Patents

Literature

63results about How to "Avoid wasting heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

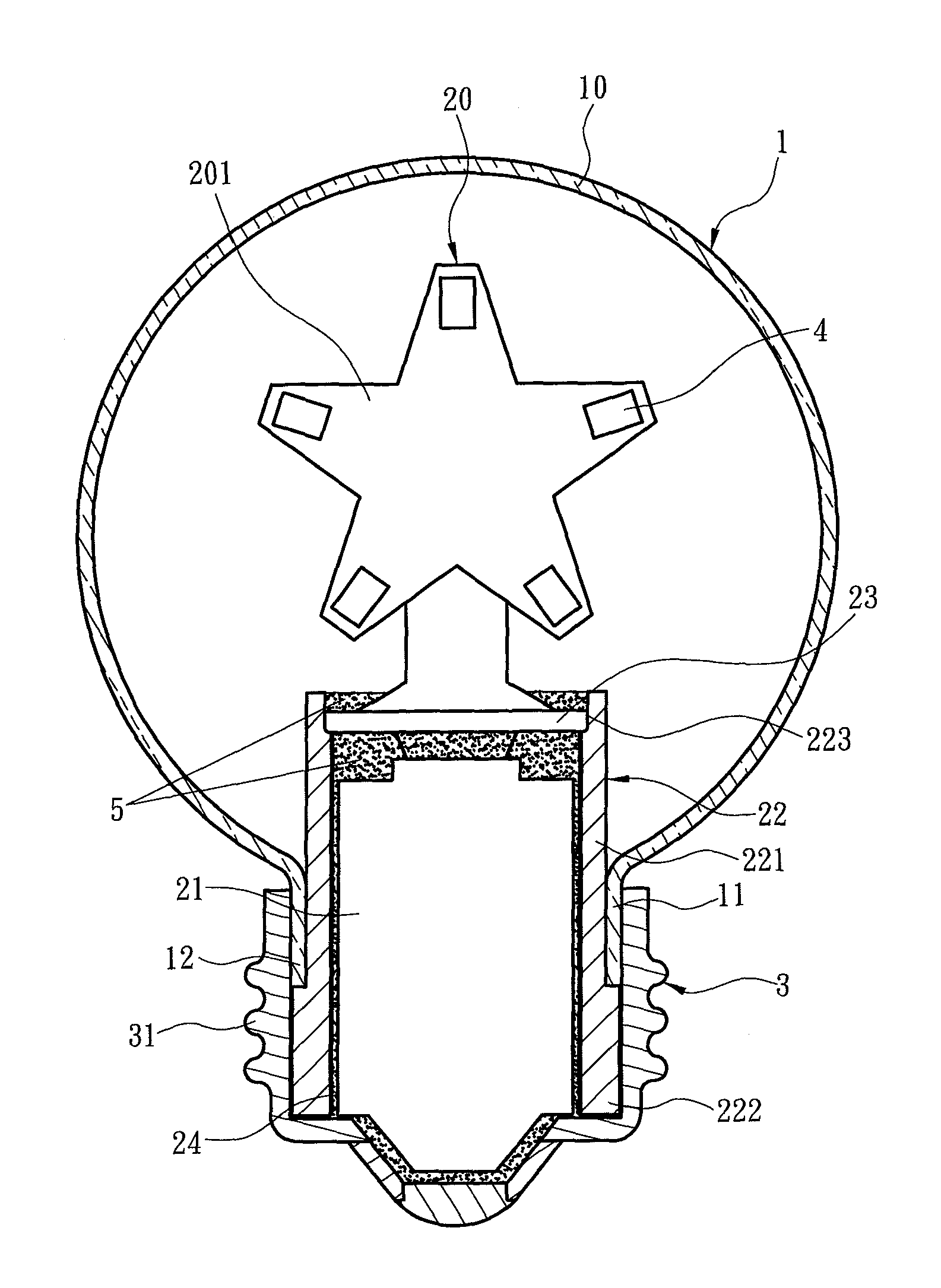

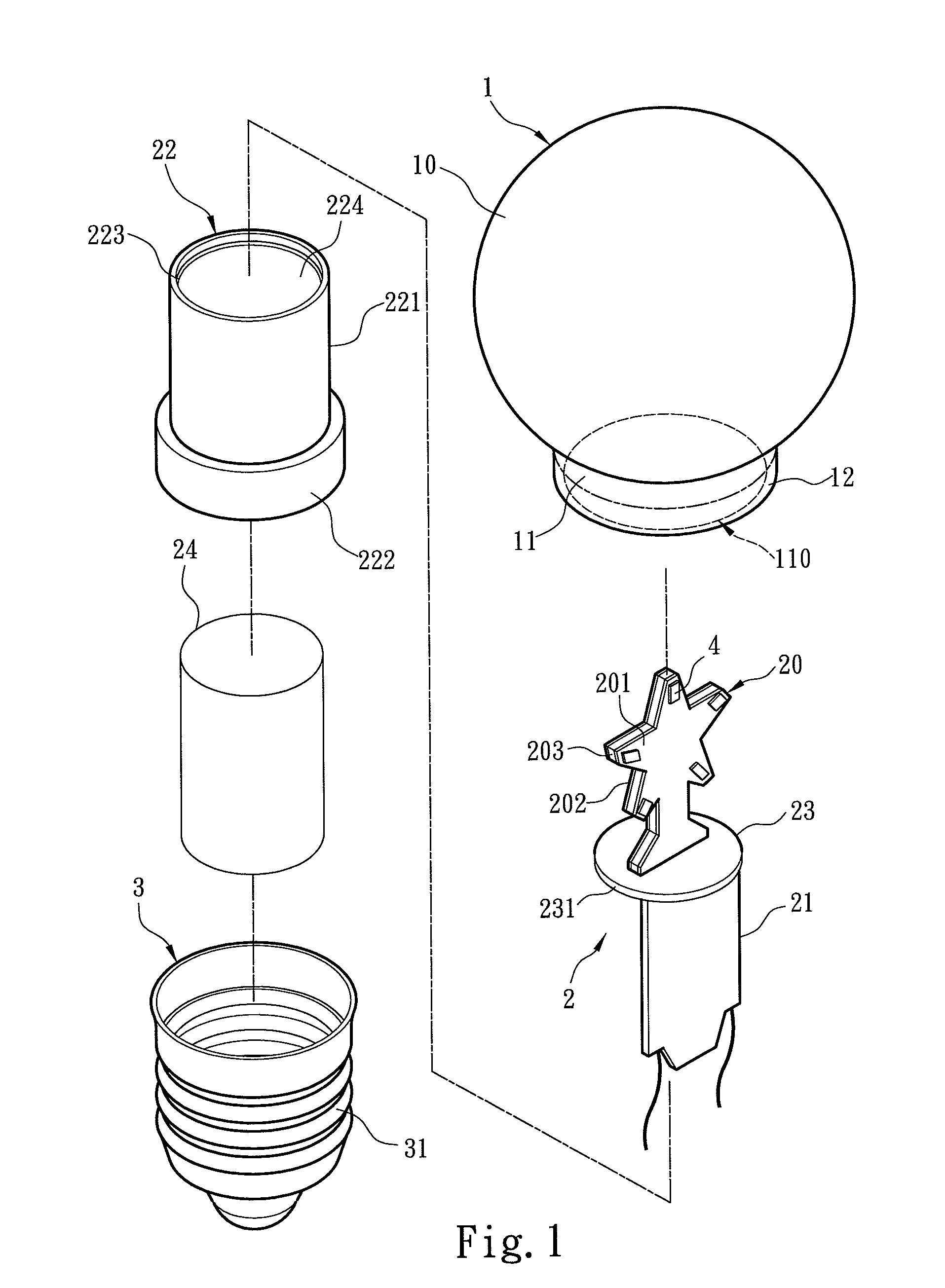

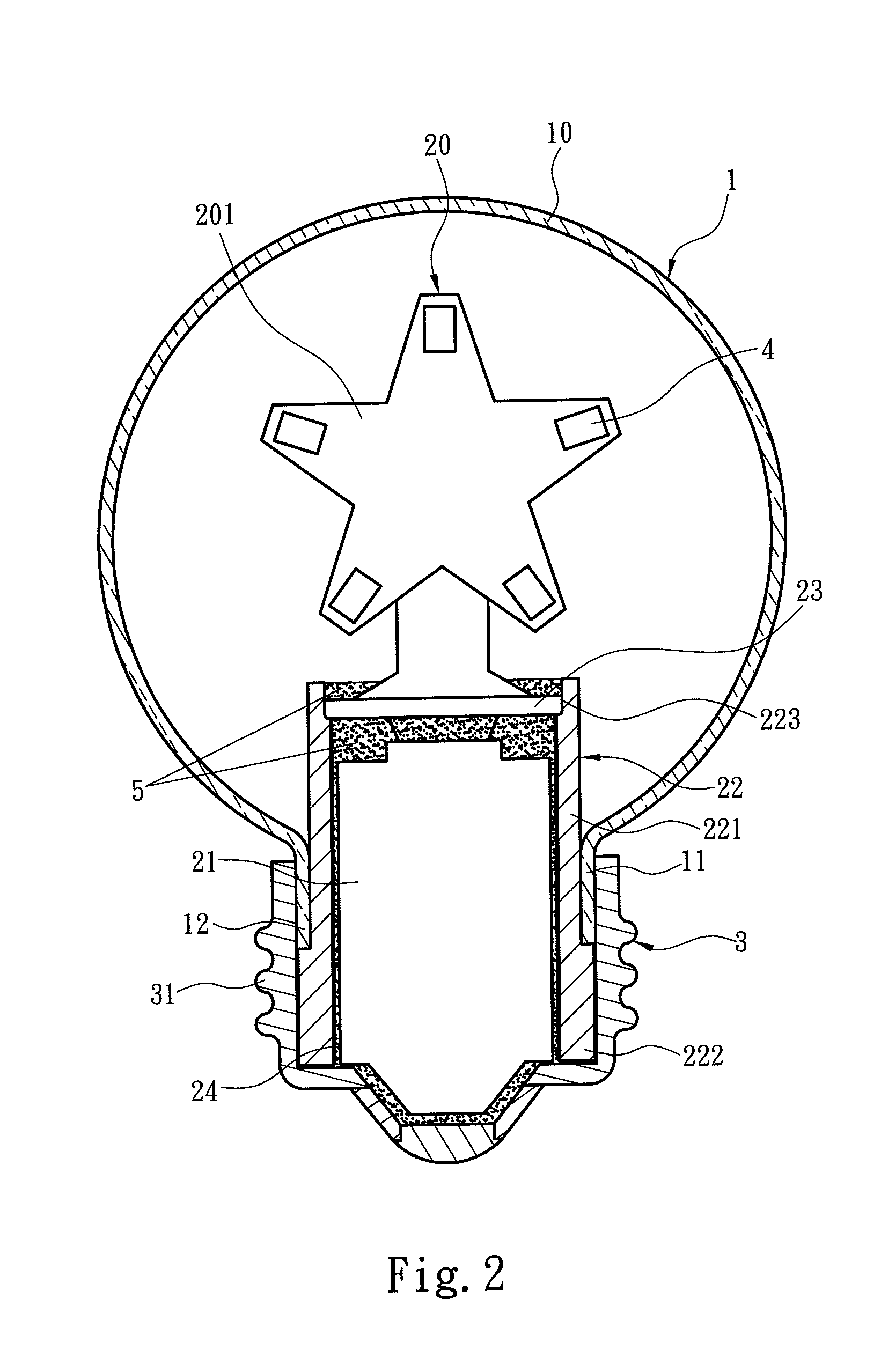

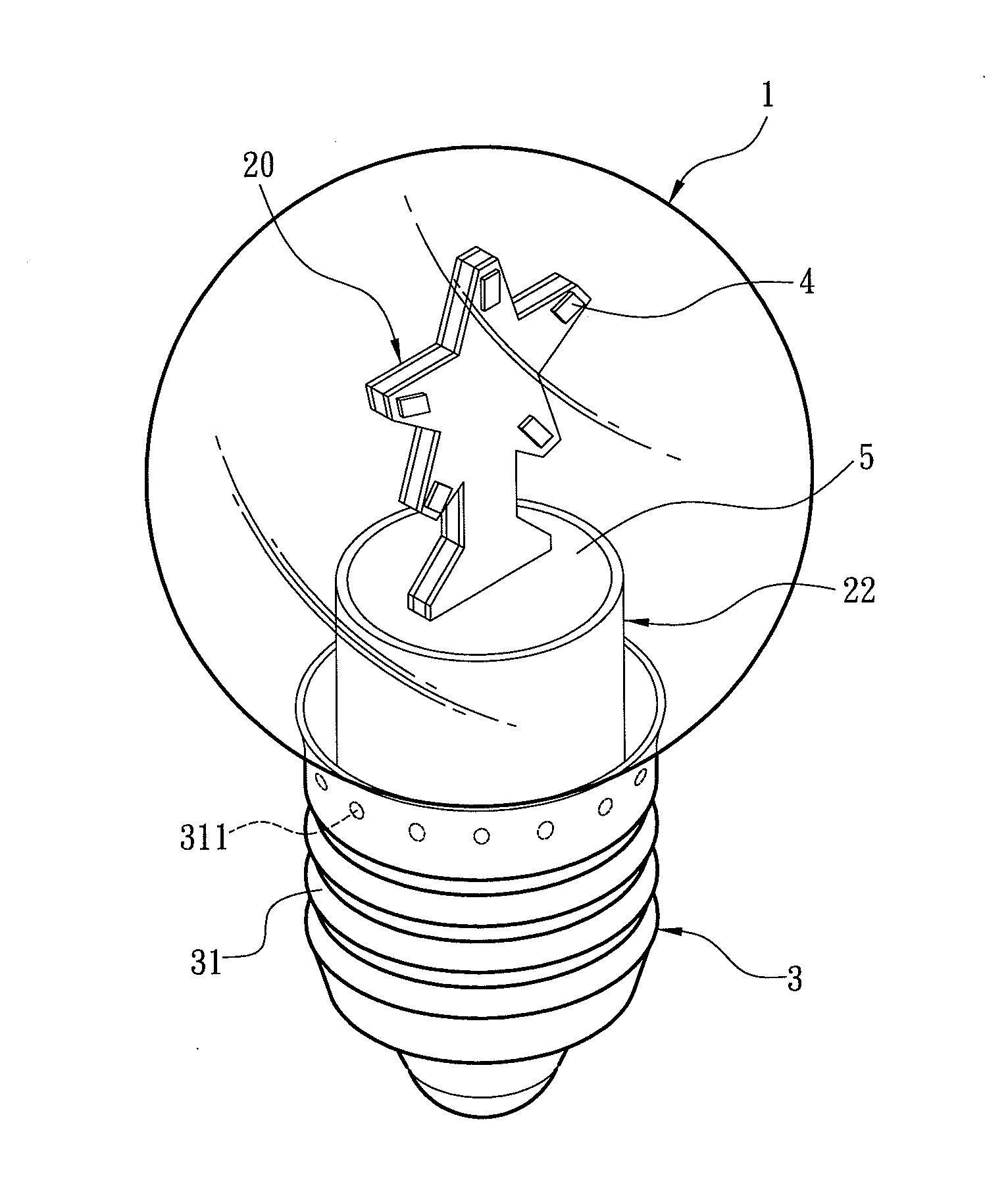

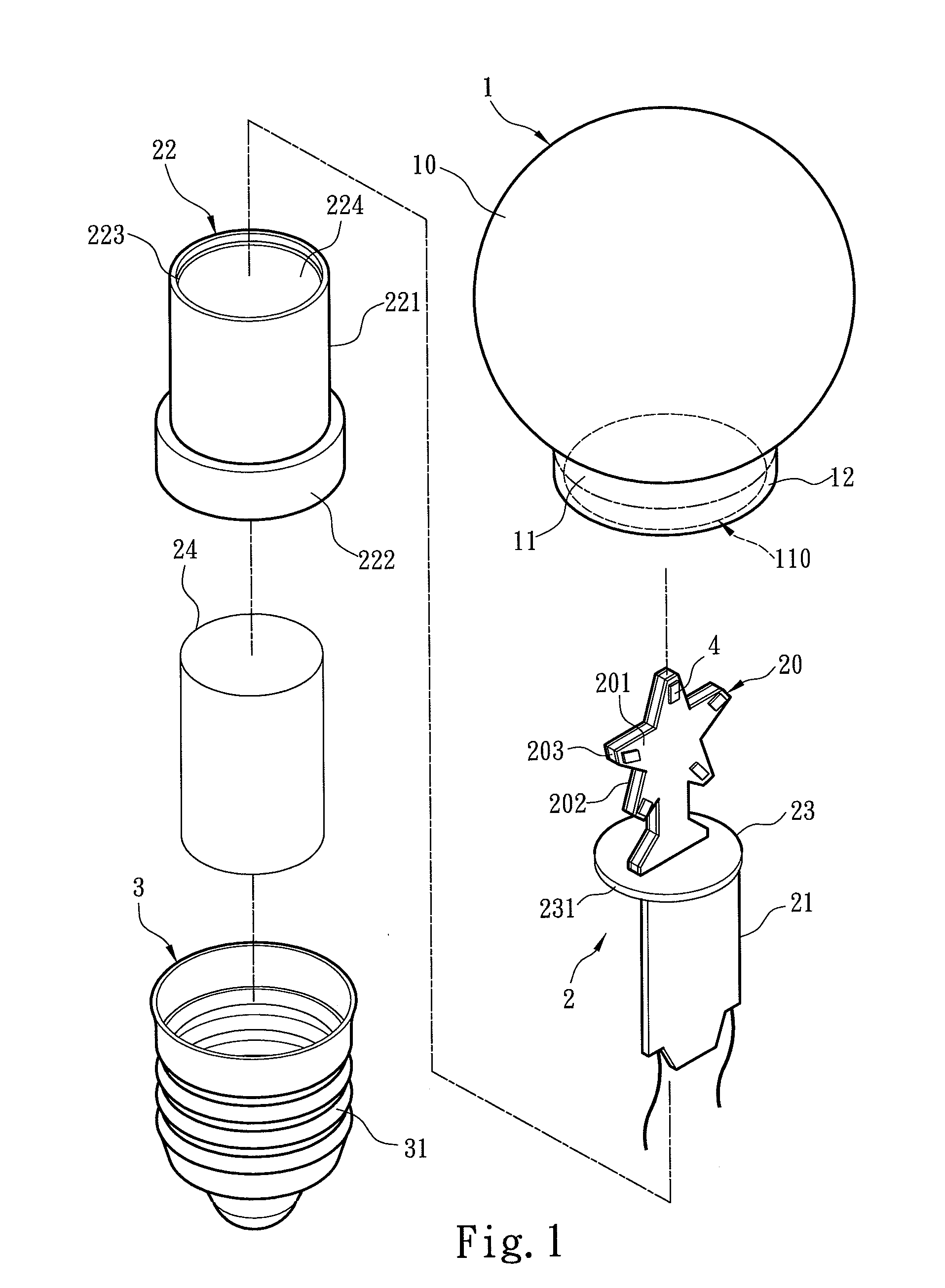

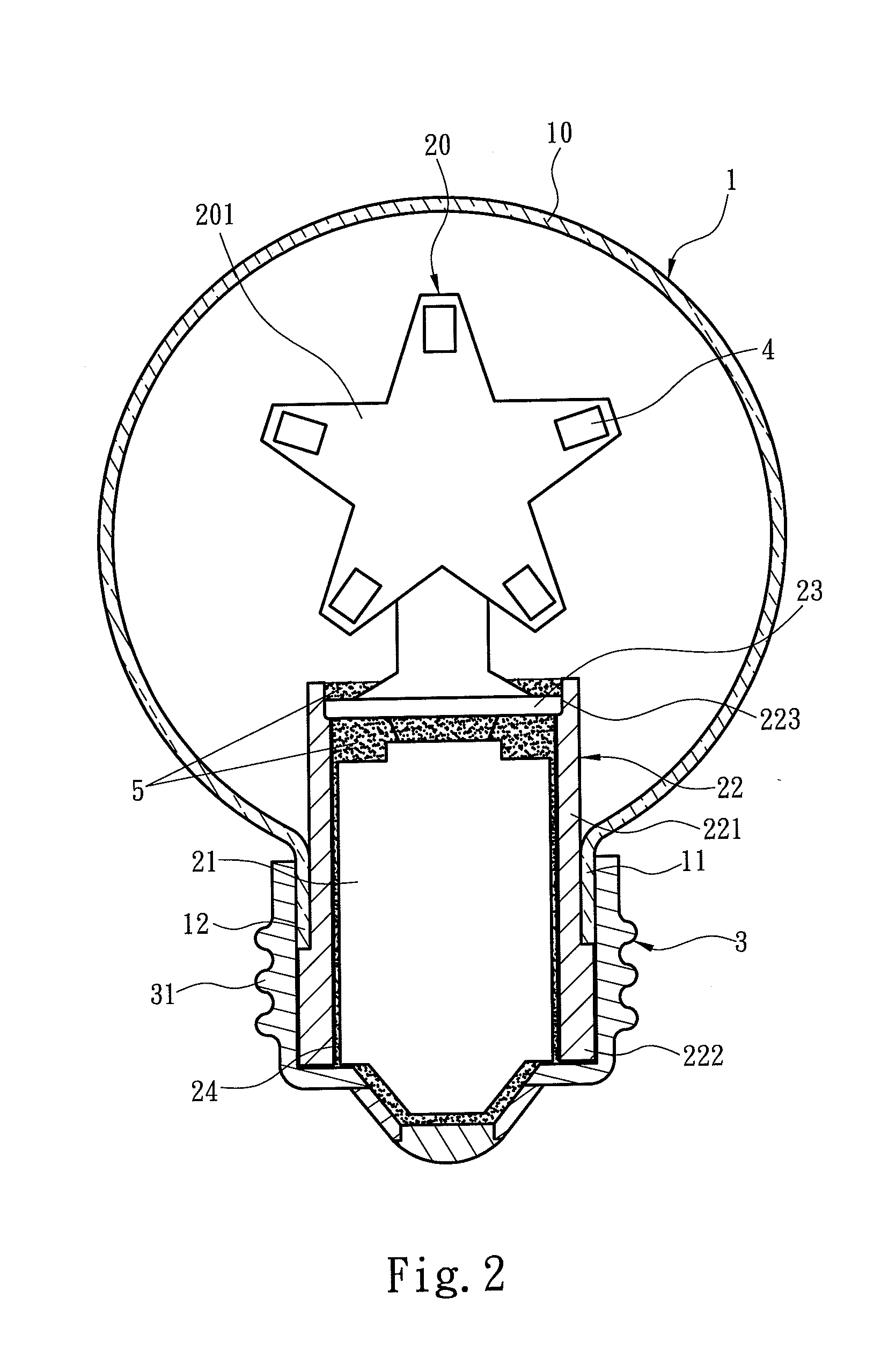

LED light bulb providing high heat dissipation efficiency

InactiveUS8641237B2Solve the low heat dissipation efficiencyHigh voltagePlanar light sourcesLighting support devicesEngineeringLamp shell

An LED light bulb includes a lamp shell, a light emitting assembly and a power receiving base. The lamp shell includes a light transmissive portion and a holding portion. The light emitting assembly includes a light source baseboard located in the light transmissive portion and a circuit board connecting to the light source baseboard. The circuit board is surrounded by a heat sink. The heat sink includes a heat collecting section and a holding section extended from the heat collecting section into the power receiving base such that the power receiving base fully encases the heat sink without exposing. The inner surface of the power receiving base connects to the outer surface of the holding section so that heat generated by the light source baseboard is absorbed by the heat collecting section and transmitted via the holding section to the power receiving base for dissipating.

Owner:HSU WEI LIN

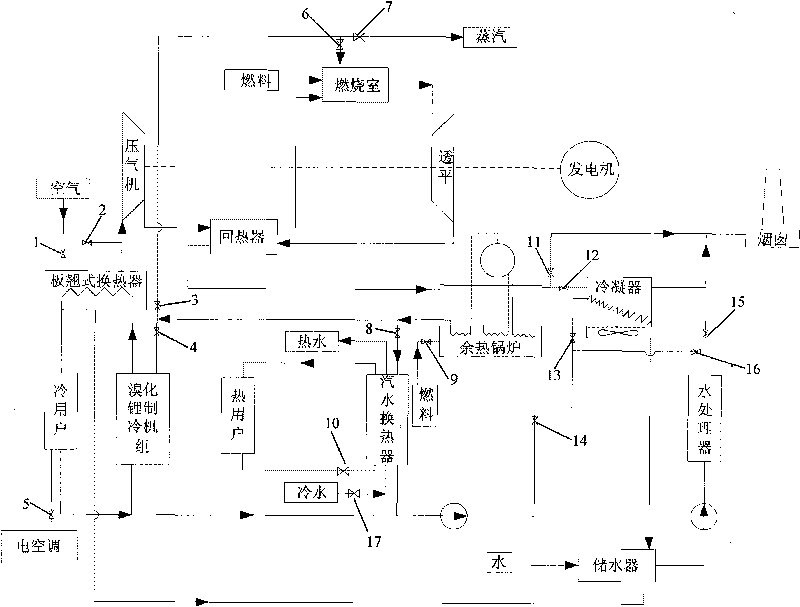

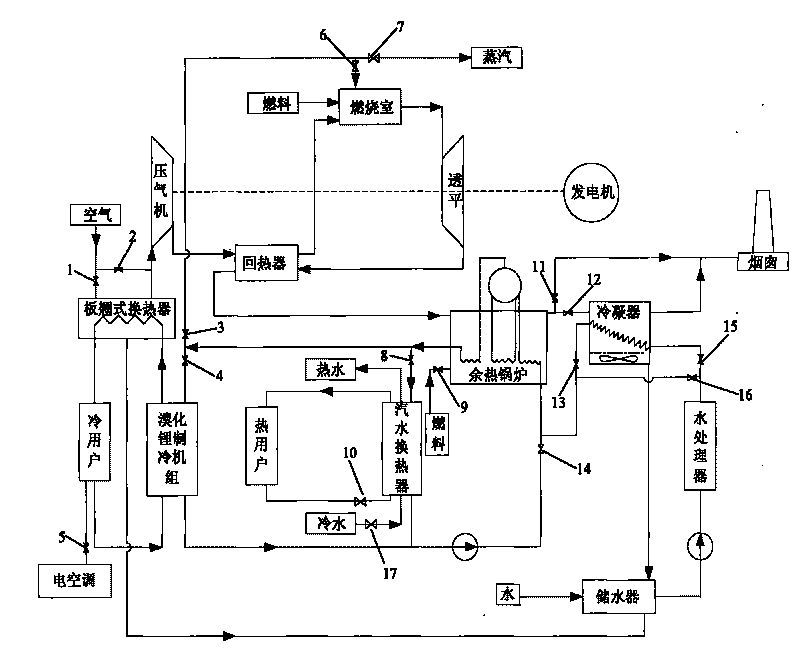

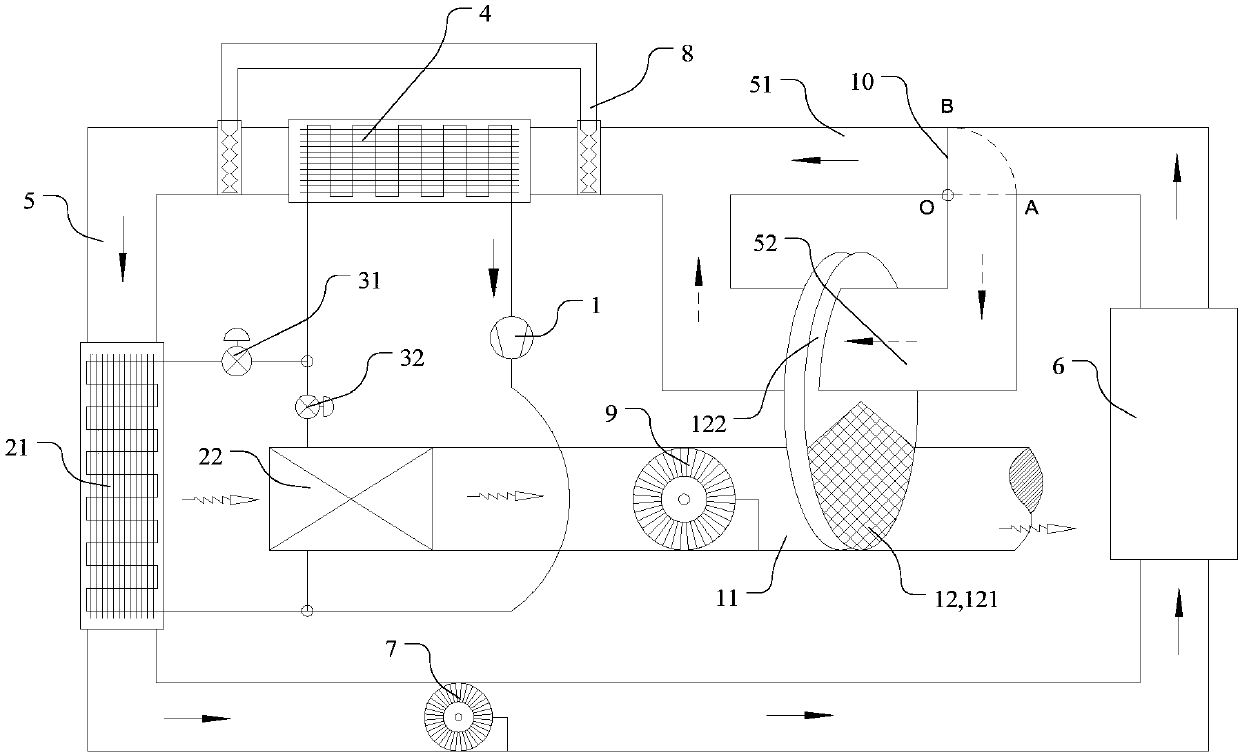

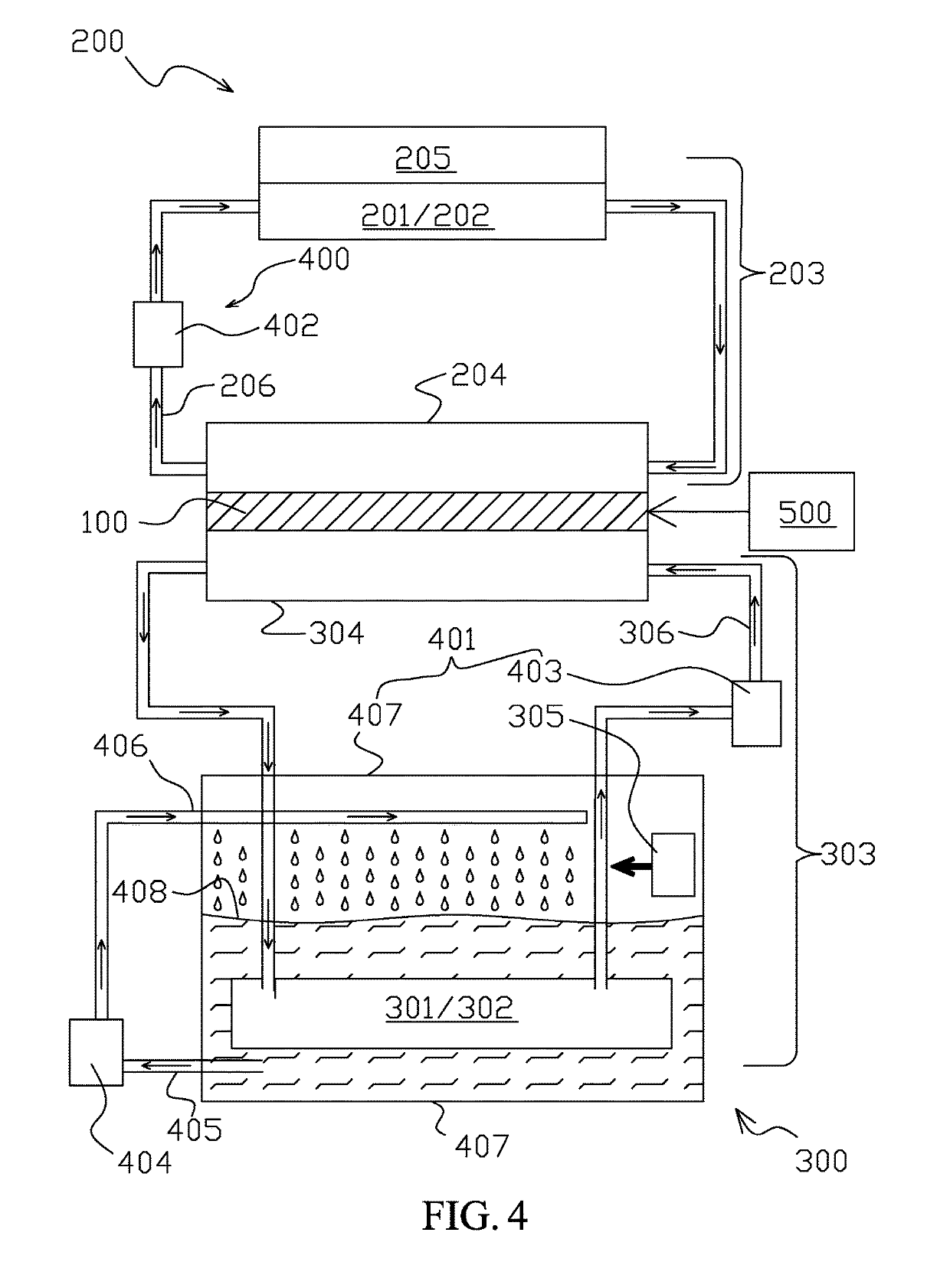

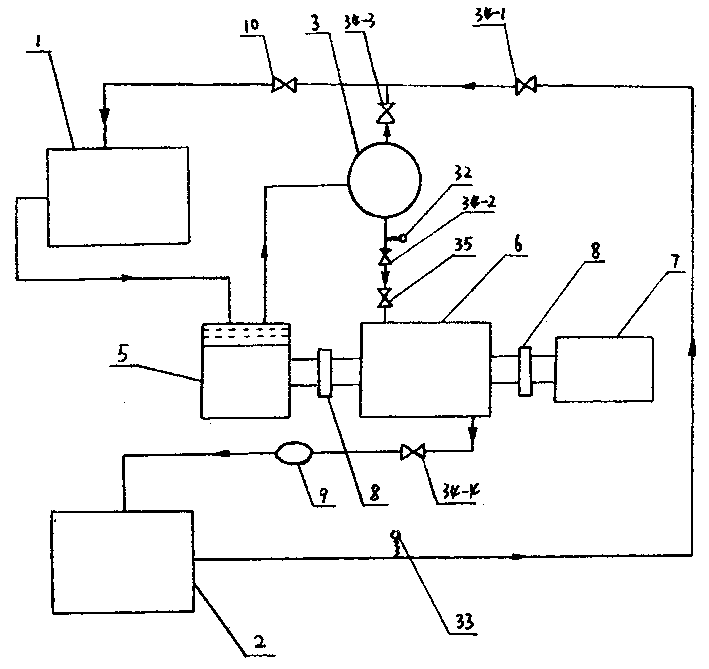

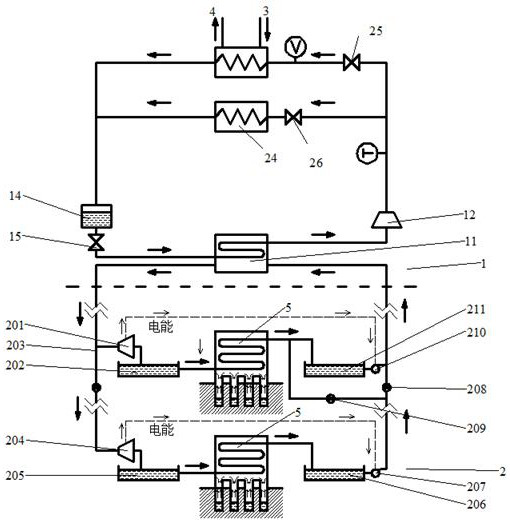

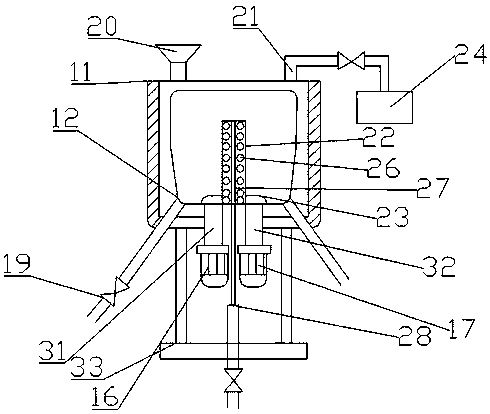

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

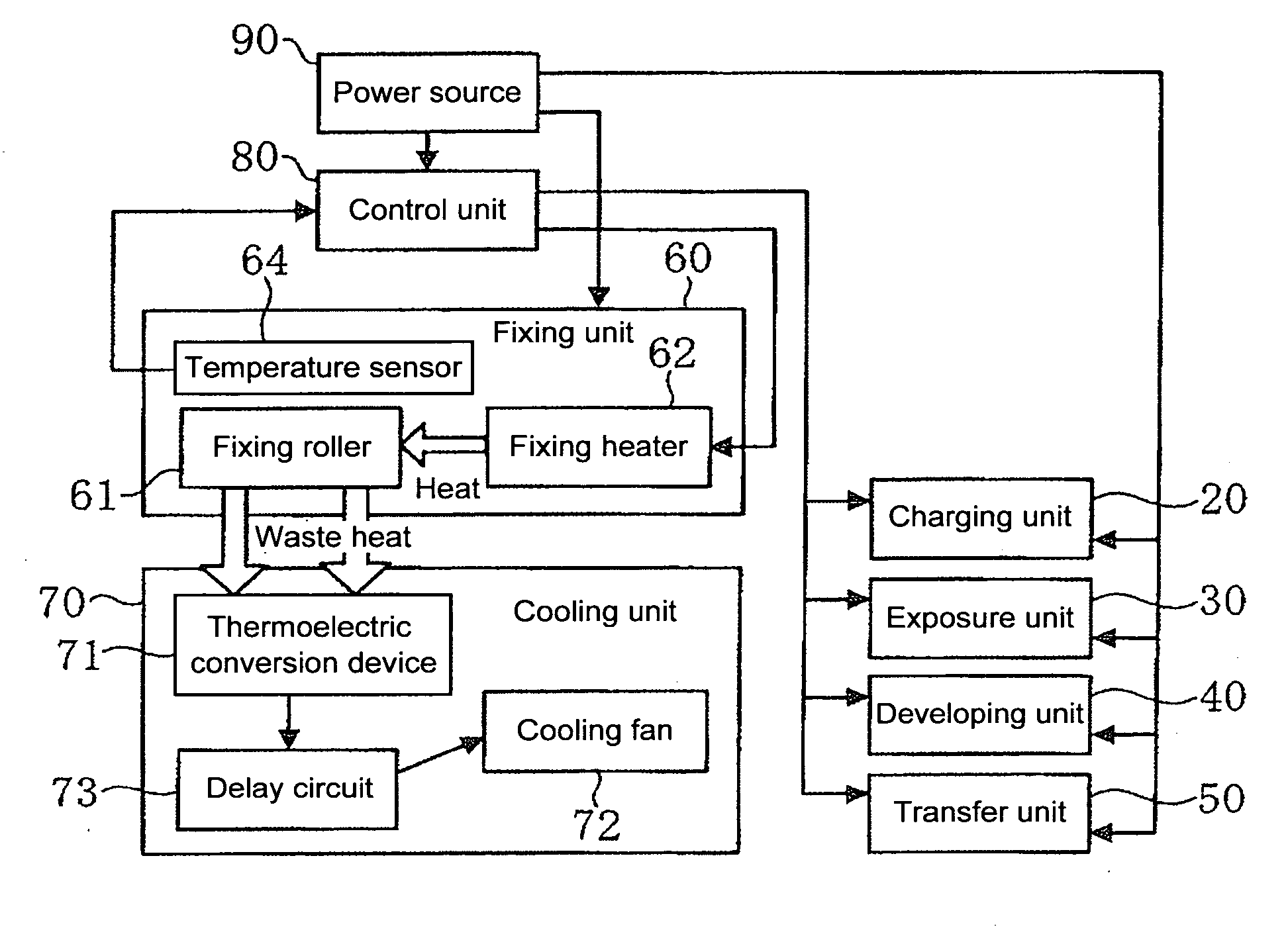

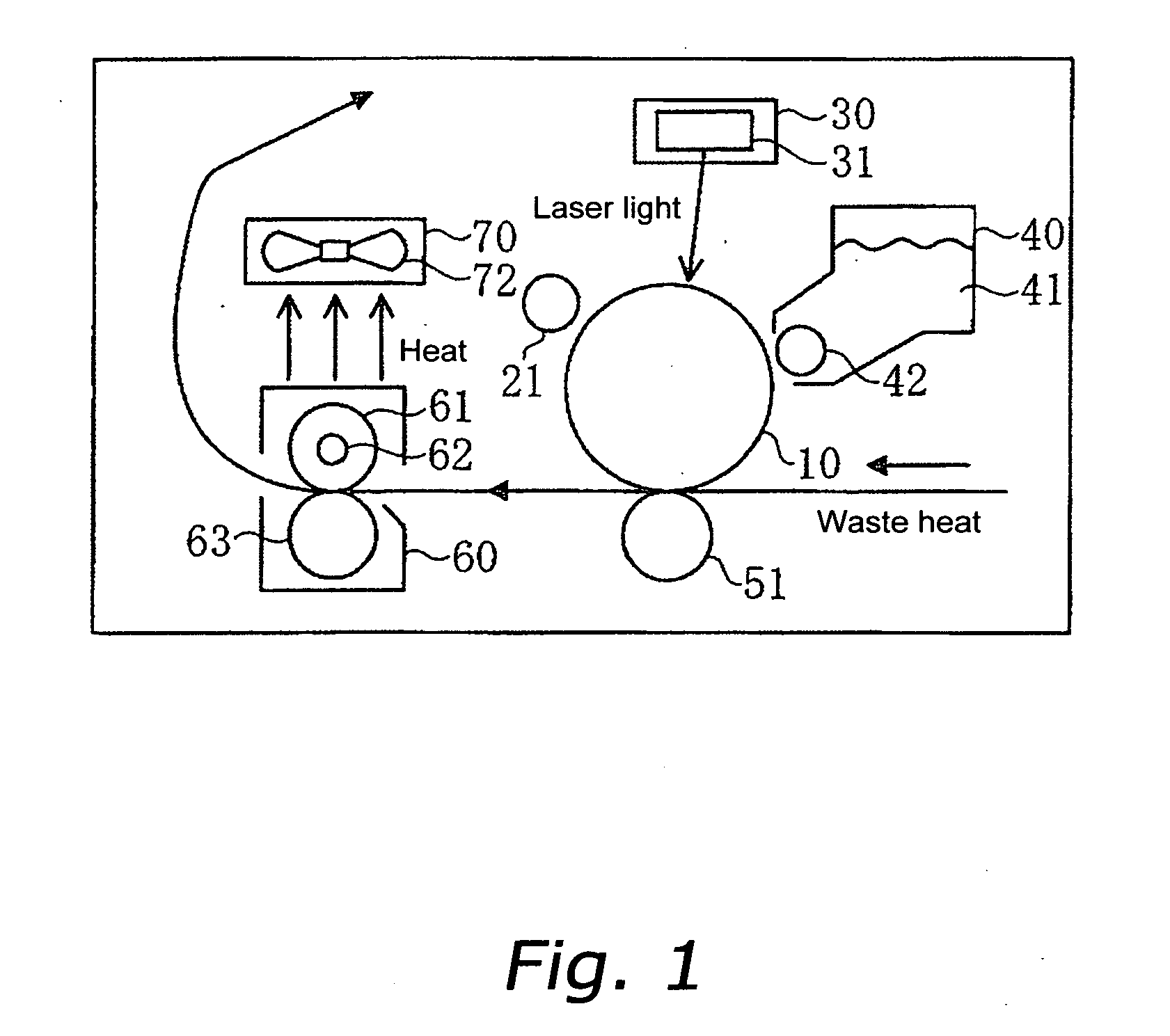

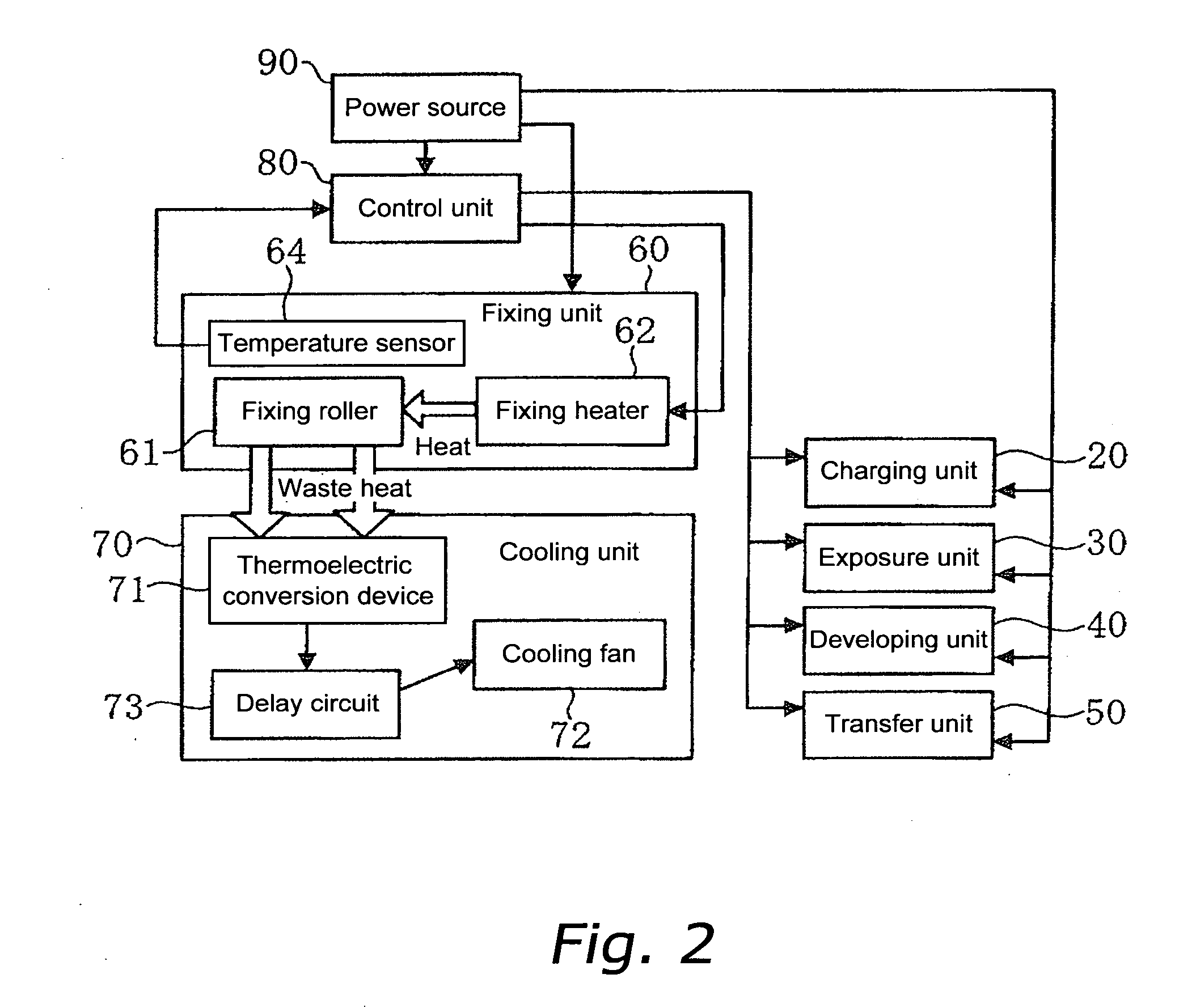

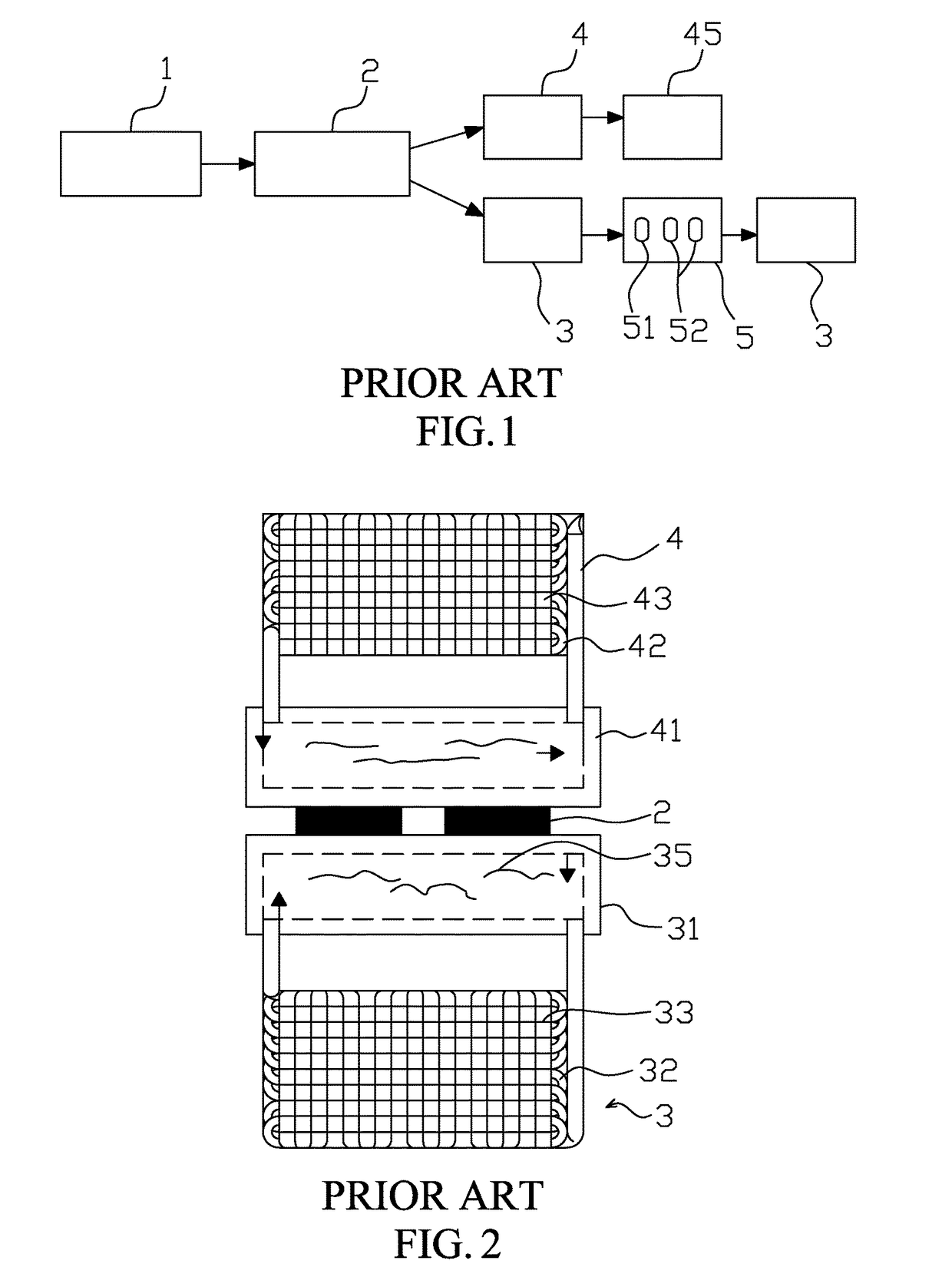

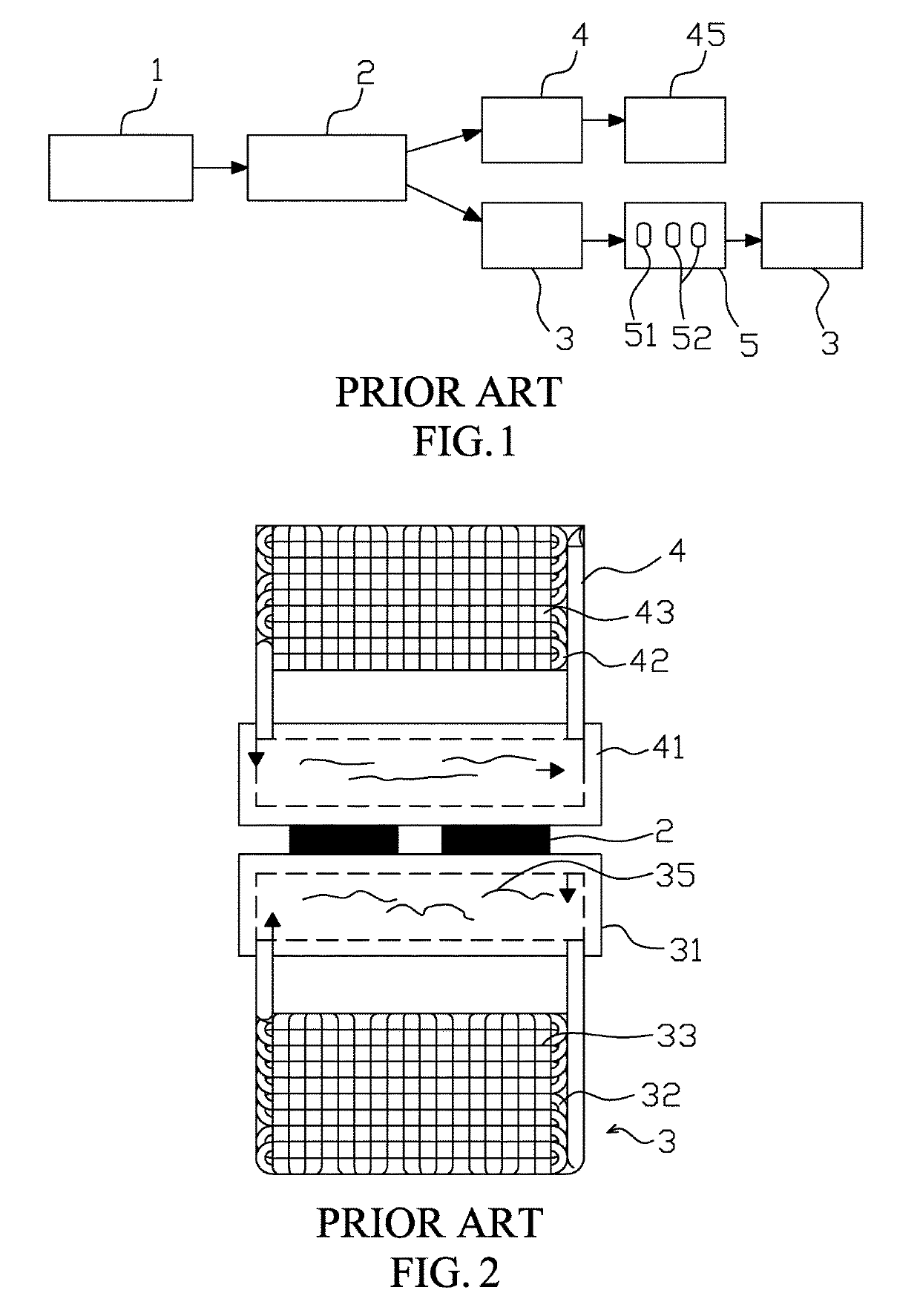

Image forming device

InactiveUS20070098432A1Reduce supplyAvoid wasting heatElectrographic process apparatusElectricityImage formation

An image forming device in which a fixing unit is powered from the power supply, and a cooling unit is driven by electricity obtained by supplying waste heat from the fixing roller to a thermoelectric conversion device. After turning the image forming device ON, when the temperature of the fixing roller reaches a certain temperature thermoelectromotive force is generated in the thermoelectric conversion device. When the power supply is turned OFF, the thermoelectromotive force in the thermoelectric conversion device becomes zero when the temperature of the fixing roller drops to a certain temperature. Also, a delay circuit is provided between the thermoelectric conversion device and the cooling fan, so supply of electricity to the cooling fan is later than the time that thermoelectromotive force is generated, and the time that power supply to the cooling fan stops is also later than the time that the thermoelectromotive force becomes zero.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

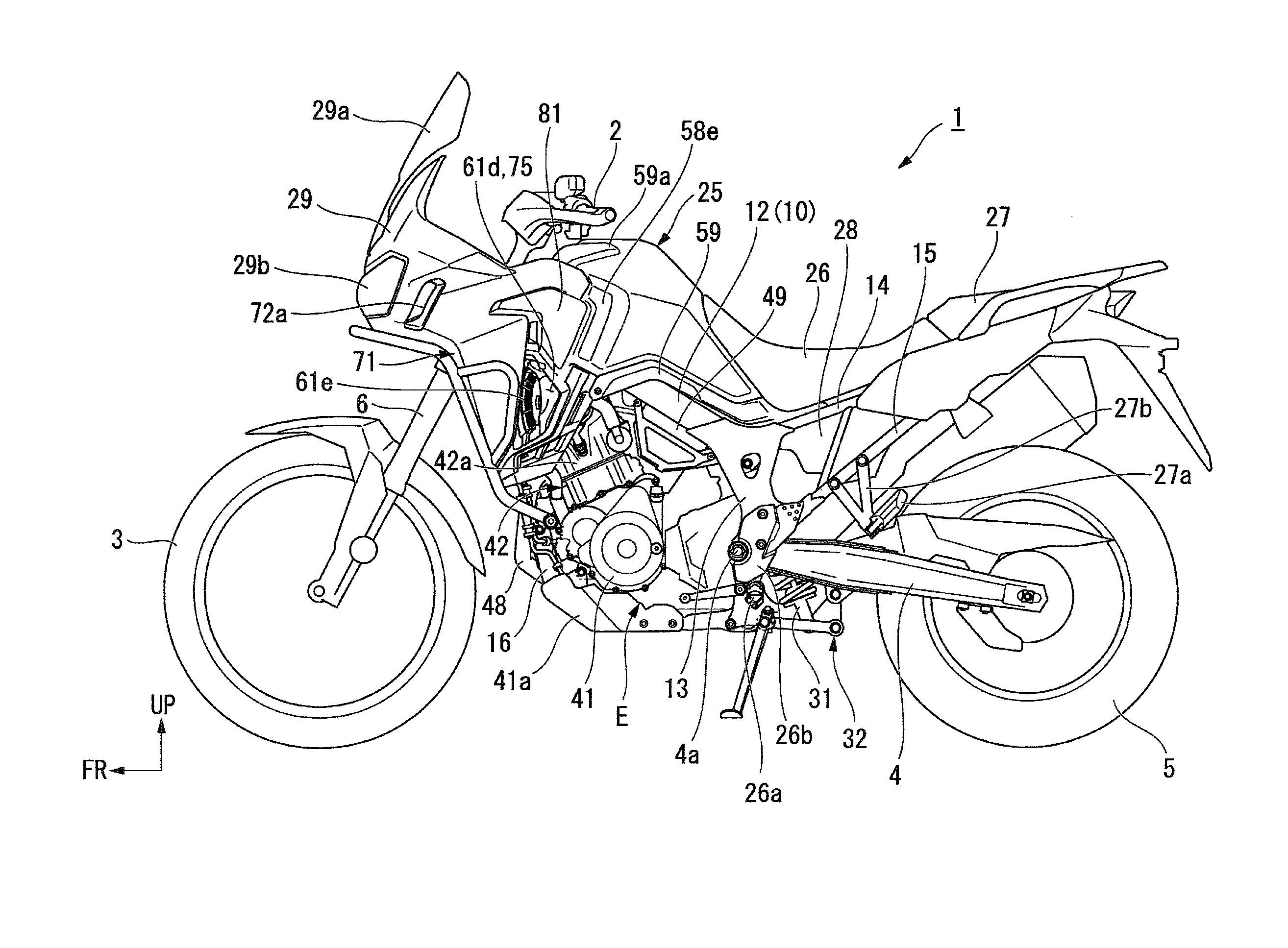

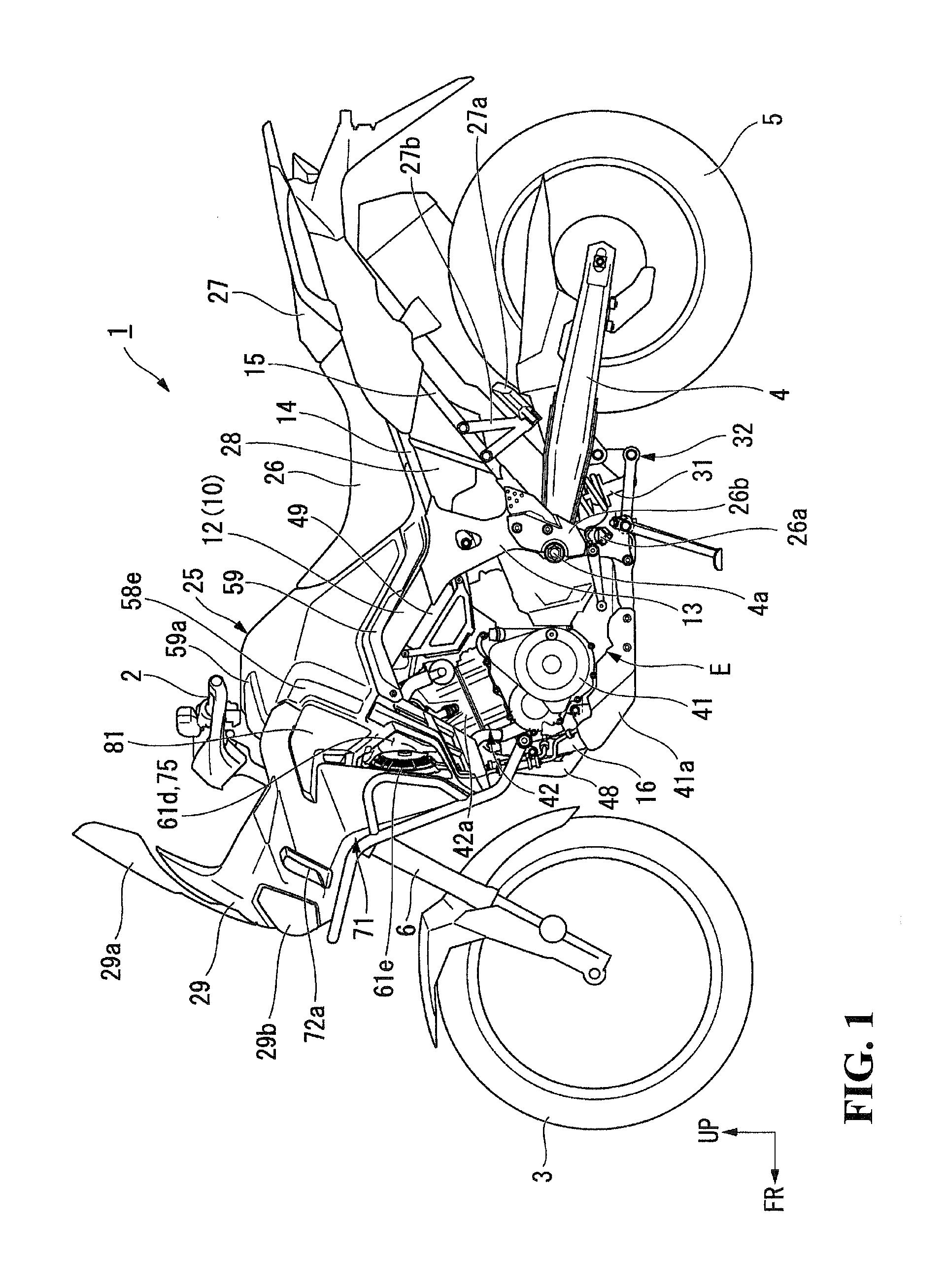

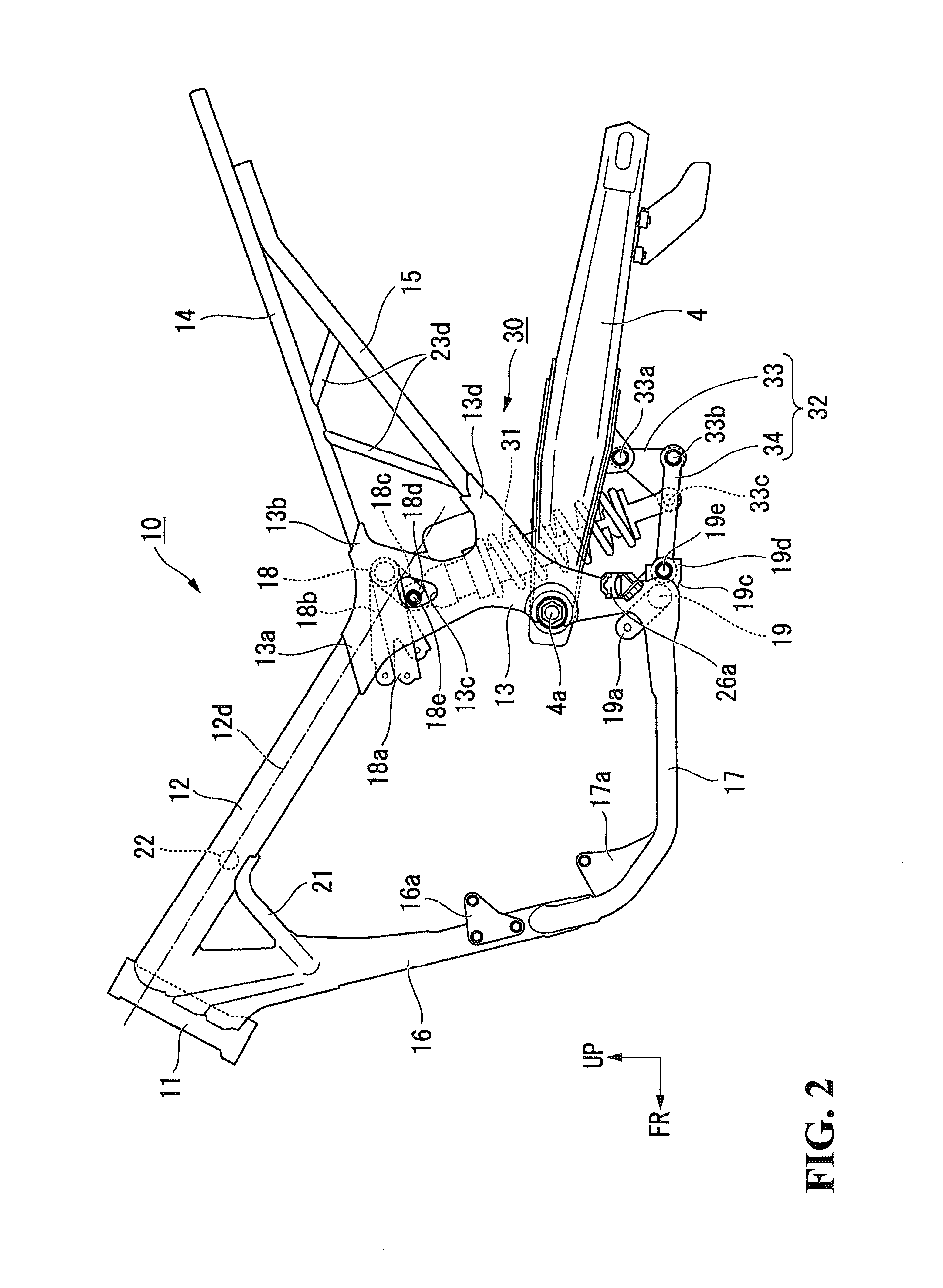

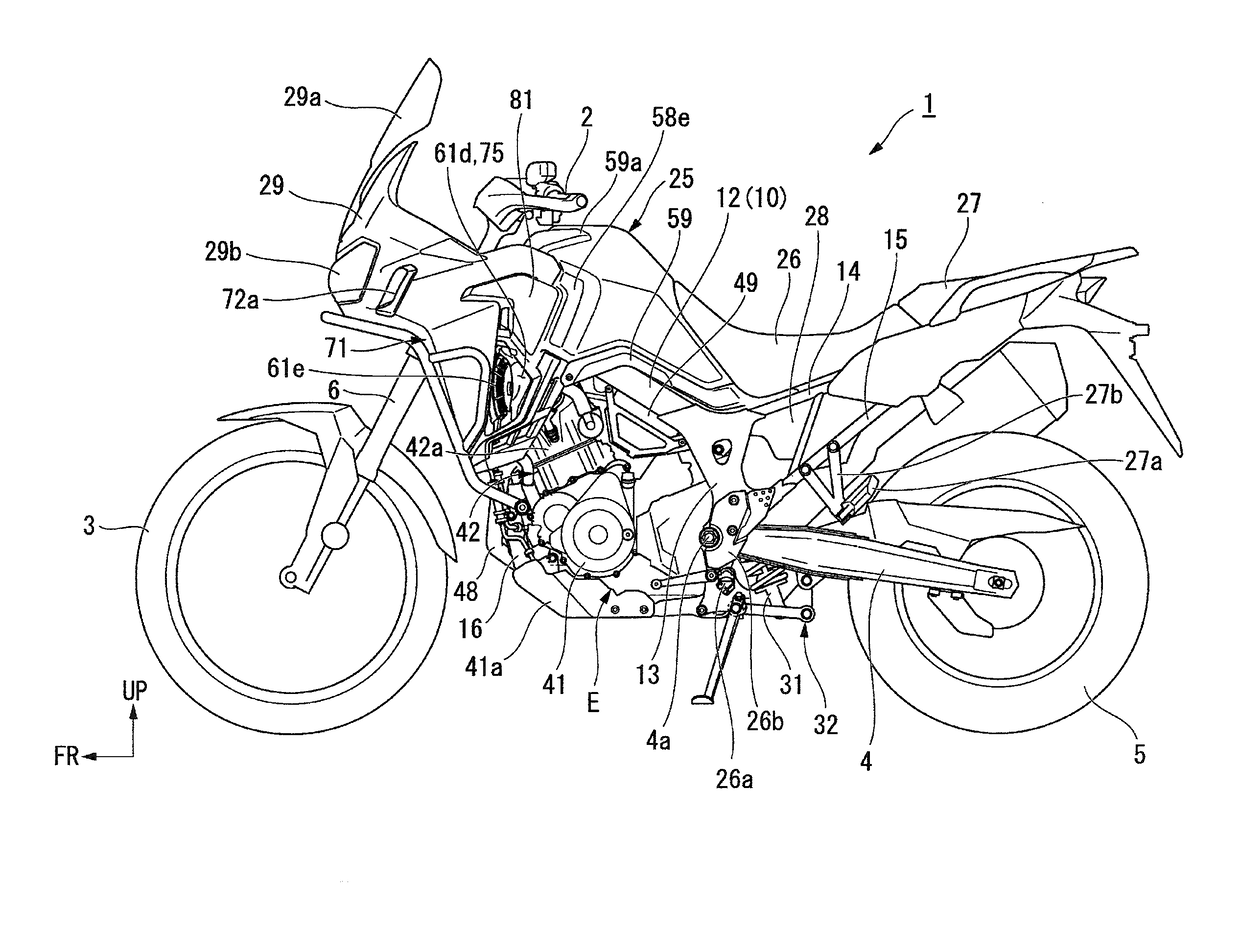

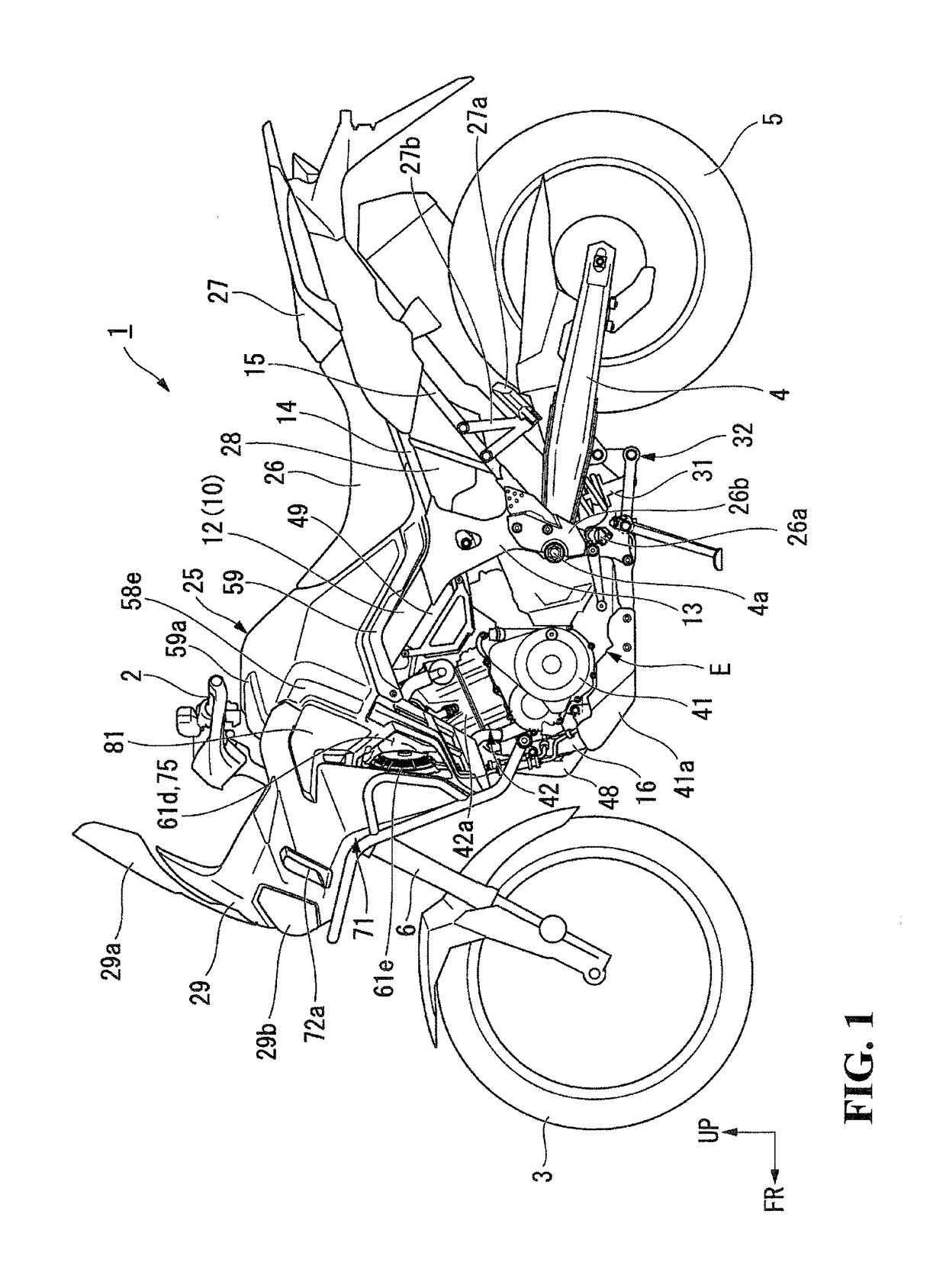

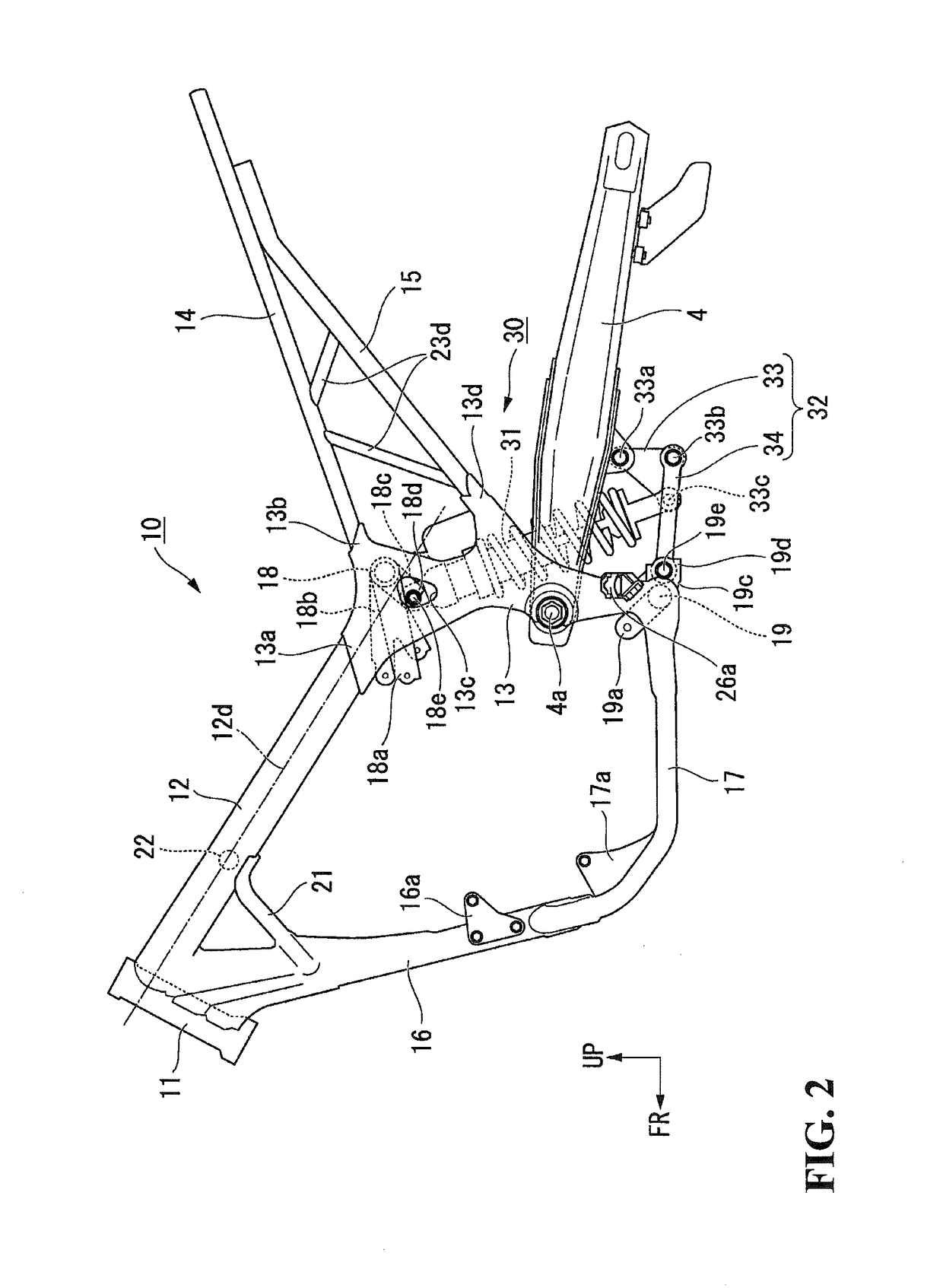

Saddle-ride type vehicle

ActiveUS20160244116A1Avoid wasting heatWaste heatWeather guardsMotorcyclesCylinder headAutomotive engineering

A saddle-ride type vehicle in which an engine is supported on a body frame and radiators are disposed forward of the engine is provided, wherein waste heat of the radiators is prevented from reaching the engine. The saddle-ride type vehicle includes a radiator shroud 71 that covers a range from a lateral side of a radiator 61 to a lateral side of a cylinder head 42a of the engine E. The radiator shroud 71 has an exhaust port 75 opening outward in a vehicle width direction. The saddle-ride type vehicle also includes a partition wall 82A between the radiator and the cylinder head 42a. The partition wall 82A separates a rear space 61d of the radiator 61 and the cylinder head 42a from each other and brings the rear space 61d into communication with the exhaust port 75 of the radiator shroud 71.

Owner:HONDA MOTOR CO LTD

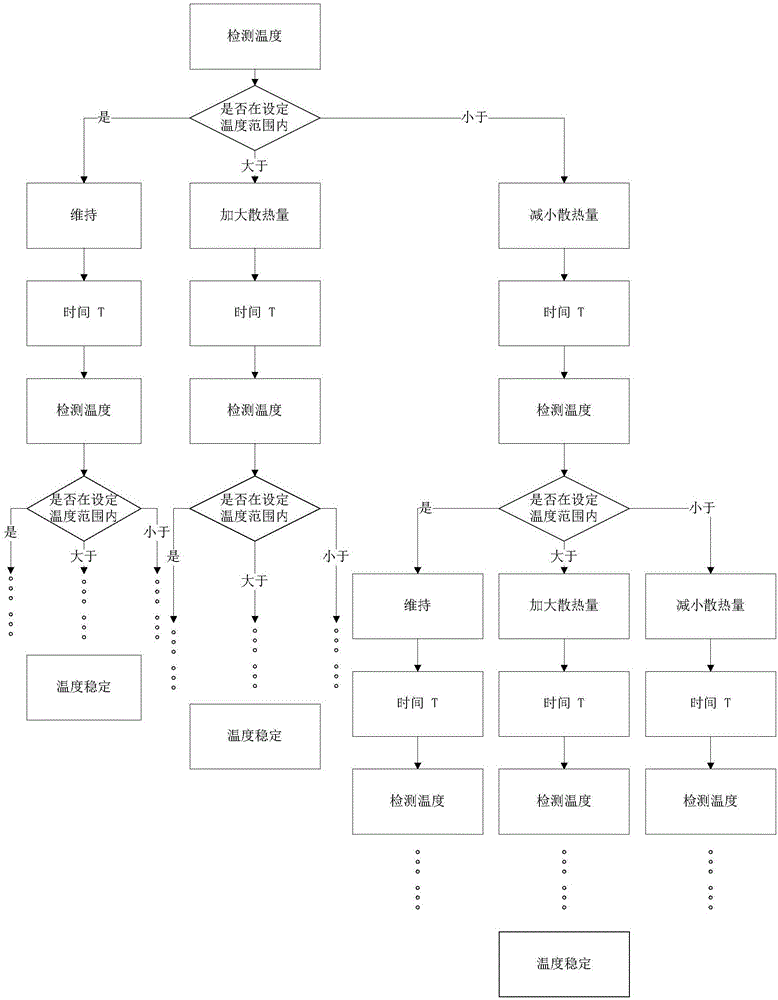

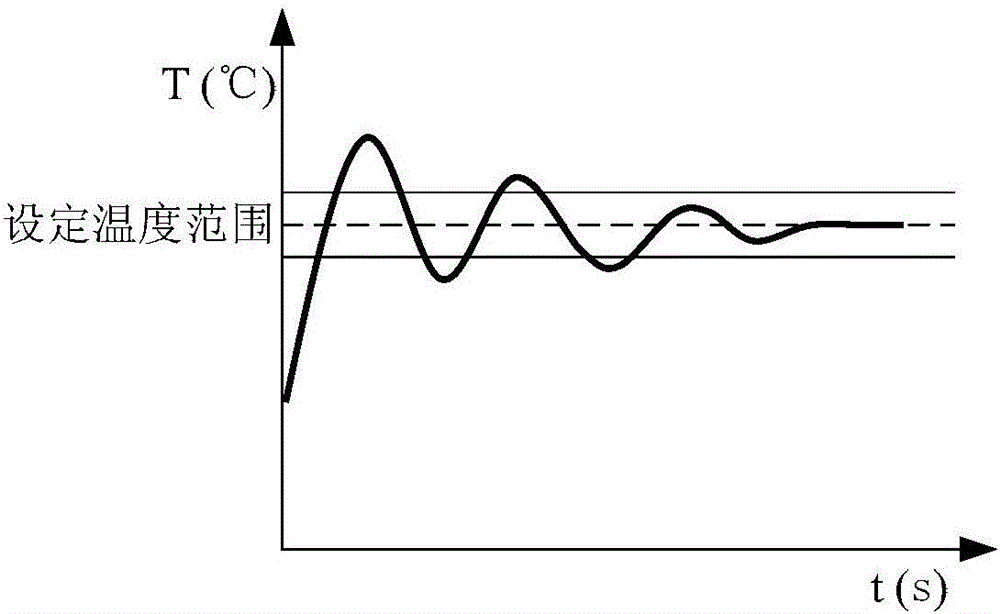

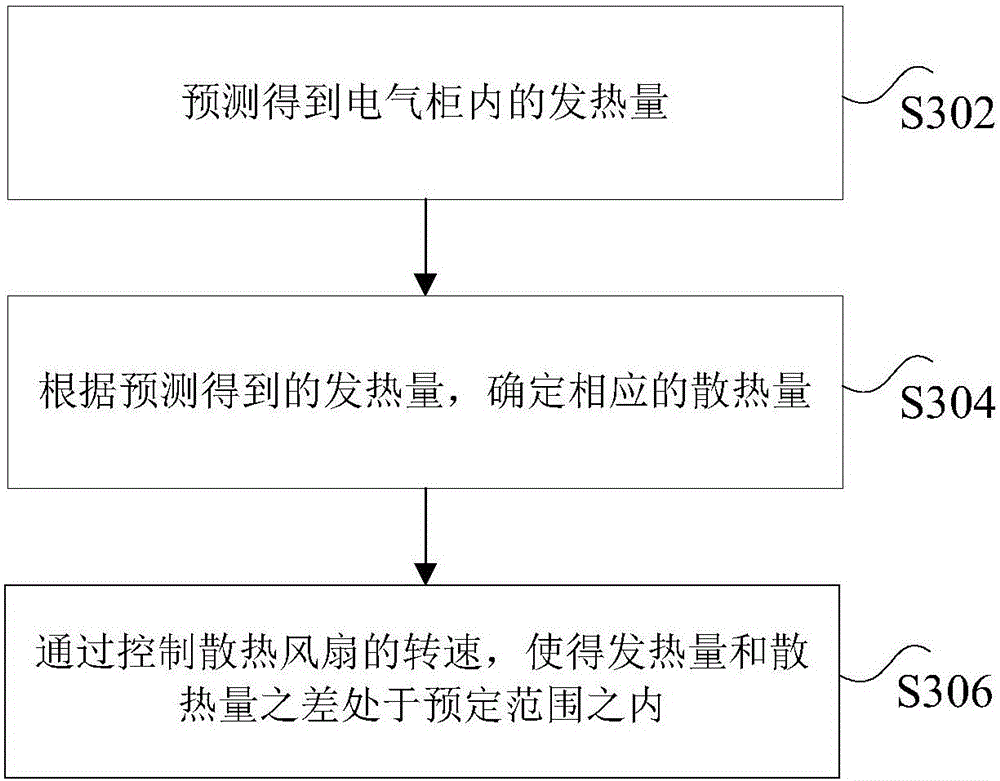

Heat dissipation control method, device and system for electrical cabinet

ActiveCN106255392AAvoid wasting heatStable wind speedDigital data processing detailsModifications using gaseous coolantsComputer fanEngineering

The invention discloses a heat dissipation control method, device and system for an electrical cabinet. The method comprises the steps: predicting and obtaining the generated heat in the electrical cabinet; determining corresponding dissipated heat according to the obtained generated heat; and enabling the difference between the generated heat and the dissipated heat to be within a preset range through controlling the rotating sped of a cooling fan. The method solves technical problems that the control is lagged and the temperature is liable to fluctuate when a conventional electrical cabinet heat dissipation method controls the rotating speed of the cooling fan through detecting the environment temperature of the interior of the electrical cabinet.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

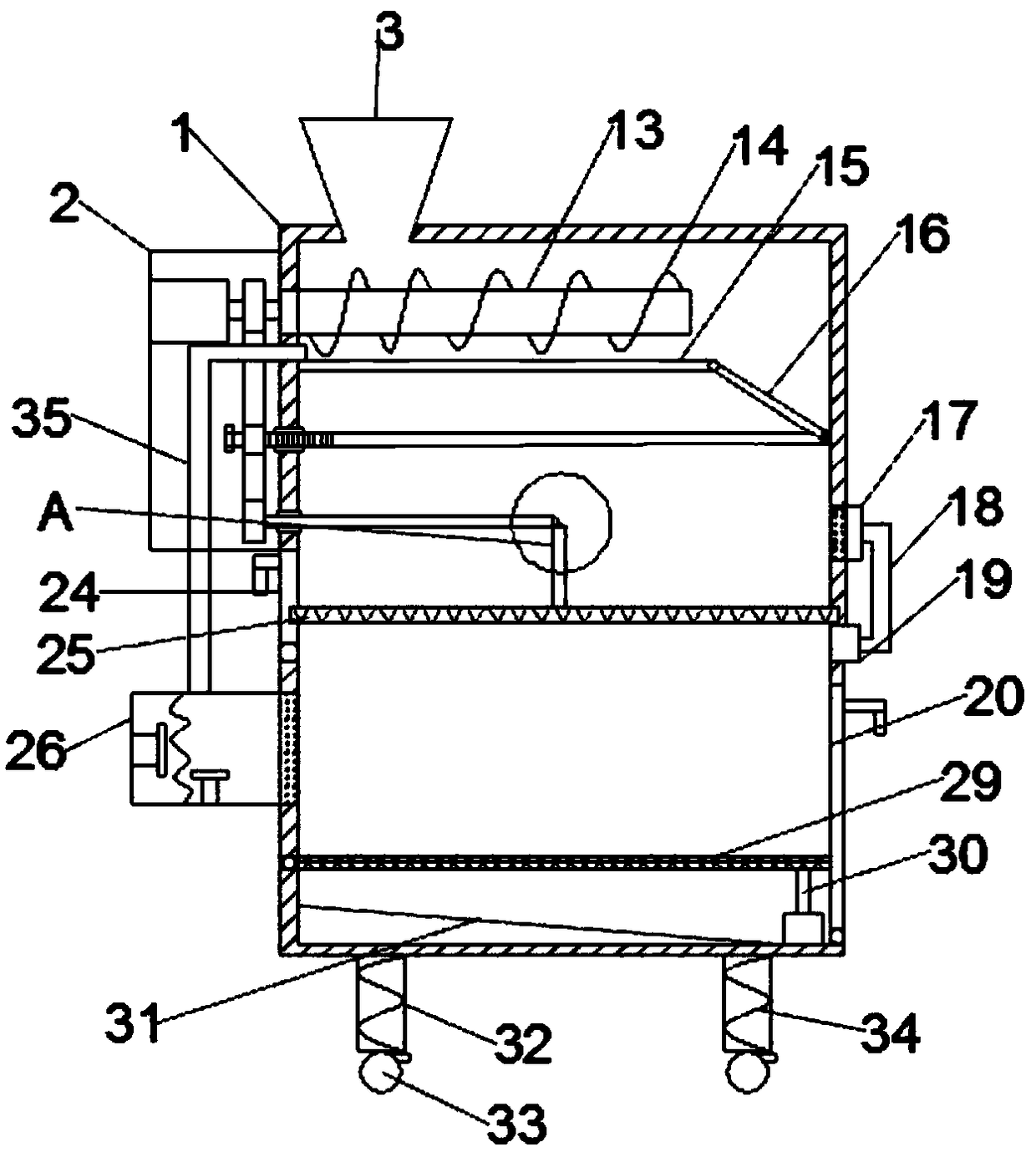

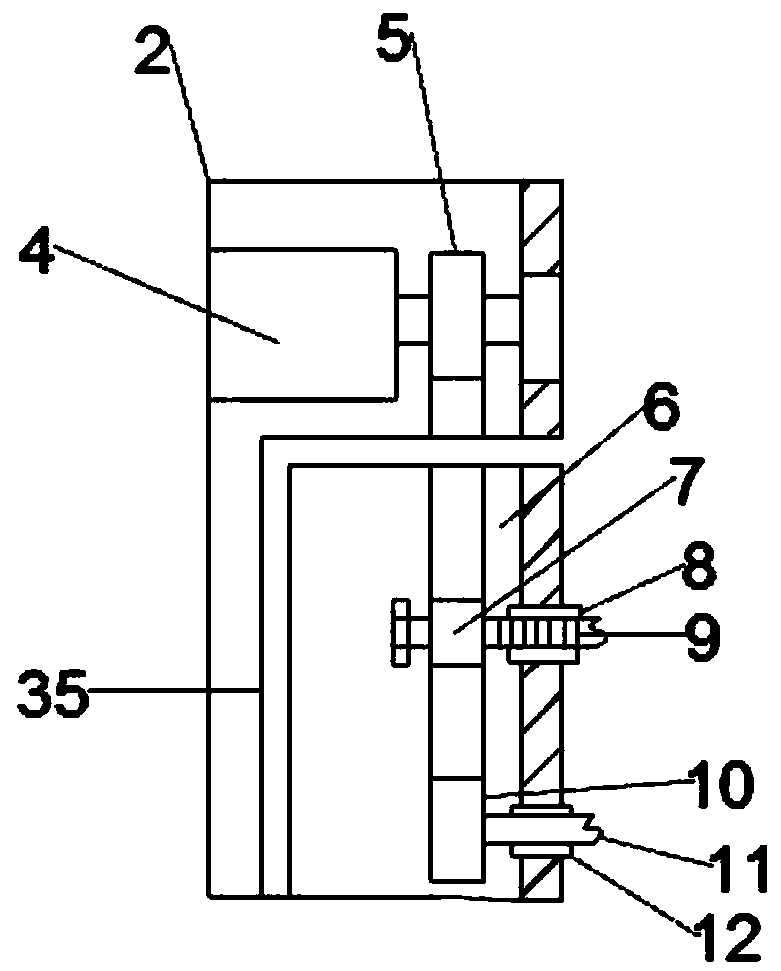

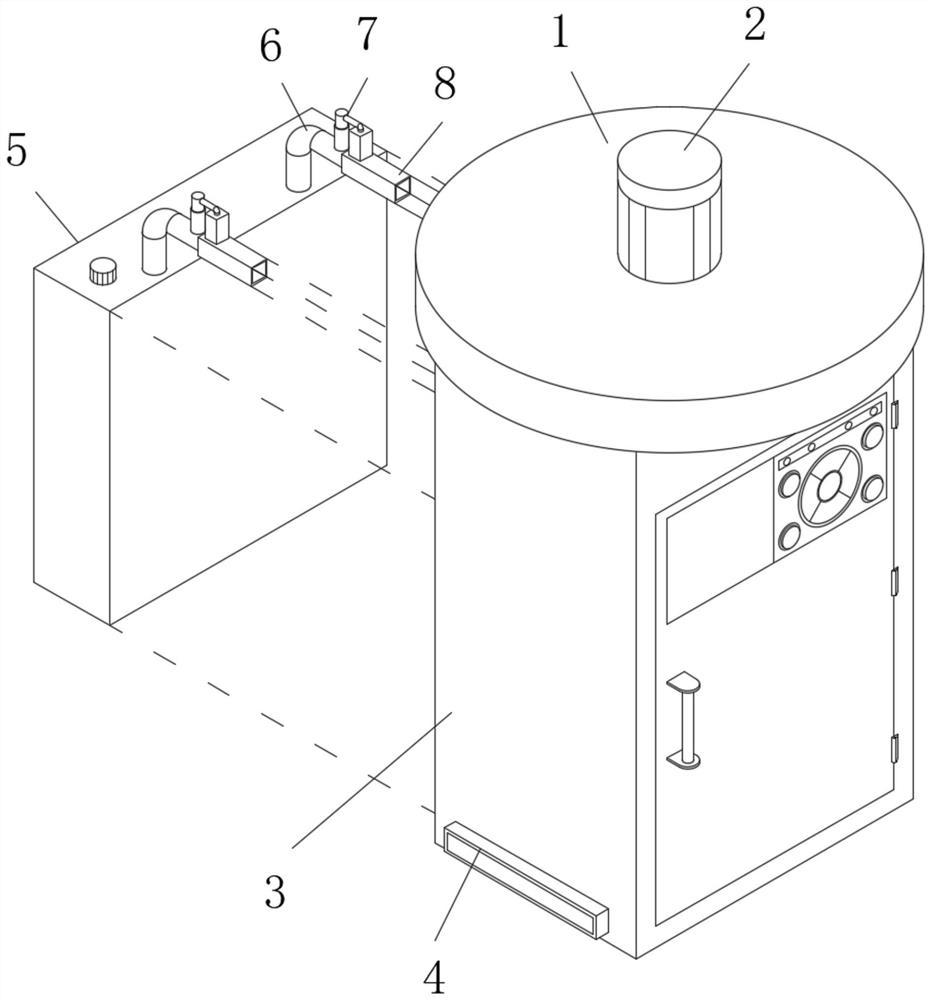

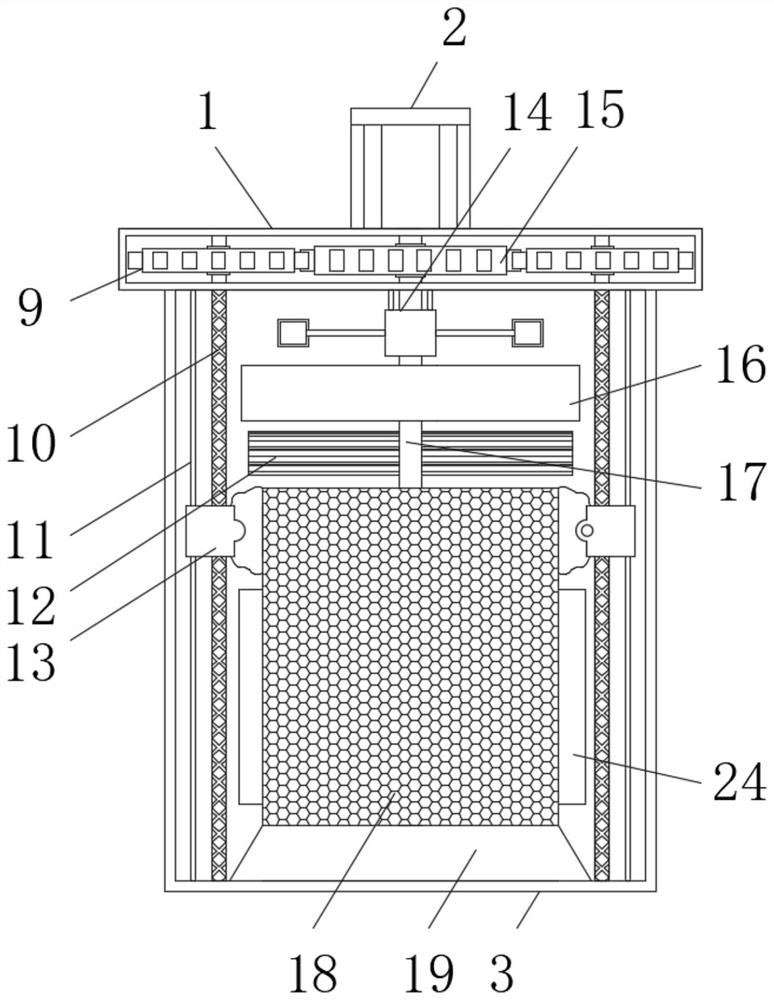

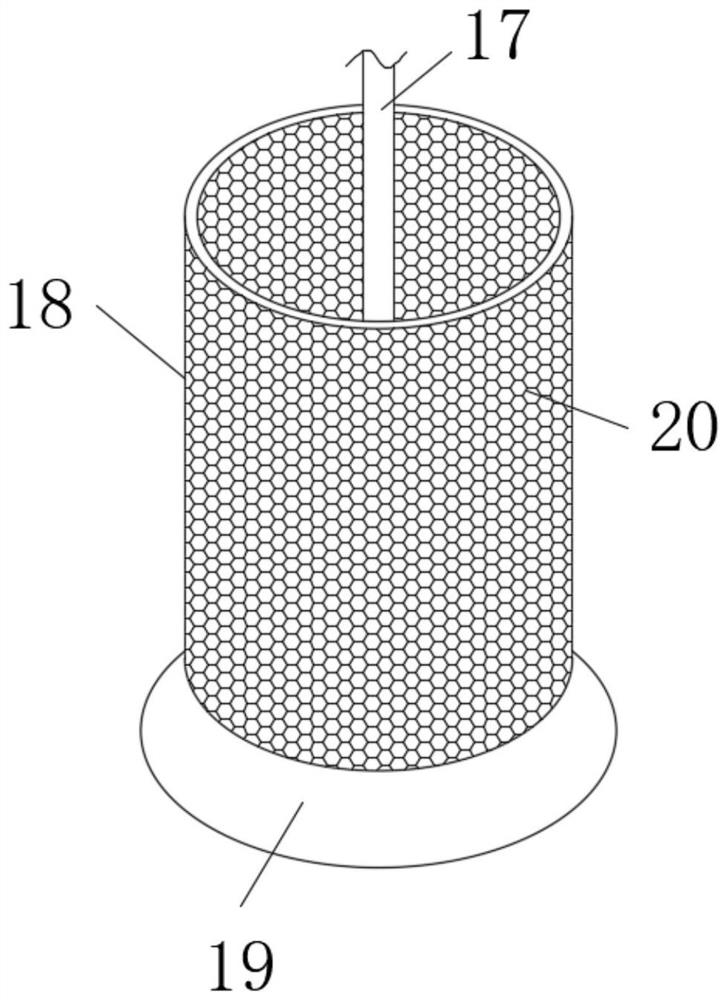

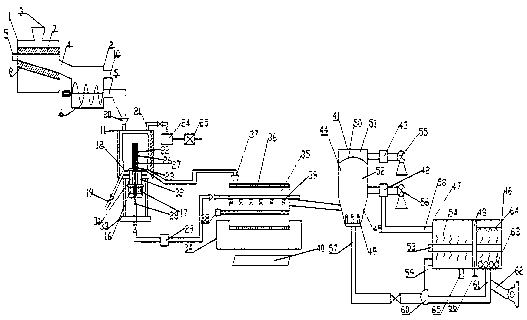

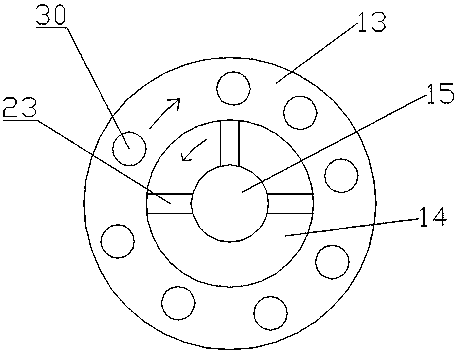

Drying and screening device for agricultural cereals

PendingCN108787413AAvoid wasting heatSimple structureSievingScreeningAgricultural engineeringLeft wall

The invention discloses a drying and screening device for agricultural cereals. The drying and screening device for agricultural cereals comprises a main body, a power box and a heating box. The rightend of the left wall of the power box is fixedly connected to the left end of a motor, the right end of an output shaft of the motor is fixedly connected to a sleeve, the right end of the output shaft of the motor is fixedly connected to a first transmission wheel on the right side of the sleeve, the first transmission wheel is connected to a second transmission wheel and a third conveyor belt through a conveyor belt, separately, the second transmission wheel is arranged at the left end of a first rotating rod, the right end of the first rotating rod s connected to one end of a hinge plate, spiral blades are arranged on the sleeve, the sleeve is arranged in the supporting plate, the left end of the supporting plate is fixedly connected to the inner surface of the left wall of the main body, and the third conveyor belt is fixedly connected to the right end of a second rotating rod. The drying and screening device for agricultural cereals disclosed by the invention is energy-saving, candry agricultural cereals for three times simultaneously, is high in drying efficiency, can adjust the discharging speed of agricultural crops, and is high in practicality and suitable for being popularized.

Owner:兰州集智信息技术有限公司

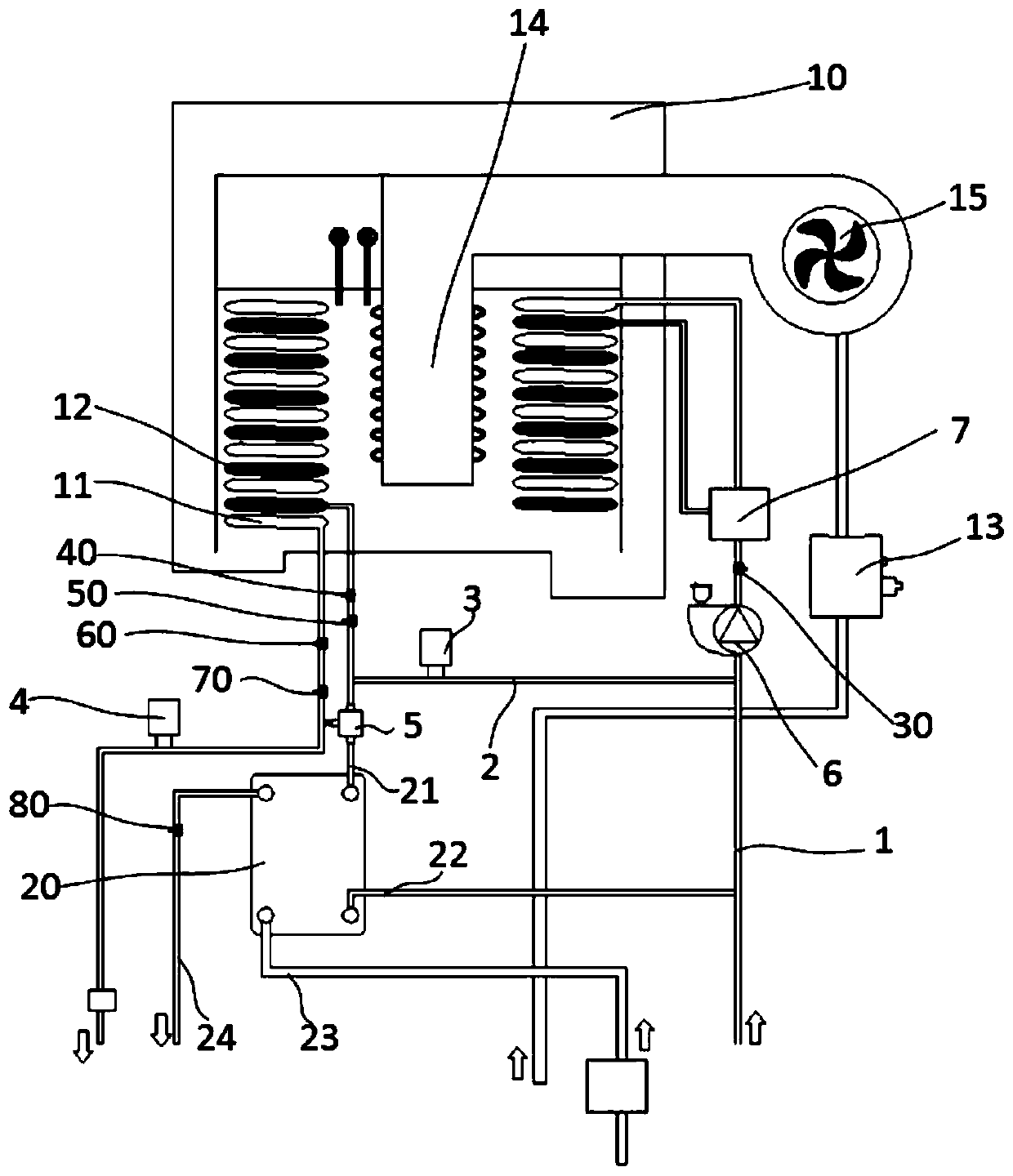

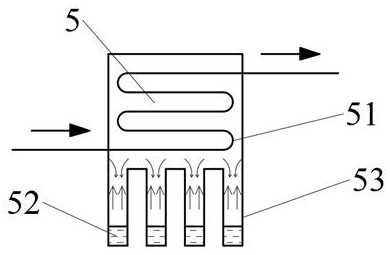

Heat pump drying system and control method thereof

PendingCN107560232AAvoid wasting heatImprove energy efficiencyHeat pumpsFluid circulation arrangementWorking fluidEvaporator

The invention provides a heat pump drying system and a control method thereof. The heat pump drying system comprises a heat pump system and a circulating channel used for circulating a circulating working medium in a space to be dried; a compressor, condensers, throttling elements and an evaporator are arranged on a refrigerant flowing path of the heat pump system, and the evaporator is located inthe circulating channel. The heat pump drying system further comprises a moisture absorption device, wherein the moisture absorption device can be used for conducting moisture absorption on the circulating channel and can conduct regeneration treatment on the moisture absorption device through heat of the condensers. In this way, when the circulating working medium in the circulating channel doesnot need to be heated by the condensers, auxiliary dehumidification can be conducted through the heat emitted by the condensers, heat waste is avoided, the energy source utilization rate is increased, and the dehumidification efficiency of the heat pump drying system can be improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

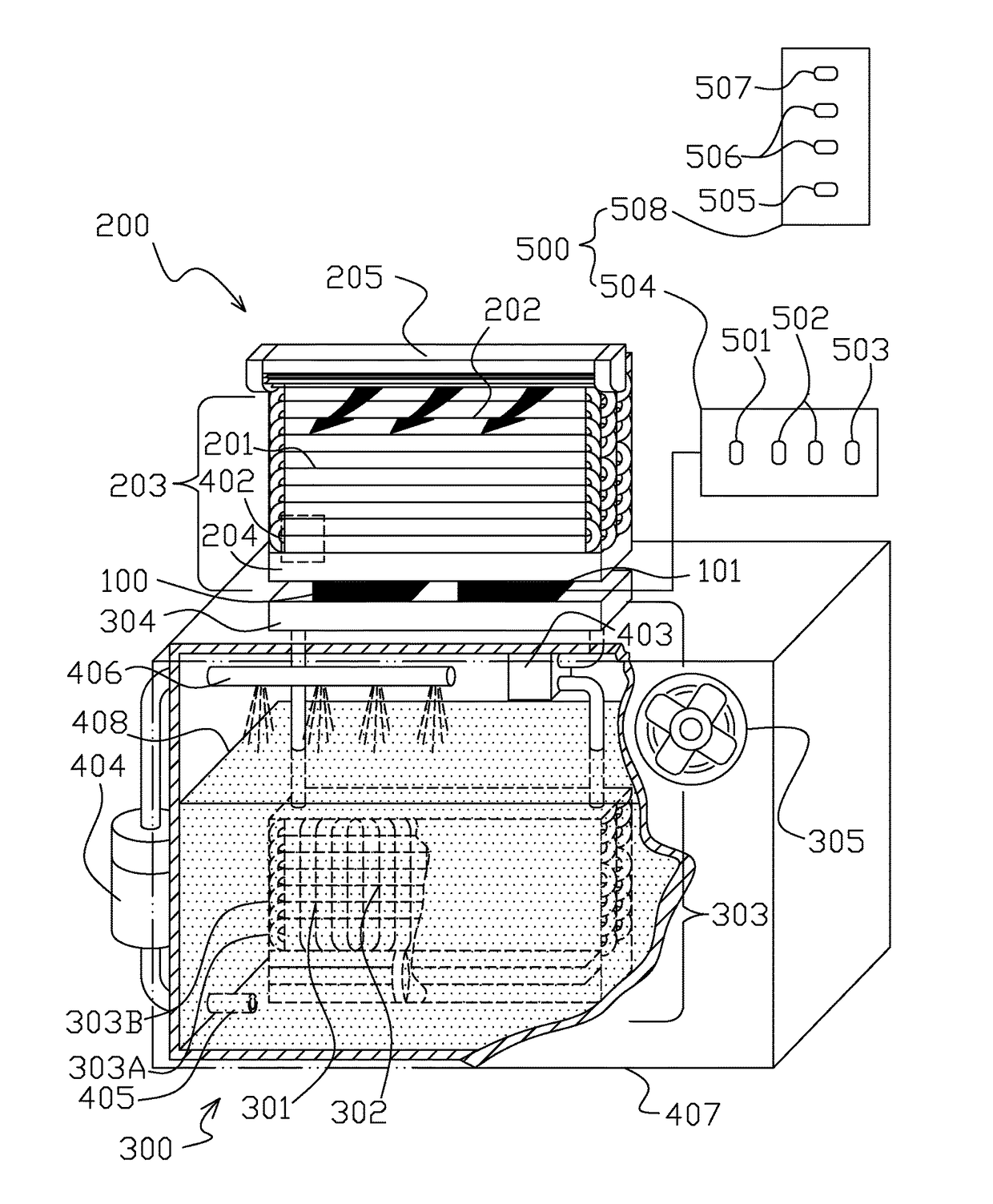

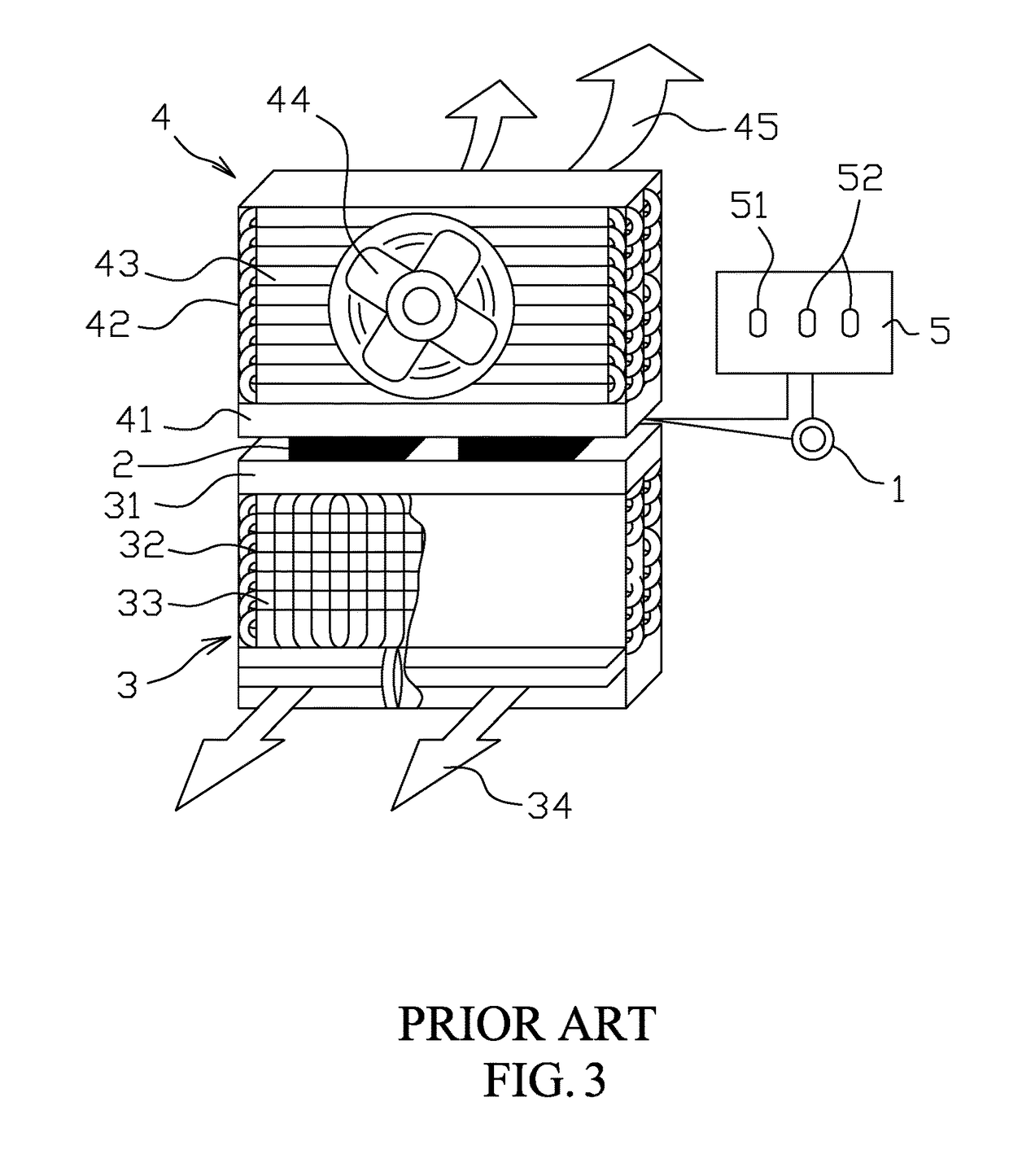

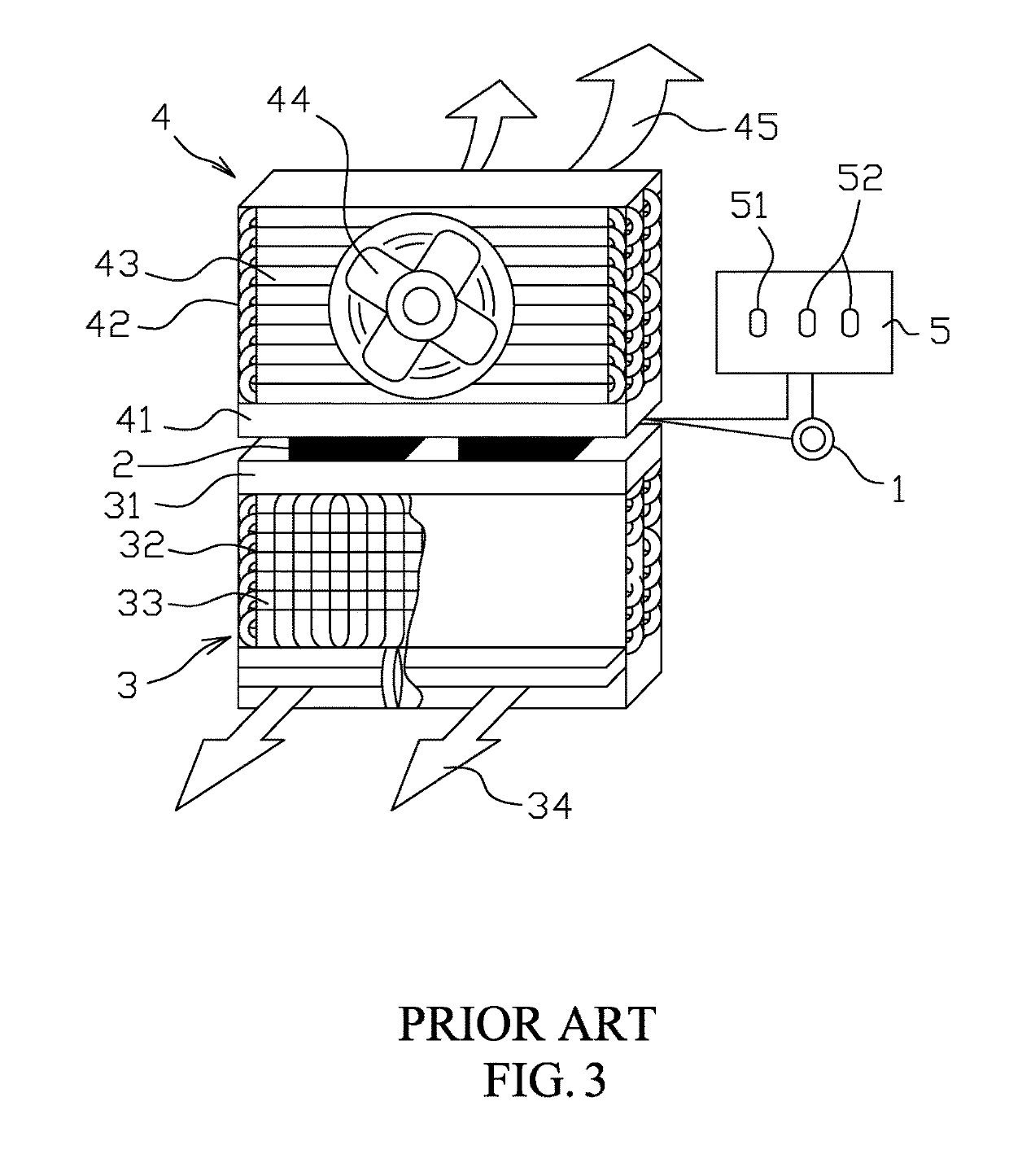

Semiconductor-based air conditioning device

ActiveUS20180023823A1Improve efficiencyAdversely affectedInternal combustion piston enginesMachines using electric/magnetic effectsTemperature controlThermoelectric cooling

The semiconductor-based air conditioning device includes at least a thermoelectric cooling chip, a cooling circulating member, a heat dissipating member, and a power provisioning and temperature controller. The cooling circulating member is joined to a cold production surface, and the heat dissipating member is joined to a heat production surface, of the thermoelectric cooling chip. Each of the cooling circulating member and the heat dissipating member includes a circulating box, a fan, and an auxiliary conduction device. Each circulating box is covered with fins and surrounding pipes. Each fan is located adjacent to corresponding fins. Each auxiliary conduction device includes an electrical pump. Fluid is stored and circulated in the surrounding pipes of each circulating box. Each electrical pump is configured to pump the fluid in a corresponding circulating box, and fluid is circulated to absorb the cold or heat from the thermoelectric cooling chip.

Owner:CHEN CHUAN SHENG

LED light bulb providig high heat dissipation efficiency

InactiveUS20130208474A1Solve the low heat dissipation efficiencyHigh voltagePlanar light sourcesPoint-like light sourceEngineeringLamp shell

An LED light bulb includes a lamp shell, a light emitting assembly and a power receiving base. The lamp shell includes a light transmissive portion and a holding portion. The light emitting assembly includes a light source baseboard located in the light transmissive portion and a circuit board connecting to the light source baseboard. The circuit board is surrounded by a heat sink. The heat sink includes a heat collecting section and a holding section extended from the heat collecting section into the power receiving base such that the power receiving base fully encases the heat sink without exposing. The inner surface of the power receiving base connects to the outer surface of the holding section so that heat generated by the light source baseboard is absorbed by the heat collecting section and transmitted via the holding section to the power receiving base for dissipating.

Owner:HSU WEI LIN

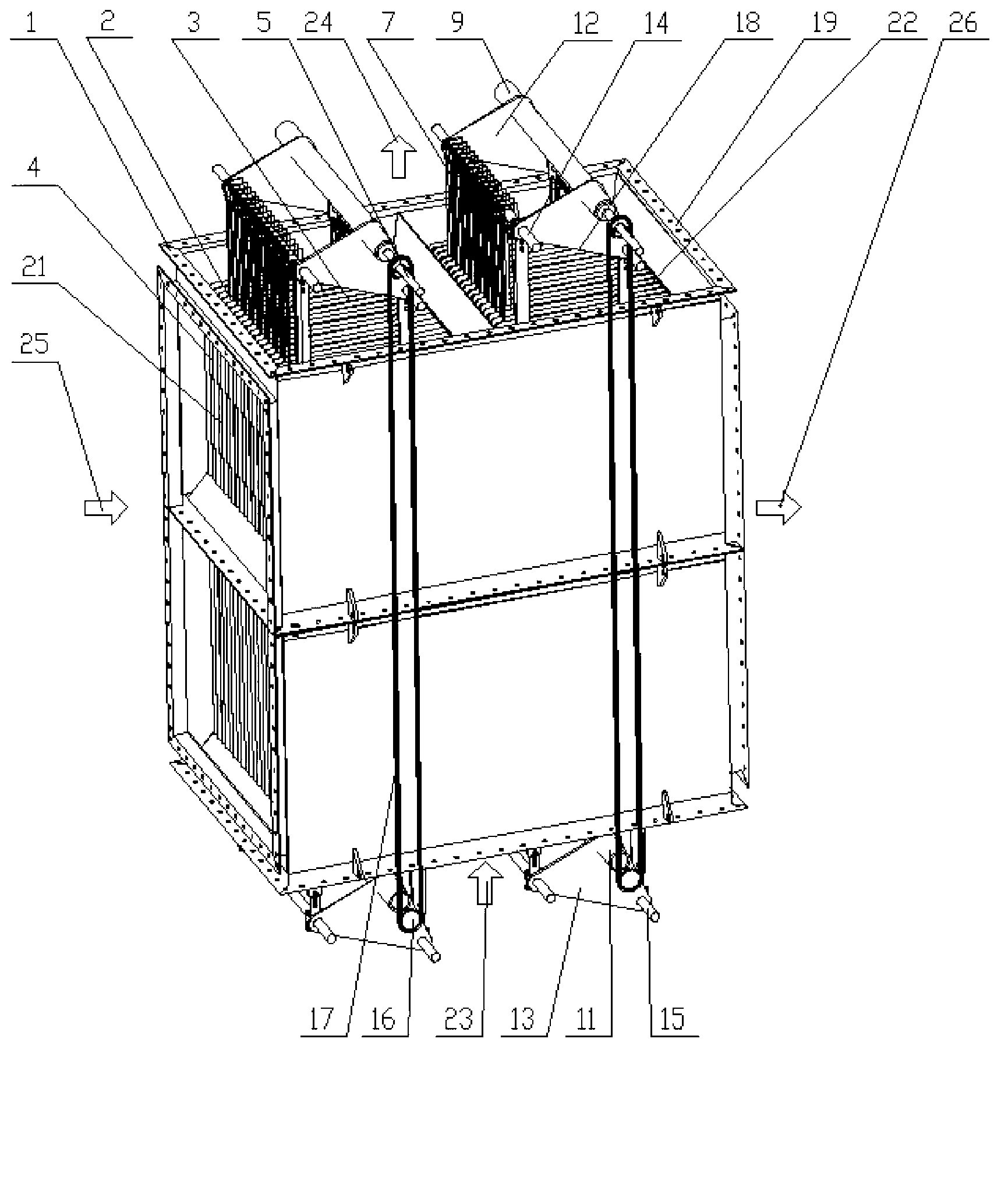

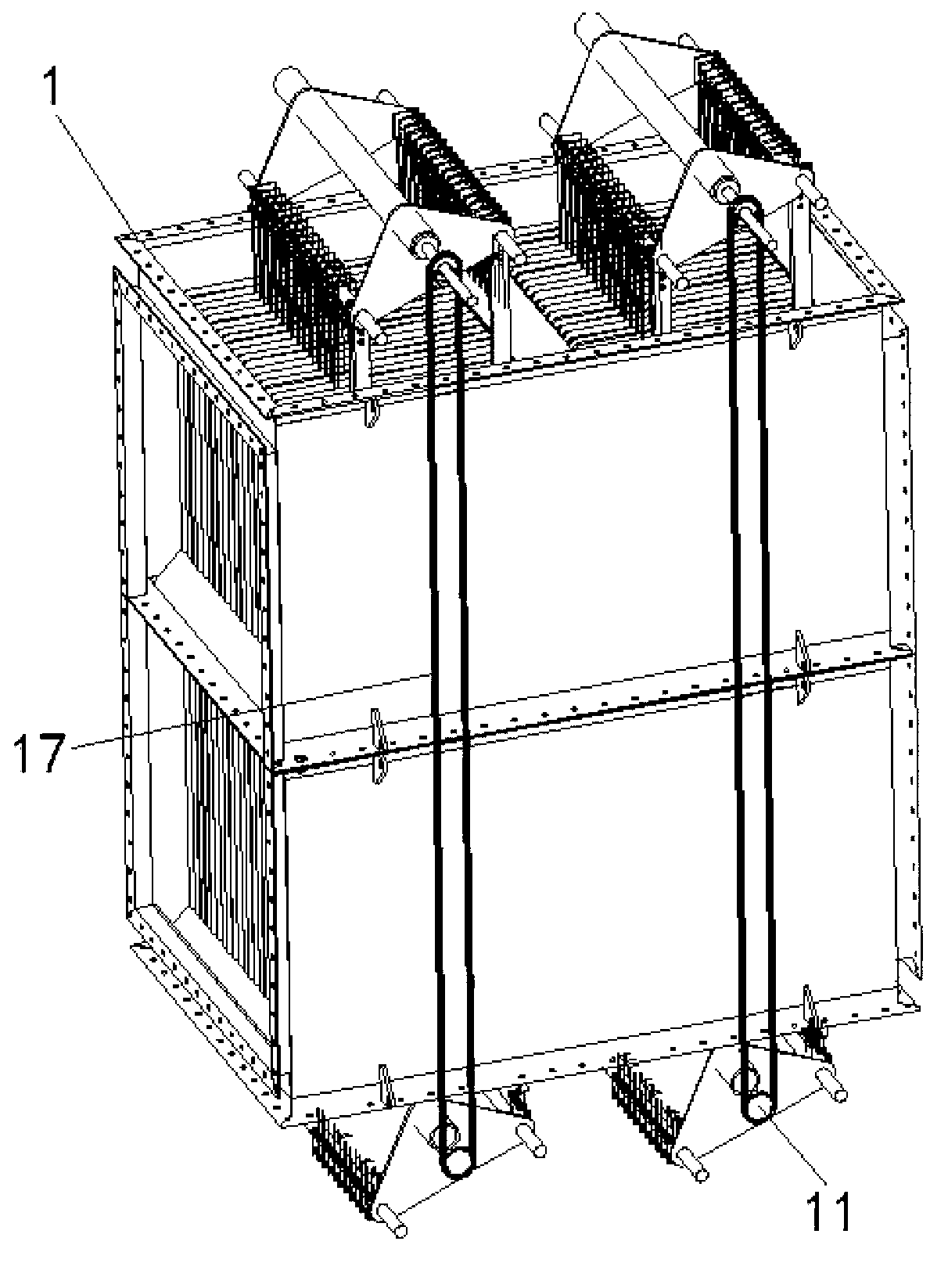

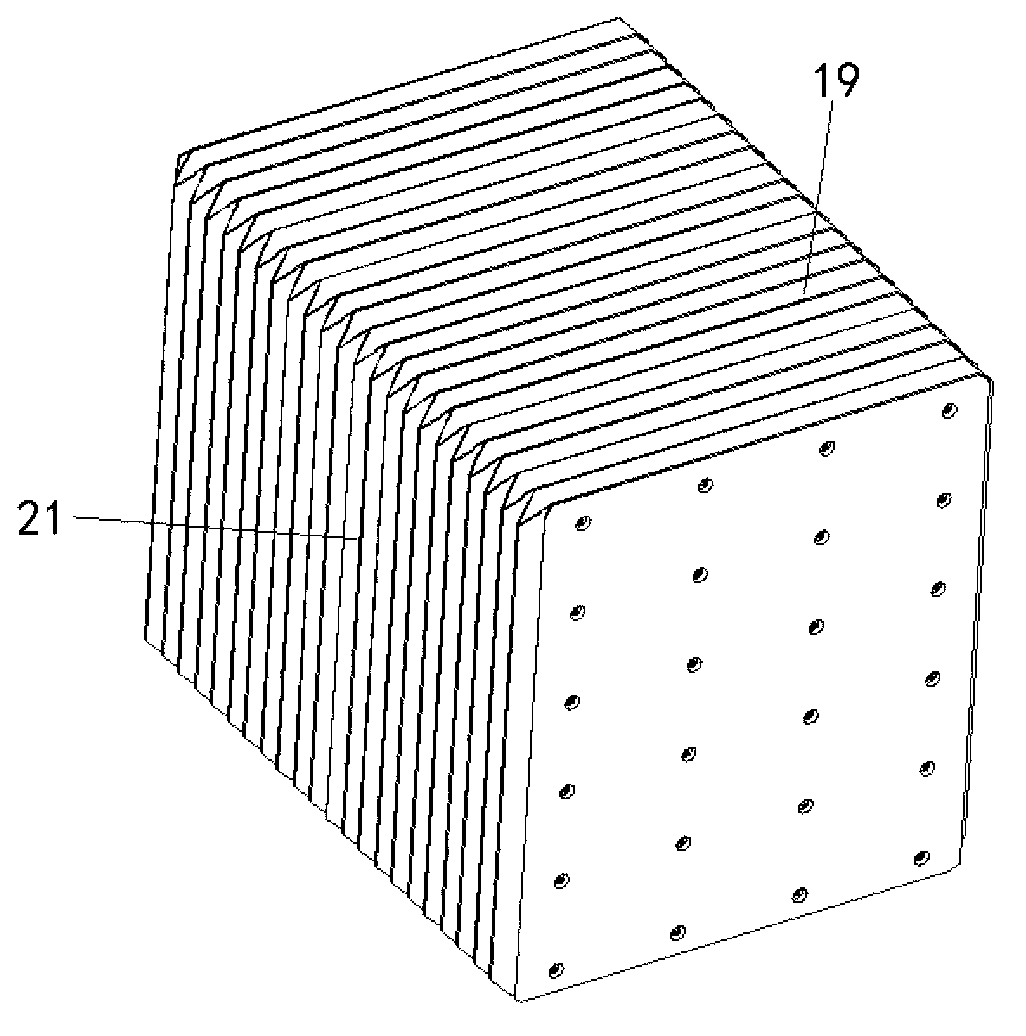

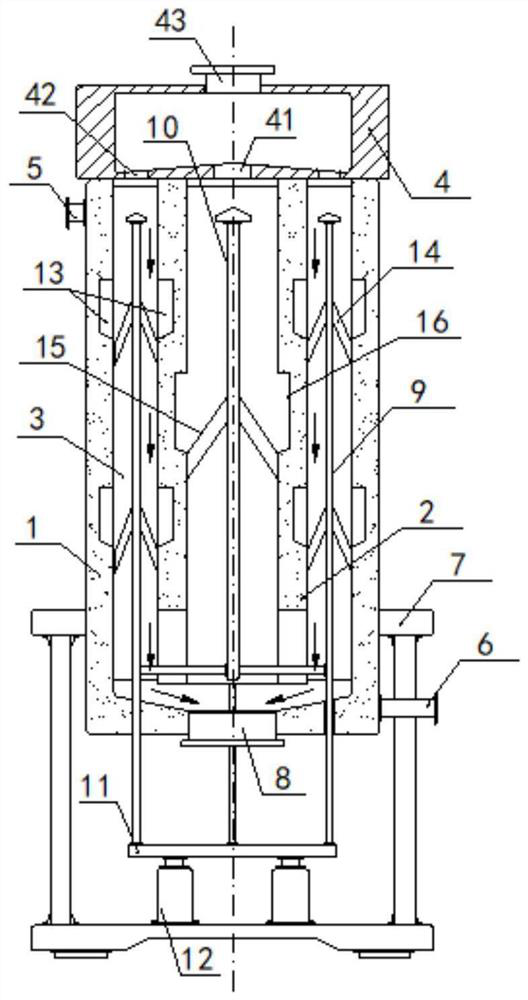

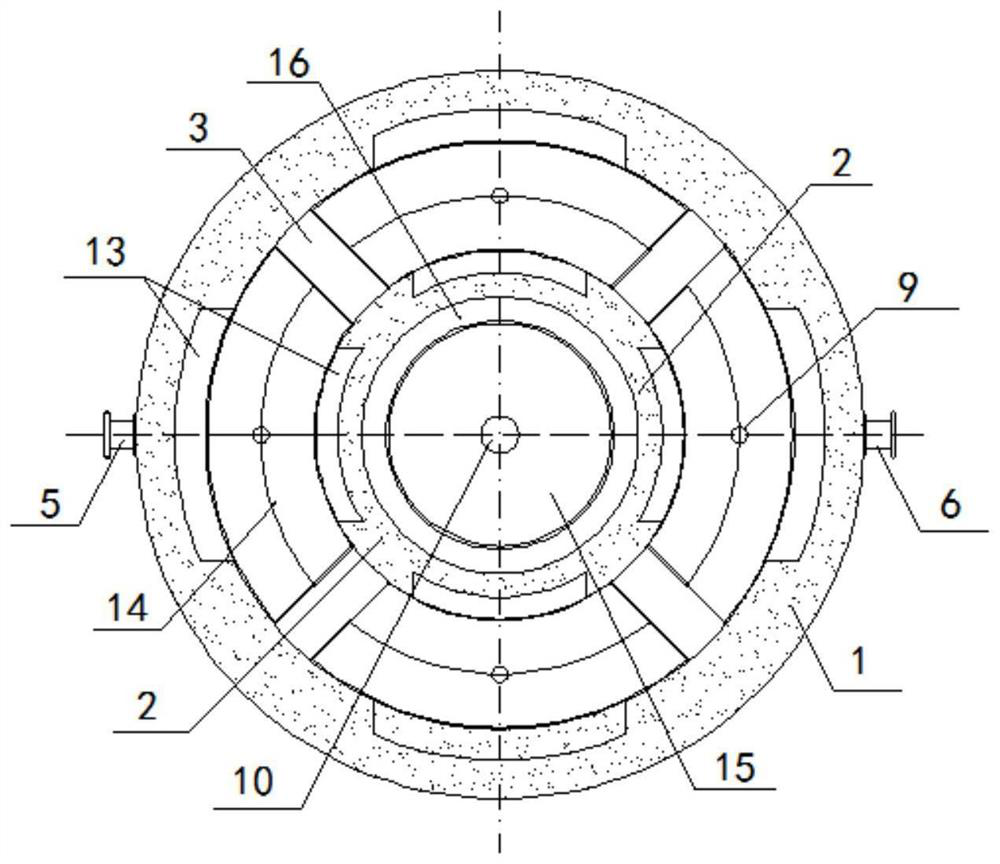

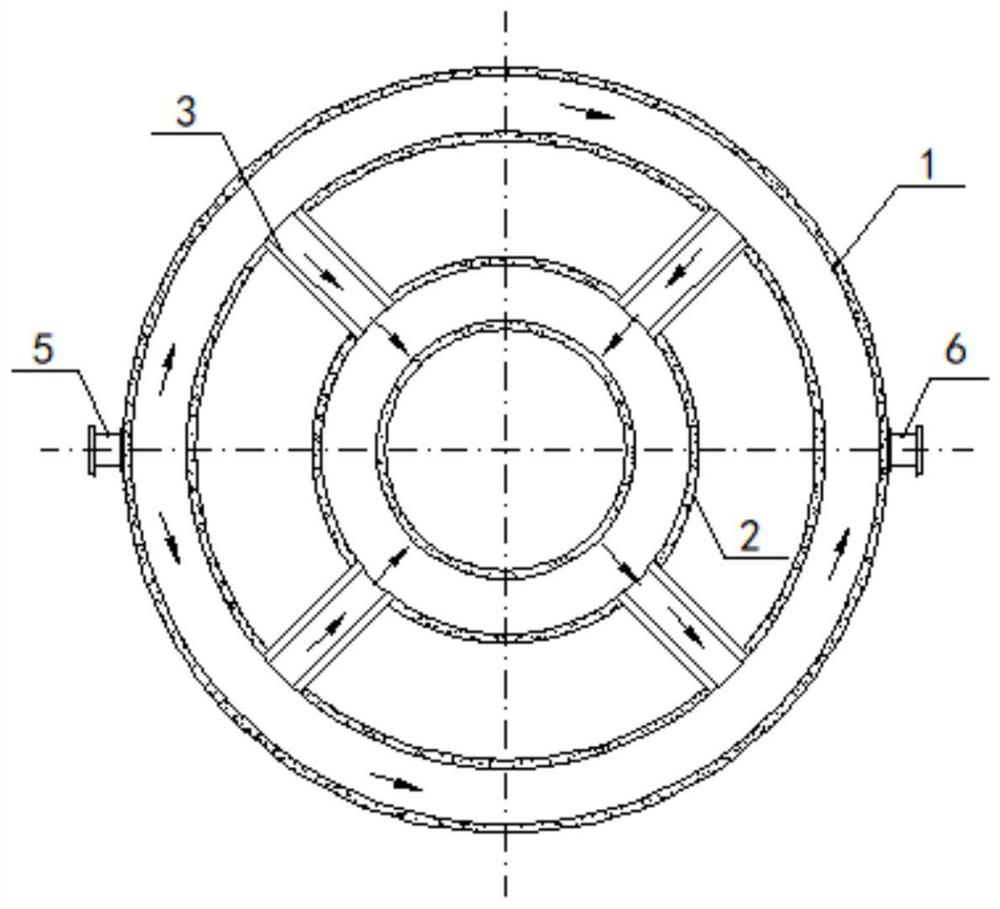

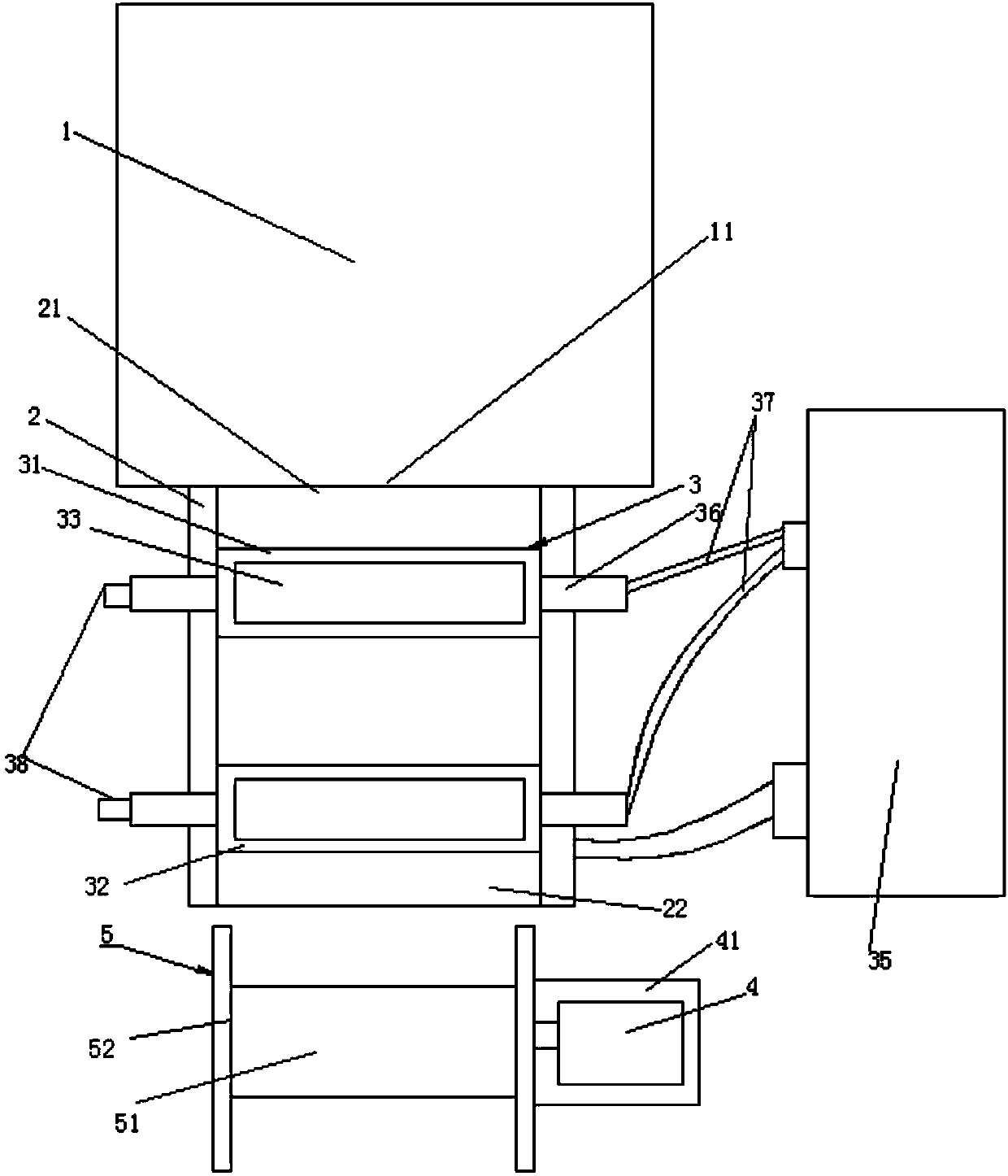

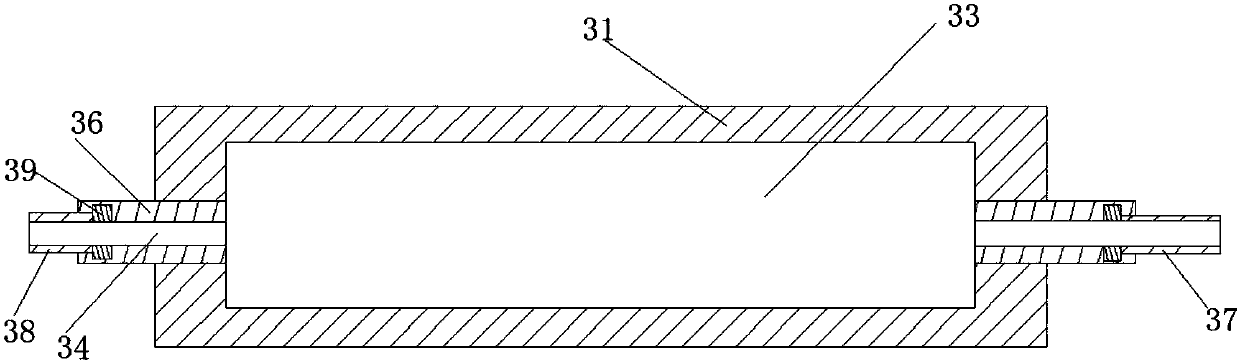

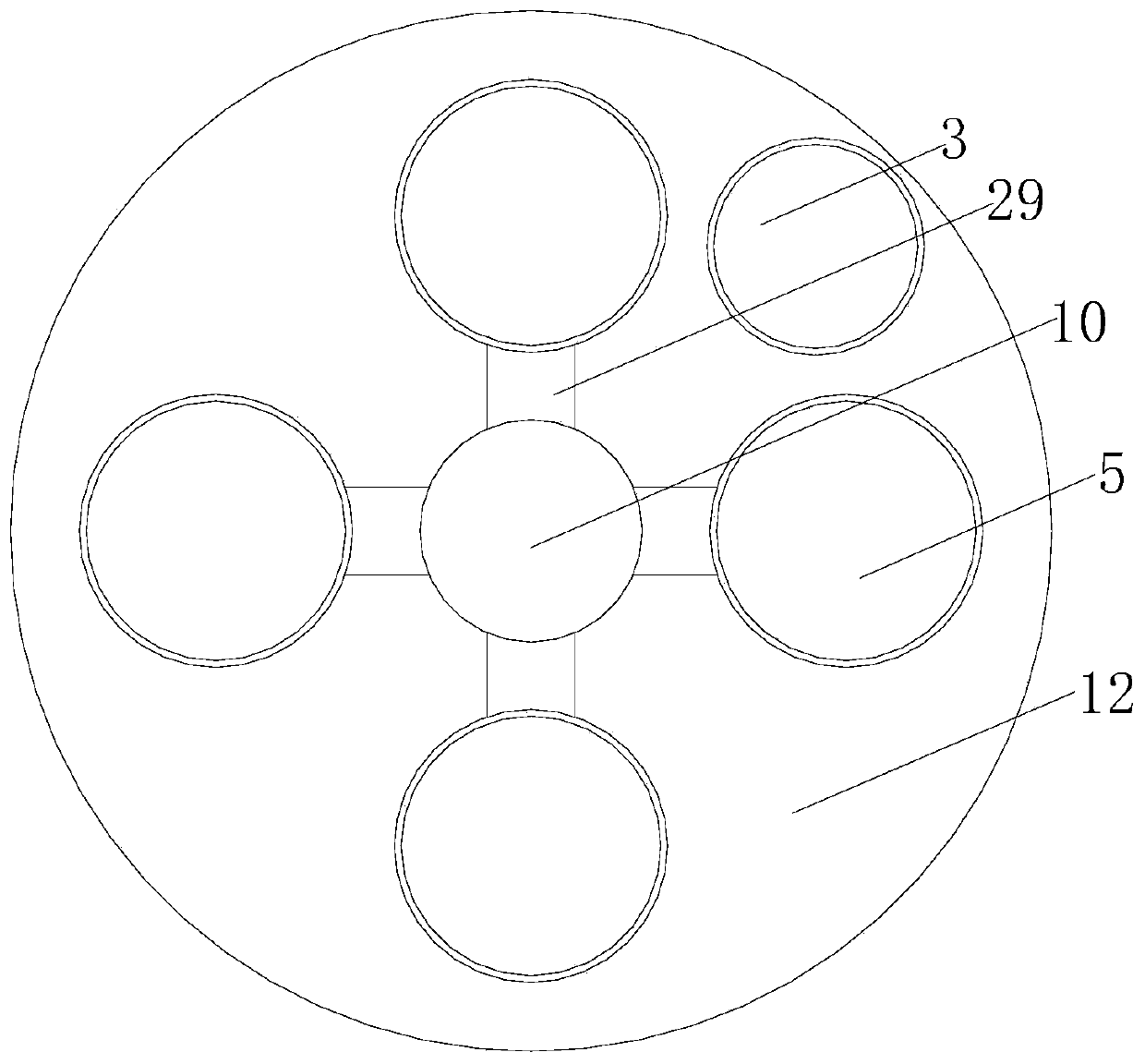

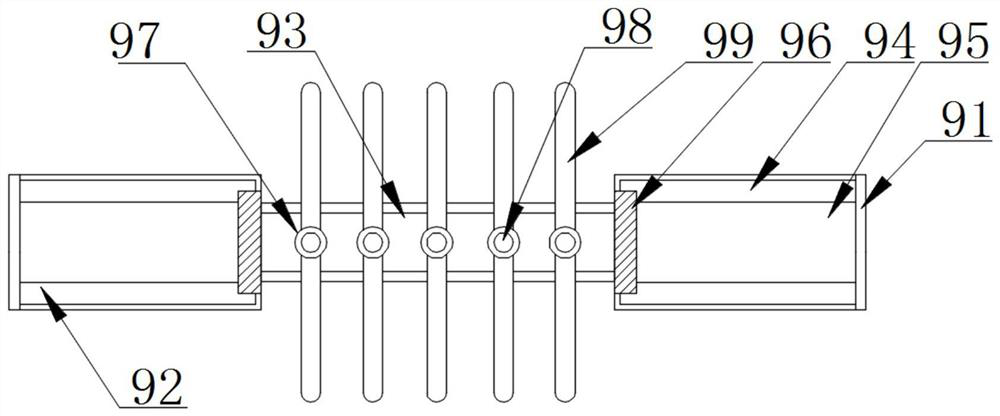

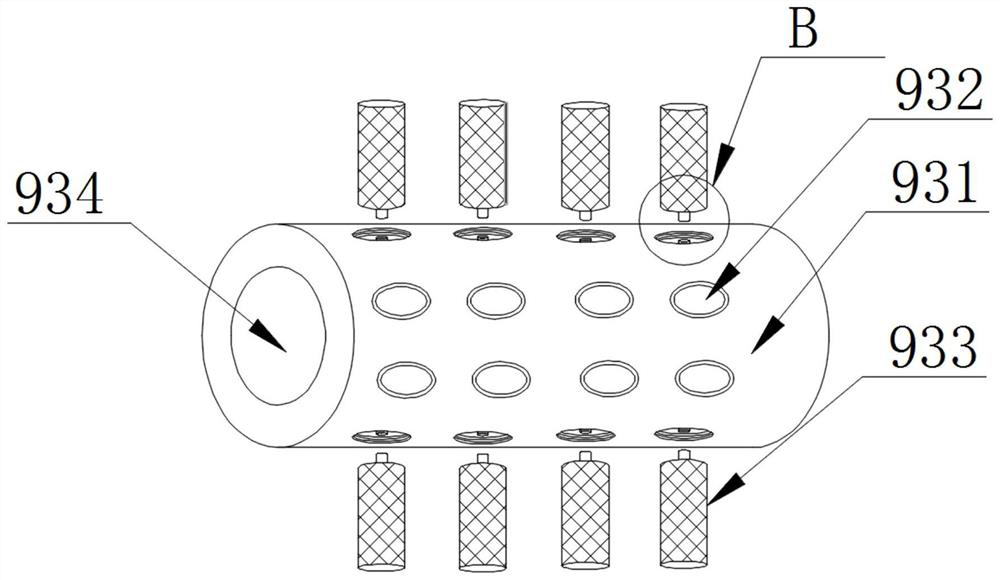

Heat exchanger used for recycling exhaust gas and waste heat of rotary hearth furnace

ActiveCN103063065AAvoid wasting heatEfficient recyclingStationary plate conduit assembliesNon-rotary device cleaningExhaust fumesInto-structure

The invention provides a heat exchanger used for recycling exhaust gas and waste heat of a rotary hearth furnace. A plurality of heat exchanging pieces (2) are arranged in a heat exchanger framework (1) of the heat exchanger, the plurality of heat exchanging pieces (2) form a plurality of high temperature channels (3) and a plurality of low temperature channels (4), and the heat exchanger further comprises an ash scrapping device (5). The ash scrapping device (5) comprises a control part (6) and a plurality of scrapers (7) used for scraping dust containing zinc on the surfaces of the heat exchanging pieces (2), the scrapers (7) are designed into structures penetrating through the high temperature channels (3), and the scrapers (7) are connected with the control part (6). The control part (6) is arranged into a structure capable of controlling the scrapers (7) to perform vertical movement on the surfaces of the heat exchanging pieces (2). The heat exchanger used for recycling exhaust gas and waste heat of the rotary hearth furnace not only achieves recycle and cyclic utilization of heat energy of high temperature waste heat, but also avoids pollution on the environment caused by resource waste and waste gas emission.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

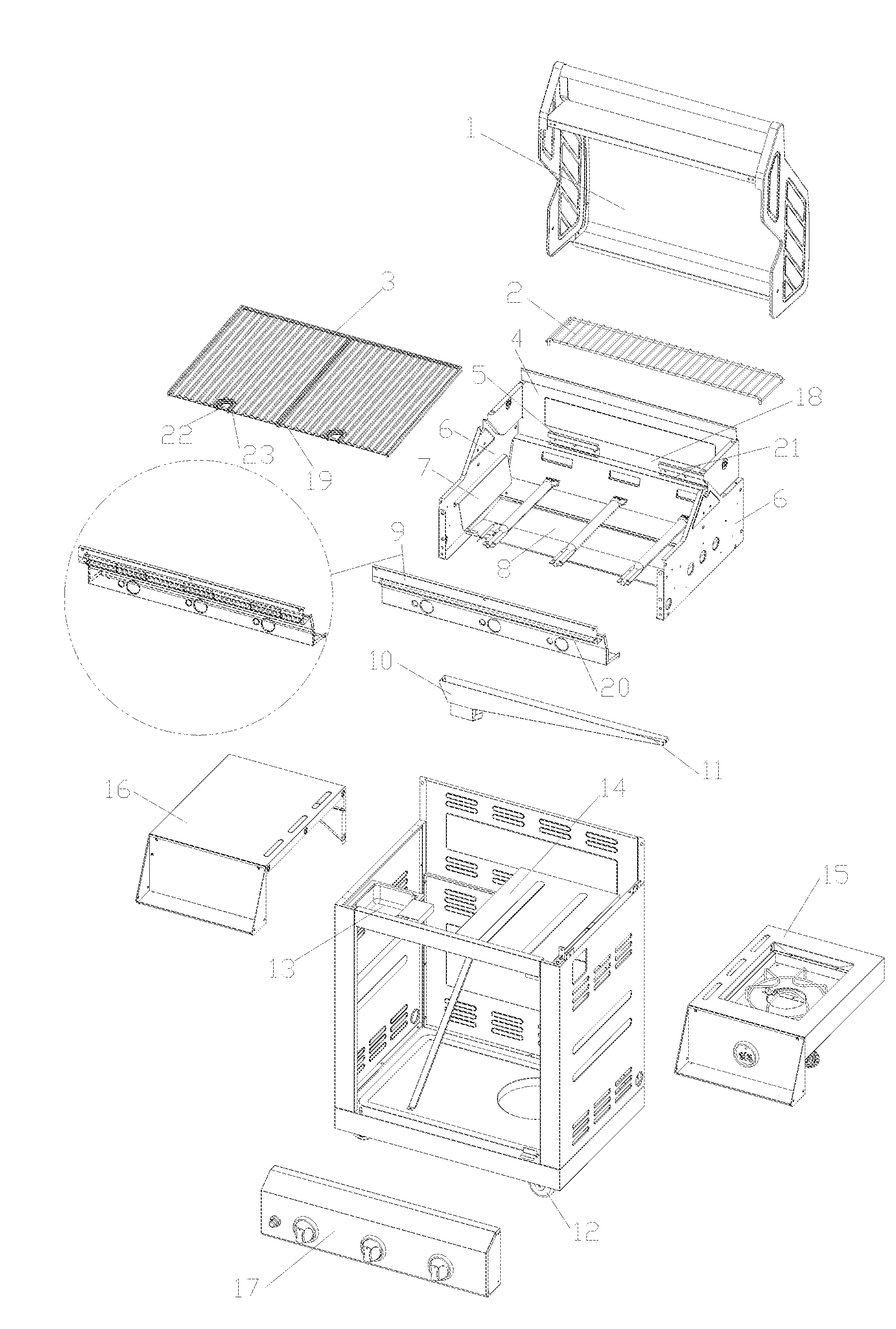

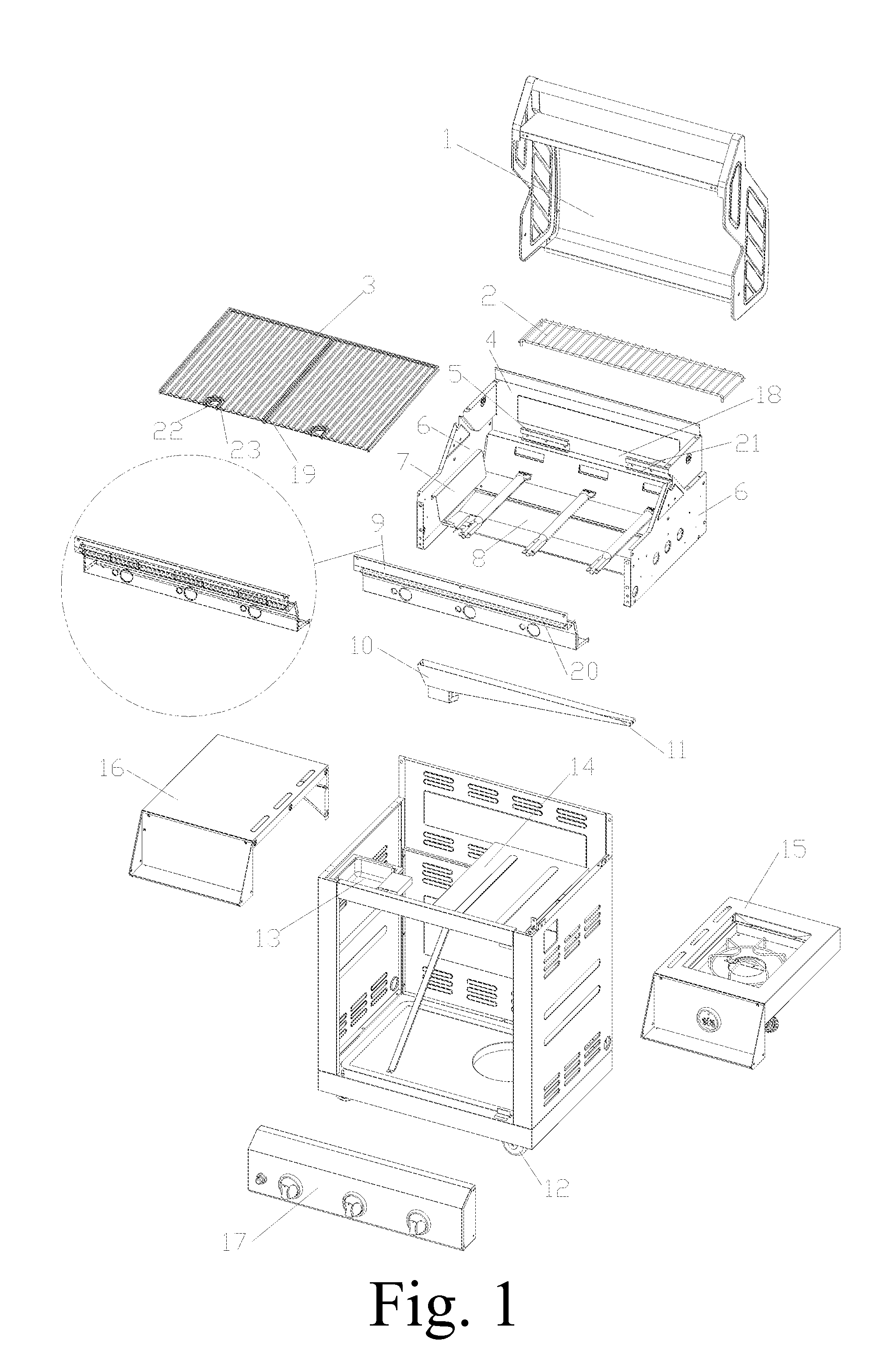

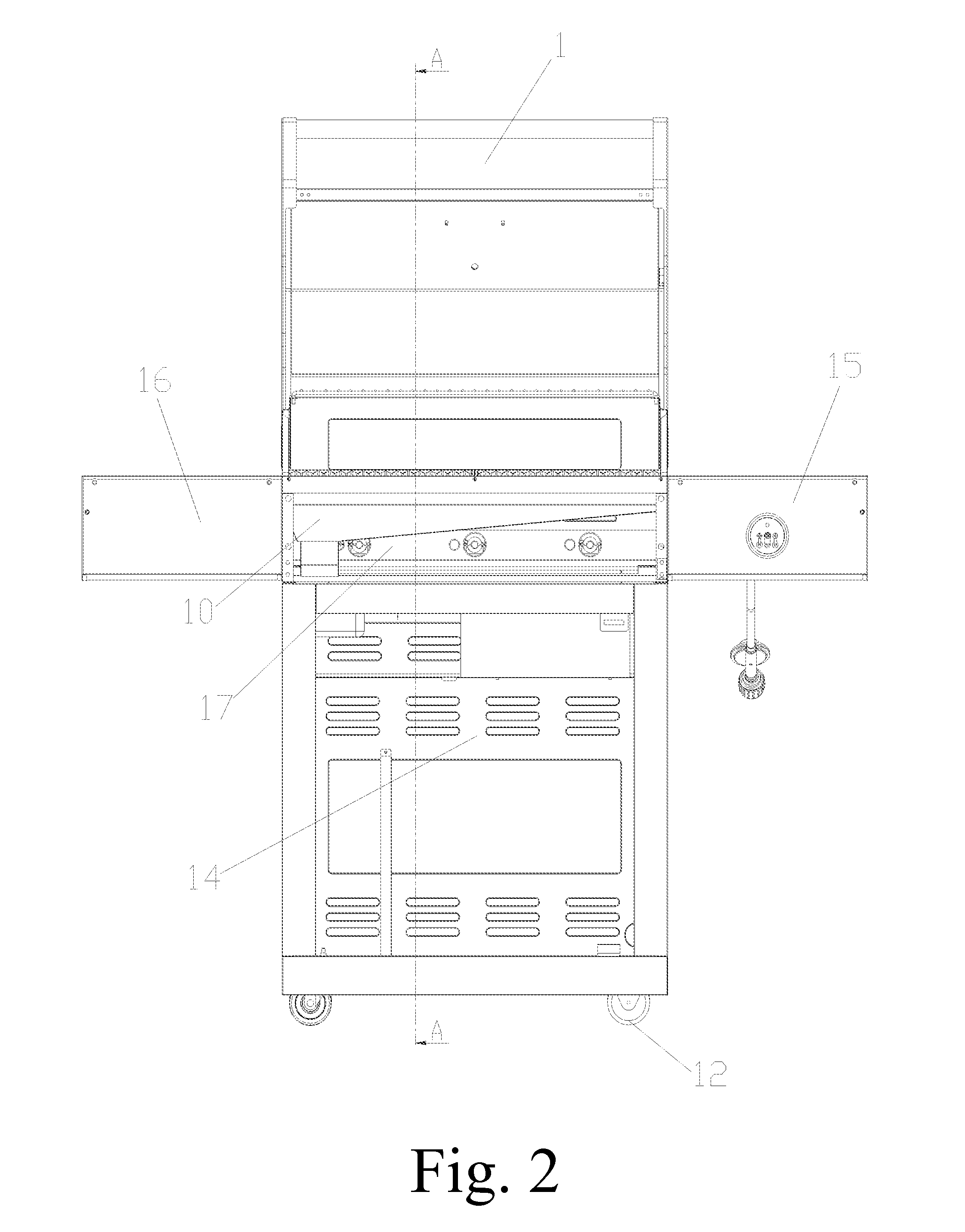

Grill

InactiveUS20140290498A1Avoid wasting heatSimple structureFood scienceOil and greaseMarine engineering

A grill includes an upper cover, a supporting body and a grill frame. The grill frame is provided on the supporting body. The grill frame includes left and right boards, a back board and a front board, which all enclose into the grill frame. Heaters are provided within the grill frame and a roasting plate which tilts towards a front of the grill frame is provided above the heaters. The roasting plate has slots from which oil and grease drip down into an oil dripping slot provided on the front board and then into an oil guiding slot provided below the front board. The oil guiding slot has an oil channel of a certain angle. An oil collecting box is provided below a side of the oil guiding slot. A warming net is provided above the roasting plate and mounted on the left and right boards.

Owner:CHANGSHA ELETRIC DRIVE SYST TECH CO LTD

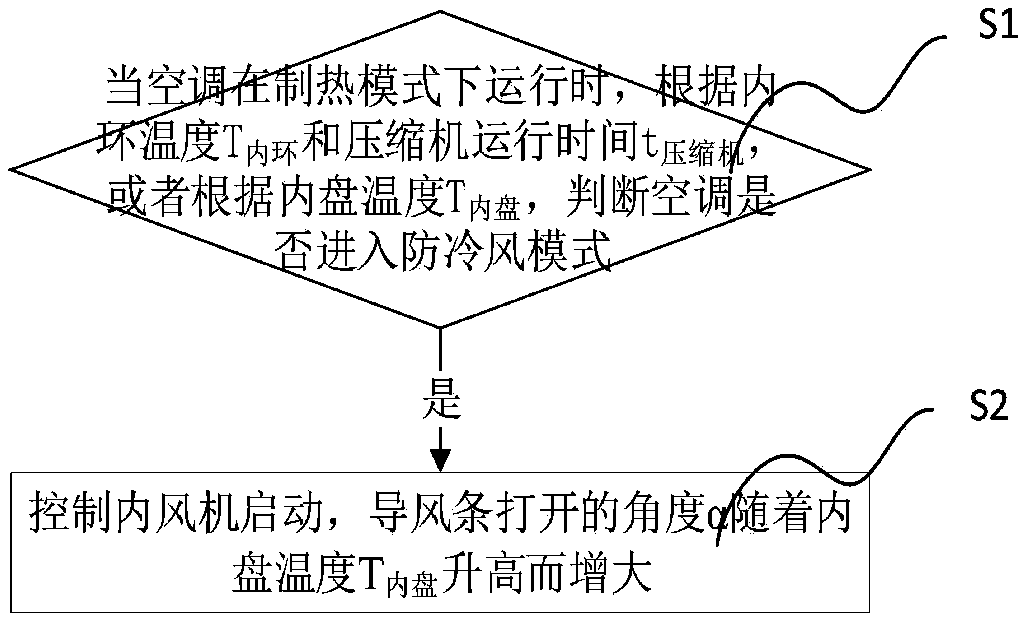

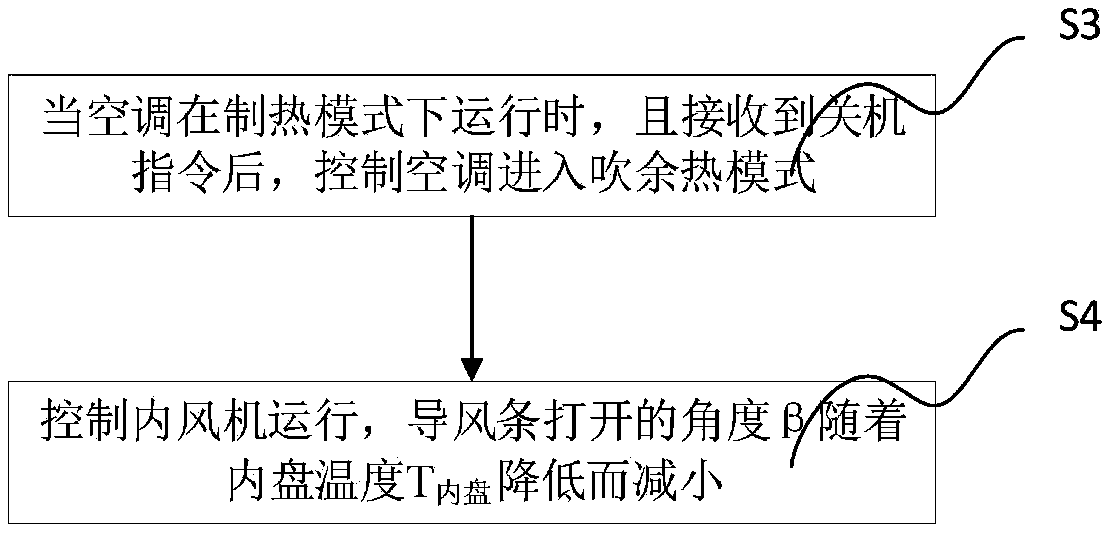

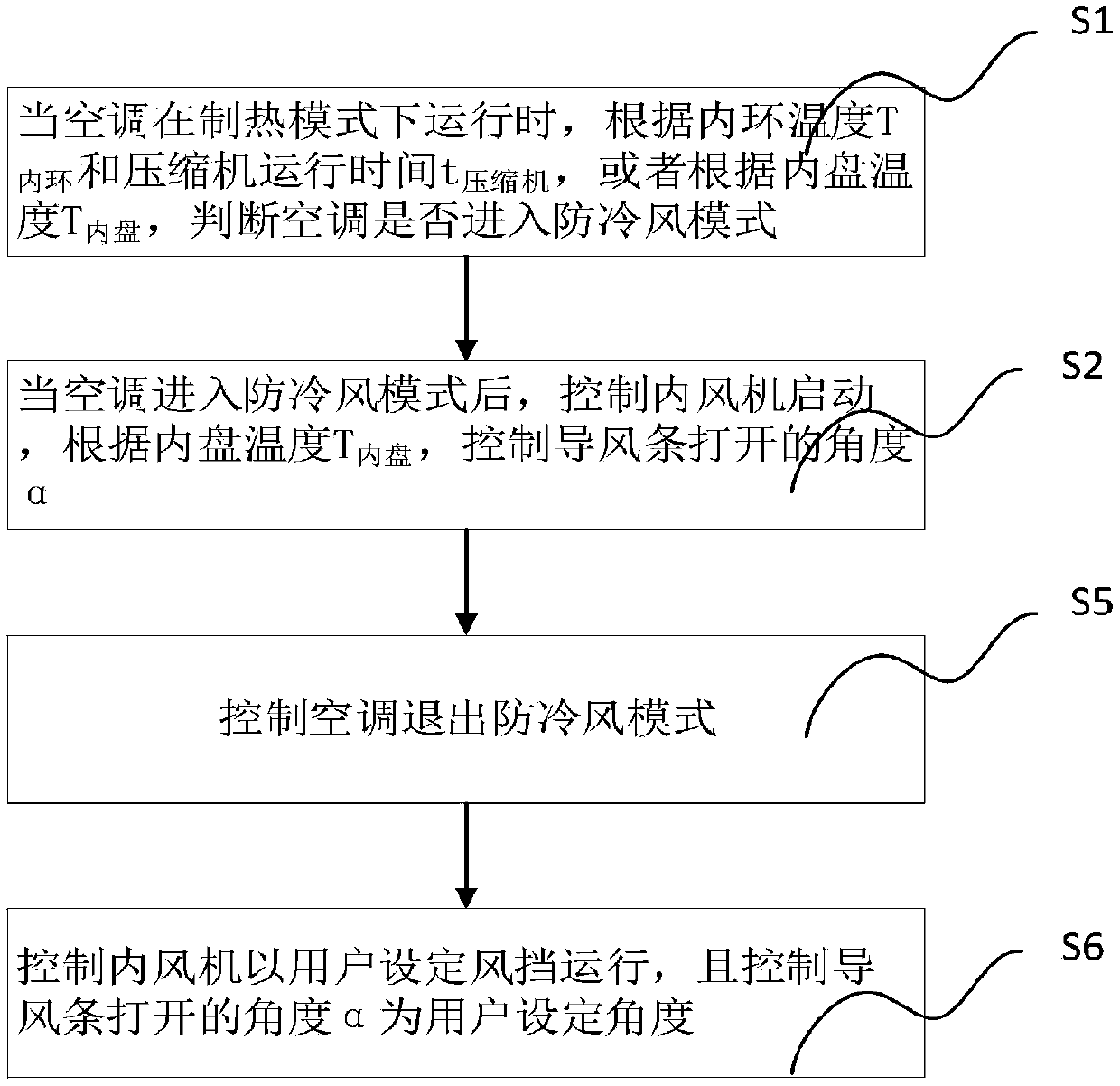

Control method and control device of air conditioner, storage medium and air conditioner

InactiveCN111023483AAchieve waste heatAvoid wasting heatMechanical apparatusSpace heating and ventilation safety systemsPhysicsEngineering

The invention provides a control method and a control device of an air conditioner, a storage medium and an air conditioner. The control method includes the following steps that when the air conditioner runs in a heating manner, according to the inner ring temperature T inner ring and the compressor running time t compressor, or according to the inner disc temperature T inner disc, whether the airconditioner gets into a cold air preventing manner or not is judged; after the air conditioner gets into the cold air preventing manner, an inner draught fan is controlled to be started, and the opening degrees alpha of air guide strips are increased along with increase of the inner disc temperature T inner disc; when the air conditioner runs in the heating manner, after a shutdown instruction isreceived, the air conditioner is controlled to get into a waste heat blowing manner; and when the air conditioner gets into the waste heat blowing manner, the inner draught fan is controlled to run,and the opening angles beta of the air guide strips are reduced along with decrease of the inner disc temperature T inner disc.

Owner:NINGBO AUX ELECTRIC

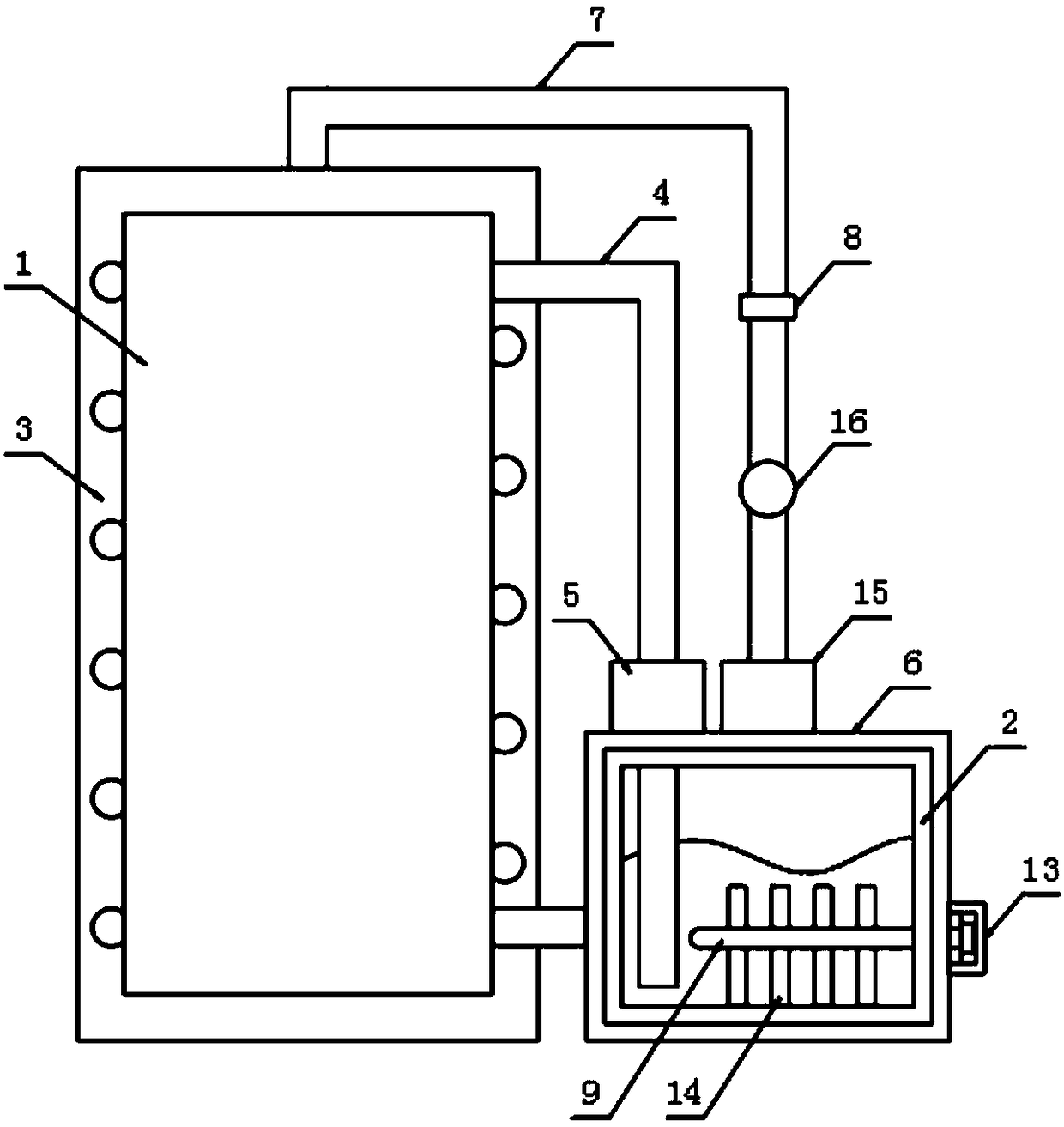

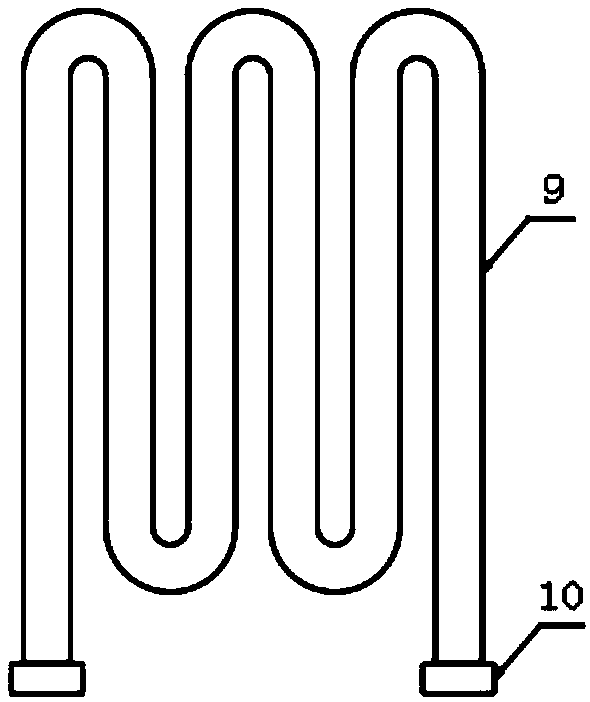

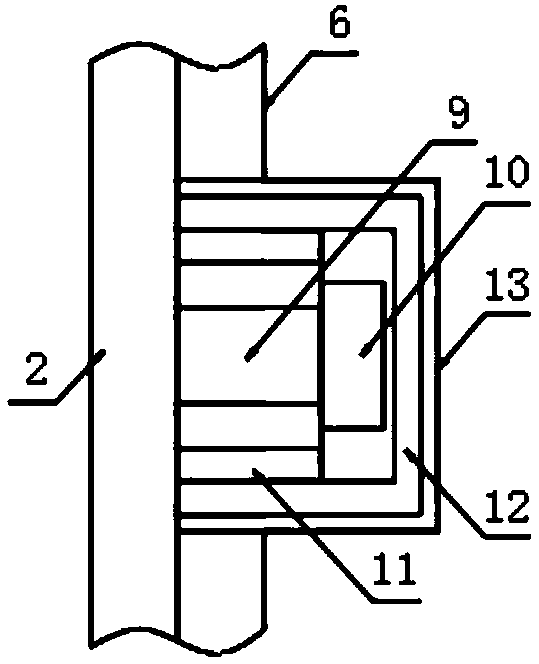

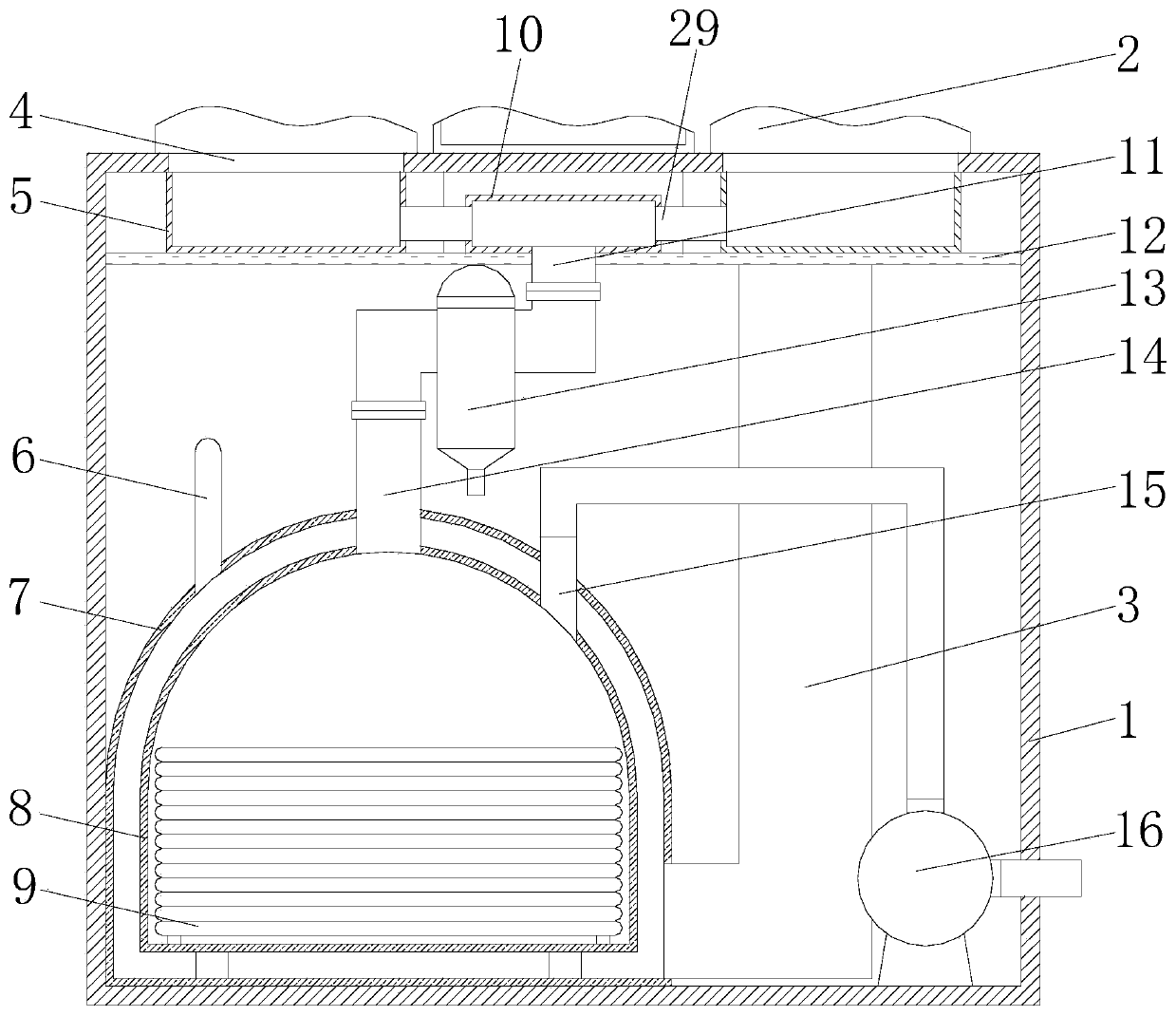

Energy-saving coal gasification reacting furnace and method

PendingCN109370658APrevent idlingRealize energy savingChemical industryGasification processes detailsEngineeringProduct gas

The invention discloses an energy-saving coal gasification reacting furnace and method. The energy-saving coal gasification reacting furnace comprises a reacting furnace body and a steam supply cavity, wherein the steam supply cavity is arranged on one side of the reacting furnace body, and the outside of the reacting furnace body is provided with a spiral heat exchange tube which is provided witha water pumping unit; the top of the steam supply cavity is provided with a steam discharging pipe which is provided with a steam conveying unit, a gas flow metering unit and a pipe opening and closing unit; the inside of the steam supply cavity is provided with a snake-like heat exchange pipe, the end portion of the snake-like heat exchange pipe is provided with an internal joint, the outside ofthe internal joint is provided with a connecting ring fixed onto the side surface of the steam supply cavity, a sealing cover is connected in a sleeve mode outside the connecting ring, and the innerwall of the steam supply cavity is provided with a heating element. The energy-saving coal gasification reacting furnace avoids an idle state of the reacting furnace body to maximize energy-saving effects, and meanwhile, is reasonable in design and high in practicality.

Owner:HAMKOO TECH DALIAN

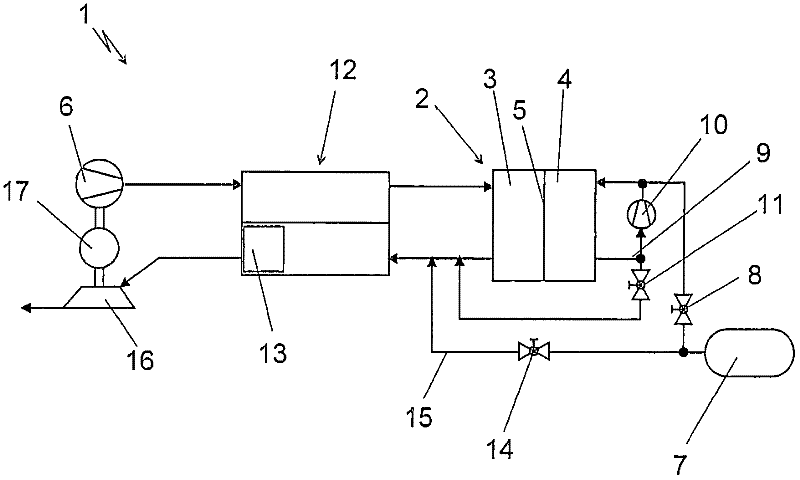

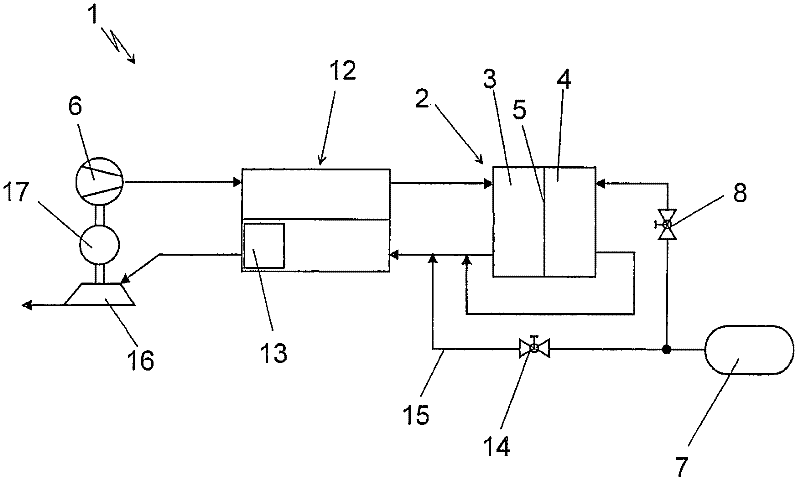

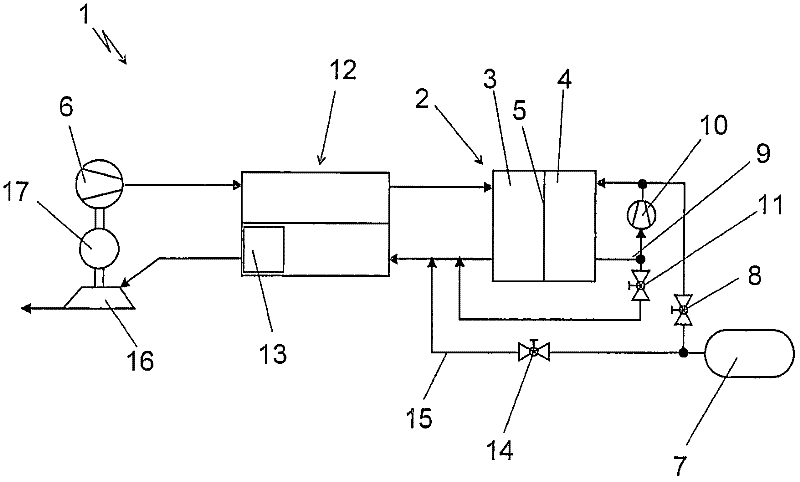

Fuel cell system comprising at least one fuel cell

A fuel cell system (1) comprises at least one fuel cell (2) that has a cathode region (3) and an anode region (4). The fuel cell system further comprises an exchanging device (12), through which an intake air stream flowing to the cathode region (3) and a used air stream discharged from the cathode region (3) flow. In said exchanging device (12), heat is transferred from the intake air stream to the used air stream, and steam is simultaneously transferred from the used air stream to the intake air stream. The fuel cell system also comprises a compressor (6) which can be driven at least in an assisting manner by a turbine (16). Said turbine (16) is disposed downstream of the exchanging device (12) and is penetrated by used air. Furthermore, a catalytic material, to which a fuel-containing gas can be fed, is disposed upstream of the turbine (16). According to the invention, the catalytic material (13) is integrated into the exchanging device (12) at the used air end, to which an exhaust gas from the anode region (4) can be fed.

Owner:DAIMLER AG

Semiconductor-based air conditioning device

ActiveUS10386085B2Adversely affectedDissipated more quicklyInternal combustion piston enginesMachines using electric/magnetic effectsTemperature controlThermoelectric cooling

The semiconductor-based air conditioning device includes at least a thermoelectric cooling chip, a cooling circulating member, a heat dissipating member, and a power provisioning and temperature controller. The cooling circulating member is joined to a cold production surface, and the heat dissipating member is joined to a heat production surface, of the thermoelectric cooling chip. Each of the cooling circulating member and the heat dissipating member includes a circulating box, a fan, and an auxiliary conduction device. Each circulating box is covered with fins and surrounding pipes. Each fan is located adjacent to corresponding fins. Each auxiliary conduction device includes an electrical pump. Fluid is stored and circulated in the surrounding pipes of each circulating box. Each electrical pump is configured to pump the fluid in a corresponding circulating box, and fluid is circulated to absorb the cold or heat from the thermoelectric cooling chip.

Owner:CHEN CHUAN SHENG

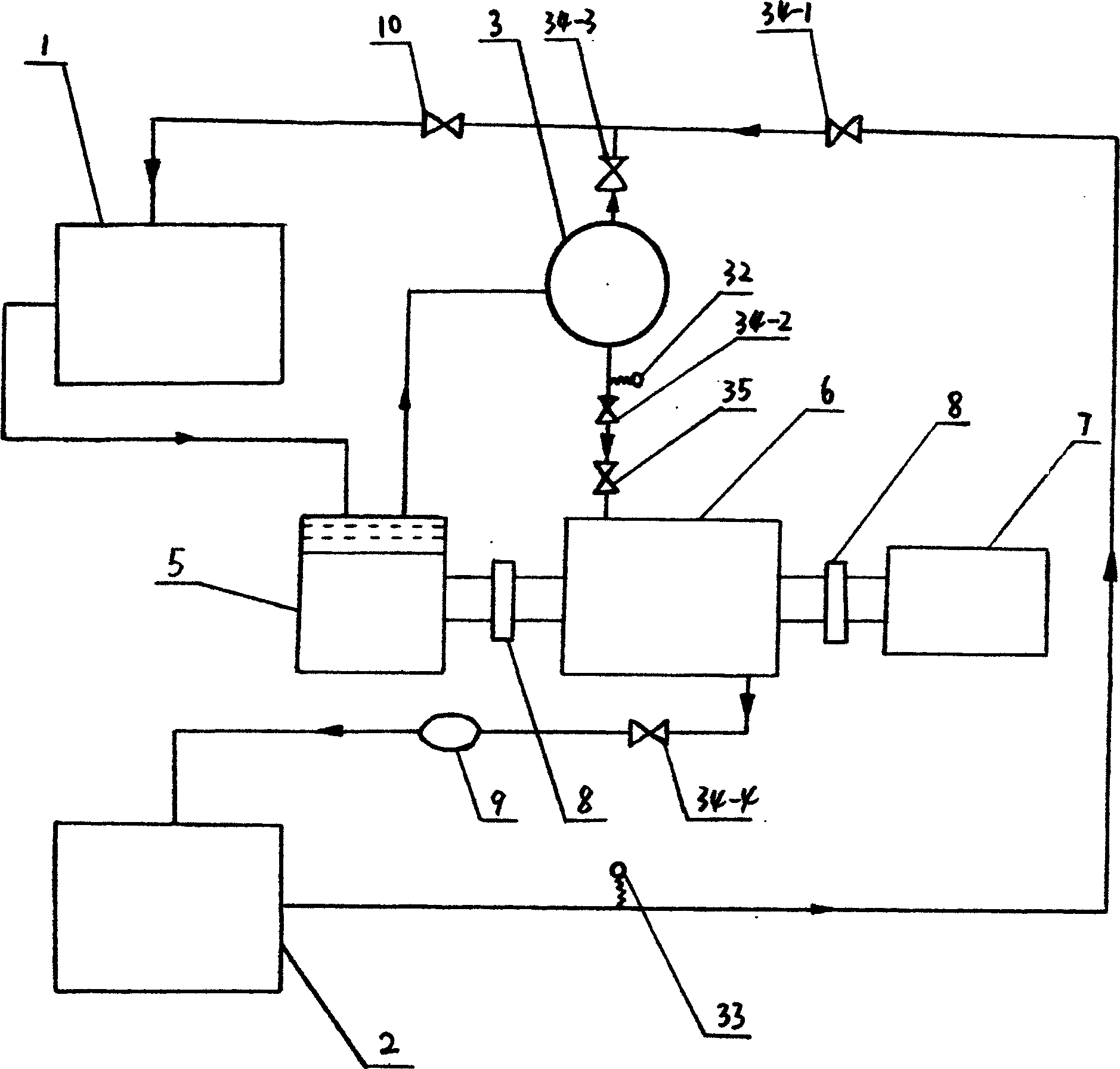

Cooling medium engine apparatus

InactiveCN1448617ASolve environmental pollutionAvoid wasting heatEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringRefrigerated temperature

The present invention relates to evaporation refrigerating system and is especially one kind of refrigerant engine plant for evaporation refrigerating system. Between the refrigerating compressor and heat radiator, there are successively connected energy accumulator, high pressure sensor D1, solenoid valve F2, regulating valve, refrigerant engine and solenoid valve F4; between the heat radiator and the decompressor there are successively connected low pressure sensor D2 and solenoid valve F1; and between the energy accumulator and the decompressor there is pipeline connected solenoid valve F3. The main shaft of the refrigerant engine is connected to the refrigerating compressor; and the refrigerant engine is one refrigerator driven turbine. The refrigerant engine plant has no environmental pollution and high heat efficiency.

Owner:于泷

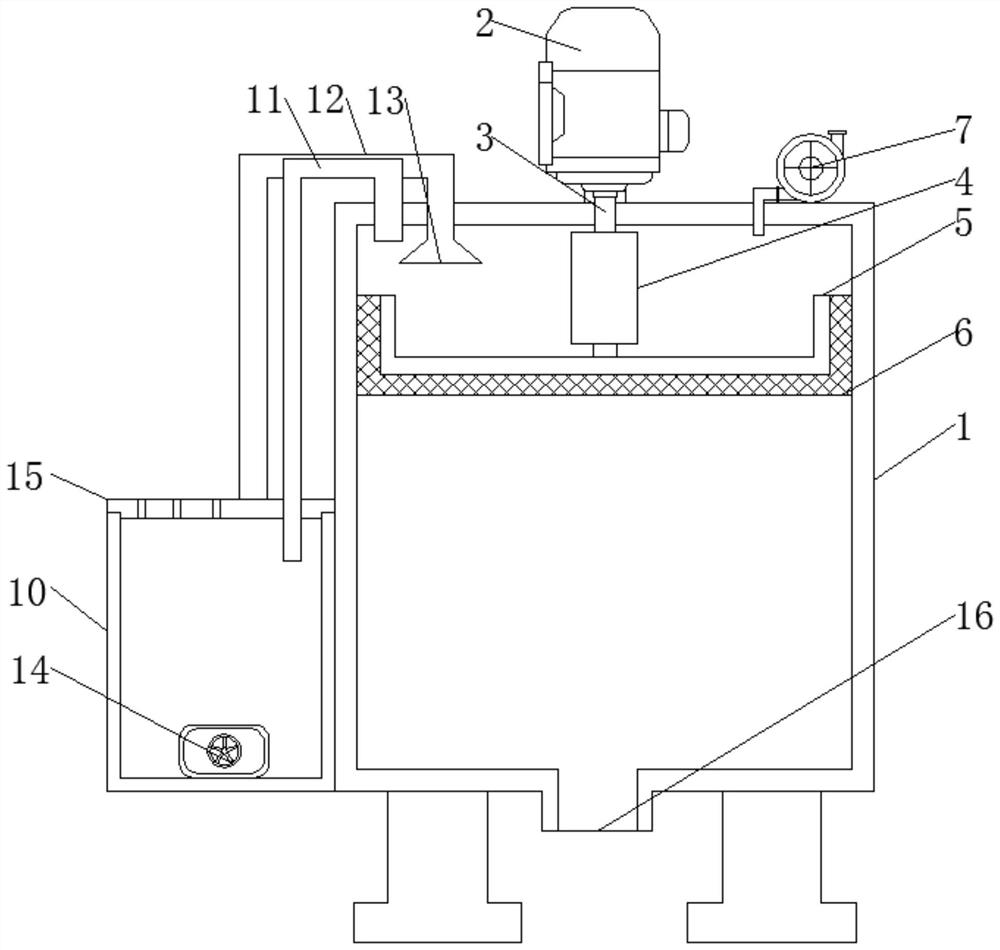

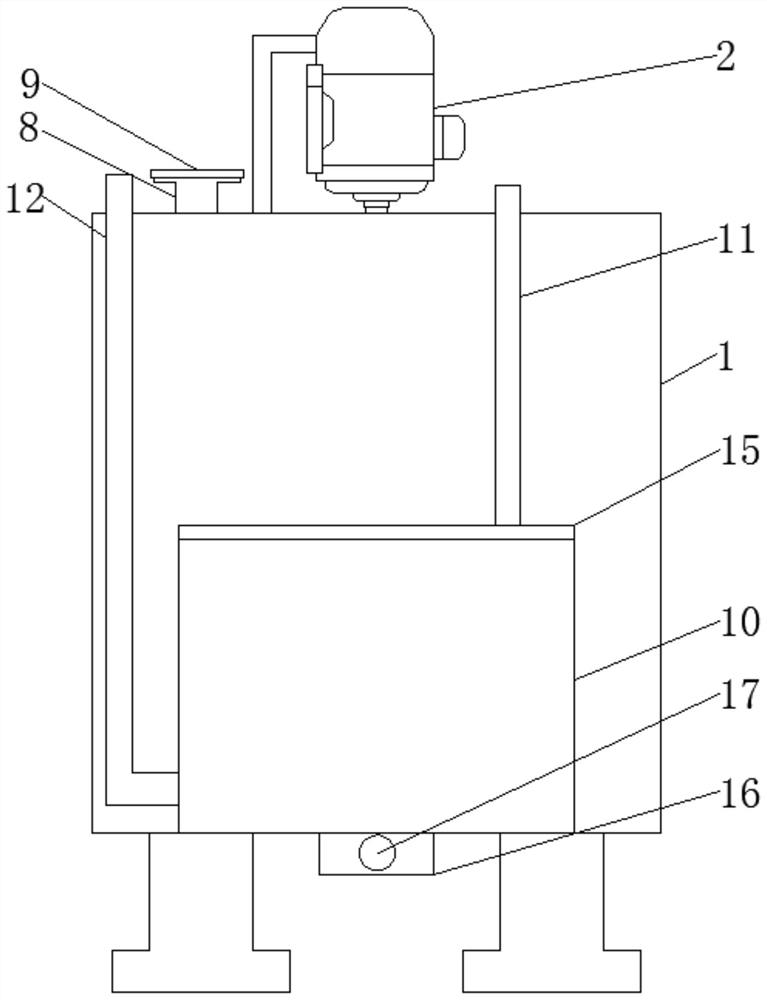

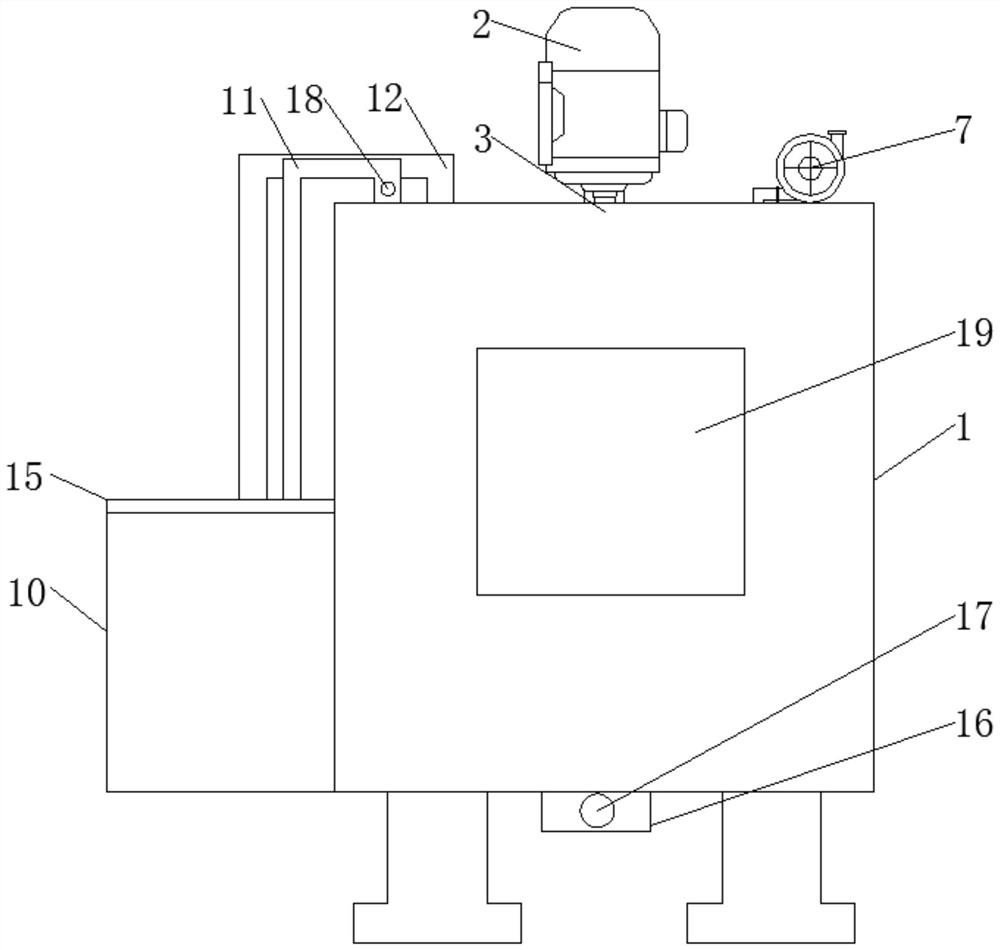

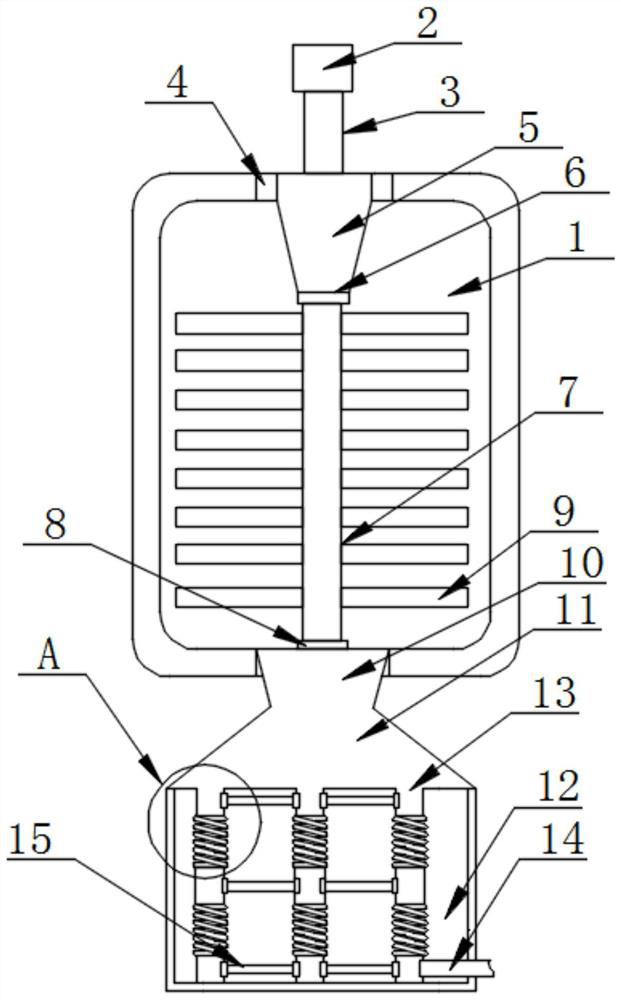

Reaction kettle with cooling device

InactiveCN111672437AImprove cooling effectAvoid wasting heatHollow article cleaningChemical/physical/physico-chemical processesCold airElectric discharge

The invention discloses a reaction kettle with a cooling device. The reaction kettle comprises a reaction kettle body, a motor is arranged at the top of the reaction kettle body; the motor is connected with an electric telescopic rod through a motor shaft; the electric telescopic rod is arranged in the reaction kettle body; the end, away from the reaction kettle body, of the electric telescopic rod is connected with a supporting frame, an air cooler is arranged on the right side of the motor, the air cooler is connected with the reaction kettle body, meanwhile, a feeding port is formed in therear side of the motor, a discharging port is formed in the bottom of the reaction kettle body, and an electric discharging valve is arranged on the discharging port. When the reaction kettle needs tobe cooled, the air cooler discharges cold air into the reaction kettle body, so that the reaction kettle body can be cooled, and meanwhile, waste heat in the reaction kettle body can be discharged into a water tank through an exhaust pipeline to heat water in the water tank, so that the heat dissipation capacity of the reaction kettle can be improved conveniently, and waste of the waste heat canbe avoided.

Owner:盐城艾肯科技有限公司

Saddle-ride type vehicle

ActiveUS9919756B2Avoid wasting heatWaste heatWeather guardsMotorcyclesCylinder headAutomotive engineering

Owner:HONDA MOTOR CO LTD

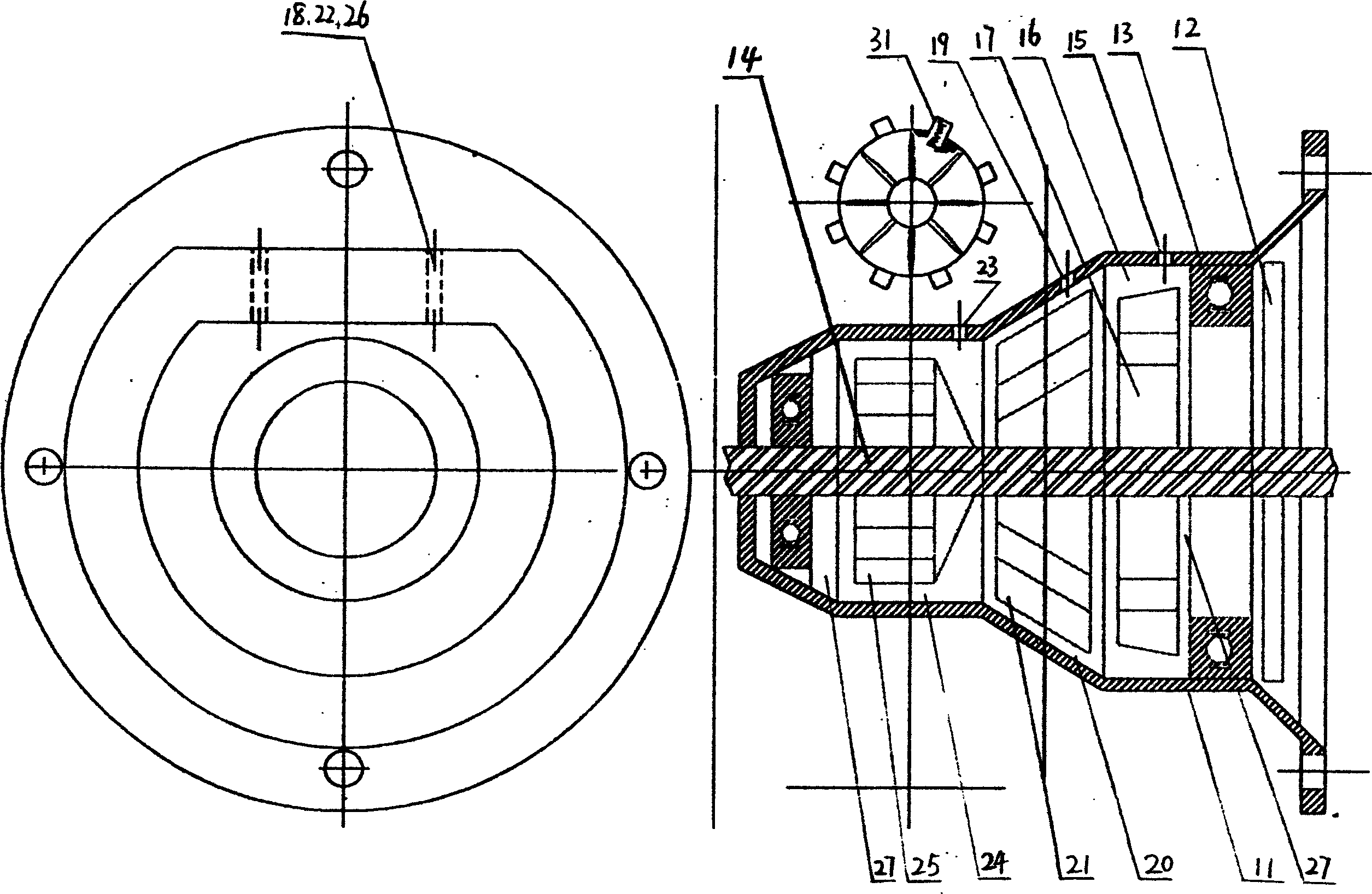

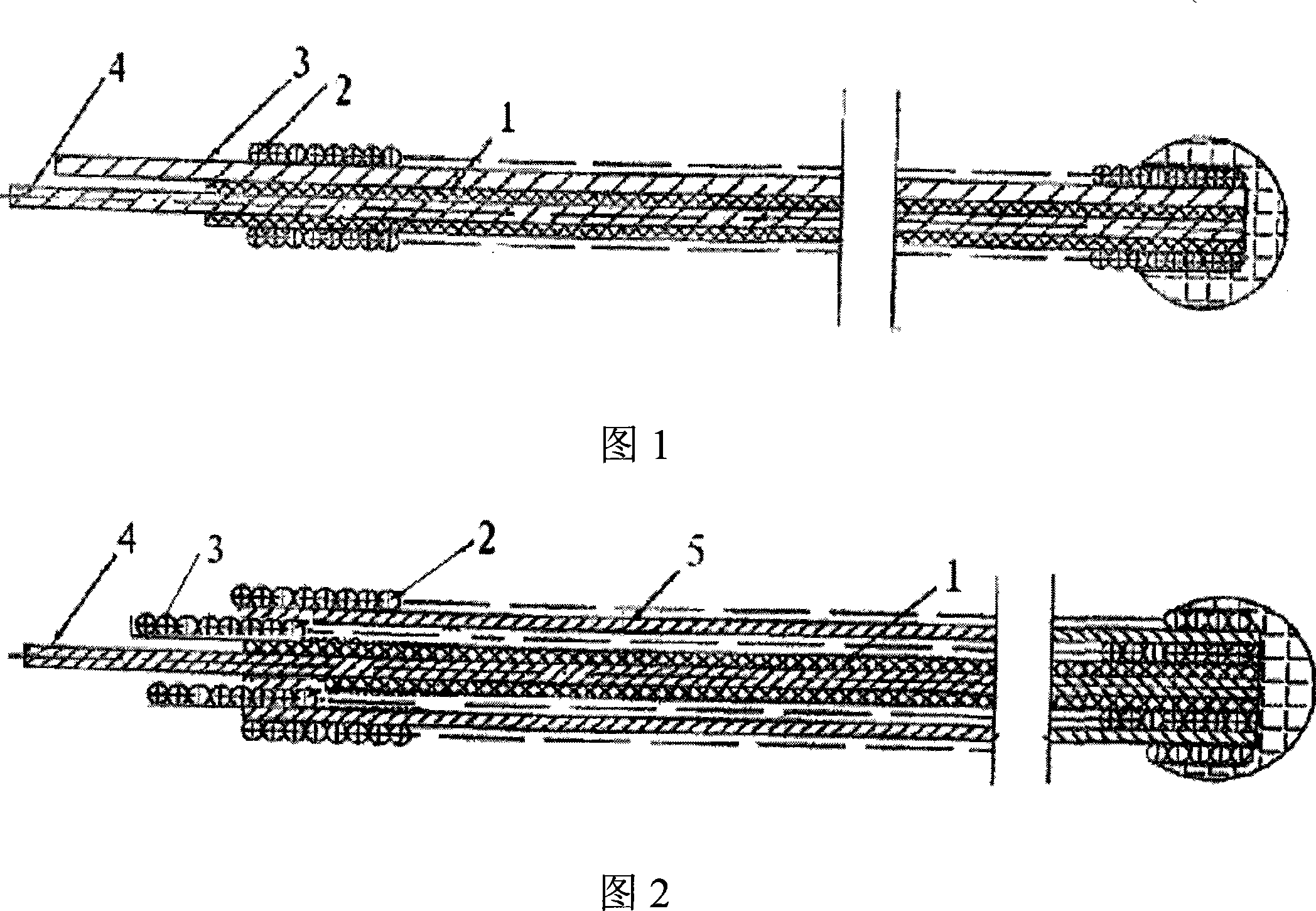

Oil-temperature heating wire

InactiveCN101178041AImprove Thermal Efficiency ApplicationsImprove heating efficiencyMachines/enginesThermal treatment of fuelInsulation layerEngineering

The invention relates to an oil temperature heating wire, in particular to a heating wire used in a diesel oil circuit, belonging to heating wire structural technical field. The oil temperature heating wire changes the heating type from built-out type to built-in type. The invention is characterized in that the invention comprises a heating wire anode 4; the exterior of the heating wire anode 4 is coated with a heating wire anode insulation layer 1; a heating wire cathode 3 is arranged at the exterior of the heating wire anode insulation layer 1; the exterior of the heating wire cathode 3 is provided with a heating wire protection spring 2 with protection function. The invention changes the existing built-out heating type into the built-in heating type, thus improving the heat efficiency application of the heating of oil circuit, ensuring the requirements of the oil circuit to the heat and avoiding the shortage that the built-out heating type wastes heat and time.

Owner:孙靖茗

Slag cooler for utilizing and recycling waste heat of slag

InactiveCN114857606AEasy injectionIncrease the heat exchange areaLighting and heating apparatusIncreasing energy efficiencyThermodynamicsSlag

The invention discloses a slag cooler for slag waste heat utilization and recovery. The slag cooler comprises an outer shell mechanism and an inner shell mechanism installed in the outer shell mechanism. A placing frame is fixed on the outer side of the lower end of the shell mechanism; a water inlet is fixed to the left side of the upper end of the shell mechanism, and a water outlet is formed in the right side of the lower end of the shell mechanism. Connecting plates are installed on the inner wall of the outer shell mechanism at equal intervals, and the other ends of the connecting plates are connected with the outer side face of the inner shell mechanism. Wherein a discharging opening is fixed to the bottom end of the shell mechanism, and a feeding frame is installed at the upper end of the shell mechanism. The slag cooler for slag waste heat utilization and recovery is provided with the hollow outer shell mechanism, the hollow inner shell mechanism and the hollow connecting plate, so that the heat exchange area is increased conveniently, the slag waste heat recovery efficiency of slag cooling can be improved, waste heat recovered in the later period can be used for preheating furnace water, steam for preheating the furnace water can be saved, and the energy consumption is reduced. And the waste heat can be well recycled.

Owner:金钰丹

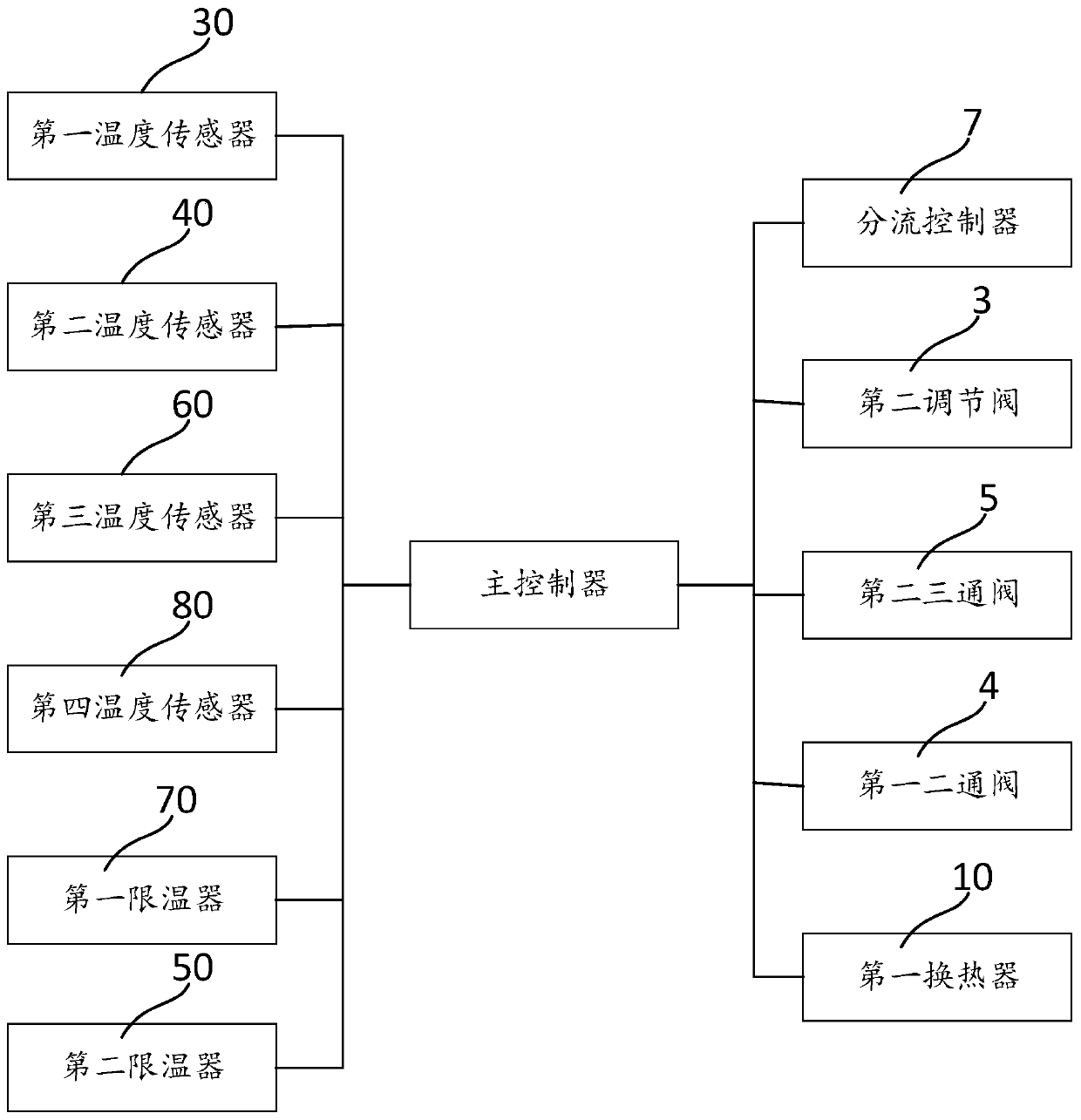

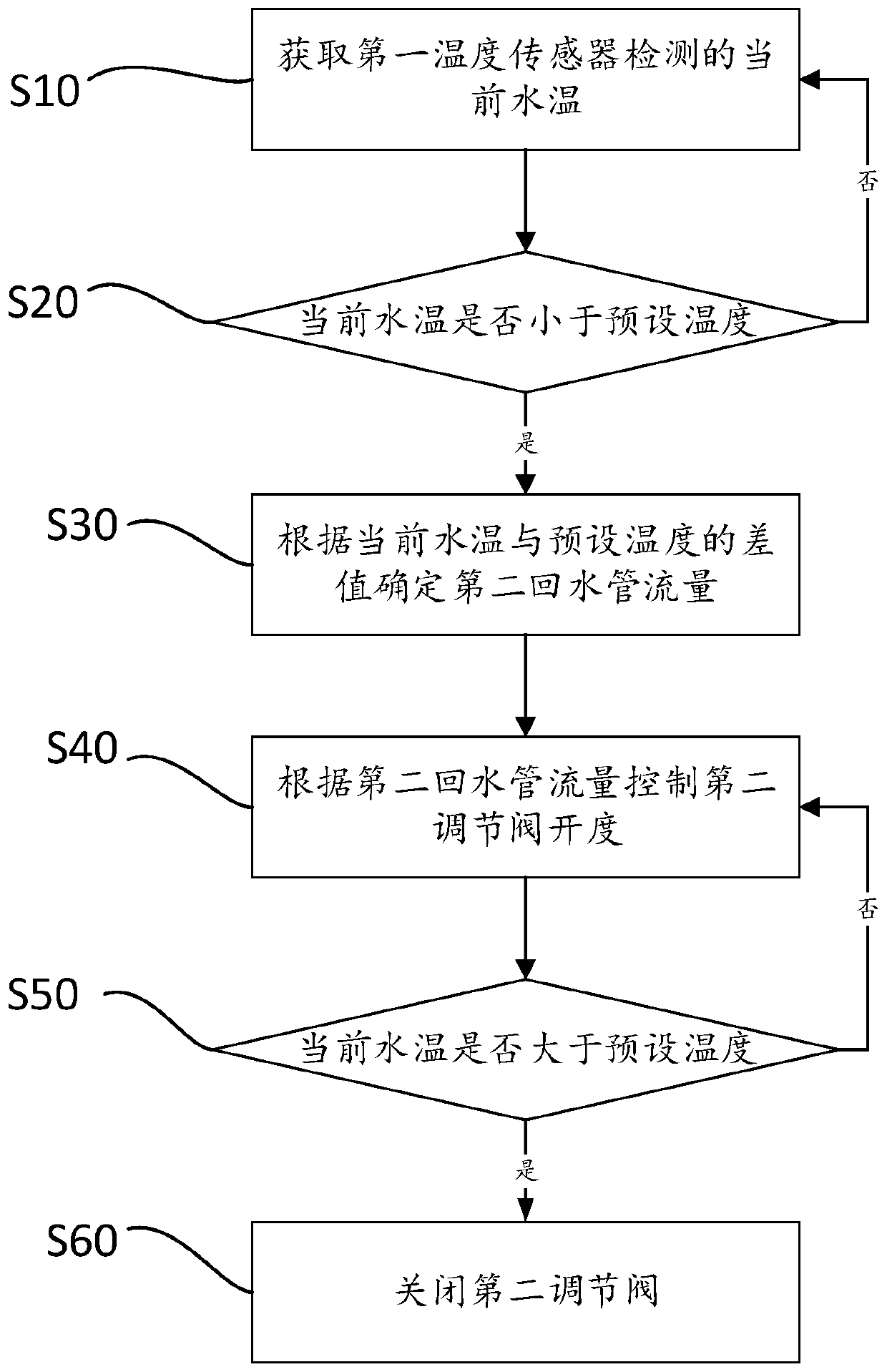

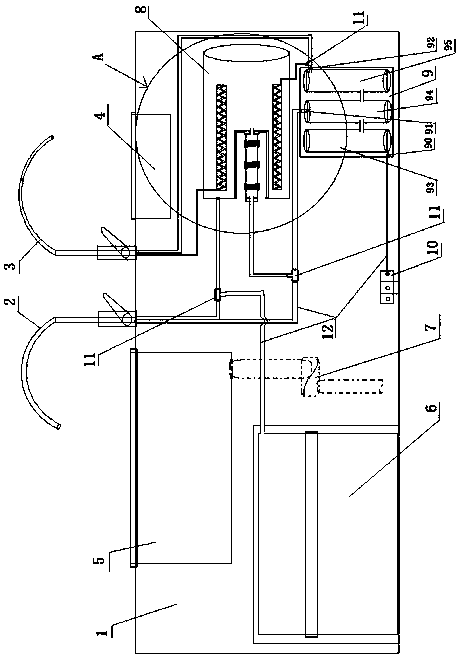

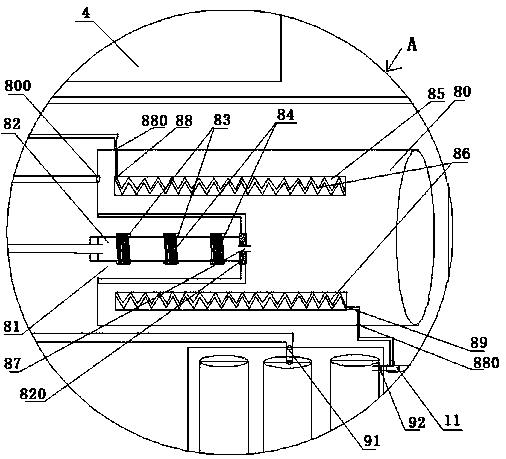

Water heater and control method thereof

PendingCN111043751AAvoid wasting heatImprove efficiencyWater heatersDomestic water consumptionWater pipe

The invention relates to the field of water heaters, in particular to a water heater and a control method thereof. The water heater comprises a diverting controller, a first heat exchanger, and a second heat exchanger, wherein the diverting controller is arranged on a first water return pipe and is suitable for diverting the first water return pipe into two paths and controlling the flow of the two outlet ends; the first heat exchanger comprises a first heating pipe and a second heating pipe which are independent from each other, the inlet end of the first heating pipe and the inlet end of thesecond heating pipe communicate with the two outlet ends of the diverting controller, and the outlet end of the first heating pipe communicates with a heating loop; and a first medium inlet end communicates with the outlet end of the second heating pipe, a first medium outlet end communicates with the first water return pipe, and a second medium inlet end and a second medium outlet end of the second heat exchanger communicate with a domestic water pipeline. The water heater can realize simultaneous supply of domestic hot water and heating.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Multifunctional integrated sink structure with instant hot water

PendingCN110344477AEnsure instant resultsAvoid wasting heatDomestic plumbingMultistage water/sewage treatmentUsabilityEngineering

The invention discloses an integrated sink which is convenient in use and practical, is integrated with instant hot water (including boiled water for washing) and automatic dish washing with boiled water and has strong further function expansion usability. The invention studies and improves the multifunctional integrated sink structure with instant hot water. The multifunctional integrated sink structure includes a cabinet for supporting the structure, a sink and a faucet. The sink is embedded in the upper end of the cabinet. The inside of the cabinet is provided with a small electric water heater, a water purification device and a dishwasher at the lower end of the sink. An annular heat collecting plate is placed in an innovatively introduced container and cooperates with a circuitous curved flow channel structure, and cold water enters an electromagnetic heater through a water inlet pipe for preheating and then immediately enters the annular heat collecting plate for concentrated heating. During the electromagnetic heating, hot water in the container can ensure that high temperature environment can be instantly obtained in the curved flow channel, which provides a significant effect for ''instant hot'' or oven ''instant boiling'' of the whole integrated sink.

Owner:广东鑫禄莱电器股份有限公司

A fiber cloth spinning device with a cooling function

The invention provides a fiber cloth spinning device with a cooling function. The device comprises a spinning device body, wherein the spinning device body comprises a discharge port; a cooling devicecomprises a box body, a first rotating roller, a second rotating roller and an air supply device; the box body comprises a feeding end and a discharging end; the feeding end is connected with the discharge port; containing cavities are formed in the first rotating roller and the second rotating roller; the air supply device comprises an air outlet pipe and an air inlet pipe; the first rotating roller and the second rotating roller are respectively arranged at two ends of the box body; the two rollers are rotationally connected with the box body respectively; the air inlet pipe is connected with one side of the first rotating roller and one side of the second rotating roller; the air outlet end is connected with the other sides of the first rotating roller and the second rotating roller respectively; the air inlet pipe and the air outlet pipe communicate with the containing cavities; a collecting device comprises a collecting roller, baffles located at the two ends of the collecting roller and a driving motor, the two ends of the collecting roller are rotationally connected with the two baffles respectively, and the output end of the driving motor is connected with any end of the collecting roller. The problem that after fiber cloth is stored, adjacent fiber cloth adheres to each other is solved.

Owner:衢州菁英科技有限公司

Ground source heat pump system capable of accumulating heat according to indoor temperature

ActiveCN112696845AGuaranteed full useAvoid wasting heatMechanical apparatusHeat pumpsHeat spreaderHeat pump

The invention provides a ground source heat pump system capable of accumulating heat according to indoor temperature. The system further comprises a heat accumulator, the heat accumulator is arranged on a heat accumulator pipeline connected with a heat exchanger pipeline in parallel, the heat exchanger pipeline and the heat accumulator pipeline are provided with a fifth valve and a sixth valve correspondingly, and a controller is in data connection with the fifth valve and the sixth valve. An outlet is connected with a heating radiator, the heating radiator is arranged indoors, a temperature sensor is arranged indoors, the temperature sensor is in data connection with the controller, and the controller automatically adjusts the opening degrees of the fifth valve and the sixth valve according to the detected room temperature. By controlling the opening degrees of the fifth valve and the sixth valve according to the indoor temperature, the heat demand can be reduced when the indoor temperature is increased, more heat is stored through the heat accumulator under the condition of meeting the heat demand of a client, and therefore sufficient utilization of the heat is guaranteed, and heat waste is avoided.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD

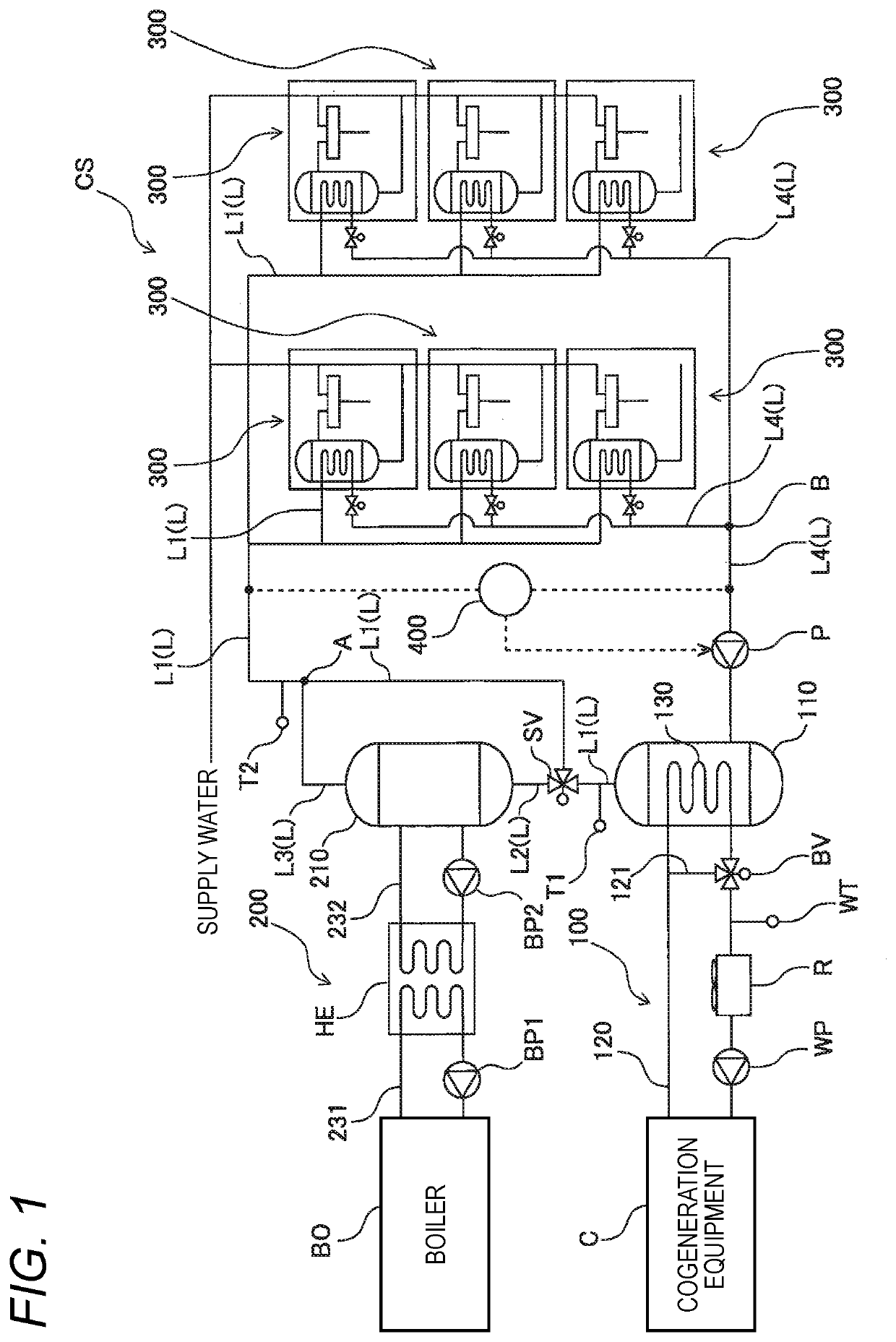

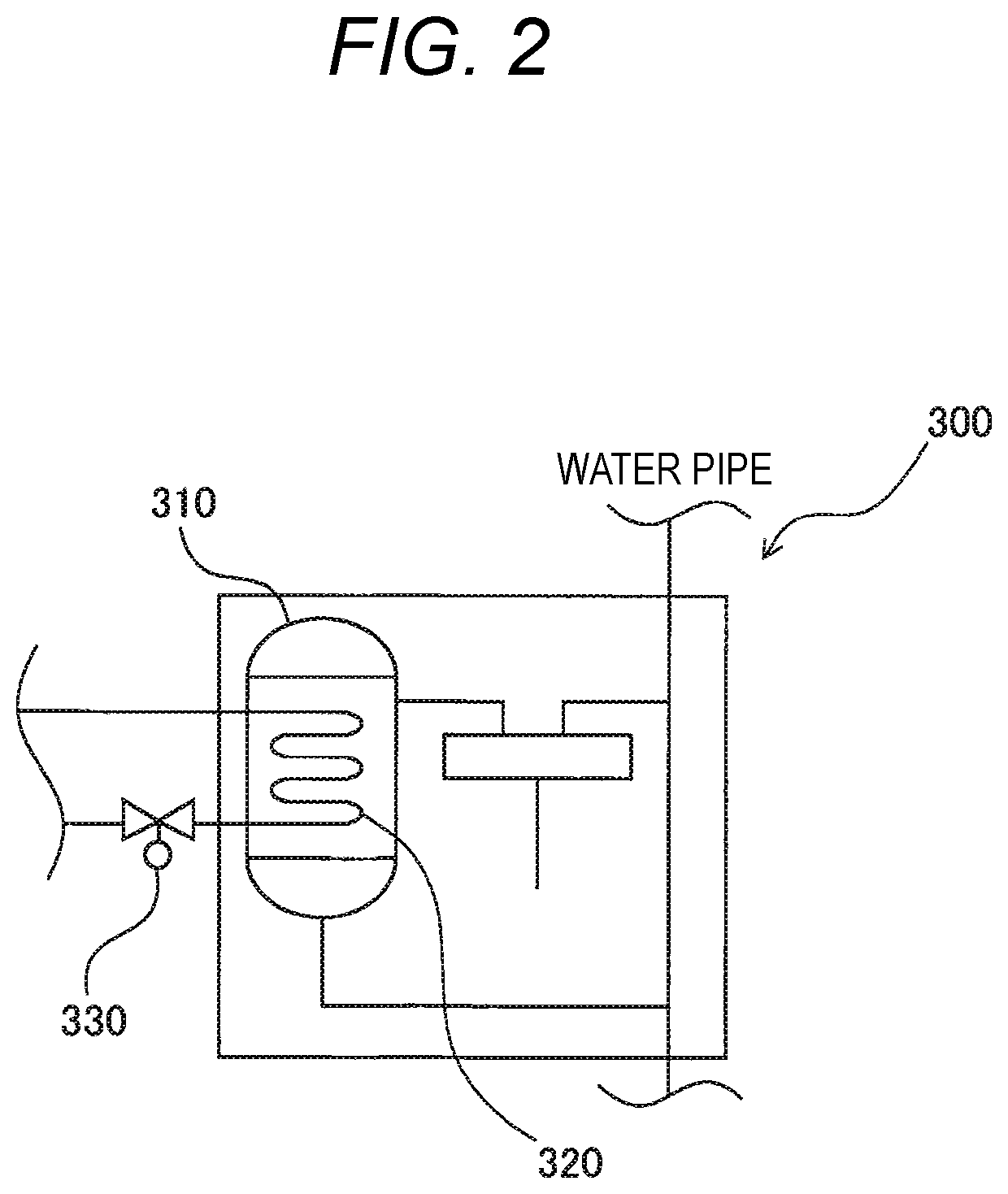

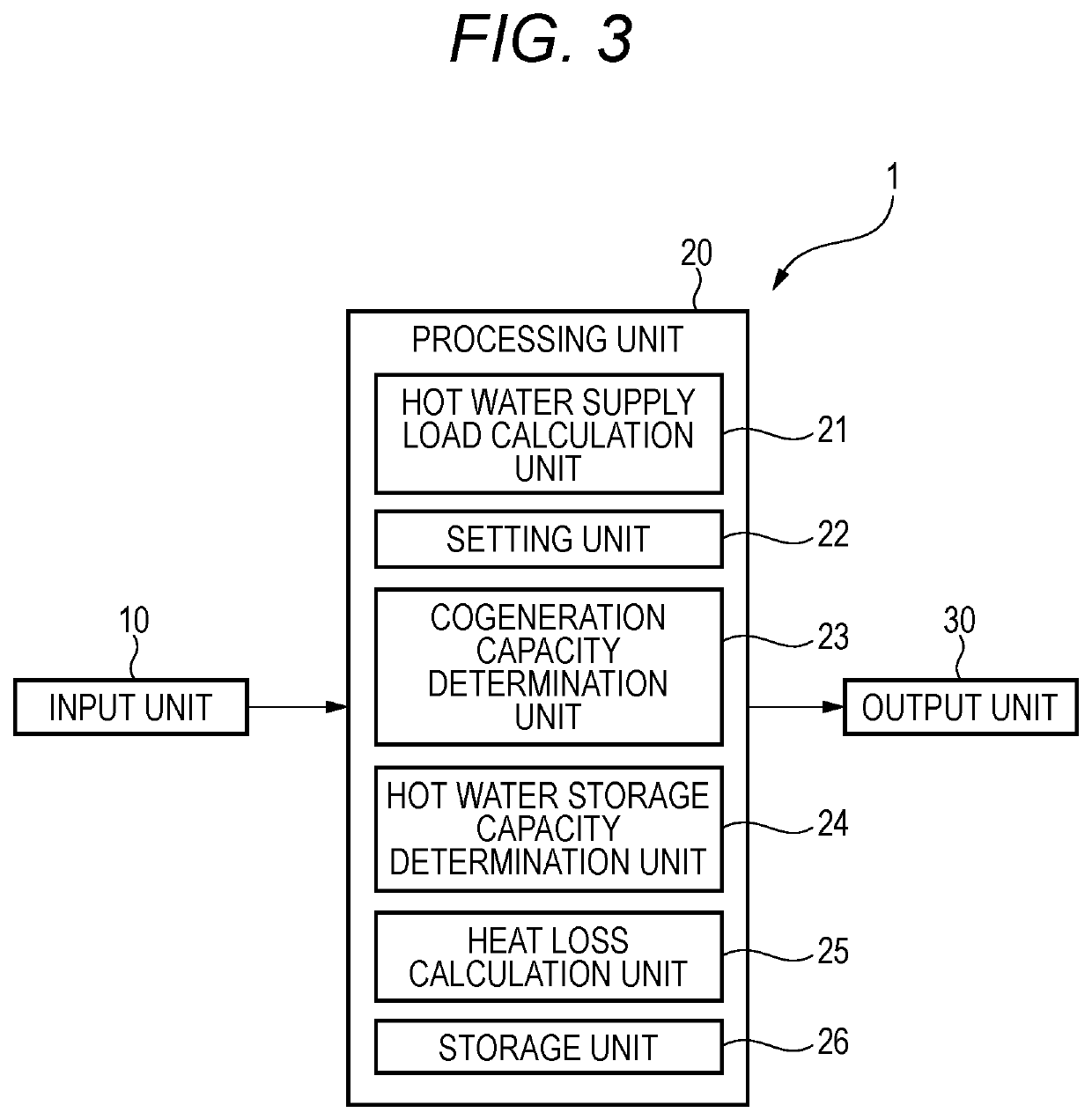

Equipment determination method of cogeneration system, equipment determination device thereof, and computer readable recording medium thereof

ActiveUS20210302032A1Easy to optimizeAvoid wasting heatRecuperative heat exchangersComputer controlWater storageCogeneration

An equipment determination method of a cogeneration system includes the steps of: calculating a total hot water supply load for each day over a predetermined period longer than a specific period based on each unit hot water supply load for hour according to hot water supply use by consumers; setting as a representative period a specific period on which the total hot water supply load becomes at least a low load among the calculated total hot water supply load for each day; determining a capacity of the cogeneration equipment based on the total hot water supply load on the set representative period; and determining a capacity of the plurality of hot water storage tanks based on an amount of hot water supply load exceeding the capacity of the determined cogeneration equipment among each unit hot water supply load for two or more divided periods including the set representative period.

Owner:YAZAKI ENERGY SYST

Disinfection device for nursing

ActiveCN113499459AEffective DisinfectionClose contact and squeezeLavatory sanitoryHeatGear wheelWater vapor

The invention relates to a disinfection device for nursing, and the device comprises a machine shell; a top disc is fixedly mounted at the top of the machine shell, a water outlet is formed in the side wall of the machine shell, a driving motor is fixedly mounted at the top of the top disc, and a mounting main shaft is fixedly mounted at one end of an output shaft of the driving motor; a transmission lead screw is rotationally mounted on the inner wall of the top disc, a driving gear and a driven gear are fixedly mounted outside the mounting main shaft and the transmission lead screw correspondingly, and the driving gear and the driven gear are connected in a meshed mode. The heat recovery box is arranged outside the device, waste heat in the device can be effectively collected, waste is avoided, water vapor generated by waste heat recovery can be used for conducting reverse compensation and disinfection on the interior of the device, additional driving energy is not needed, energy is saved, the disinfection effect can be improved, and meanwhile, due to the design of the gas control mechanism, automatic operation of gas control can be achieved, manual management is not needed, intellectualization is achieved through a physical structure, and the using effect is improved.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

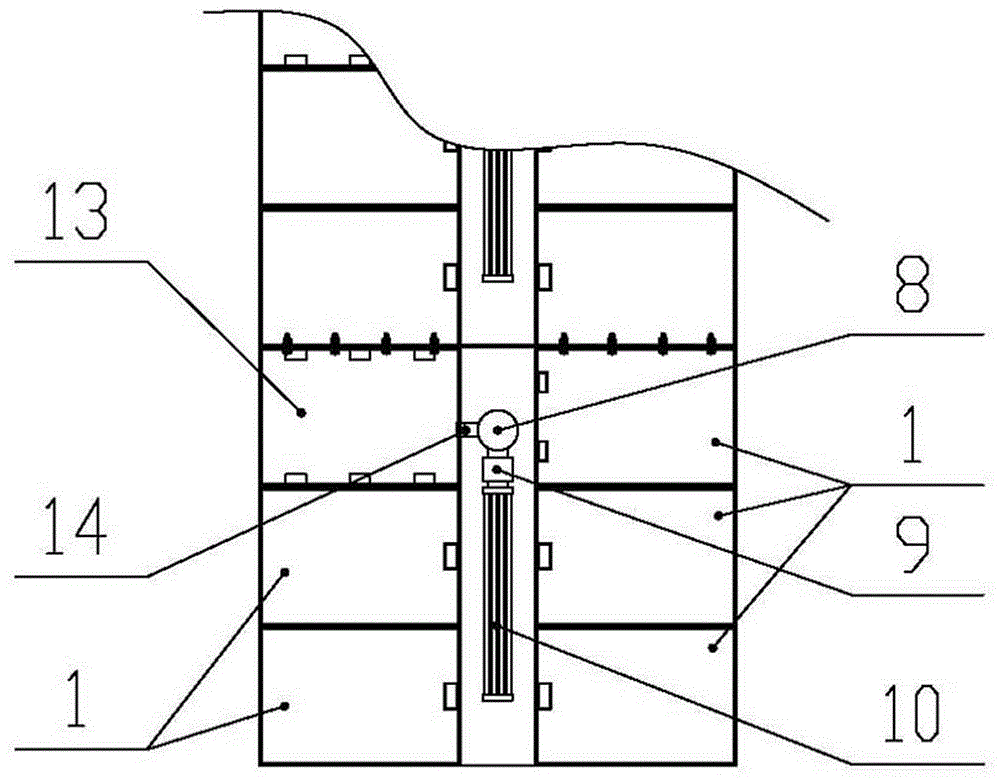

Steam heating device for green food production

ActiveCN111012160APrevent disengagementReduce access difficultySteam cooking vesselsWarming devicesThermodynamicsProcess engineering

The invention discloses a steam heating device for green food production. The device includes a tank body, wherein first communicating openings are formed in the top of the tank body in a penetratingmanner; steam cabinets are arranged at the top of the tank body and located above the first communicating openings; a heat preservation shell is arranged on one side of the interior of the tank body;a heating water tank is fixedly installed in the heat preservation shell through a cushion block; a heating wire is arranged in the heating water tank; and a steam outlet pipe is installed in the middle of the top of the heating water tank in a penetrating and inserting mode. According to the steam heating device, through cooperation of the first communicating openings, steam distributing bins, asteam collecting box, a steam-water separator, the steam outlet pipe and second communicating openings, the four steam cabinets can be heated through steam at the same time, meanwhile, the number of heated materials in the same time is greatly increased, and therefore the material heating efficiency can be improved, the steam utilization rate is increased, steam waste can be prevented, and the cost can be reduced.

Owner:CHAOHU MEADVILLE FOOD CO LTD

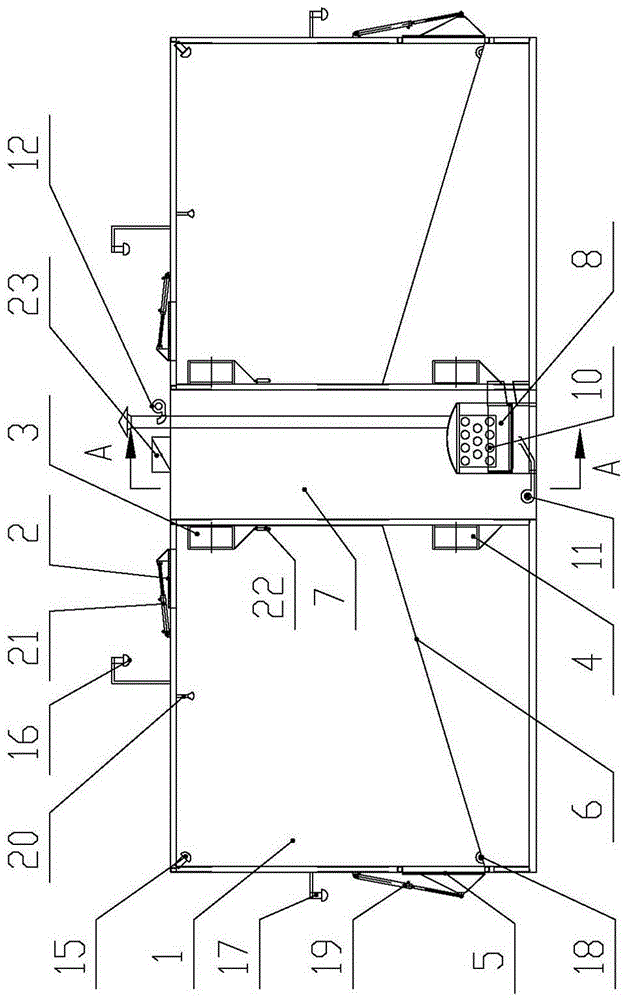

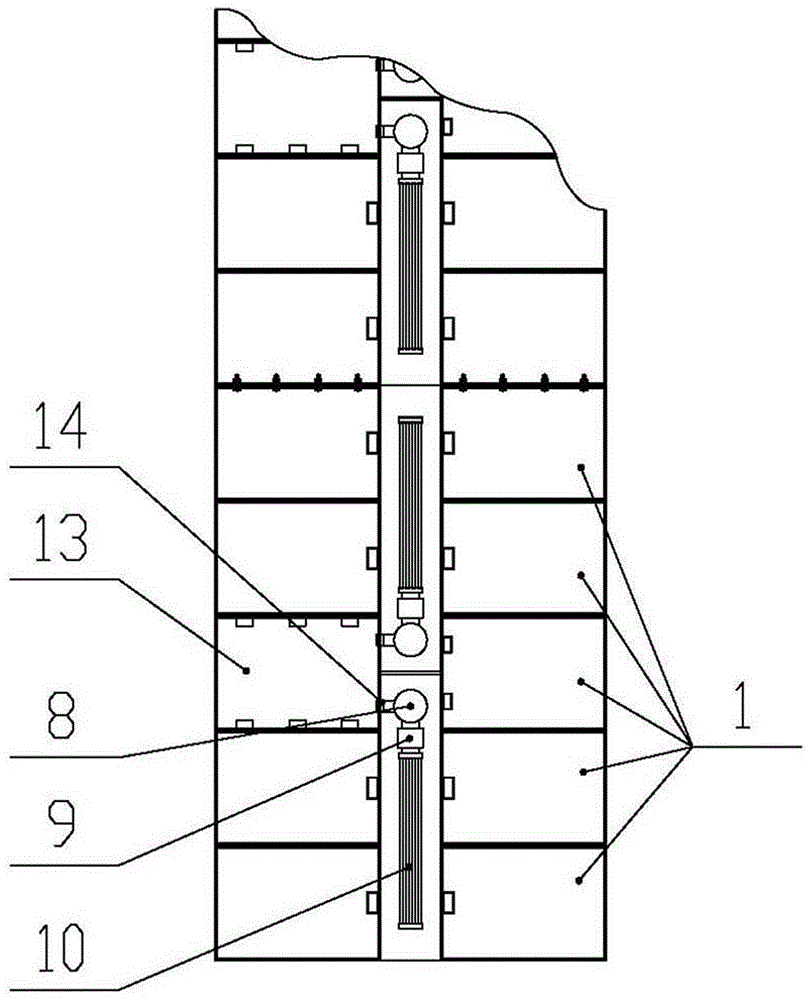

Unit type heat source system of corn ear dryer

PendingCN105660849ALayout scienceSmall footprintClimate change adaptationSeed preservation by dryingUnit typeSource system

The invention relates to a unit type heat source system of a corn ear dryer. The unit type heat source system comprises a left row of drying rooms, a right row of drying rooms, and an independent and sealed heat source center which is formed between the two rows of drying rooms, wherein the left row of drying room and the right row of drying rooms are arranged in a spaced manner; each row of the drying rooms comprises at least one independent drying chamber, and a feeding door capable of being opened and closed is arranged at the top part of each drying chamber; an upper circulating fan and a lower circulating fan which are communicated with the heat source center respectively are arranged on the side wall, close to the heat source center, of each drying chamber. Due to the implementation of the technical scheme, the unit type heat source system organically combines the drying chambers and the heat source center into a unit by the arrangement that the heat source center is formed between the two rows of drying rooms, and heat in the heat source center can be reasonably and uniformly provided for each drying chamber by the upper circulating fans and the lower circulating fans, therefore, the arrangement is scientific, and the occupied area is saved; heat generated by the heat source center directly enters the drying chambers without consumption halfway, so that waste of waste heat is avoided, and a large amount of energy consumed by use of high-power fans due to long-distance heat sending is saved.

Owner:石河子市华农种子机械制造有限公司

Flue gas filtering and purifying device for vacuum filter

ActiveCN112933752AIncrease contact areaGuaranteed purification effectDispersed particle filtrationTransportation and packagingFlue gasDrive shaft

The invention discloses a flue gas filtering and purifying device for a vacuum filter, and particularly relates to the field of vacuum filters. The device comprises a filter cavity, a control motor, a driving shaft, a circulation hole and a sealing sleeve, wherein the top end of the filter cavity is provided with a mounting hole and an air inlet, and the bottom end of the air inlet is attached to a sealing ring. According to the invention, through the cooperation of filtering discs and filtering strips, the problems that the flue gas filtering and purifying effect is poor and the requirement of comprehensive purification cannot be met in the prior art are avoided, the filtering discs are driven to rotate at a high speed in the filter cavity, and the filtering discs are arranged in the filter cavity in batches, so that the contact area with flue gas is enlarged, the flue gas is filtered and purified more effectively, filtrate on the surfaces of the multiple filter strips interacts with the flue gas, the flue gas in the filter cavity is comprehensively purified, the purification effect is guaranteed, and the practicability of the device is improved.

Owner:DATANG HUAIBEI POWER PLANT

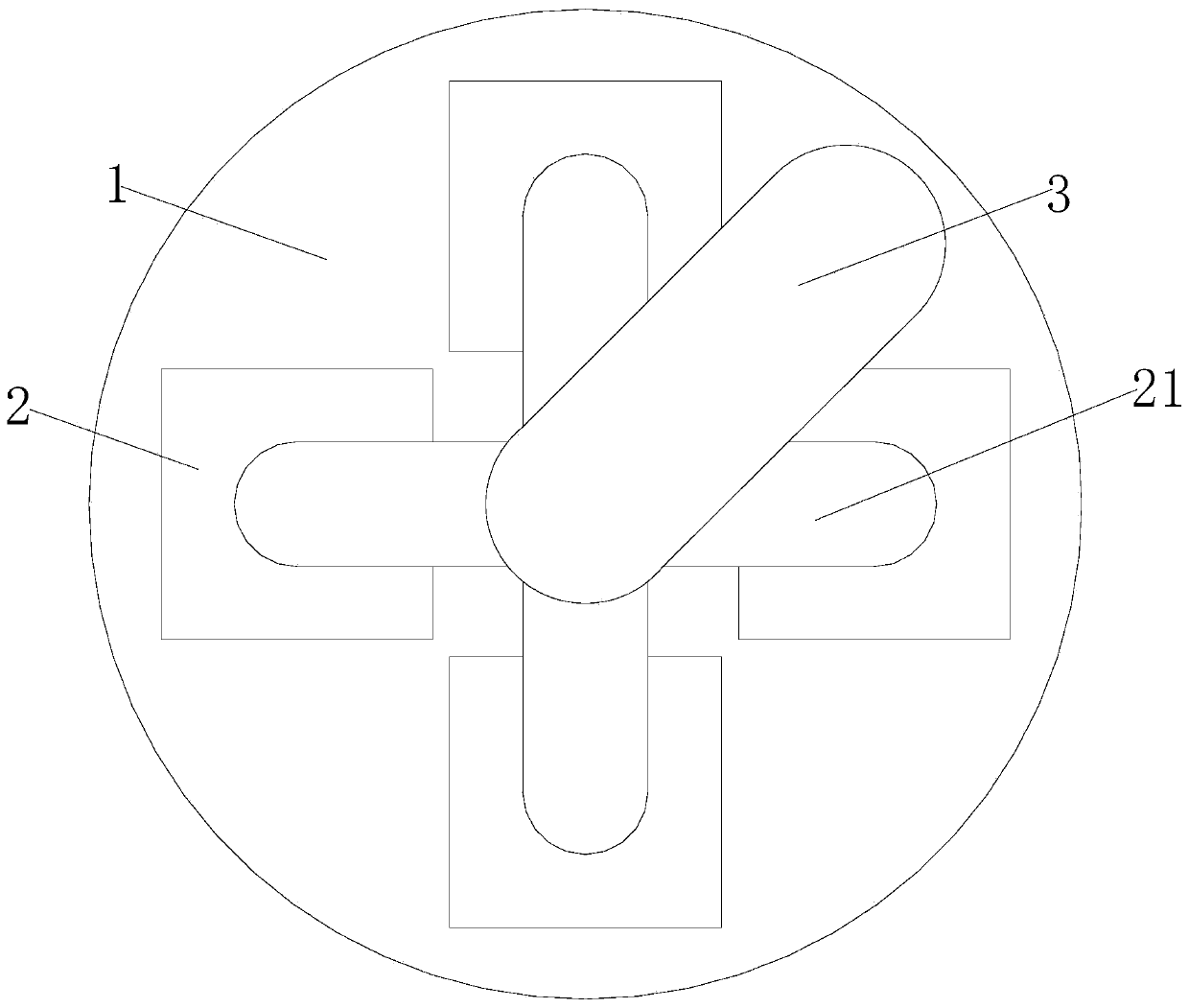

Sesame seed processing system for sesame candies

The invention discloses a sesame processing system for sesame candy, which comprises a device for removing impurities, a peeling device, a separation device, a drying device and a frying device. The device for removing impurities includes a tank for removing impurities and a presoaking tank. Cylinder and inner cylinder, the separation device includes a fixed frame and a water spray pipe, and the fixed frame is provided with a sieve barrel; the drying device includes a drying barrel, a collection chamber and an impurity chamber, and the frying device includes a roasting device and a cooling cylinder. Through the sesame processing system for sesame sugar of the present invention, the continuity of the whole process of the sesame processing system is realized.

Owner:黄林海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com