Non-zillerite environment protection energy-saving diaphragm cloth and weaving method thereof

An energy-saving, asbestos-free technology, applied to textiles, papermaking, textiles, fabrics, etc., to achieve the effect of promoting exports and major economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

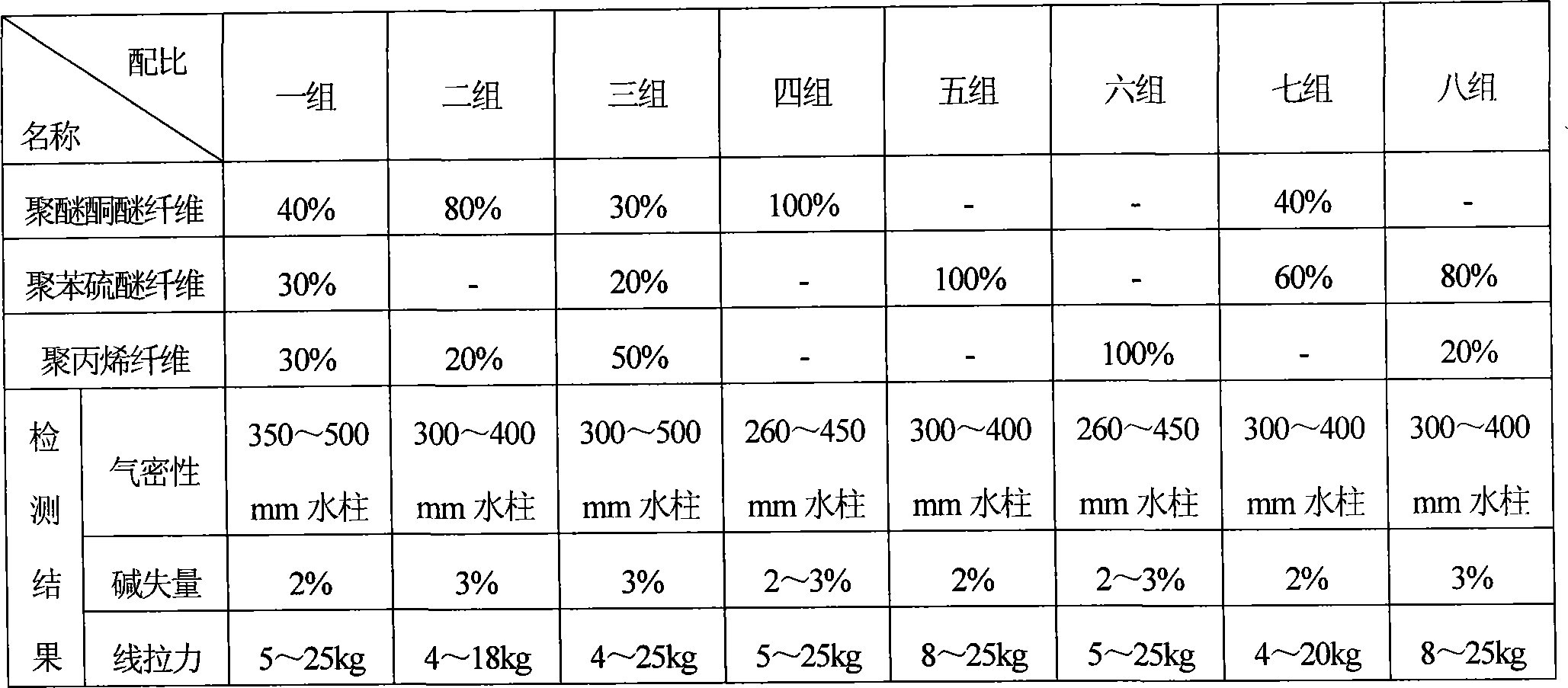

[0022] Specific Embodiment 1: The asbestos-free, environmentally friendly and energy-saving diaphragm cloth of this embodiment is woven from one, two or three of polyether ketone ether fibers, polyphenylene sulfide fibers, and polypropylene fibers, and Diaphragm cloth that meets the following conditions: (1) unit weight: 0.5-1.5kg / square meter; (2) cloth thickness range: 0.5-1.5mm; (3) warp and weft density: warp 100-280 / 10cm, weft 56- 150 pieces / 10cm; (4) Alkali loss: no more than 2%; (5) Airtight performance No air bubbles are allowed within 2 minutes under the pressure of 300 mm water column.

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that when polyether ketone ether fiber and polyphenylene sulfide fiber are used as raw materials, the mass percentage of the two is 30-70:30-70.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 in that when polyphenylene sulfide fibers and polypropylene fibers are used as raw materials, the mass percentage of the two is 70-95:5-30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com