Oil-temperature heating wire

A heating wire and oil temperature technology, which is applied to fuel heat treatment devices, engine components, machines/engines, etc., can solve problems such as insufficient combustion, inability to drive normally, and low oil temperature, avoid heat and time, and ensure timely Adjustment, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

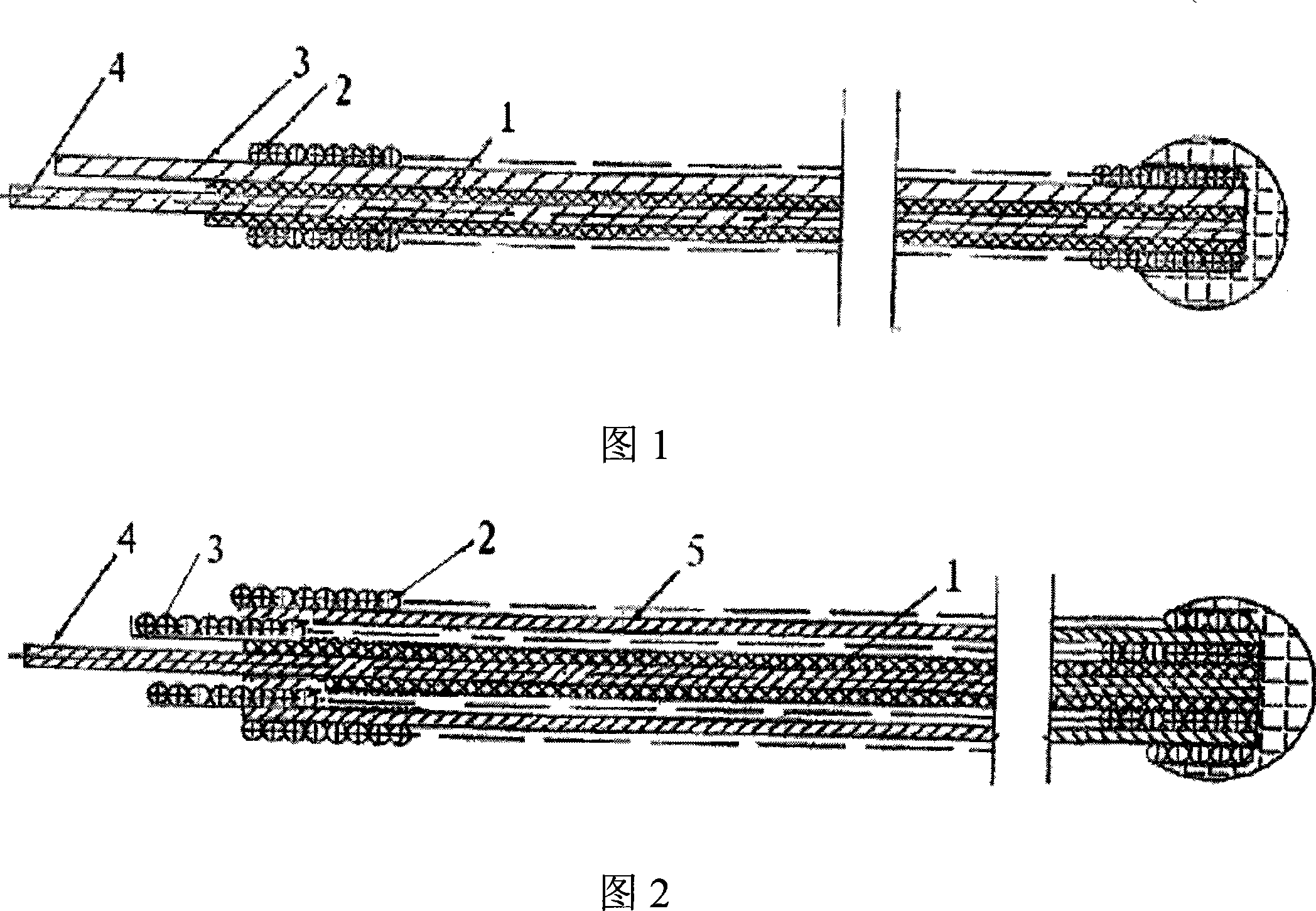

[0014] An oil temperature heating line in this embodiment refers to Figure 1, and the existing external heating method is changed to an embedded type, which is installed in the diesel input pipeline, including the positive electrode 4 of the heating line, and the outside of the positive electrode 4 of the heating line is covered with a layer The heating wire positive insulation layer 1, the heating wire negative pole 3 is arranged on the outside of the heating wire positive insulation layer 1, the heating wire negative pole 3 is provided with a heating wire protection spring 2 for protection, and the heating wire negative pole 3 is attached to the heating wire in a linear shape. The outer side of the positive insulating layer 1 of the heating wire; the number of the negative poles 3 of the heating wire is two, and the positive and negative poles of the heating wire are made of copper wire with high thermal conductivity, and the positive and negative poles of the heating wire are...

Embodiment 2

[0016] Referring to Figure 2, an oil temperature heating line of this embodiment changes the existing external heating method into an embedded type, and is installed in the diesel input pipeline, including the positive electrode 4 of the heating line, and the outside of the positive electrode 4 of the heating line is covered with a layer The heating wire positive insulation layer 1, the heating wire negative electrode 3 is arranged on the outside of the heating wire positive insulation layer 1, the heating wire negative electrode 3 is provided with a heating wire negative insulation layer 5, and the heating wire negative insulation layer 5 is provided with a protective The heating wire protection spring 2 has three heating wire negative electrodes 3. In order to increase heat dissipation and heat, the heating wire negative electrode 3 is evenly wound on the outer periphery of the heating wire positive insulation layer 1, and the heating wire positive and negative electrodes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com