Tunneling angle fine-tuning device of shield machine

A technology of angle fine-tuning and shield machine, which is applied to mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as increasing the adjustment range of scraper excavation angle, dust and mud pollution, and impact, so as to protect safety and stability, improve The effect of driving precision and ensuring adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

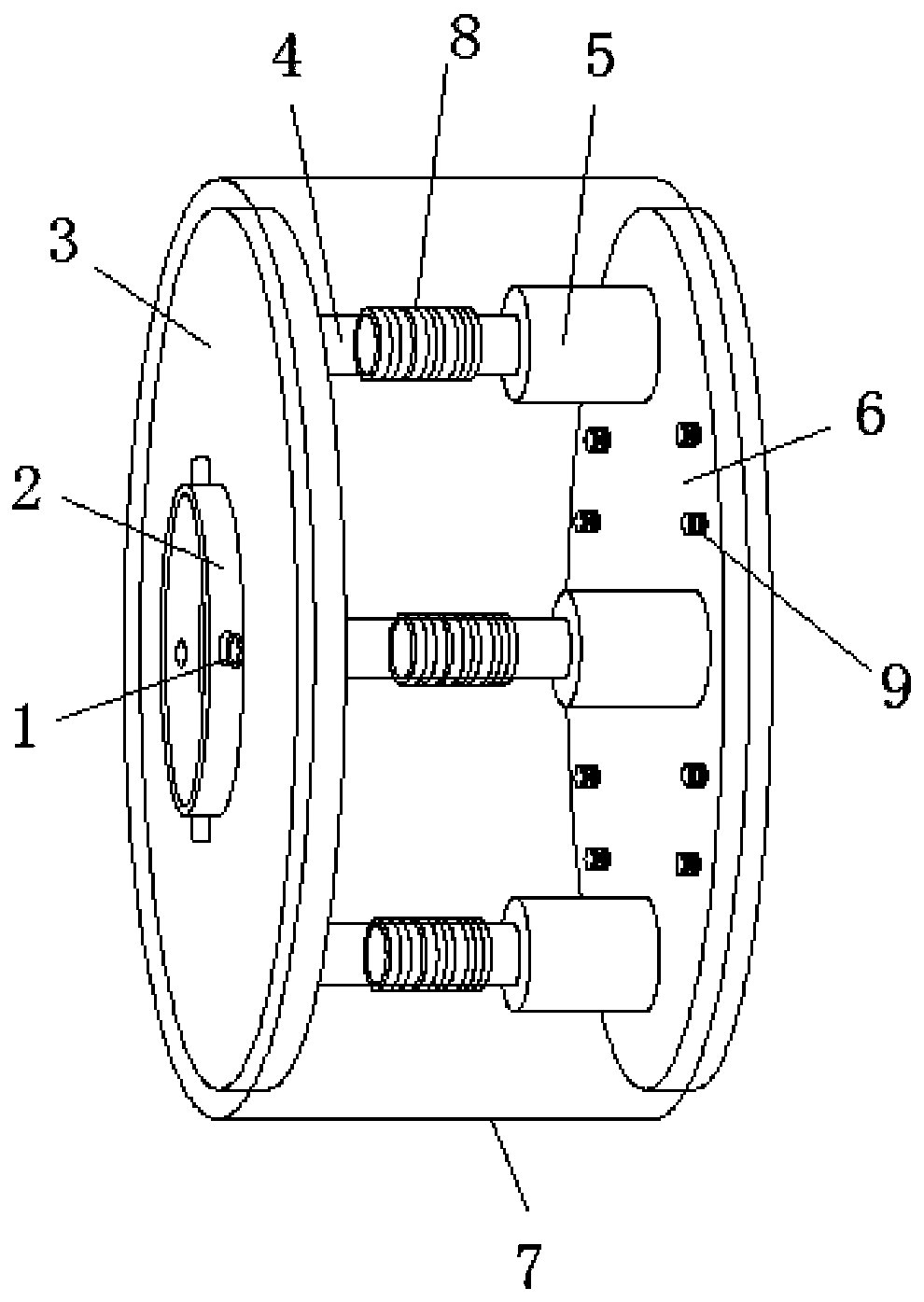

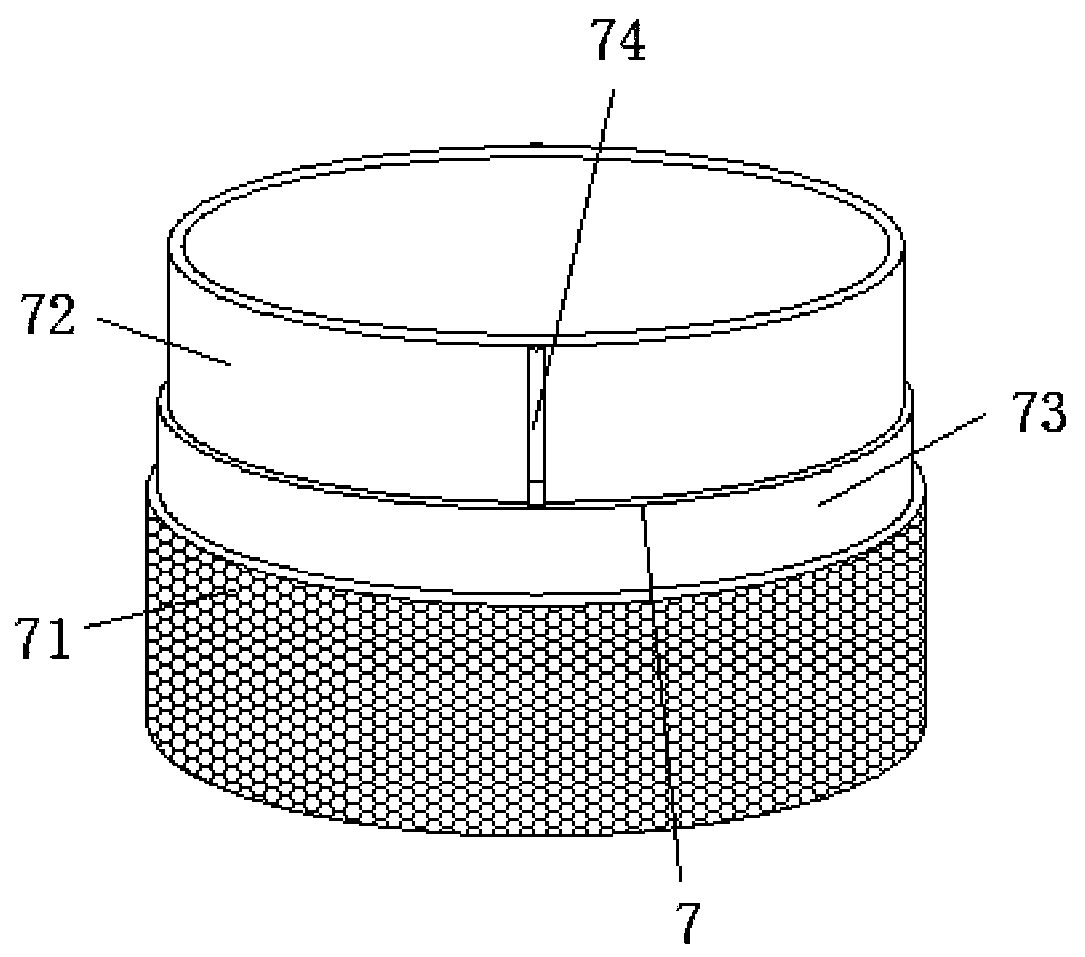

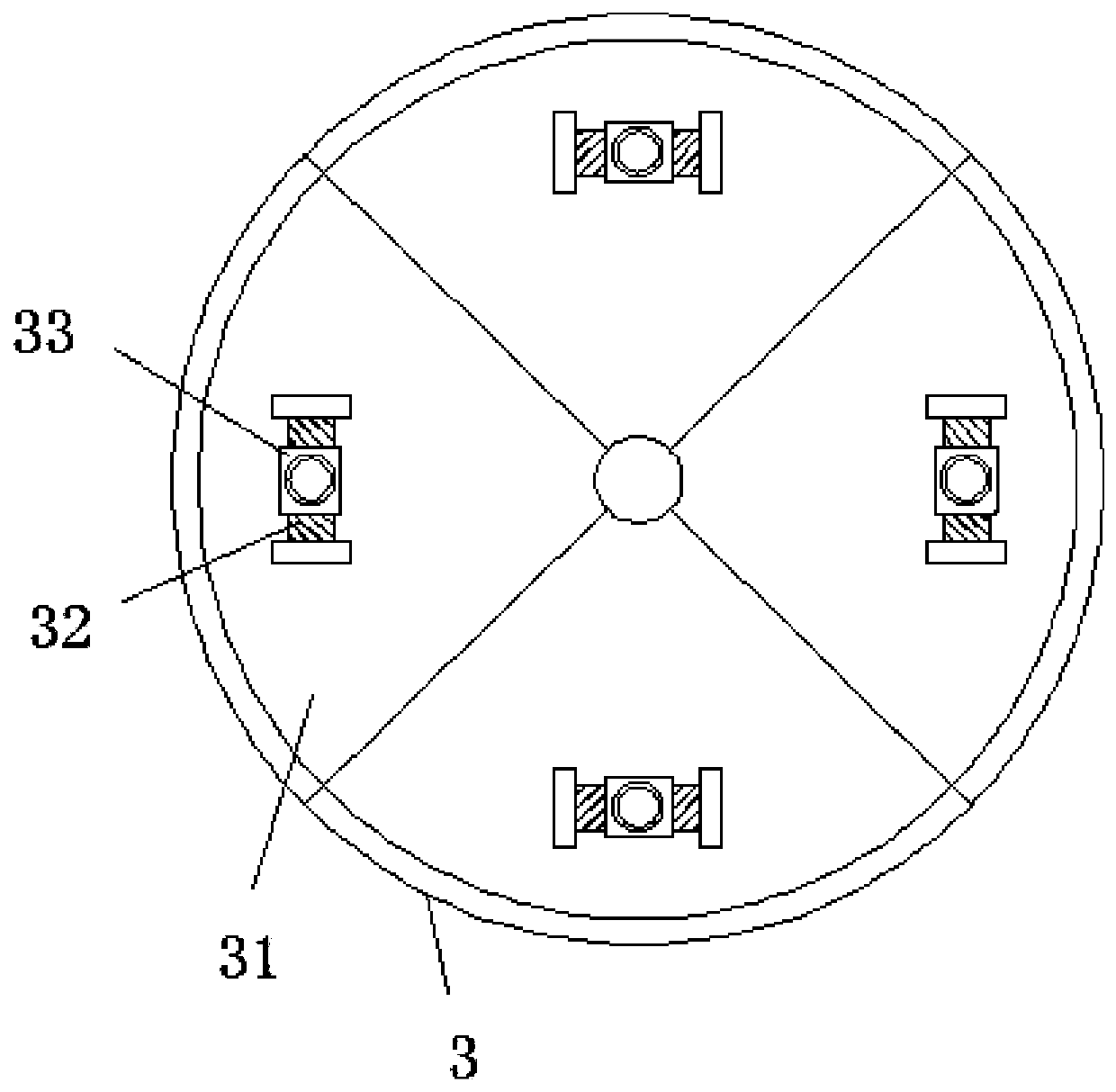

[0034] see Figure 1~6 , in the embodiment of the present invention, the fine-tuning device for the tunneling angle of the shield machine includes a tunneling plate 3, a hydraulic cylinder 5, a positioning plate 6 and a sealing cover 7, wherein several positioning plates 6 of the same specification are fixed on the shield machine knife On the surface of the disc, the positioning plate 6 has a ring shape on the face away from the cutter head of the shield machine and is welded with a plurality of hydraulic cylinders 5 in an equiangular structure; it is characterized in that,

[0035] The piston rod end of the hydraulic cylinder is connected with a transmission rod 4 by a telescopic compensation assembly 8;

[0036] The outer surface of the driving plate 3 is welded with a blade mounting ring 2, and the outer surface of the blade mounting ring 2 is threadedly connected with a positioning pin 1, and the scraper frame is embedded in the blade mounting ring 2, and is positioned by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com