A kind of preparation method of zinc oxide polyester fiber deposited on the surface of titanium dioxide

A technology of polyester fiber and titanium dioxide, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component polyester rayon, etc., can solve the problems of low antibacterial efficiency, decreased antibacterial effect, additional pollution, etc., and achieve better antibacterial effect , increase added value, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

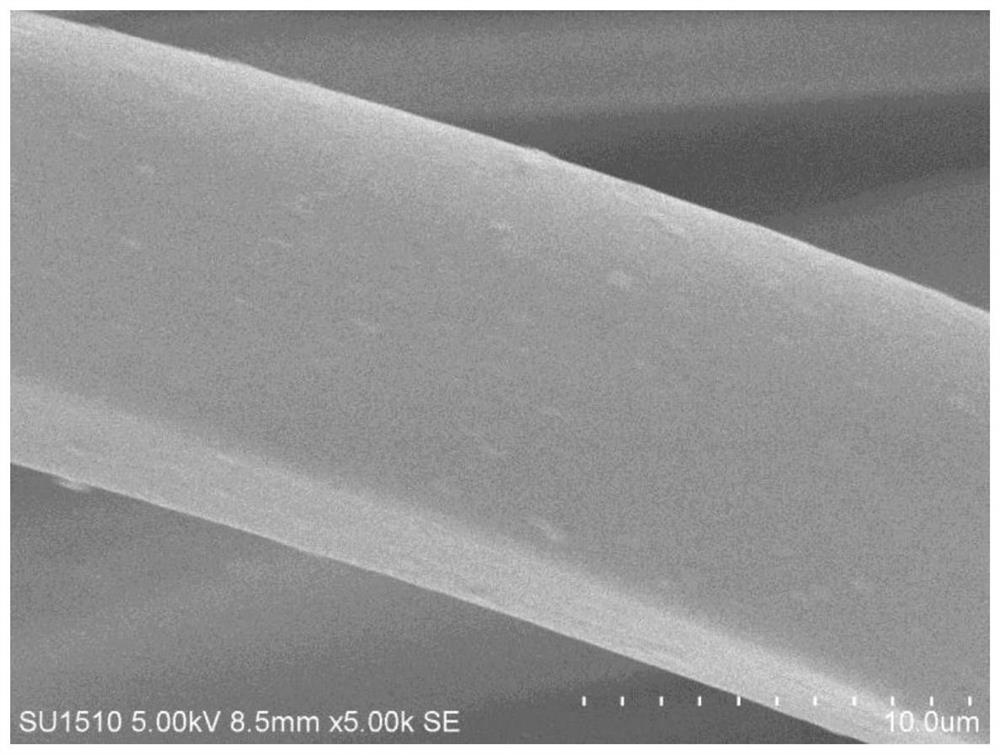

Image

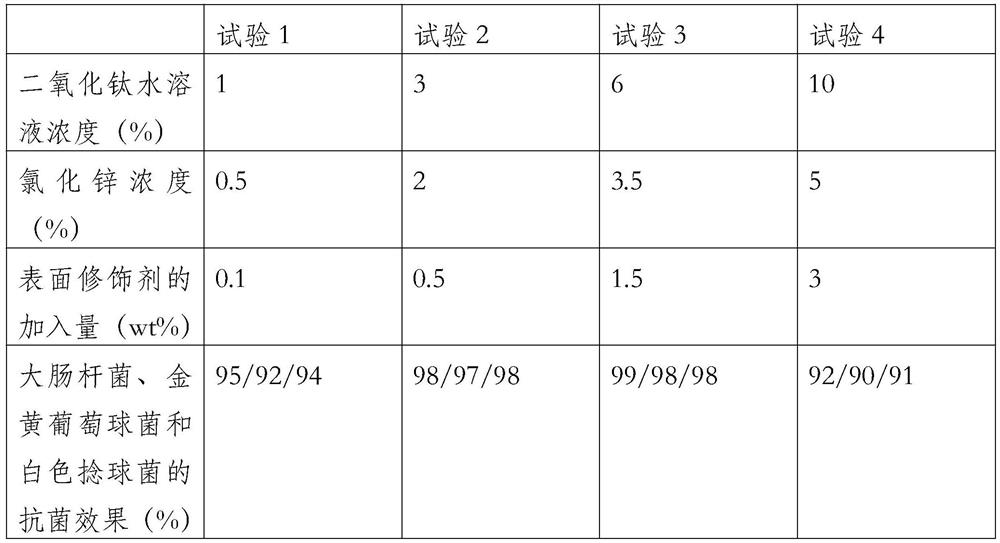

Examples

Embodiment 1

[0025] A preparation method for depositing zinc oxide polyester fiber on the surface of titanium dioxide, comprising the following steps:

[0026] (1) Prepare nano antibacterial powder with a particle size of less than 100nm, specifically: select titanium dioxide with a particle size of 25 nanometers as the substrate, and deposit nano-zinc oxide on the surface of titanium dioxide by chemical precipitation. The specific process is to select a nano-titanium dioxide aqueous solution, The concentration is 10%, add zinc chloride, the concentration is 0.5%, adjust the pH value to 7 by dropping a low concentration (0.1%) sodium hydroxide solution, react at 180°C for 3 hours in a hydrothermal kettle, and obtain nano powder by rotary evaporation body;

[0027] (2) Surface modification of nano antibacterial powder: surface modification of nano antibacterial powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 2000 rpm, and the surface modifier is sprayed ...

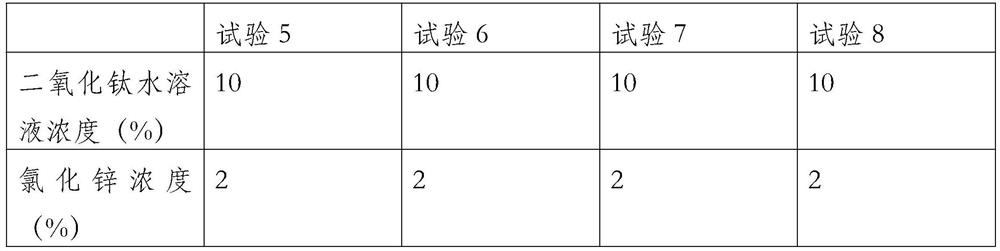

Embodiment 2

[0031] A preparation method for depositing zinc oxide polyester fiber on the surface of titanium dioxide, comprising the following steps:

[0032] (1) Prepare nano antibacterial powder with a particle size of less than 100nm, specifically select titanium dioxide with a particle size of 25 nm as the substrate, and deposit nano-zinc oxide on the surface of the titanium dioxide by chemical precipitation. The specific process is to select a nano-titanium dioxide aqueous solution with a concentration of 10%, add zinc chloride with a concentration of 1%, adjust the pH value to 7 by dropping a low-concentration (0.1%) sodium hydroxide solution, and react at 180°C through a hydrothermal kettle 3h, obtain nanopowder through rotary evaporation;;

[0033] (2) Surface modification of nano antibacterial powder: surface modification of nano antibacterial powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 2000 rpm. The surface modifier is sprayed into the na...

Embodiment 3

[0037] A preparation method for depositing zinc oxide polyester fiber on the surface of titanium dioxide, comprising the following steps:

[0038] (1) Prepare nano antibacterial powder with a particle size of less than 100nm, specifically select titanium dioxide with a particle size of 25 nm as the substrate, and deposit nano-zinc oxide on the surface of the titanium dioxide by chemical precipitation. The specific process is to select a nano-titanium dioxide aqueous solution with a concentration of 10%, add zinc chloride with a concentration of 2%, adjust the pH value to 7 by dropping a low-concentration (0.1%) sodium hydroxide solution, and react at 180°C through a hydrothermal kettle 3h, obtain nanopowder through rotary evaporation;

[0039] (2) Surface modification of nano antibacterial powder: surface modification of nano antibacterial powder through a high-speed kneader at a temperature of 20°C and a stirring speed of 2000 rpm. The surface modifier is sprayed into the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com