Preparation method of compound antibacterial deodorizing functional masterbatch and fibers

A technology of compound antibacterial and functional masterbatch, applied in the field of fiber preparation and compound antibacterial and deodorizing masterbatch, can solve the problems of increasing disputes, unacceptable, high processing cost, and achieve the goal of increasing added value, reducing pollution and expanding exports. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

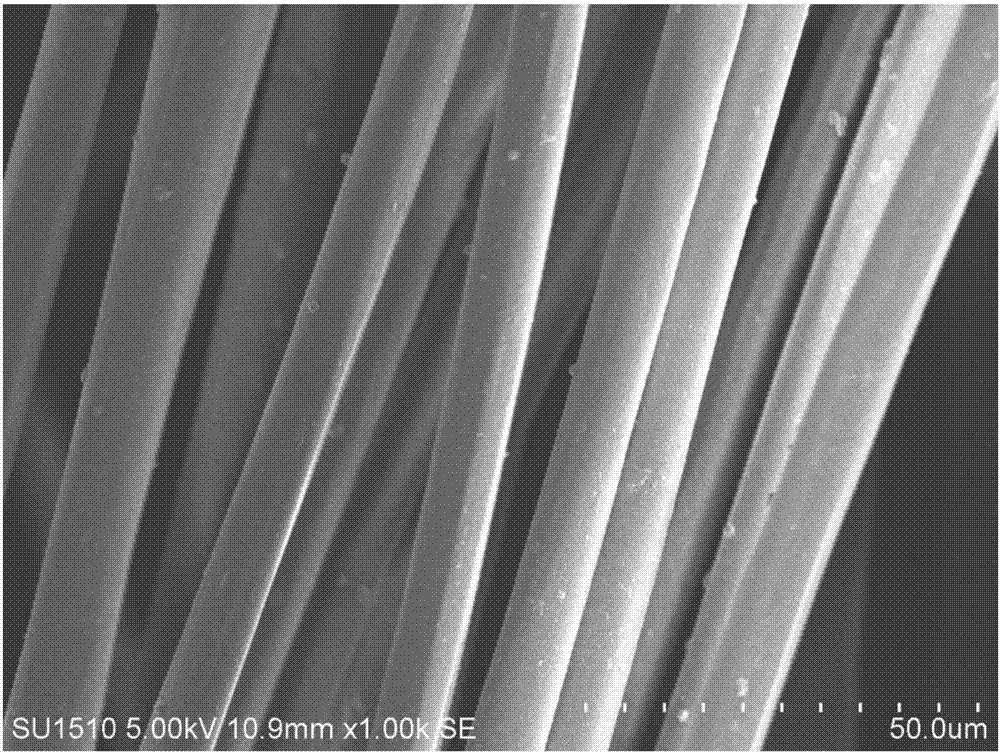

Image

Examples

Embodiment 1

[0032] Prepare cuprous oxide powder with a particle size of less than 2 μm by mechanical pulverization;

[0033] Surface modification of cuprous oxide powder: surface modification of cuprous oxide powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 500 rpm. The surface modifier is added through a metering device and mixed with cuprous oxide powder , the addition of the surface modifier is 1wt% of the mass of the cuprous oxide powder, mixed at high speed for 90min, and the surface modifier is the active silicone series surface modifier vinyltrimethoxysilane;

[0034] Functional composite resin powder configuration: Sodium dodecylbenzenesulfonate and polyethylene polyamine are mixed with resin powder through a pre-mixer according to the molar ratio of 9:1 to obtain functional composite resin powder. The ratio of mixed material to resin powder 1:20;

[0035] Preparation of antibacterial and deodorant masterbatch: Mix the surface-modified cuprous ...

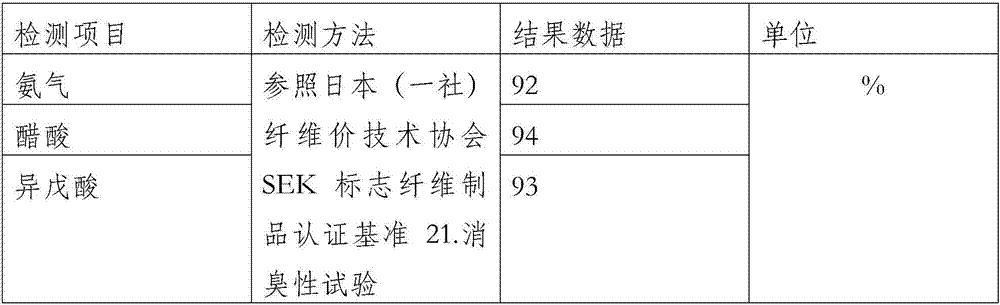

Embodiment 2

[0037] Prepare cuprous oxide powder with a particle size of less than 2 μm by mechanical pulverization;

[0038] Surface modification of cuprous oxide powder: surface modification of cuprous oxide powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 500 rpm. The surface modifier is added through a metering device and mixed with cuprous oxide powder , the addition of the surface modifier is 1wt% of the mass of the cuprous oxide powder, mixed at high speed for 90 minutes; the surface modifier is the active silicone series surface modifier vinyltrimethoxysilane;

[0039] Functional composite resin powder configuration: Sodium dodecylbenzenesulfonate and polyethylene polyamine are mixed with resin powder through a pre-mixer at a molar ratio of 9:1 to obtain a functional composite resin powder. The ratio of the mixed material to the resin powder 1:20;

[0040]Preparation of antibacterial and deodorant masterbatch: Mix the surface-modified cuprous ox...

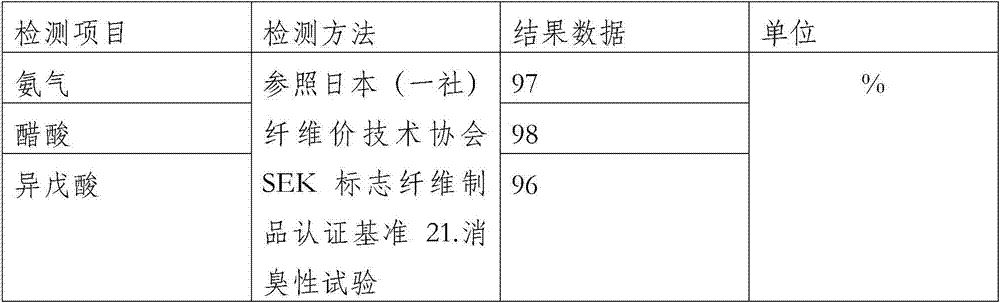

Embodiment 3

[0046] Prepare cuprous oxide powder with a particle size of less than 2 μm by mechanical pulverization;

[0047] Surface modification of cuprous oxide powder: surface modification of cuprous oxide powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 500 rpm. The surface modifier is added through a metering device and mixed with cuprous oxide powder , the addition of the surface modifier is 5wt% of the mass of the cuprous oxide powder, mixed at high speed for 90min; the surface modifier is the active silicone series surface modifier 3-aminopropyltrimethoxysilane;

[0048] Functional composite resin powder configuration: Sodium dodecylbenzenesulfonate and polyethylene polyamine are mixed with PBT resin powder through a pre-mixer at a molar ratio of 1:9 to obtain a functional composite resin powder, and the mixed material and resin powder The body ratio is 1:20;

[0049] Preparation of antibacterial and deodorant masterbatch: Mix the surface-modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com