Preparation method of in-situ polymeric composite conductive/antistatic fiber

An anti-static fiber, composite conductive technology, applied in the manufacture of conductive/anti-static filament, single-component polyester rayon, single-component polyamide rayon, etc., can solve fabric stripes, increase disputes, difficult Acceptance and other issues to achieve the effect of increasing added value, reducing pollution and expanding exports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

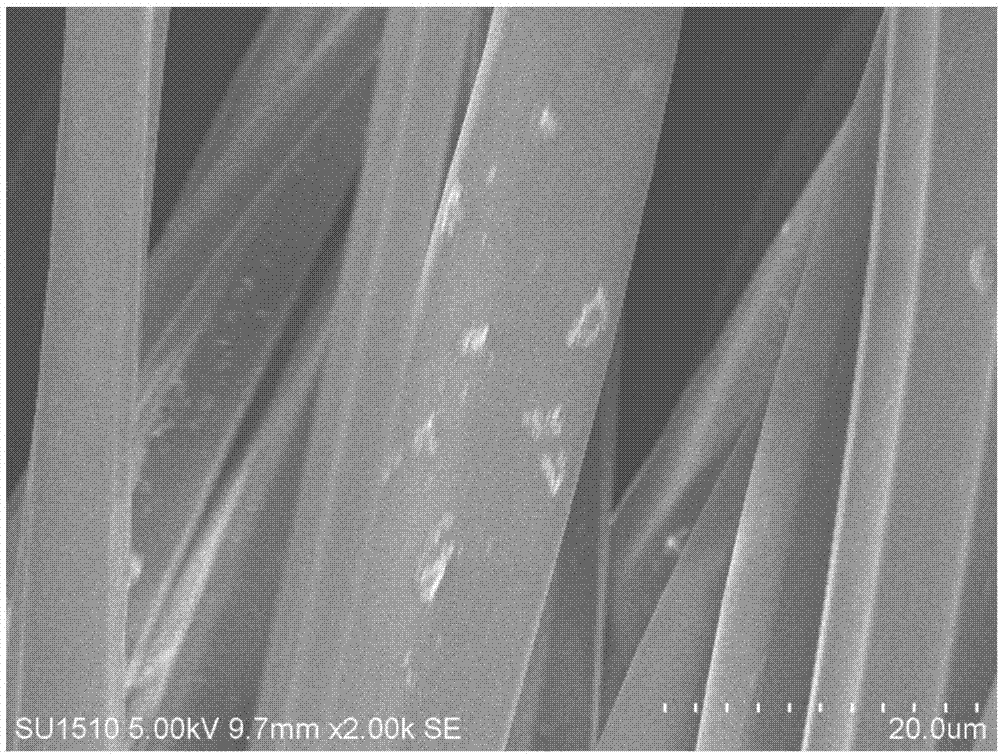

Image

Examples

Embodiment 1

[0030] (1) Prepare the montmorillonite powder with a particle size less than 500nm by mechanical pulverization;

[0031] (2) The montmorillonite powder is prepared into a conductive nano-conductive powder through the interpenetrating network polymerization of conductive organic matter, that is, the conductive organic monomer is added to the nano-montmorillonite suspension at a temperature of 200 ° C , the pressure is 0.5MPa and under the conditions of nitrogen-doped titanium dioxide, reaction polymerization is carried out to form conductive nano-powder with interpenetrating network structure, wherein the addition amount of conductive organic monomer is 20% of the mass of nano-montmorillonite;

[0032] (3) Surface modification of nano-conductive powder: surface-modify the nano-conductive powder through a high-speed kneader, the temperature is 60°C, the stirring speed is 1000 rpm, and the surface modifier is sprayed into the nano-conductive powder through the atomization device ...

Embodiment 2

[0039](1) Prepare the montmorillonite powder with a particle size less than 500nm by mechanical pulverization;

[0040] (2) The montmorillonite powder is prepared into a conductive montmorillonite powder through the interpenetrating network polymerization of conductive organic matter, that is, the conductive organic monomer is added to the nano-montmorillonite suspension at a temperature of 100 ° C , the reaction polymerization is carried out under the conditions of 0.1MPa and dibutyltin to form a conductive nano-powder with an interpenetrating network structure, wherein the added amount of the conductive organic monomer is 10% to 50% of the mass of the nano-montmorillonite;

[0041] (3) Surface modification of nano-conductive powder: surface-modify the nano-conductive powder through a high-speed kneader, the temperature is 60°C, the stirring speed is 1000 rpm, and the surface modifier is sprayed into the nano-conductive powder through the atomization device body mixing, the a...

Embodiment 3

[0047] (1) Prepare the montmorillonite powder with a particle size less than 500nm by mechanical pulverization;

[0048] (2) The montmorillonite powder is prepared into a conductive montmorillonite powder through the interpenetrating network polymerization of conductive organic matter, that is, the conductive organic monomer is added to the nano-montmorillonite suspension at a temperature of 300 ° C , the reaction polymerization is carried out under the conditions of 1MPa and nitrogen-doped titanium dioxide to form conductive nano-powder with an interpenetrating network structure, wherein the added amount of the conductive organic monomer is 10-50% of the mass of nano-montmorillonite;

[0049] (3) Surface modification of nano-conductive powder: surface-modify the nano-conductive powder through a high-speed kneader, the temperature is 60°C, the stirring speed is 1000 rpm, and the surface modifier is sprayed into the nano-conductive powder through the atomization device body mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com