Patents

Literature

111results about How to "Expand exports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

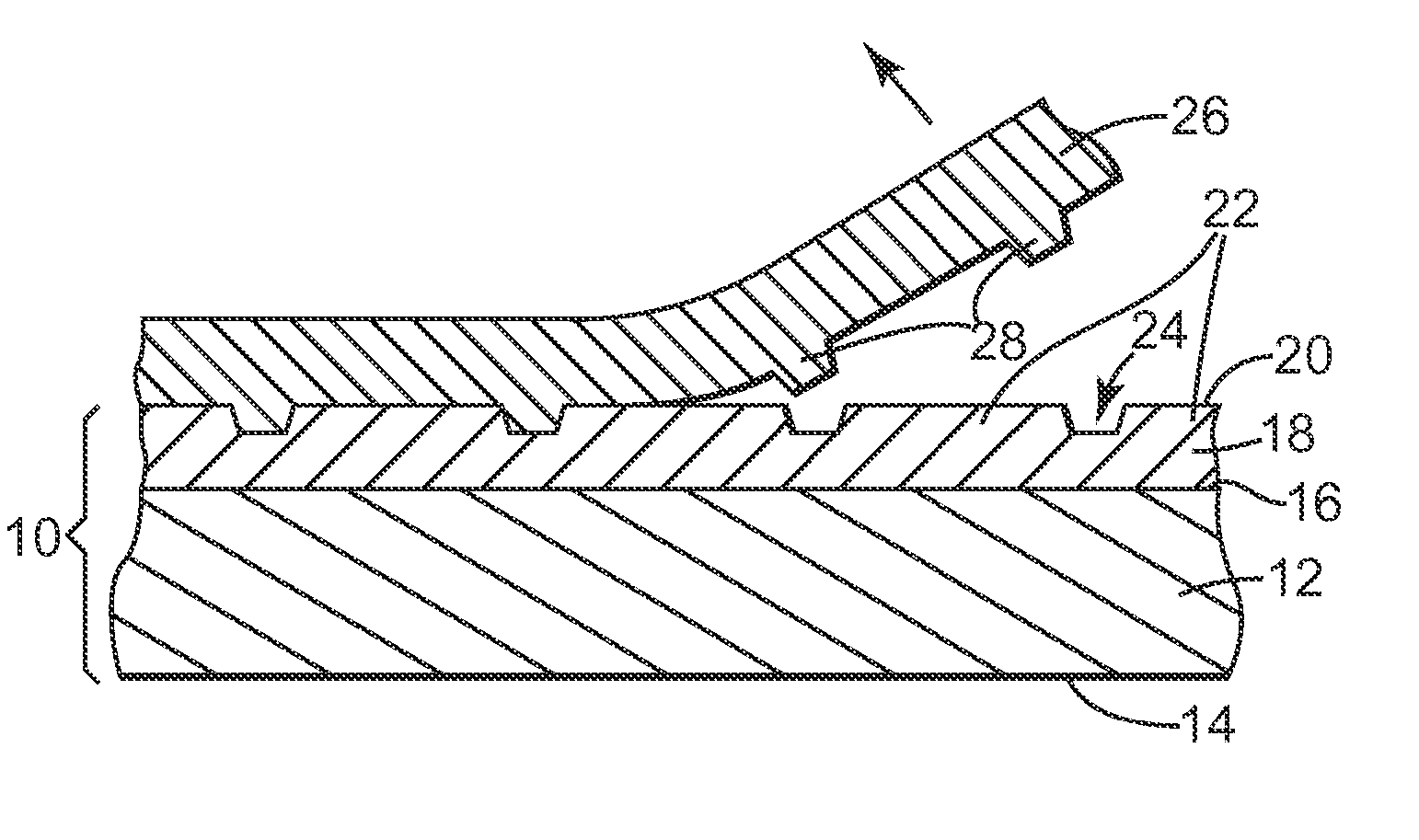

Shunt device and method for treating glaucoma

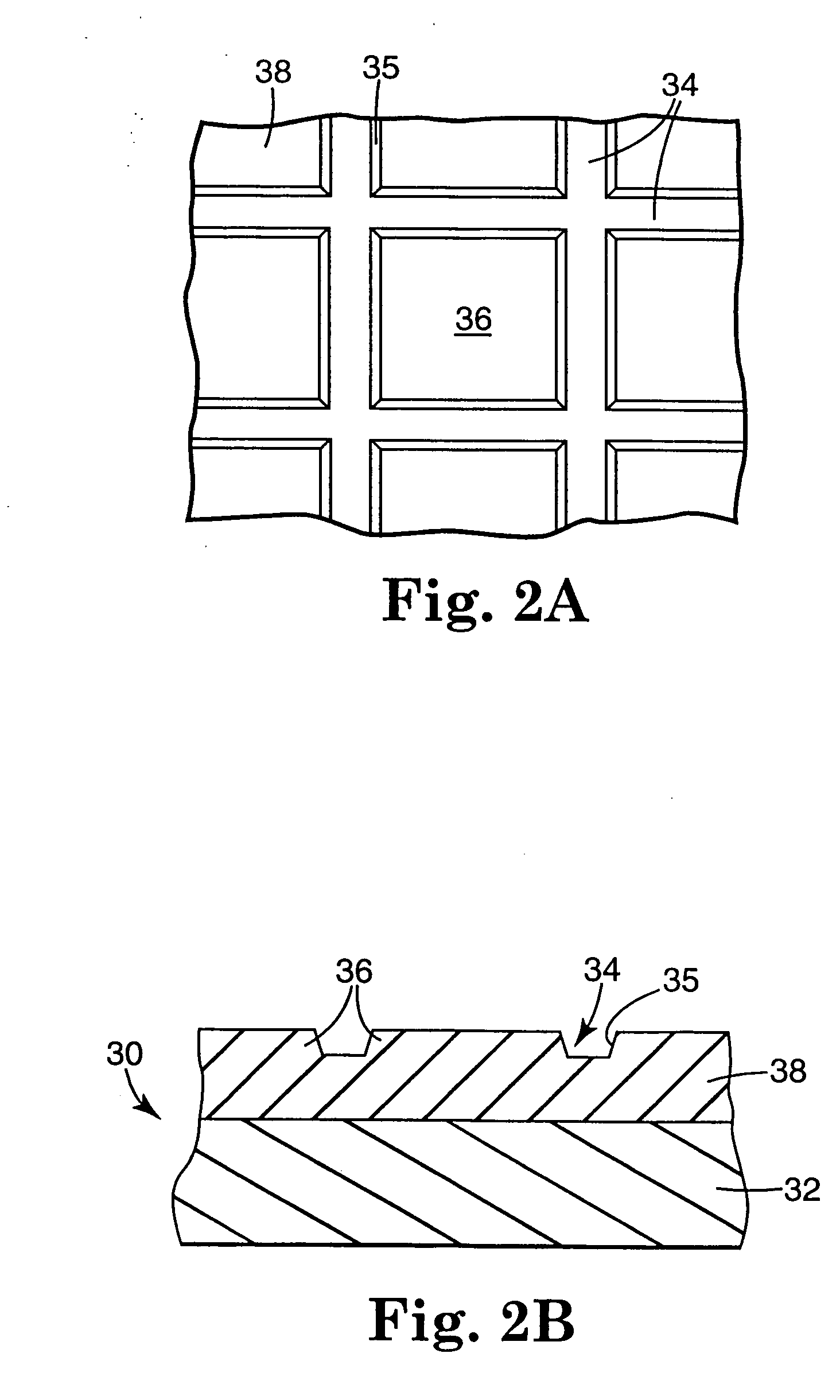

InactiveUS20050119601A9Expand exportsFacilitates the normal physiologic pathwayEye surgeryMedical devicesShunt DeviceAqueous humor

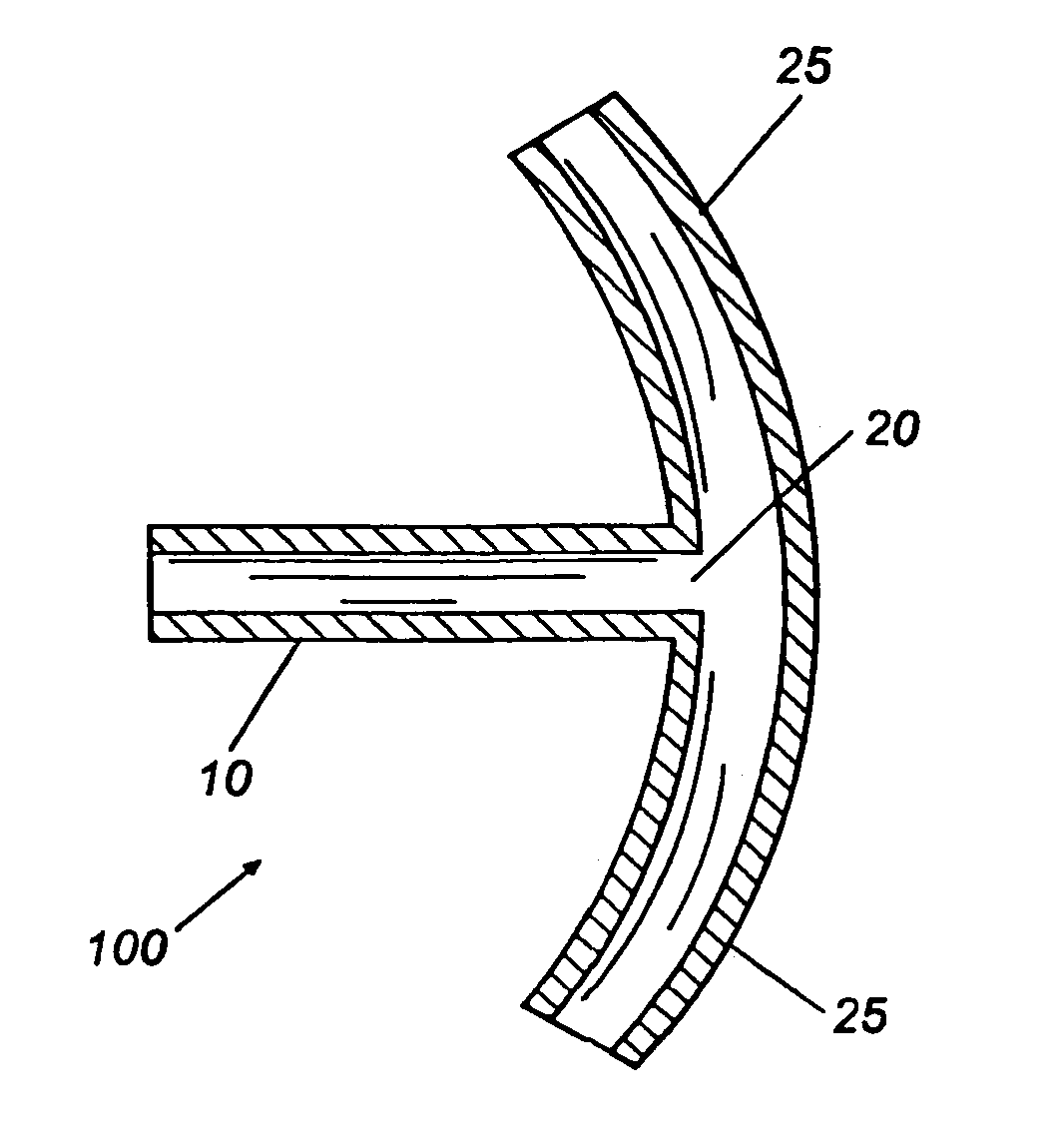

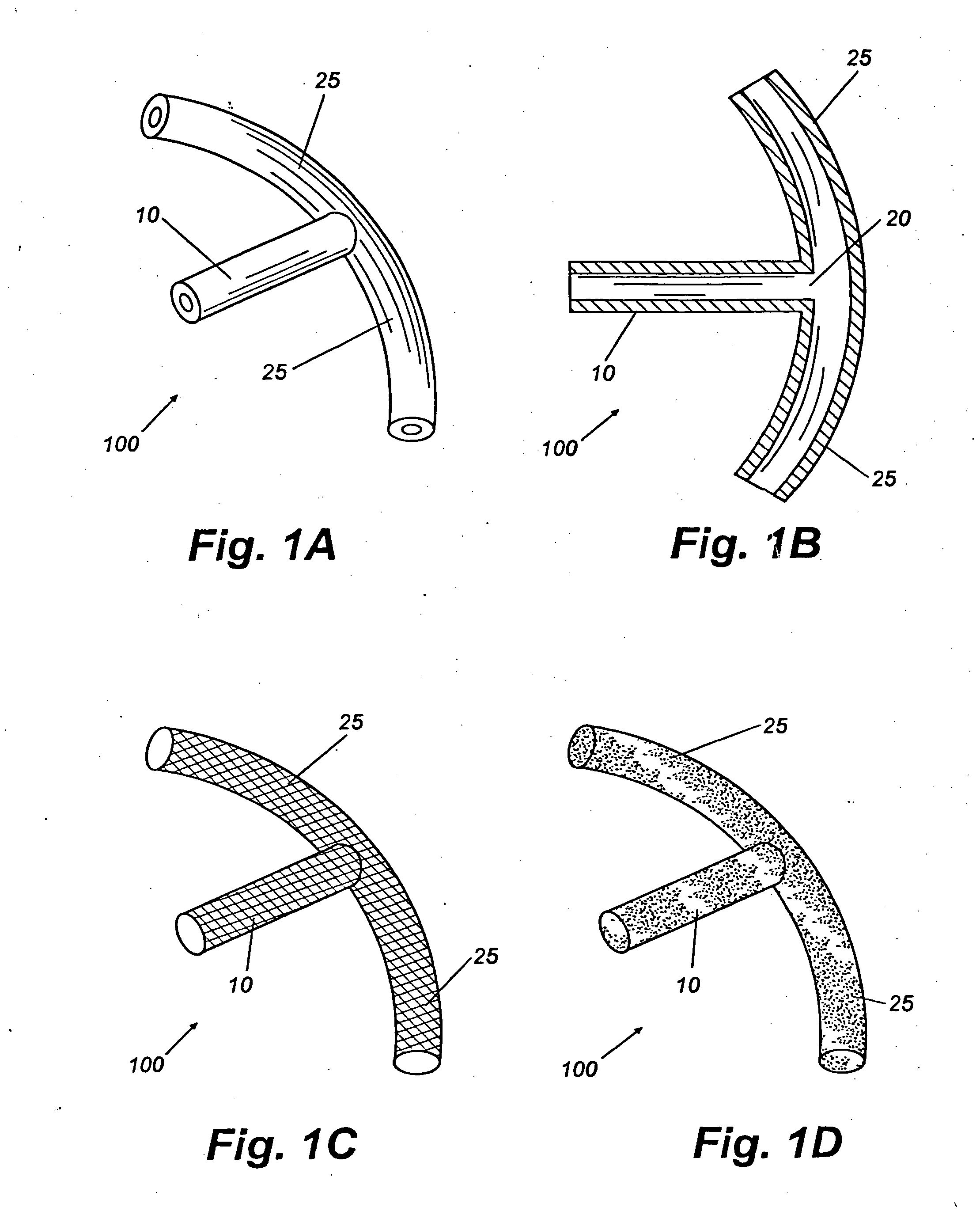

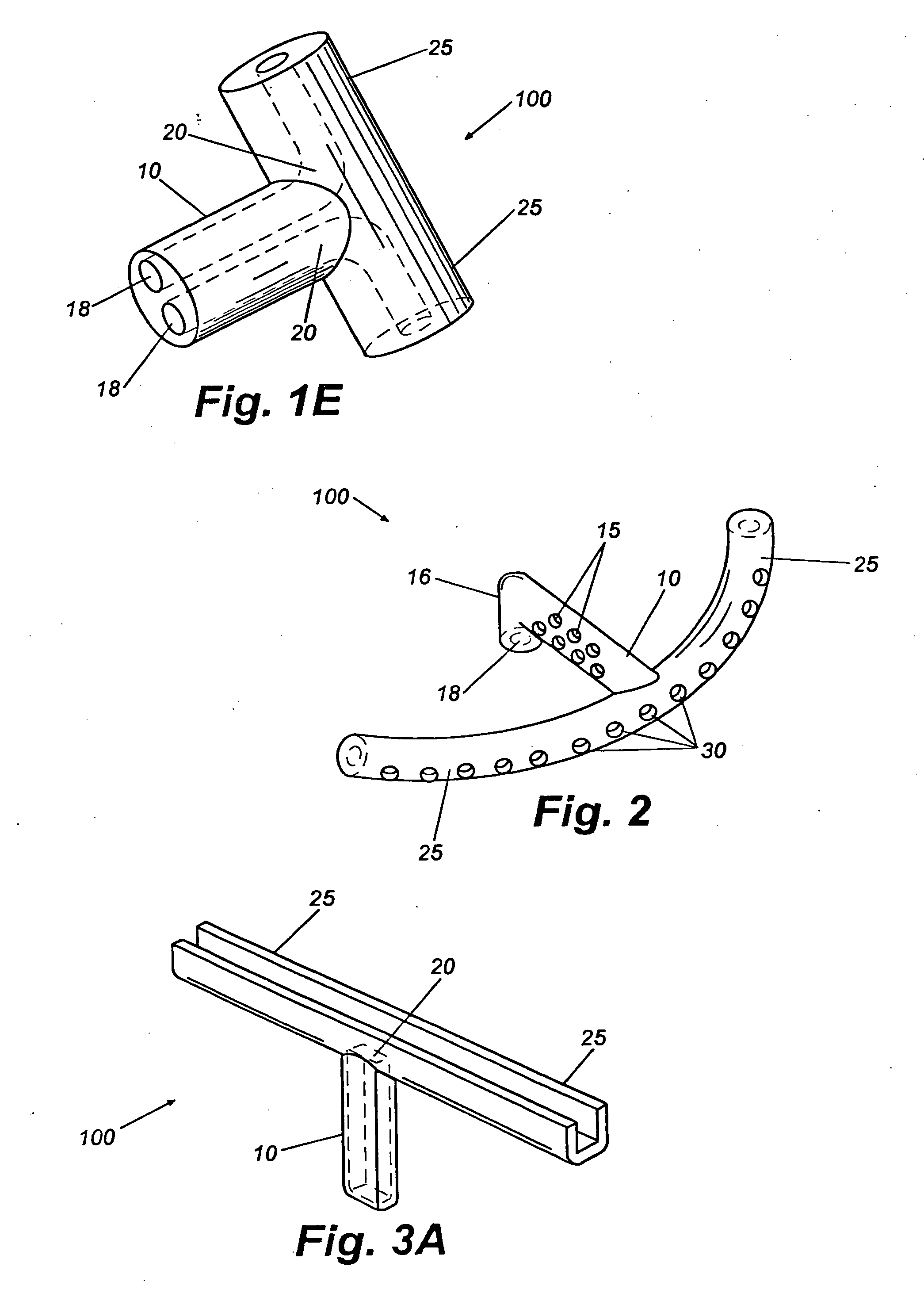

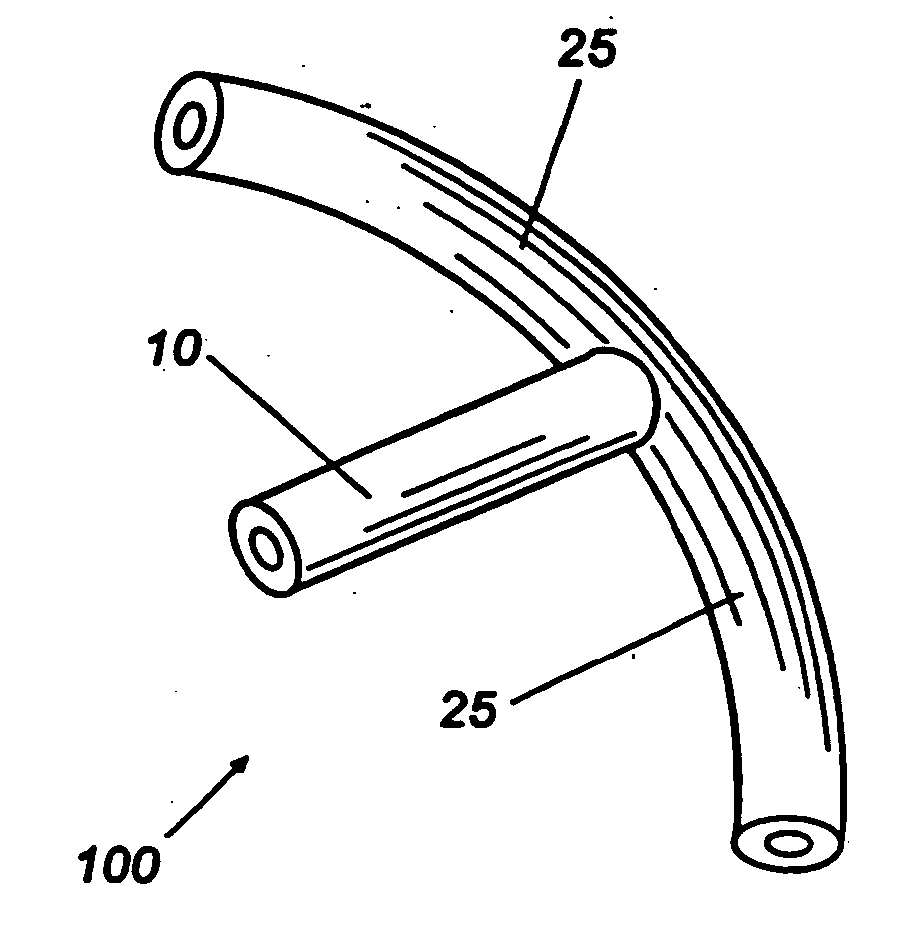

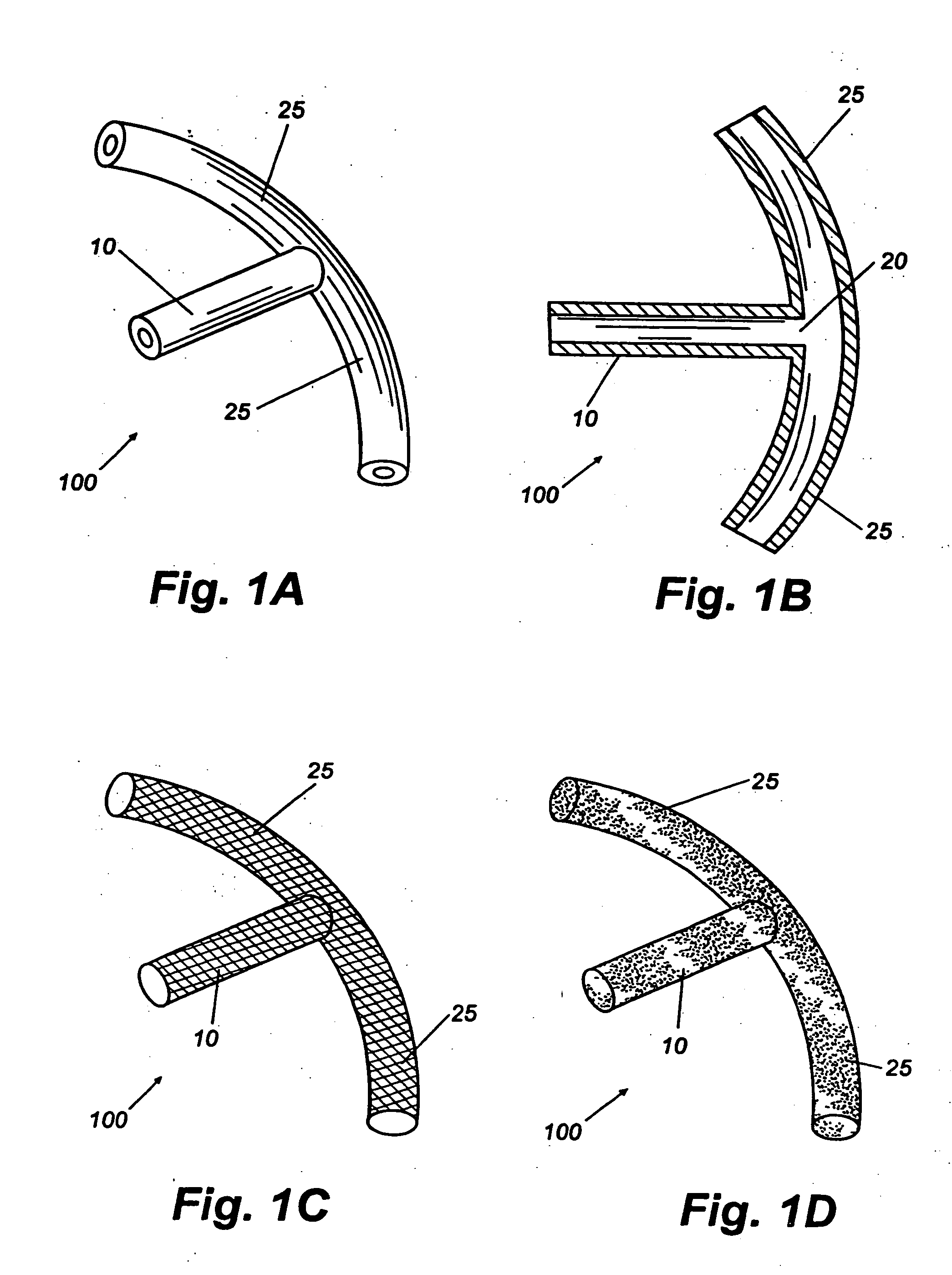

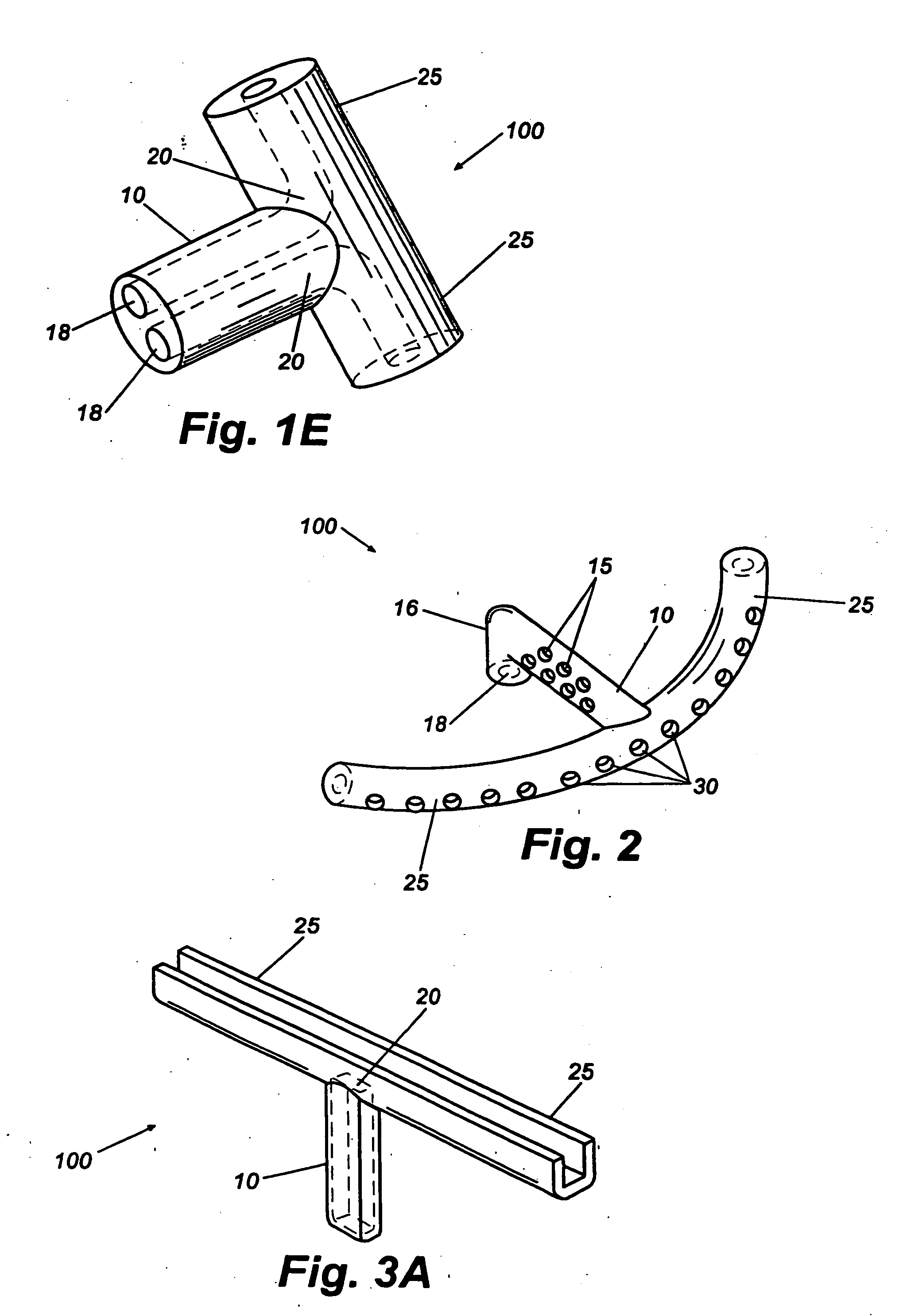

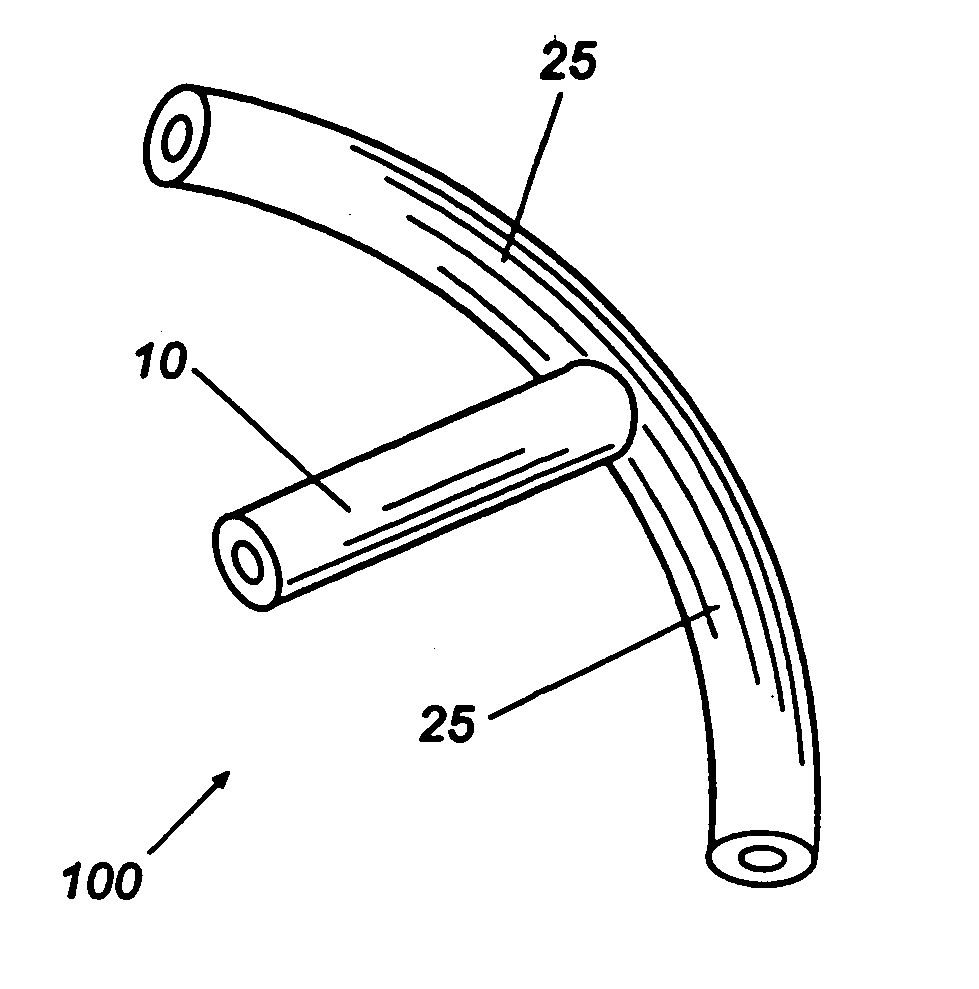

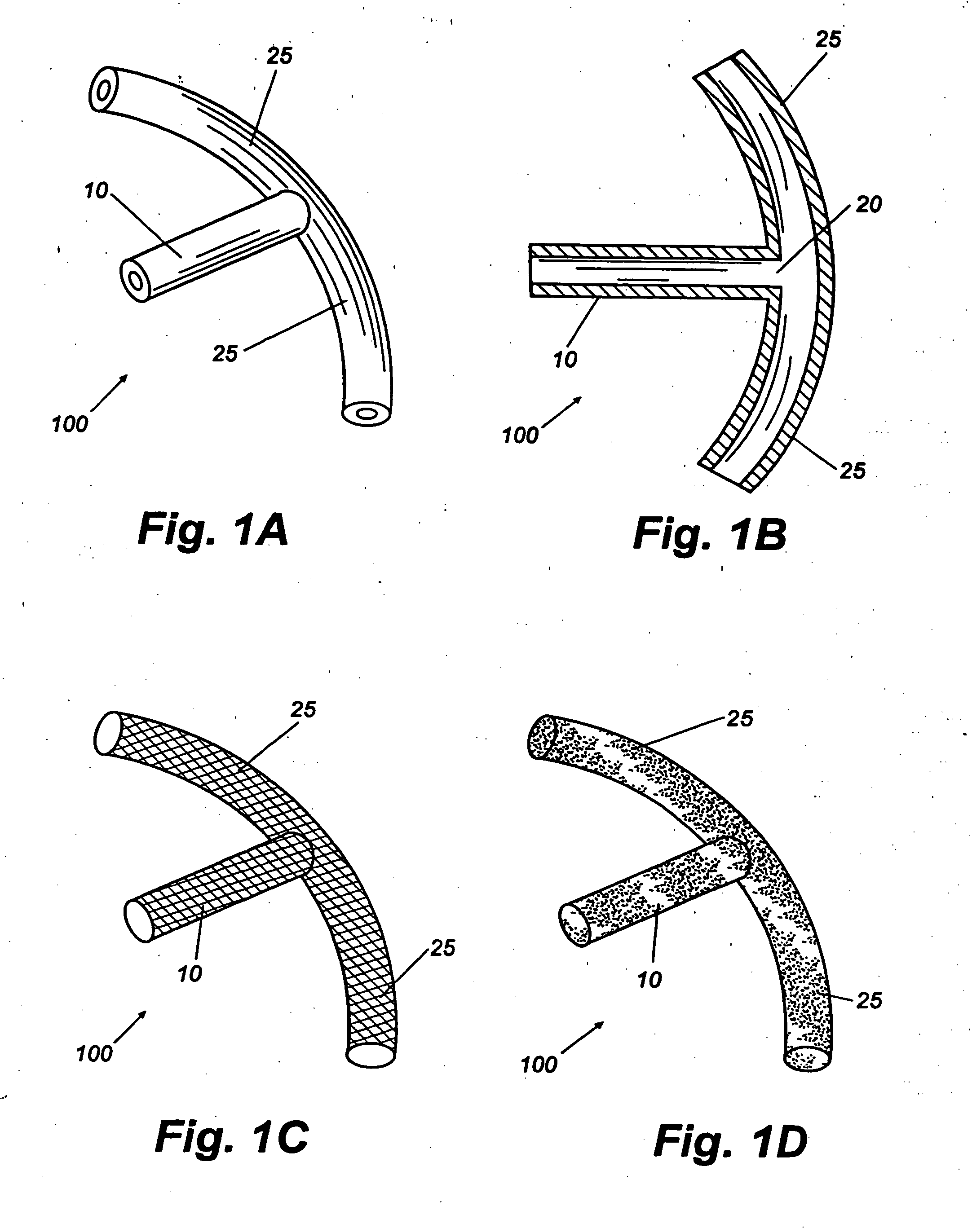

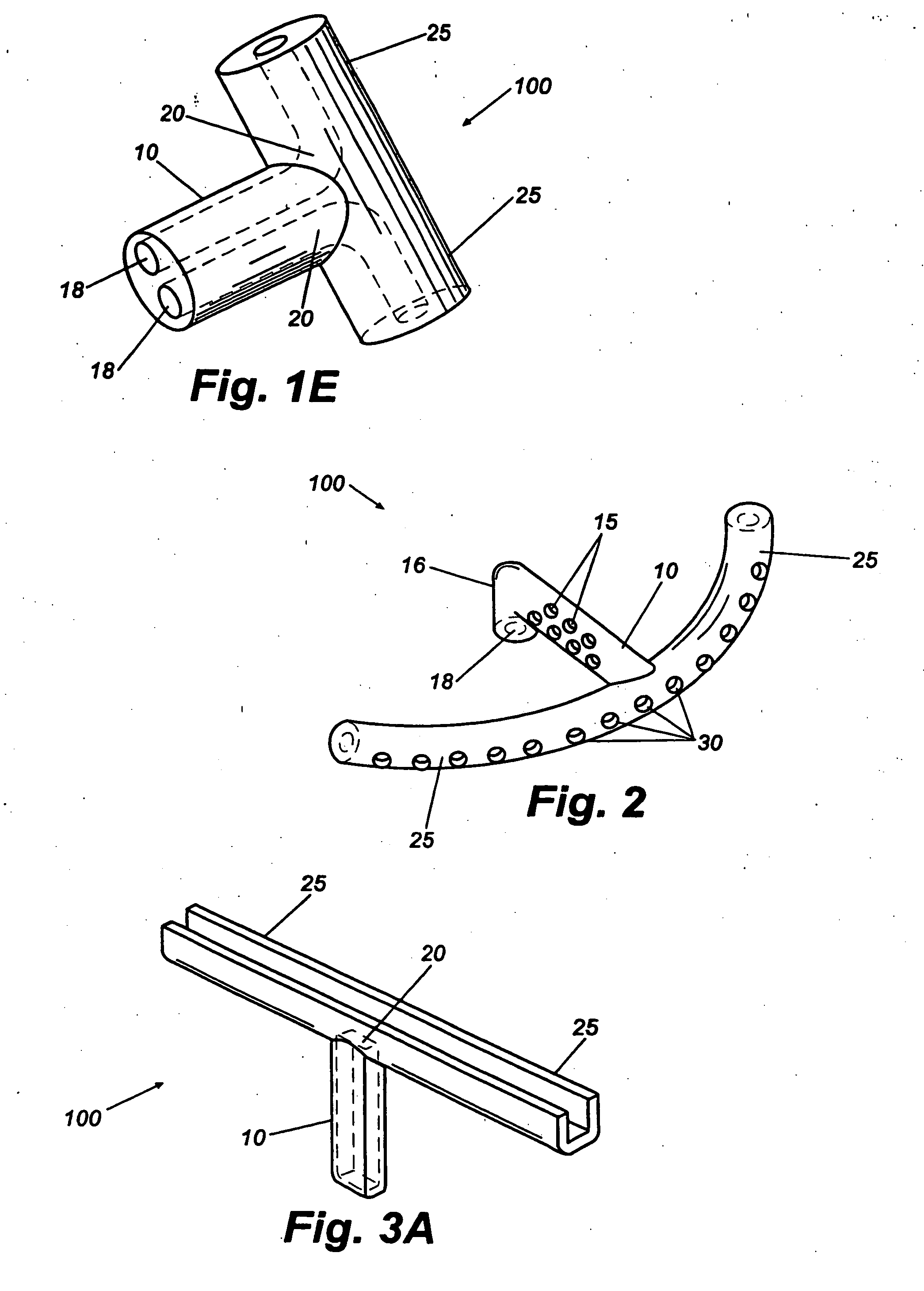

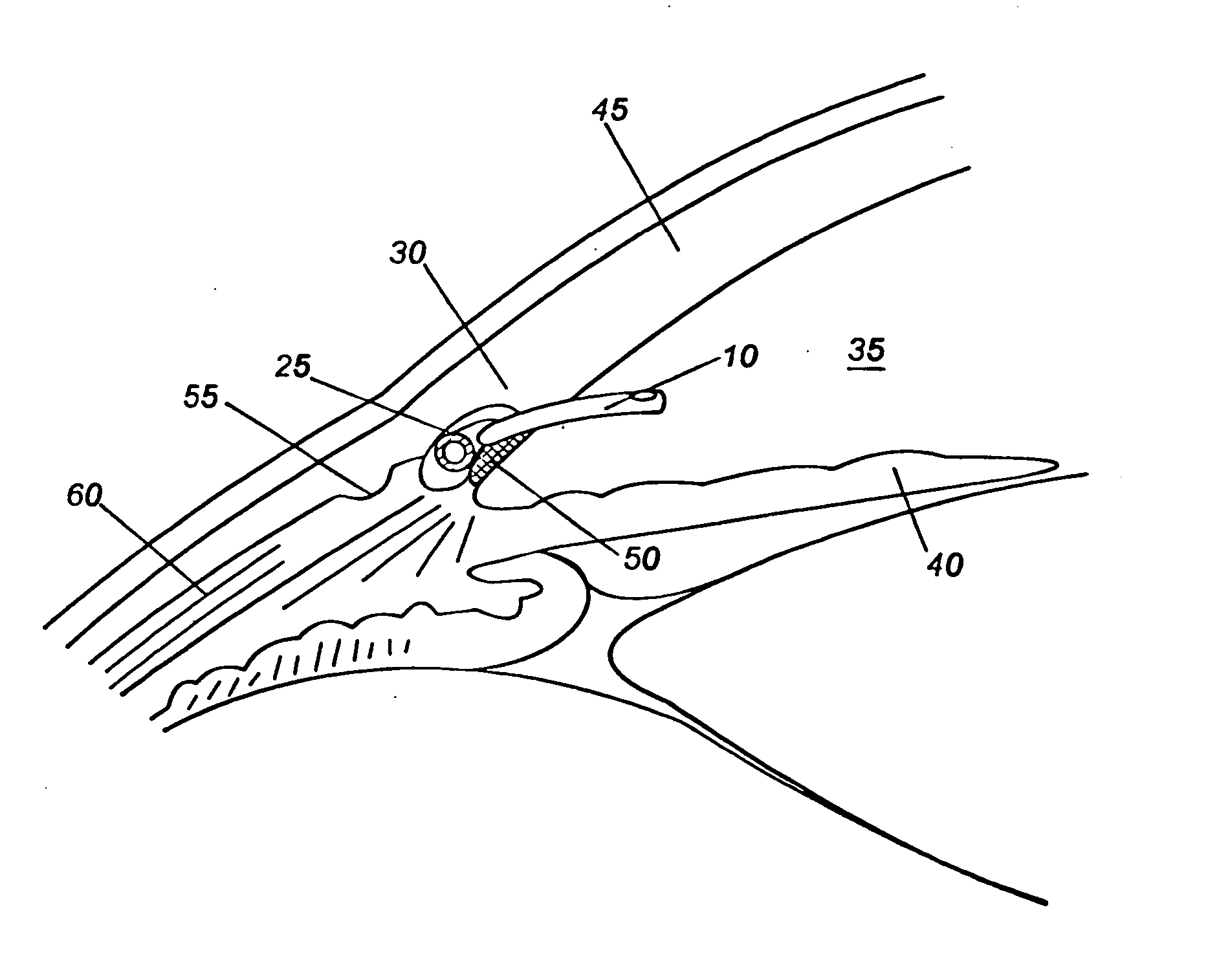

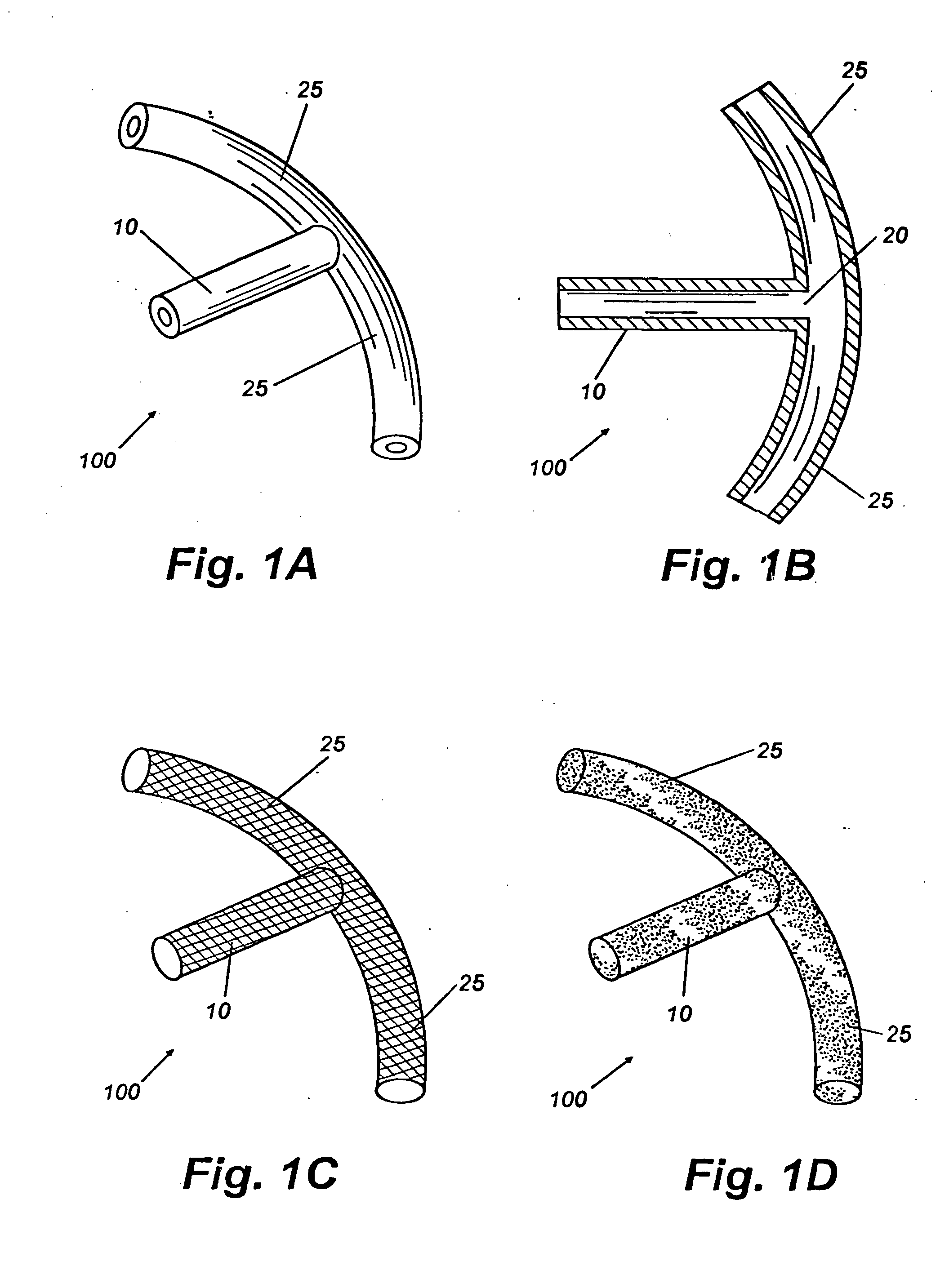

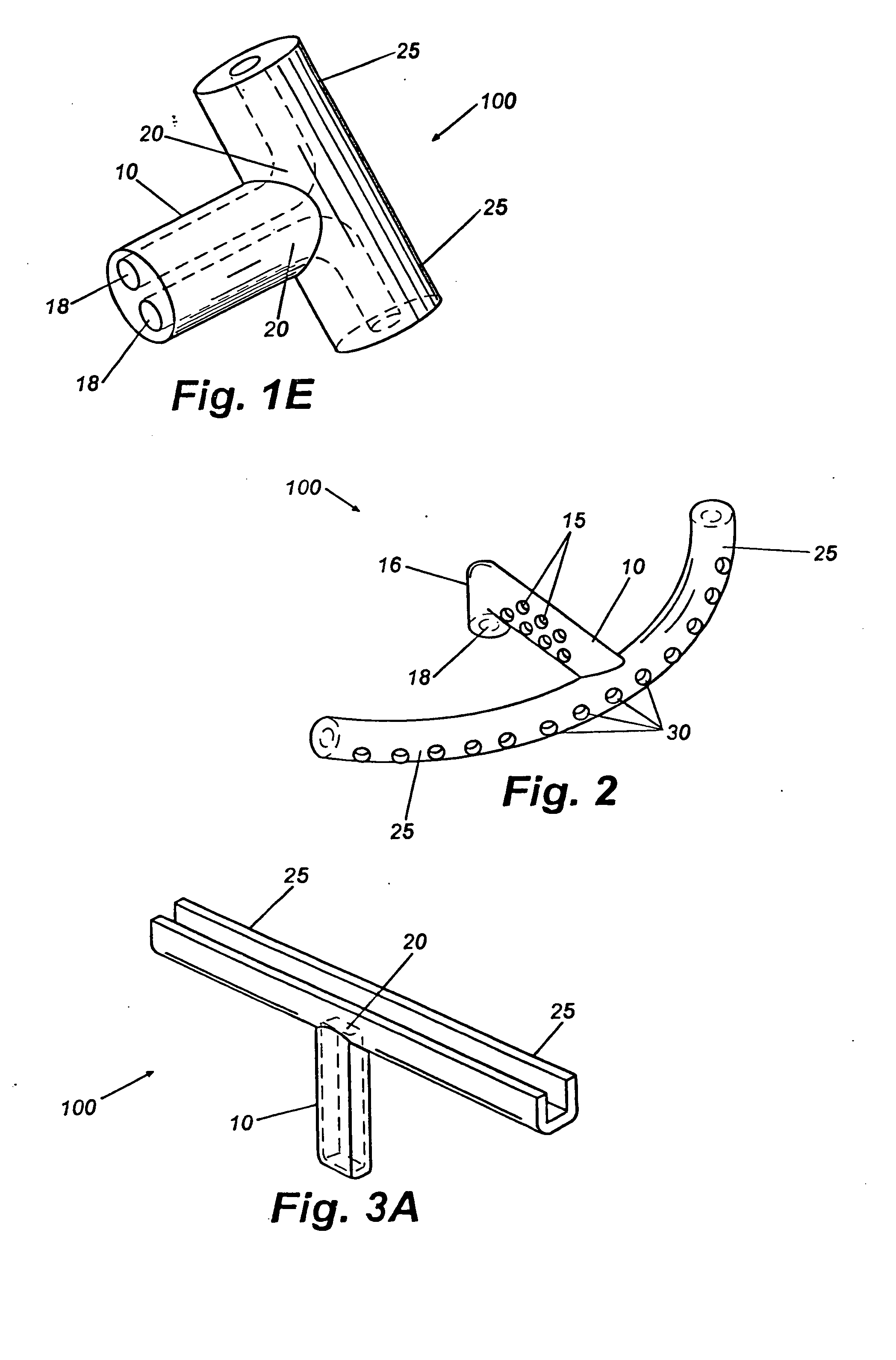

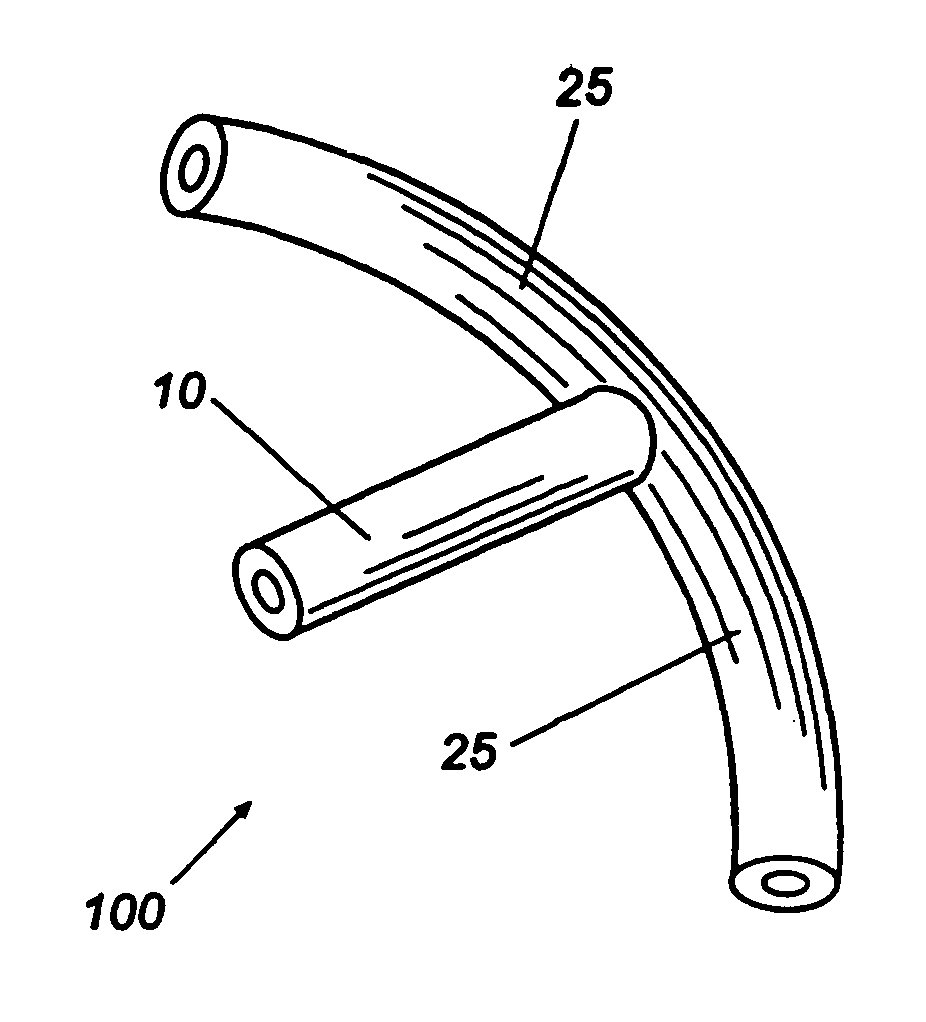

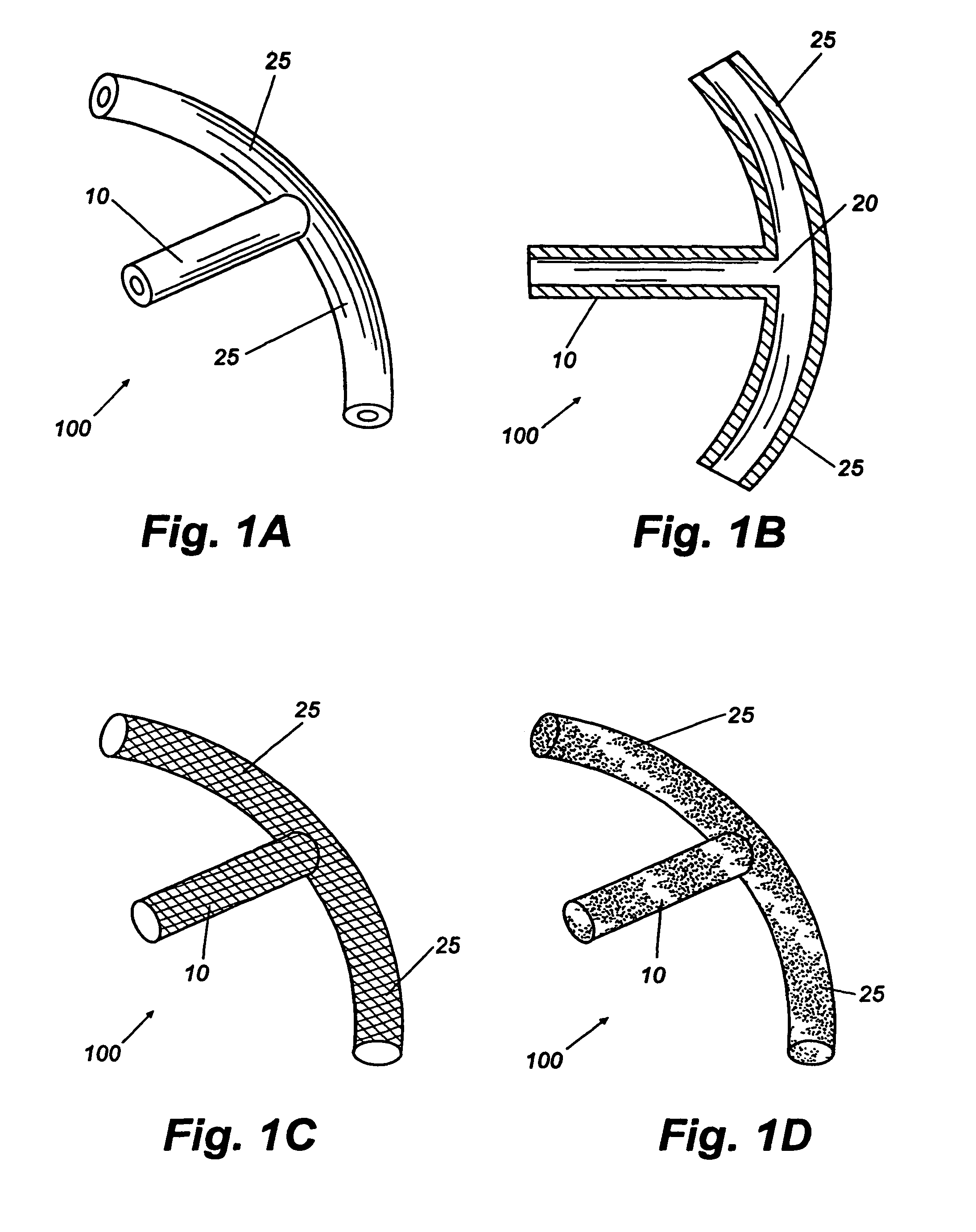

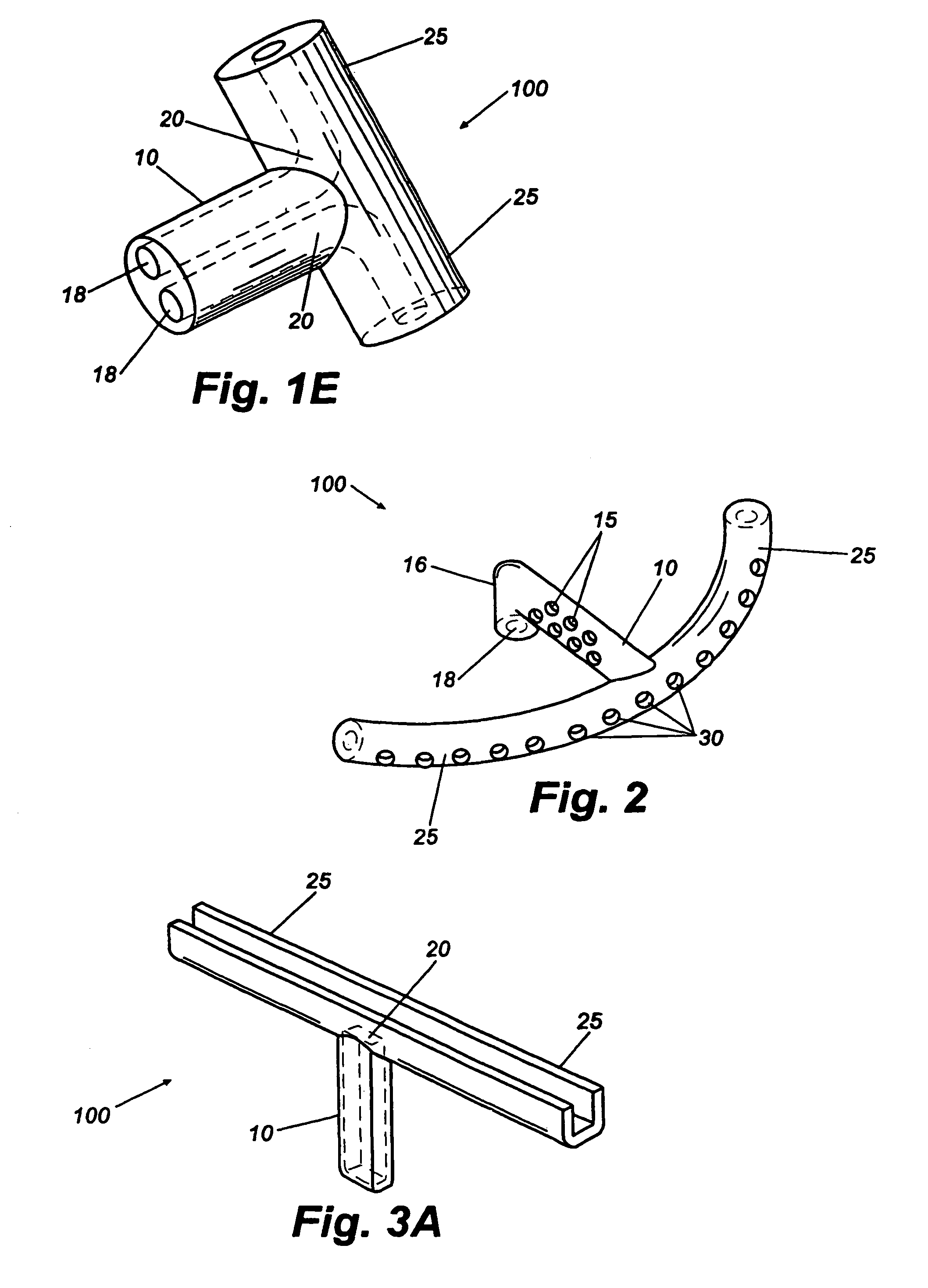

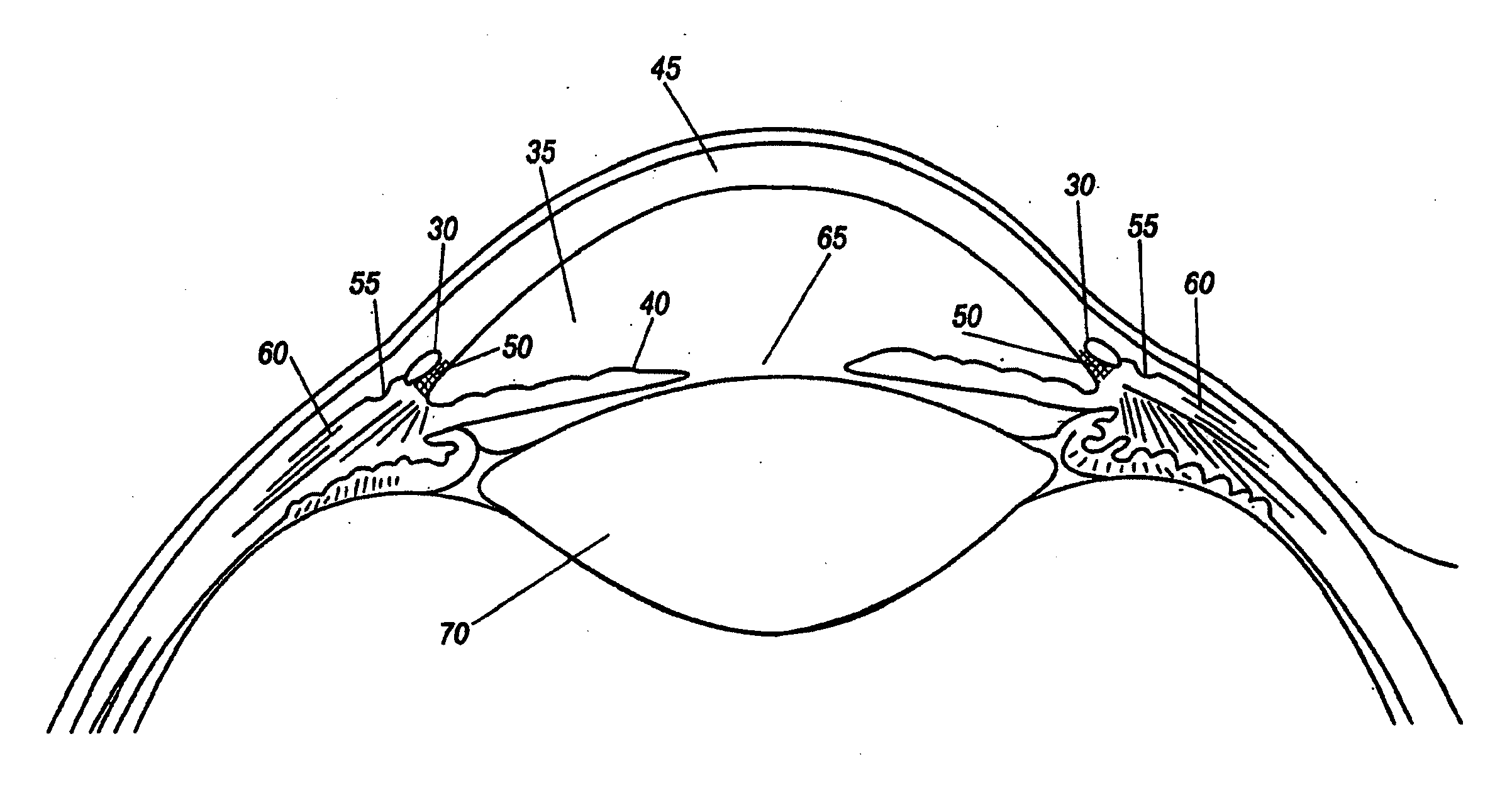

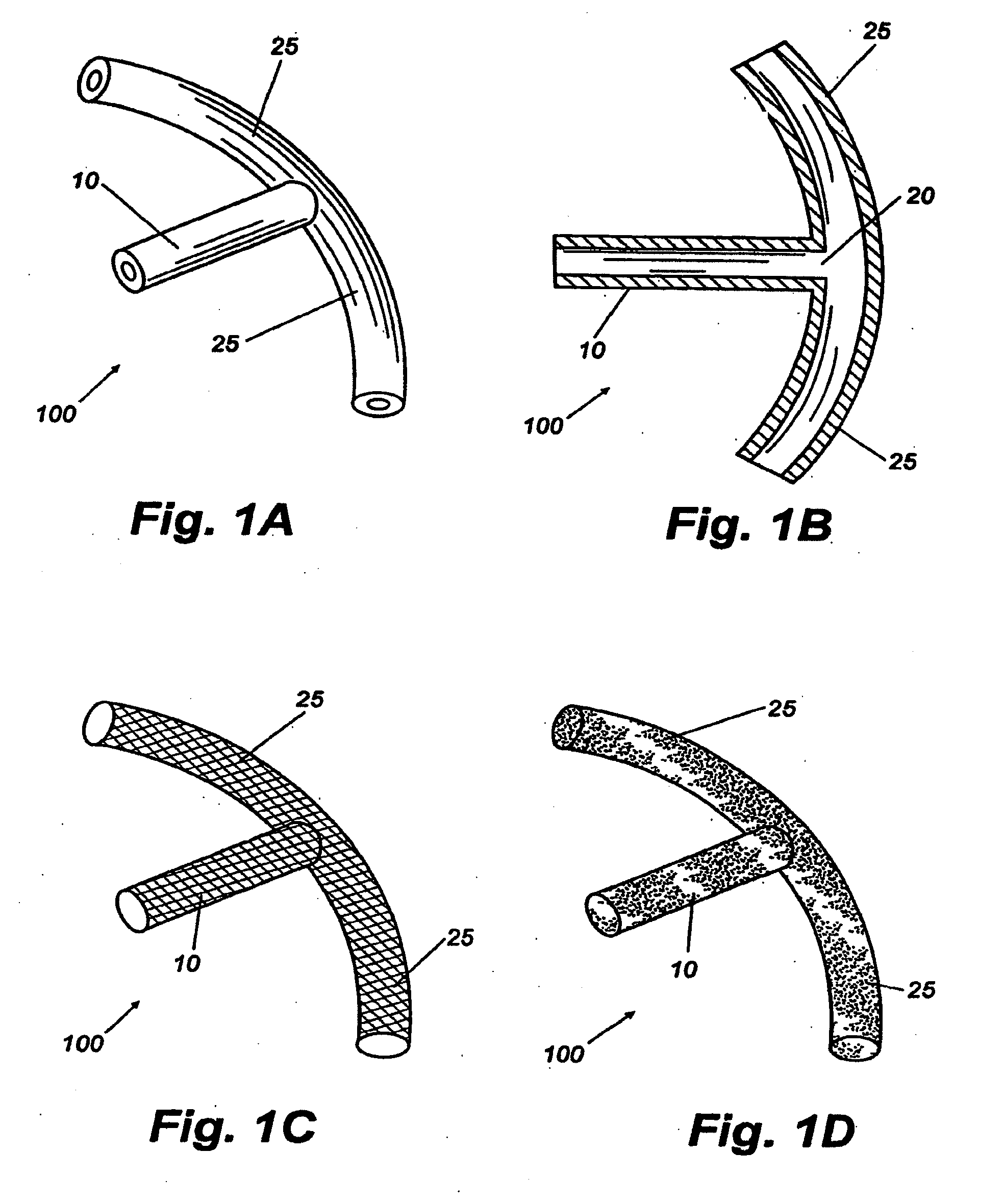

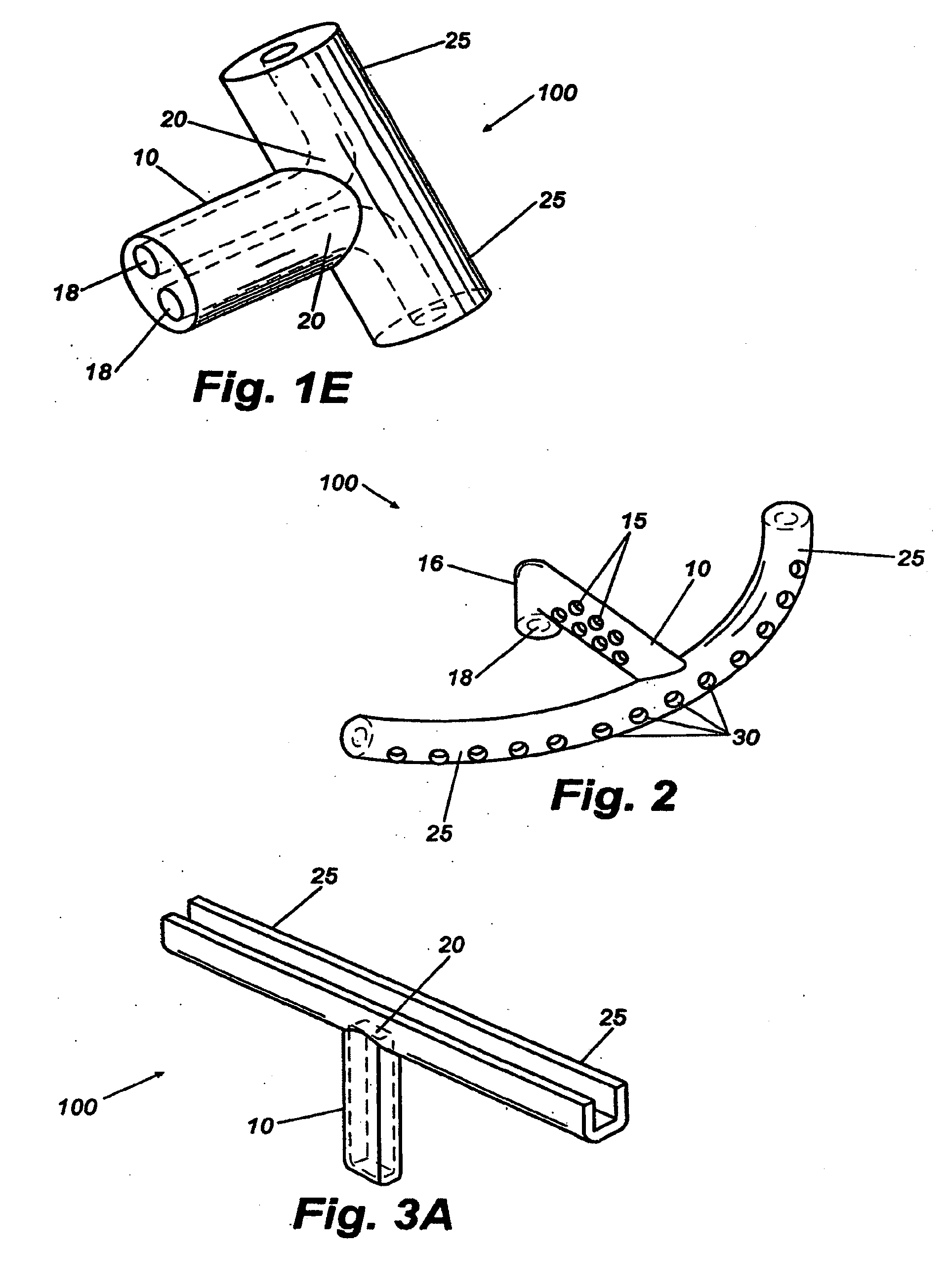

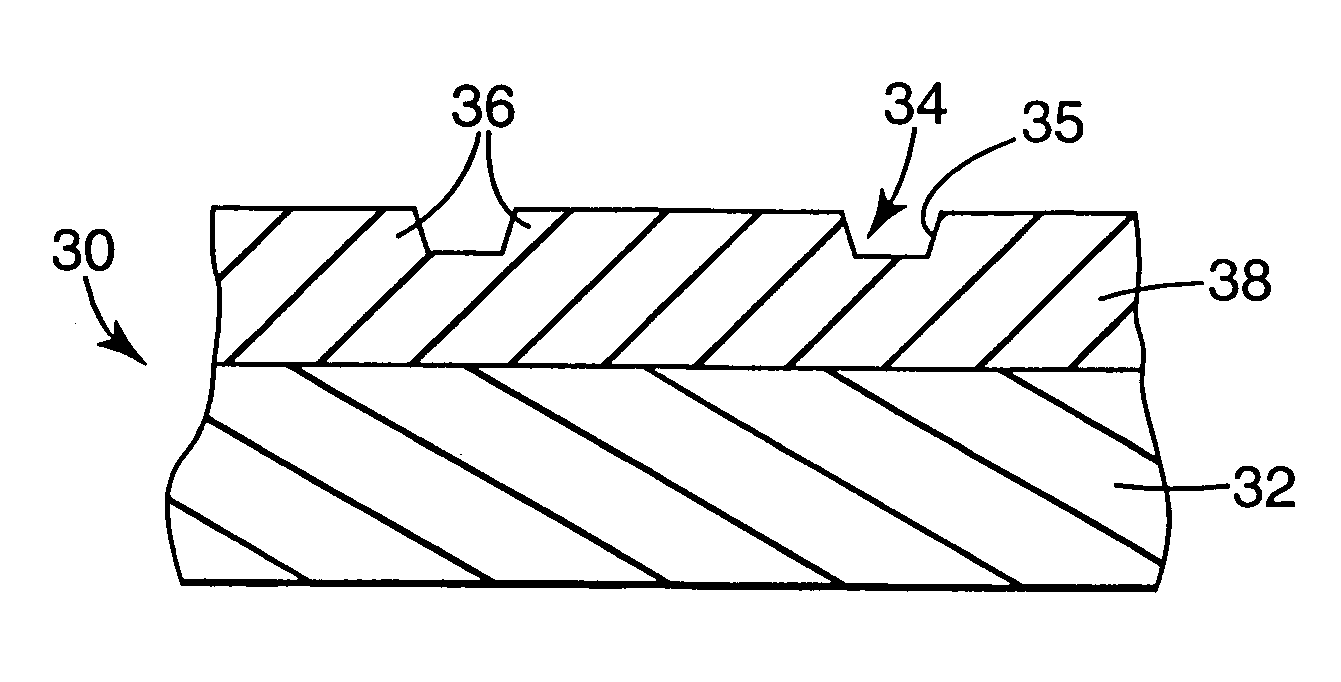

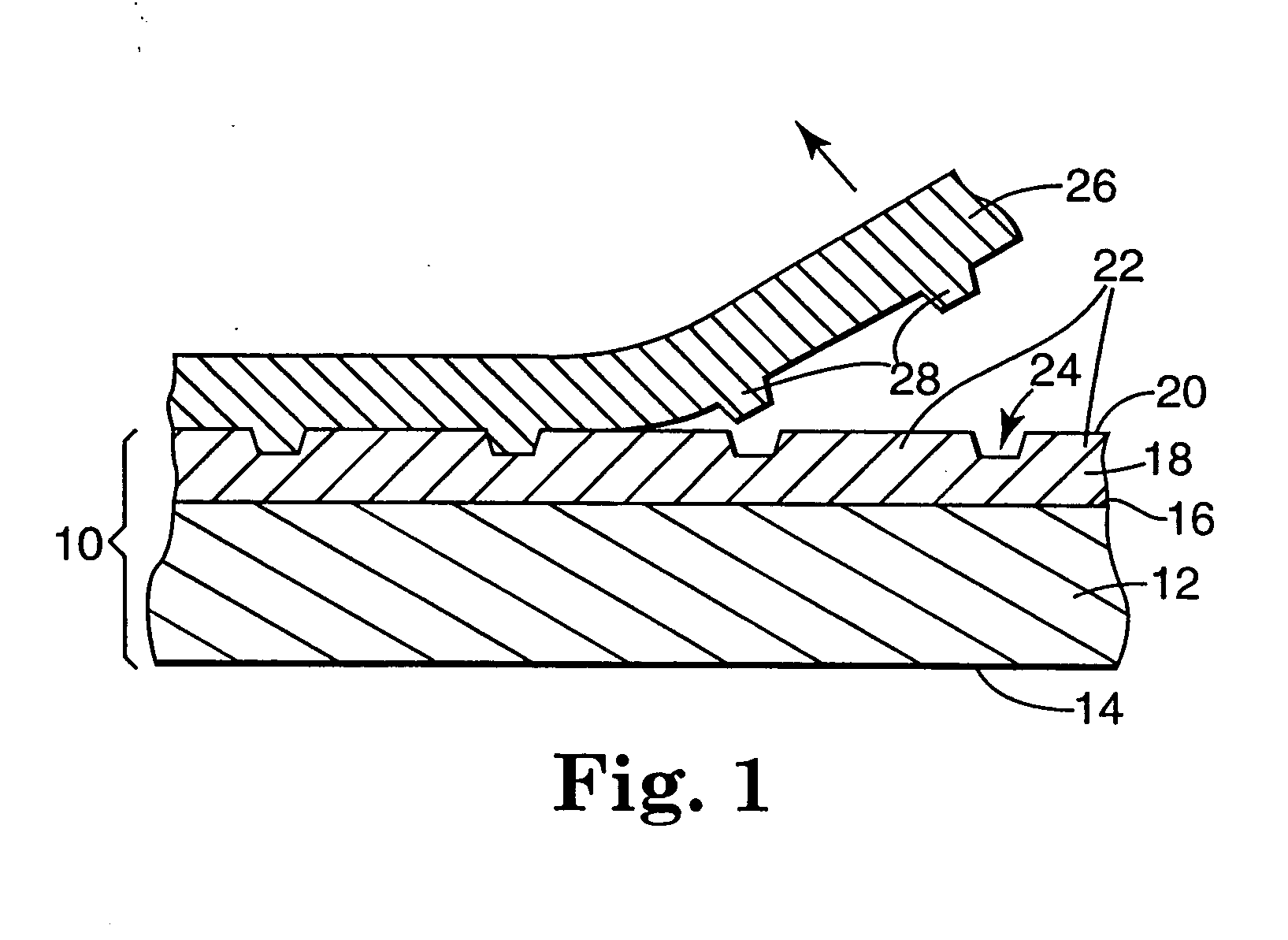

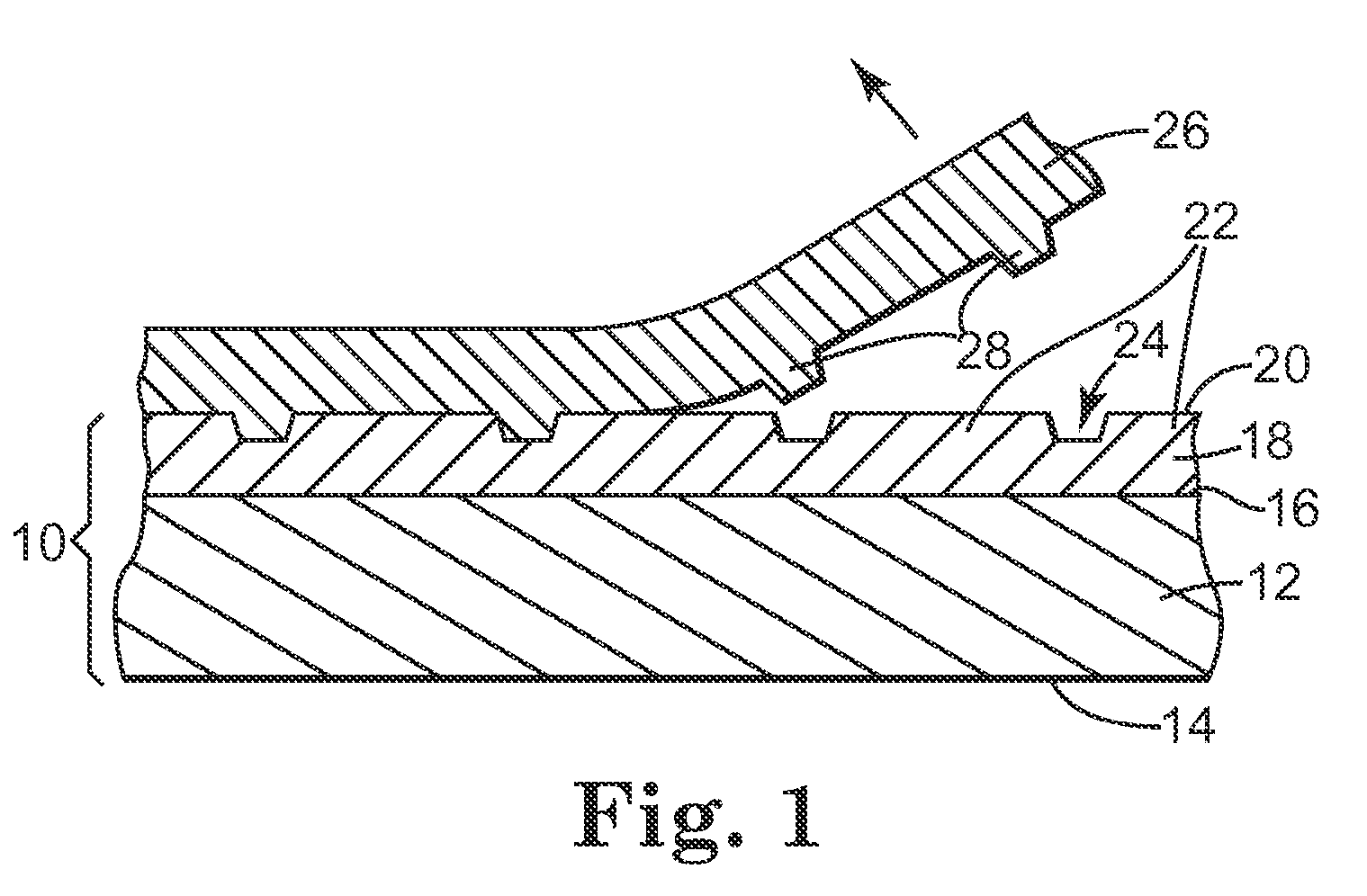

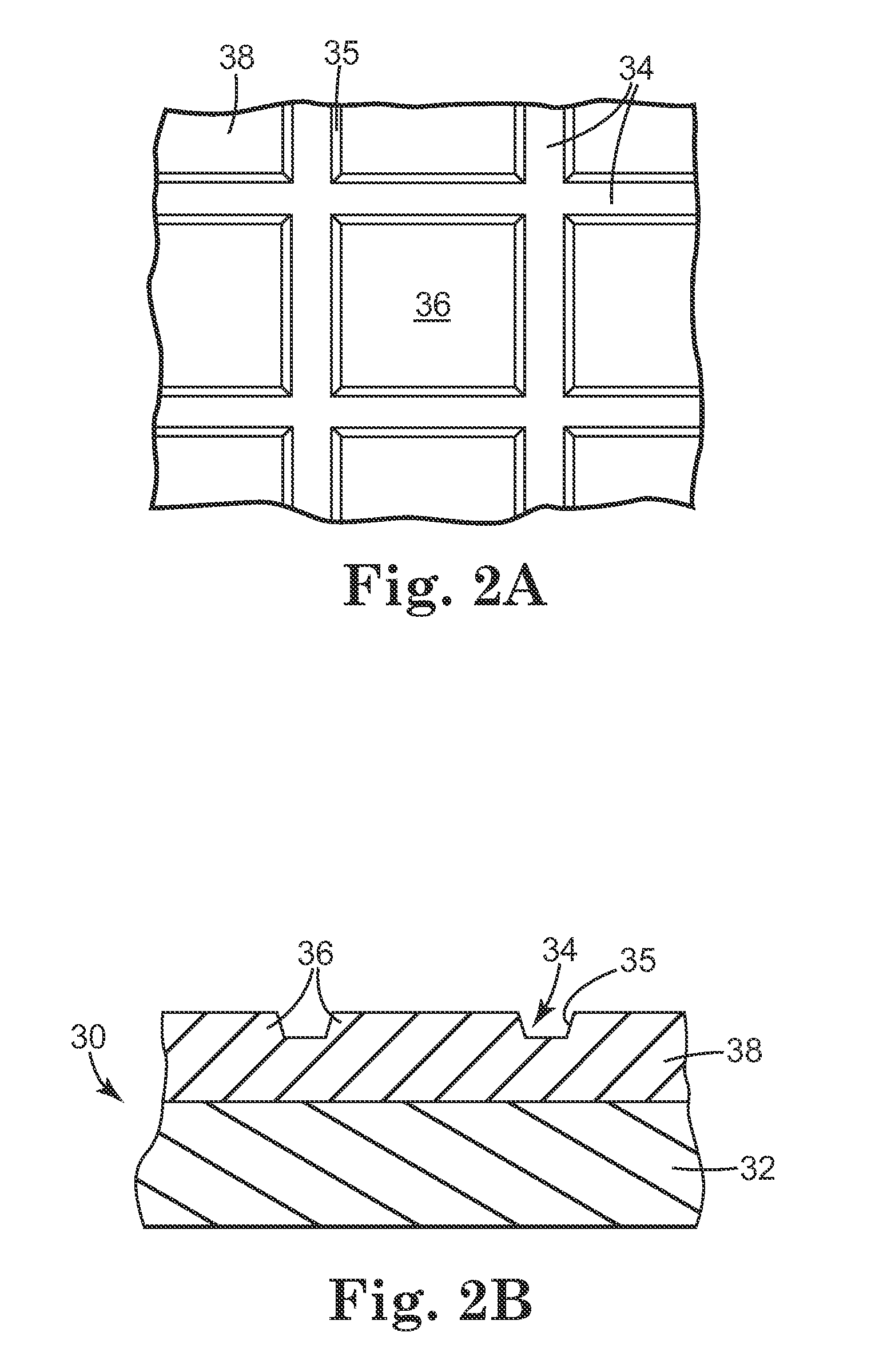

The present invention provides a shunt for the flow of aqueous humor from the anterior chamber of the eye to Schlemm's canal. The device comprises at least one lumen and optionally has at least one anchor extending from the proximal portion within the anterior chamber to assist in placement and anchoring of the device in the correct anatomic position.

Owner:GMP VISION SOLUTIONS

Shunt device and method for treating glaucoma

InactiveUS20050090807A1Increase egressExpand exportsEye implantsEar treatmentSchlemm's canalSurgical procedures

Shunt devices and a method for continuously decompressing elevated intraocular pressure in eyes affected by glaucoma by diverting excess aqueous humor from the anterior chamber of the eye into Schlemm's canal where post-operative patency can be maintained with an indwelling shunt device which surgically connects the canal with the anterior chamber. The shunt devices provide uni- or bi-directional flow of aqueous humor into Schlemm's canal.

Owner:GLAUKOS CORP

Shunt device and method for treating glaucoma

InactiveUS20050090806A1Increase egressExpand exportsEye implantsEar treatmentSchlemm's canalSurgical procedures

Shunt devices and a method for continuously decompressing elevated intraocular pressure in eyes affected by glaucoma by diverting excess aqueous humor from the anterior chamber of the eye into Schlemm's canal where post-operative patency can be maintained with an indwelling shunt device which surgically connects the canal with the anterior chamber. The shunt devices provide uni- or bi-directional flow of aqueous humor into Schlemm's canal.

Owner:GLAUKOS CORP

Shunt device and method for treating glaucoma

InactiveUS20050038334A1Easy to optimizeExpand exportsOrganic active ingredientsEye surgeryShunt DeviceAqueous humor

The present invention provides a shunt for the flow of aqueous humor from the anterior chamber of the eye to Schlemm's canal. The device comprises at least one lumen and optionally has at least one anchor extending from the proximal portion within the anterior chamber to assist in placement and anchoring of the device in the correct anatomic position.

Owner:GLAUKOS CORP

Shunt device and method for treating glaucoma

InactiveUS7850637B2Expand exportsFacilitates the normal physiologic pathwayEye implantsEar treatmentShunt DeviceAqueous humor

Shunt devices and a method for continuously decompressing elevated intraocular pressure in eyes affected by glaucoma by diverting excess aqueous humor from the anterior chamber of the eye into Schlemm's canal where post-operative patency can be maintained with an indwelling shunt device which surgically connects the canal with the anterior chamber. The shunt devices provide uni- or bi-directional flow of aqueous humor into Schlemm's canal.

Owner:GLAUKOS CORP

Shunt device and method for treating ocular disorders

InactiveUS20100004580A1Expand exportsFacilitates the normal physiologic pathwayEye surgeryWound drainsShunt DeviceAqueous humor

Owner:GLAUKOS CORP

Adhesive-backed articles

InactiveUS20060188704A1Expand exportsAdversely affecting appearanceMechanical working/deformationLamination ancillary operationsEngineeringPressure sensitive

Owner:3M INNOVATIVE PROPERTIES CO

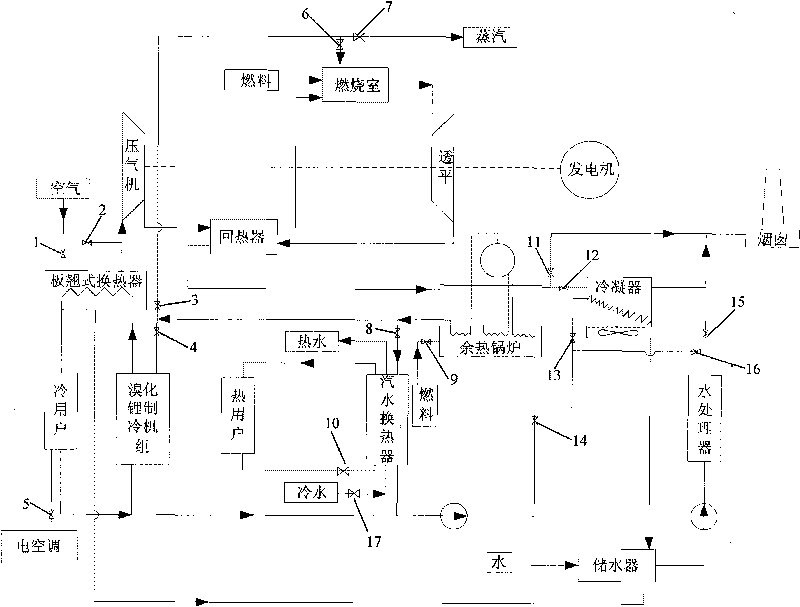

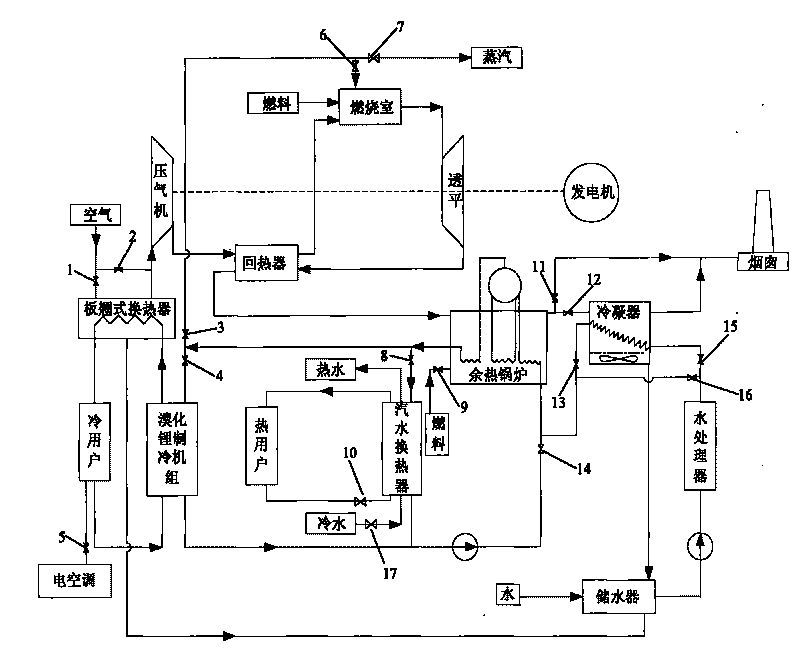

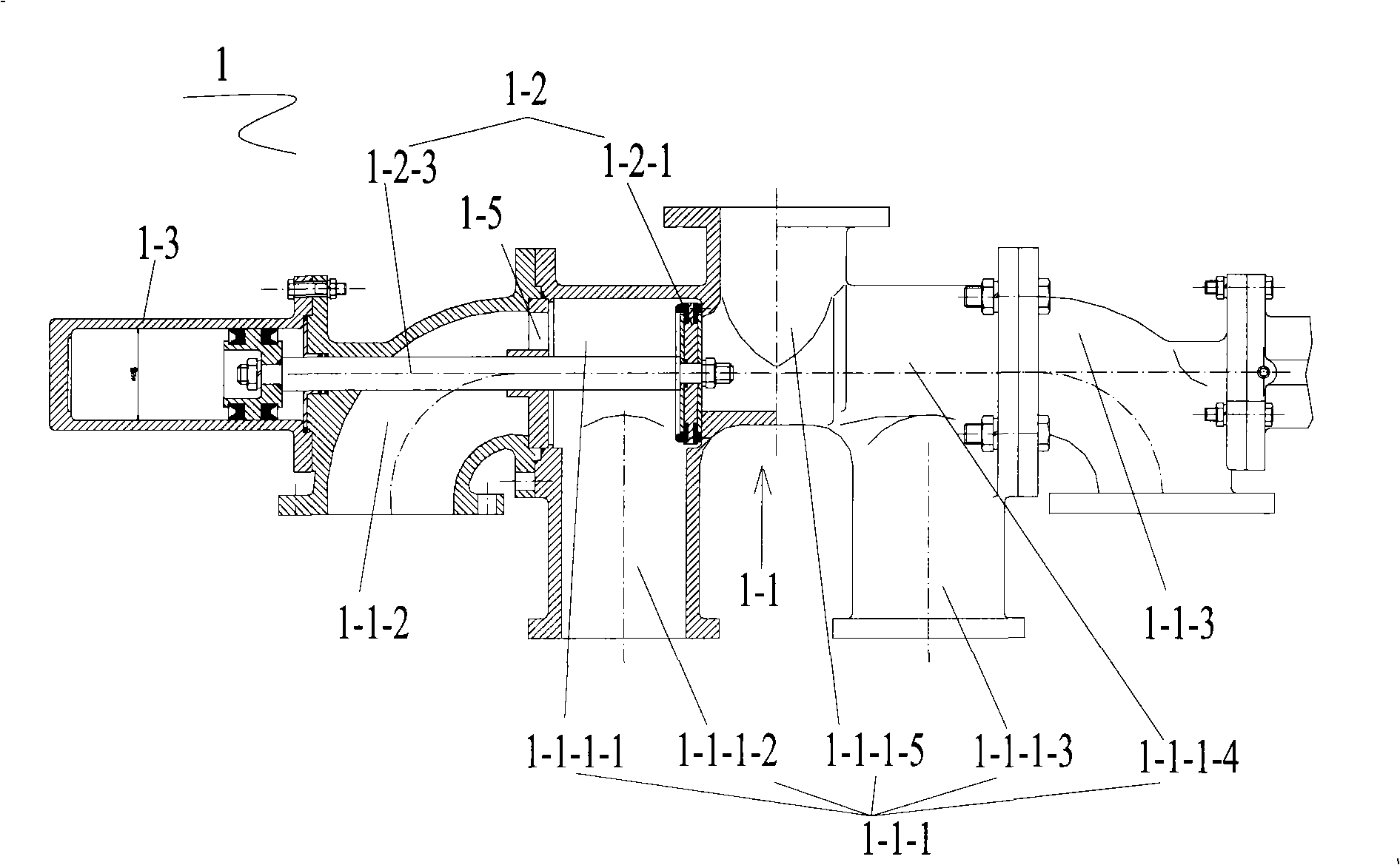

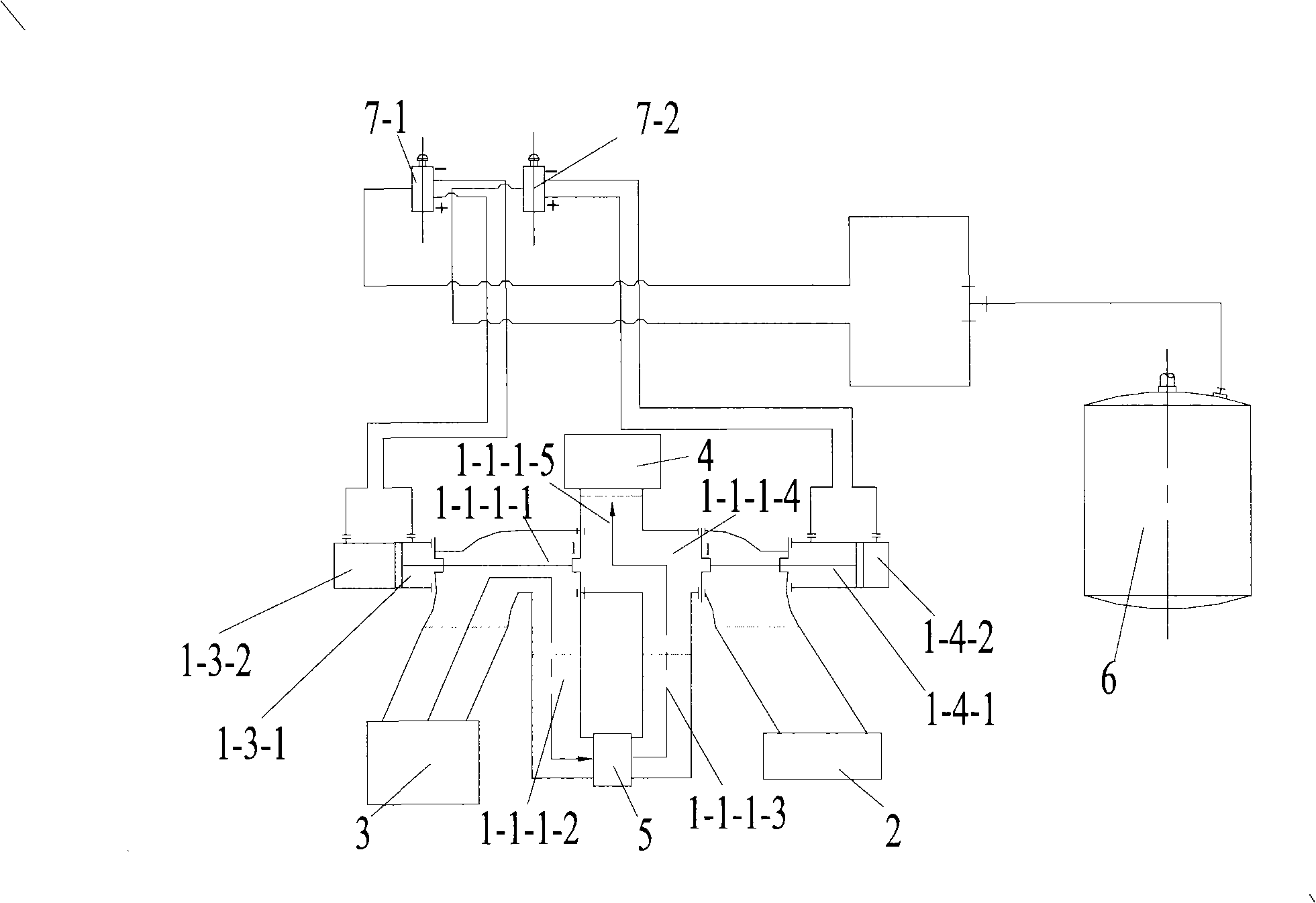

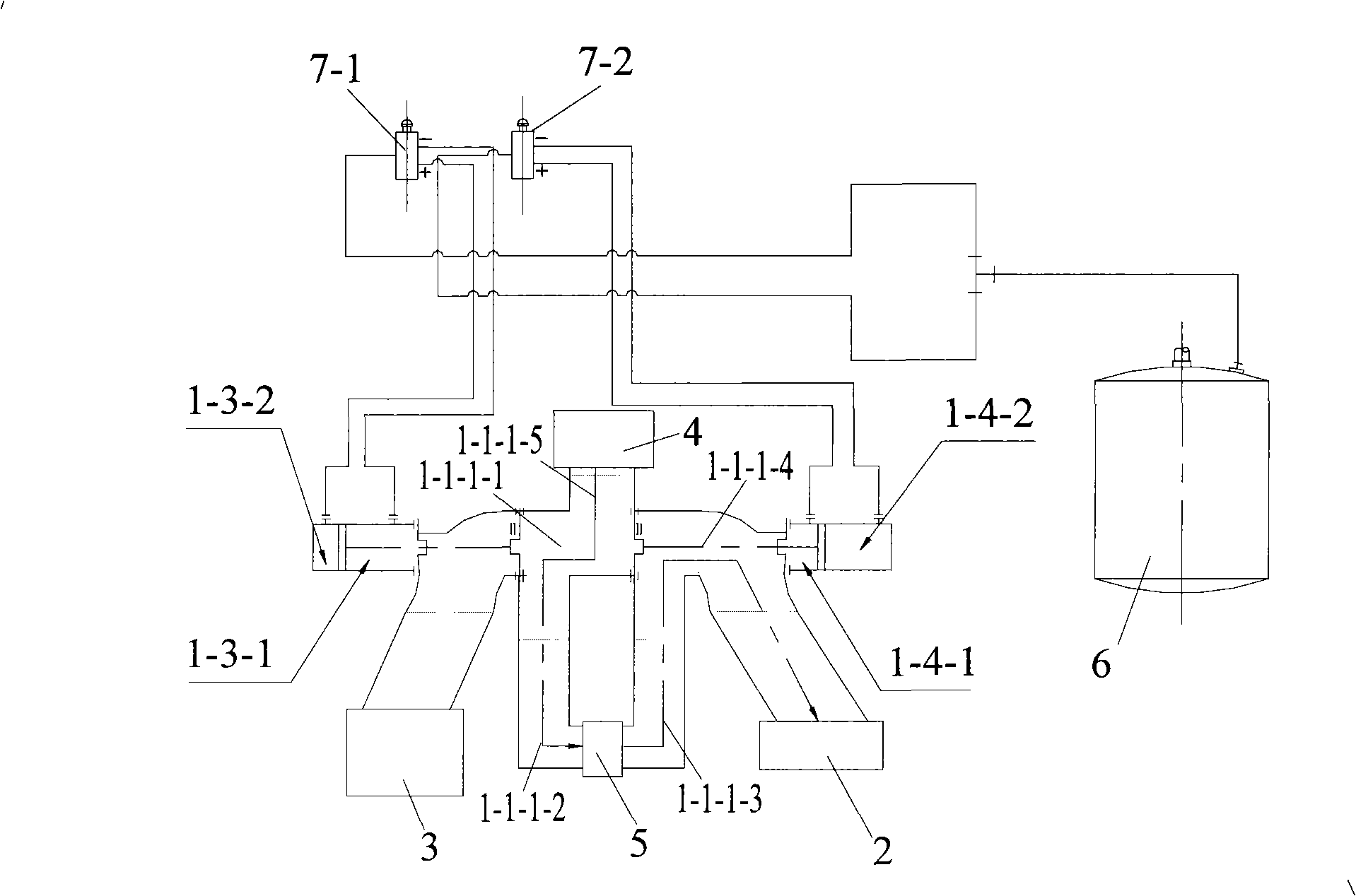

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

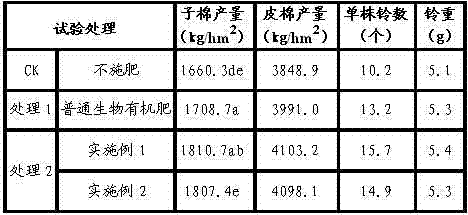

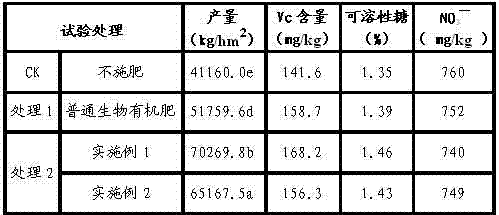

Novel green biological organic fertilizer and preparation method thereof

InactiveCN104744171ATurn over evenlyPrevent compactionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyInsect pest

The invention discloses a novel green biological organic fertilizer and belongs to the technical field of agricultural biological fertilizers. The novel green biological organic fertilizer is prepared from the following raw materials: straw mixture, seaweed residue, humic acid, amino acid and multifunctional zymophyte. The novel green biological organic fertilizer provided by the invention has the advantages that nutrients required by crops can be provided, incidence of plant diseases and insect pests can be greatly reduced, usage amount of pesticide is reduced, and crop yield and quality are improved.

Owner:SHANDONG TIANWEI BIOTECH CO LTD

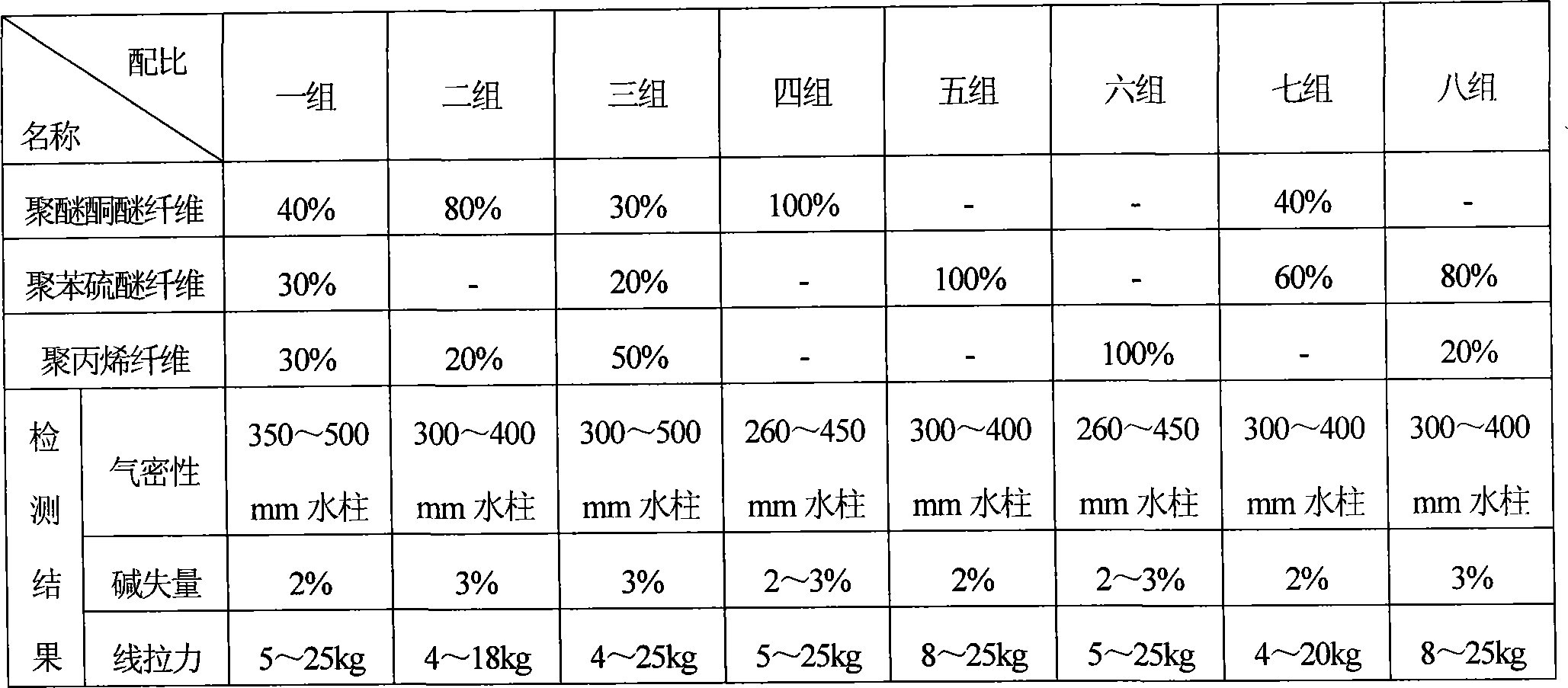

Non-zillerite environment protection energy-saving diaphragm cloth and weaving method thereof

ActiveCN101195944AImprove the level ofBreak down trade barriersMonocomponent polyethers artificial filamentMonocomponent polypropylene artificial filamentLongitudeKetone

The invention provides asbestos free environment protective and energy-saving type diaphragm cloth and the weaving method, which relates to diaphragm material and the weaving method. The diaphragm cloth of the invention adopts one, two or three component(s) from the polyether ketone ether fiber, the polyphenyl thioether fiber, and the polypropylene fiber, and meets the following requirements: unit weight: 0.5 to 1.5 kg / square meter; cloth thickness range: 0.5 to 1.5 mm; gauge of cloth: longitude 100 to 280 piece / 10 cm, latitude 56 to 150 piece / 10 cm; alkali loss: no larger than 2 percent; airtight protection performance: no air bubble produced in two minutes under the pressure of 300 mm water column, and the weaving can be performed according to the wool spinning technology and the cotton spinning technology. The invention breaks the trade barrier of the developed countries, the overall level of the hydrogen making and oxygen making equipment of our country is enhanced, and the pollution to the environment and the harm to the human body by the asbestos dust are reduced. Compared with the traditional asbestos diaphragm cloth, the thickness of the production can be reduced as low as 55 to 85 percent, and more than 10 percent of the energy can be conserved.

Owner:牡丹江市旺通新型隔膜材料有限责任公司

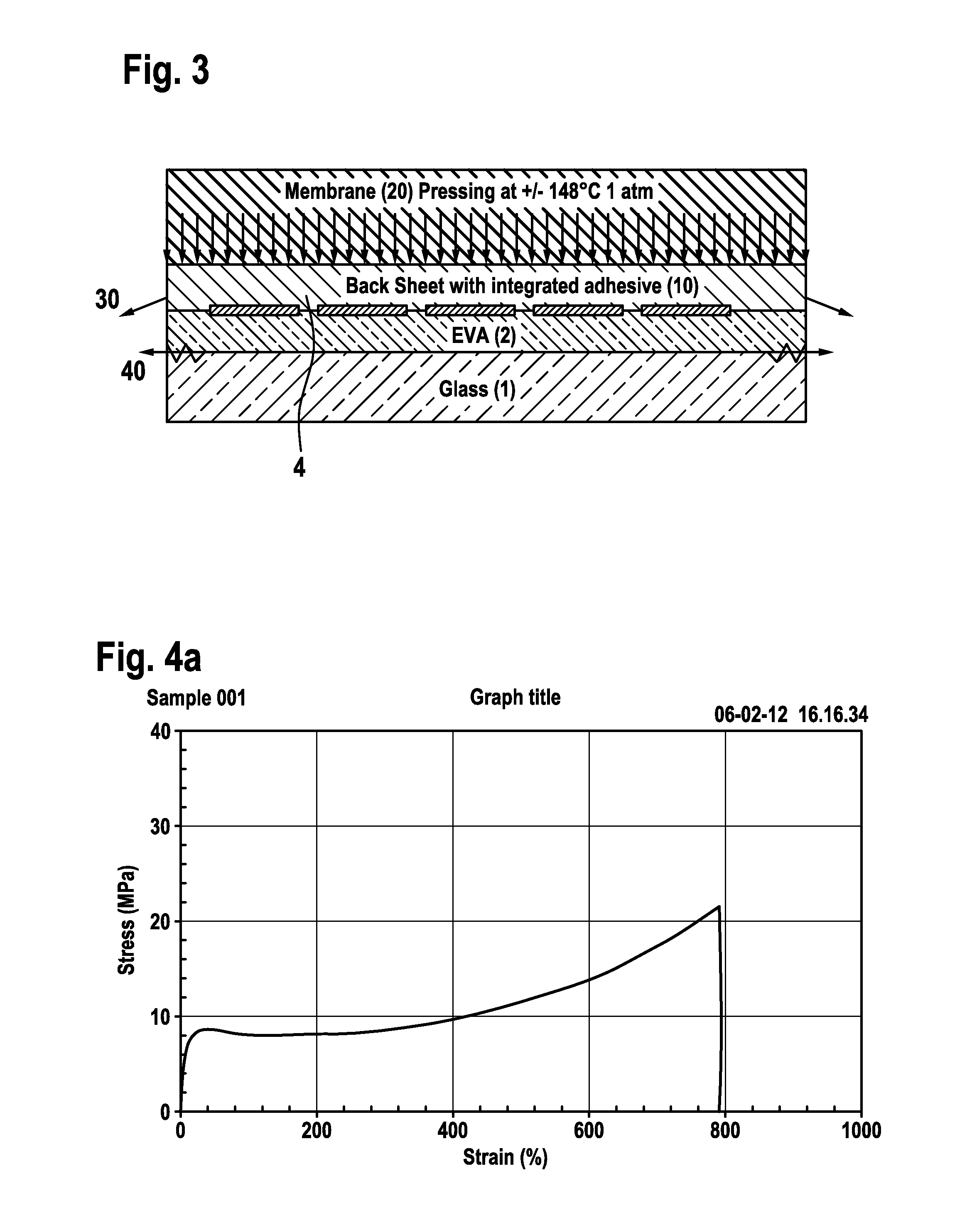

Backsheet and photovoltaic modules comprising it

InactiveUS20150027516A1Controlling the riskExpand exportsPV power plantsSynthetic resin layered productsHeat stabilityUltimate tensile strength

A coextruded backsheet on base of TPO layers, mainly FPP based layers and heat resistant and barrier layers, where the FPP layers dominate in the tensile strength of the backsheet by addition of fillers and the FPP layers have excellent long term heat stability by addition of specific heat stabilizers.Thanks to its relative softness, the stresses on PV cells are reduced, compared to PET based backsheet. Advantageous combinations with VLDPE based encapsulants are described.

Owner:RENOLIT BELGIUM

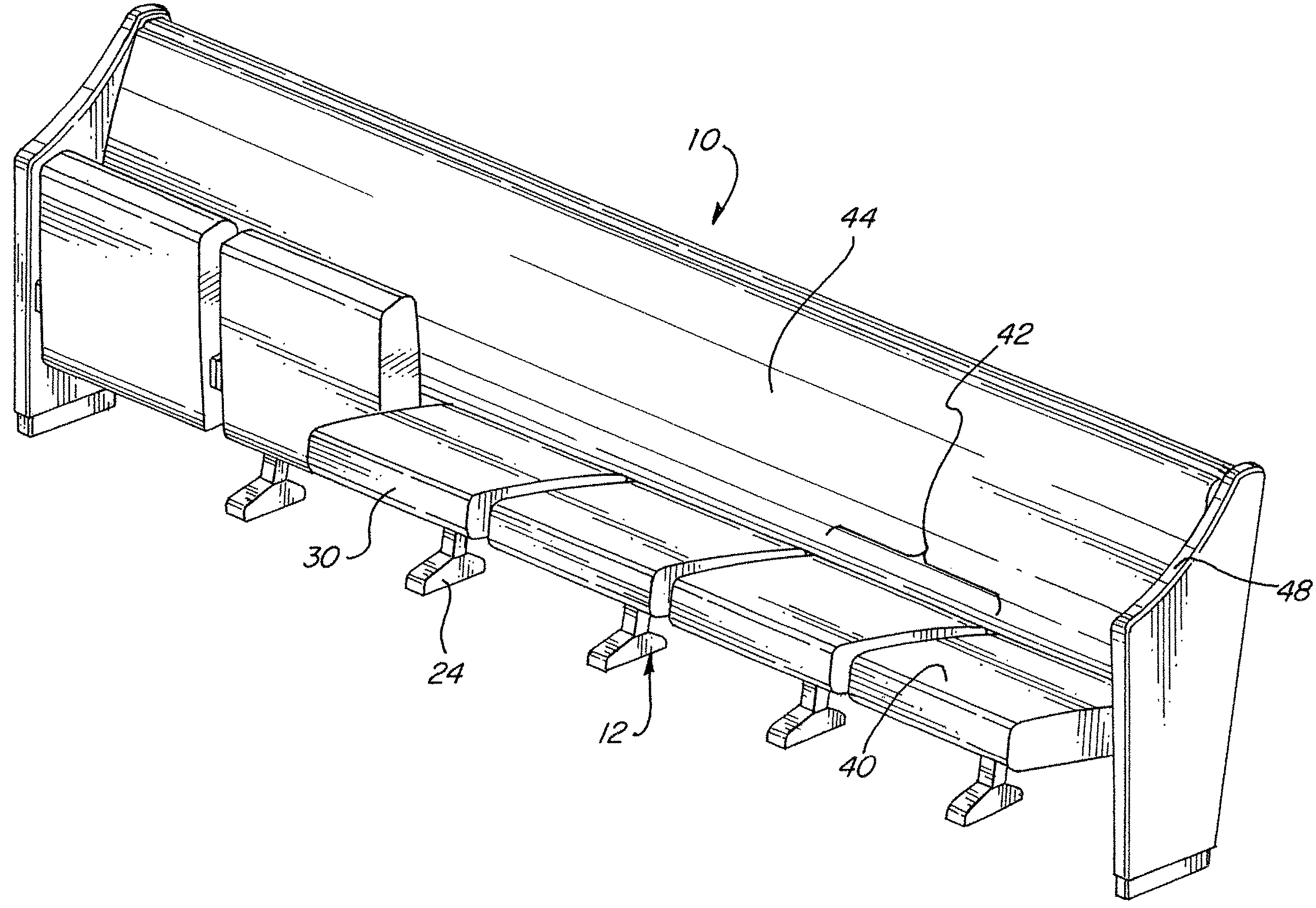

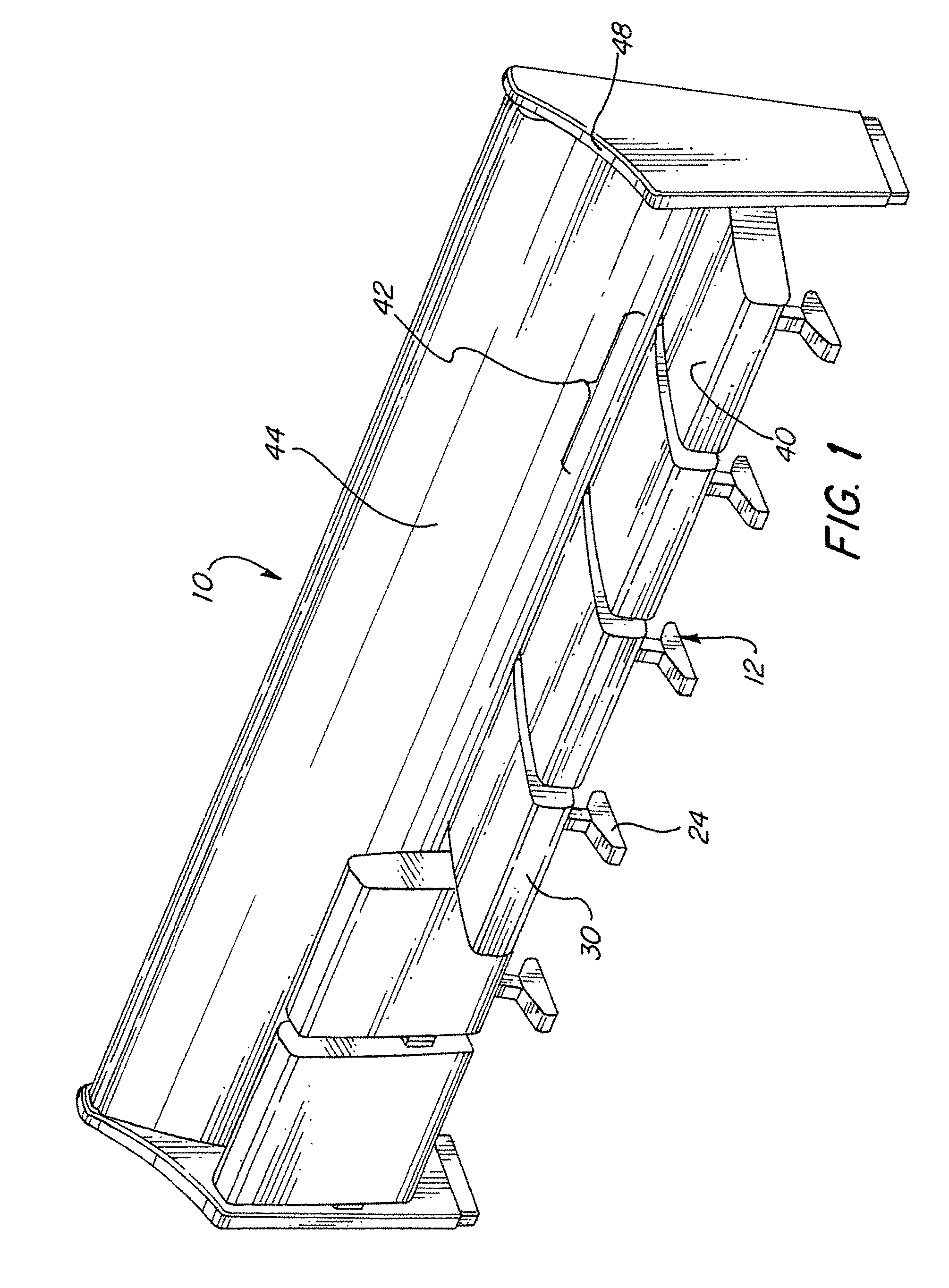

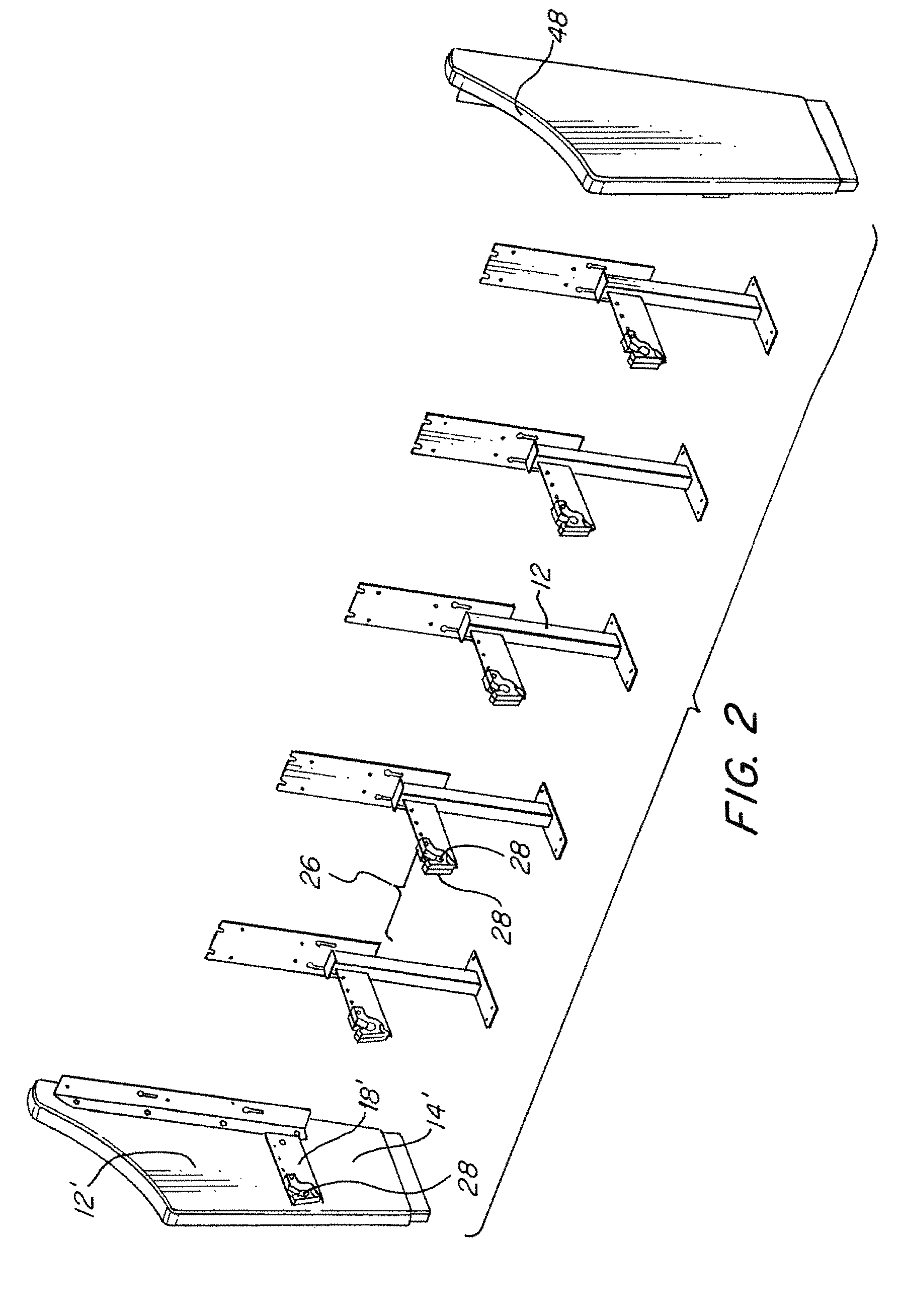

Pew style seating assembly

A pew style seating assembly includes a plurality of seat members, each of which is pivotable, independently from all others of the plurality of seat members, between an occupied position and an unoccupied position. Each seat member, when in the occupied position, defines a seating area above a top surface thereof, with the seating areas defined by the plurality of seat members defining a continuous and uninterrupted pew seating area spanning the plurality of seat members. The seating assembly further includes a single, continuous seat back attached to each of the seat support members and spanning the entire pew seating area, such that the plurality of seat members are associated with the single, continuous seat back.

Owner:SERIES INT

Processing method of green tea

ActiveCN102960482APromote sustainable developmentImprove tree down ratePre-extraction tea treatmentGreen teasProcess engineering

The invention provides a processing method of green tea, which is used for solving the problem of bitter taste of a large amount of green tea produced in Sichuan province. The processing method of the green tea is characterized by comprising the following steps of: picking fresh leaf, tedding green leaves, deactivating enzymes, rolling, conducting first-step roasting, conducting secondary rolling, conducting deblocking, conducting second-step roasting, spreading and airing, roasting to be dry, spreading and airing, and drying and extracting flavor, wherein twice rolling processes are carried out by hot rubbing. According to the processing method of the green tea, the bitter taste of the large amount of the green tea produced in the Sichuan province can be effectively reduced, the quality of tea leaves can be improved, and the heavy, mellow, fresh and brisk degrees can be increased; and the good foundation is established for expanding the tea markets of Sichuan and promoting the export of the tea in Sichuan.

Owner:YIBIN CHUANHONG TEA IND GRP

Beneficial biological bacterium fermented microbial organic fertilizer

InactiveCN105418335AEasy to stackEfficient use ofCalcareous fertilisersSuperphosphatesBiotechnologyDry weight

The invention relates to a beneficial biological bacterium fermented microbial organic fertilizer to solve the problem of harms of organic wastes to the environment. The beneficial biological bacterium fermented microbial organic fertilizer is prepared through fermenting raw materials by beneficial biological bacteria, and the raw materials comprise, by weight, 10-15% of active humic acid, 3-9% of a nitrogenous fertilizer, 1.5-4.5% of a phosphate fertilizer, 1.5-4.5% of a potash fertilizer, 1-3% of a boron fertilizer, 0.5-1.5% of a silicon fertilizer, 0.3-0.7% of an iron fertilizer, 0.3-0.7% of a zinc fertilizer, 0.3-0.7% of a copper fertilizer, 0.2-0.4% of a magnesium fertilizer, 0.2-0.4% of a manganese fertilizer, 0.3-0.7% of a calcium fertilizer, 0.3-0.7% of a molybdenum fertilizer, 0.3-0.7% of a vanadium fertilizer, and the balance of an organic matter ferment material (metered by dry weight). The beneficial biological bacterium fermented microbial organic fertilizer has the advantages of low production cost, soil improvement, improvement of the quality of crop products, improvement of the output of the crops, promotion of development of the agriculture with Chinese characteristics, high harmless degree, absorption facilitation, slow synergism, yield and income increase, soil fertility raising, and balanced nutrition, and is helpful for naturally decomposing various beneficial components in soil after being applied in order to make the decomposed beneficial components be absorbed and utilized by plants.

Owner:张秀丽

Material formula of bioorganic fertilizer

InactiveCN104671856APrevent compactionIncrease air permeabilityBio-organic fraction processingOrganic fertiliser preparationTree rootFeces

The invention relates to the field of an organic fertilizer preparation process and in particular relates to a material formula of a bioorganic fertilizer. The material formula comprises the following components: 50-60 parts of tree root debris, 40-50 parts of chicken and duck dung, 30-50 parts of dried seaweed, 2-5 parts of a decomposition agent, 15-20 parts of swill and a proper amount of vinegar. The material formula has the characteristics that the material formula can conduce to conditioning soil and increasing the activation rates of microorganisms in soil; in particular, by adding the tree root debris and the chicken and duck dung, soil hardening can be overcome, the soil air permeability can be improved, and the soil becomes more fertile, so that the yields of food crops, commercial crops, vegetables and melons and fruits are substantially increased; the quality of agricultural products is improved, and fruits have bright colors and uniform sizes and ripen in a concentrated manner; the sugar contents and vitamin contents of melon agricultural products are increased, so that the melon agricultural products have good tastes and are beneficial to expanding export and increasing the selling prices.

Owner:SHANDONG NONGKEYUAN BIOTECH

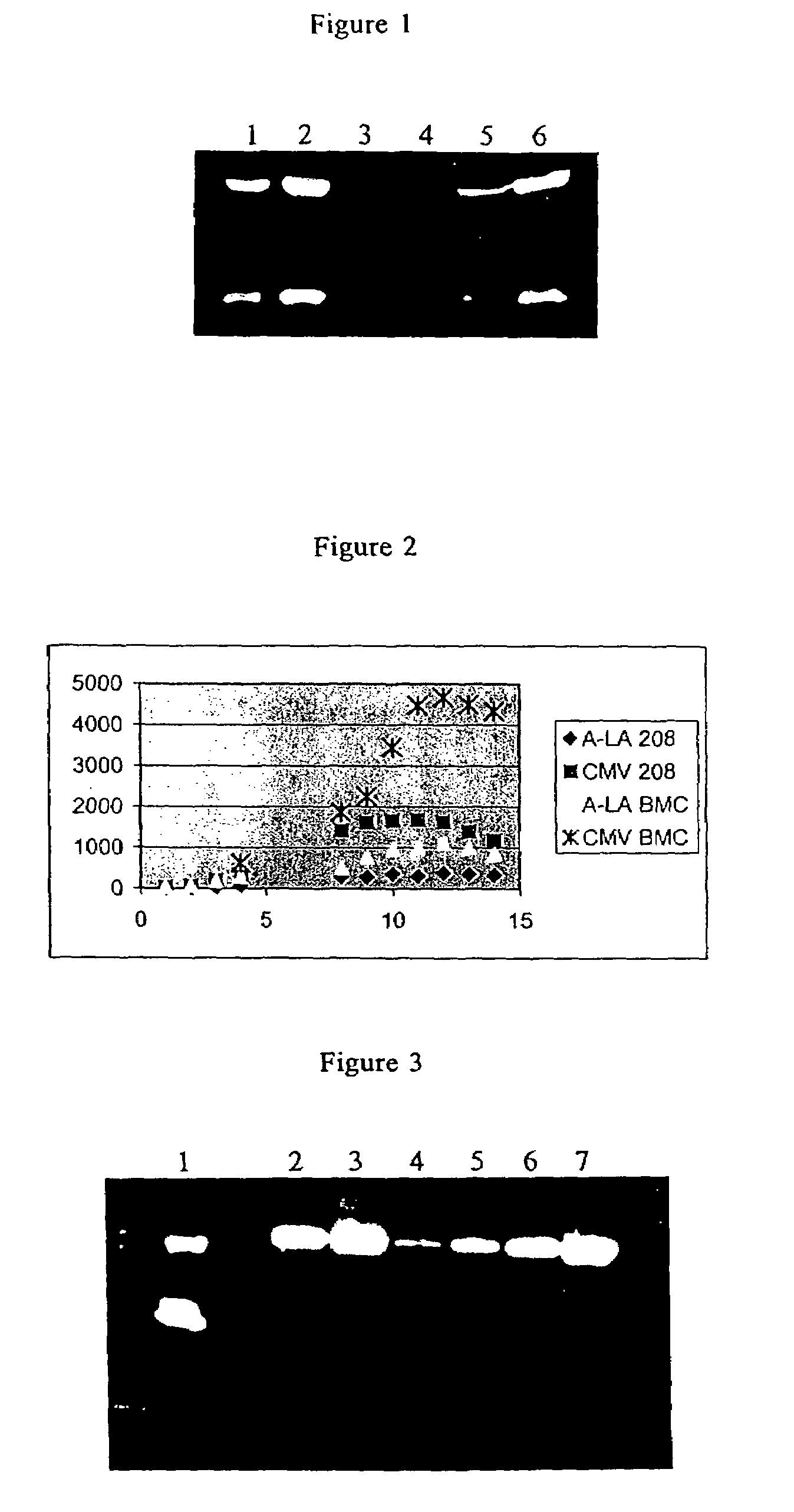

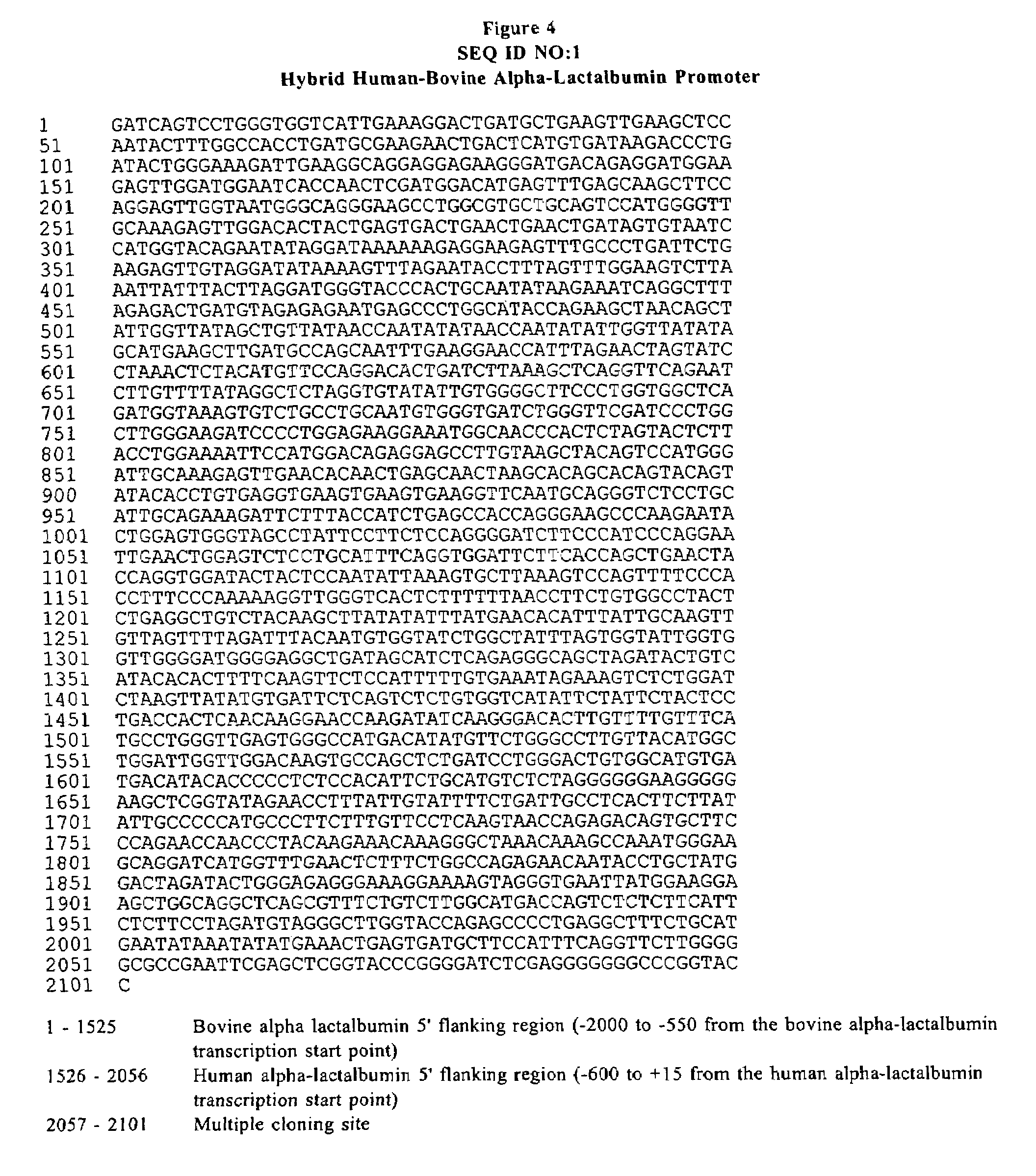

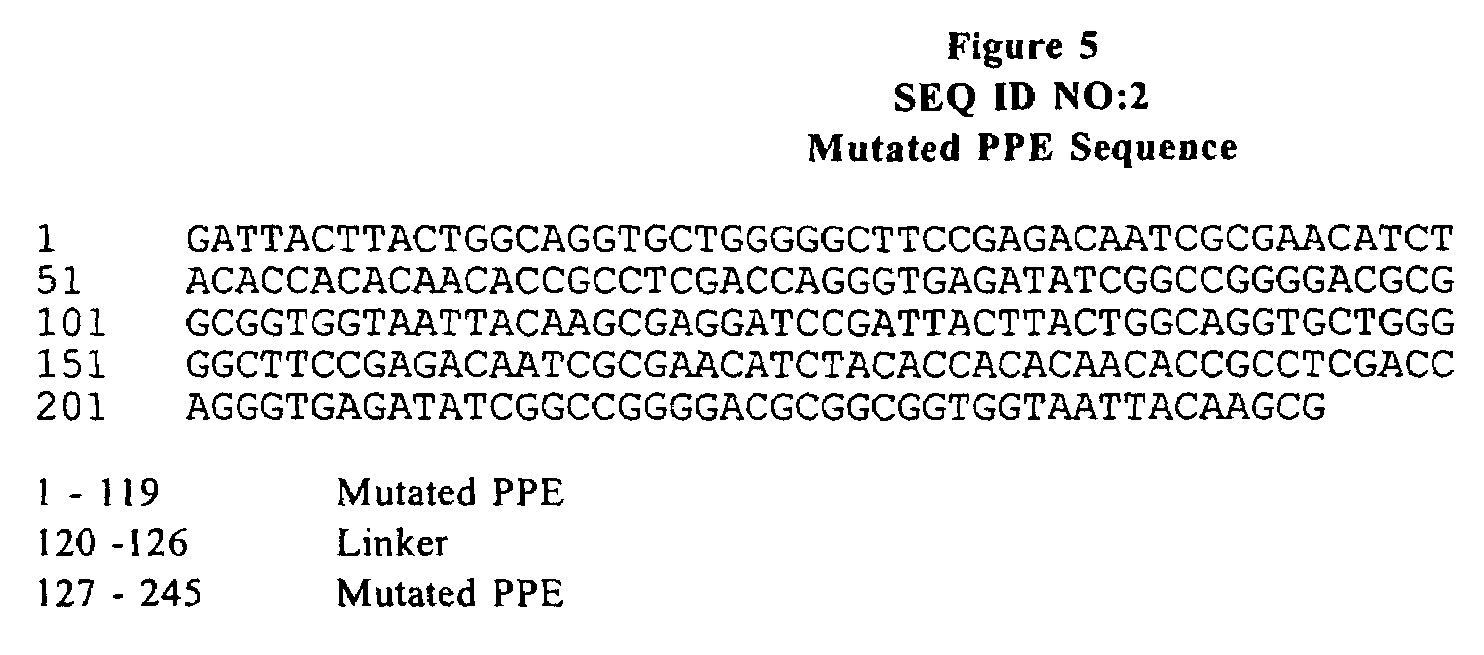

Expression vectors

InactiveUS7378273B2Expand exportsBiocideFungiHigh-Throughput Screening MethodsHigh-throughput screening

The present invention provides novel regulatory elements and vectors for the expression of one or more proteins in a host cell. The present invention also provides methods for expressing one or more proteins, such as antibodies, in a host cell. These methods utilize the novel regulatory elements and vectors of the present invention for the expression of proteins in a host cell. The host cells are used for producing various protein products, including but not limited to pharmaceutical proteins, antibodies, variants of proteins for use in screening assays, and for direct use in high throughput screening.

Owner:CATALENT USA WOODSTOCK INC +3

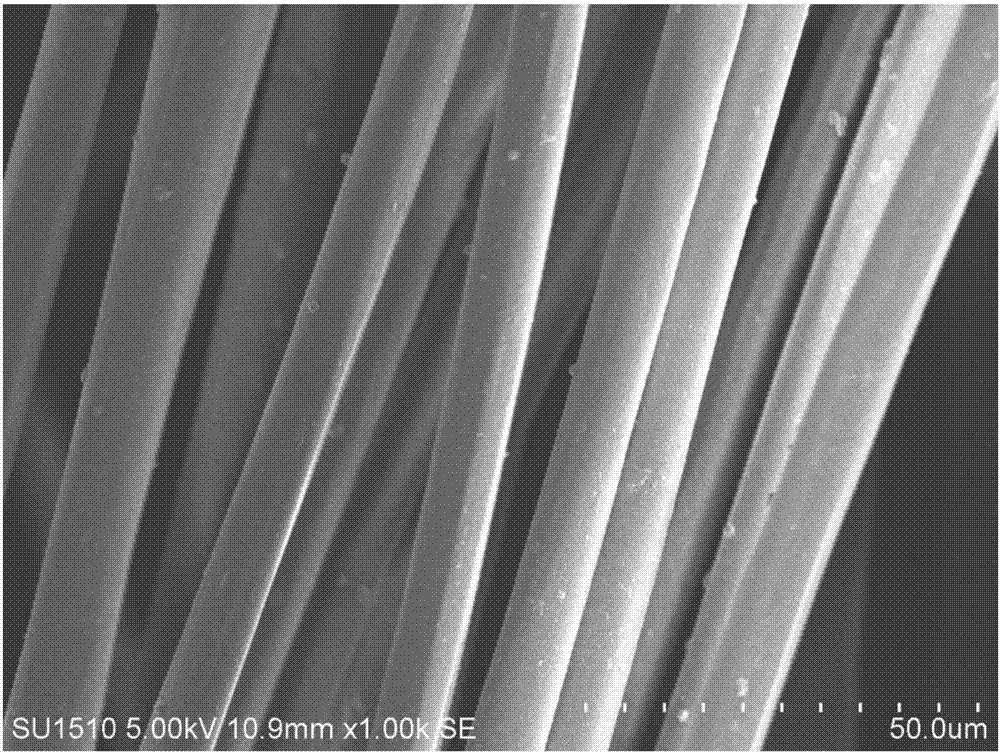

Preparation method of compound antibacterial deodorizing functional masterbatch and fibers

ActiveCN106977751AWith permanent antibacterial functionExpand exportsConjugated synthetic polymer artificial filamentsArtifical filament manufactureMasterbatchFiber

The invention provides a preparation method of compound antibacterial deodorizing functional masterbatch and fibers. The preparation method of compound antibacterial deodorizing functional masterbatch comprises surface modification of copper serial powder, configuration of functional compound resin powder and preparation of the compound antibacterial deodorizing functional masterbatch. The novel antibacterial deodorizing functional masterbatch and fibers prepared by a brand new antibacterial compound mechanism have a permanent antibacterial function, the mechanical property can reach the standard of common fibers, various weaving demands can be fully met, the cost is equivalent to that of antibacterial post-treatment, and the pollution is reduced. According to the preparation method provided by the invention, export of textiles can be expanded, and the additional value of the textiles is increased.

Owner:ZHEJIANG YINYU NEW MATERIAL CO LTD

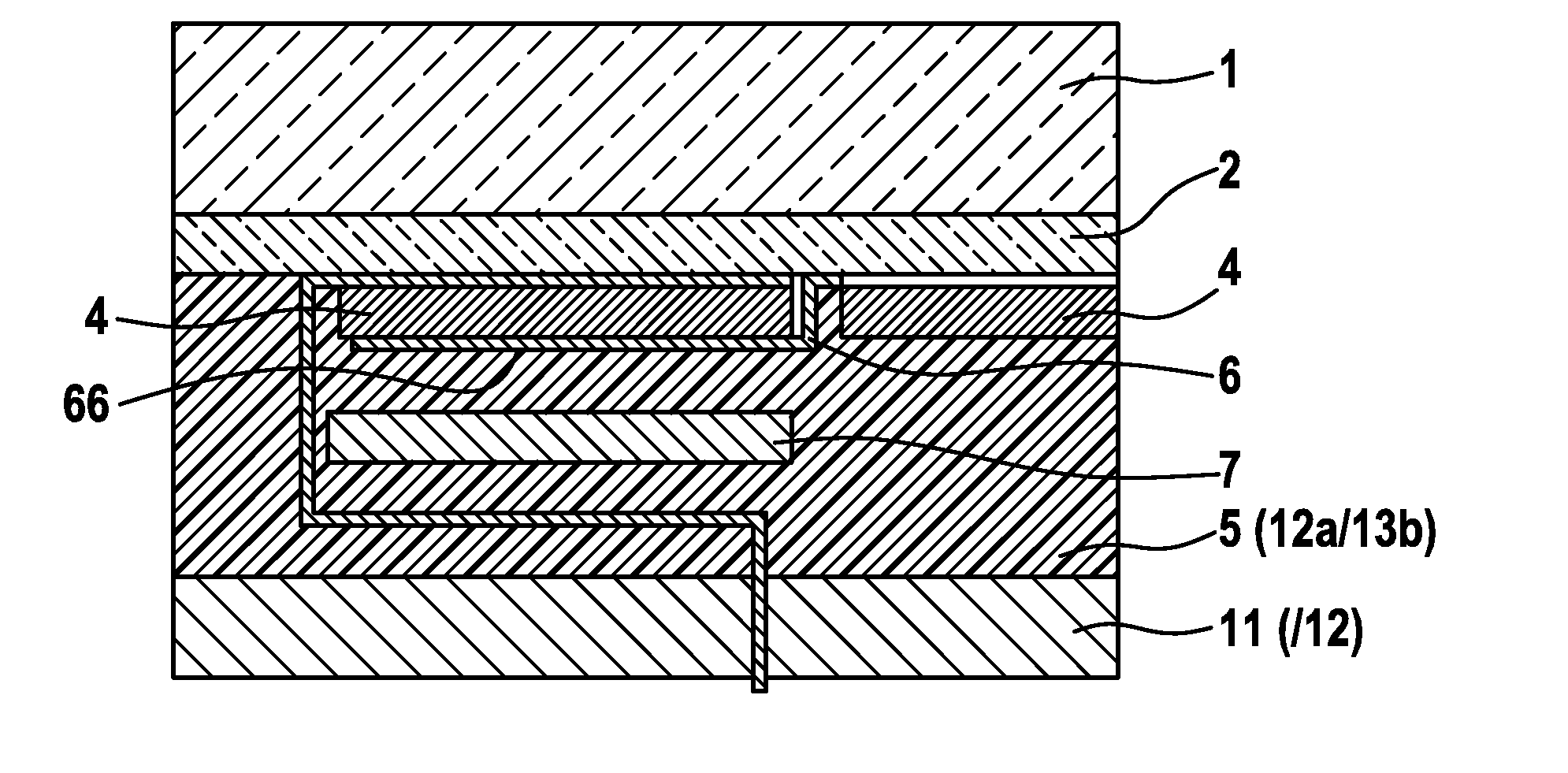

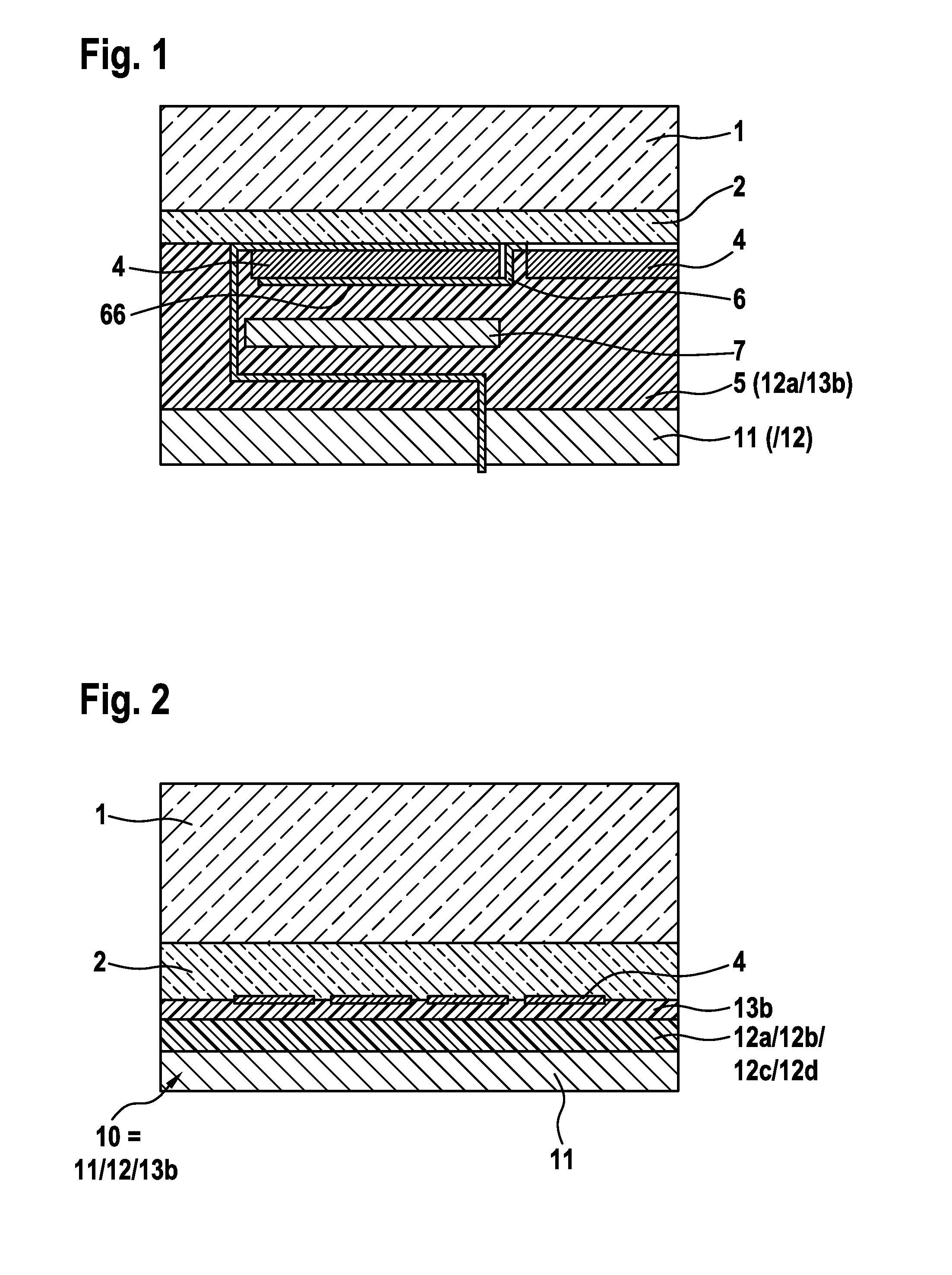

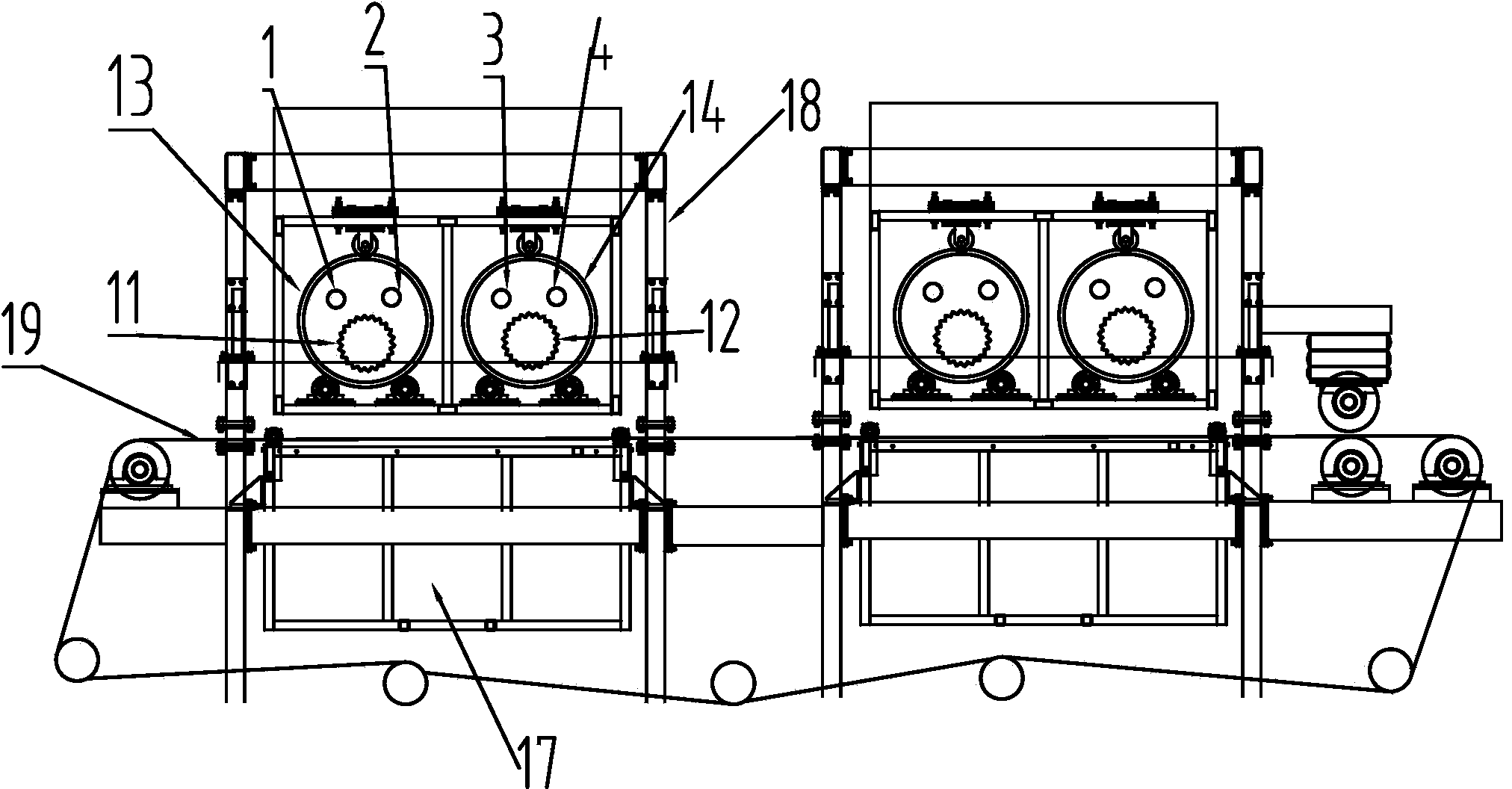

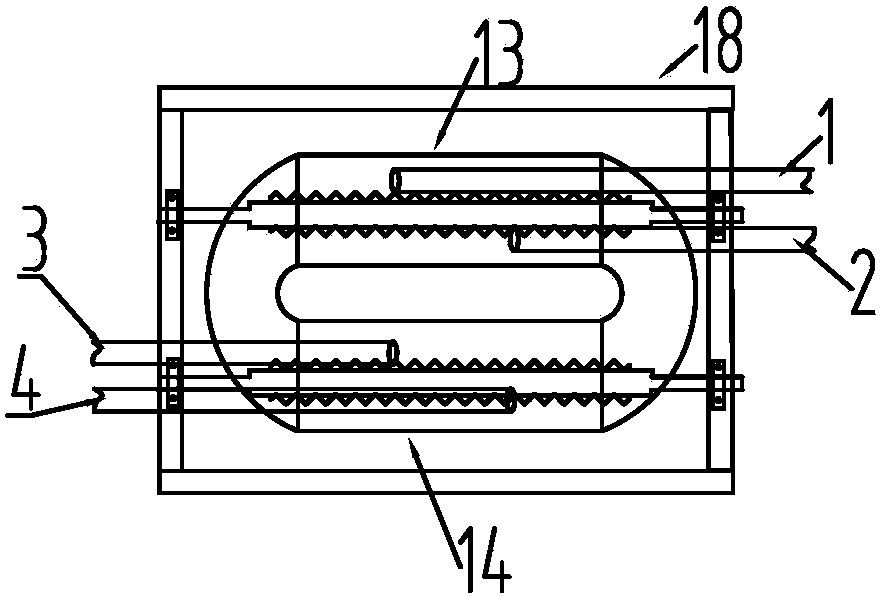

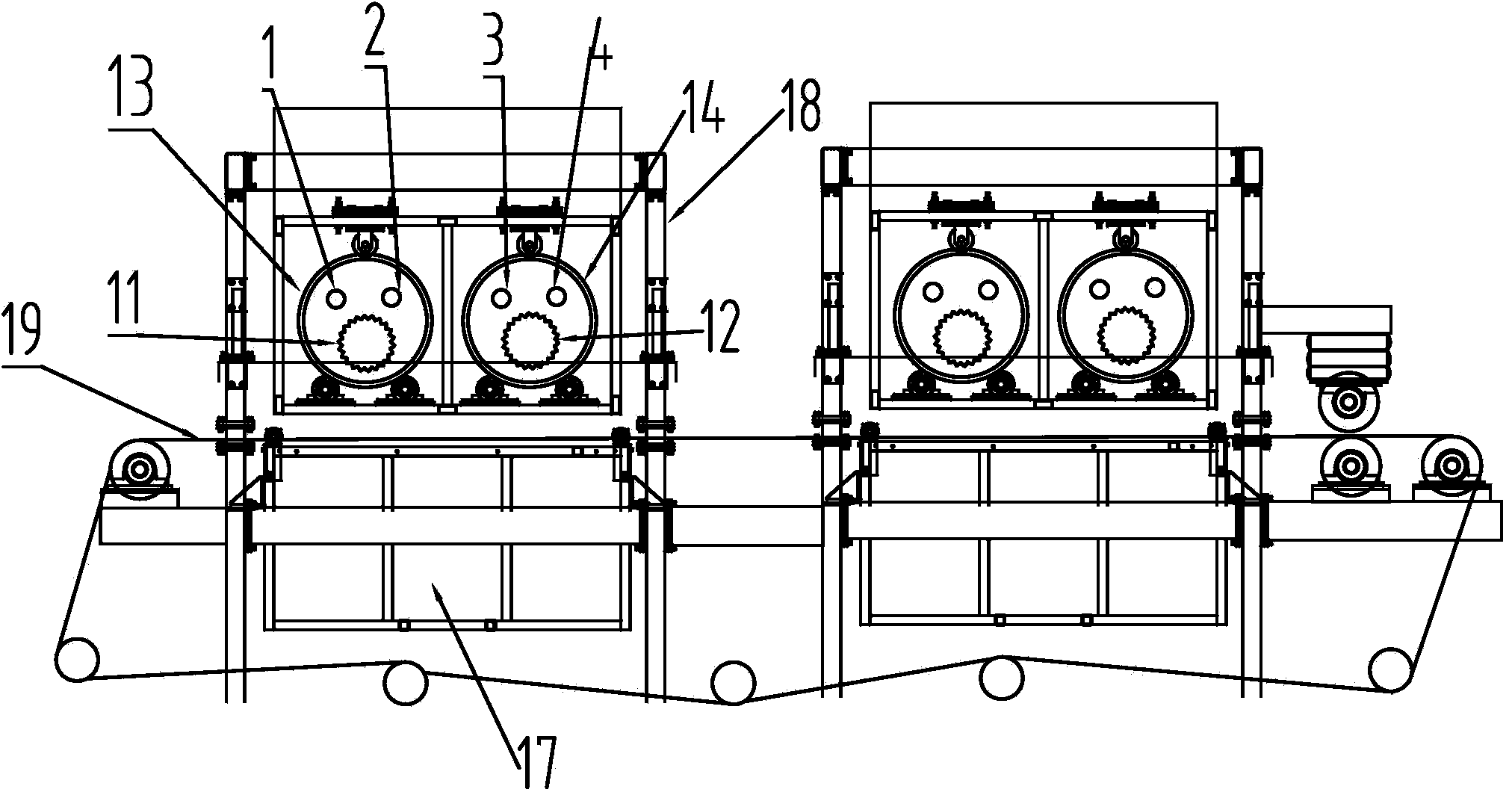

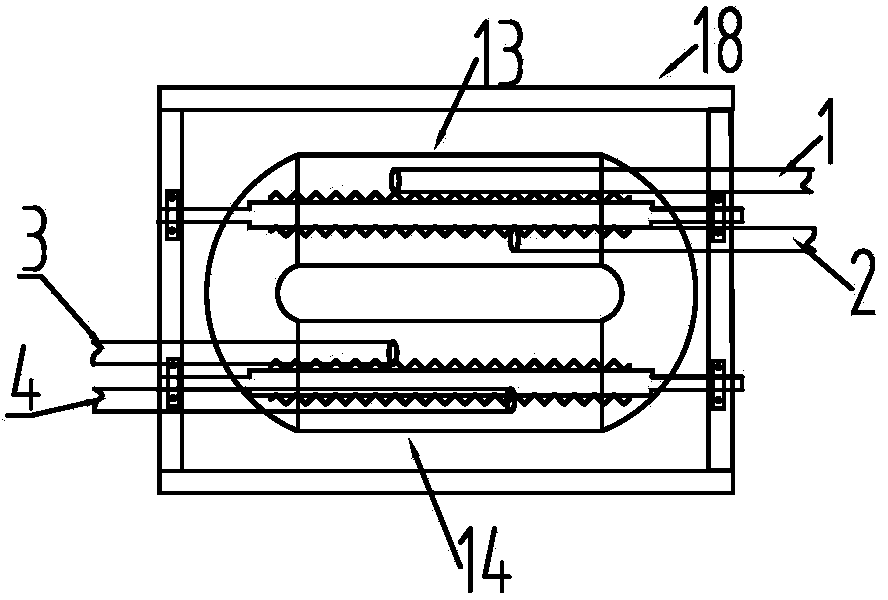

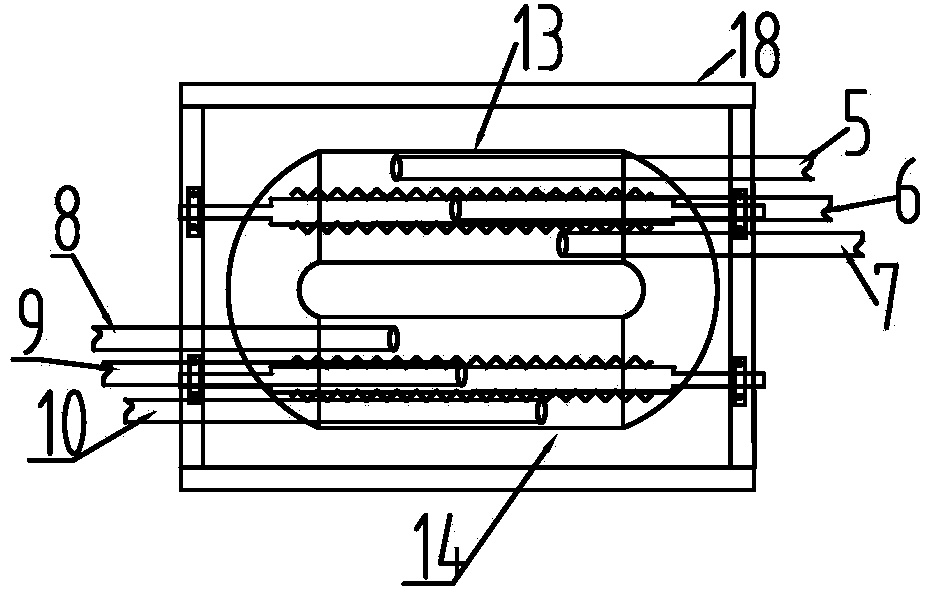

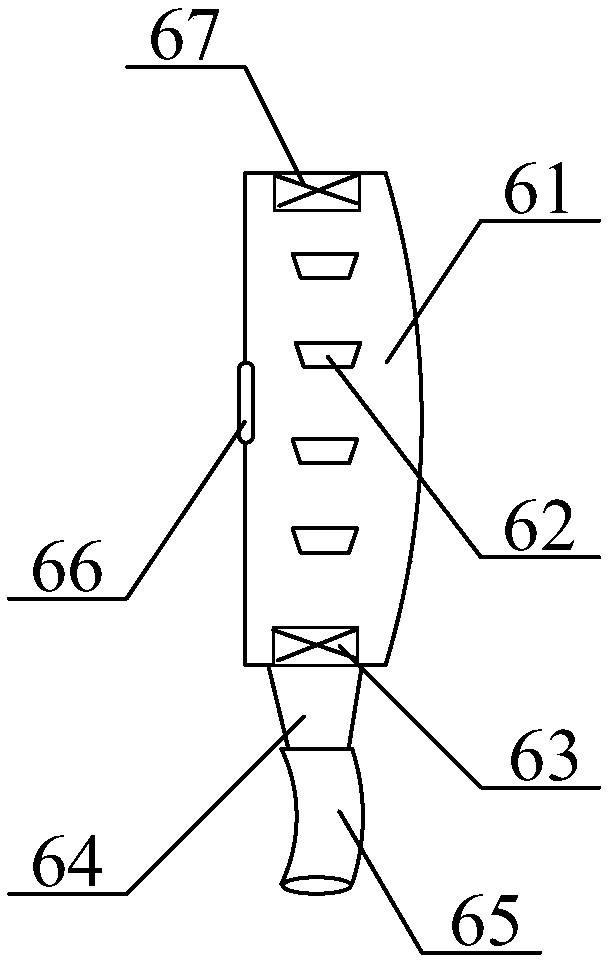

Substrate forming device for producing reconstituted tobaccos through dry paper-making method

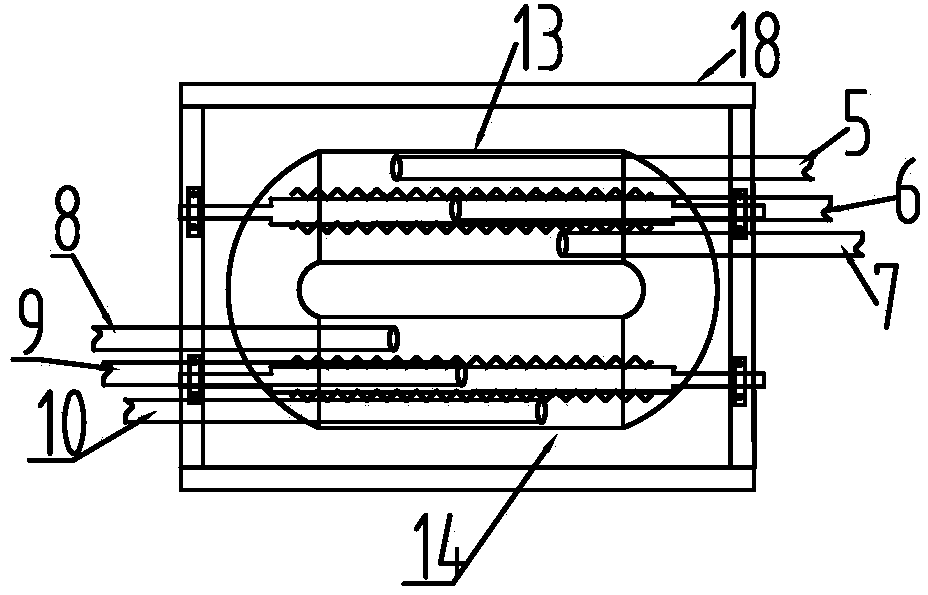

The invention relates to a substrate forming device for producing reconstituted tobaccos through a dry paper-making method. The substrate forming device comprises a forming mesh belt, a mesh belt conveying device, a machine frame 18 and forming heads. Each set of forming heads is symmetrically provided with a first screen drum 13 and a second screen drum 14, two fiber conveying pipes are arranged in each screen drum in the axial length direction of the screen drum, the two fiber conveying pipes are symmetrically arranged on the upper half portion in the corresponding screen drum, the lower portions of the screen drums are provided with scattering rollers, and the scattering rollers are located under the centers of the screen drums. Front annular channels are arranged between the fronts of the first screen drums and the fronts of the second screen drums, rear annular channels are formed between the backs of the first screen drums and the backs of the second screen drums, and the annular channels enable the inner spaces of the screen drums to be communicated. Two fiber conveying pipes are arranged in each screen drum and the lengths of the fiber conveying pipes are different, so that fiber outlets are increased, and the fiber conveying accuracy is effectively improved; a front annular channel and a rear annular channel are formed between the two screen drums in each forming head to communicate the spaces in the two screen drums, so that fibers stacked inside the parts, located at the two ends of each screen drum, of a box body are reduced.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

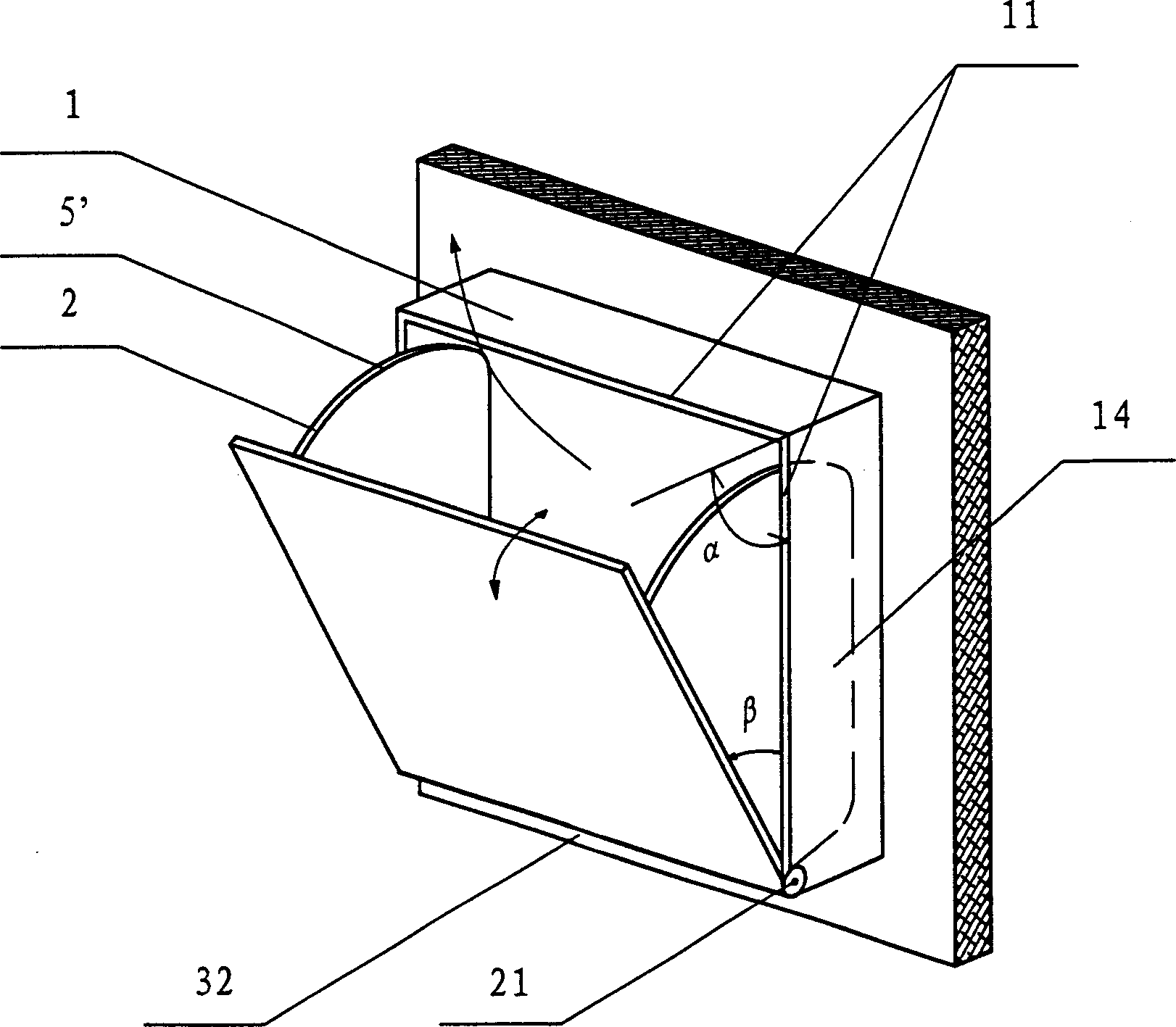

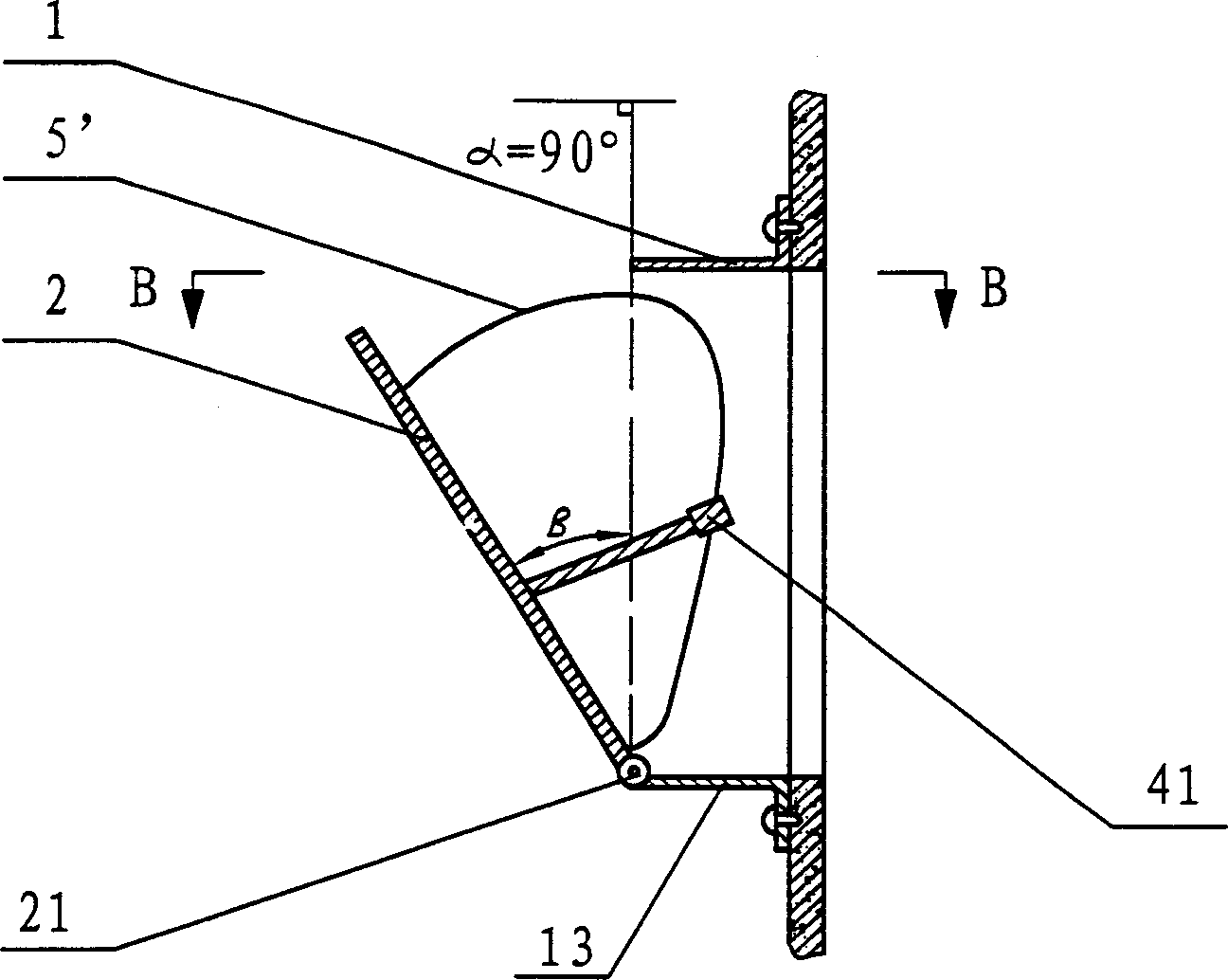

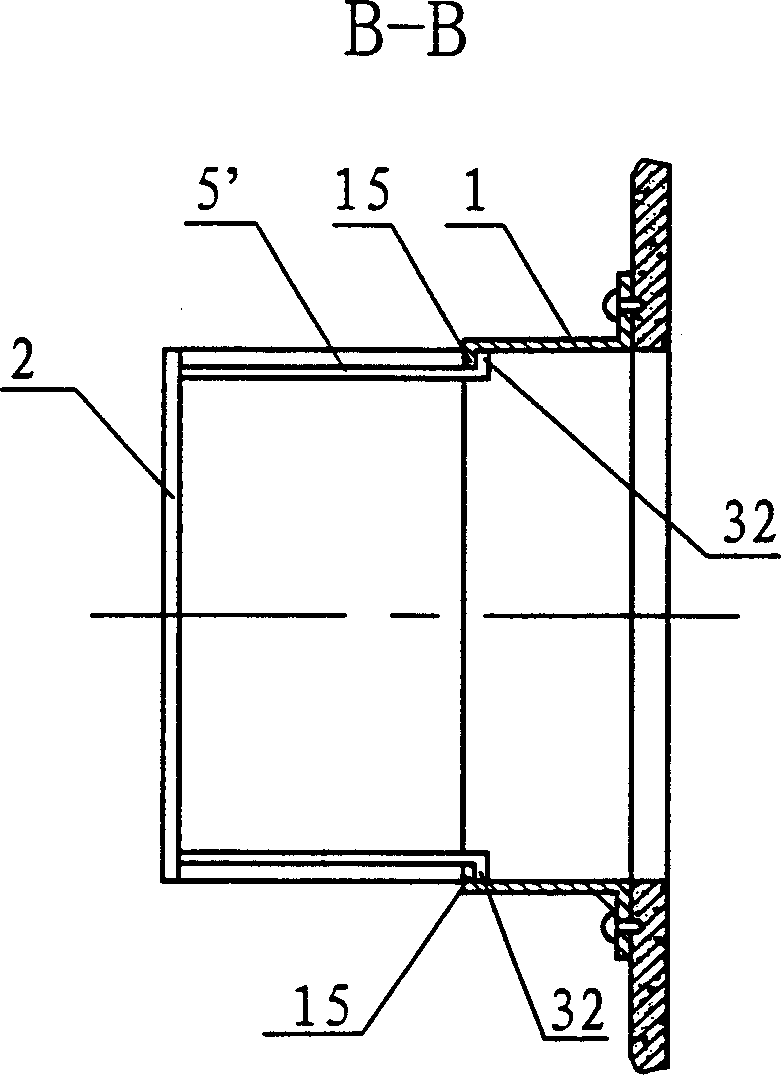

Flow guiding type exhaust check valve

InactiveCN1467398AExpand exportsNo more difficult installation problemsCheck valvesExhaust valveJet flow

The invention relates to a non-return exhaust valve used for the concentration discharging of flue gas in the dwelling construction comprising, valve body, valve block and valve block and returning apparatus, wherein the lower end of the valve block is hinged to the exit end floor of the valve body, the returning apparatus is arranged on the valve block, two flow guiding flaps are arranged on the two sides of the valve block, a stopping means for limiting valve maximum open angle is arranged on the valve block. The invention solves the problem of the difficulty of the jet flow tube mounting, it can reduce the cost and increase the packing performance.

Owner:林润泉

Basal piece forming device for reconstituted tobacco production by means of dry method of paper-making

The invention relates to a basal piece forming device for reconstituted tobacco production by means of a dry method of paper-making. The device comprises a forming mesh belt, a mesh belt conveying device, a machine frame 18 and forming heads, wherein each forming head is provided with a first screen drum 13 and a second screen drum 14 which are symmetrically arranged, two fiber conveying pipelines are arranged in each screen drum in the axial length direction and are symmetrically located on the upper half portion of the screen drum, a scattering roller is arranged on the lower half portion of each screen drum and located under the circle center of the screen drum, and a front annular channel and a rear annular channel are arranged on the front portion of each first screen drum and the corresponding second screen drum and on the rear portion of the first screen drum and the second screen drum respectively to enable the internal space of the screen drums to be communicated. Due to the fact that two fiber conveying pipelines in different lengths are arranged inside each screen drum, the number of fiber outlets is increased, and then fiber conveyance accuracy is effectively improved; the front annular channel and the rear annular channel are arranged between the two screen drums of each forming head to enable the space of the two screen drums to be communicated, and accumulation of fibers in the portions, on the two sides of each screen drum, of the interior of a box body is reduced.

Owner:GUANGDONG GOLDEN LEAF TECHNOLOGY DEVELOPMENT CO LTD

Yellow wine uncooked wheat starter and preparation method thereof

PendingCN108865560AImprove glycationImprove liquefactionMicroorganism based processesAlcoholic beverage preparationWine industryAspergillus oryzae

The invention belongs to the field of wine brewing, and relates to yellow wine production, in particular to yellow wine uncooked wheat starter and a preparation method thereof. The preparation methodis characterized in that on the basis of a traditional uncooked wheat starter preparation process, the wheat starter raw material composition is changed; wheat and malt after the wheat sprouting are mixed uniformly according to a certain proportion and are used as wheat starter raw materials; meanwhile, aspergillus oryzae is used as a reinforced strain for preparing bran seed starter for inoculation; a novel yellow wine uncooked wheat starter is made, so that the saccharification power and the liquefaction power of the wheat starter are improved; the wheat starter consumption and the production cost of yellow wine enterprises are reduced; meanwhile, the yellow wine quality is improved. The application of the novel uncooked wheat starter has positive significance on the sustainable development of yellow wine industry.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Adhesive-backed articles

InactiveUS20080105356A1Expand exportsAdversely affecting appearanceLamination ancillary operationsDecorative surface effectsEngineeringPressure sensitive

Owner:3M INNOVATIVE PROPERTIES CO

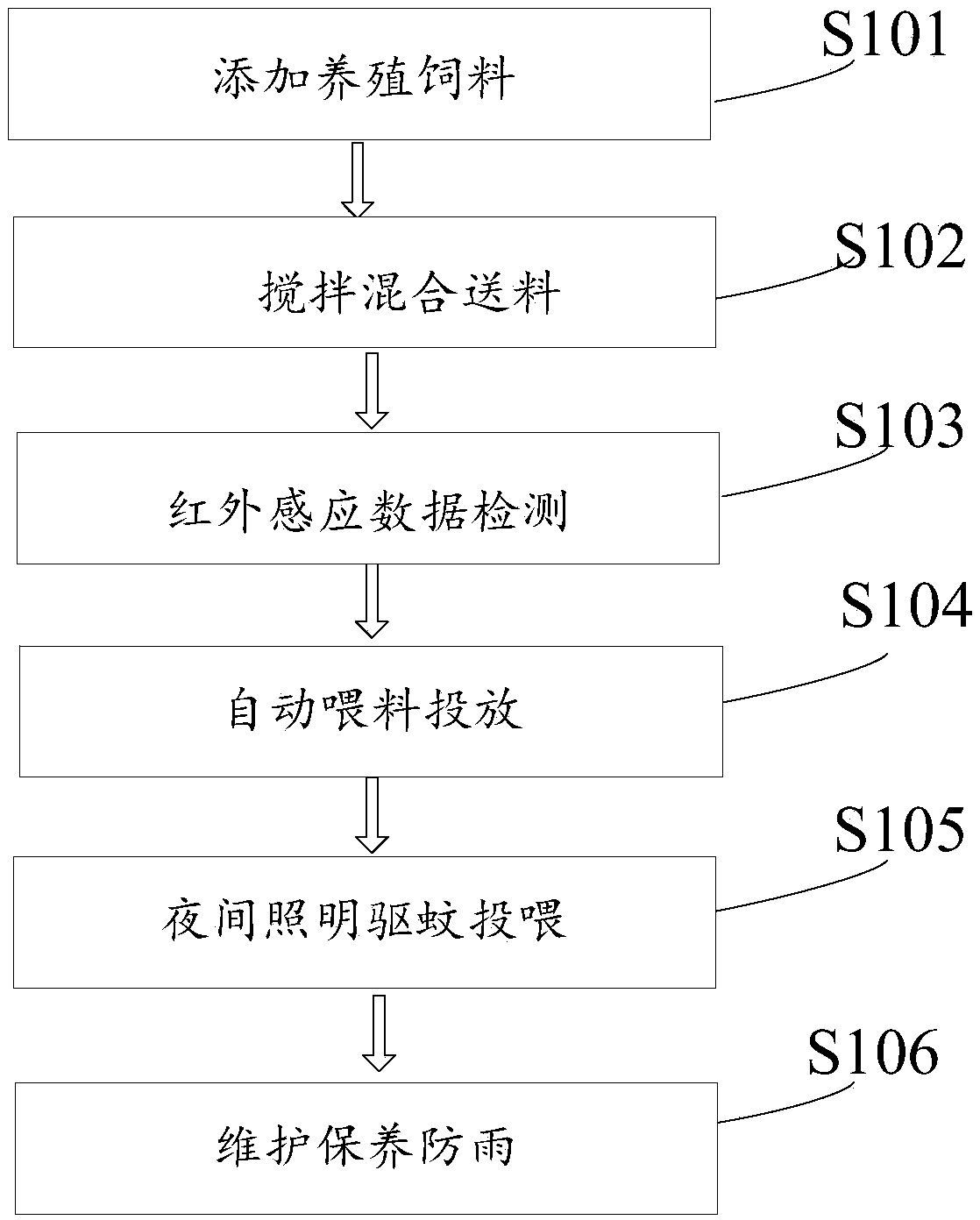

Internet-of-things type aquaculture fully-automatic feed-releasing device and application method thereof

ActiveCN108990861APlay the role of sealing protectionAvoid damageClimate change adaptationPisciculture and aquariaThe InternetEngineering

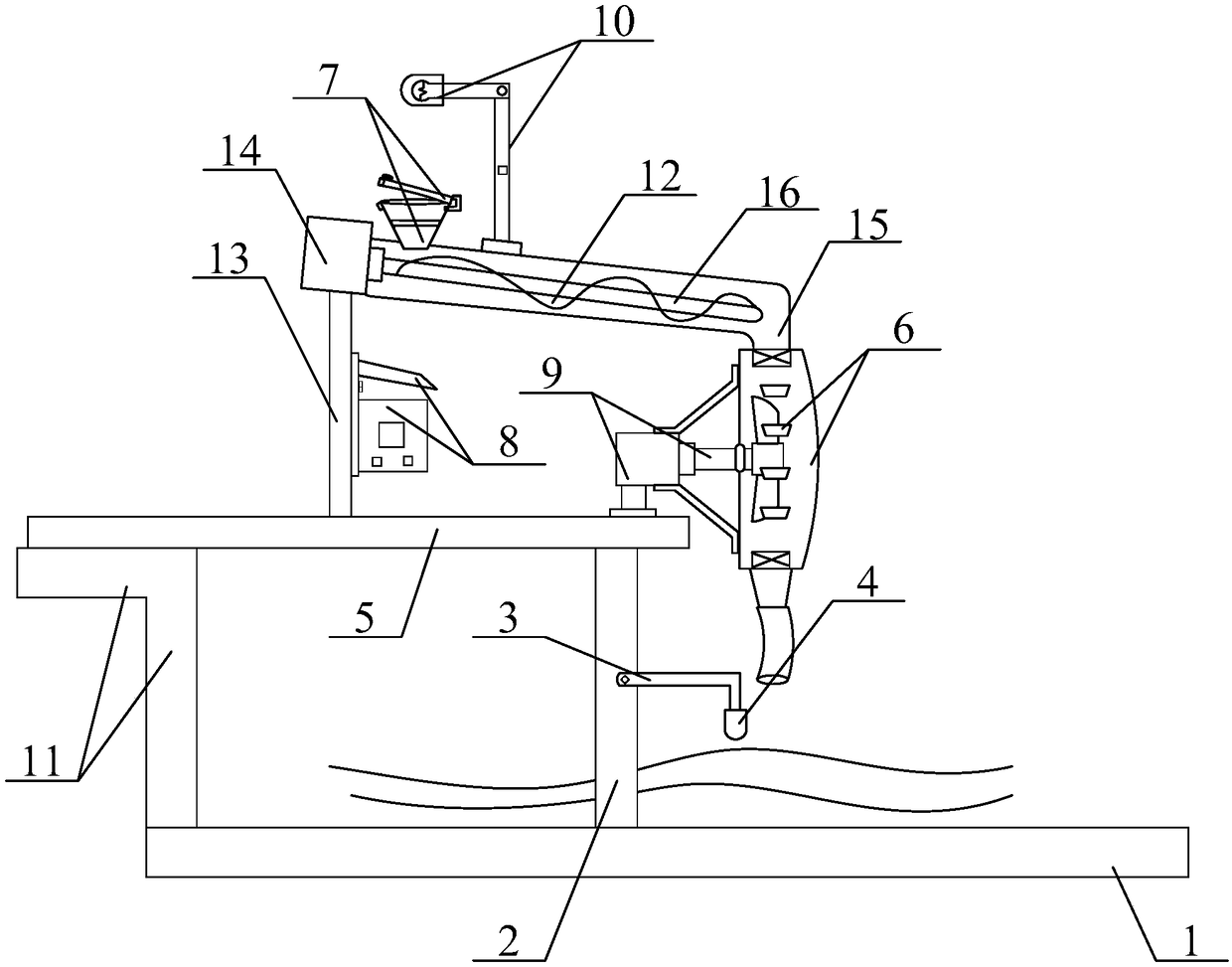

The invention provides an internet-of-things type aquaculture fully-automatic feed-releasing device. The internet-of-things type aquaculture fully-automatic feed-releasing device comprises an aquaculture pool bottom, a supporting stand column, an L-shaped supporting rod, an infrared sensor, a feed-releasing workbench, a multi-angle feed-releasing drum structure, a feed-filterable feeding hopper structure, an insulating protective control box structure, a feed-distribution stirring blade structure, an anti-mosquito illuminating lamp structure, an embankment, a rotating auger blade, a feed-conveying supporting rod, a feed-conveying motor, a feed-guiding cylinder and a stirring feed-conveying shaft. The aquaculture fully-automatic feed-releasing device provided by the invention has the following advantages: through additional arrangement of more outlets for feeding of a feed, multi-angle feeding of the feed can be realized; the needs of aquaculture of multiple water areas are met; meanwhile, through the rotating auger blade for secondary stirring of the feed and filtering of the feed in the feed feeding process, odor is prevented from entering the automatic feed-releasing device to affect performing of feed releasing; and during operation at night, a matched illuminating mosquito-repellent unit is supplied to facilitate feed feeding.

Owner:WUXI NANLIGONG TECH DEV

Preparation method of bio-organic fertilizer

InactiveCN104261909AImprove fertilizer use efficiencyPrevent soil compactionBio-organic fraction processingExcrement fertilisersWater contentNutrient

The invention discloses a preparation method of a bio-organic fertilizer which is prepared from nitrate mud, animal waste, flint clay, a rapeseed cake, phosphorus powder, plant ash and biogas fluid via combination and fermentation. The preparation process comprises the following steps: respectively airing the nitrate mud, the flint clay, the phosphorus powder, the rapeseed cake, the plant ash and the animal waste until the water content of the materials is lower than 12%, then respectively smashing the materials, mixing the materials and stirring uniformly to obtain a mixed material, mixing the biogas fluid with the mixed material to stir uniformly and adjusting the water content of the mixed material to 55-65%, and carrying out pile fermentation. The bio-organic fertilizer is wide in raw material source, low in cost, simple in preparation process, low in prepared product cost, comprehensive in nutrient element and good in fertilizer effect, and has the properties of increasing the organic matters of the soil, improving the soil structure, promoting the microbial activities of the soil, strengthening the fertilizer maintenance and fertilizer supply of the soil, increasing the crop output and improving the agricultural product quality.

Owner:林文罗

Nylon-bagged black/dark tea-hawthorn mixed tea with functions of promoting digestion, reducing lipid level and relieving constipation

InactiveCN102550741AReduce environmental pollutionKeep the original flavor of the materialPre-extraction tea treatmentFermented teaDigestion

The invention relates to the technical field of health beverages for office consumers and in particular relates to a bagged tea beverage which is made from the mixture of black tea, Poria brick dark tea and hawthorn, has the functions of promoting digestion, reducing lipid level and relieving constipation, is packaged with triangular three-dimensional bags in food-grade transparent nylon filter cloth material and is convenient to drink. The invention adopts the technical scheme as follows: the bagged tea is made from the following three raw materials in percentage by weight: 40% of black tea, 40% of Poria brick dark tea and 20% hawthorn. The bagged tea is suitable for white-collar office workers who are in sub-health state in the modern fast-paced life and suffer from dyspepsia, hyperlipoidemia and constipation. The invention is helpful for improving and preserving the health of office consumers.

Owner:杨正 +1

Two-position five-way changing-over valve and sprinkling control system using same

ActiveCN101338822AReduced parts countSimple structureOperating means/releasing devices for valvesMultiple way valvesControl systemManipulator

The present invention discloses a two-position five-way reversing valve. The valve body of the two-position five-way reversing valve comprises a five-way pipe, a first bent pipe and a second bent pipe; the five-way pipe is provided with five pipe sections which are distributed in the form of an approximate star, wherein, the first and the fourth pipe sections are respectively communicated with the fifth pipe section, the second pipe section is communicated with the first pipe, and the third pipe section is communicated with the fourth pipe section; one end of the first bent pipe and one end of the second bent pipe are respectively connected with the outlets of the first and the fourth pipe sections of the five-way pipe. The valve core of the two-position five-way reversing valve comprises a first sealing valve, a second sealing valve, a first link rod and a second link rod; wherein, the first and the second sealing valves are respectively arranged in the first and the fourth pipe sections of the five-way pipe; the first and the second sealing valves are respectively assembled on one end of the first link rod and one end of the second link rod, and the other ends of the first and the second link rods respectively penetrate the first and the second bent pipes and are connected with the output ends of a first manipulator and a second manipulator used to push the valve core to shift relative to the valve body. The two-position five-way reversing valve, which has the advantages of simple structure, convenient control and low cost, can satisfy the requirement on high-speed and large-flow multi-path spraying. On the basis of the two-position five-way reversing valve, the present invention also discloses a spraying control system using the two-position five-way reversing valve, which has two independent spraying paths.

Owner:CHINA FIRST HIGHWAY ENG

Preparation method of in-situ polymeric composite conductive/antistatic fiber

ActiveCN107022805AWith permanent antistatic functionExpand exportsElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSpin speedSurface modification

The invention provides a preparation method of an in-situ polymeric composite conductive / antistatic fiber. The preparation method comprises the following steps of carrying out the surface modification of nano conductive powder, preparing an antistatic master batch, and drying the antistatic master batch for 2 to 8 hours at a temperature of 100 to 180 DEG C, uniformly mixing the antistatic master batch with a basic resin slice, and afterwards, carrying out melt spinning, so as to obtain the in-situ polymeric composite conductive / antistatic fiber, wherein a spinning speed is 600m / min to 3,000m / min; the initial pressure of a spinning component is 8MPa to 16MPa. A brand-new antistatic mechanism is adopted by the preparation method to prepare a novel antistatic fiber; the in-situ polymeric composite conductive / antistatic fiber has a permanent antistatic function; the mechanical performance can reach the standard of a common fiber; the requirements of various kinds of weaving are completely met; the cost is equivalent to that of antistatic finishing, which is only quarter of that of the using of a white conductive fiber; the pollution is reduced; by using the preparation method, the export of a textile can be expanded; the value added of the textile is promoted.

Owner:ZHEJIANG YINYU NEW MATERIAL CO LTD

Recycled organic fertilizer

InactiveCN103787701ABalanced fertilizer effectImprove fertilizer efficiencyOrganic fertilisersEcological environmentSludge

The invention provides a recycled organic fertilizer obtained by reusing sludge, cob and plant ash. The recycled organic fertilizer can improve and renovate organic matters in soil, promote microbe breeding, improve water retention and fertilizer conservation capability of soil, improve a soil structure, promote tight combination of nitrification, growth promotion and biological control, create a good ecological environment for good growth of plants and really realize continuous development of agriculture. Sludge, livestock and poultry faeces, plant ash, bone paste and EM bacteria are mixed into the recycled organic fertilizer. A weight ratio of sludge, livestock and poultry faeces, plant ash, bone paste to EM bacteria is 25: 40: 10: 20: 5. The recycled organic fertilizer can reduce use of chemical fertilizer, purify the local environment, greatly utilize and recover livestock and poultry faeces, change waste into valuables, improve farmer income, accord with a currently recommended strategic conception of rapid development of agricultural products and really realize continuous development of agriculture.

Owner:吴根义 +1

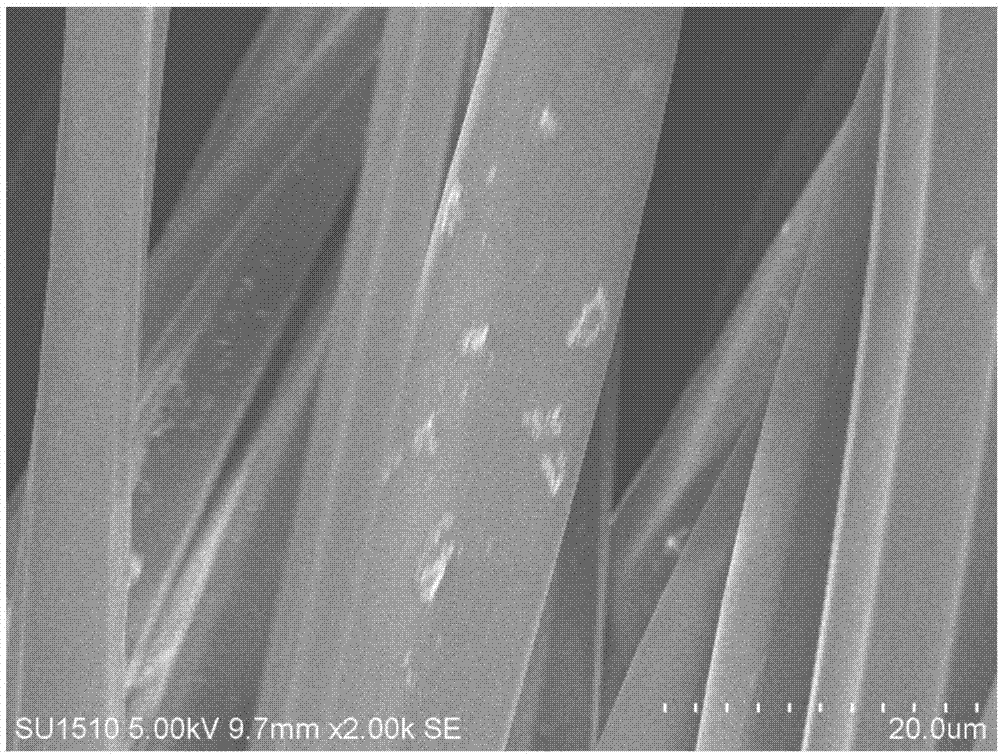

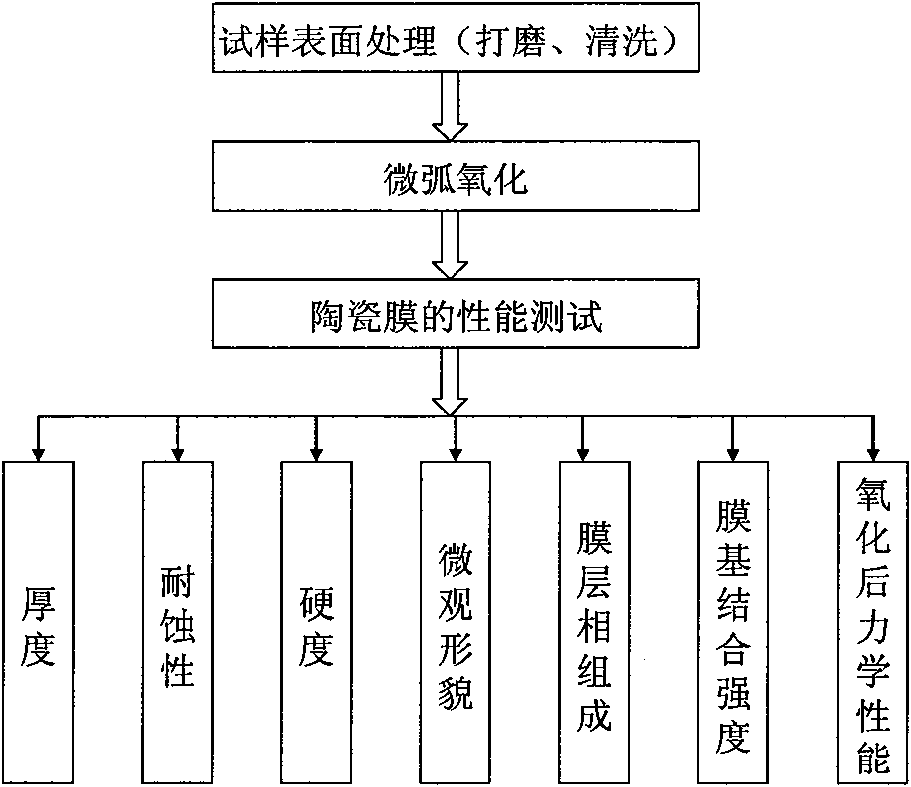

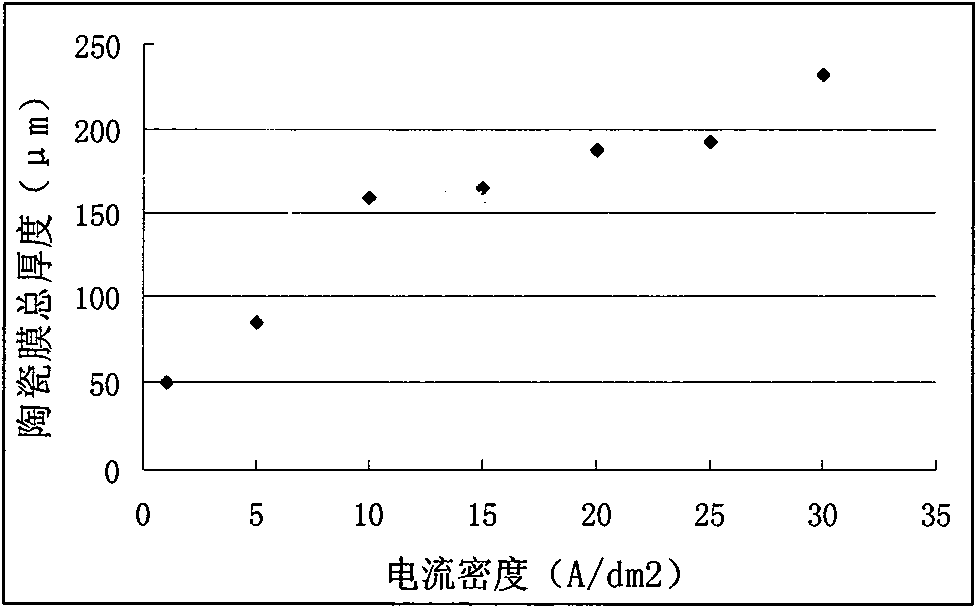

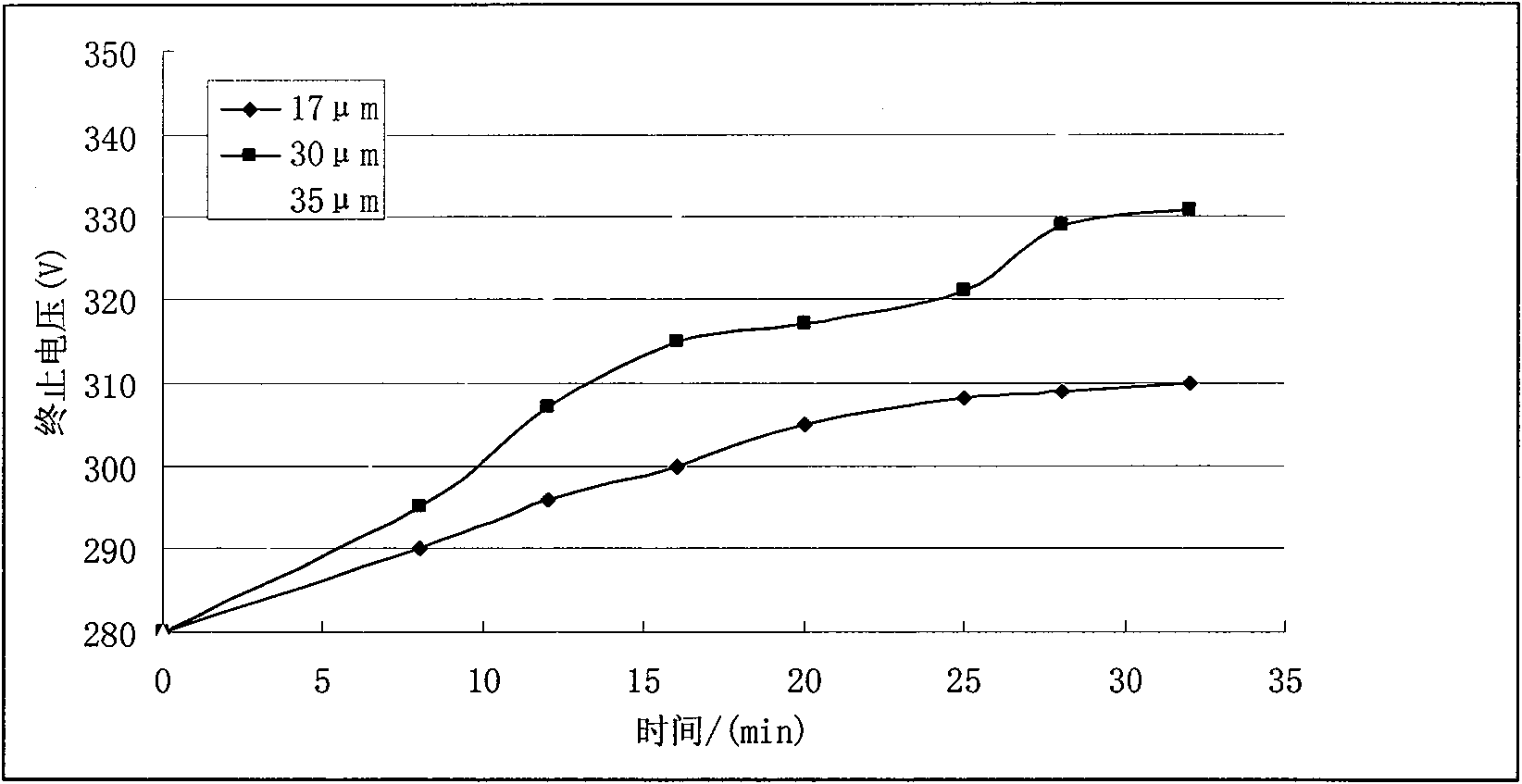

Microarc oxidation-based surface modifying method for air-conditioner parts of vehicle

InactiveCN102108538AImprove bindingIncrease productivityAnodisationImpulse frequencyPlasma electrolytic oxidation

The invention provides a microarc oxidation-based surface modifying method for air-conditioner parts of a vehicle. The method comprises the following steps: removing grease on the surface of a part to be processed; grinding the part surface by a grinding machine to remove burr on the surface of the part; placing the grinded part in a microarc oxidation tank, forming a compact microarc oxidation film layer on the part surface through microarc oxidation, wherein, during microarc oxidation, the impulse frequency of a power supply is between 600 and 800HZ, the pulse duty cycle is 20 percent, the positive pulse number is 20, the negative pulse number is 1, the current density is between 5 and 20dm<2>, the voltage is between 0 and 350V, the electrolyte temperature is between 15 and 45 DEG C, and the time of microarc oxidation is between 5 and 45 minutes; the electrolyte of microarc oxidation comprises 7 to 11g / L silicate, 1.5 to 4.5g / L boric acid, 0.5 to 1.2g / L potassium hydroxide and 2.1ml / L hydrogen peroxide. The microarc oxidation-based surface modifying method for the air-conditioner parts of the vehicle has the advantages of high production efficiency, and is water-saving, energy-saving, environment-friendly.

Owner:刘远彬

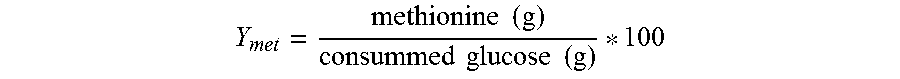

Method and microorganism for methionine production by fermentation with improved methionine efflux

ActiveUS20170240938A1High expressionMethionine export is enhancedBacteriaDepsipeptidesEscherichia coliMicroorganism

The present invention is related to a recombinant microorganism optimised for the fermentative production of methionine and / or its derivatives, wherein in said recombinant strain, the methionine efflux is enhanced by overexpressing the homologous logous genes of ygaZ and ygaH genes from Escherichia coli. It is also related to a method for optimising the fermentative production of methionine or its derivatives comprising the steps of: a. culturing a recombinant microorganism wherein in said microorganism, the methionine efflux is enhanced by overexpressing the ygaZH homologous genes of ygaZ and ygaH genes from Escherichia coli, in an appropriate culture medium comprising a fermentable source of carbon and a source of sulphur, and b. recovering methionine and / or its derivatives from the culture medium.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com