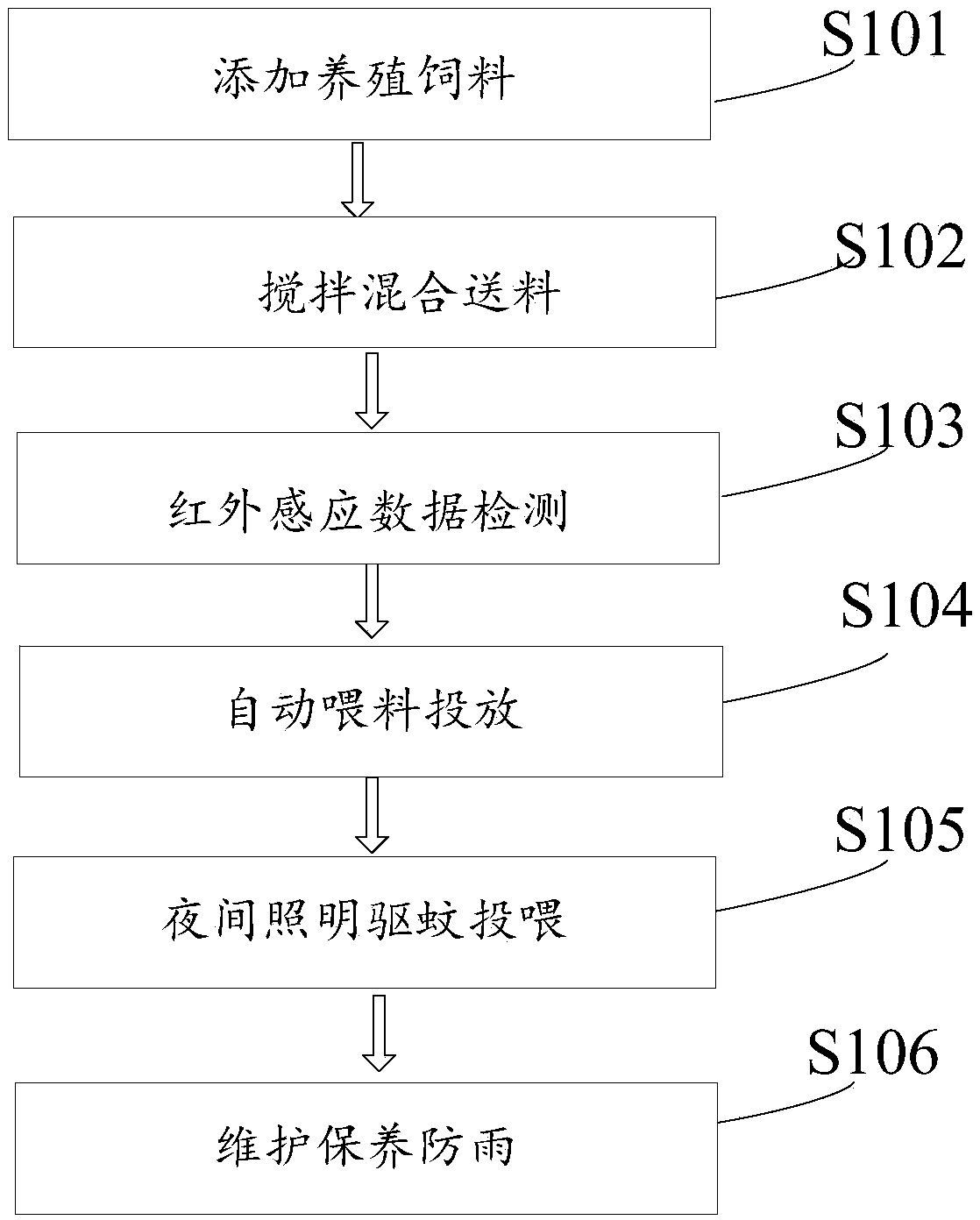

Internet-of-things type aquaculture fully-automatic feed-releasing device and application method thereof

An aquaculture and feeding device technology, applied in application, fish farming, climate change adaptation and other directions, can solve the problems of lack of secondary stirring of feed, inability to multi-angle feed, lack of feed filtering function, etc., to achieve convenient feeding , The effect of reducing the amount of labor and improving the efficiency of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

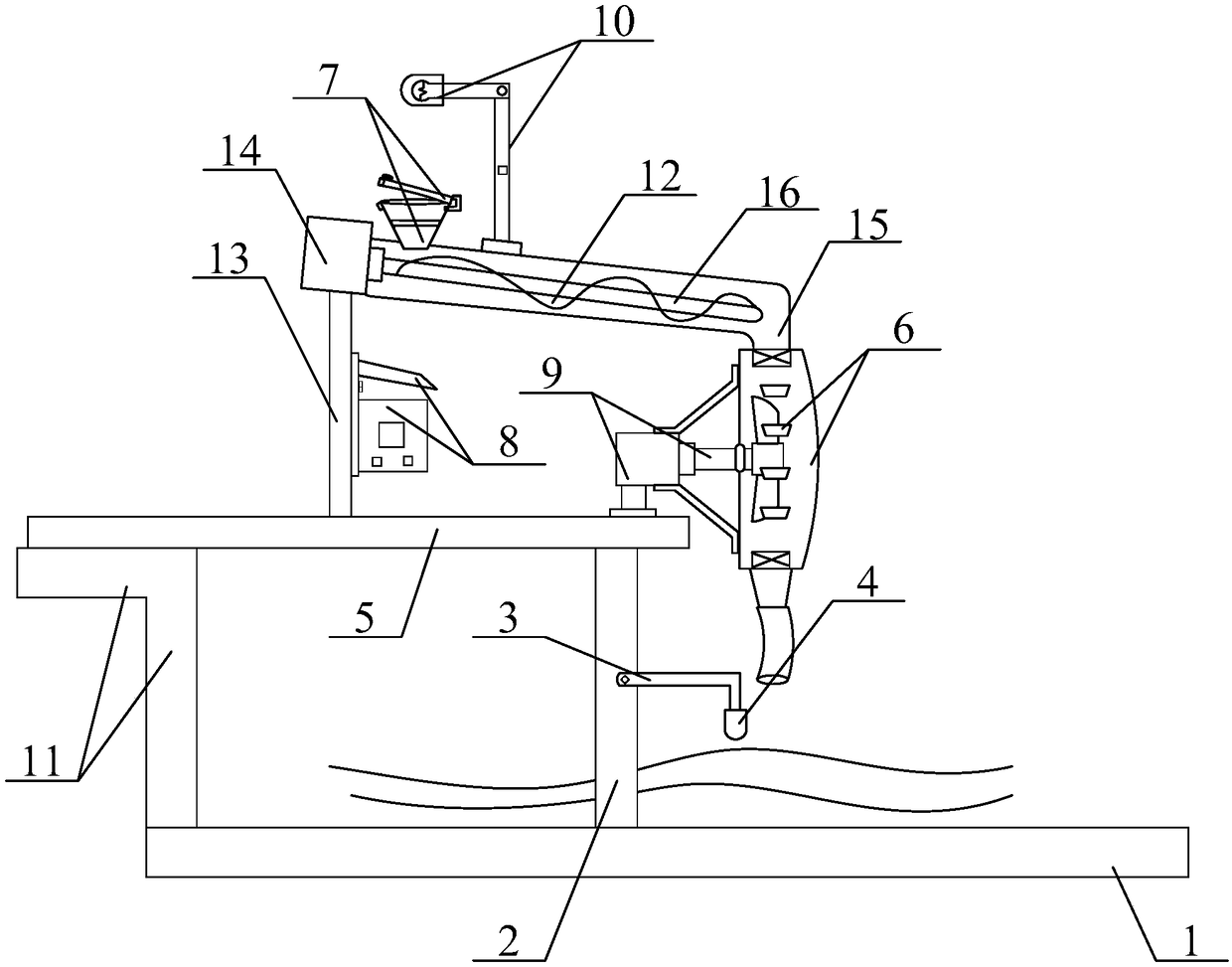

[0045] The present invention will be further described below in conjunction with accompanying drawing:

[0046] In the picture:

[0047] as attached figure 2 to attach Figure 8 shown

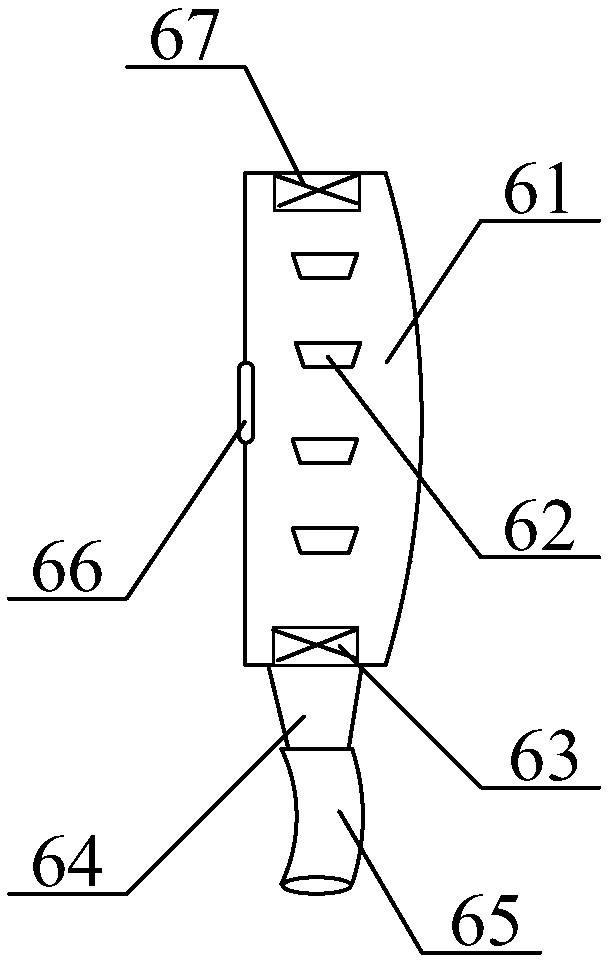

[0048] An Internet of Things type aquaculture automatic feeding device, comprising an aquaculture pool bottom 1, a support column 2, an L-shaped support rod 3, an infrared sensor 4, a feeding table 5, and a multi-angle feeding cylinder structure 6, which can Filter feed hopper structure 7, insulation protection control box structure 8, material distribution mixing blade structure 9, mosquito-proof lighting structure 10, embankment 11, rotating dragon blade 12, feeding support rod 13, feeding motor 14, material guide cylinder 15 and the stirring and feeding shaft 16, the lower end of the support column 2 is inserted on the left side of the upper surface of the bottom 1 of the aquaculture pond, and the upper end of the support column 2 is bolted to the right side of the lower surface of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com