Patents

Literature

315results about How to "Comfortable touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for making functionalized films for cleaning products

InactiveUS7727946B2Difficult to handleLow costOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsWater solubleCleaning product

Owner:MONOSOL LLC +1

Functionalized films

InactiveUS20060257596A1Avoid contactMore economicallyEnvelopes/bags making machineryOrganic detergent compounding agentsWater solubleAqueous solution

Process for making a functionalized substrate in the form of a water-soluble film carrying a coating of a functional composition, the process comprising applying to at least one side of the film an aqueous solution comprising one or more functional materials to form the coating wherein the coating is formed from a plurality of layers in a stepwise manner and / or the aqueous solution comprises a film insolubilizer agent.

Owner:MONOSOL LLC +1

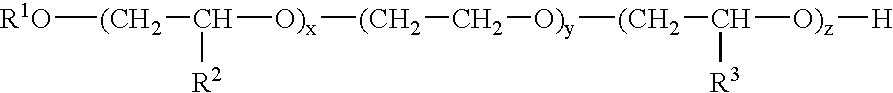

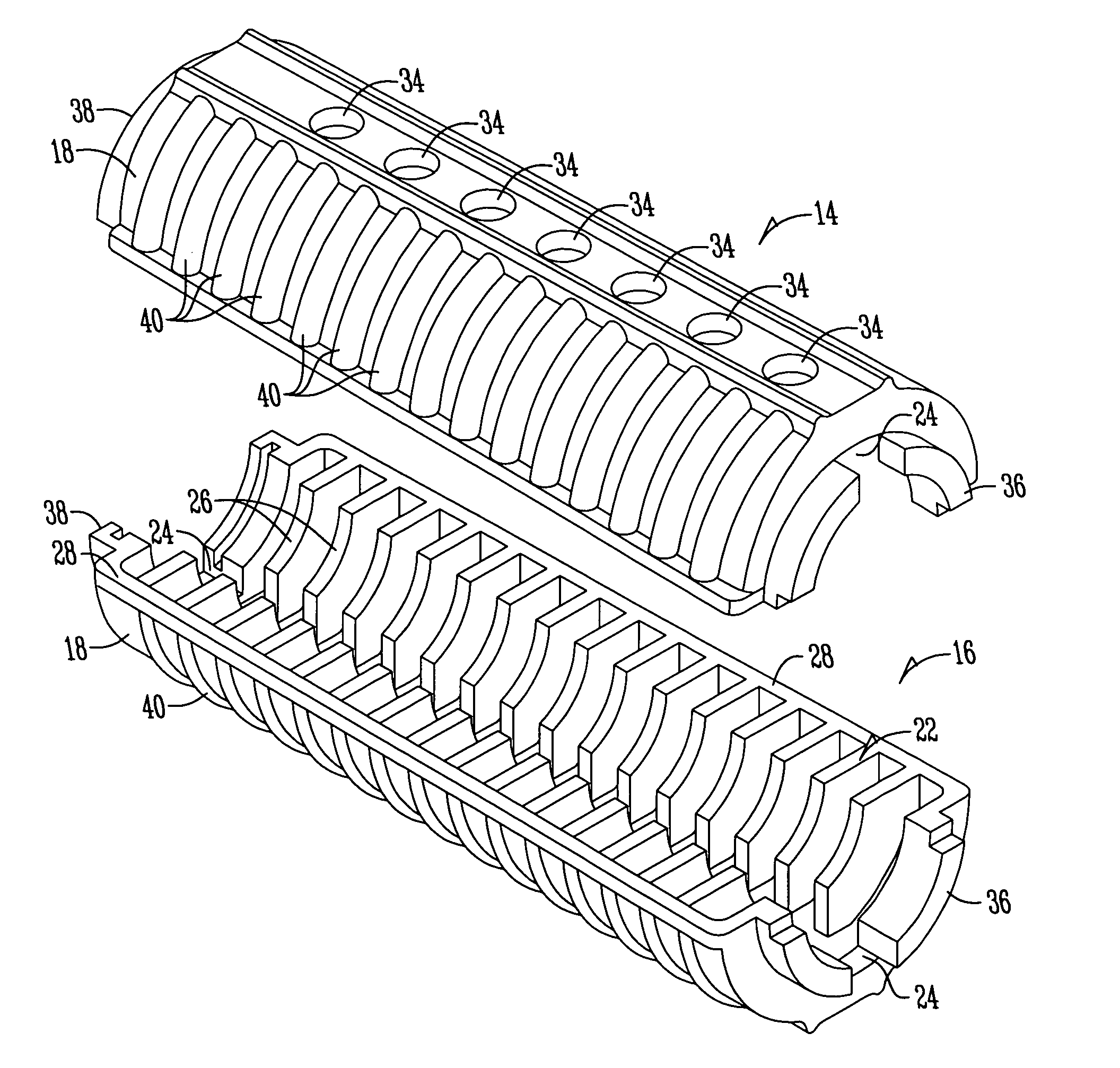

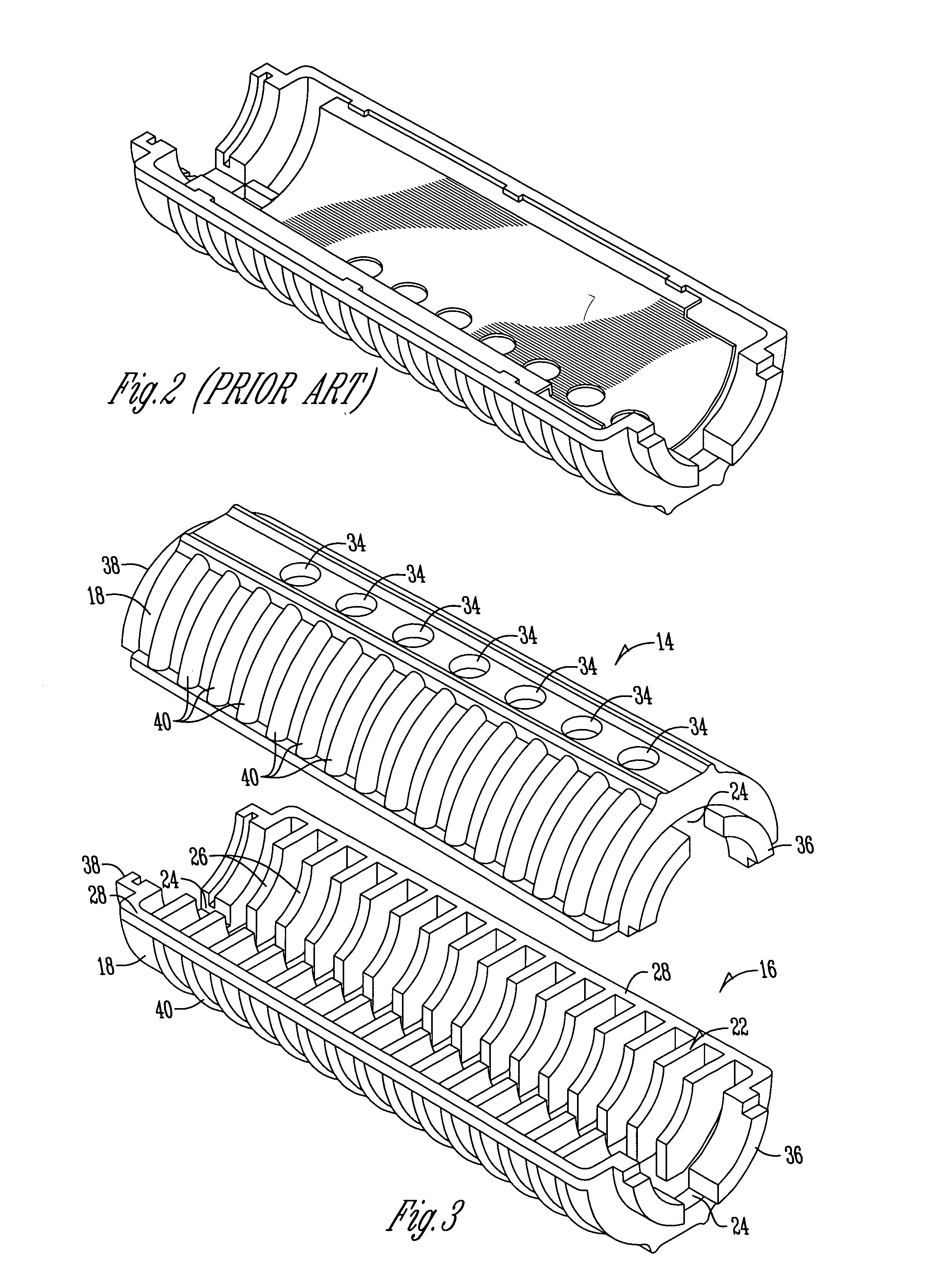

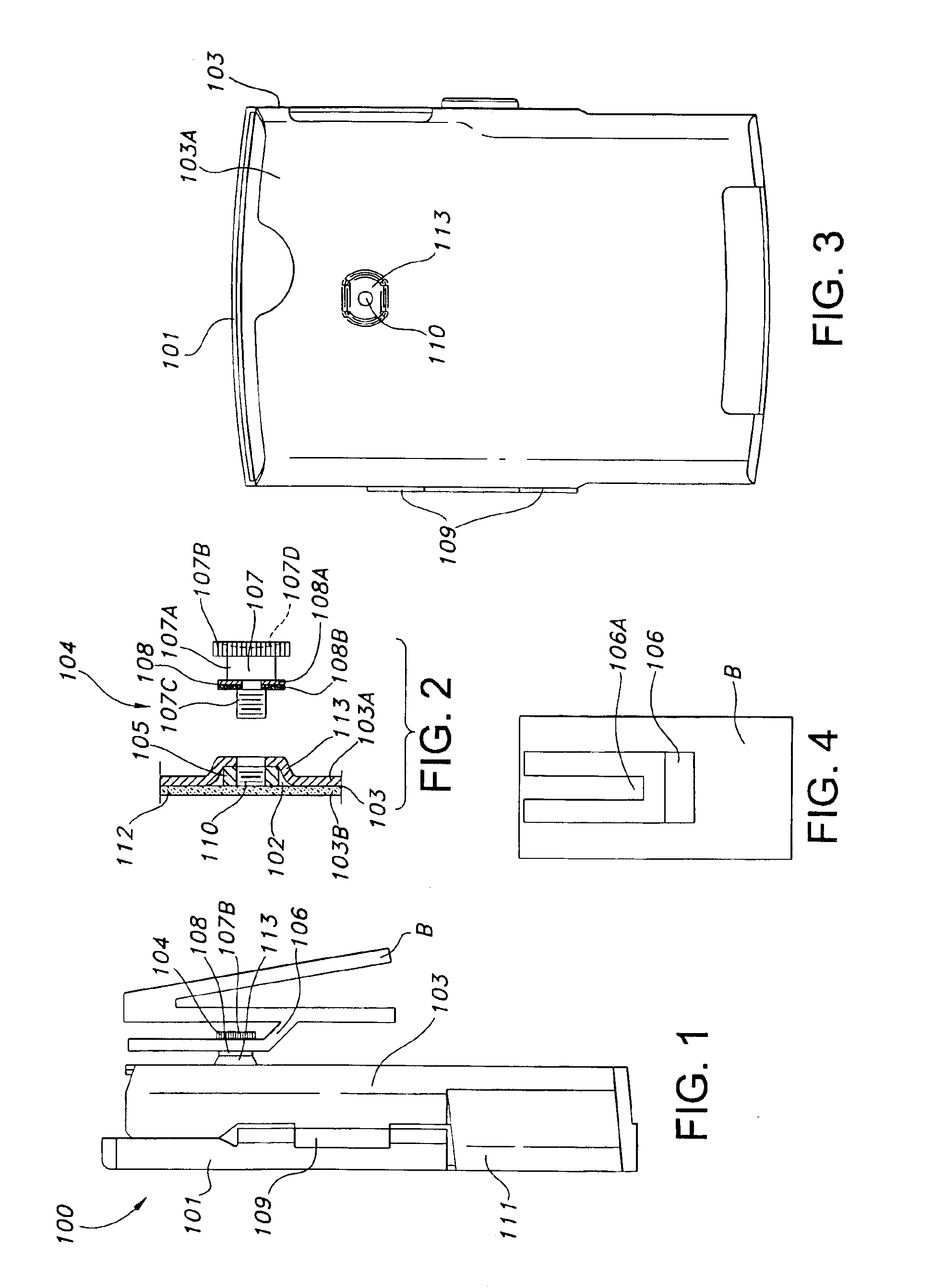

Finned carbine handguard assembly

ActiveUS6945154B1Improve impact resistanceHigh strengthVentillation systemsWeapon cleaningPlastic materialsEngineering

A gun barrel handguard includes half sections having longitudinally spaced apart fins of plastic material positioned around the exterior of the gun barrel for absorbing heat but preventing it from being quickly transmitted to the exterior of the handguard.

Owner:JJE BRANDS LLC

Multi-Function Surface Treatment Tool

InactiveUS20070209133A1Readily visually monitoredLow costLiquid surface applicatorsBathroom accessoriesPersonal careMassage

A chemical-mechanical applicator for treating and cleaning surfaces in the domestic, automotive aftermarket, personal care and cosmetic sectors. The applicator wets, agitates / massages, and scrapes off residue leaving a surface dry and clean without soiling users hands. The applicator is a blade like device integrated with a dispenser device that is coupled to one or more reservoirs from which fluids are dispensed onto a surface. The blade carries a multiplicity of pads interspersed with scraper edges. The pads are used for rubbing and swabbing off. The scrappers are used for scraping and drying by squeegee action, the collected up used fluids retained within the blade.

Owner:LINZELL GEOFFREY ROBERT

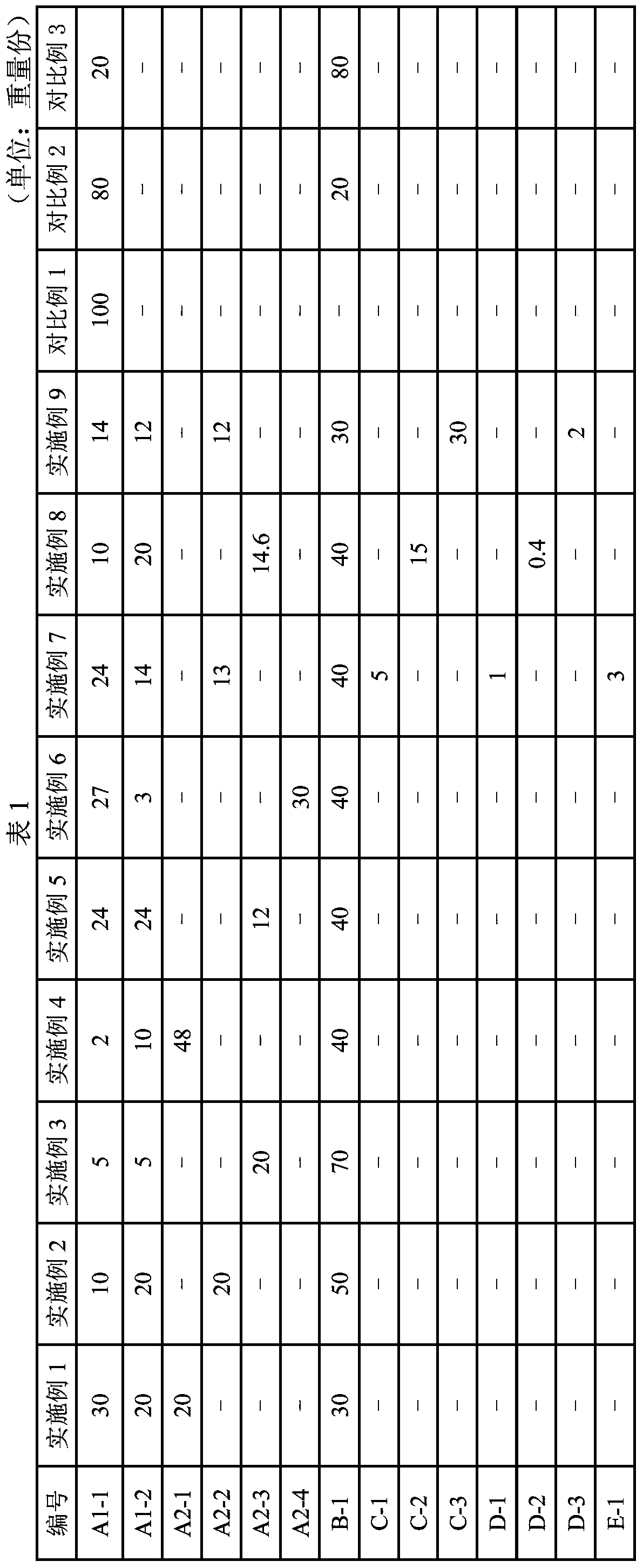

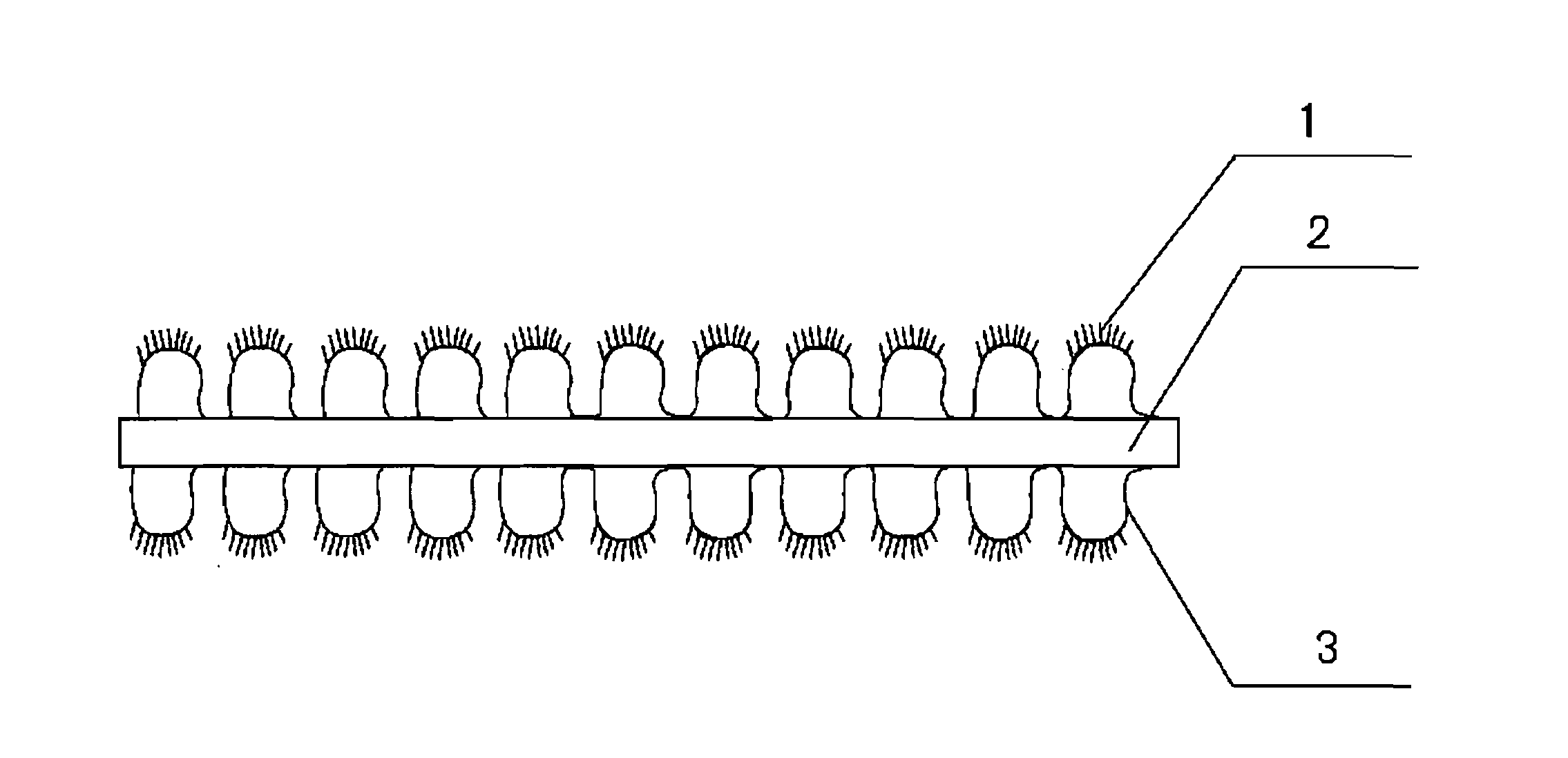

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

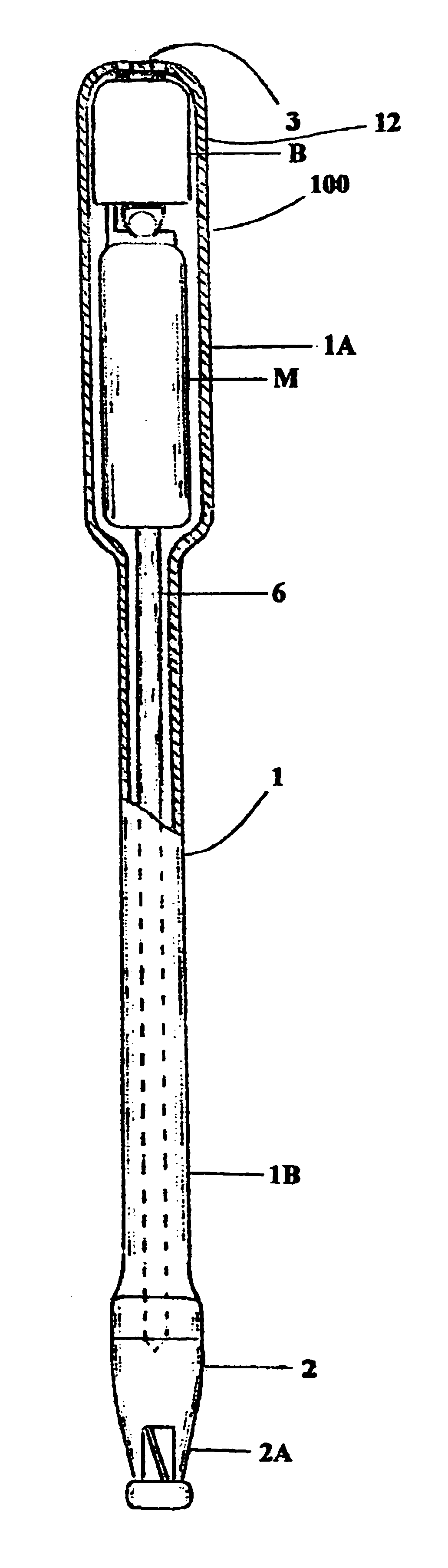

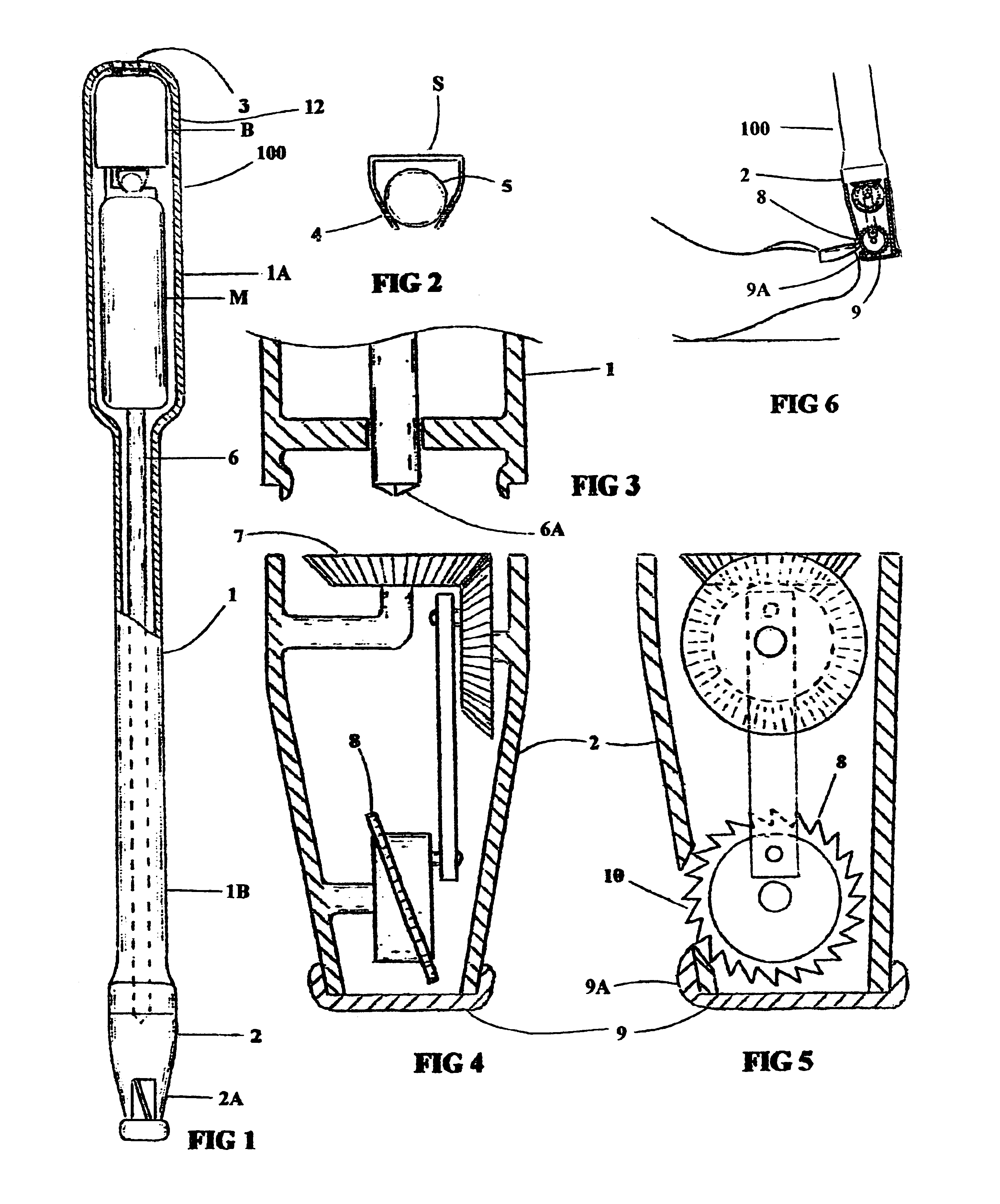

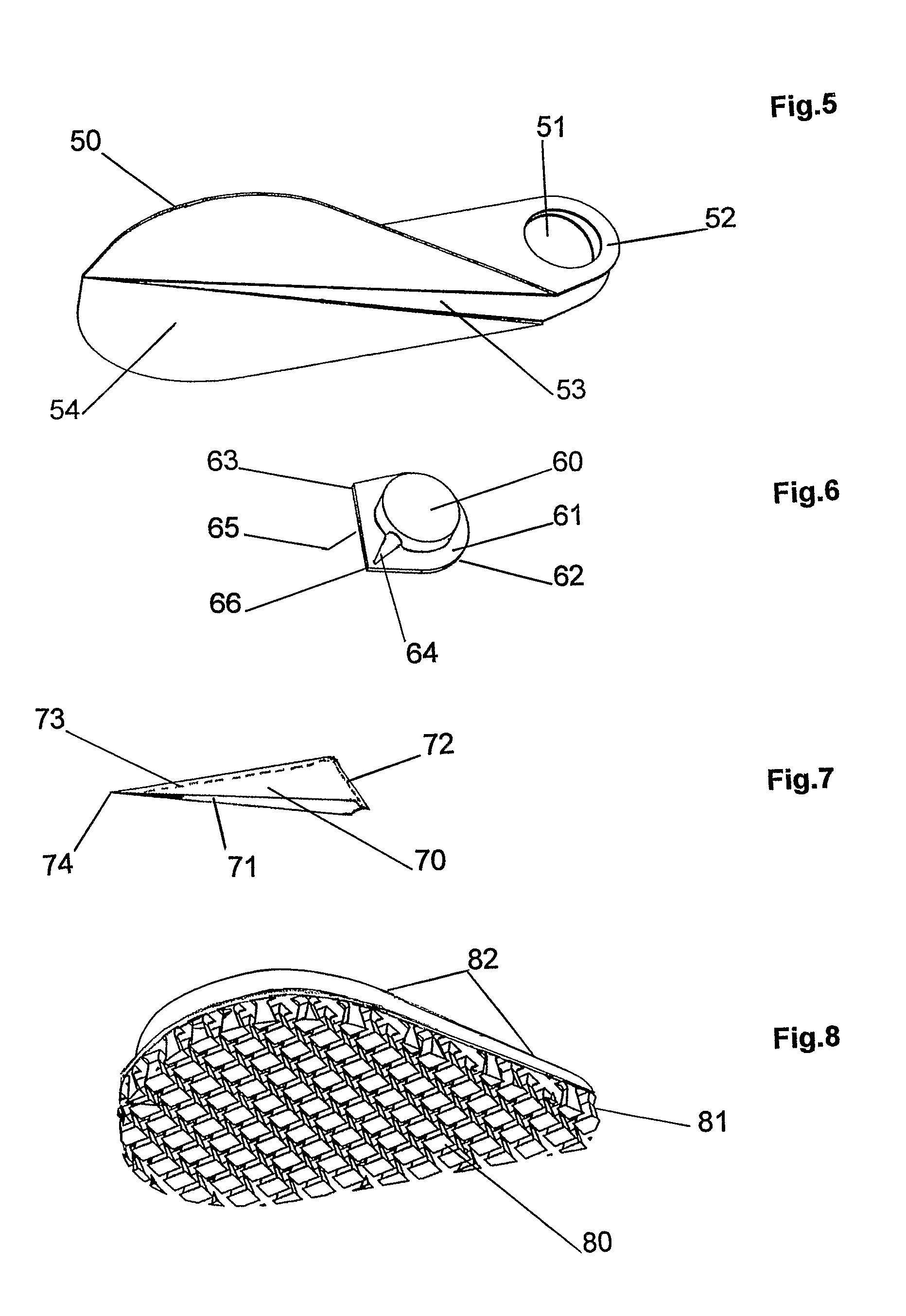

Nail trimmer

InactiveUS6865812B1Sufficient forceComfortable postureManicure/pedicureMetal working apparatusGear wheelEngineering

A nail trimmer for enabling a person to comfortably trim toenails without having to take on an awkward or uncomfortable posture. The nail trimmer has a long extension housing, which has a handle at its upper end and a trimmer unit at its lower end. A battery operated motor and on / off switch are incorporated into the handle end. A detachable trimmer unit is connected at the lower end. A dado cutting blade and a gear unit are enclosed in the trimmer unit. An opening in the trimmer unit housing provides access to the cutting edge of the blade.

Owner:MARTIN JR ROY C

Protective case for use with a belt

InactiveUS6905051B2Comfortable touchShock absorptionTravelling sacksTravelling carriersEngineeringSurface plate

Owner:CHEE BILL TSANG CHUN

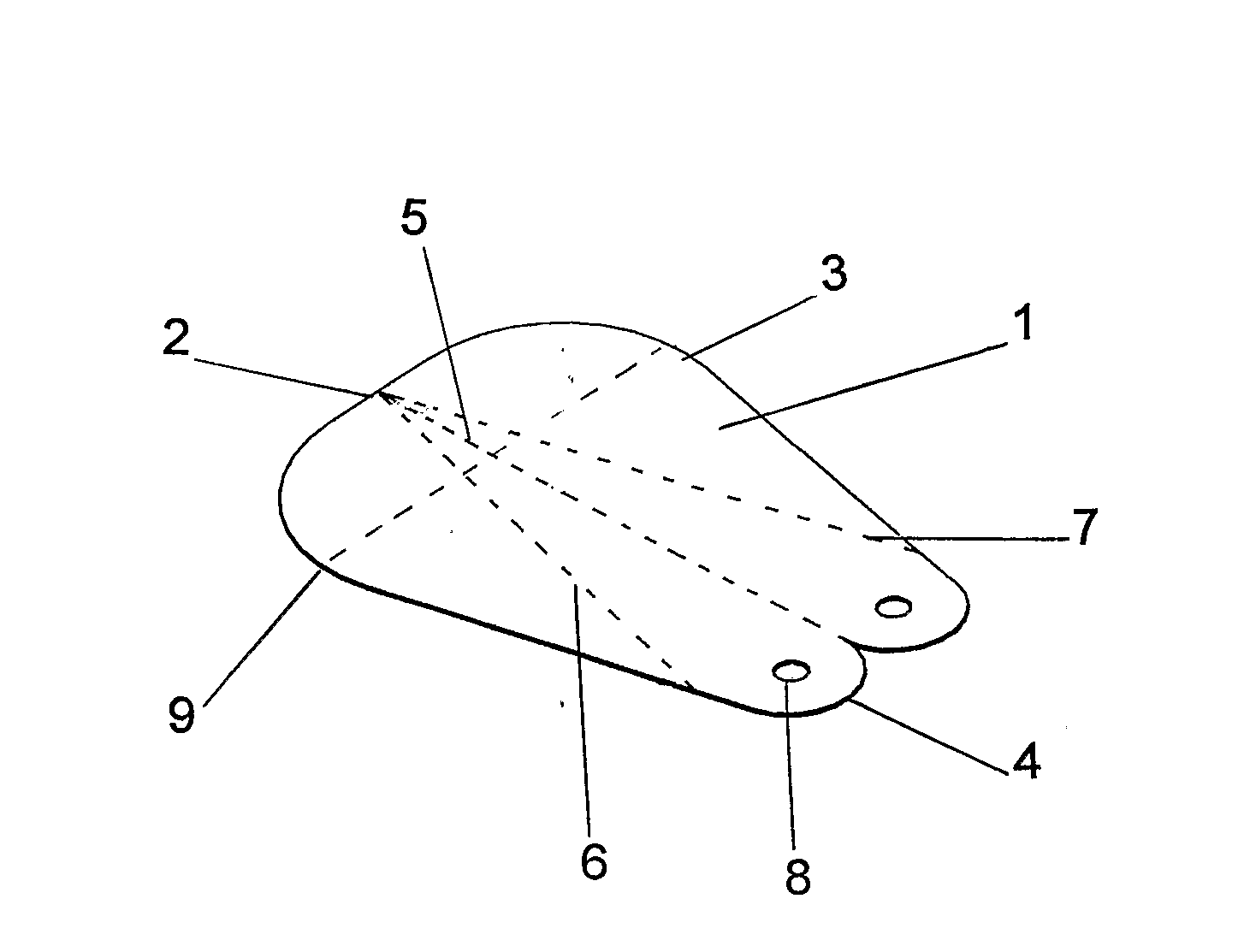

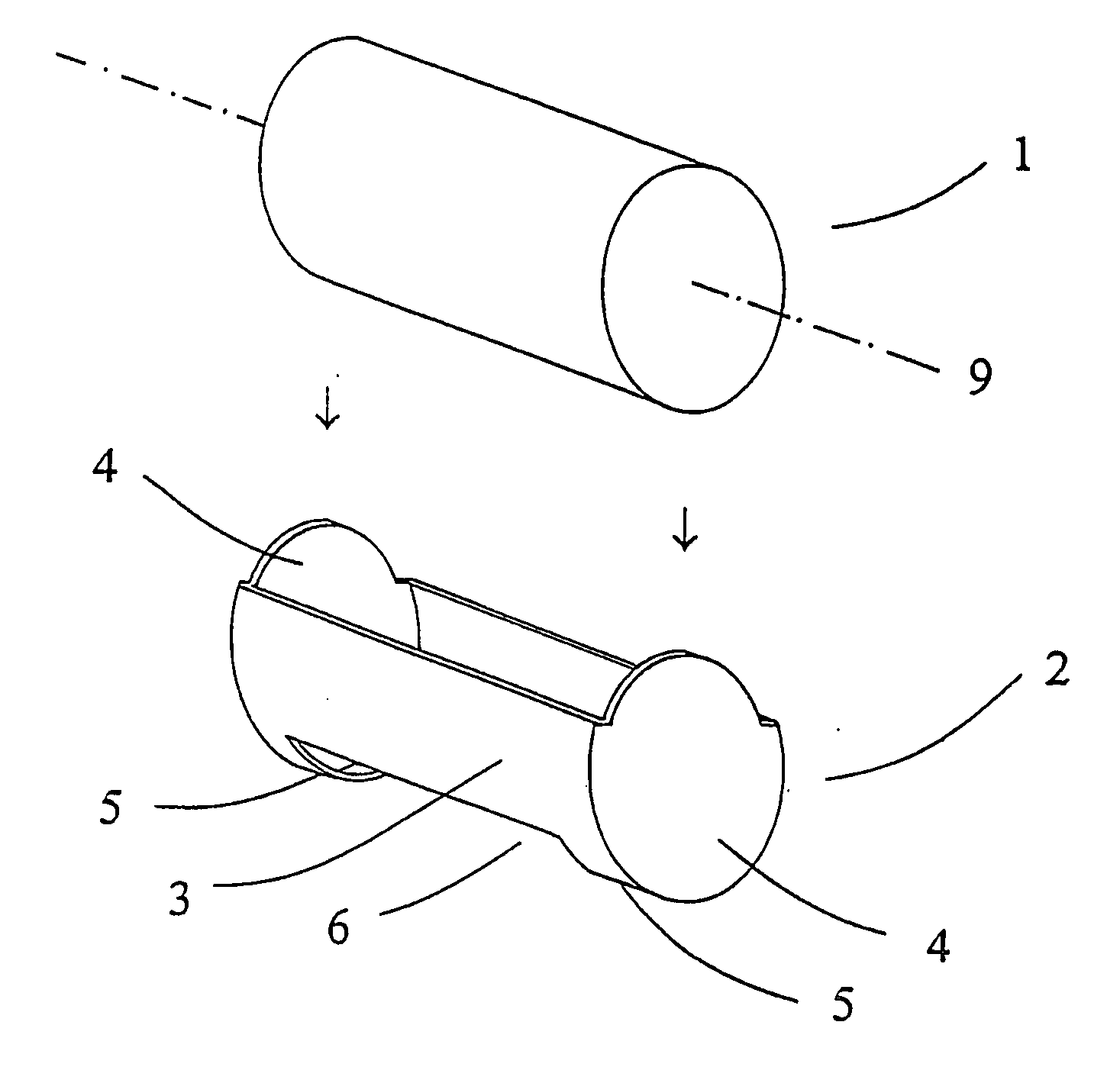

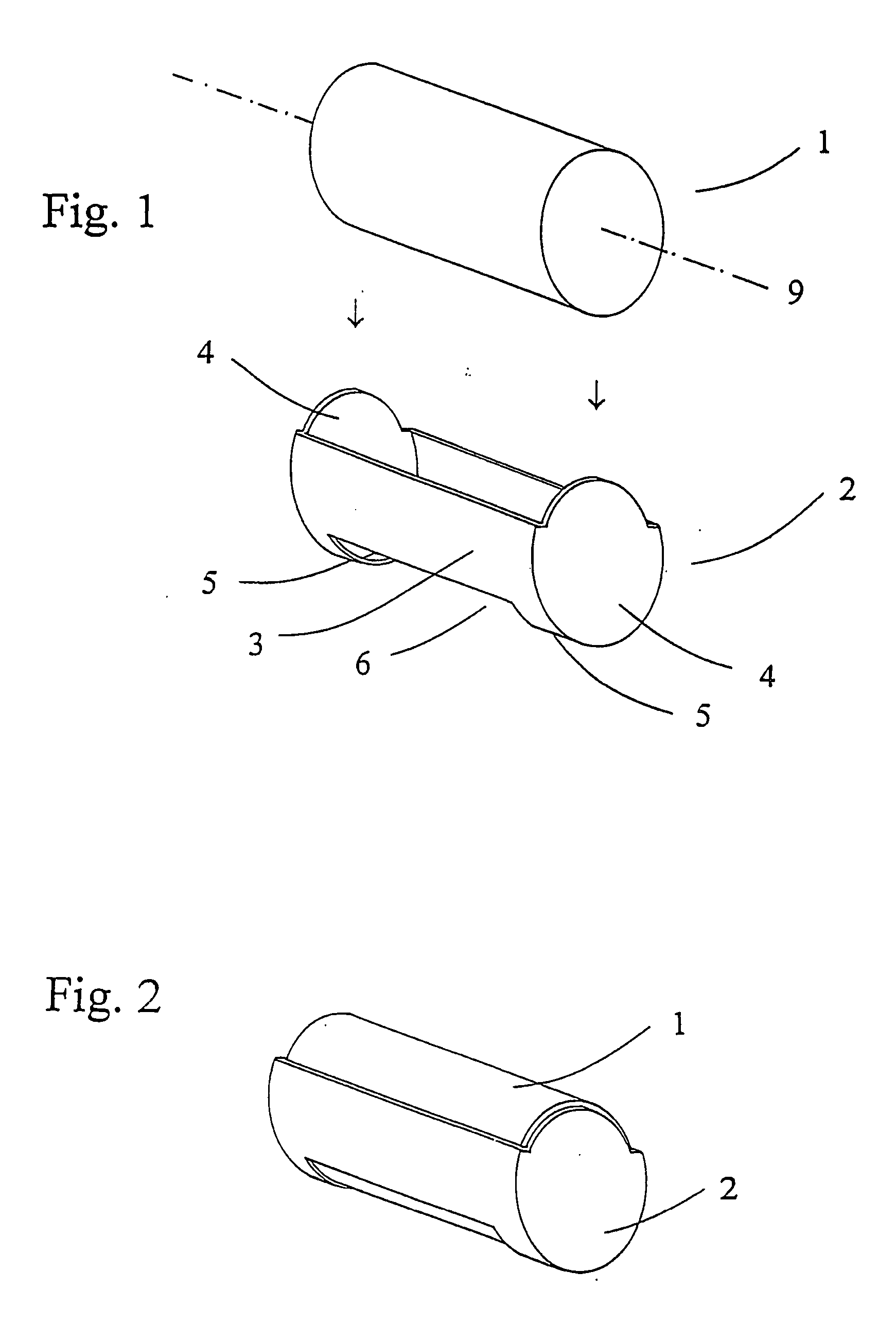

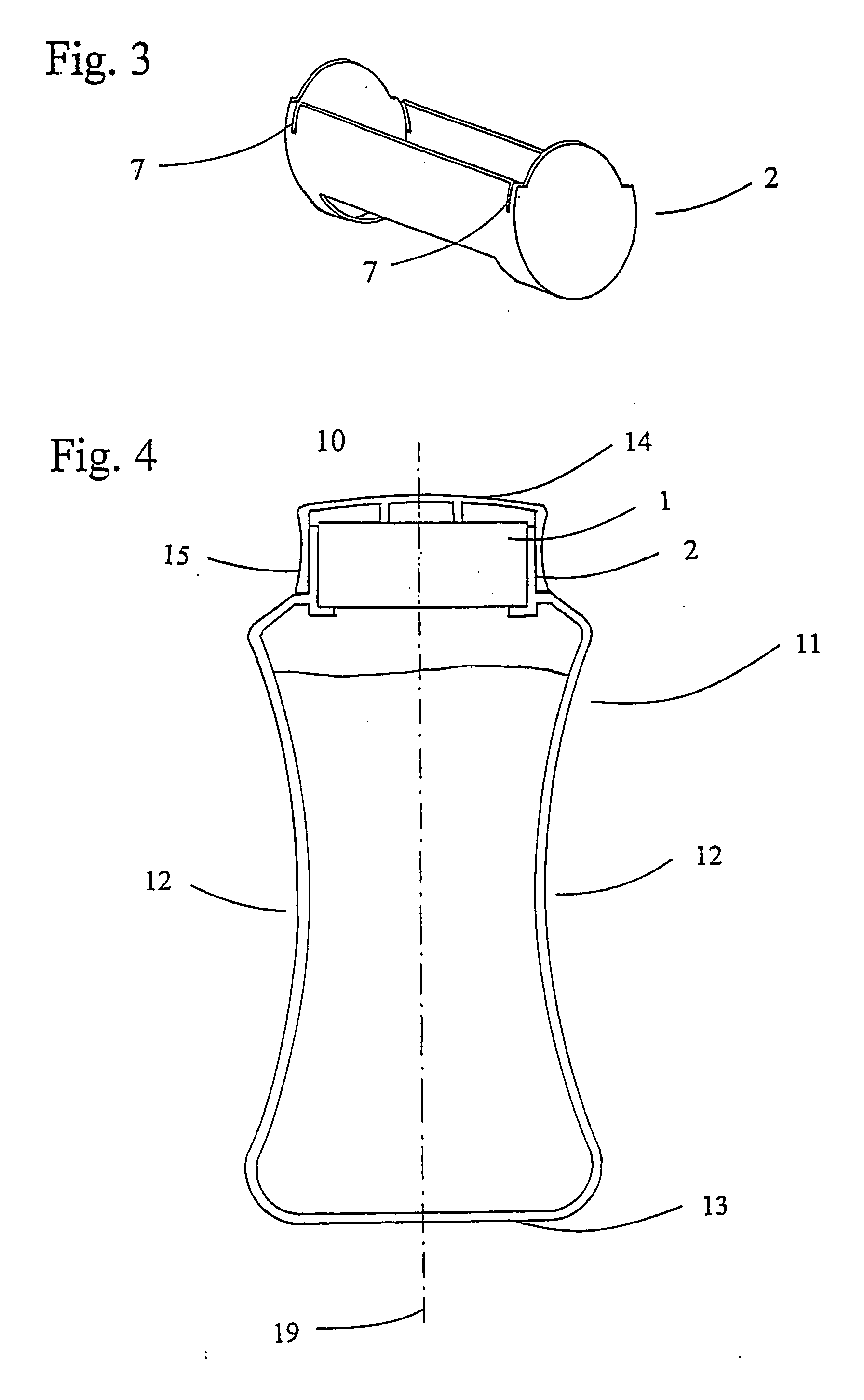

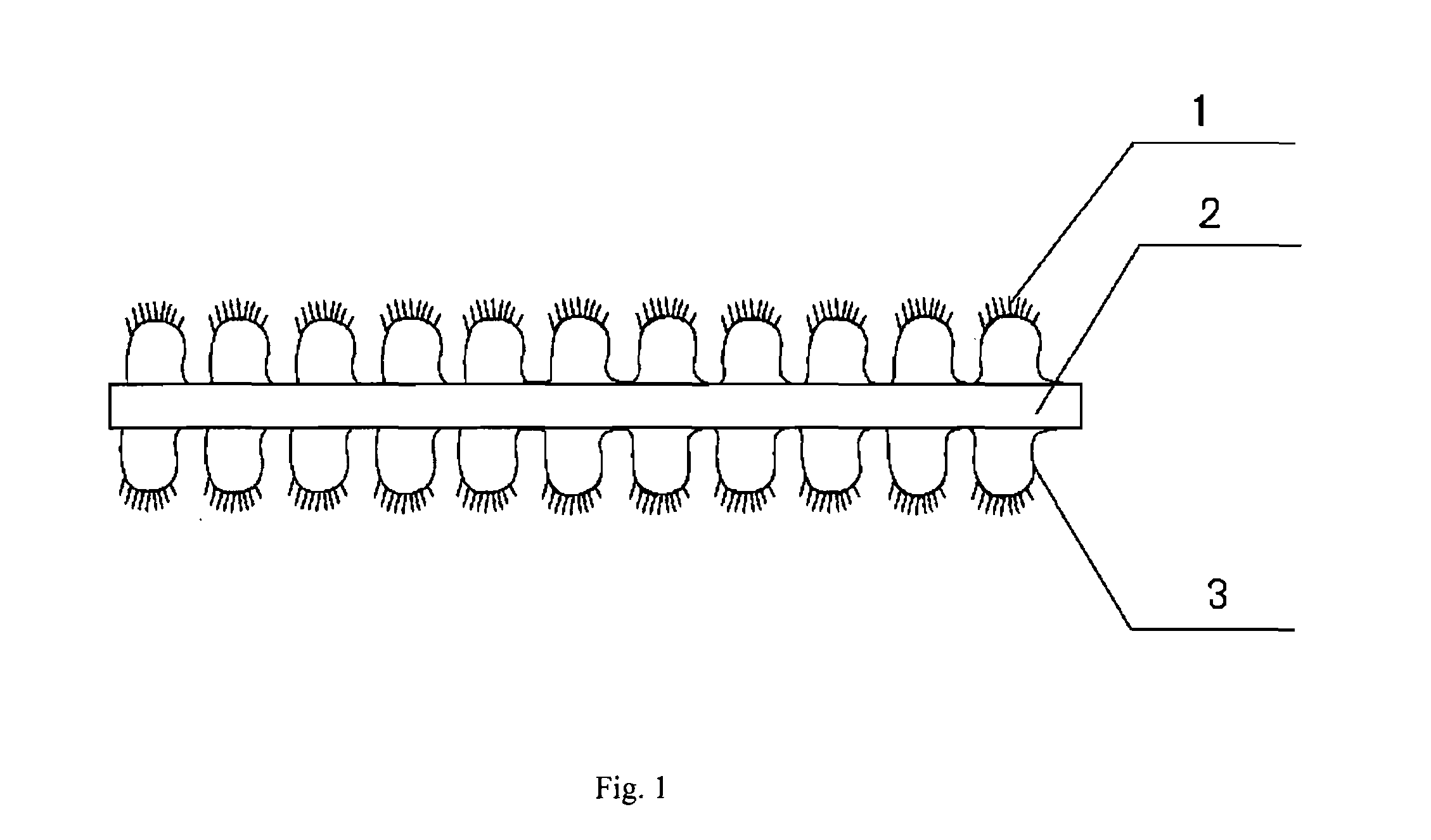

Cylindrical applicator for dispensing cosmetic compositions

InactiveUS20070071538A1Prevent leakageComfortable touchPackaging toiletriesPackaging cosmeticsSkin surfacesTissue skin

Cylindrical applicator for dispensing cosmetic compositions in the form of liquid, cream, gel or other, onto the human skin. The invention comprises an applicator in the form of a cylinder (1) of rigid material, encased by pressure inside a seat (2) of resilient material, said seat consists of two semicircular guides (3), joined by two support circles (4), and two inferior braces (5) that define the distribution opening (6), being said cylinder (1) free to roll. The present invention is the main part of the head section of various packages. Said cylinder (1) is coated by the cosmetic product when the container is turned upside-down, and rolled against the skin, applying the product uniformly. When pressed down by internal elements of the cap, the cylinder (1) seal the distribution opening (6). With a larger area of application, the present invention is used to apply a large number of cosmetic products to extensive areas, like the face or the body.

Owner:DORIA ANTONIO SILVIO SAMPAIO

Microporous plastic film

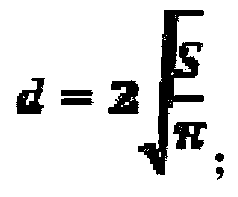

ActiveCN104164067AFully biodegradableWill not cause white pollutionMoisture permeabilityPlastic film

The invention relates to a microporous plastic film. According to the invention, an area of surface pores with diameters within a range of 0.2-7mum accounts for 0.5-15% of a total surface area. A water resistance of the film is higher than 800mm, and a moisture permeability of the film is higher than 1000g / m<2>.day. A stiffness of the film is lower than 40mm. The microporous plastic film provided by the invention has complete biodegradability, and does not cause white pollution. The film is green and environment-friendly, and has good waterproof performance and moisture permeability. The film is soft, and provides a comfortable touch. The film has good forming and processing performances, and can be applied in fields such as sanitary materials, clothing, and building. The microporous plastic film has waterproof, moisture-permeating, and air-permeating effects.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Leadless bone porcelain and method for preparing same

The invention discloses leadless bone china and a preparation method thereof. The leadless bone china consists of cattle bone coal, pig bone coal, sandstone in Datong, quartz, feldspar, kaolin, calcined kaolin, and bentonite. The preparation method is as follows: leadless bone china is sorted manually, pulverized and processed; b. calcining, ball milling and alkaline cleaning process equipment and process are adopted for the bone coal; c. wet process is adopted for preparing semi-finished china and glaze; d. roll forming process and chain-type dryness are adopted for flat products and products in regular shape; e. high temperature biscuit firing with natural gas and medium and low temperature glaze firing are adopted; f. machine and manual spraying glazing are adopted for glazing; g. a roller hearth furnace is adopted for enamel firing in the environment of natural gases. The leadless bone china is primarily prepared with sandstone in Datong; the molding ratio of the product is as high as 96 percent; the product is transparent, light, fine and hard; the china is harder, whiter and more transparent than the ordinary china.

Owner:SHANXI MINGHE CERAMIC

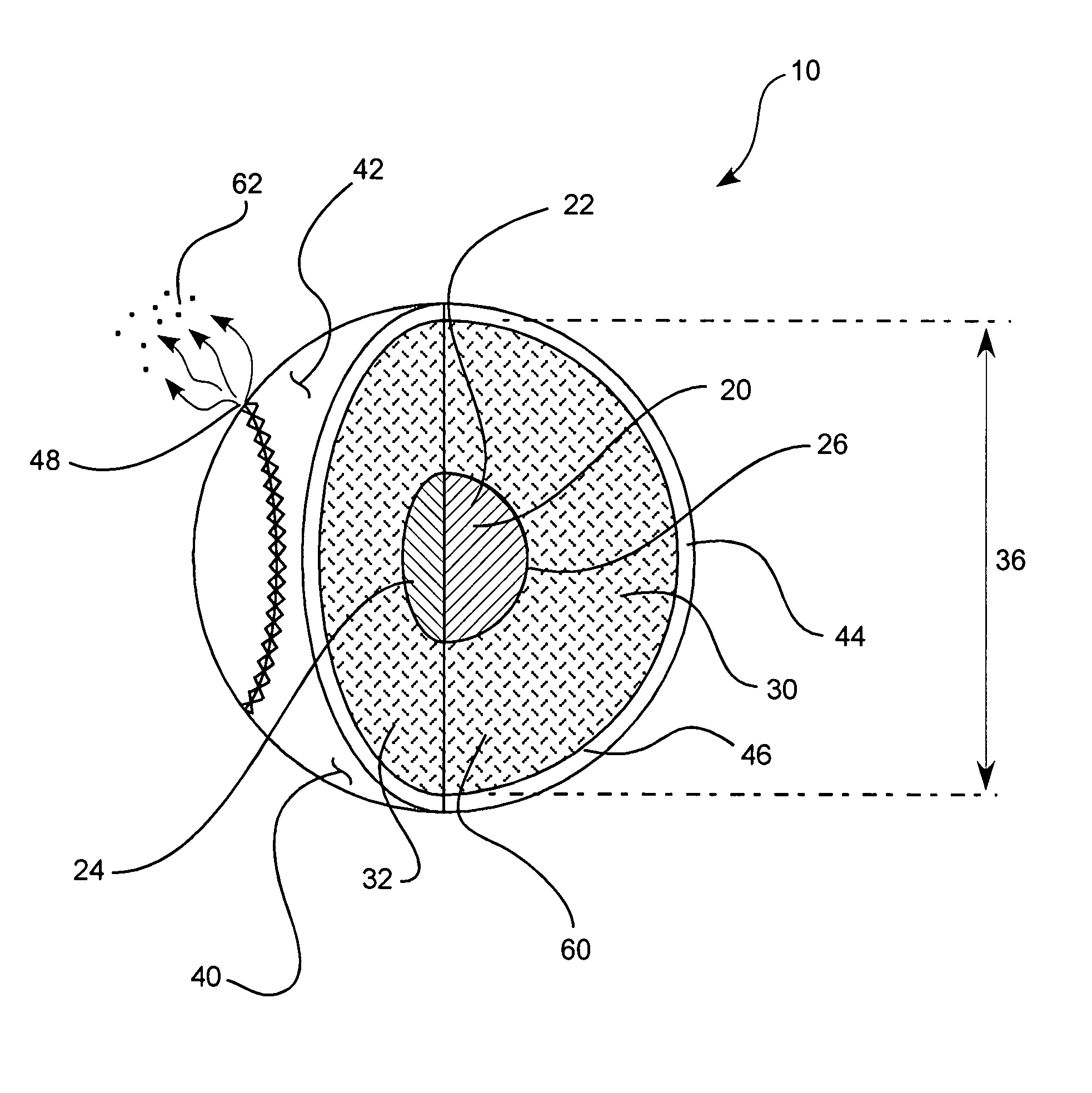

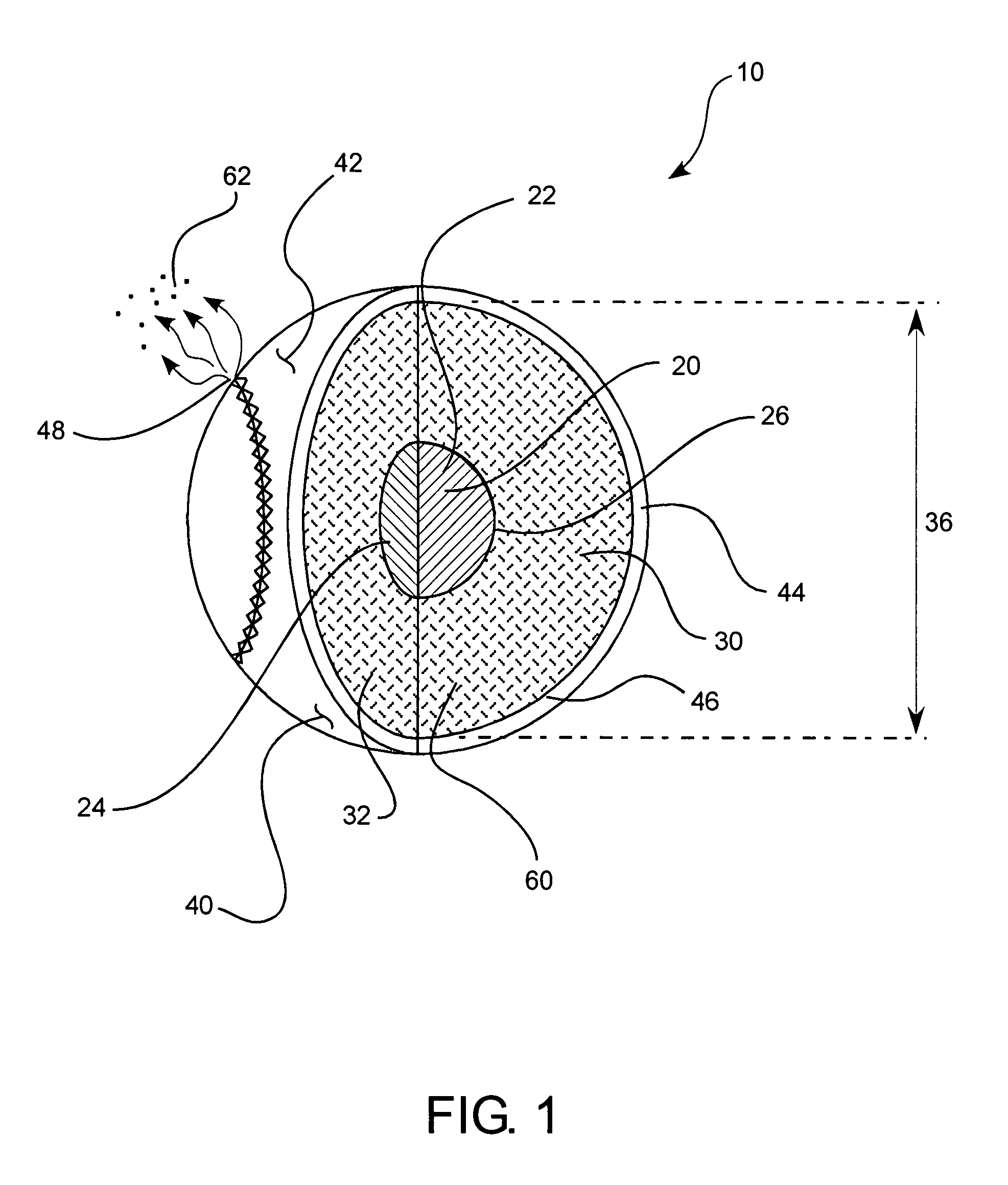

Aromatherapy puffer ball

ActiveUS7815878B1Easily located and positionedComfortable handlingSmall article dispensingCapsAromatherapyThree dimensional shape

An air freshener device includes an open-cell, polyurethane foam body having a scent material interspersed in the foam body that is capable of diffusing out of the foam, and a flexible cover surrounding and conforming to the foam body having at least one hole in the cover to facilitate the release of scent. The foam body can be flexible and compressible, and also resilient and returnable to its original configuration. The flexible cover can have a fabric shell that is soothing to the touch, and may also have a non-porous inner liner to contain the scent material and prevent it from migrating out of the foam body. In addition, the air freshener can have a freestanding, self-supported, three-dimensional shape, and can be fashioned into the shape of a common sports ball, such as a baseball.

Owner:HANDSTANDS PROMO LLC

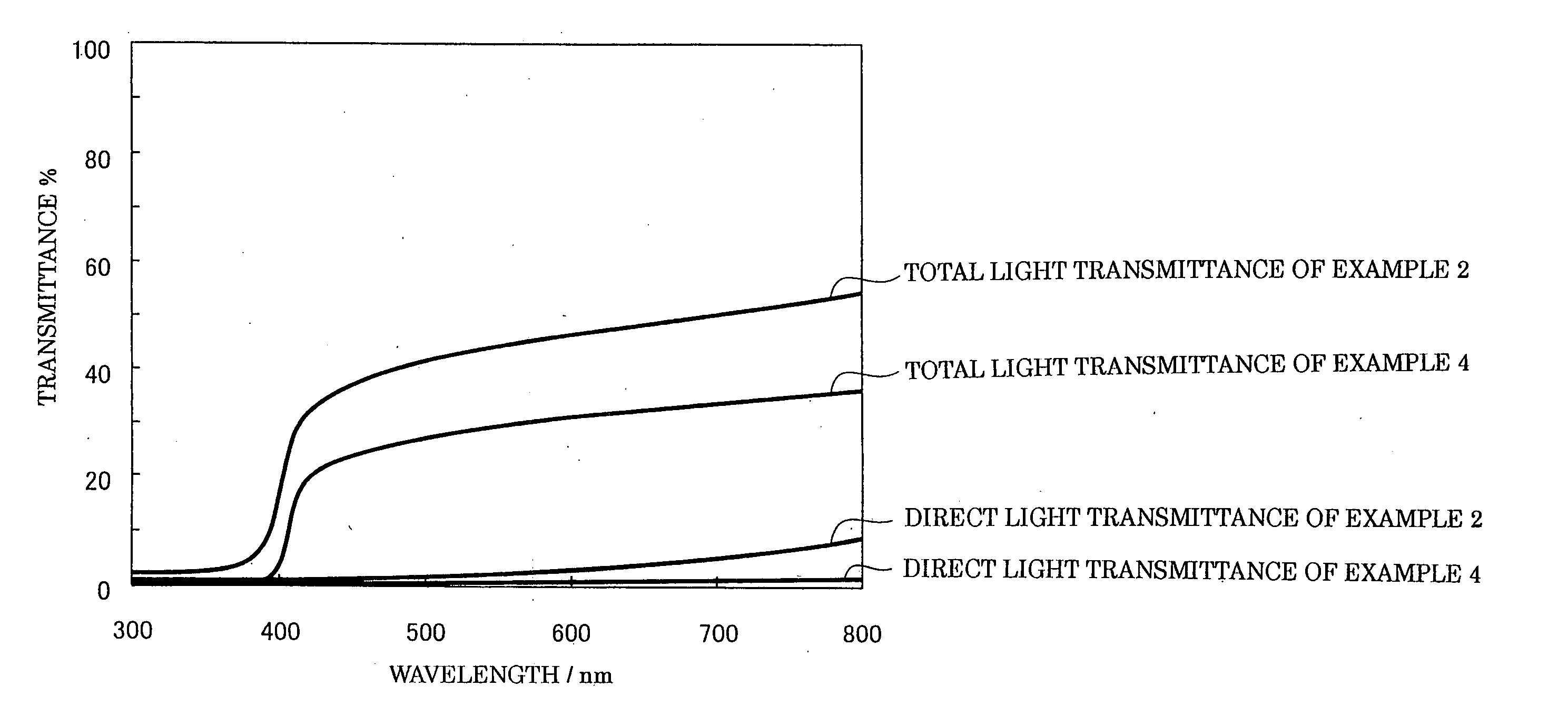

Flaky particles, and cosmetic, coating material composition, resin composition and ink composition ezch containing the same

InactiveUS20050113485A1Improve the scattering effectDifficult to seeCosmetic preparationsPigmenting treatmentDiffusionRefractive index

Flaky particles suitable for a filler having high durability and high weatherability which absorbs reduced amount of visible light and effectively scatters visible light are provided. By using the flaky particles to be contained, a cosmetic or the like capable of giving good usability such as spreading well on the skin, exhibiting bright and clear appearance for long period is provided. The flaky particles comprise mother particles of metallic oxide of low refractive index and microparticles of metallic oxide of high refractive index having a mean particle size of 160-450 nm dispersed inside the mother particles in an amount of 5-50% by weight, wherein the flaky particles have a light diffusion degree of 80 or more. The flaky particles preferably have a mean particle size of 5-500 μm, a mean thickness of 0.1-5 μm, and a mean aspect ratio of 5-300.

Owner:NIPPON SHEET GLASS CO LTD

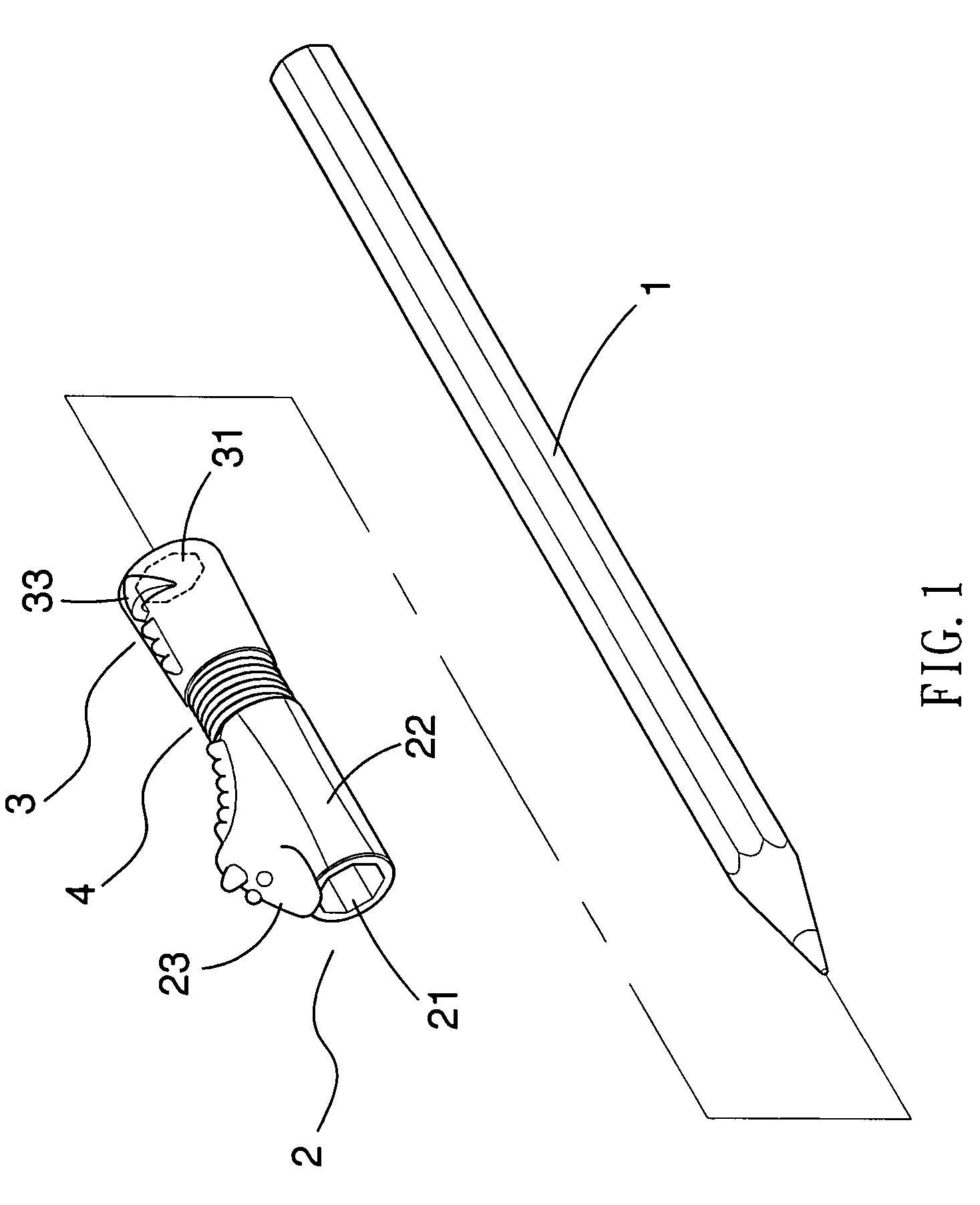

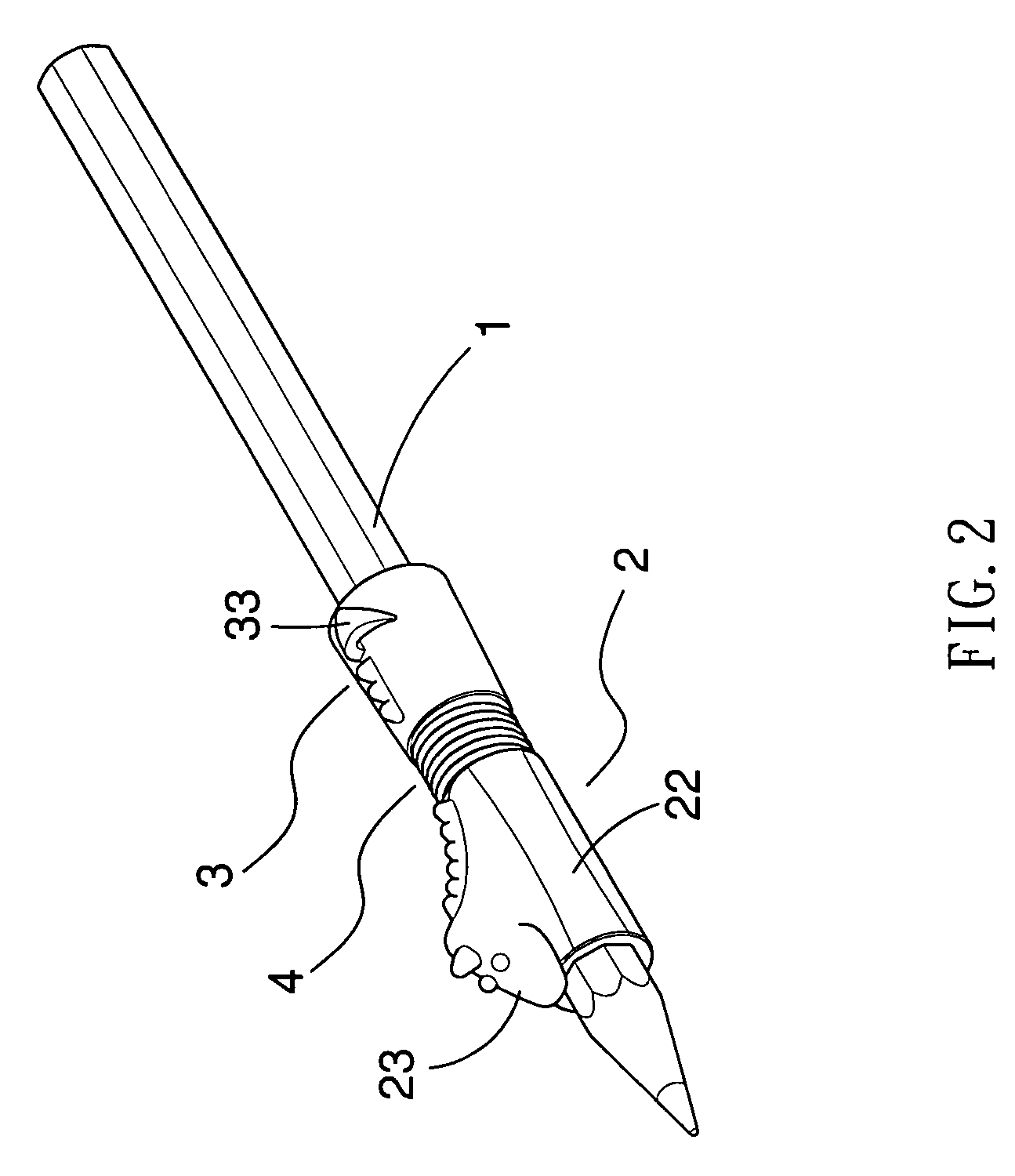

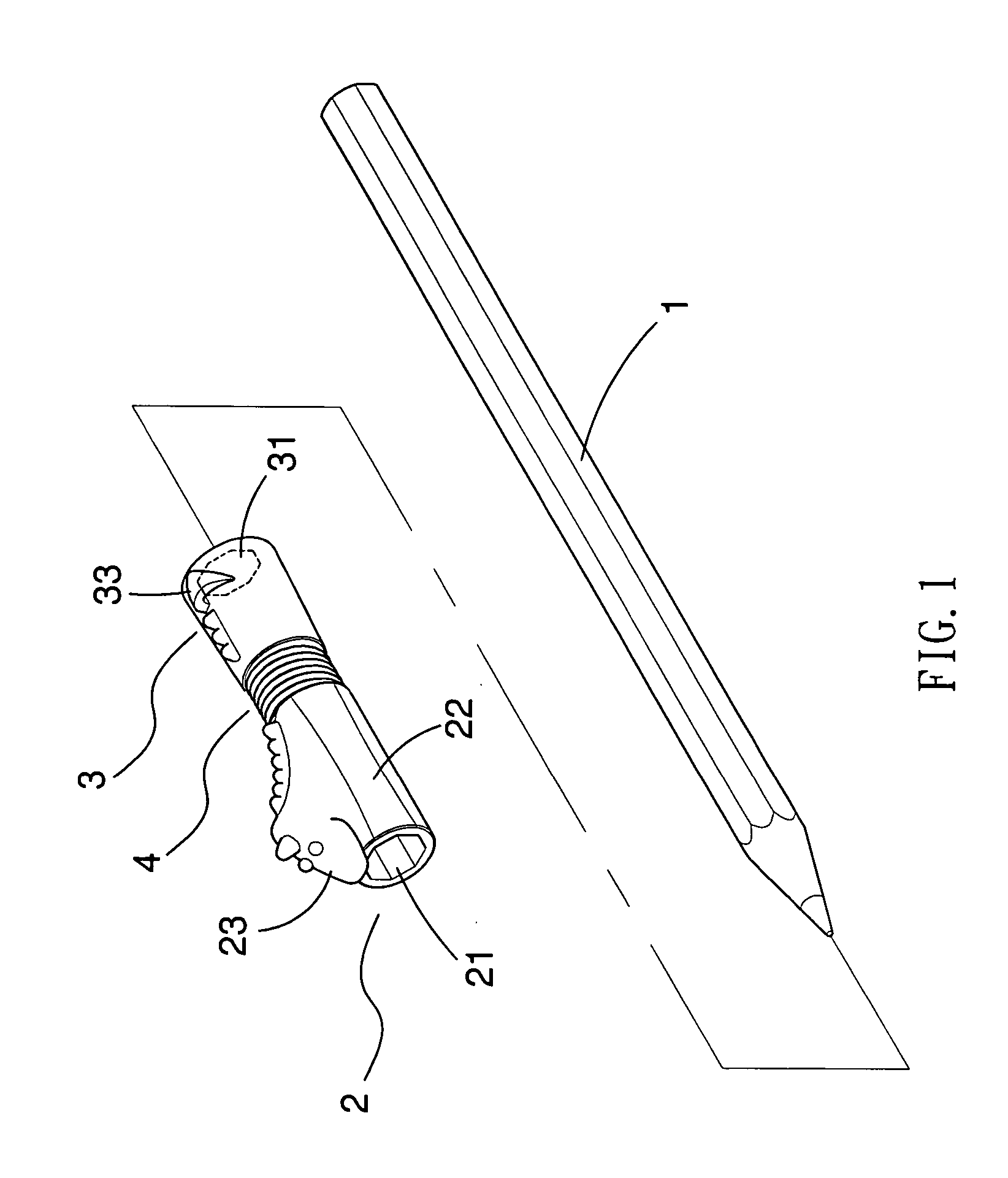

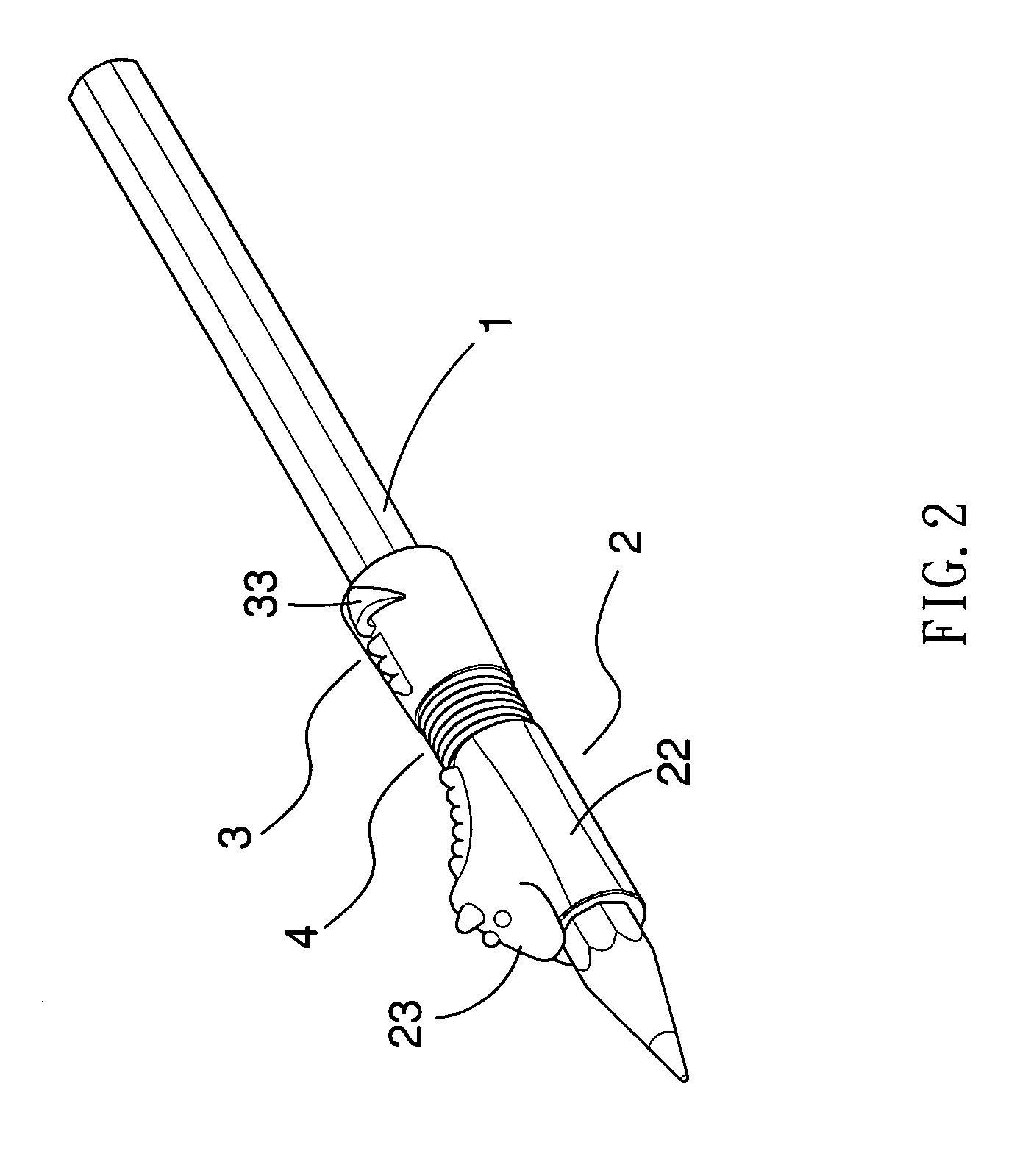

Adjustable dual sleeve pen holding auxiliary device

InactiveUS7014379B2Comfortable touchAdjustable distanceTravelling carriersHoldersIndex fingerBiomedical engineering

Owner:CHENG DIDO

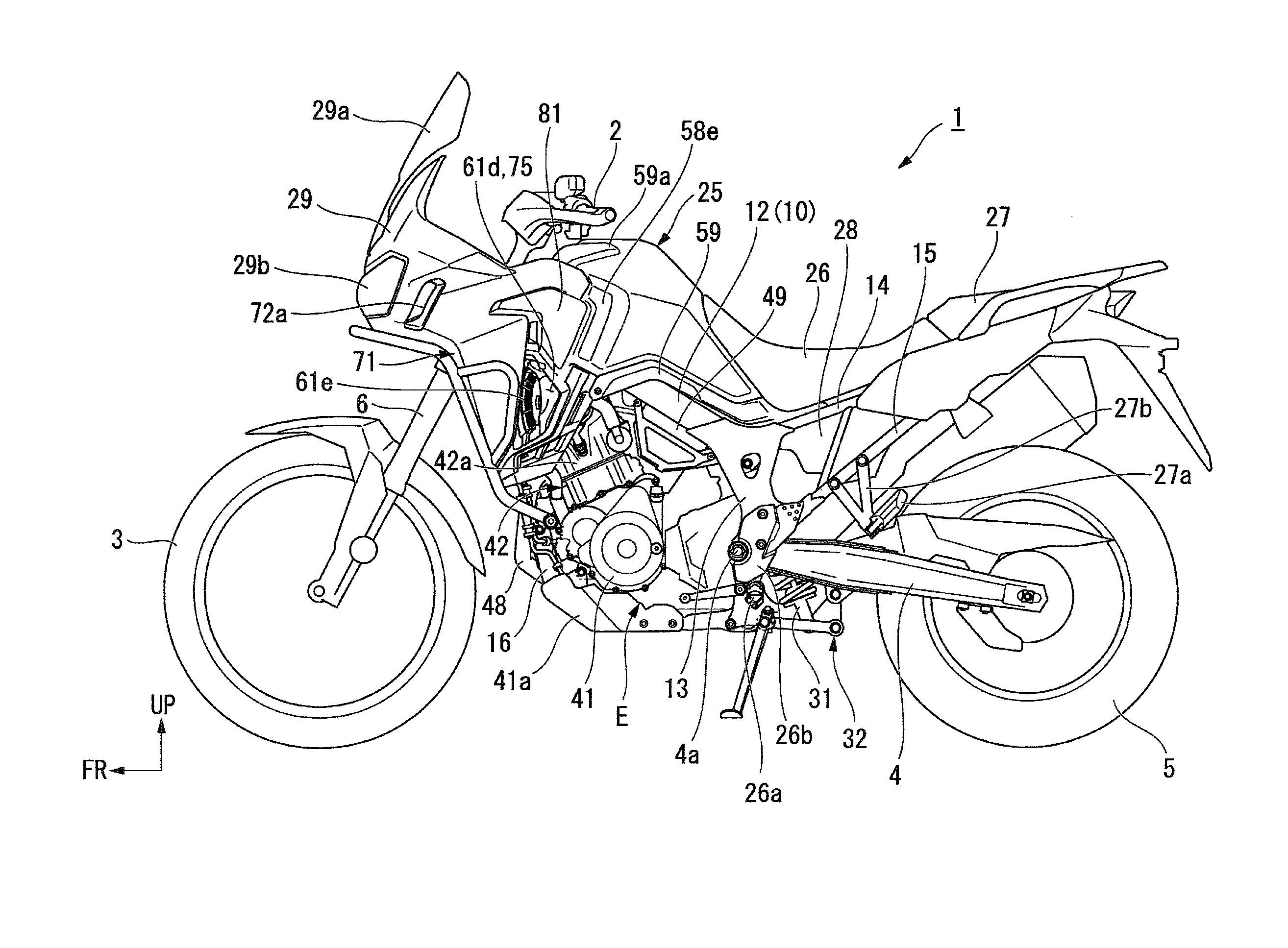

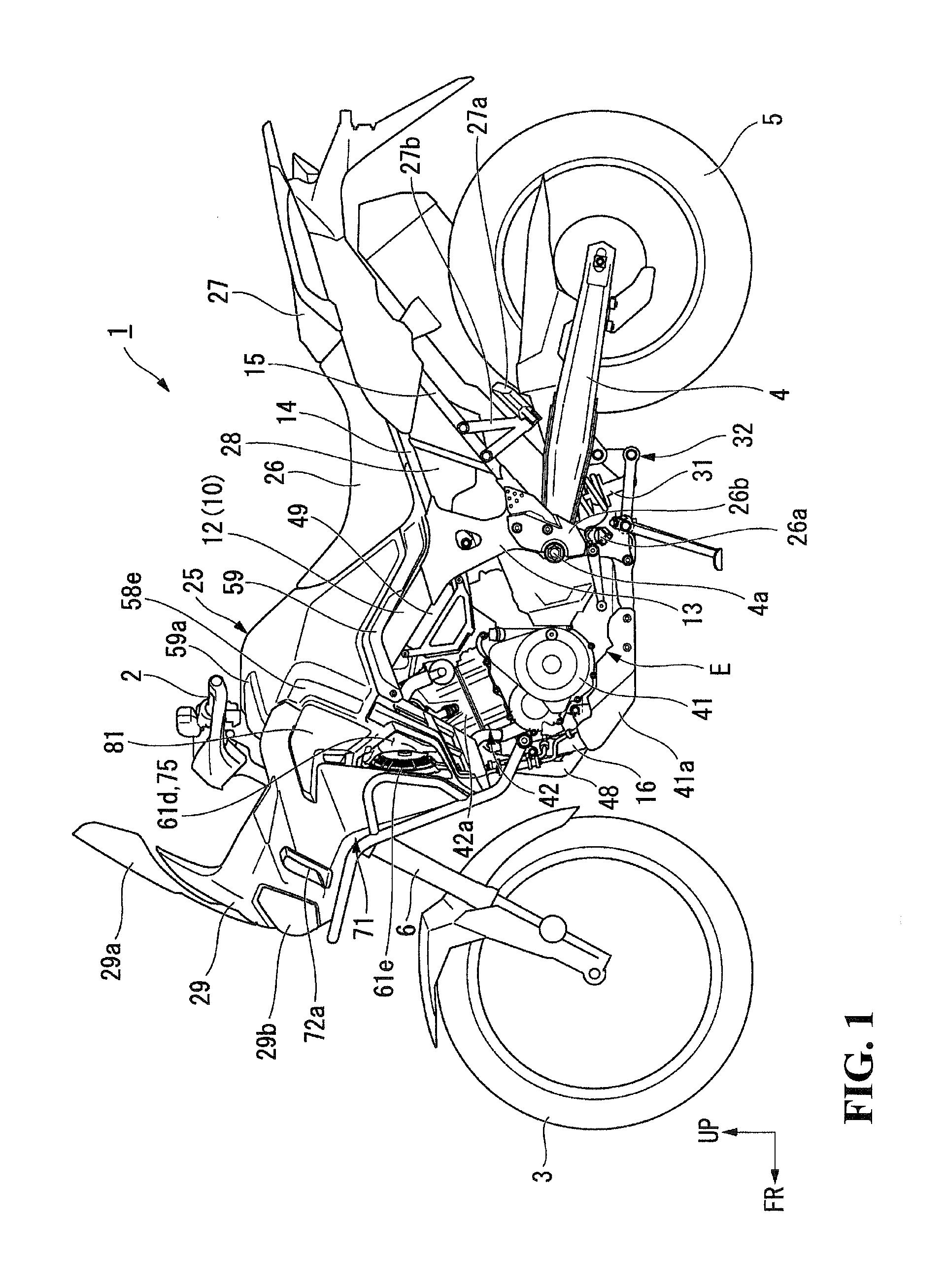

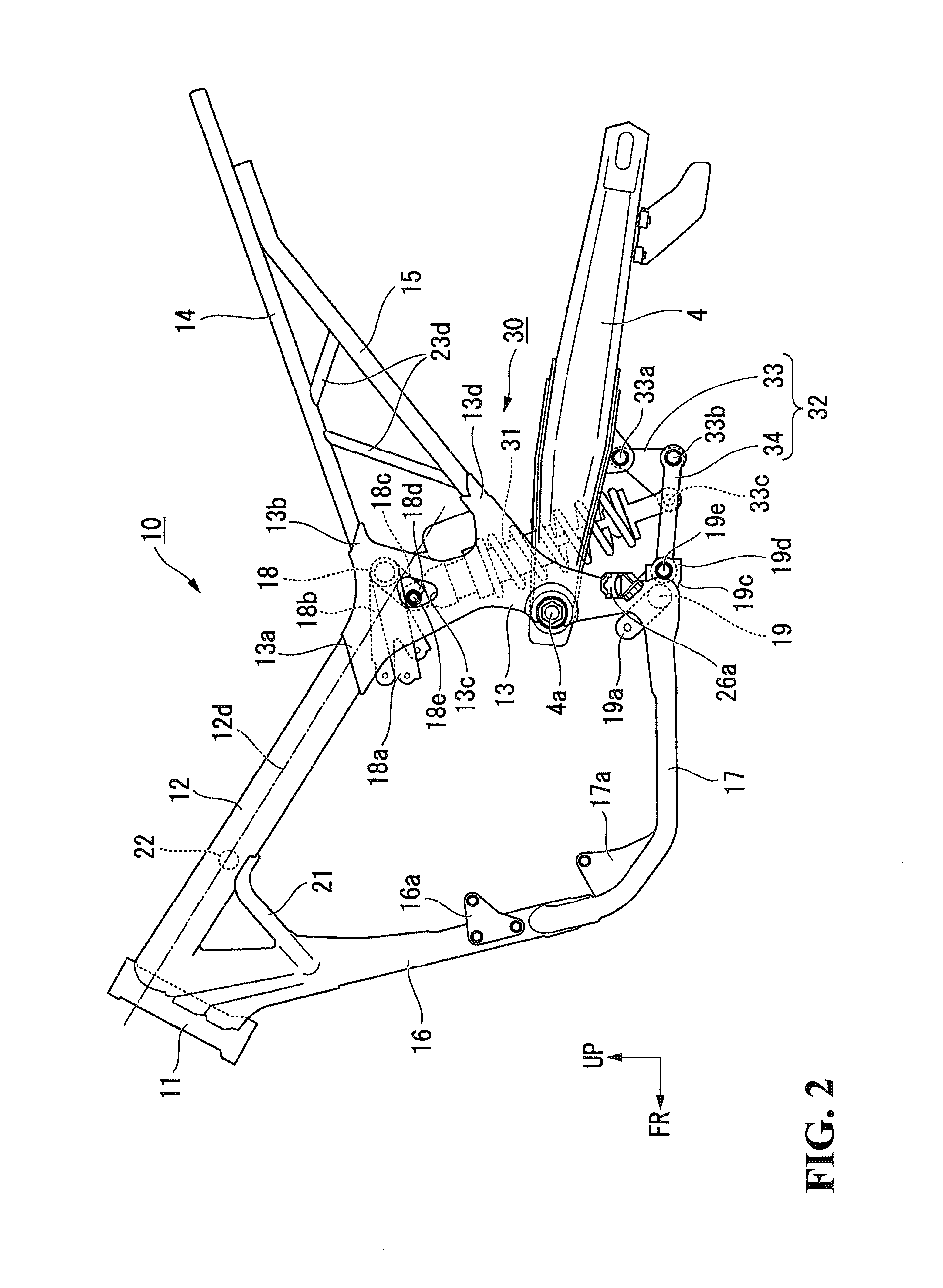

Saddle-ride type vehicle

ActiveUS20160244116A1Avoid wasting heatWaste heatWeather guardsMotorcyclesCylinder headAutomotive engineering

A saddle-ride type vehicle in which an engine is supported on a body frame and radiators are disposed forward of the engine is provided, wherein waste heat of the radiators is prevented from reaching the engine. The saddle-ride type vehicle includes a radiator shroud 71 that covers a range from a lateral side of a radiator 61 to a lateral side of a cylinder head 42a of the engine E. The radiator shroud 71 has an exhaust port 75 opening outward in a vehicle width direction. The saddle-ride type vehicle also includes a partition wall 82A between the radiator and the cylinder head 42a. The partition wall 82A separates a rear space 61d of the radiator 61 and the cylinder head 42a from each other and brings the rear space 61d into communication with the exhaust port 75 of the radiator shroud 71.

Owner:HONDA MOTOR CO LTD

Method for manufacturing dampproof abrasion resistant wood floor

InactiveCN101856832AImprove physical and chemical propertiesExtended service lifeWood working apparatusMaterials preparationTouch Senses

The invention relates to a method for manufacturing a dampproof abrasion resistant wood floor, which comprises the processes of material preparation, colour separation, grading, parallel spray of edge paint, aqueous adhesive coating, elastic primer coating and putty filling. The method is characterized by adding the following processes of: sticking a dampproof film which is formed by sequentially laminating a moulding film, a protecting film and a water isolating film on the bottom surface and the side surface of a floor; adding hard primer on the surface of the floor by adopting a paint laminating method, sequentially coating sanding primer, coloring primer, rolling finish, sprinkling finish, and finally rolling abrasion resistant paint. The wood floor manufactured by adopting the method can improve the physiochemical performance of the floor, prolongs the service life, has good effects of damp prevention, corrosion prevention, deformation resistance, static electricity prevention, radiation prevention and sound isolation, has strengthened protective force of the finish and comfortable touch sense, and is tougher and more abrasion-resistant.

Owner:江苏徐家木业有限公司 +1

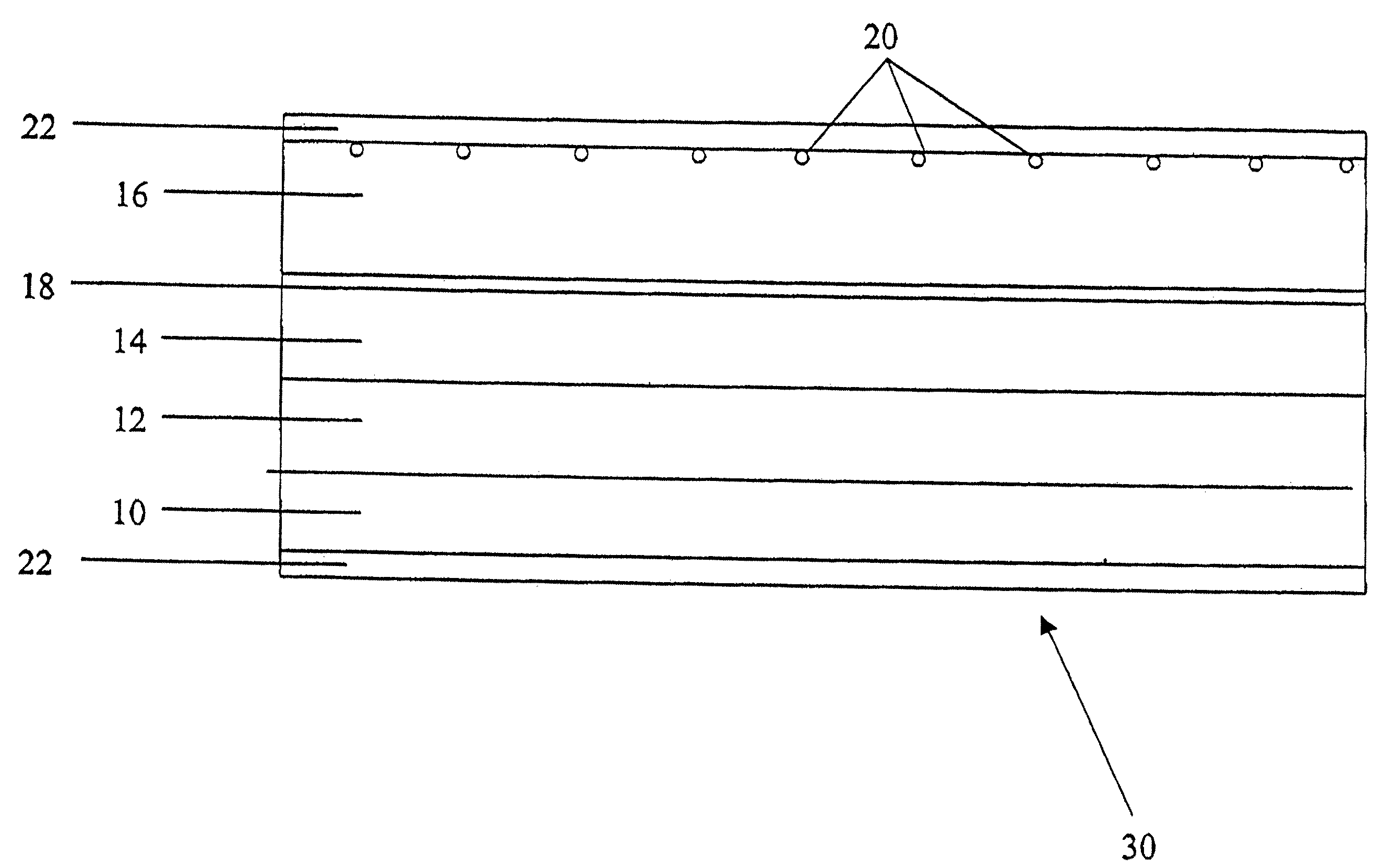

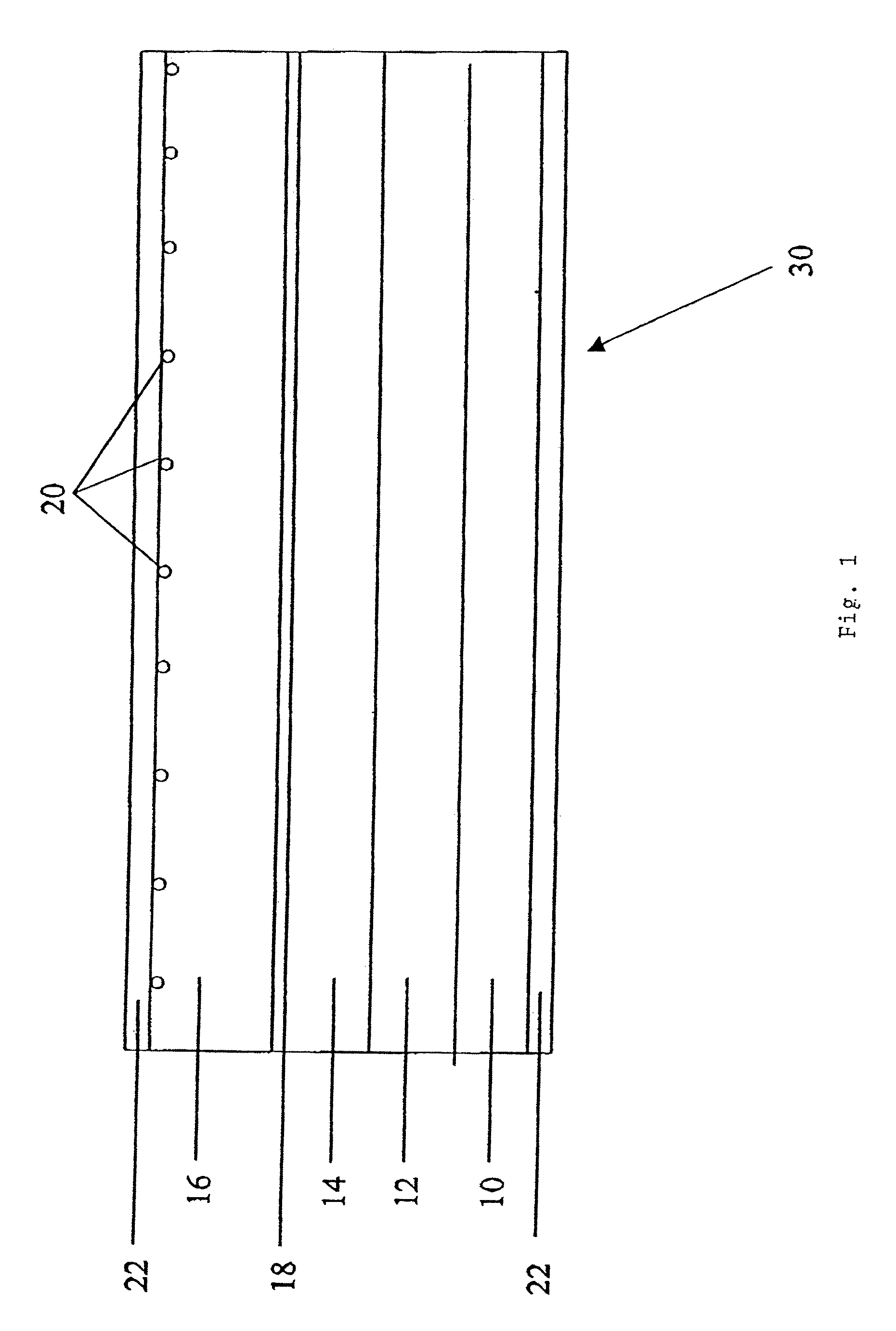

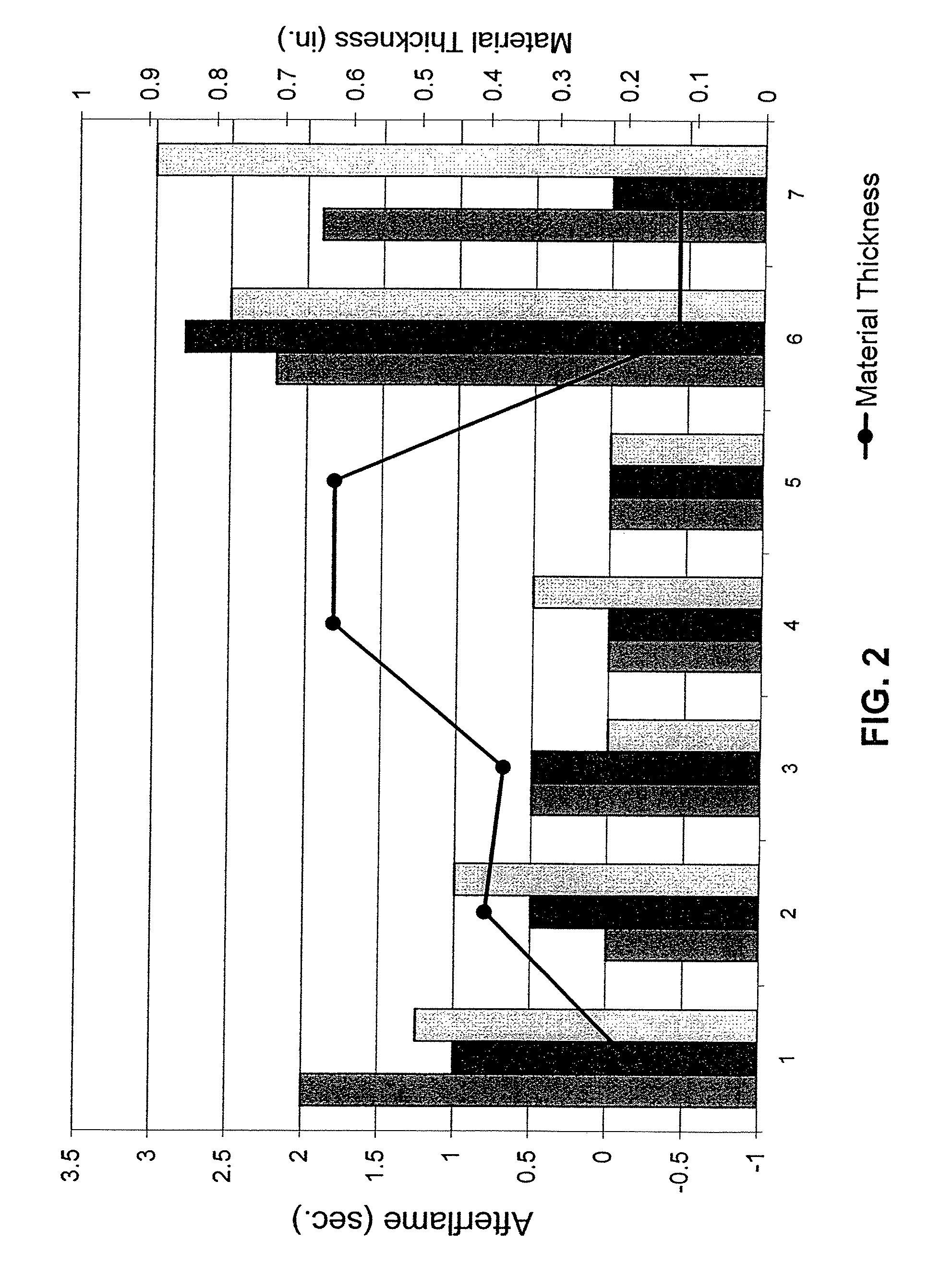

Thermal and acoustic insulation fabric

InactiveUS7632766B2Improve corrosion resistanceIncrease capacitySynthetic resin layered productsFire rescueAluminium oxideBlanket

Owner:TEX TECH INDS INC

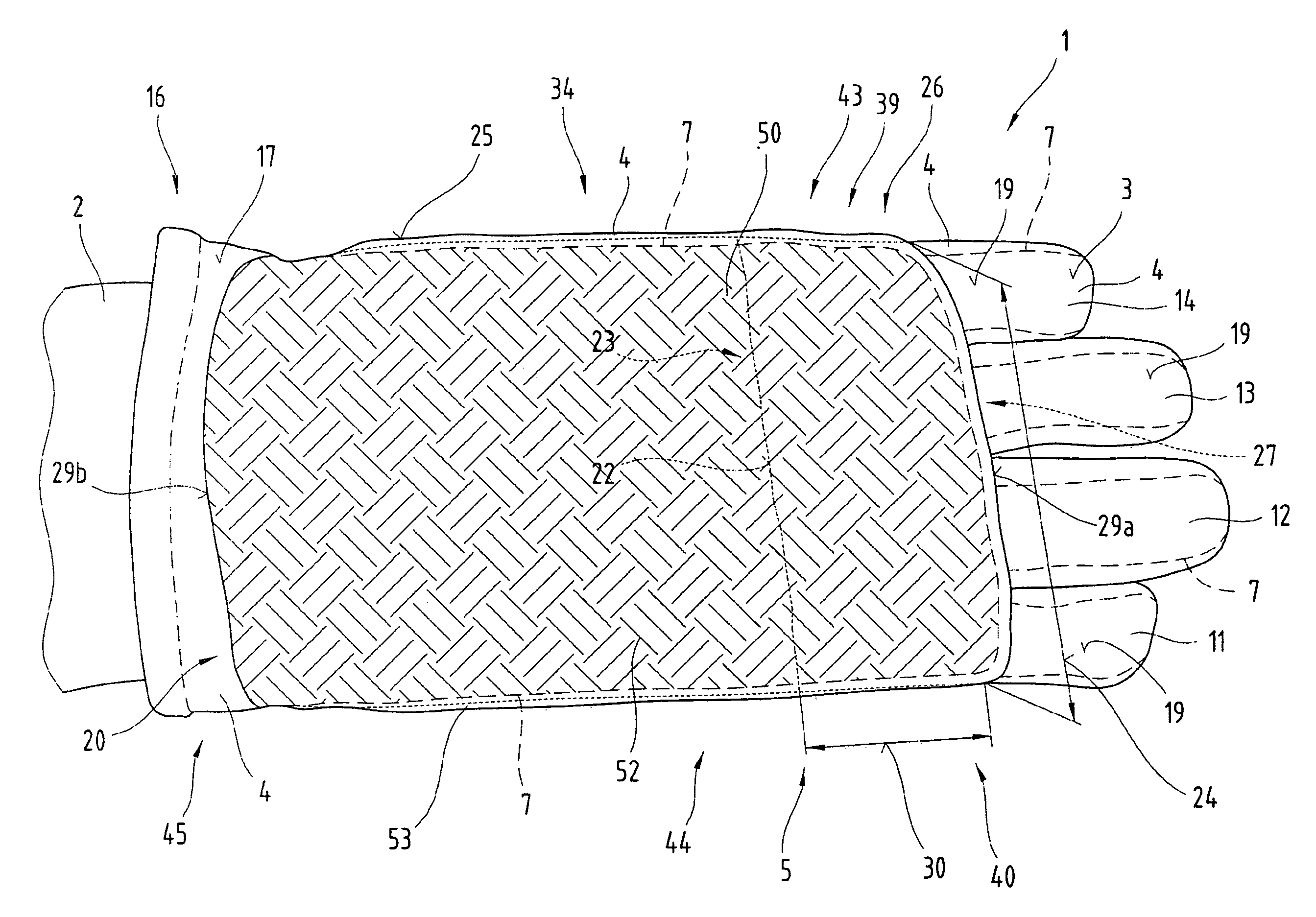

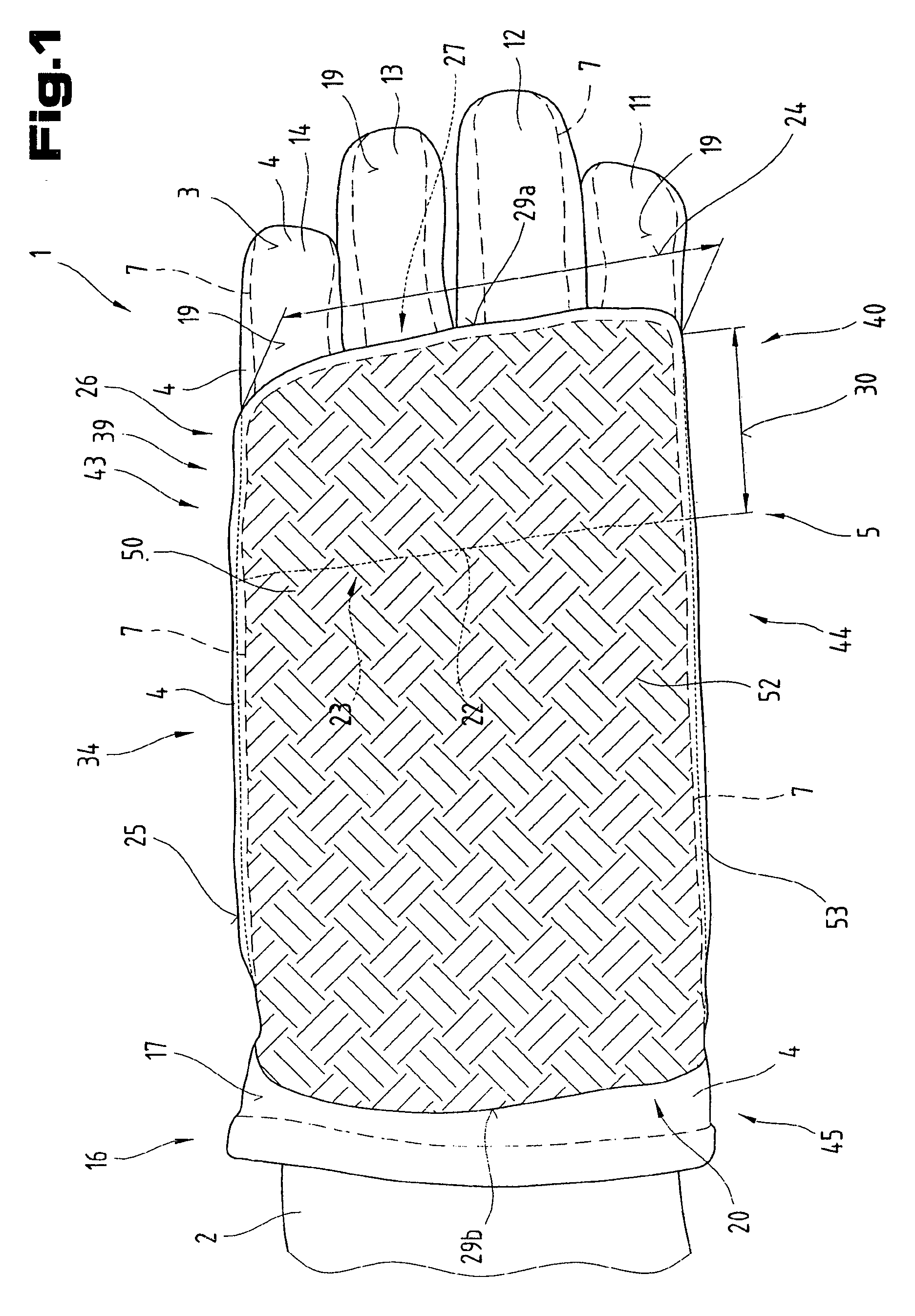

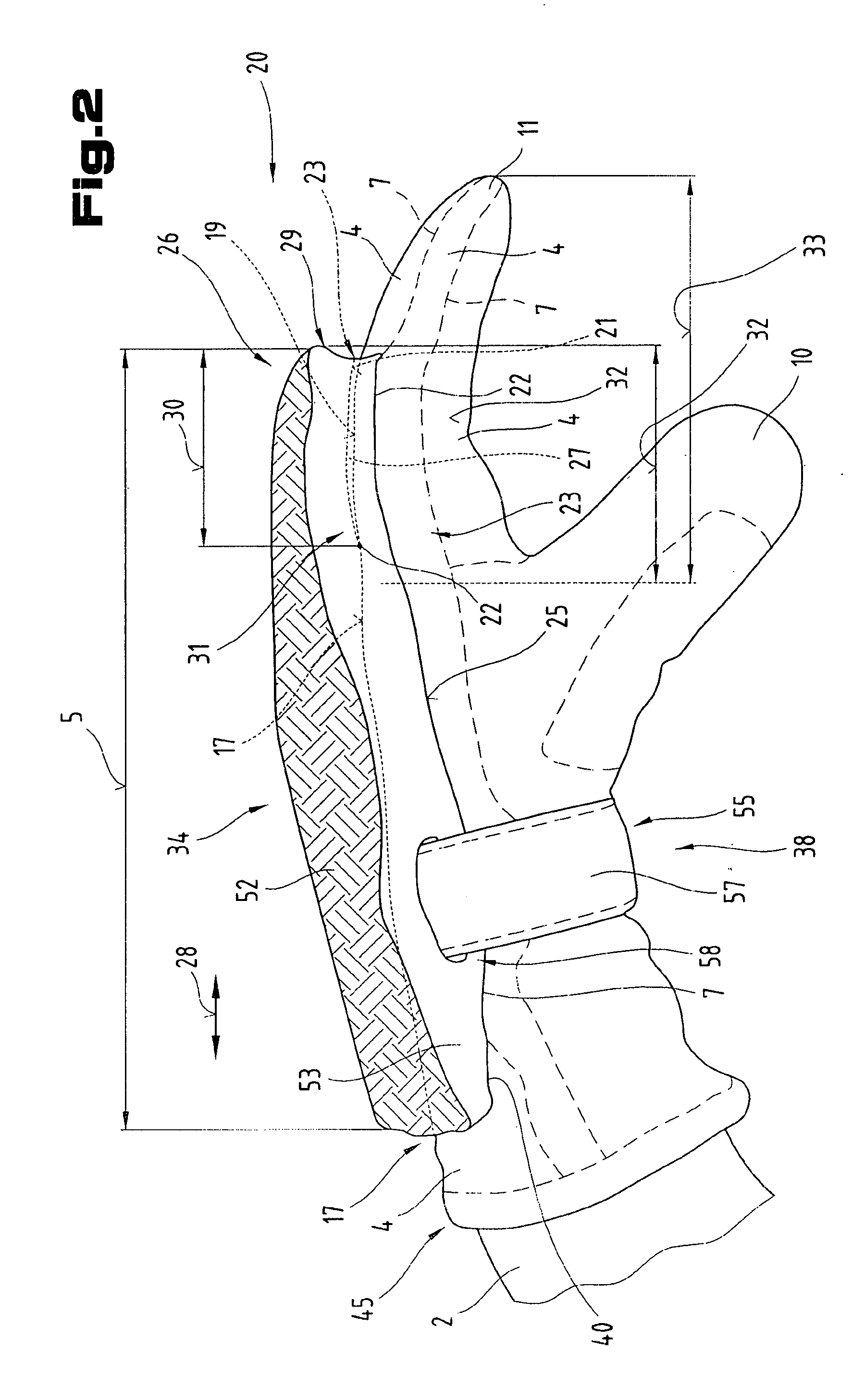

Protective glove

InactiveUS20090126058A1Function increaseUsable stowage spaceGlovesEye treatmentForeign matterEngineering

The invention relates to a protective glove (1) for protecting certain regions of a user's hand (2) against foreign bodies impacting with it such as bullets and / or stabbing or cutting devices, with a lining (4) made from a material that is not or not very resistant to stabs, cuts or incisions and is not bullet-proof, for example a textile fabric, a leather, a laminate or similar, comprising several glove fingers (10 to 14), and a glove top face (17) extends on an external surface (3) of the lining (4) in the region of finger top sides (19) and in a top hand region (15), and a bullet-proof and / or cut or stab inhibiting protective padding (20) is built up on or placed on certain regions of the glove top face (17) starting from a padding bottom face (21) and is attached to the lining (4) at joining points (22), and the protective padding (20) prevents penetration by foreign bodies impacting with it to a glove interior lying underneath it.

Owner:ESKA LEDERHANDSCHUHFAB & CO

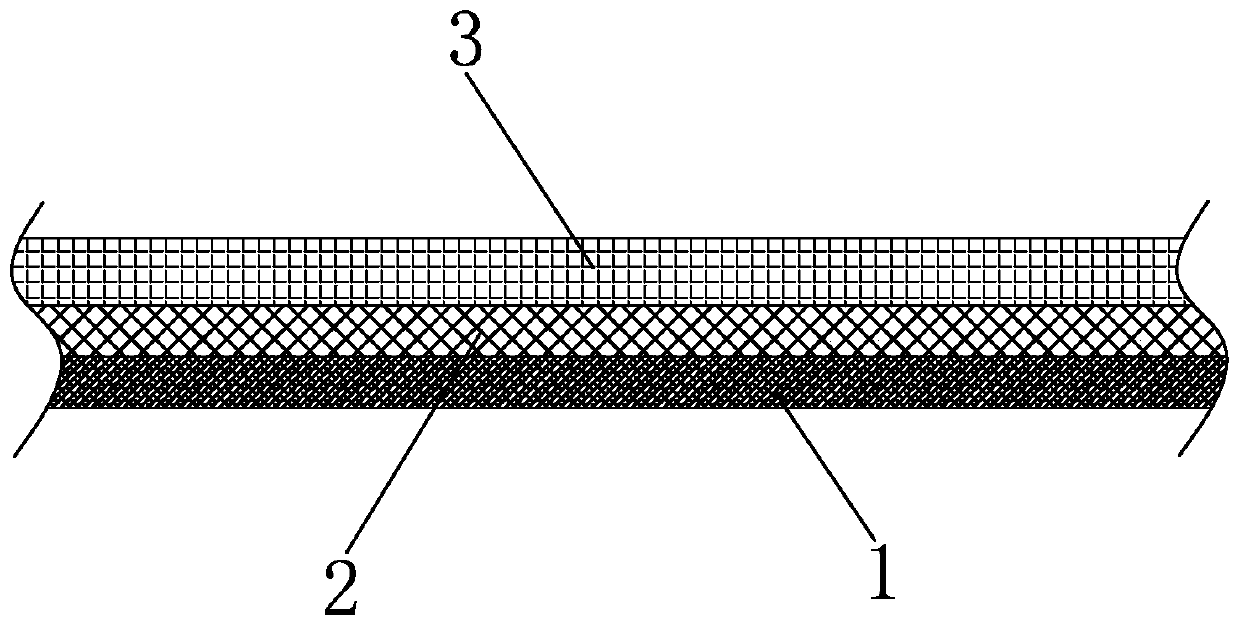

Highly-waterproof highly-breathable nanofiber membrane and preparation method thereof

PendingCN110258021AImprove yieldGood flexibilityLiquid repellent fibresAbrasion resistant fibresPolyvinyl butyralFiber

The invention discloses a highly-waterproof highly-breathable nanofiber membrane and a preparation method thereof. The highly-waterproof highly-breathable nanofiber membrane comprises a PVB electrospun membrane, a PVDF electrospun membrane and a FPU electrospun membrane which are stacked and composited from inside to outside, the PVB electrospun membrane is formed by interweaving polyvinyl butyral nanofiber of 150-400nm in average diameter, the PVDF electrospun membrane is formed by interweaving polyvinylidene fluoride nanofiber of 400-600nm in average diameter, and the FPU electrospun membrane is formed by interweaving fluorosilane modified polyurethane nanofiber of 200-300nm in diameter. The preparation method is simple and reasonable in process and low in manufacturing cost, and the highly-waterproof highly-breathable nanofiber membrane prepared by the method is high in strength, waterproofness and one-way breathability.

Owner:江苏三丰特种材料科技有限公司

Mint fiber spunlace non-woven mask substrate and preparation method thereof

The invention relates to an antibacterial healthcare spunlace fabric, in particular to a preparation method and application of a mint fiber spunlace non-woven mask substrate. The mint fiber spunlace non-woven mask substrate is prepared from, by weight, 10-100% of mint fiber, 0-90% of copper ammonia fiber, 0-90% of pearl fiber, 0-90% of viscose and 0-90% of polyester fiber. The mint fiber spunlacenon-woven mask substrate has the advantages that the developed mint fiber spunlace non-woven mask substrate is soft in touch and good in adsorption, has the water wetting and lightsome skin feeling and has the efficient anti-aging, anti-radiation, anti-bacterial and anti-oxidative effects, and the mask substrate has the functions of preserving moisture, activating cells, supplying oxygen and the like, and achieves the nourishing, nutritional and healthcare effects on the skin.

Owner:ZHONGYUAN ENGINEERING COLLEGE

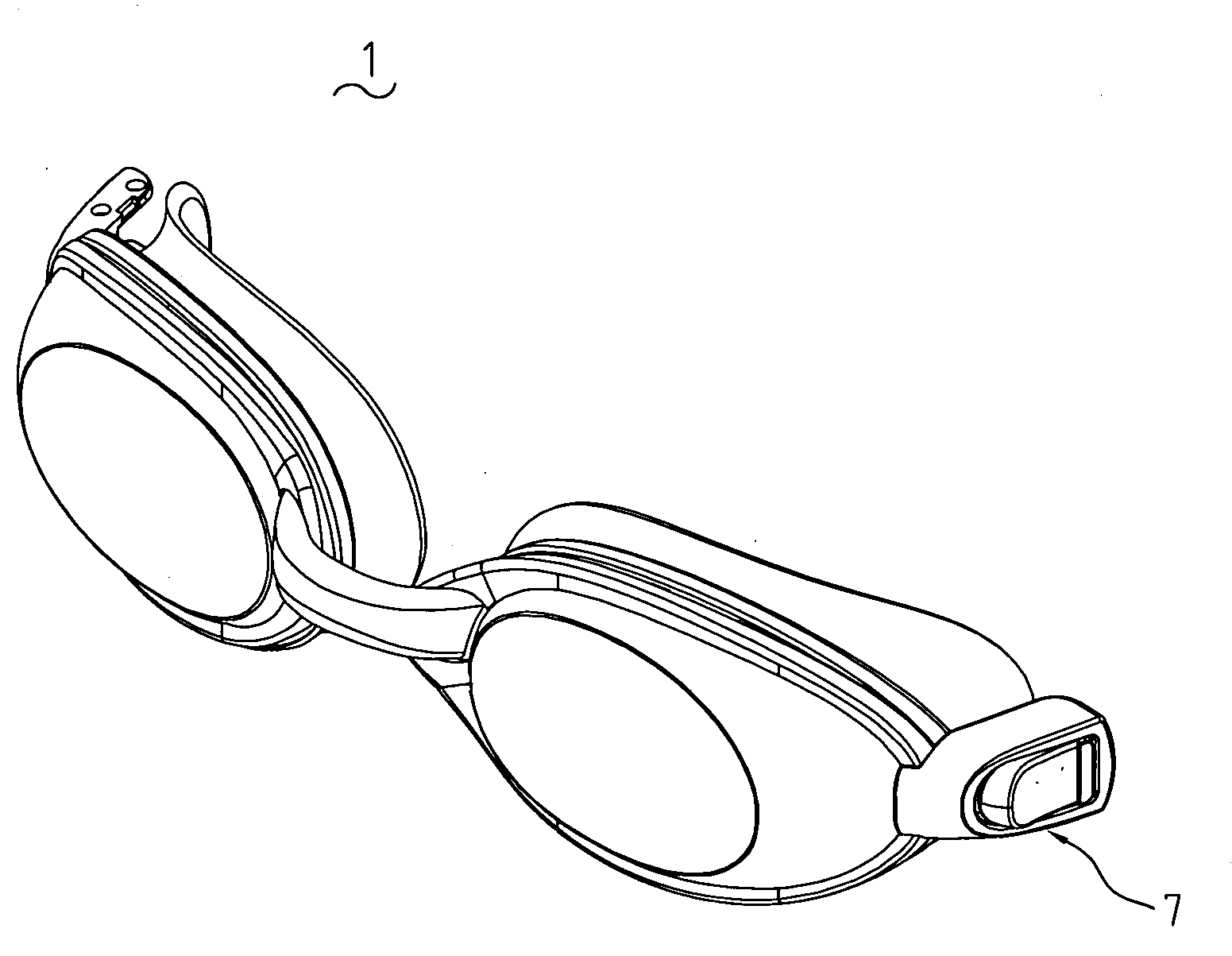

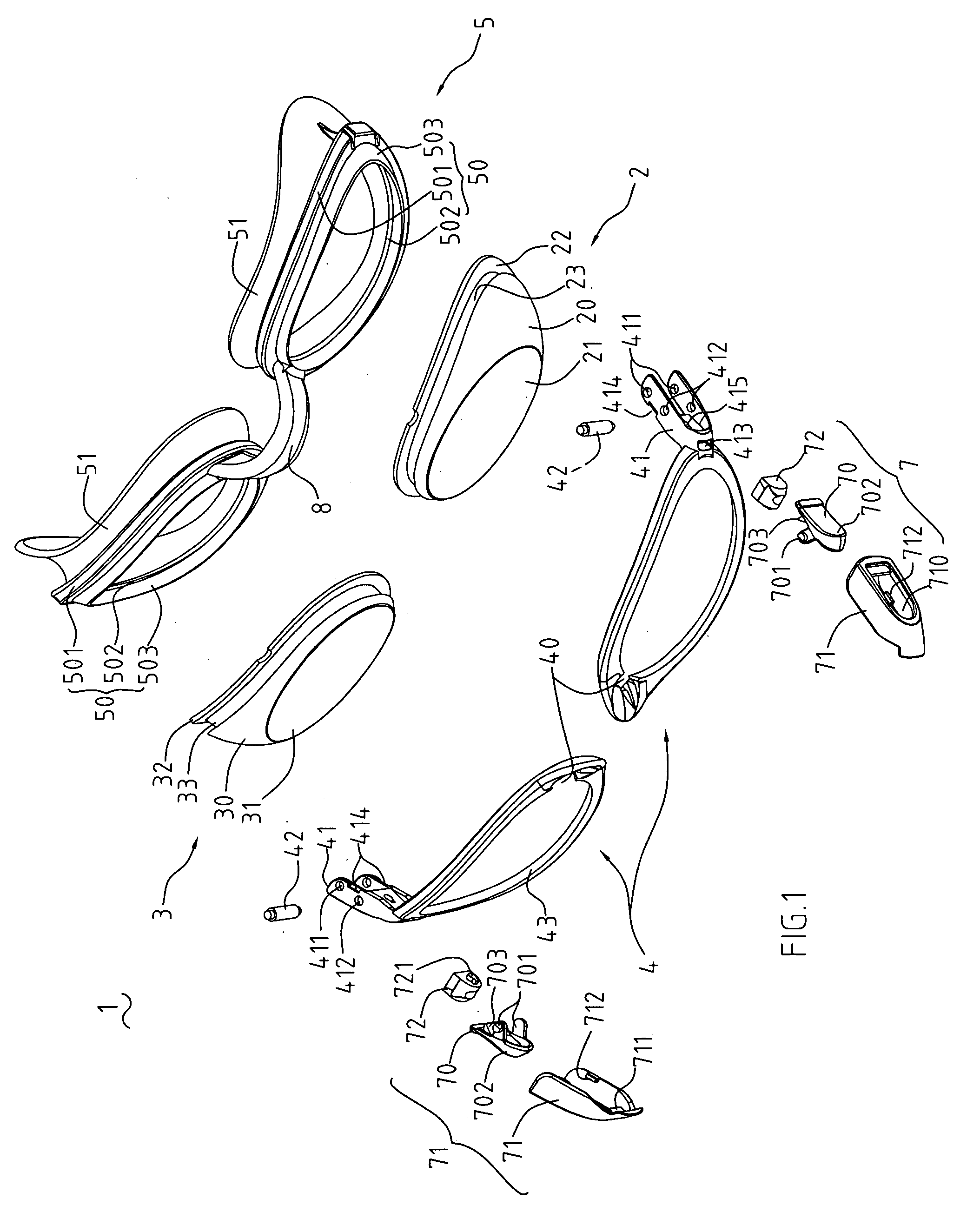

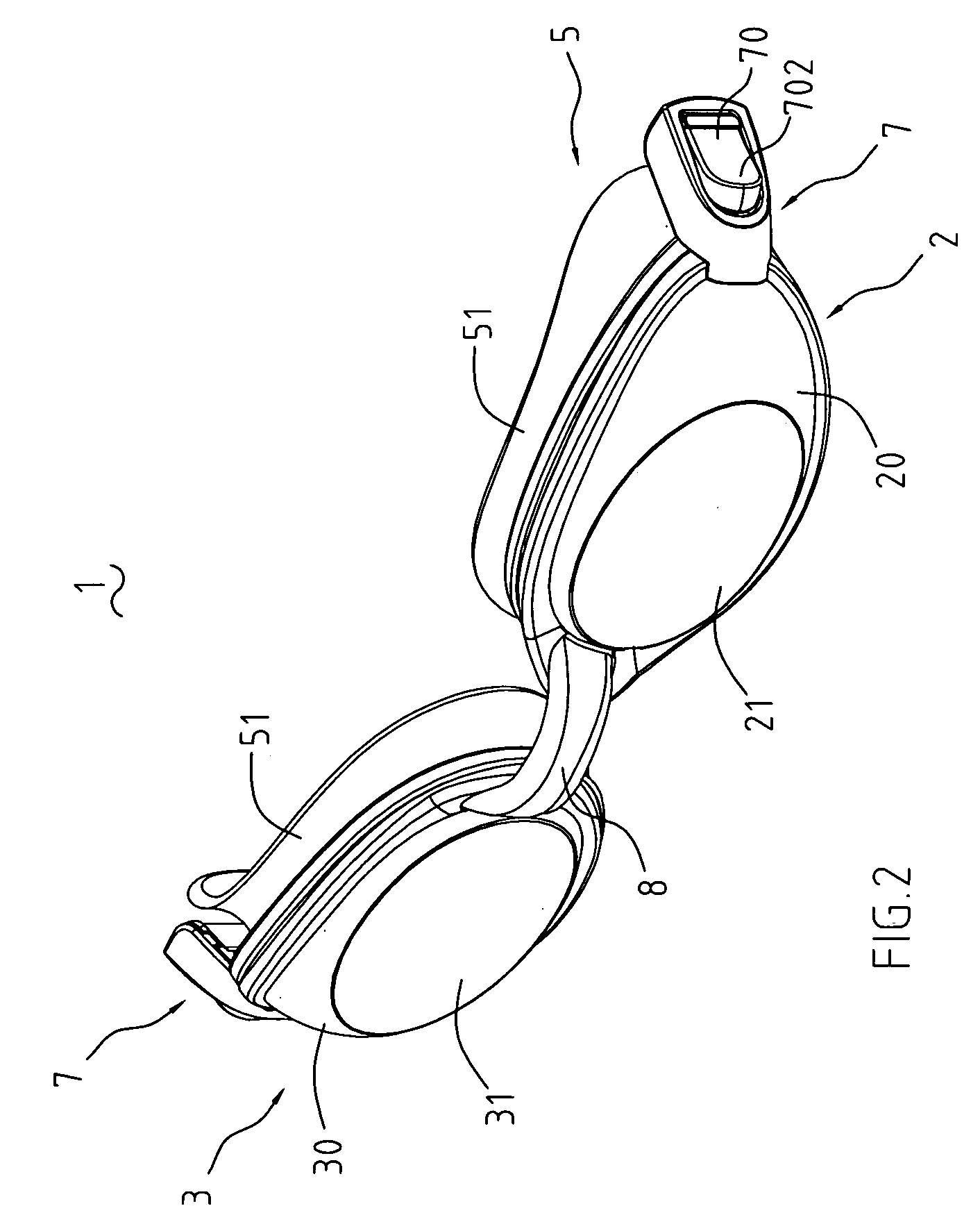

Swimming goggles

Swimming goggles include a left frame, a right frame, hard enveloping frames, soft pads and a head strap. Each of the left frame and the right frame has a frame body and a lens, the frame body forming a flange thereon. The hard enveloping frames abut against sides of the flanges, and form positioning portions on inward sides thereof, and connecting devices on outward sides thereof. The soft pads are respectively assembled on the flanges of the left frame and the right frame, and are unitarily connected by a connecting portion. Each soft pad includes a touch portion for touching a user's face, and an assembling portion for covering the flange. The head strap is assembled on the connecting devices of the hard enveloping frames. The swimming goggles are worn comfortably and suit for users with different face profiles. At the same time, the swimming goggles prevent from leakage.

Owner:CHIANG HERMAN

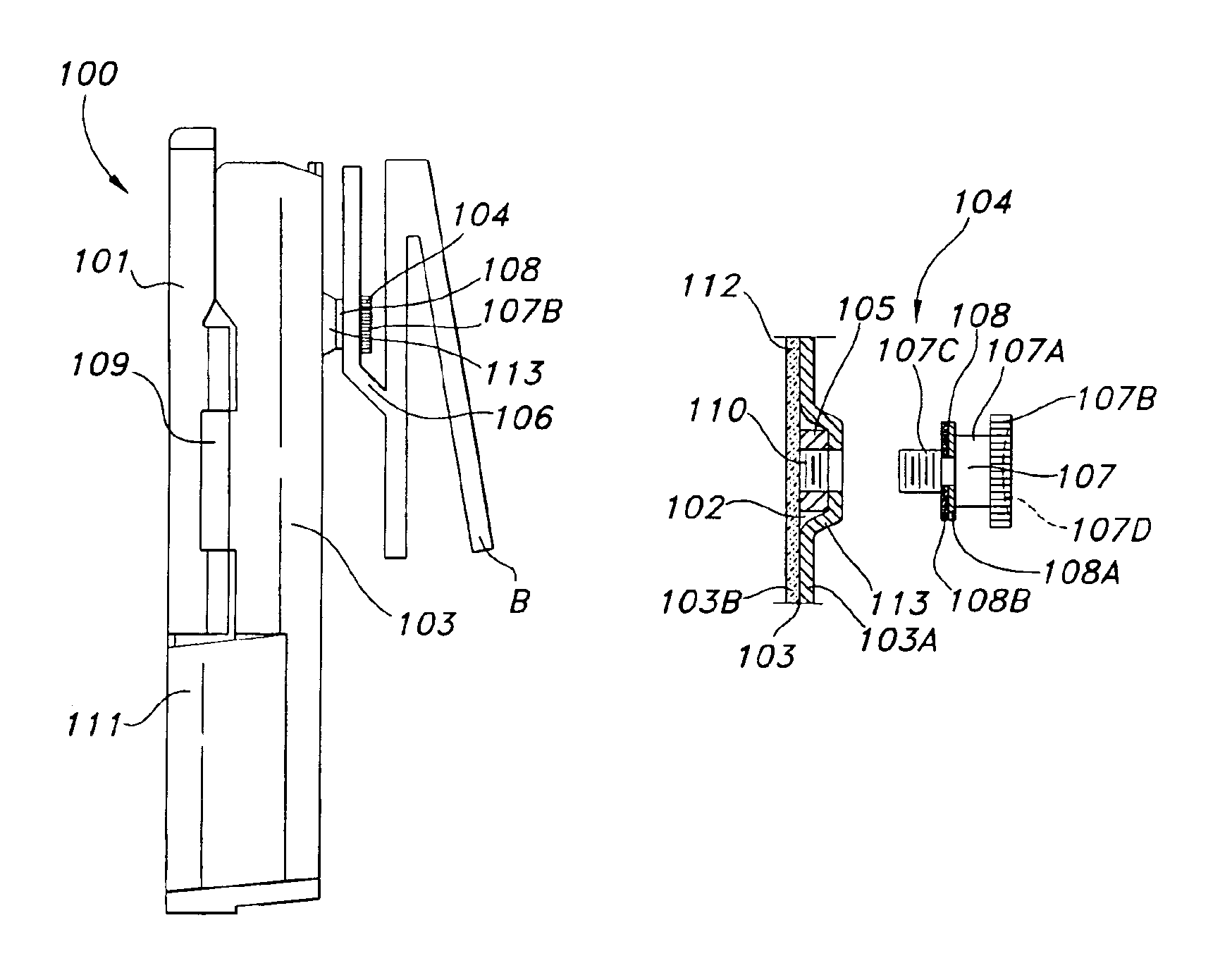

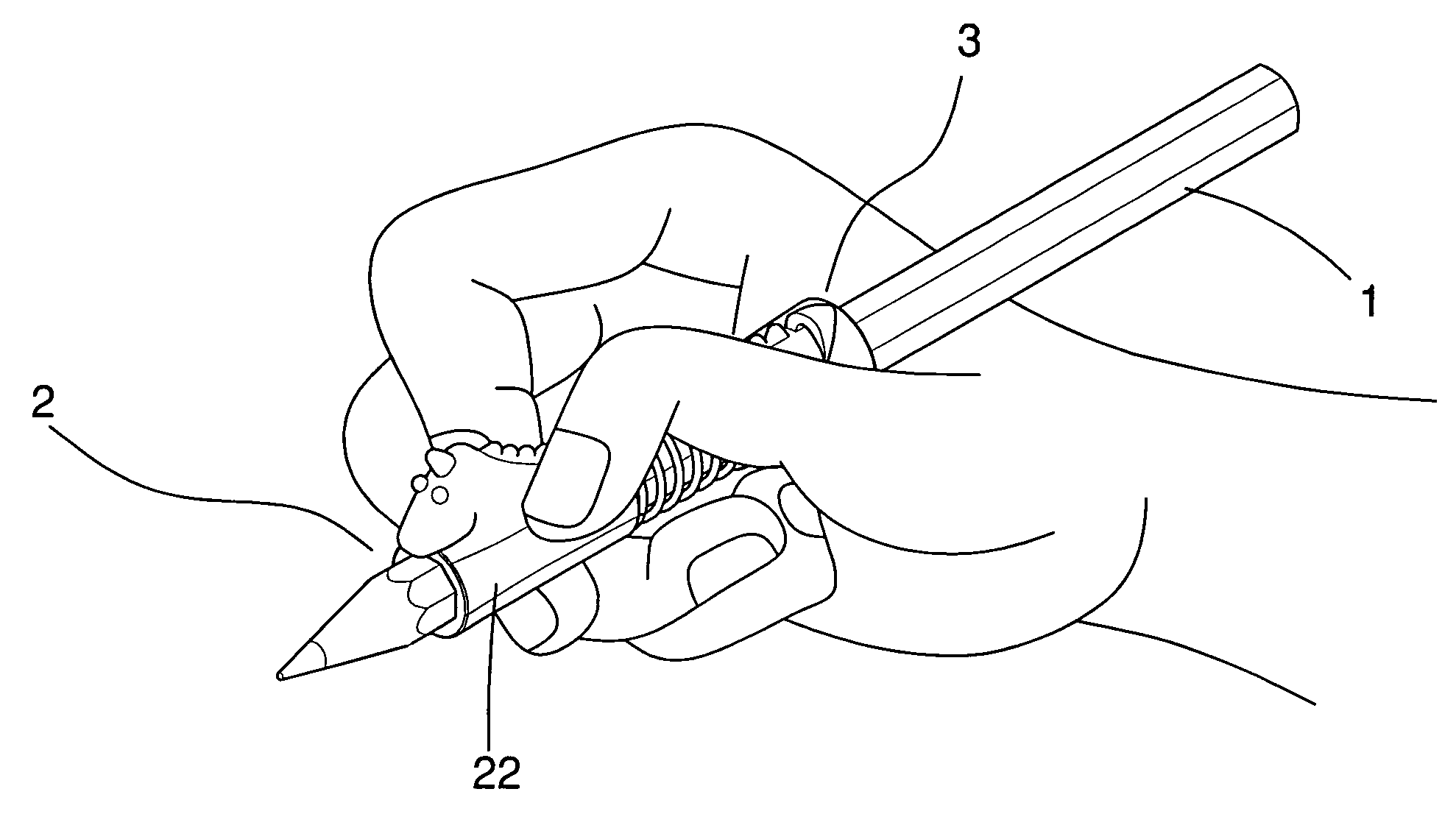

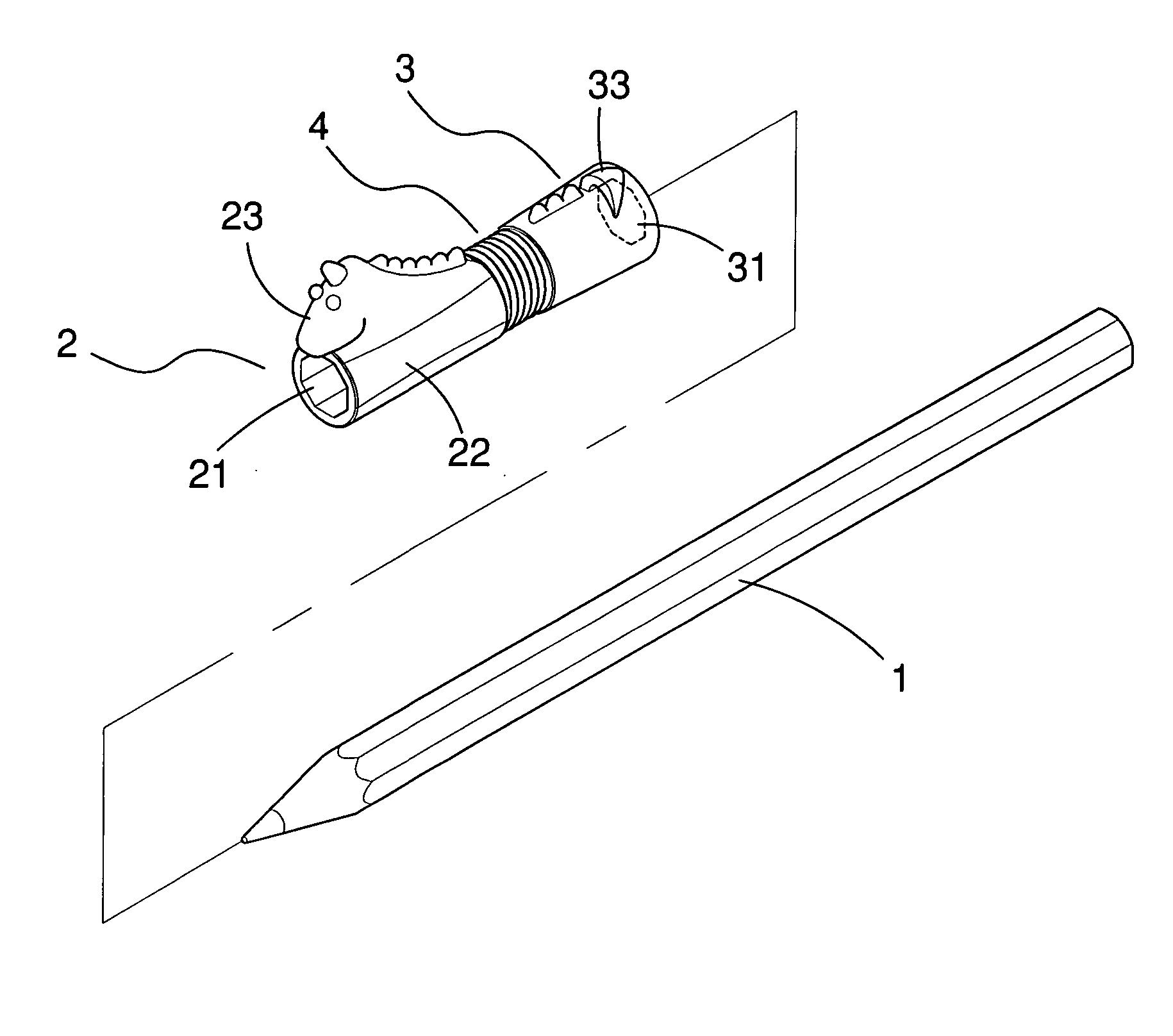

Adjustable dual sleeve pen holding auxiliary device

InactiveUS20050286962A1Comfortable touchAdjustable distanceTravelling carriersHoldersEngineeringBiomedical engineering

A pen holding auxiliary device not only provides comfortable touches but also the distance between the sleeves is adjustable to fit users' hands of different sizes. The device mainly comprises a front sleeve, a back sleeve and a length adjustable element. The front sleeve slidably embraces a shaft of the pen for being placed between finger tips. The back sleeve slidably embraces the shaft of the pen for being placed against a part of the hand between a thumb and an index finger thereof. The length adjustable element surrounds the shaft of the pen and connects the front sleeve with one end and connects the back sleeve with the other end.

Owner:CHENG DIDO

Corn fiber quilt preparation method

A corn fiber quilt preparation method is characterized in that the preparation method adopts corn fiber as the filler of the quilt core and comprises the following steps: sampling shell fabric, clipping and sewing, weighting raw materials, matching and mixing, opening and carding, air-assisted filling, carding and lapping and non-gel shaping, filling and coating, sealing and basting, examine and packaging and warehousing the finished products. The corn fiber is used as the filler of the quilt core, the quilt is loose, comfortable and durable, the quilt can easily recovery after extrusion and is easy to wash, the product appearance can not be changed for a long time and the corn fiber also has the characteristics of good heat preservation and humidity-discharging.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Leno Jacquard Weaving Technology

The invention discloses a leno jacquard weaving process, which is characterized in that the warp weaving saros weaving or common weaving is controlled by a pre-made skein jacquard device and a post-made common jacquard device. The warp is composed of a ground warp and a twisted warp, and the warp and weft can be freely combined with common yarns and fancy yarns, and the fancy yarns are in an irregular concave-convex three-dimensional shape. The process includes the following steps: the first step: designing the weave structure of the leno jacquard, the layout of the warp and weft yarn-dyed stripes; the second step: weaving according to the designed weave layout, the ground warp and twisted warp, The ratio of the number of intermediate weft yarns to fancy weft yarns is 1-3:1-3. 1-5:1-5. The invention provides a brand-new leno jacquard weaving method, which enables the production of leno jacquard fabrics favored by consumers in larger quantities and provides more affordable fabrics.

Owner:LUOLAI LIFESTYLE TECH CO LTD

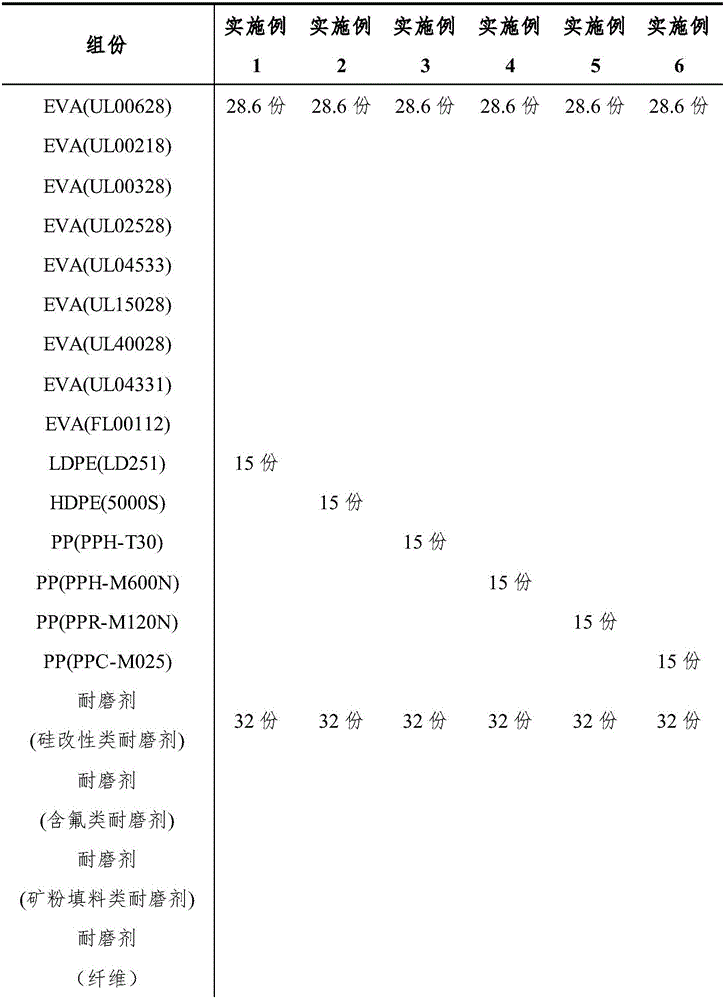

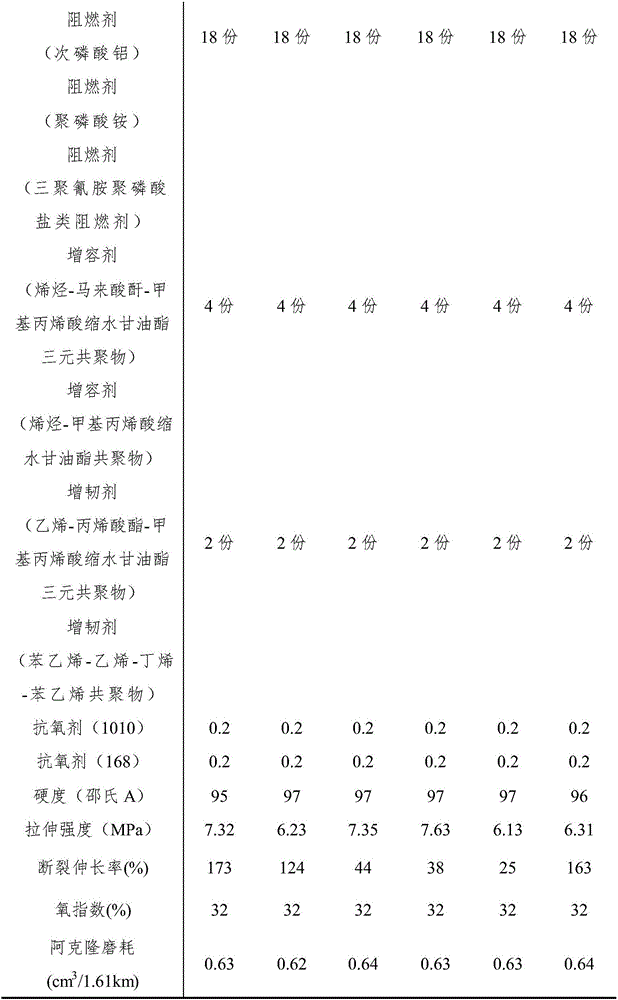

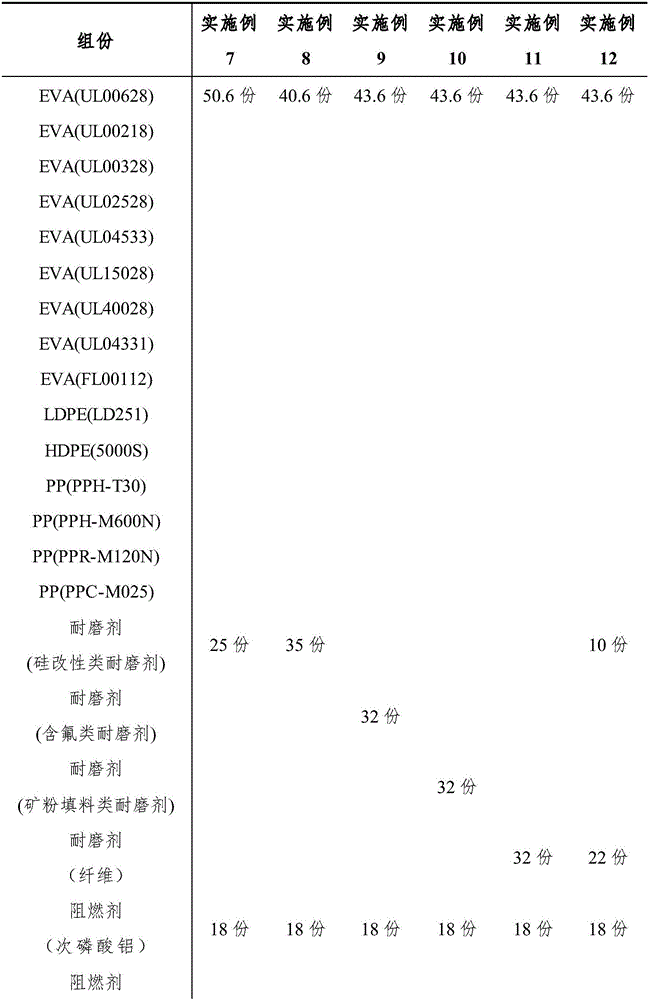

EVA (ethylene-vinyl acetate) wear-resistant nonflammable elastomer material and preparation method thereof

The invention relates to an EVA (ethylene-vinyl acetate) wear-resistant nonflammable elastomer material which is composed of 28.6-51.6 wt% of ethylene-vinyl acetate copolymer, 0-15 wt% of polyethylene or 0-15 wt% of polypropylene, 25-35 wt% of anti-wear agent, 10-20 wt% of flame retardant and 2.4-4.8 wt% of other modifying aids. The other modifying aids are two or more of an antioxidant, a compatibilizer and a toughener. The preparation method comprises the following steps: uniformly mixing the ethylene-vinyl acetate copolymer, polypropylene or polyethylene, anti-wear agent, flame retardant and modifying aids through a high-speed mixer, and carrying out melt blending through a Banbury mixer or double screw extruder to prepare the wear-resistant nonflammable elastomer material and formed products thereof. The EVA wear-resistant nonflammable elastomer material has favorable hand feeling and comfort degree, and has higher commercial value in the fields of floor, wall surfaces, automobile interior decorations and the like. The defective goods can be recovered to enhance the yield in the material forming process. Compared with the like materials prepared from rubber or PVC, the EVA wear-resistant nonflammable elastomer material has the advantages of simpler and more convenient preparation technique and lower equipment investment.

Owner:联泓(江苏)新材料研究院有限公司 +1

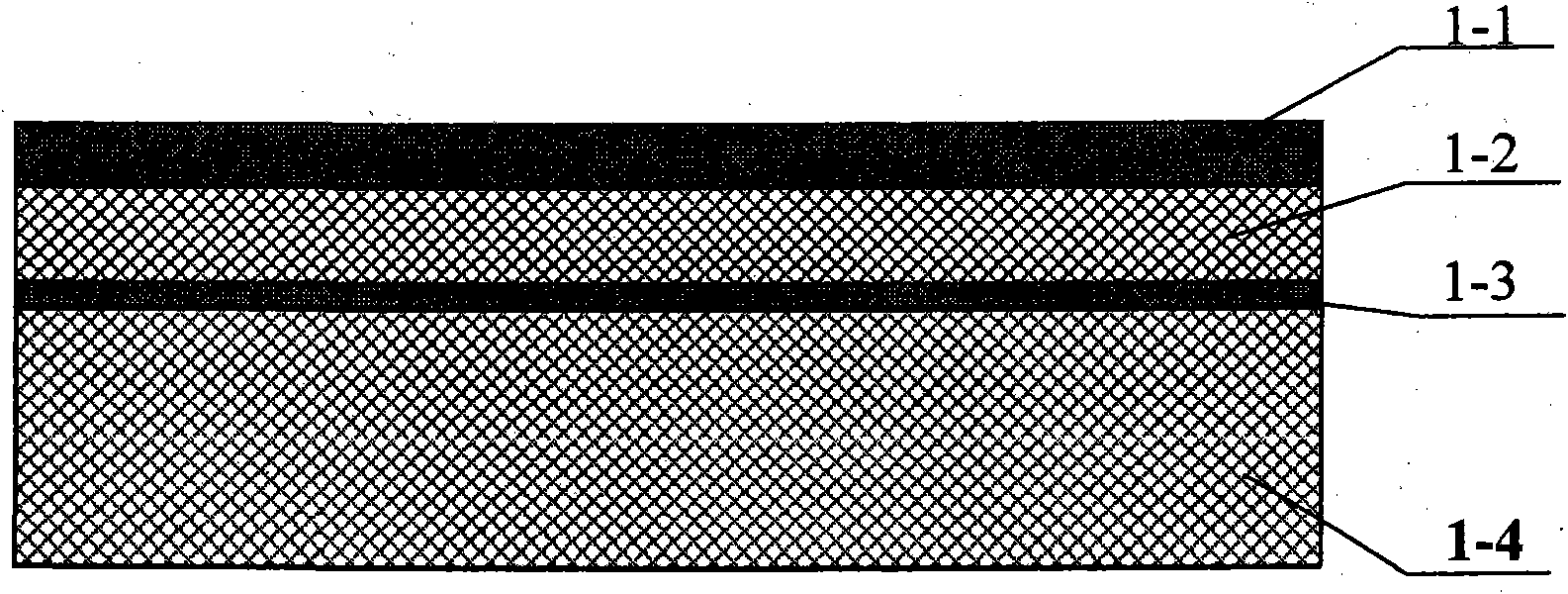

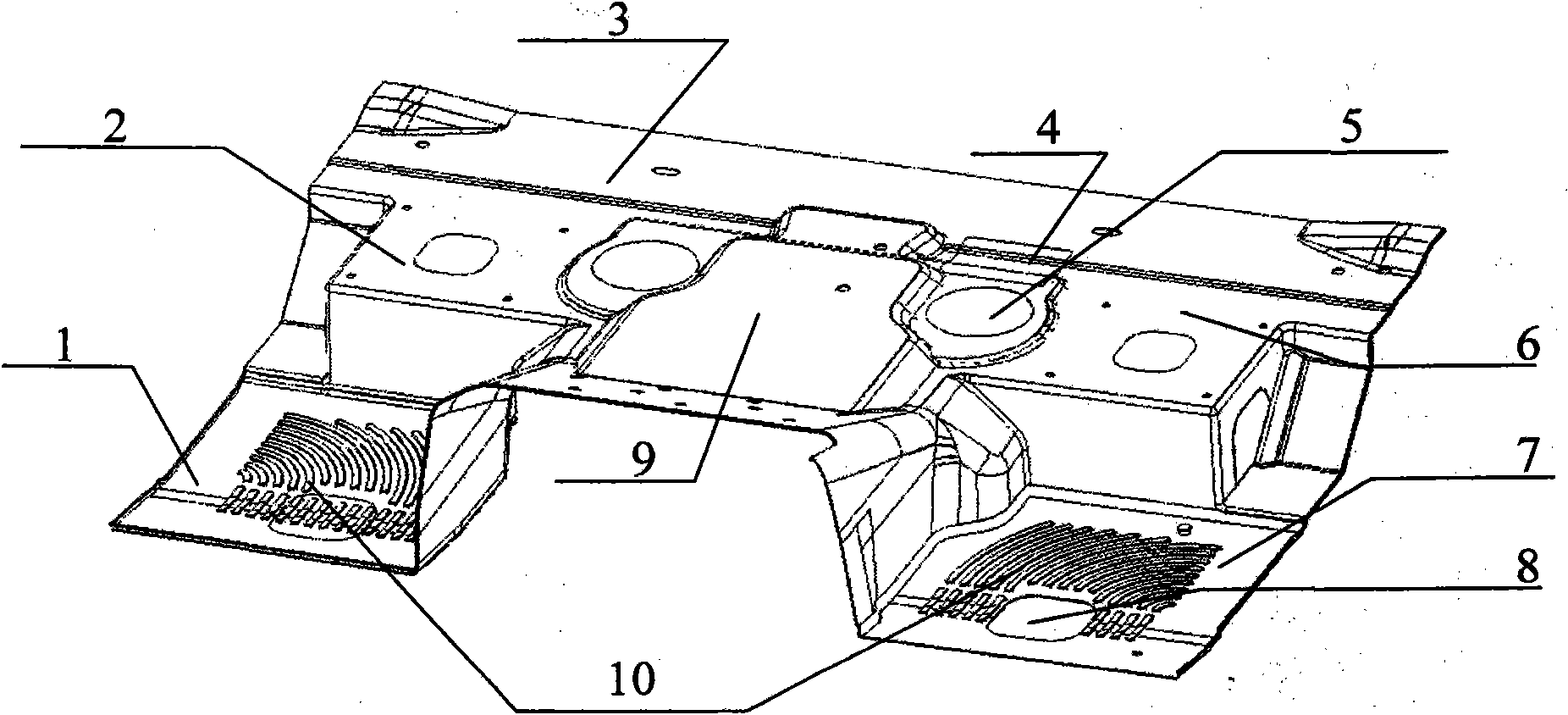

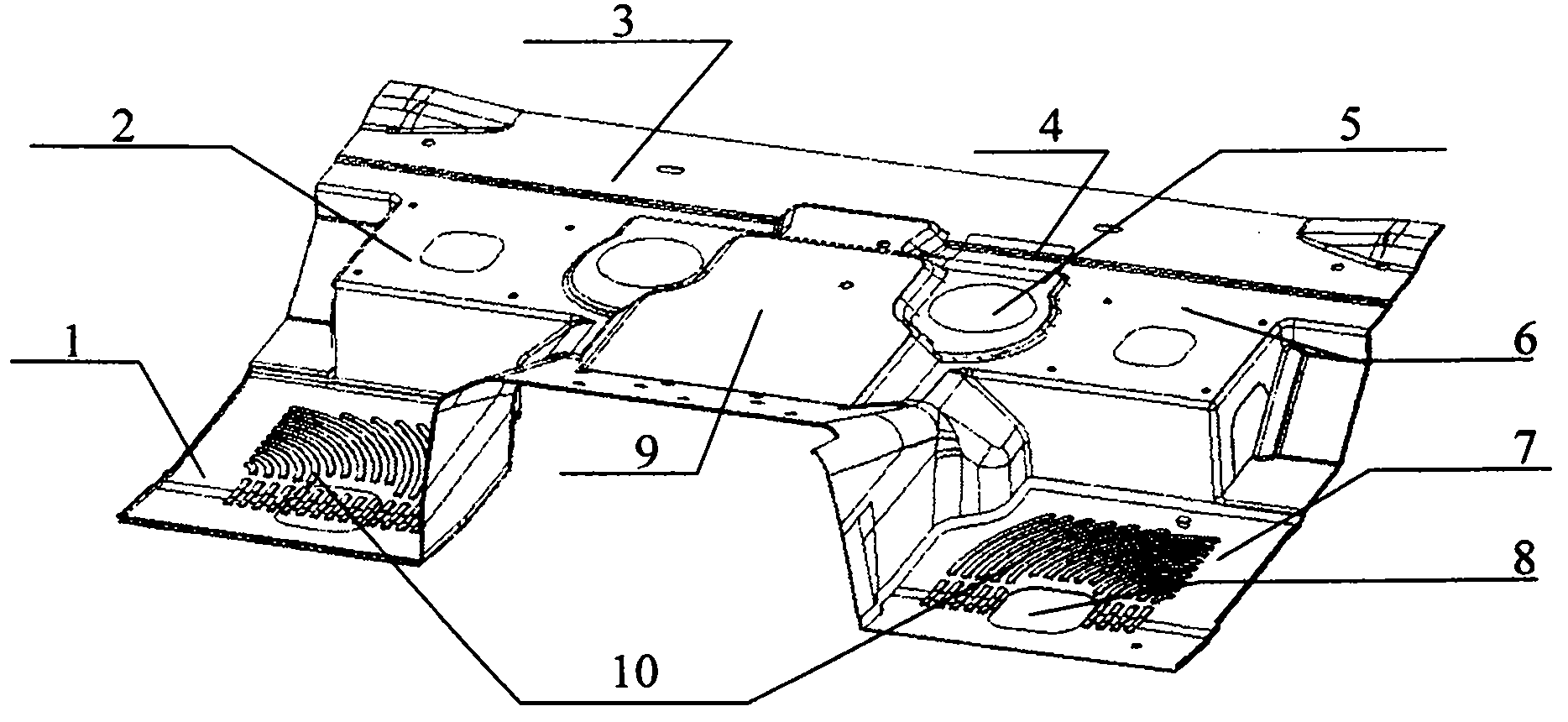

Method for producing automotive sound-absorption and heat-insulation integrated carpet

ActiveCN101830188ASolve sound absorption and heat insulationAddress personalizationVehicle arrangementsLayered productsPunchingHazardous substance

The invention relates to a method for producing an automotive sound-absorption and heat-insulation integrated carpet and belongs to the technical field of automotive interior decorations. In the method, an environmentally-friendly 3.5 millimeter (including 0.8 millimeters of a toughening layer, 2.5 millimeters of a foaming layer and 0.2 millimeter of a bottom film protective layer) PVC foamed leather is mainly used and subjected to heating, baking, vacuum forming, cooling forming, 8 millimeter cotton-based sound-absorption and heat-insulation carpet compression and lamination, shearing, hole making, punching and inspection to produce a finished product. The method solves and improves the indexes, such as sound absorption, heat insulation, dust prevention, attractive appearance and easy cleaning, of the automotive carpet and makes the automotive carpet reach international advanced level-III and meet the design requirements on environmental protection, attractive appearance, comfortableness, sound absorption and heat insulation of an automotive cab. In a plastic absorption process, a pneumatic pre-feeding device is used to ensure the thickness of the foamed leather on the highly-stretched part of the large section of the product, so the overall quality of the product is improved, the quality consistency of the product is guaranteed, the production efficiency is improved greatly and the labor intensity is relieved greatly. The compression and lamination of the sound-absorption and heat-insulation carpet improve the sound and heat insulation performance of the product and make the appearance of the product smooth and elegant and touch comfortable. In the while production process of the product, no harmful matter is produced, and the product is an environmentally-friendly product.

Owner:XIAN TIANRUI AUTOMOBILE INTERIORS

Towels of micro fibers of polyester/polyamide bi-components and the method of making

InactiveUS20130189473A1Comfortable to touchHigh absorbencyPattern makingLayered productsPolyesterMicrofiber

A fabric with polyester / polyamide bi-components microfibers may include a warp knitted double-sided base fabric with polyester / polyamide bi-components microfibers that is treated by a chemical splitting process. Both sides of the double-sided base fabric may have at least 10 loop piles per square centimeter. Each loop pile may have at least one single thread loop. The bottom of the loop piles may be connected to the base fabric. The loops may be arranged orderly to form a planar structure that has the feature that the loop piles on one side of the base fabric may have plush-like structures at the top sections. The loops may be fractured by sanding the loops with a sand paper of 200-600 grits at about 1 / 10 to 5 / 10 of a thickness of the loop piles to form the plush-like structures.

Owner:ZIBO UNION PLUSH PRODS +1

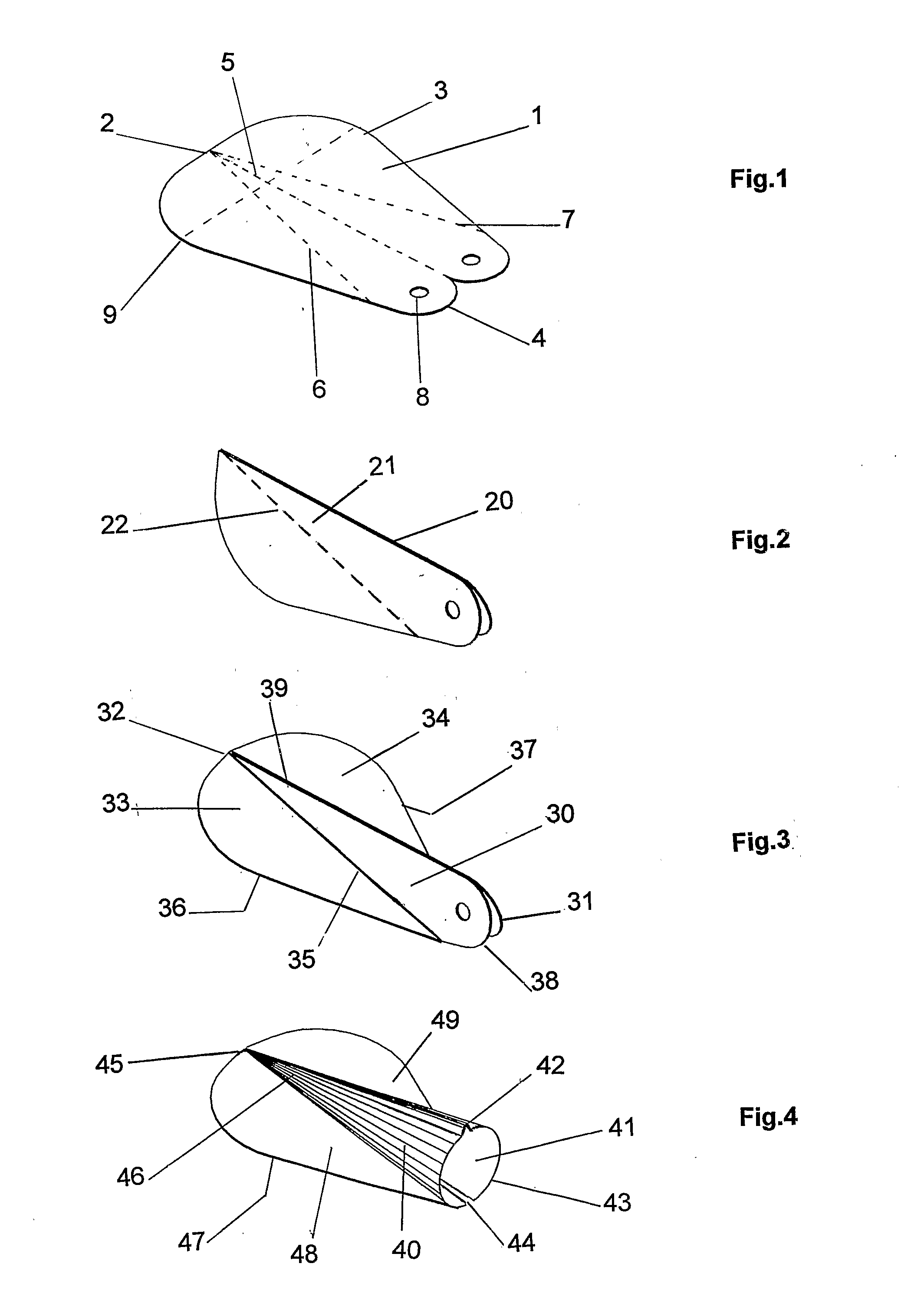

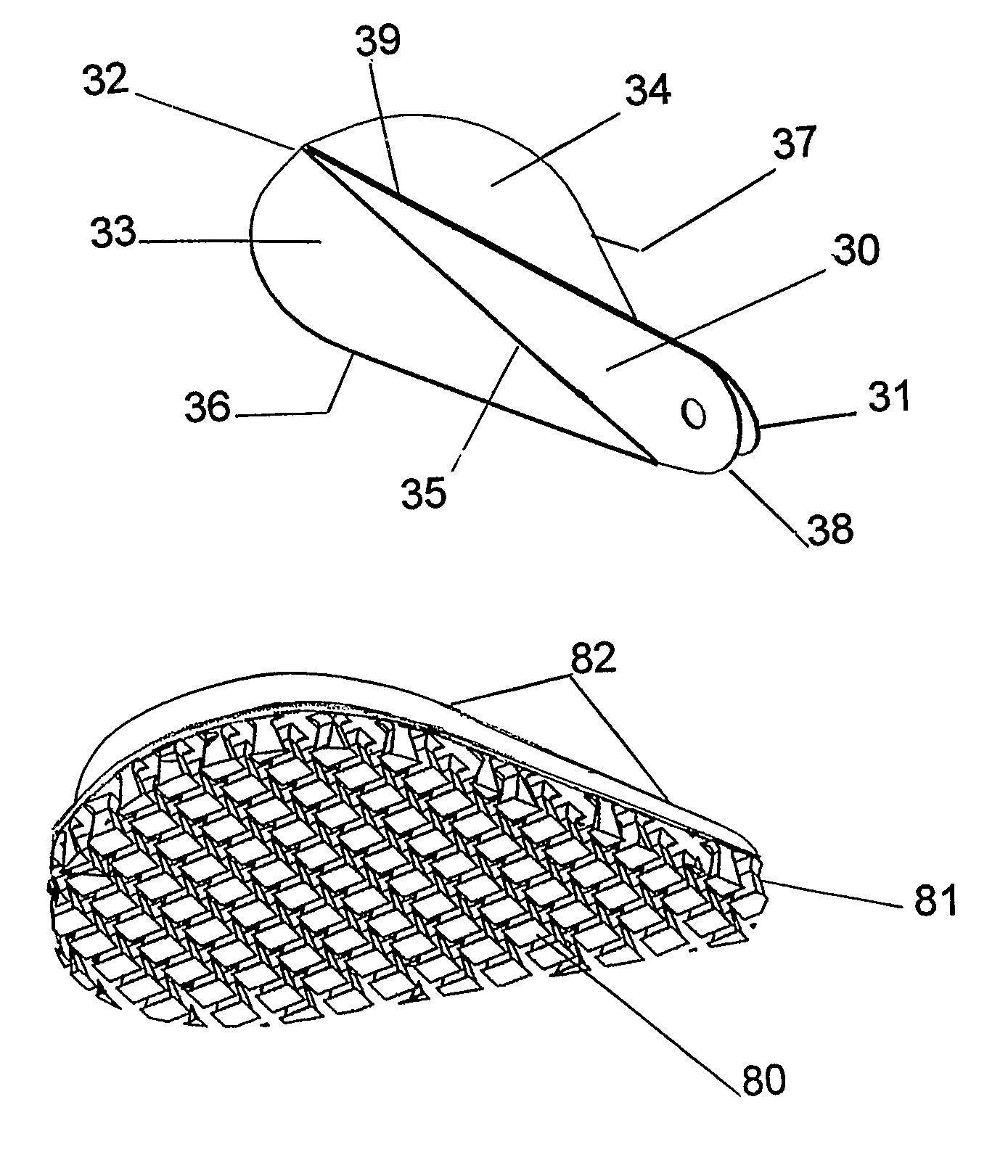

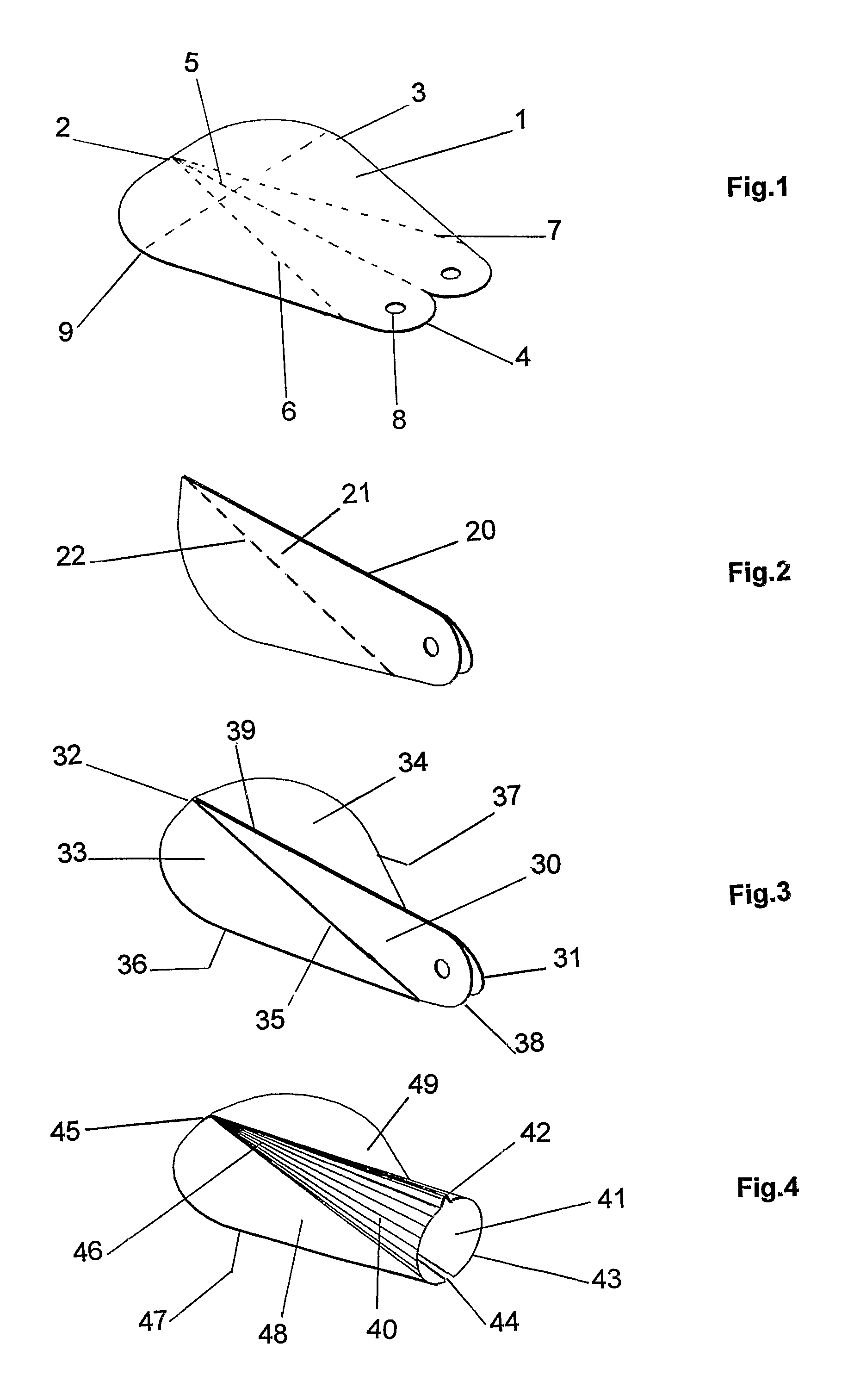

Multi-function surface treatment tool

InactiveUS8272801B2Readily visually monitoredLow costLiquid surface applicatorsBathroom accessoriesSkin treatmentsBiomedical engineering

A tool for treating a surface by rubbing and including means to dispense onto the surface stuff, for example, a lotion for skin treatment, and including also a pair of opposed fins which are supported by a stiff, tapered, upstanding spine portion that traverses the tool and has an upper radial face for wiping and scrapping stuff, the fins extending laterally of and along the lower length of the spine portion and having an under face for rubbing contact with the surface, and each fin having optionally an upper absorbent face on each side of the spine portion to provide a swabbing capability, and the tool having a distal end and a proximal end, with the upstanding spine portion narrowing toward the distal end of the tool and the spine portion being hollow and shaped towards the proximal end for holding of the tool directly or coupled to a holdable object and also a method for making the tool.

Owner:LINZELL GEOFFREY ROBERT

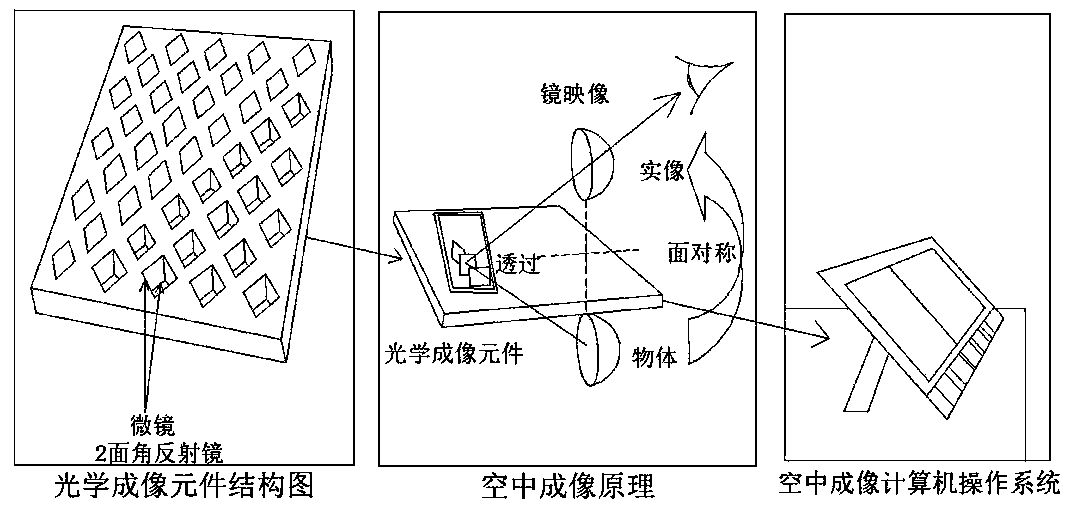

Real-time touch control system for realizing aerial imaging according to laser image technology

PendingCN108267862ASave spaceImprove compatibilityInput/output for user-computer interactionGraph readingDirect touchControl system

The invention discloses a real-time touch control system for realizing aerial imaging according to laser image technology. The real-time touch control system comprises a laser image system, an aerialimaging system and an air touch control feedback system. The invention combines software and hardware of laser image technology to realize the touch control of an aerial non-medium floating imaging picture. The aerial imaging of the invention needs no medium and saves space, and direct touch is possible; and the line of sight can pass through without being obstructed. The aerial imaging of the invention has no requirements on the system of a host or the content that can be 2D or 3D, and is highly compatible; and has a strong technology sense, provides the most comfortable aerial imaging picture for different users, and brings a new visual and interactive experience. The position at which the real-time touch control system of the invention can be installed can be changed according to the required industry and scene. The invention can meet the needs of different users, so that different users can comfortably view the aerial imaging picture and touch control the aerial imaging picture inreal time.

Owner:XIANGHANG SHANGHAI TECH CO LTD

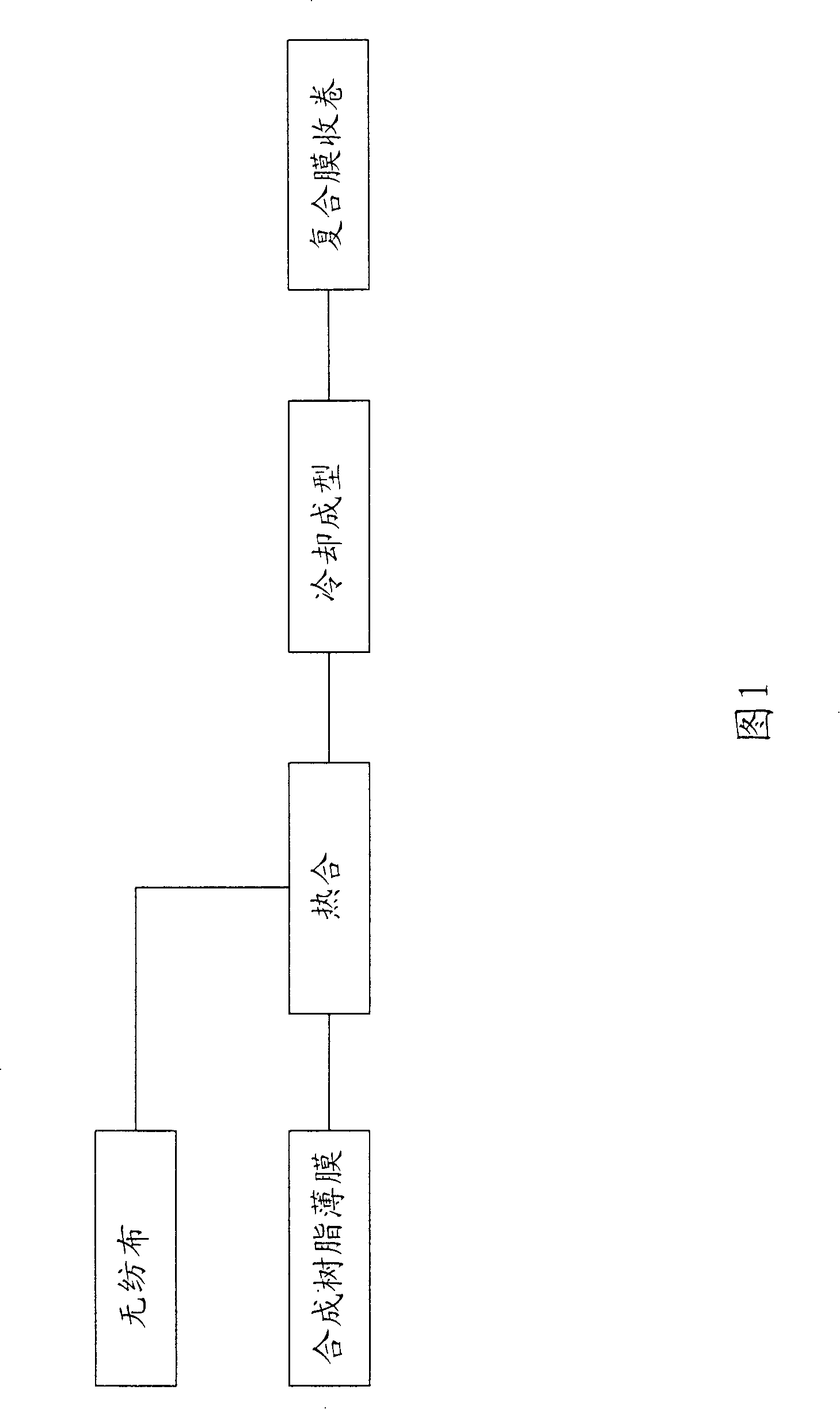

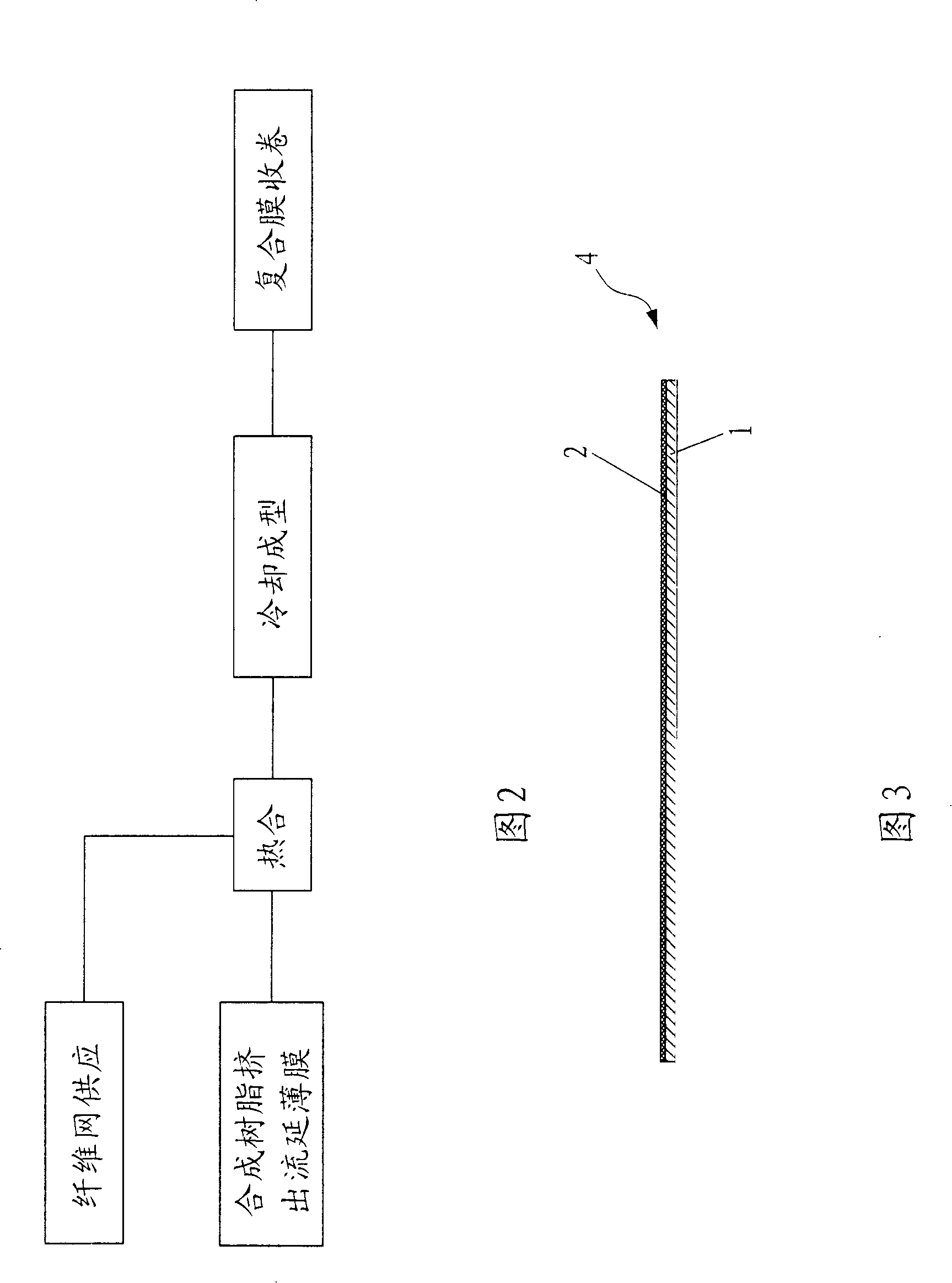

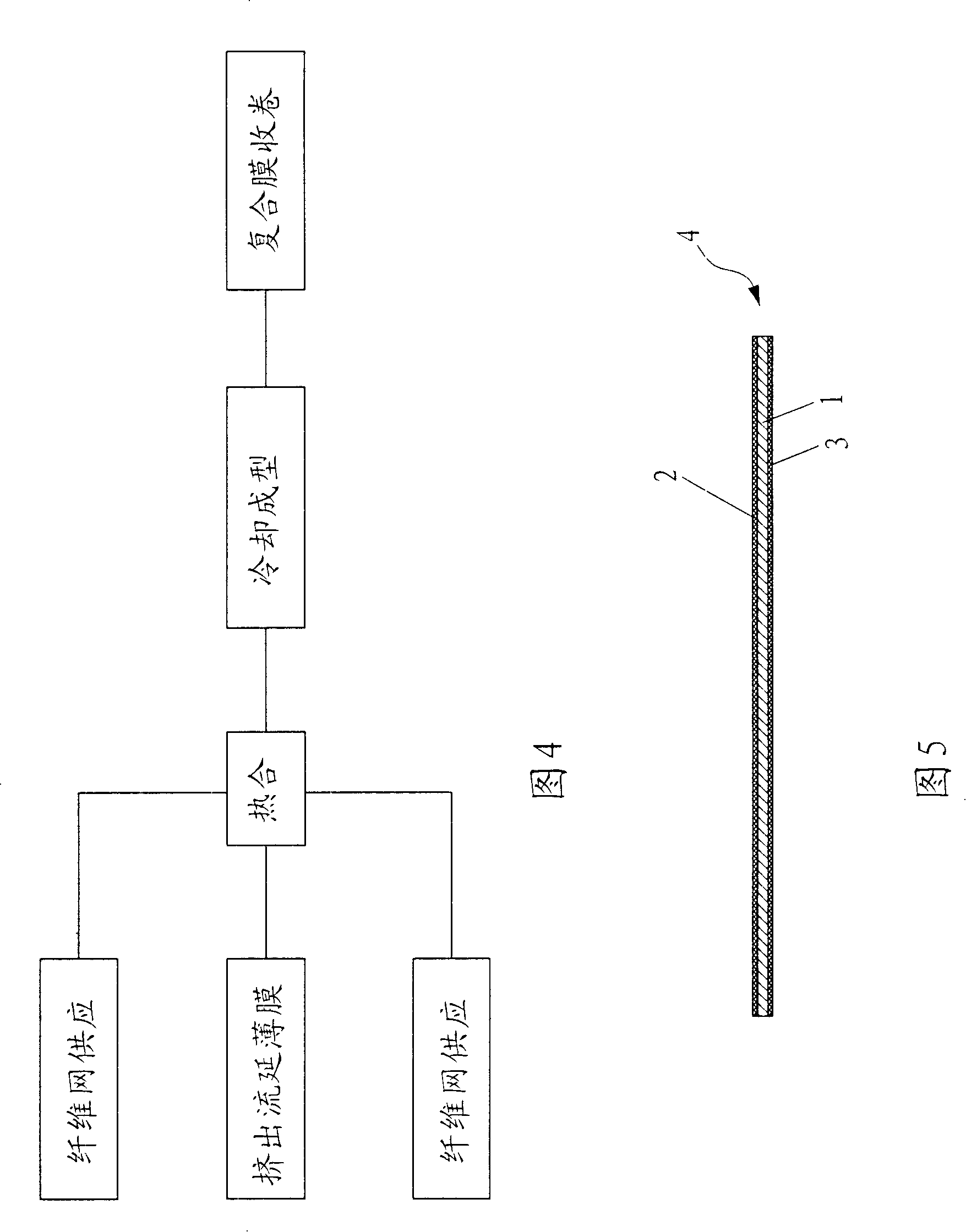

Fibre synthetic plastic film and production method thereof

ActiveCN101181832AReduce thicknessAvoid allergiesLamination ancillary operationsPersonal careFiberGram

The invention relates to a fiber synthesizing plastic film and production method, A) fiber net supplying procedure; B) film extrusion casting procedure: synthetic resin forms an extrusion casting film; C) thermal sealing procedure: an outlet of the fiber net supplying procedure is thermally sealed with the extrusion casting film in a melting state, with the casting film being extruded in the filmextrusion casting procedure; D) molding procedure: the plastic film with fiber adhered on the surface is thermally sealed in the thermal sealing procedure and is done with a corresponding molding method to form the plastic film with fiber adhered on the surface; E) wind up procedure: the synthesizing plastic film is wound up to become molding. The fiber nets of the production method utilize thin nets stuck naturally among fiber silk when the fiber is unfolded to be compounded with the plastic film in the melting state. The fiber nets can reduce the thickness of layering net and omit a cementing procedure or the thermal sealing procedure, thus effectively reducing gram weight formed by the fiber nets. The surface fiber of a compounding film compounded by the fiber nets and the synthesizingplastic film is soft with comfortable tactility and good for skin.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

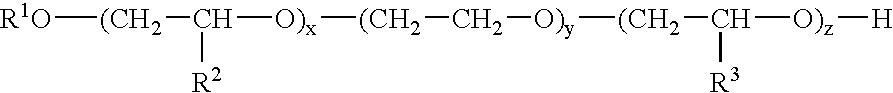

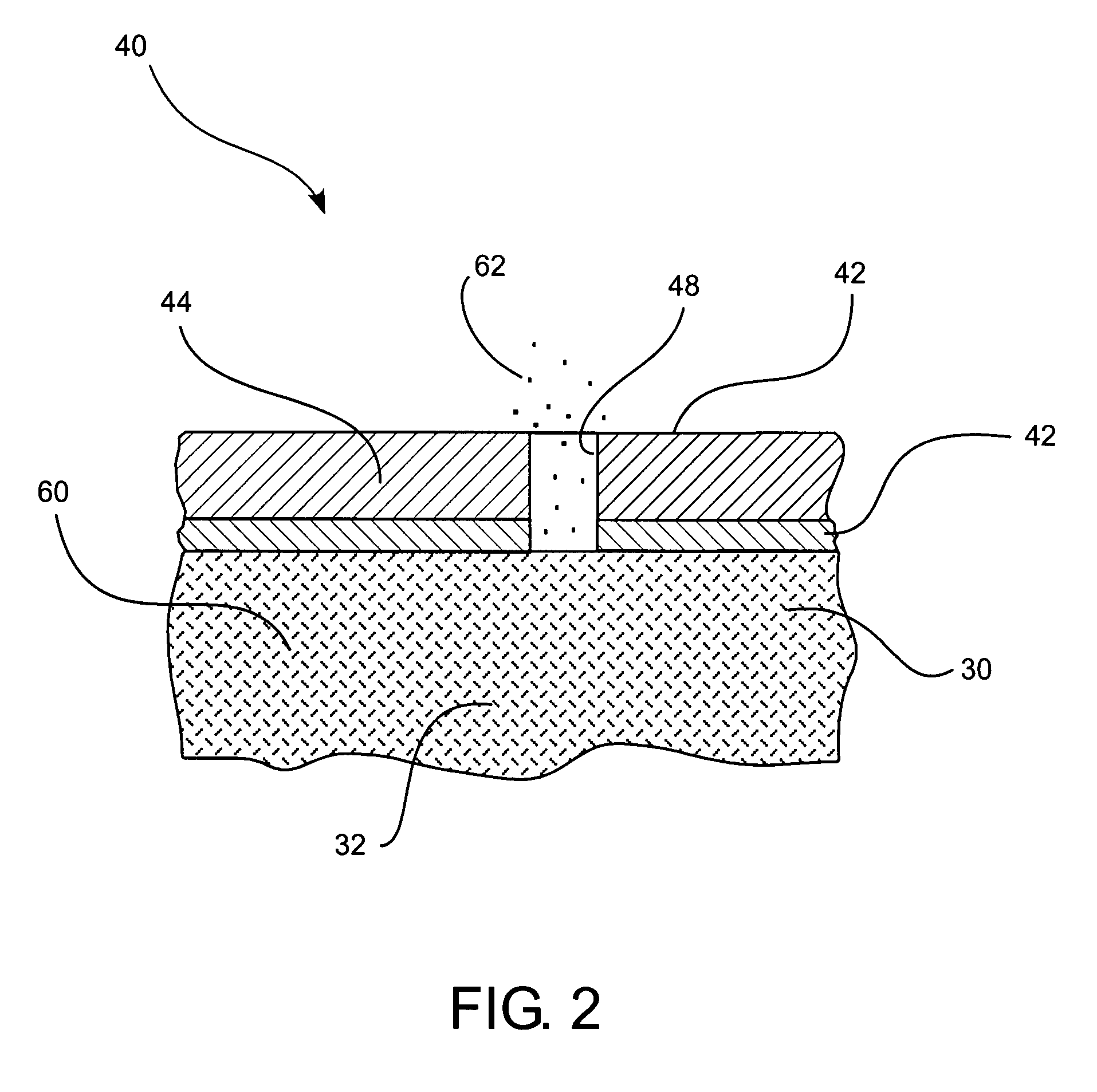

Vehicle interior article of skin-integrated laminate, method for manufacturing non-foaming polyurethane resin and method for manufacturing skin-integrated laminate using the same

The present invention is directed to skin-integrated laminates and their use as vehicle interior articles, in which the laminates feel comfortable to the touch and have a high quality of external appearances. The invention also relates to a method for manufacturing these non-foaming polyurethane resins for use as design skins in vehicle interior articles and to a method for manufacturing a skin-integrated laminate from these non-foaming polyurethane resins, with both methods having increased productivity and lower cost, and without any adverse influence on the work environment. The non-foaming polyurethane resin forms a design skin surface by a reaction injection molding process, in which (I) a polyol mixture of (1) a polyol, (2) a chain extender which is 1-methyl-3,5-diethyl-2,4-diaminobenzene and / or 1-methyl-3,5-diethyl-2,6-diaminobenzene, (3) a catalyst, and (4) optionally, an auxiliary agent, and (II) a polyisocyanate compound, are reacted. The surface hardness of the non-foaming polyurethane resin, as measured by an Asker A hardness meter, is from 30 to 70.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com