Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

A technology of micro gas turbine and cogeneration of cooling, heating and power, which is applied in the direction of gas turbine devices, machines using waste heat, mechanical equipment, etc., can solve the problems of power generation and power generation efficiency decline, insufficient use of flue gas, waste of flue gas, etc., to achieve Improve the power and efficiency of power generation, improve the cooling capacity of the system, and improve the effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

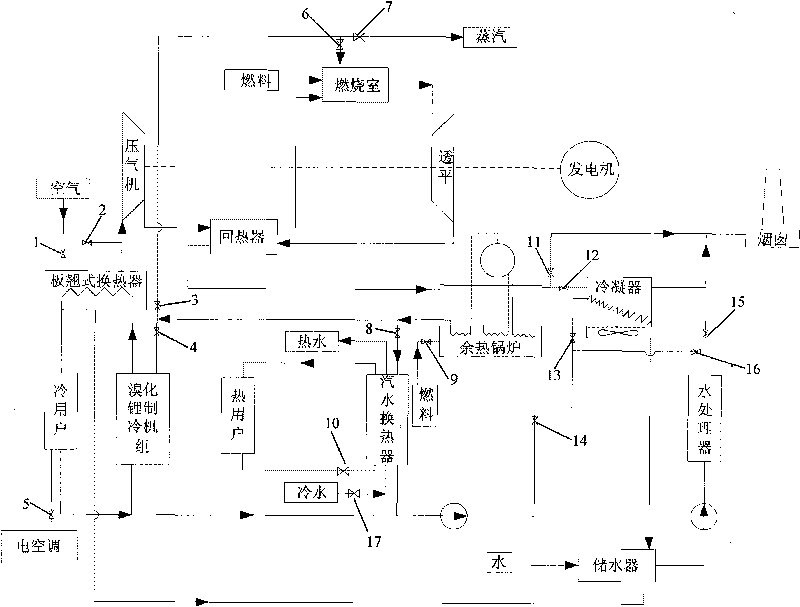

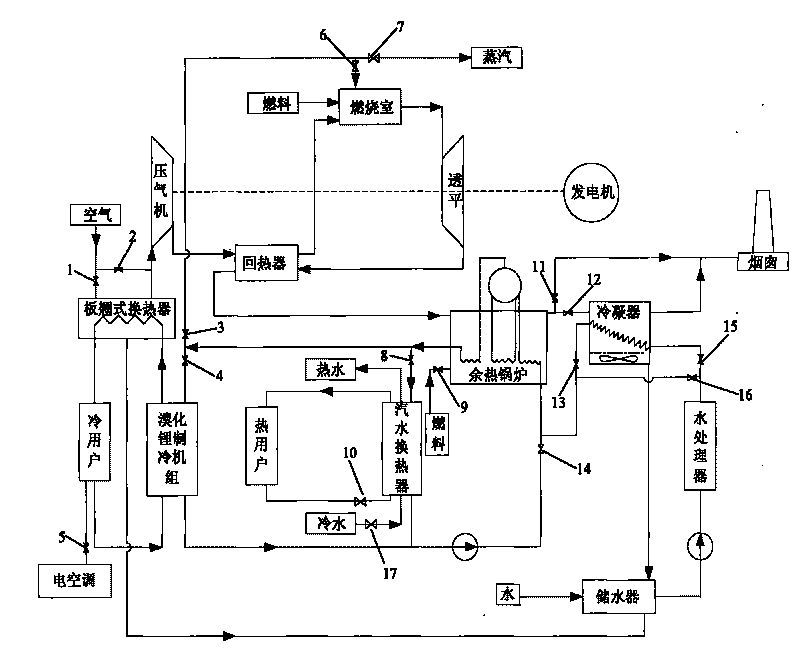

[0027] Typical winter heating working mode: the second valve 2, the eighth valve 8, the tenth valve 10, the eleventh valve 11, and the fourteenth valve 14 are opened, the ninth valve 9 is opened or closed according to the heat load, and other valves are closed . The air directly enters the compressor for compression, and then enters the combustion chamber after being heated by the flue gas in the regenerator. The gas generated by the combustion of air and fuel in the combustion chamber enters the turbine to expand and do work. The air is heated in the boiler, then enters the waste heat boiler to produce steam, and finally the flue gas is directly discharged from the chimney. The steam enters the steam-water heat exchanger to produce hot water for heating, and the steam condensed water returns to the waste heat boiler as make-up water. If additional make-up water is needed, the sixteenth valve 16 can be opened to make up water from the water storage.

Embodiment 2

[0029]Typical summer cooling working mode: the first valve 1, the fourth valve 4, the fifth valve 5, the eleventh valve 11, and the fourteenth valve 14 are opened, the ninth valve 9 is opened or closed according to the cooling load, the other valves are closure. The air first enters the plate warp heat exchanger and is cooled, then enters the compressor for compression, and then enters the combustion chamber after being heated by the flue gas in the regenerator, and the gas produced by the combustion of air and fuel in the combustion chamber enters the turbine for expansion. The flue gas from the turbine outlet first heats the air in the regenerator, then enters the waste heat boiler to produce steam, and finally the flue gas is discharged from the chimney. After the gas expands in the turbine, the air is heated in the regenerator, and then enters the waste heat boiler to produce steam, and finally the flue gas is directly discharged from the chimney. The steam produced by th...

Embodiment 3

[0031] Typical working mode without cooling and heating load (reinjection steam power generation mode): the second valve 2, the third valve 3, the sixth valve 6, the twelfth valve 12, the thirteenth valve 13, and the fifteenth valve 15 are opened, The other valves are closed. The air directly enters the compressor for compression, and then enters the combustion chamber after being heated by the flue gas in the regenerator. The gas generated by the combustion of air and fuel in the combustion chamber enters the turbine to expand and do work. The air is heated in the boiler, then enters the waste heat boiler to produce steam, and finally the flue gas is discharged from the chimney after dewatering by the condenser. The steam produced by the waste heat boiler is re-injected into the combustion chamber and burned together with fuel and air, increasing the amount of gas and thus increasing the work of the turbine. As the steam is reinjected into the combustion chamber, the flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com