Flow guiding type exhaust check valve

An exhaust valve and check technology, applied in the field of diversion check exhaust valve, can solve the problems of inconvenient installation of the jet tube, inconvenient installation of the jet tube, and decreased function of the jet tube, and achieve good sealing and reasonable structure. , the effect of increasing exports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

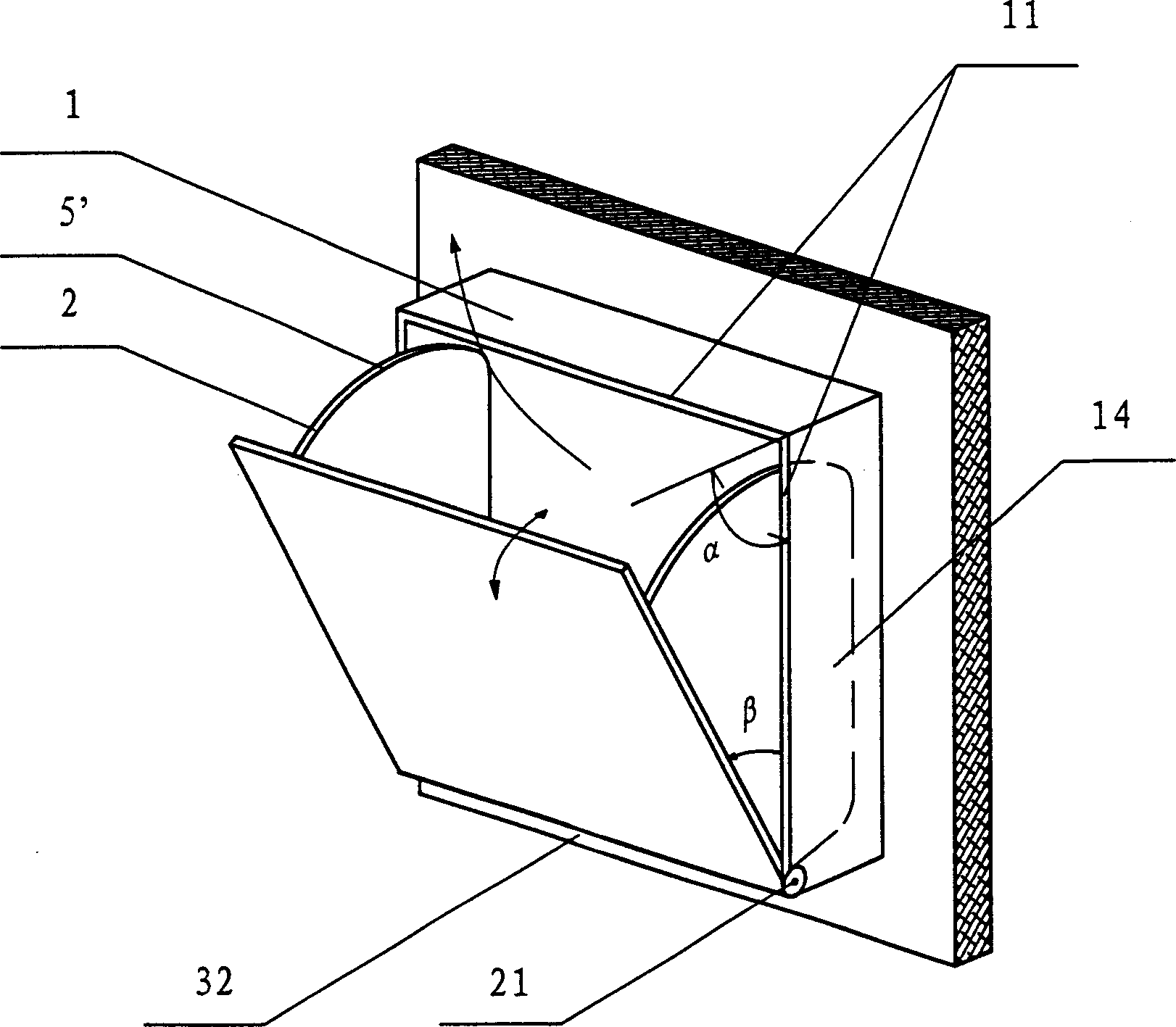

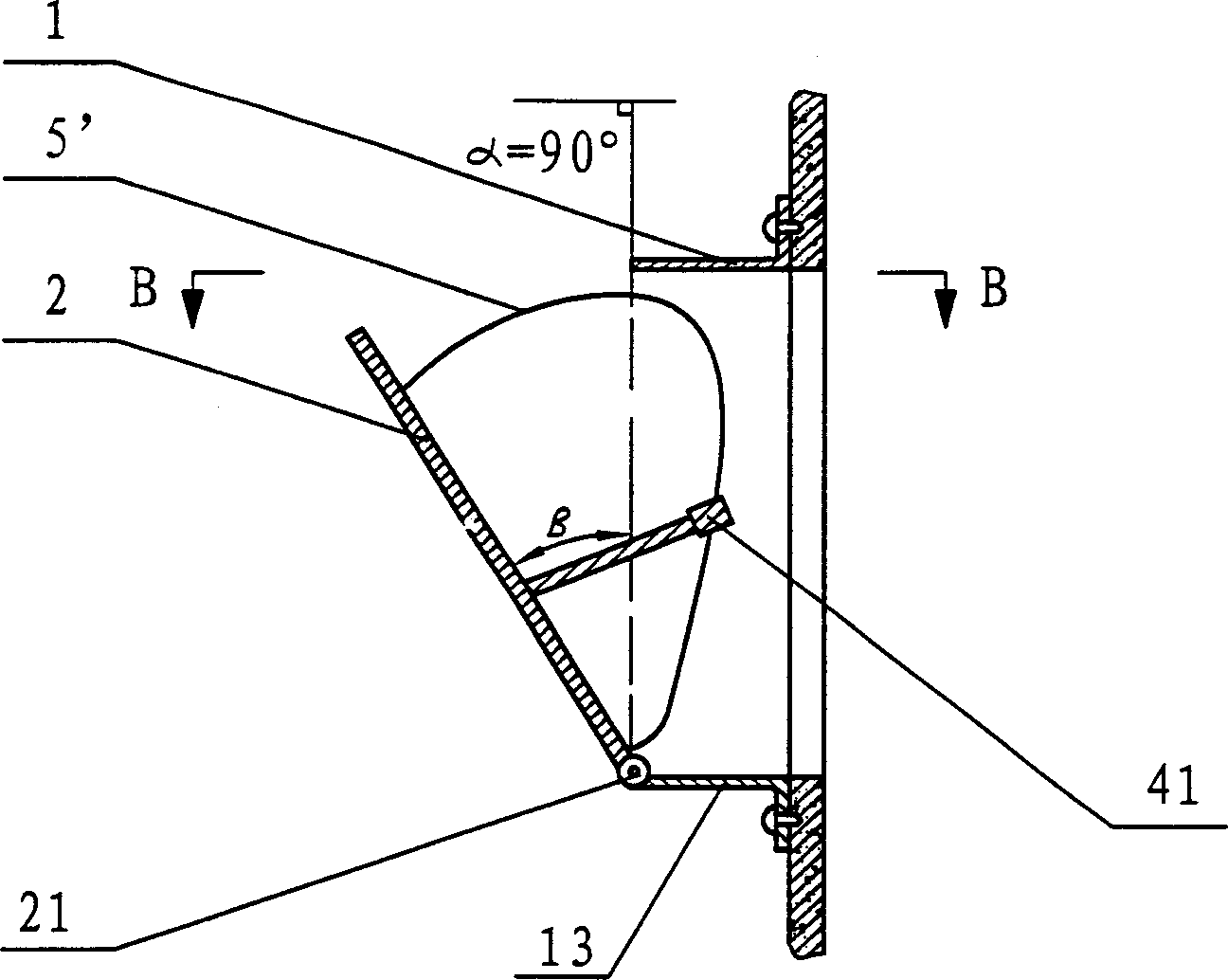

[0033] Example 1, see figure 1 , Figure A and Figure 1B , figure 1 , Figure A and Figure 1B A diversion check exhaust valve is shown in , which includes: a cylindrical valve body 1 with a rectangular cross section, a valve plate 2 and a return device, the clamp between the outlet end surface 11 of the valve body 1 and the horizontal plane The angle α is 90 degrees, the lower end of the valve plate 2 is hinged to the outlet end of the bottom surface 13 of the valve body 1 through the valve plate rotating shaft 21, and the return device fixed on the inner surface of the valve plate 2 is a weight 41. The disc 2 is within the maximum opening position, the center of gravity of the valve disc 2 and the center of gravity of the weight 41 are always on both sides of the hinge point of the valve disc shaft 21, and the gravity moment of the weight 41 on the hinge point of the rotating shaft is greater than that of the valve disc 2 on the hinge point The moment of gravity, after t...

Embodiment 2

[0034] Example 2, see figure 2 , Figure 2A with Figure 2B , figure 2 , Figure 2A with Figure 2BAnother preferred diversion check exhaust valve is shown in , which includes: a valve body 1 with a square cross section, a valve plate 2 and a return device, the outlet end of the bottom surface 13 of the valve body 1 faces The oblique upward extension is in the shape of an arc, and of course it can also extend upwards in an inclined or folded shape. The arc is the best, and the bottom ends of the two sides 14 of the valve body 1 extend together with the outlet end of the bottom surface 13, so that An inclined valve body outlet end surface 11 is formed. The angle α between the outlet end surface 11 and the horizontal plane is 45 degrees, and the lower end of the valve plate 2 is hinged to the outlet end of the bottom surface 13 of the valve body 1 through the valve plate rotating shaft 21. Figure 2A , Figure 2B Among them, the return device is a return spring 42 conne...

Embodiment 3

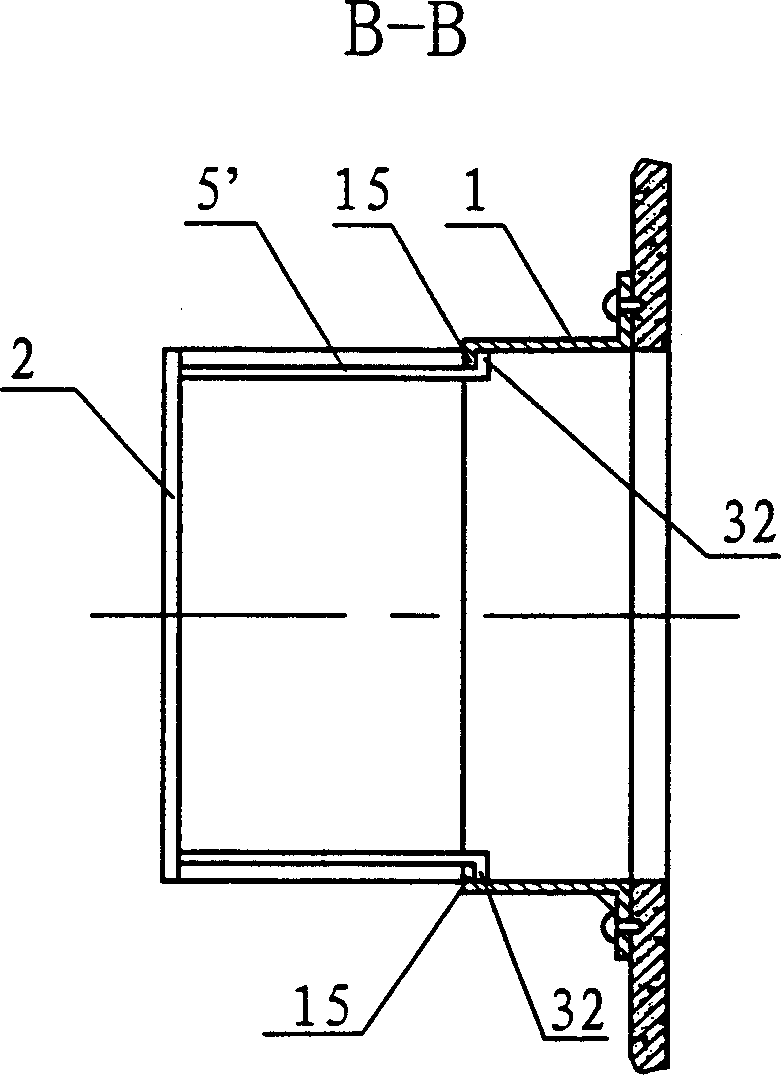

[0035] Example 3, see image 3 , image 3 shows a preferred flow diversion check exhaust valve, which includes: a valve body 1 with a square cross section, a valve plate 2 and a return device; the outlet end of the bottom surface 13 of the valve body 1 is inclined The upper part is arc-shaped, and the lower end of the valve plate 2 is hinged to the outlet end of the bottom surface 13 of the valve body 1 through the valve plate rotating shaft 21. The above-mentioned return device is connected between the valve plate 2 and the valve body 1. Return spring 42. Two guide fins are arranged on both sides of the valve sheet 2 close to the edge, and the guide fins are movable fins 5' that are perpendicular to the valve sheet 2 and fixed on both sides of the valve sheet 2. The shape of the sheet 5' is roughly fan-shaped, and the shape of the movable flap 5' is a shape capable of sealing or covering the opening between the valve sheet 2 and the side of the valve body 1 when the valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com