Thermoplastic elastomer refrigerator door sealing strip material and preparation method

A thermoplastic elastomer and refrigerator door technology, which is applied in the field of refrigerator door seal materials and preparation, can solve the problems of slow recovery of surface deformation, high requirements for transportation conditions, poor processing and molding effects, etc., and achieve fast recovery of surface deformation, wide range of hardness, The effect of convenient preparation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Adopt the preparation method of above-mentioned a kind of thermoplastic elastomer refrigerator door seal material, its concrete steps are:

[0021] Step 1: Weighing: Accurately weigh each component according to the range of parts in claim 1;

[0022] Step 2: Uniform mixing: Use a high-speed mixer to mix accurately weighed hydrogenated styrene isoprene (SEPS) or styrene-butadiene-styrene (SBS) or a mixture of both with equal proportions of filler oil , after fully mixing and absorbing the mixture, add other components in claim 1, and mix evenly to obtain powder;

[0023] Step 3: Granulation: Use a twin-screw extruder to extrude and granulate the mixed powder. The parameters of the twin-screw extruder are set to 150°C for the first zone, 155°C for the second zone, and 155°C for the third zone. The temperature of the fourth zone is 160°C, the temperature of the fifth zone is 165°C, the temperature of the sixth zone is 170°C, the temperature of the seventh zone is 170°C, t...

Embodiment 1

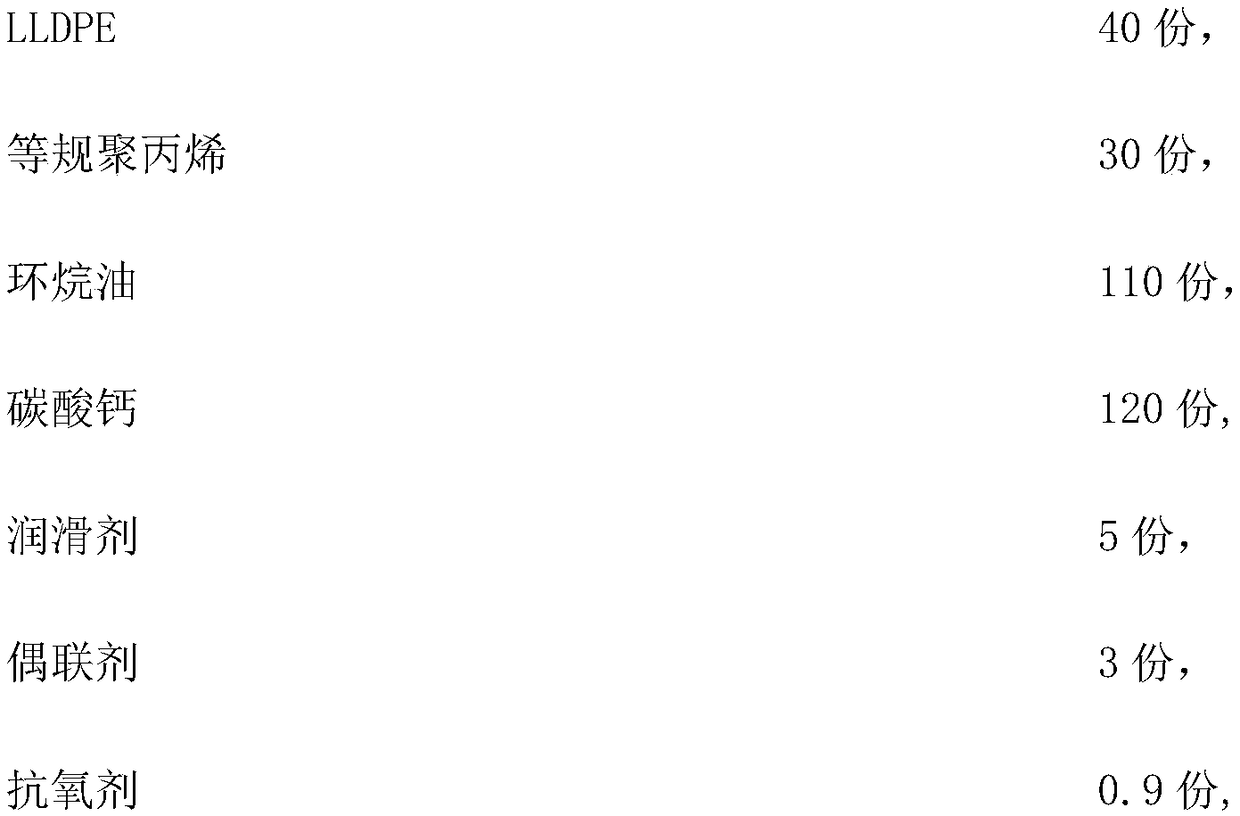

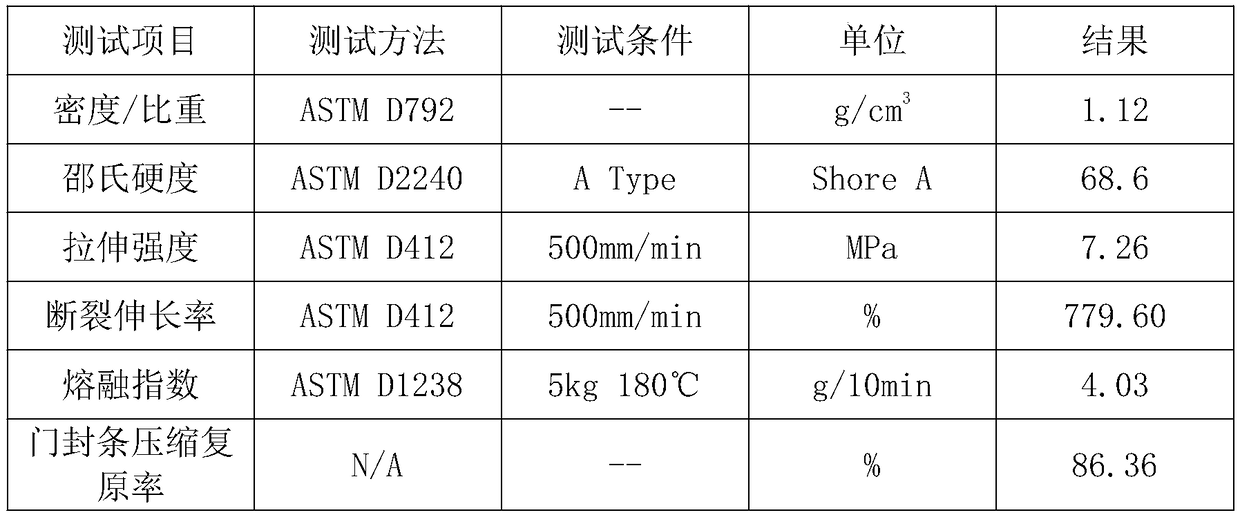

[0026] Refrigerator door seal material among the present invention is weighed by following material parts:

[0027]

[0028]

[0029] Mix SEPS, SBS and naphthenic oil in equal proportions in a high-speed mixer fully, after mixing, add the remaining components into the high-speed mixer step by step, and get powder after mixing evenly;

[0030] Extrude and granulate the above-mentioned mixed powder through a twin-screw extruder to minimize the residence time of the material in the screw. Gradually increase, and the temperature reaches the highest at the die at the rear end of the twin-screw extruder. The parameters of the twin-screw extruder are set to 150°C for the first zone, 155°C for the second zone, 160°C for the third zone, and 160°C for the fourth zone. The temperature of zone 160°C, the temperature of zone 5 is 165°C, the temperature of zone 6 is 170°C, the temperature of zone 7 is 170°C, the temperature of zone 8 is 175°C, the temperature of zone 11 is 175°C, and ...

Embodiment 2

[0037] Refrigerator door seal material among the present invention is weighed by following material parts:

[0038]

[0039]

[0040] Mix SEPS, SBS and naphthenic oil in equal proportions in a high-speed mixer fully, after mixing, add the remaining components into the high-speed mixer step by step, and get powder after mixing evenly;

[0041] Extrude and granulate the above-mentioned mixed materials through a twin-screw extruder to minimize the residence time of the materials in the screw. As the temperature rises, the temperature reaches the highest at the die at the rear end of the twin-screw extruder. The parameters of the twin-screw extruder are set to 150°C for zone 1, 155°C for zone 2, 160°C for zone 3, and 160°C for zone 4. The temperature is 160°C, the temperature in the fifth zone is 165°C, the temperature in the sixth zone is 170°C, the temperature in the seventh zone is 170°C, the temperature in the eighth zone is 175°C, the temperature in the eleventh zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com