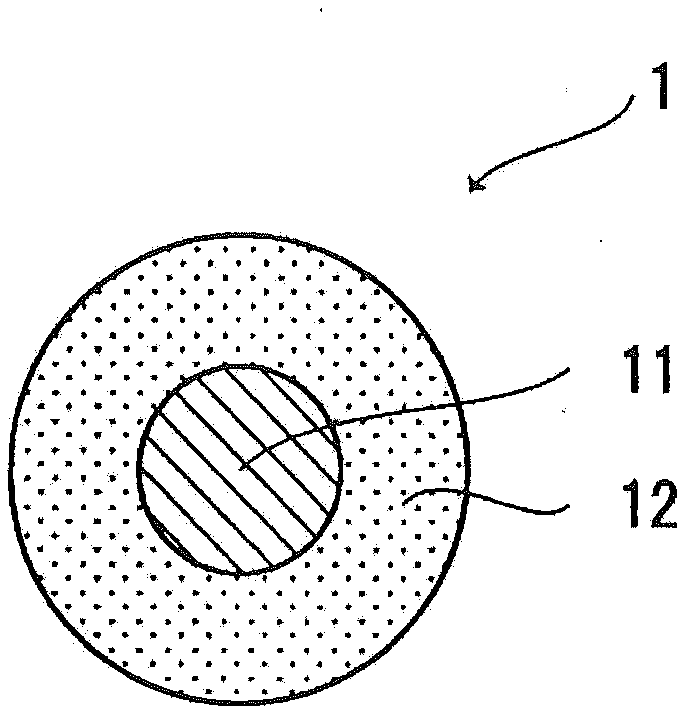

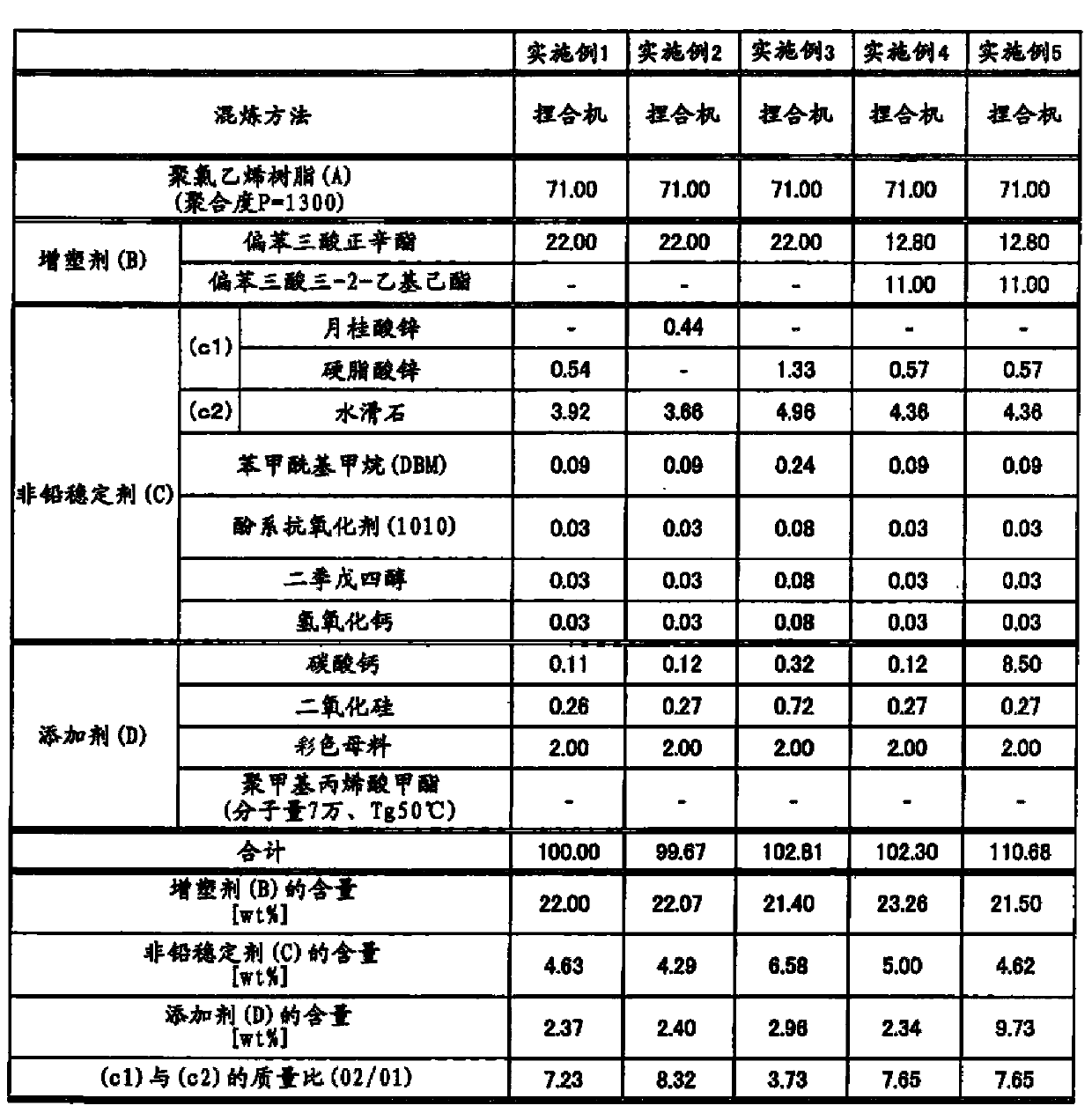

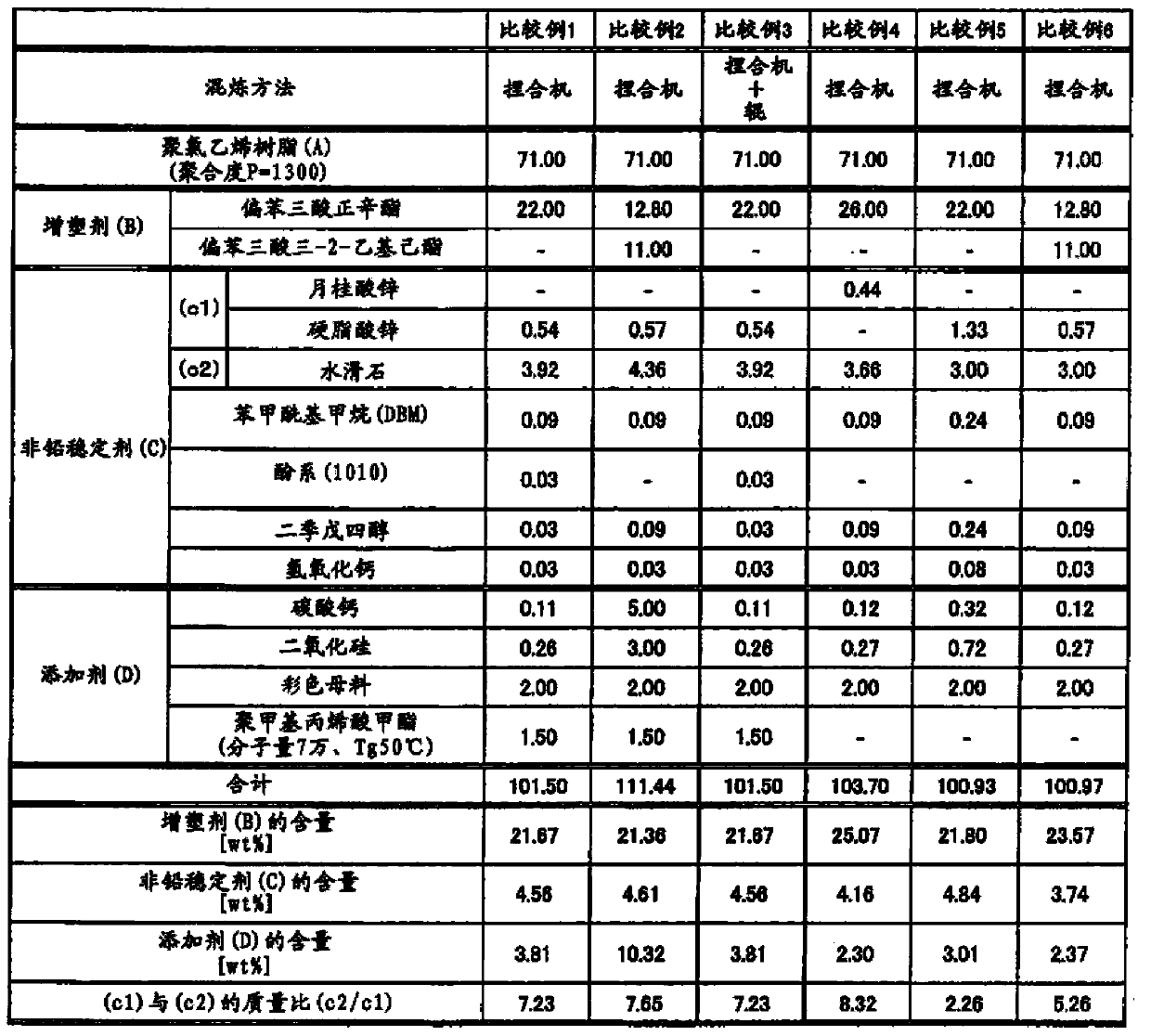

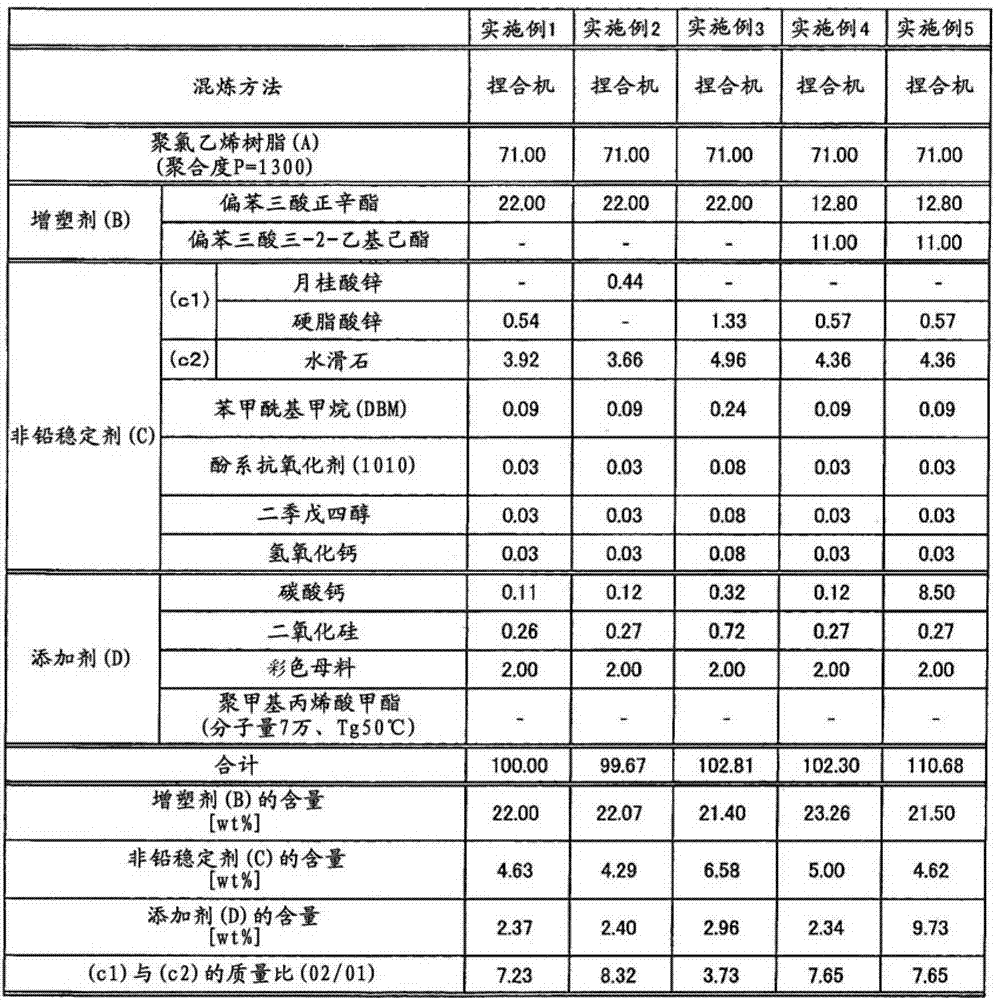

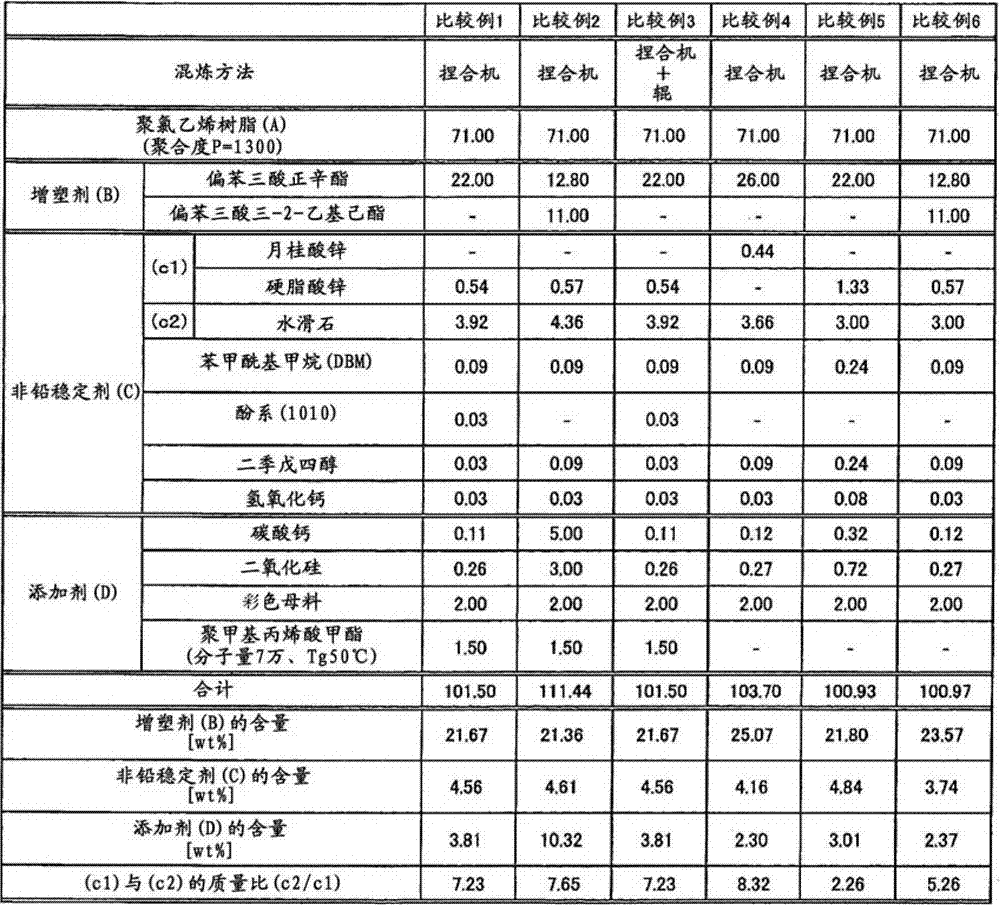

Polyvinyl chloride resin composition and insulated wire using polyvinyl chloride resin composition

ActiveCN103865191AExcellent mechanical propertiesGood cold resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer chemistryPlasticizer

A subject of the invention is to provide a polyvinyl chloride resin composition of excellent extrusion moldability, mechanical properties and cold resistance and an insulated wire using the polyvinyl chloride resin composition. The method to solve the problem of the invention relates to a polyvinyl chloride resin composition which comprises polyvinyl chloride resin (A), a plasticizer (B) and a non-lead stabilizer (C), and does not contain polymethyl methacrylate acting as a gelling agent. The non-lead stabilizer (C) comprises a zinc-containing metallic soap (c1) and hydrotalcite (c2). With respect to 100 mass% of the polyvinyl chloride resin composition, the following plasticizer (B) accounts for 19 mass% to 24 mass%, the non-lead stabilizer (C) accounts for 4 mass% or more, and a mass ratio (c2 / c1) of the hydrotalcite (c2) to the zinc-containing metallic soap (c1) is above 3.5 and below 10.

Owner:HITACHI METALS LTD

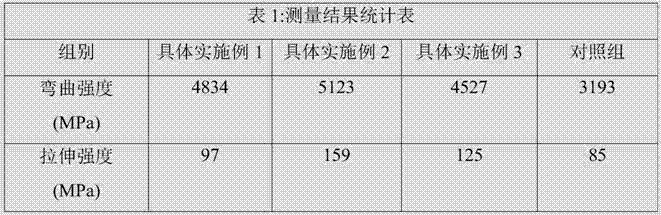

Basalt reinforced LCP composite material and preparation process thereof

InactiveCN106883636AImprove corrosion resistanceHigh tensile strengthDiphenylmethanePlastic materials

The invention relates to the field of novel plastic materials, in particular to a basalt reinforced LCP (liquid crystal polymer) composite material and a preparation method thereof. The basalt reinforced LCP composite material comprises the following component in parts by weight: 40-80 parts of LCP, 12-30 parts of basalt fiber, 0.3-0.9 part of a heat-resistant agent, 3-9 parts of a coupling agent, 3-6 parts of a main antioxidant, 1-3 parts of an auxiliary antioxidant, 1-5 parts of a compatilizer, 0.5-2 parts of a lubricant, 2-6 parts of a flame retardant, and 1-3 parts of a flame retardant synergist, wherein the heat-resistant agent is N,N'-4,4'-diphenylmethane dimalephthalamide. The basalt reinforced LCP composite material provided by the invention is high in mechanical strength, good in heat resistance and wide in application range.

Owner:深圳市华盈新材料有限公司

Method for producing an oxymethylene copolymer

Provided is a method for producing an oxymethylene copolymer having excellent extrusion moldability and reduced voids in a molded article without lowering the inherent performance of an oxymethylene copolymer. Provided is a method for producing an oxymethylene copolymer, including: a step for copolymerizing a monomer raw material containing trioxane and 5-7 mass % of 1,3-dioxolane relative to the trioxane, in the presence of 0.025-0.07 mmol of boron trifluoride per mol of trioxane and 0.006-2.0 mass % of sterically hindered phenol relative to the trioxane; a step for adding a polymerization terminator to the reaction system when the polymerization yield of this copolymer has reached 92% or higher, and terminating polymerization; and a thermal stabilization step for heating and melting the crude oxymethylene copolymer in the presence of 0.05-5 mass % of an antioxidant and 0.005-5 mass % of a nitrogen-containing compound relative to the crude oxymethylene copolymer.

Owner:MITSUBISHI GAS CHEM CO INC

Resin composition for producing insulating material and method for producing insulating material

ActiveUS20150248948A1Excellent extrusion formabilityImprove flame retardant performancePlastic/resin/waxes insulatorsSpecial tyresPolyolefinAntioxidant

A resin composition for producing an insulating material includes (A) 40 to 50% by weight of a base resin formed with a polyolefin-based resin or a derivative thereof, (B) 40 to 50% by weight of a magnesium hydroxide flame retardant of which surface is treated with vinyl silane, (C) 1 to 2% by weight of an antioxidant in which a first antioxidant and a second antioxidant are mixed in a weight ratio of 1:1 to 3, (D) 0.5 to 2% by weight of a lubricant, (E) 2 to 3% by weight of organosilane, (F) 0.05 to 0.2% by weight of an initiator, and (G) 1 to 4% by weight of a catalyst.

Owner:HYUNDAI MOTOR CO LTD +1

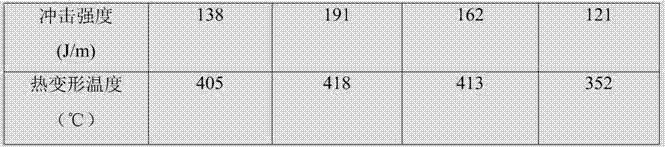

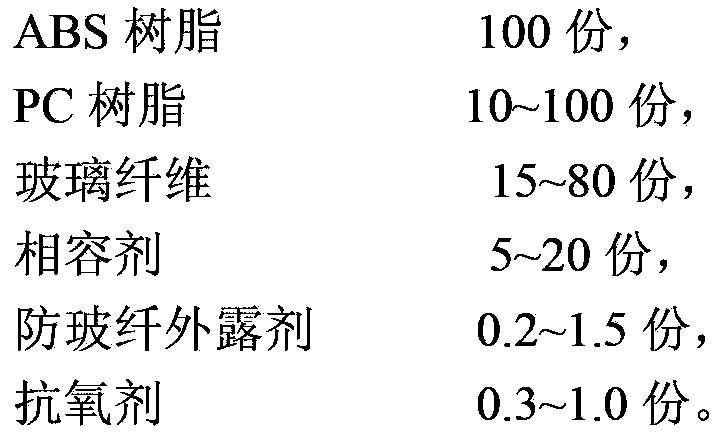

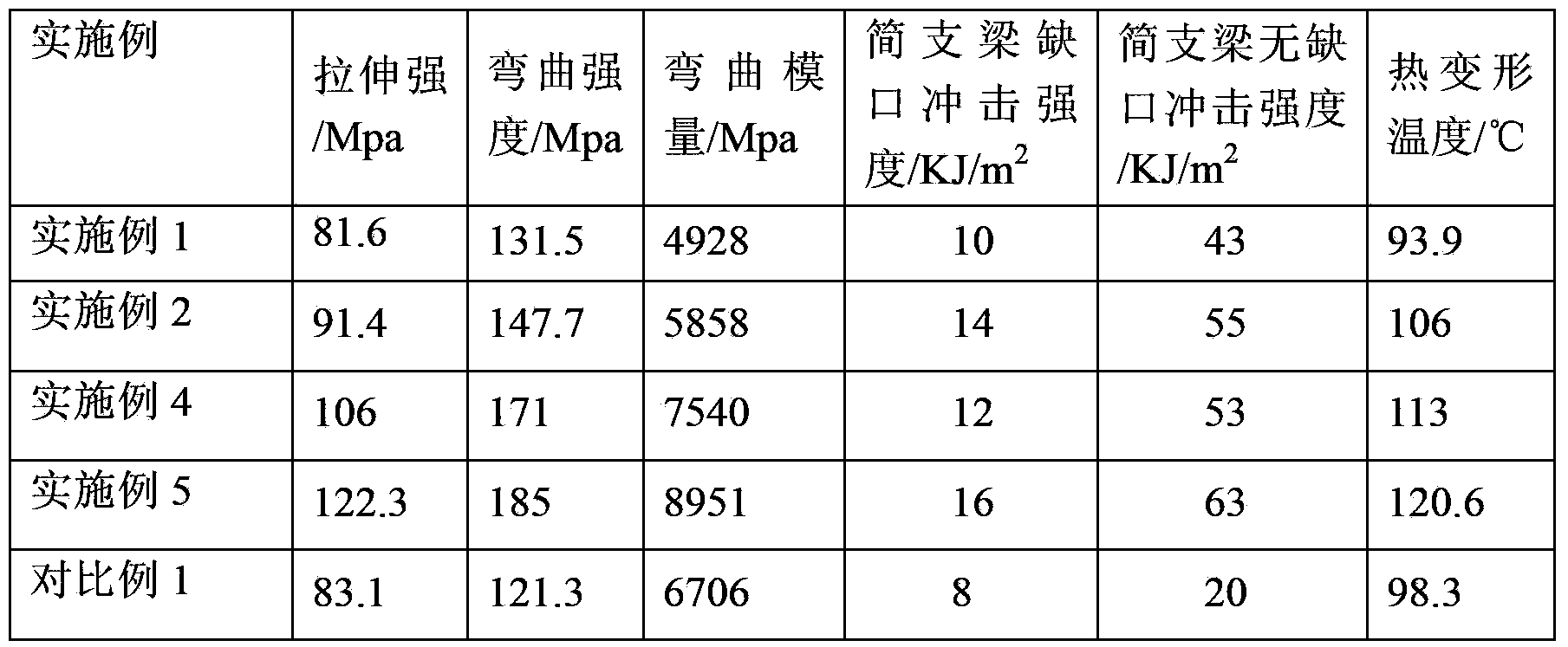

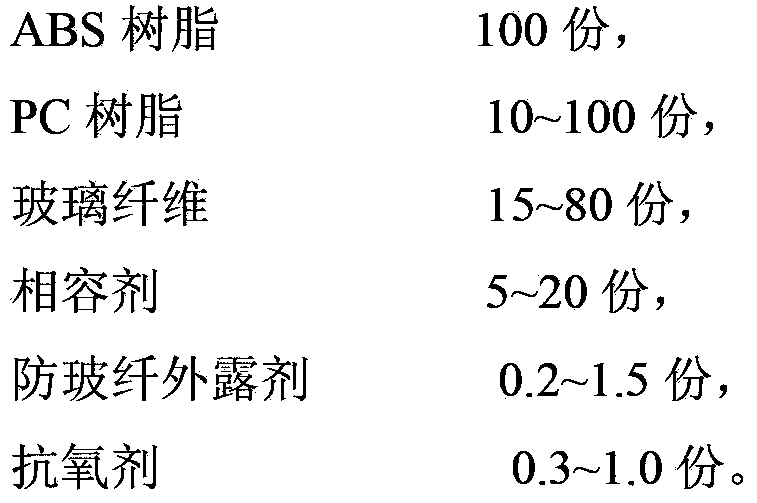

High gloss glass fiber reinforced ABS/PC material for extrusion process and preparation method thereof

Belonging to the technical field of high polymer materials, the invention relates to an ABS / PC (acrylonitrile-butadiene-styrene / polycarbonate) material and a preparation method thereof. The ABS / PC material comprises the following components by weight: 100 parts of ABS resin, 10-50 parts of PC resin, 15-80 parts of glass fiber, 5-20 parts of a compatibilizer, 0.2-1.5 parts of an anti-glass fiber exposure agent, and 0.3-1.0 part of an antioxidant. The ABS / PC material provided by the invention has excellent extrusion molding performance, the weather resistance, oil resistance, solvent resistance and physical and mechanical properties are obviously superior to those of unmodified ABS materials, and the extruded products have the characteristics of smooth surface, no floating fiber, and excellent performance, thus being widely applicable in pipelines, building profiles, sheet materials and every field of social life and having great economic and social value.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

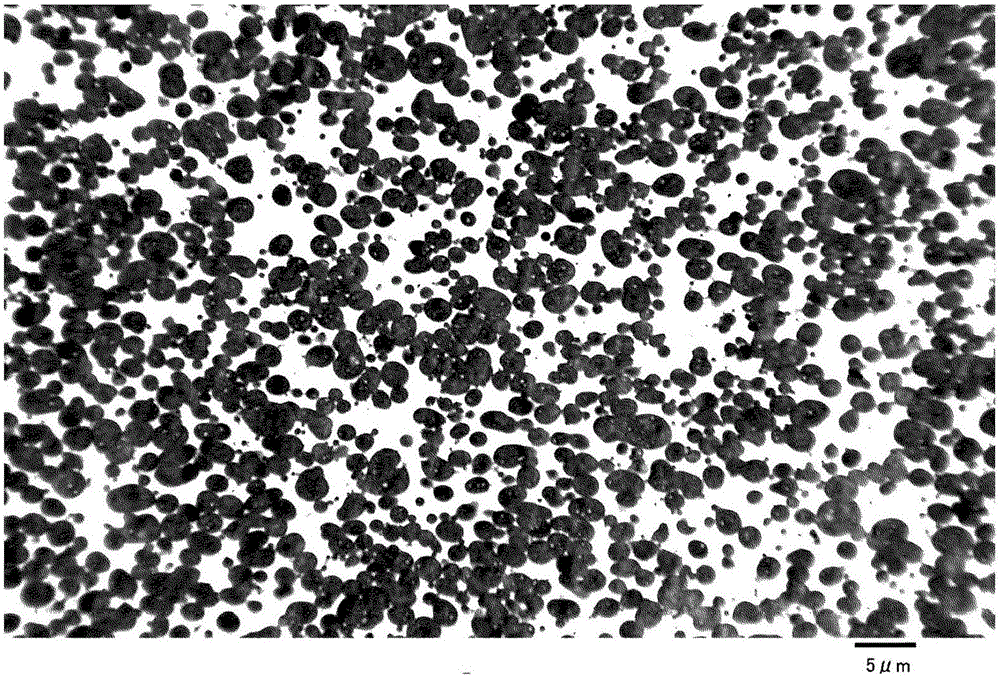

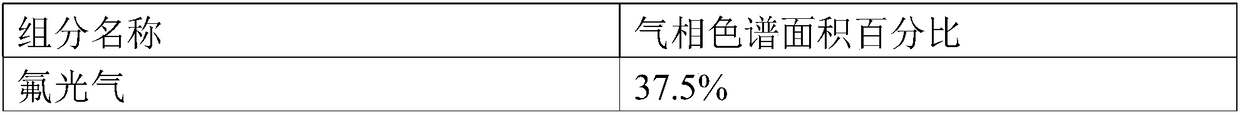

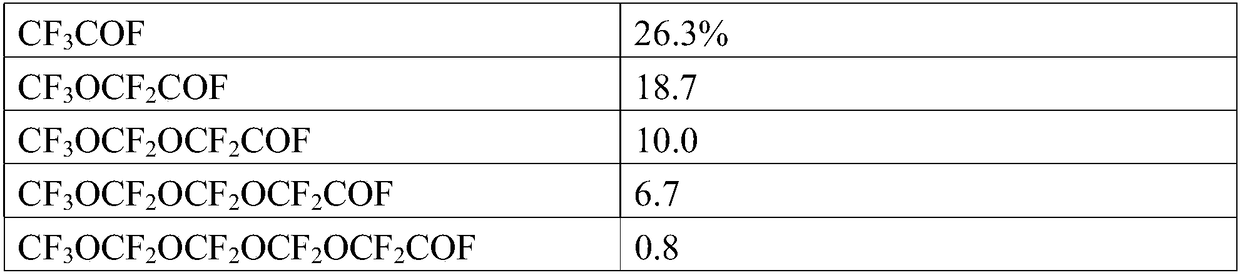

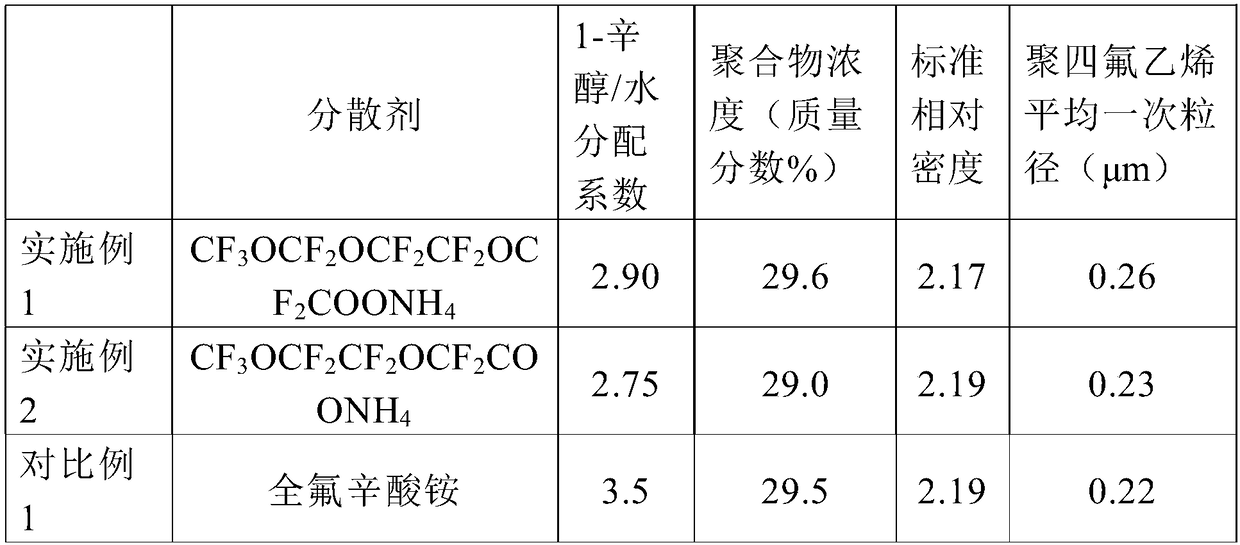

Polyfluortetraethylene water-based emulsion, polyfluortetraethylene fine powder and preparation method

ActiveCN108383933AExcellent extrusion formabilityImprove mechanical propertiesWater basedPerfluorooctanoic acid

The invention discloses a polyfluortetraethylene water-based emulsion, polyfluortetraethylene fine powder and a preparation method. The method comprises the following steps that polyfluortetraethyleneis singly subjected to emulsion polymerization in a water-based medium or is subjected to emulsion polymerization in the water-based medium together with other copolymerizable monomers to obtain thepolyfluortetraethylene water-based emulsion, wherein the emulsion polymerization process is performed under the existence condition of fluorine-containing emulsifying agents and stabilizing agents. The invention relates to the polyfluortetraethylene water-based emulsion, the polyfluortetraethylene fine powder and the preparation method. Environment problem caused by perfluoro caprylic acid or perfluoro caprylic acid salt does not exist. The water-based emulsion comprises polytetrafluoroethylene with high molecular weight; the average primary particle diameter reaches 0.18 to 0.50mu m. Variouscharacteristics such as extrusion shaping performance of the polyfluortetraethylene fine powder are excellent; the mechanical property is good; the polyfluortetraethylene fine powder can be used for preparing polyfluortetraethylene porous bodies; the obtained polyfluortetraethylene porous bodies have various excellent characteristics.

Owner:SANMING HEXAFLUO CHEM CO LTD

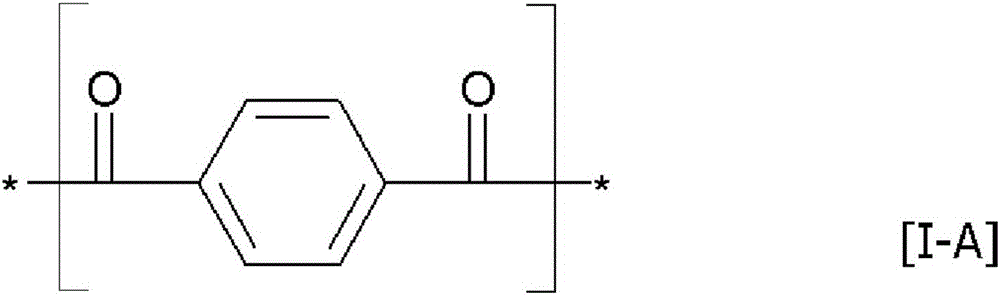

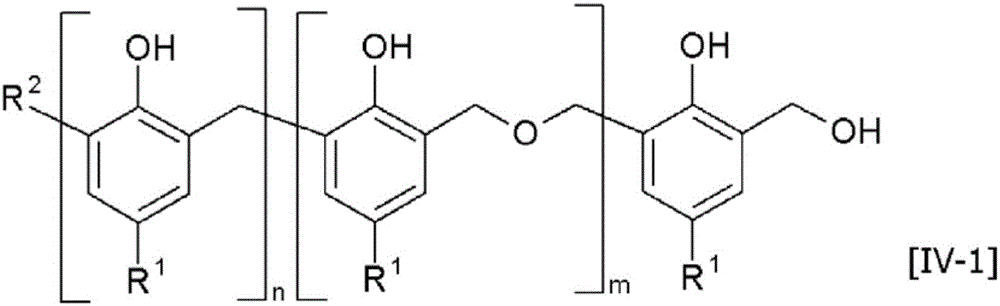

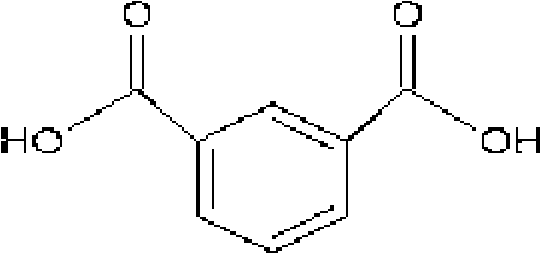

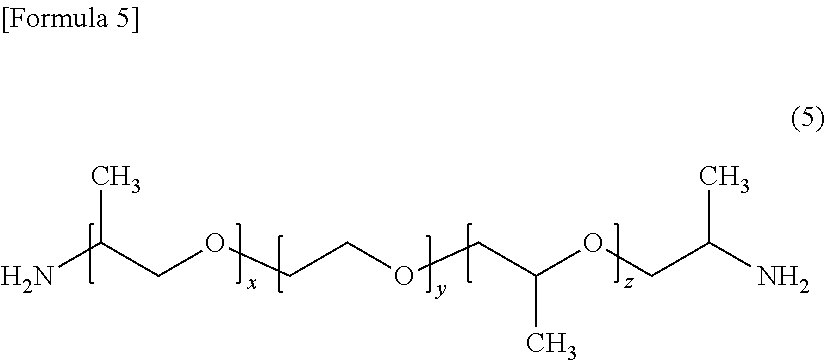

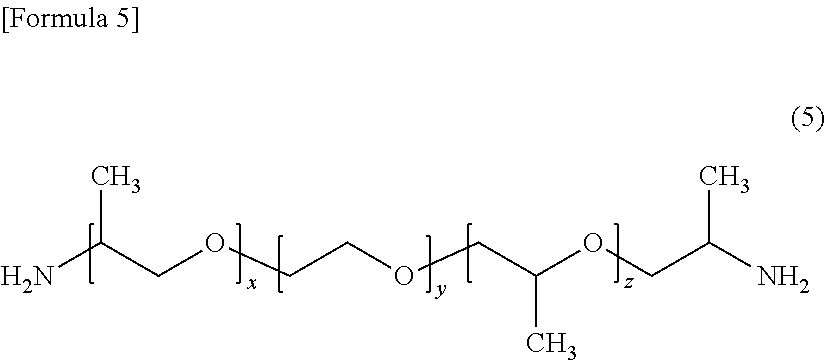

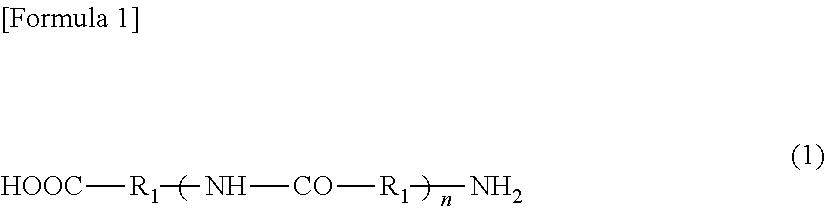

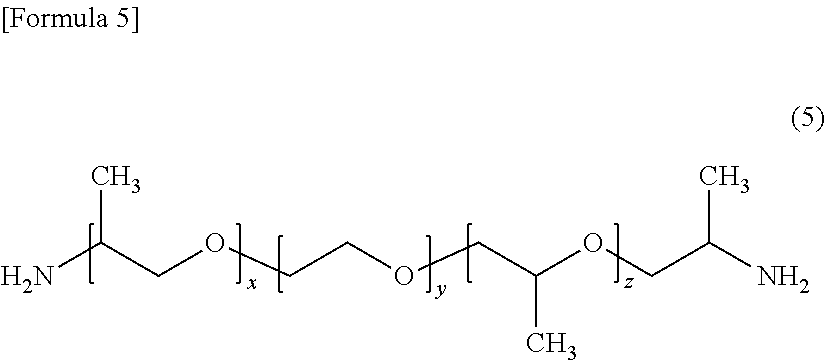

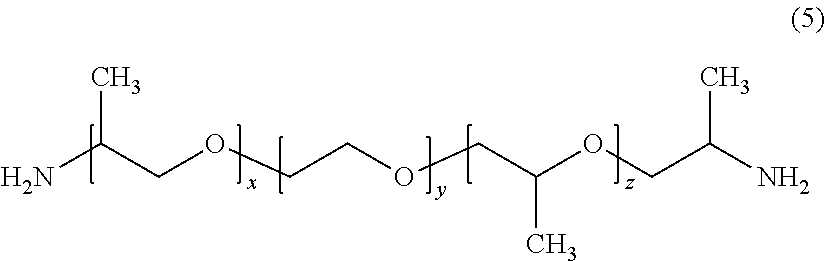

Polyamide elastomer, medical device, and method for producing polyamide elastomer

ActiveUS20180148540A1Maintain good propertiesExcellent extrusion formabilityBalloon catheterElastomerPolymer science

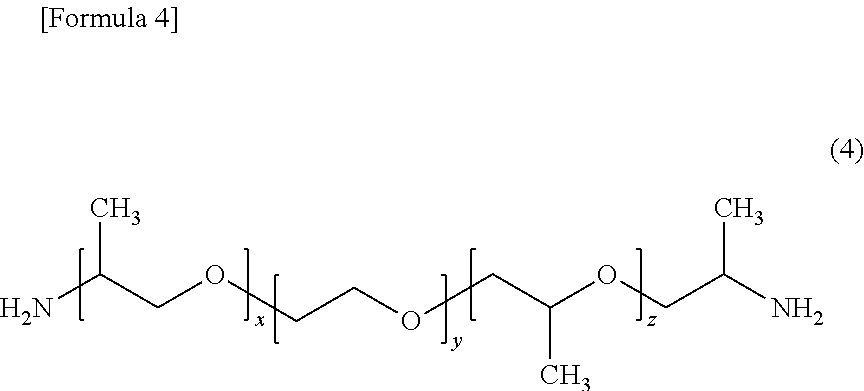

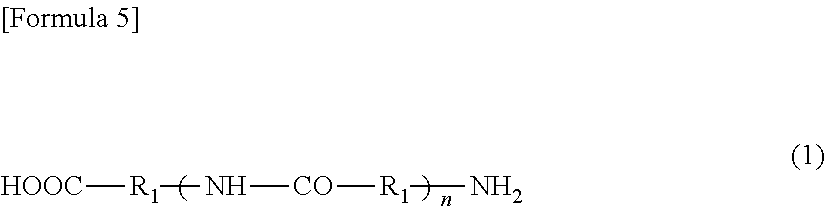

A polyamide elastomer comprising a reaction product of components (a), (b), and (c). Component (a) has the formula HOOC—R1—(-NH—CO—R1-)n—NH2 (where each R1 independently is linear saturated hydrocarbon, n represents a real number of 0 or greater, and when the formula contains multiple repeating units each containing R1, n represents a total number of those repeating units) and the Mn of component (a)=4000-10000. Component (b) has the formula HOOC—R2—COOH (where R2 represents a direct bond or a linear saturated hydrocarbon group). Component (c) has the formula H2N—R4—(-O—R4-)m—NH2 (where each R4 independently represents a saturated hydrocarbon group containing 1 or more carbon atoms; m represents a real number of 1 or more; and when the formula contains two or more types of the repeating units each containing R4, m represents a total number of the two or more types of the repeating units each containing R4).

Owner:KANEKA CORP

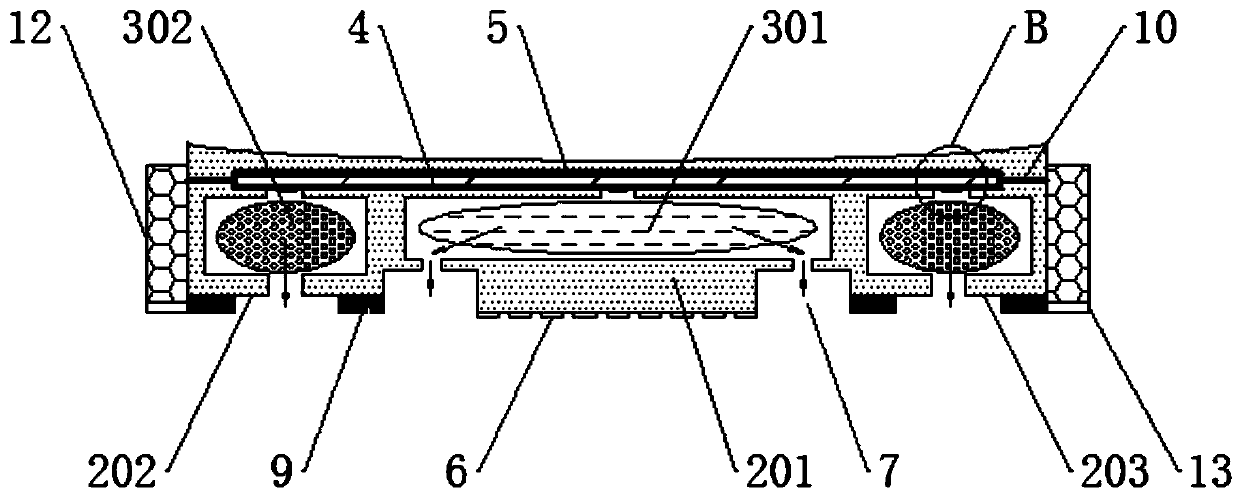

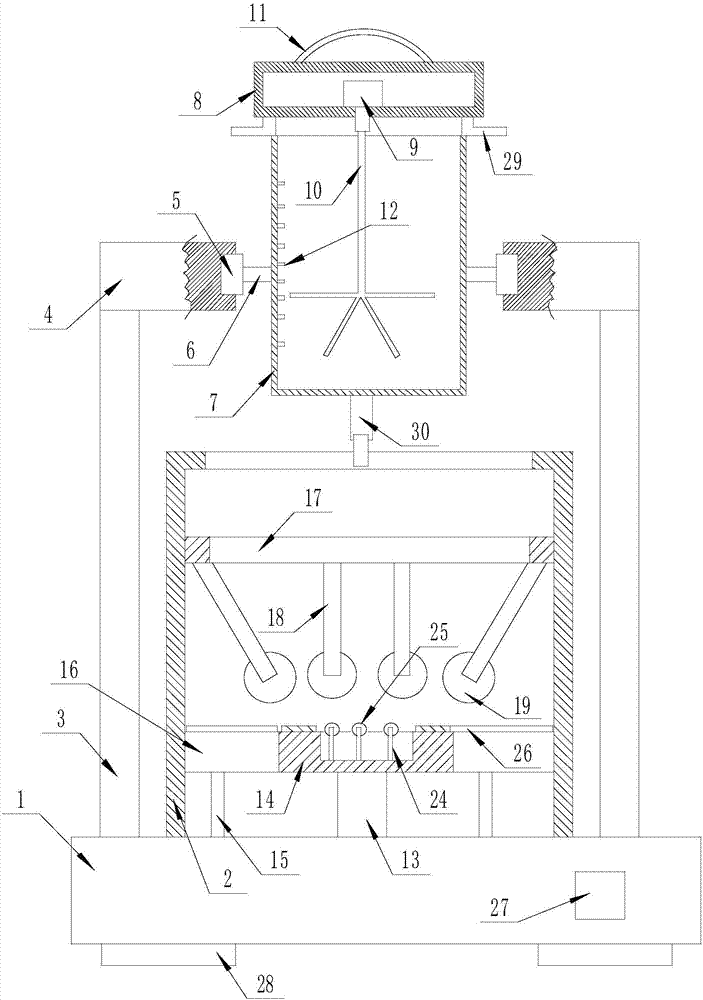

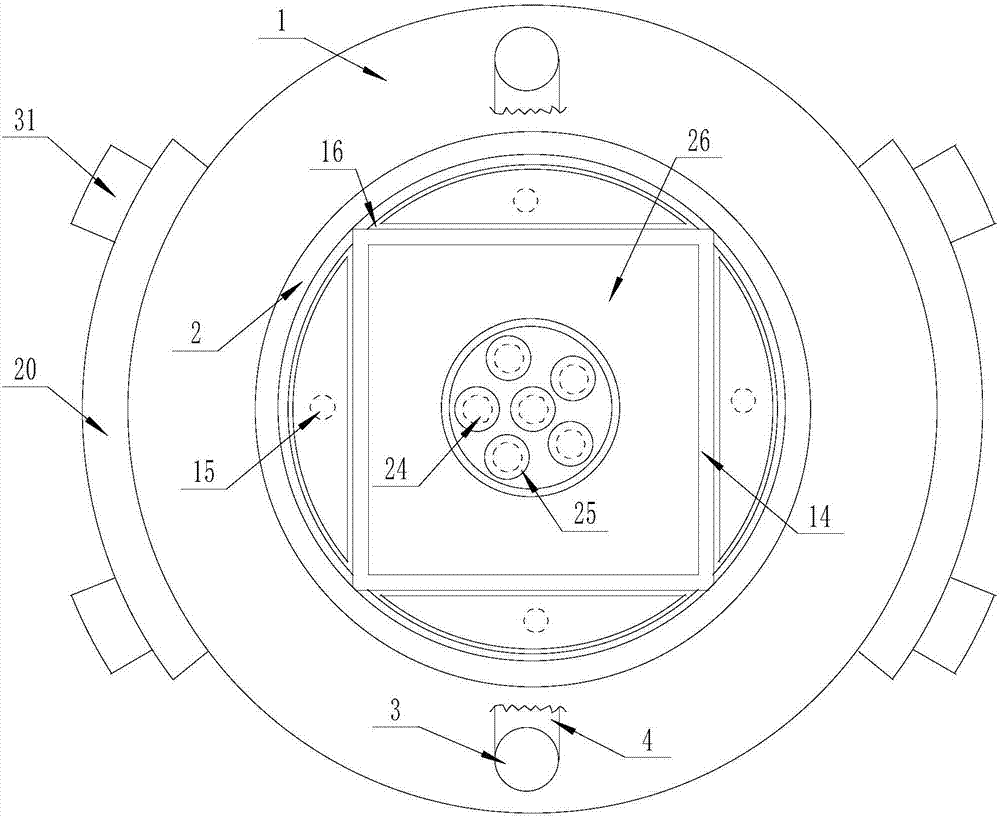

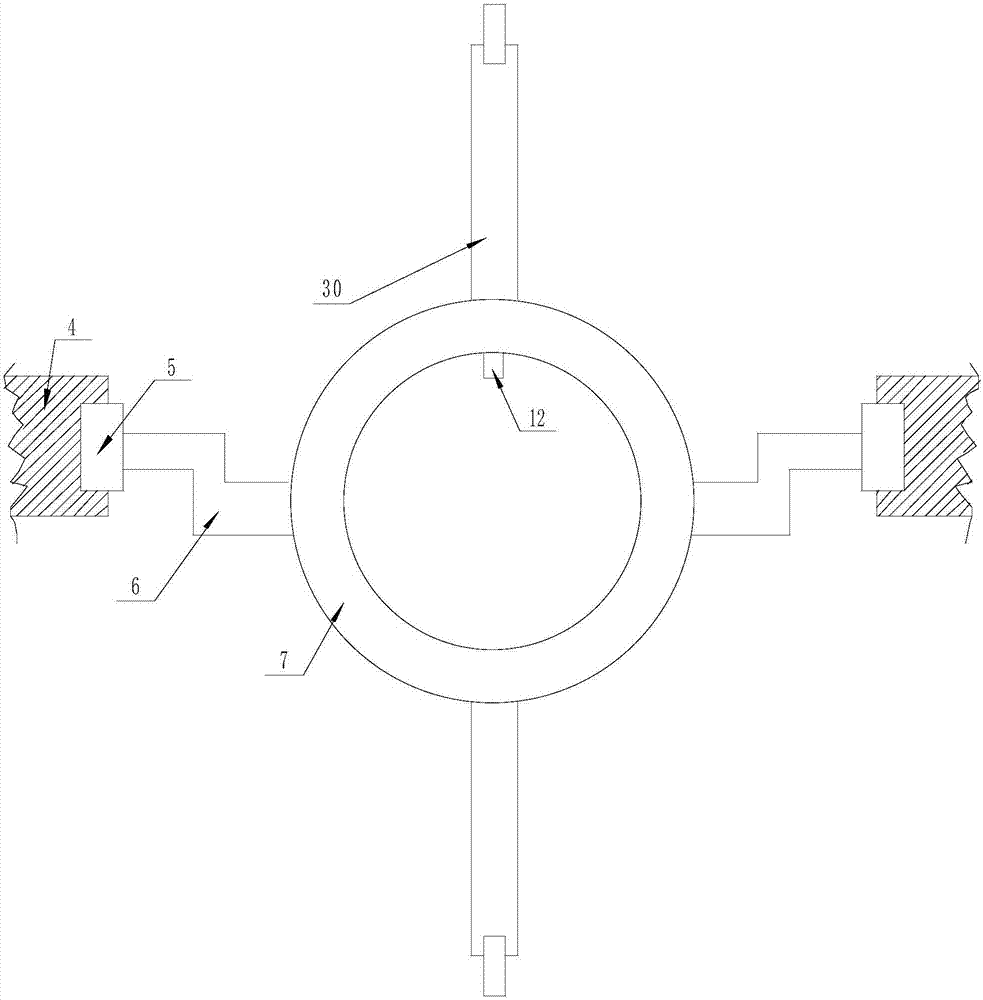

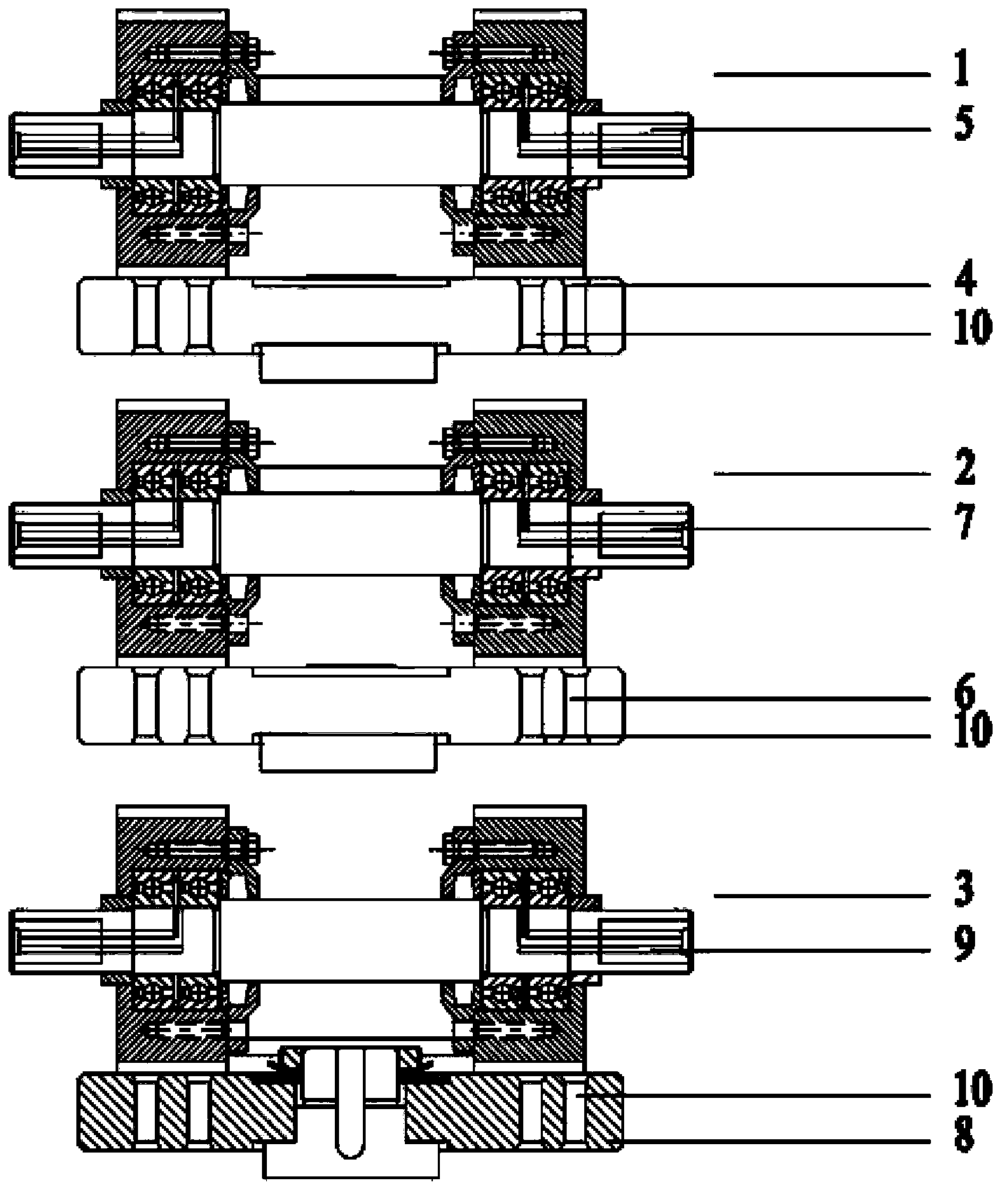

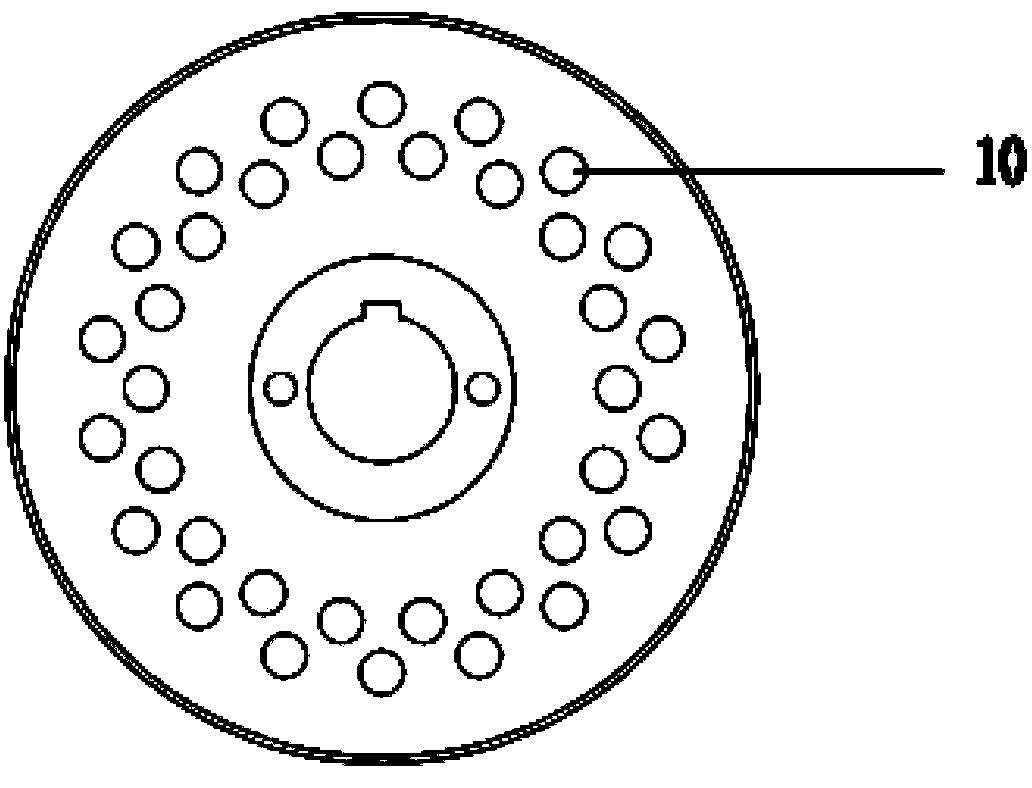

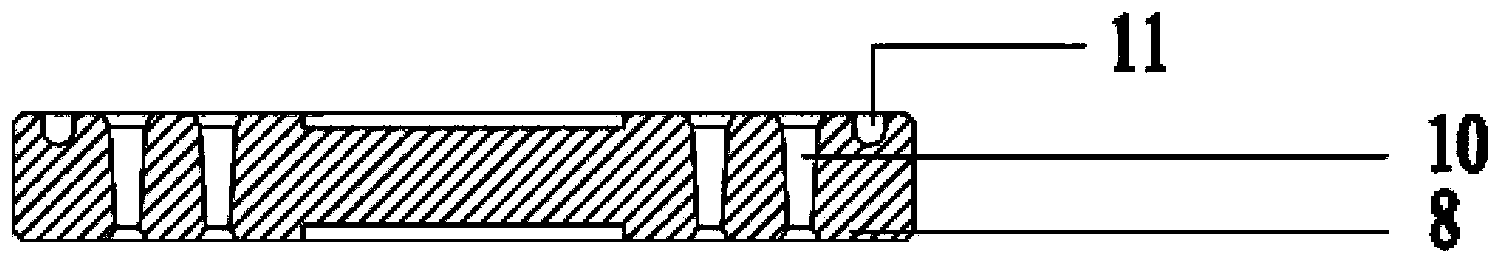

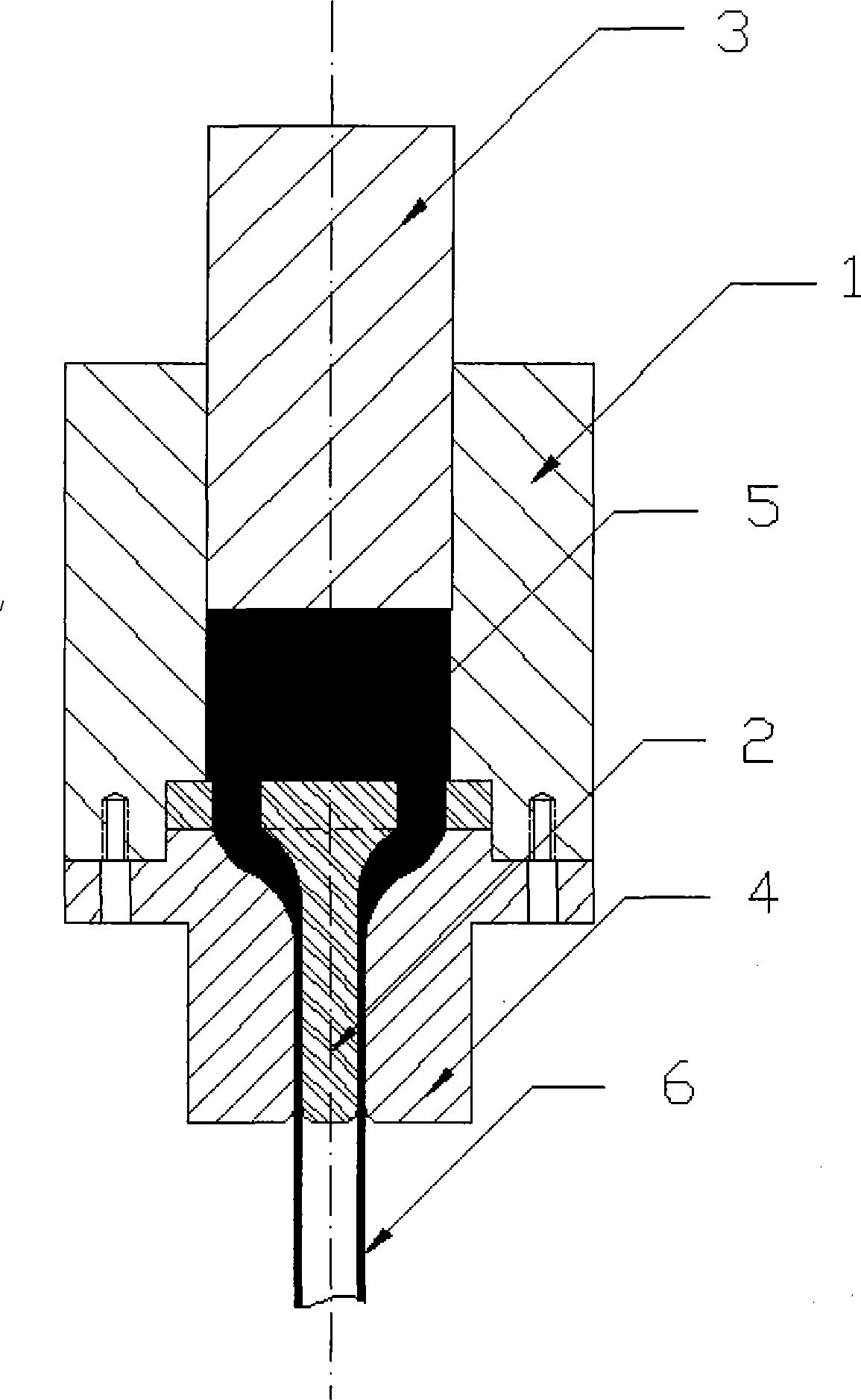

Three-layer biomass extrusion moulding device and vertical biomass extrusion moulding machine

ActiveCN103434178AChange flexibilityImproving and Enhancing Extrusion Molding EffectsShaping pressMolding machineProcess engineering

The invention provides a three-layer biomass extrusion moulding device, which comprises an upper layer extrusion moulding device, a middle layer extrusion moulding device and a lower layer extrusion moulding device, wherein the upper layer extrusion moulding device, the middle layer extrusion moulding device and the lower layer extrusion moulding device are arranged in sequence from top to bottom; any one of the extrusion moulding devices consists of a pressure roller mechanism and a flat-die plate arranged at the bottom part of the corresponding pressure roller mechanism; axes of the flat-die plates a, b and c are coincident; two rows of die holes are distributed in each flat-die plate by taking the circle center of the corresponding flat-die plate as the datum; the lower port of each die hole forms a discharge hole. A vertical main shaft is also arranged in a vertical biomass extrusion moulding machine with the three-layer biomass extrusion moulding device; the vertical main shaft consists of an upper shaft and a lower shaft; the upper shaft is sheathed with the flat-die plates in the upper layer extrusion moulding device, the middle layer extrusion moulding device and the lower layer extrusion moulding device; the lower shaft is arranged on a rack in an upper and lower two-point support bearing configuration manner. Extrusion moulding can be performed on a biomass material for three times by the three-layer biomass extrusion moulding device provided by the invention, and therefore, the extrusion moulding effect of the material is improved. Moreover, the extrusion moulding efficiency of the biomass material also can be improved.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

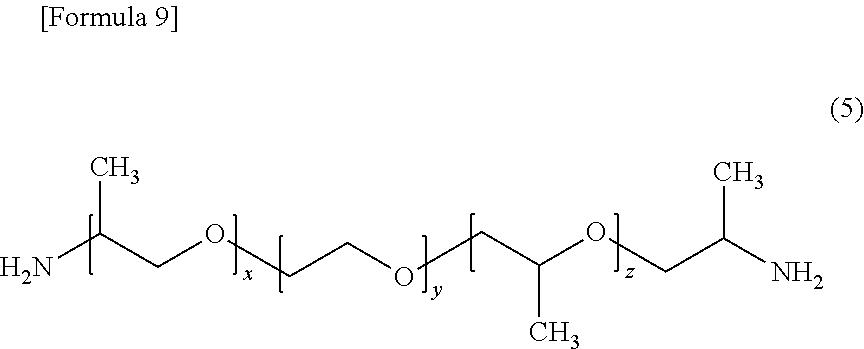

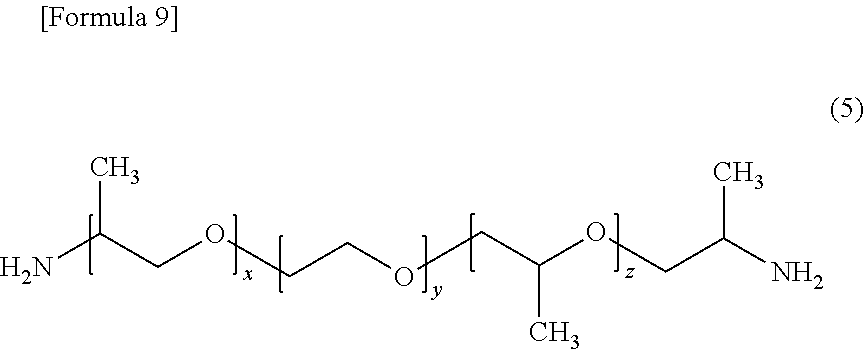

Polyamide elastomer, medical device, and method for producing polyamide elastomer

ActiveUS10400068B2Maintain good propertiesExcellent extrusion formabilityBalloon catheterMedical devicesElastomerPolyamide

Polyamide elastomer comprising reaction product of components (a), (b), (c), (d). Component (a) has formula HOOC--R.sub.1--(--NH--CO--R.sub.1--).sub.n--NH.sub.2 (where each R.sub.1 independently is linear saturated hydrocarbon, n represents a real number of 0 or greater, and when there are multiple repeating units each containing R.sub.1, n represents total number of those repeating units). Component (b) has formula HOOC--R.sub.2--COOH (where R.sub.2 represents a direct bond or a linear saturated hydrocarbon group). Component (c) has formula H.sub.2N--R.sub.4--(--O--R.sub.4--).sub.m--NH2 (where each R.sub.4 independently represents a saturated hydrocarbon group; m represents a real number of .gtoreq.1; and when there are multiple repeating units each containing R.sub.4, m represents total number of those repeating units). Component (d) has formula H.sub.2N--[--CH(CH.sub.3)CH--O--].sub.x--[CH.sub.2CH.sub.2O--].sub.y--[CH- .sub.2CH(CH.sub.3)--O].sub.z--CH.sub.2CH(CH.sub.3)(NH.sub.2) wherein (x+z) is a real number of 1 to 6 and y is a real number of 1 to 20. A molar ratio of (c) / (d) in the polyamide elastomer ranges from 9 / 1 to 1 / 9.

Owner:KANEKA CORP

ABS / PA6 material for extrusion technology and preparation method thereof

InactiveCN104119635AExcellent extrusion formabilityExtruded products have excellent performanceSolventWeather resistance

The invention belongs to the technical field of polymer materials, and relates to an ABS / PA6 material and a preparation method thereof. The ABS / PA6 material comprises the following components by weight: 100 portions of an ABS resin, 10-50 portions of PA6 resin, 20-80 portions of glass fiber, 5-15 portions of a compatible agent, 0.3-1.8 portions of a chain extension agent, 0.2-1.5 portions of a lubricant and 0.3-1.0 portion of an antioxidant. The ABS / PA6 material provided by the invention has excellent extrusion resistance, and weather resistance, oil resistance, solvent resistance and mechanical properties obviously superior to those of an unmodified ABS material, and extrusion products also have excellent performance. The ABS / PA6 material can be widely used in various areas of social life, such as pipelines, architectural section and sheet, and has great economic and social values.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Silicone rubber composition, production method therefor, and silicone rubber extrudate

Provided is a silicone rubber composition that exhibits improved moldability, particularly extrusion moldability, while also ensuring that a cured product obtained therefrom has sufficient strength. Asilicone rubber composition comprising: (A) 100 parts by mass of a base polymer formed from (A1) a polyorganosiloxane diol having a viscosity at 25 DEG C of 1 to 100 Pa*s, and (A2) a polyorganosiloxane having a viscosity at 25 DEG C of 0.2 to 40,000 Pa*s, wherein the proportion of (A1) with respect to the total amount of (A) is 20 to 100 mass%, the viscosity at 25 DEG C is 5 to 20,000 Pa*s, and the alkenyl group content is 0.001 to 0.3 mmol / g; (B) 10 to 50 parts by mass of a silica powder having a specific surface area of 50 to 400 m2 / g; (C) 1 to 10 parts by mass of an organosilazane; and (D)a catalytic amount of a curing agent.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Polyamide elastomer, medical device, and method for producing polyamide elastomer

ActiveUS10392475B2Maintain good propertiesExcellent extrusion formabilityBalloon catheterElastomerPolymer science

A polyamide elastomer comprising a reaction product of components (a), (b), and (c). Component (a) has the formula HOOC—R1—(—NH—CO—R1-)n—NH2 (where each R1 independently is linear saturated hydrocarbon, n represents a real number of 0 or greater, and when the formula contains multiple repeating units each containing R1, n represents a total number of those repeating units) and the Mn of component (a)=4000-10000. Component (b) has the formula HOOC—R2—COOH (where R2 represents a direct bond or a linear saturated hydrocarbon group). Component (c) has the formula H2N—R4—(—O—R4-)m—NH2 (where each R4 independently represents a saturated hydrocarbon group containing 1 or more carbon atoms; m represents a real number of 1 or more; and when the formula contains two or more types of the repeating units each containing R4, m represents a total number of the two or more types of the repeating units each containing R4).

Owner:KANEKA CORP

Solar cell module

InactiveCN104321885AHigh transparencyMaintain transparencyPhotovoltaic supportsOther chemical processesLong term durabilityTransmittance

Provided is a solar cell module wherein a rear surface protection sheet has excellent long-term durability, and transmissivity of ultraviolet that reaches the solar cell is retained for a long time. This solar cell module is configured by laminating a front surface protection sheet, a light receiving-side sealing sheet, a solar cell element, a rear surface-side sealing sheet, and a rear surface protection sheet in this order. The solar cell module is characterized in that the light receiving-side sealing sheet has a transmissivity of 50 % or more with respect to light having a wavelength of 300 nm, and the rear surface-side sealing sheet contains a reactive ultraviolet absorbent.

Owner:MITSUI CHEM TOHCELLO INC

A weather-resistant flame-retardant ABS/PET material for extrusion process and preparation method thereof

The invention belongs to the technical field of polymer materials, and relates to an ABS / PET material and a preparation method thereof. The material is made of the following components by weight: 100 parts of ABS resin, 10-50 parts of PET resin, 20-60 parts of glass fiber, 12-30 parts of flame retardant, 5-15 parts of compatibilizer, light stable 0.2-1.0 parts of lubricant, 0.2-1.5 parts of lubricant, 0.4-1.2 parts of antioxidant. The weather-resistant and flame-retardant ABS / PET material for extrusion prepared by the present invention has excellent extrusion formability, outstanding flame retardancy and weather resistance, can meet the needs of outdoor use, and greatly expands the application range of ABS materials , Oil resistance, solvent resistance and physical and mechanical properties are significantly better than unmodified ABS materials, and the extruded products have excellent performance. It can be widely used in various fields of social life such as pipelines, building profiles and panels, and has great economic and social value.

Owner:HEFEI GENIUS NEW MATERIALS

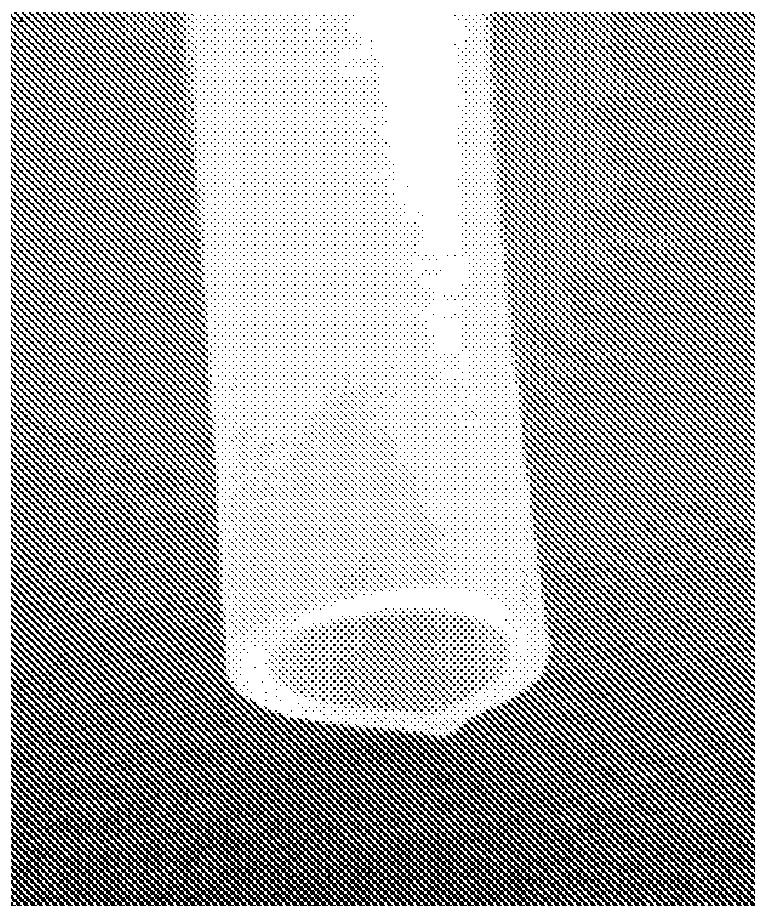

Preparation method of silicon carbide ceramic tubular product

InactiveCN101580390BExcellent extrusion formabilityControllable tube shapeThermal dilatationShock resistance

The invention belongs to the technical fields of a silicon carbide ceramic material and a preparation method thereof, in particular relates to a preparation method of a silicon carbide ceramic tubular product with high strength, high thermal conduction, low expansion, high thermal-shock resistance performance and controllable external dimensions. The silicon carbide ceramic tubes have even texture and uniform tubular wall thickness; the thickness of each tubular wall can be controlled from 0.5 mm to 20 mm, each tubular outer diameter can be from 5 mm to 100 mm, the silicon carbide ceramic tube with the longest length is limited by a sintering furnace, and each tubular wall can be in a compact structure or a micropore structure. The silicon carbide ceramic tubular product uses organic resin and SiC powder as main raw materials and utilizes an extrusion molding technology to prepare a tubular precast blank which is compacted and equalized at a high temperature, pyrolysed to forma final product after reaction, infiltration and sintering. The silicon carbide ceramic tubular product has the fundamental characteristics of SiC ceramics, such as high strength, low thermal expansion coefficient, high thermal conduction, chemical corrosion resistance, oxidation resistance, good high temperature stability, strong thermal-shock resistance performance, and the like. The preparation method has simple technology, convenient operation, no complicated equipment and low manufacture cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Polyvinyl chloride resin composition and insulated wire using the polyvinyl chloride resin composition

ActiveCN103865191BExcellent mechanical propertiesImprove cold resistancePlastic/resin/waxes insulatorsInsulated cablesPlasticizerPolyvinyl chloride

An object of the present invention is to provide a polyvinyl chloride resin composition excellent in extrusion moldability, mechanical properties, and cold resistance, and an insulated electric wire using the polyvinyl chloride resin composition. As a method for solving the problem of the present invention, it relates to a polyvinyl chloride resin composition containing a polyvinyl chloride resin (A), a plasticizer (B), a non-lead stabilizer (C), and does not contain The non-lead stabilizer (C) contains zinc metal soap (c1) and hydrotalcite (c2), and contains 19% by mass or more and 24% by mass relative to 100% by mass of the polyvinyl chloride resin composition. The plasticizer (B) below, the non-lead stabilizer (C) at 4% by mass or more, and the mass ratio (c2 / c1) of the hydrotalcite (c2) to the zinc metal soap (c1) are 3.5 to 10.

Owner:HITACHI METALS LTD

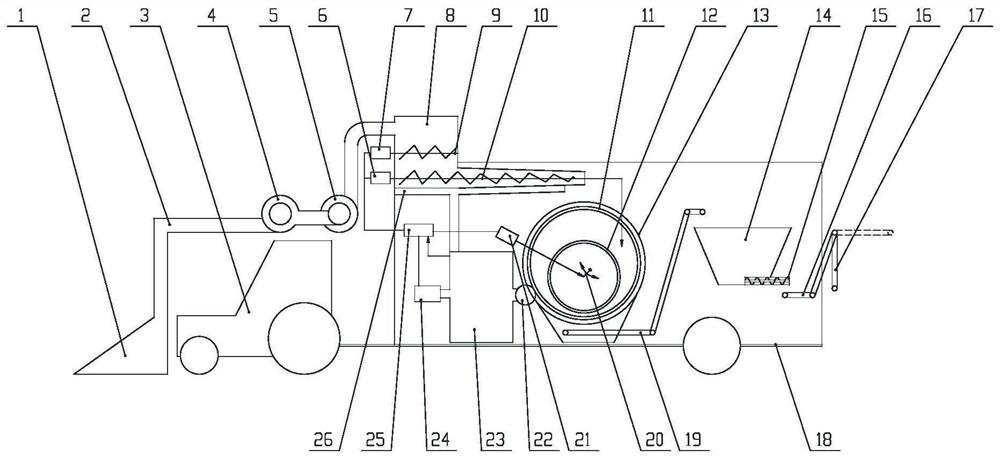

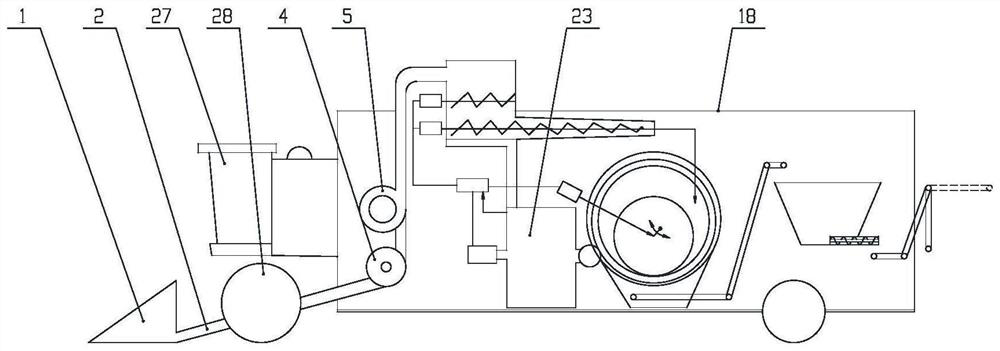

A Walking Straw Extrusion Forming Machine and a Field Straw Extrusion Forming Method

ActiveCN110692369BImprove granulation effectExcellent extrusion formabilityMowersBalingMolding machineProcess engineering

A walking straw extrusion molding machine, including a tractor, a straw harvesting device, a feeding device, a crushing device, a raw material storage box, a feeding device, an extrusion molding device, a molding material conveying device, a finished product hopper, a discharging device and Car body; the straw harvesting device is set on the front side of the tractor, and the car body is set on the rear side of the tractor and connected with the tractor; crushing device, feeding device, raw material storage box, conveying device, extrusion molding device, forming The material conveying device, the finished product hopper, and the unloading device are sequentially arranged on the car body, and the crushing device is connected with the straw harvesting device. A field straw extrusion molding method. The invention has the advantages of good granulation effect, good extrusion molding effect, small volume, more durable and the like. The invention belongs to the technical field of biomass energy.

Owner:长沙中能装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com