Patents

Literature

940results about How to "Improve drilling accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

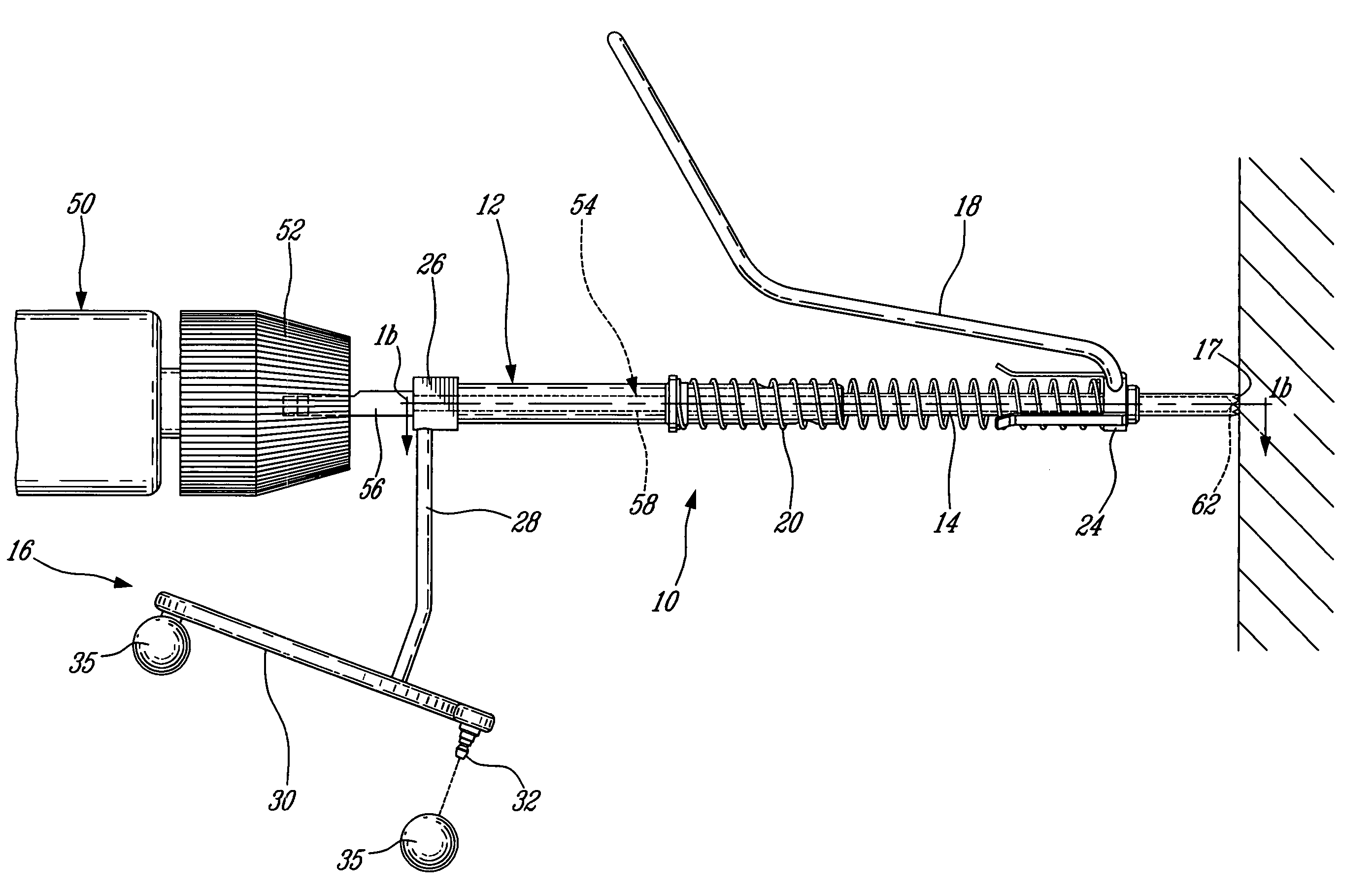

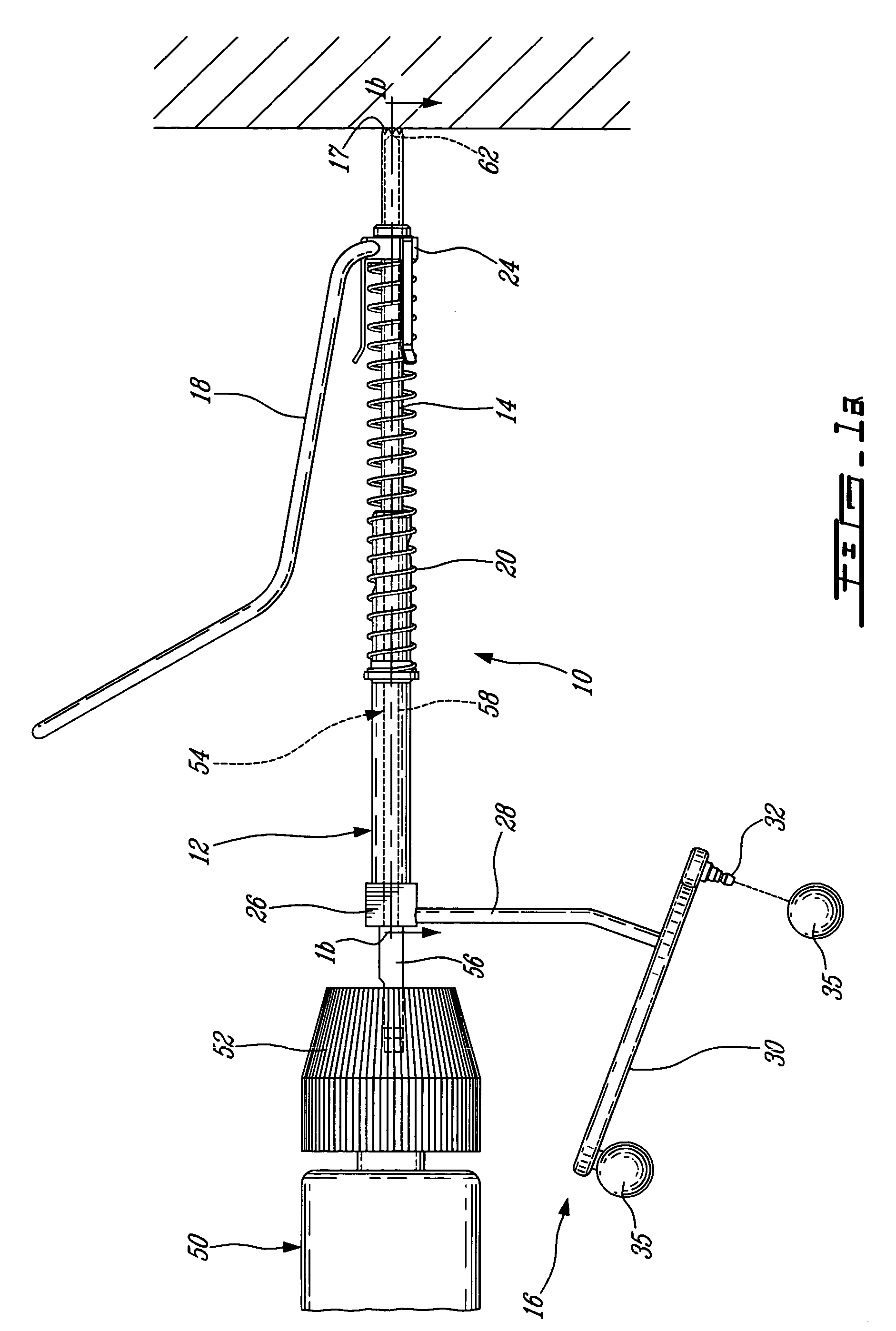

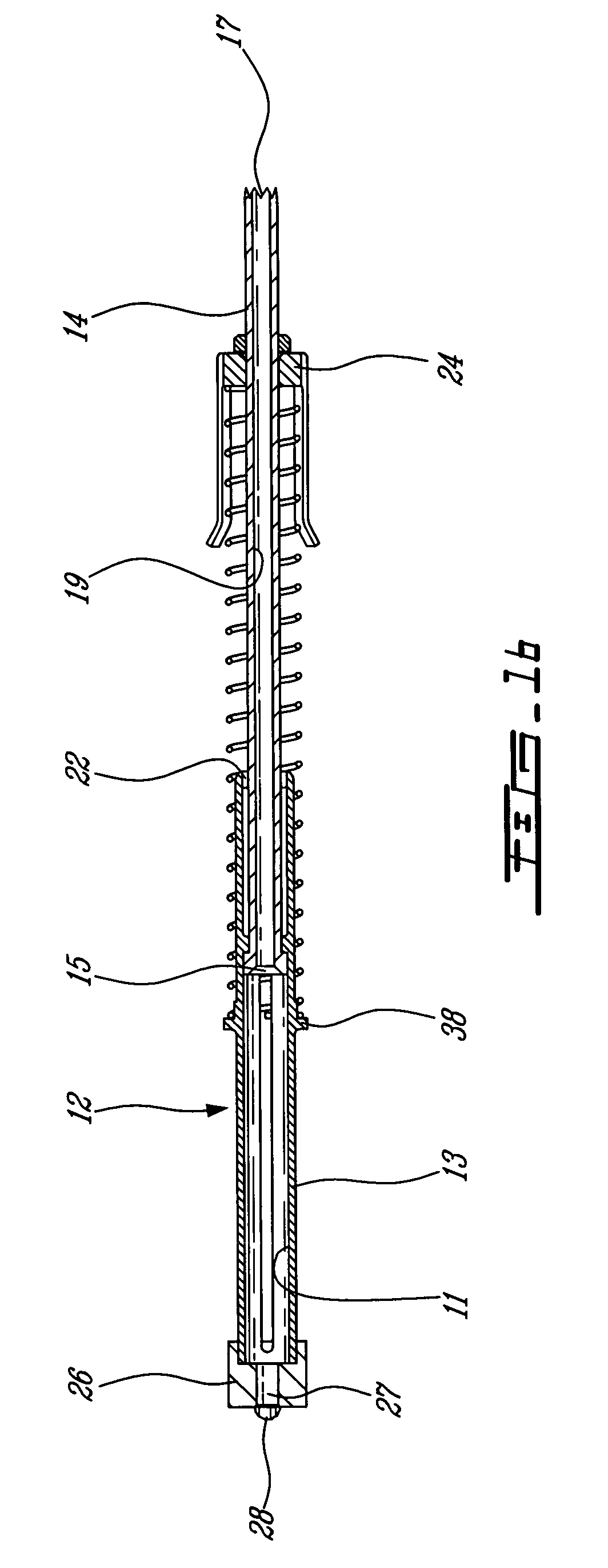

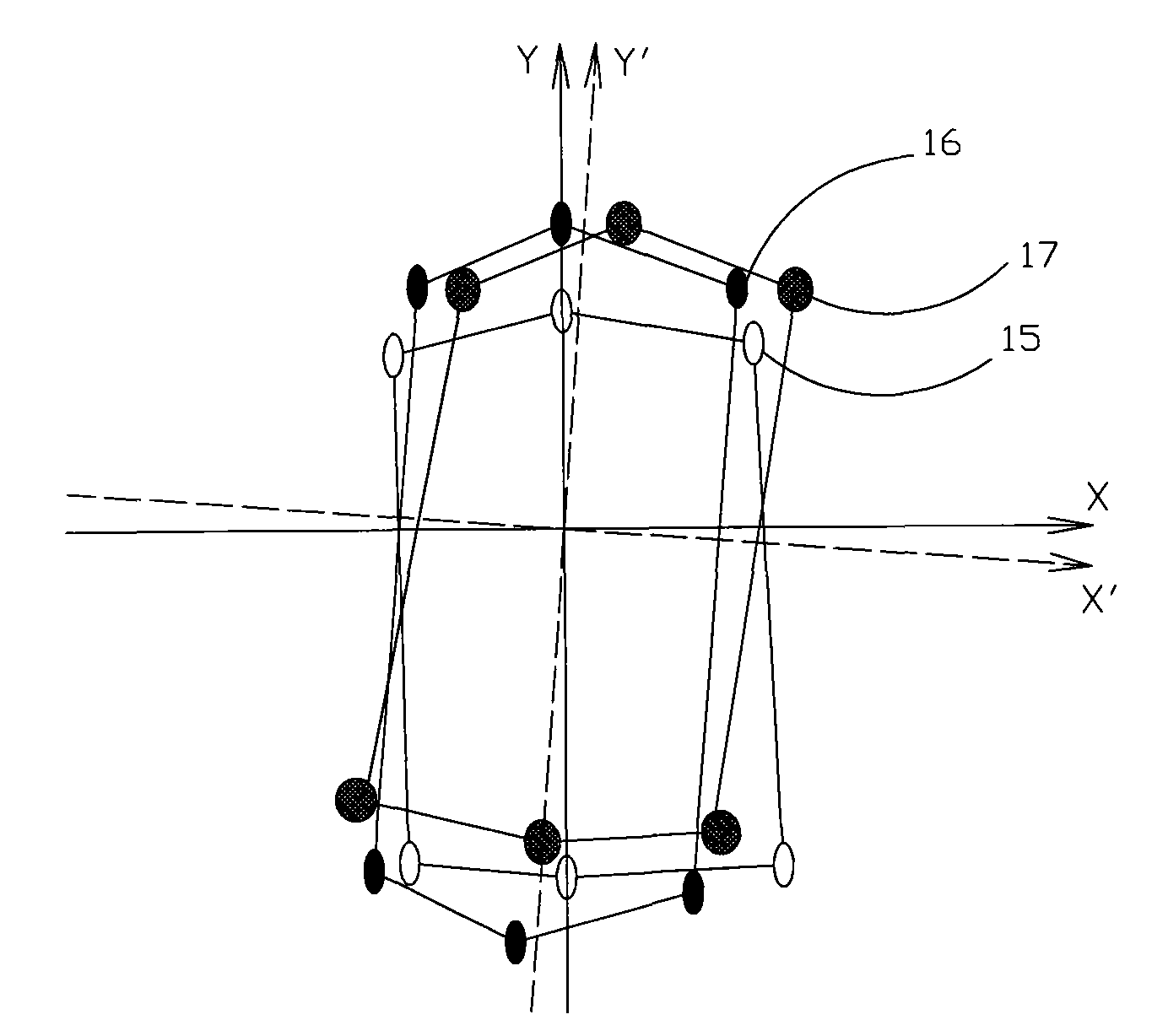

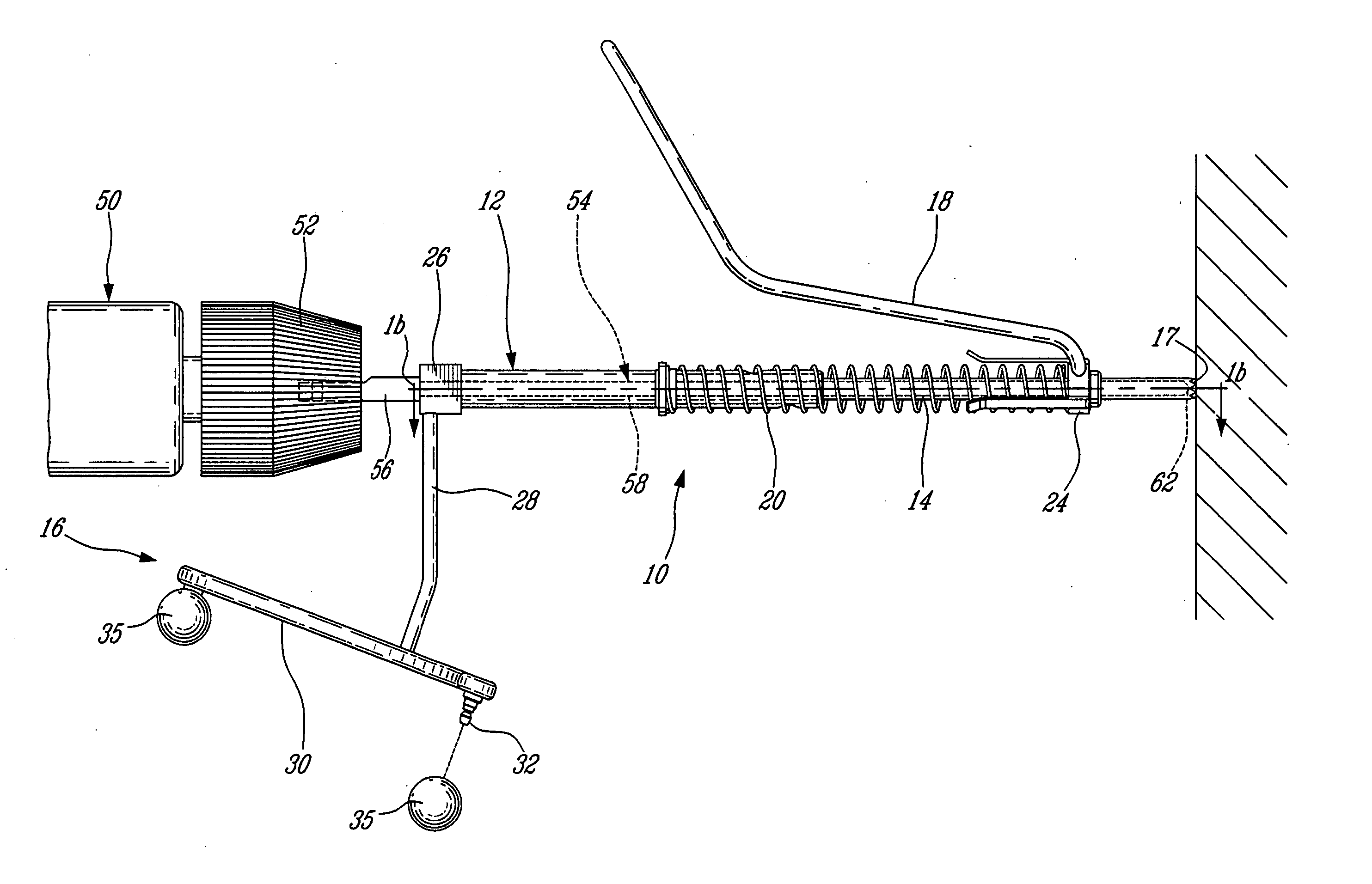

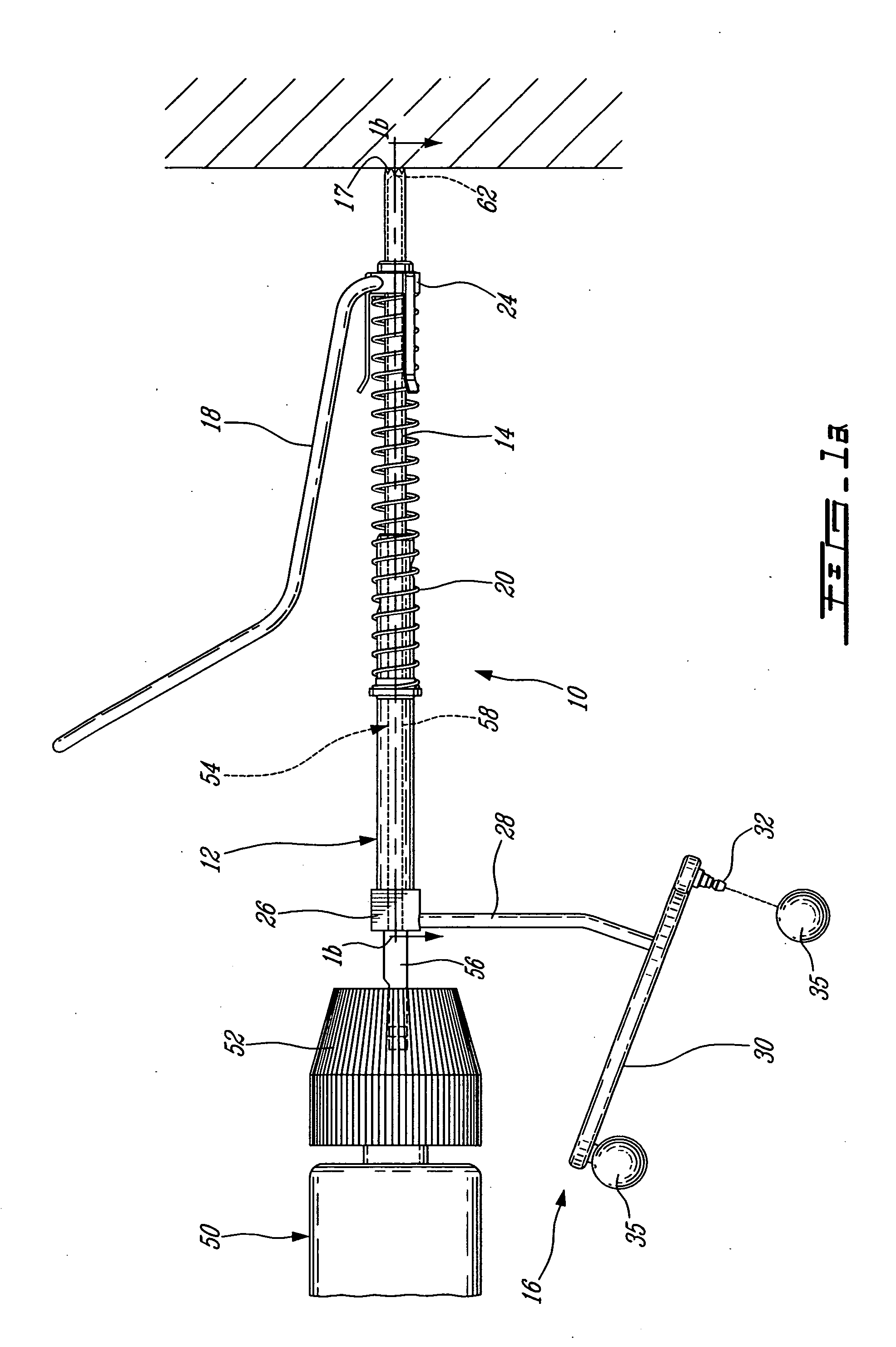

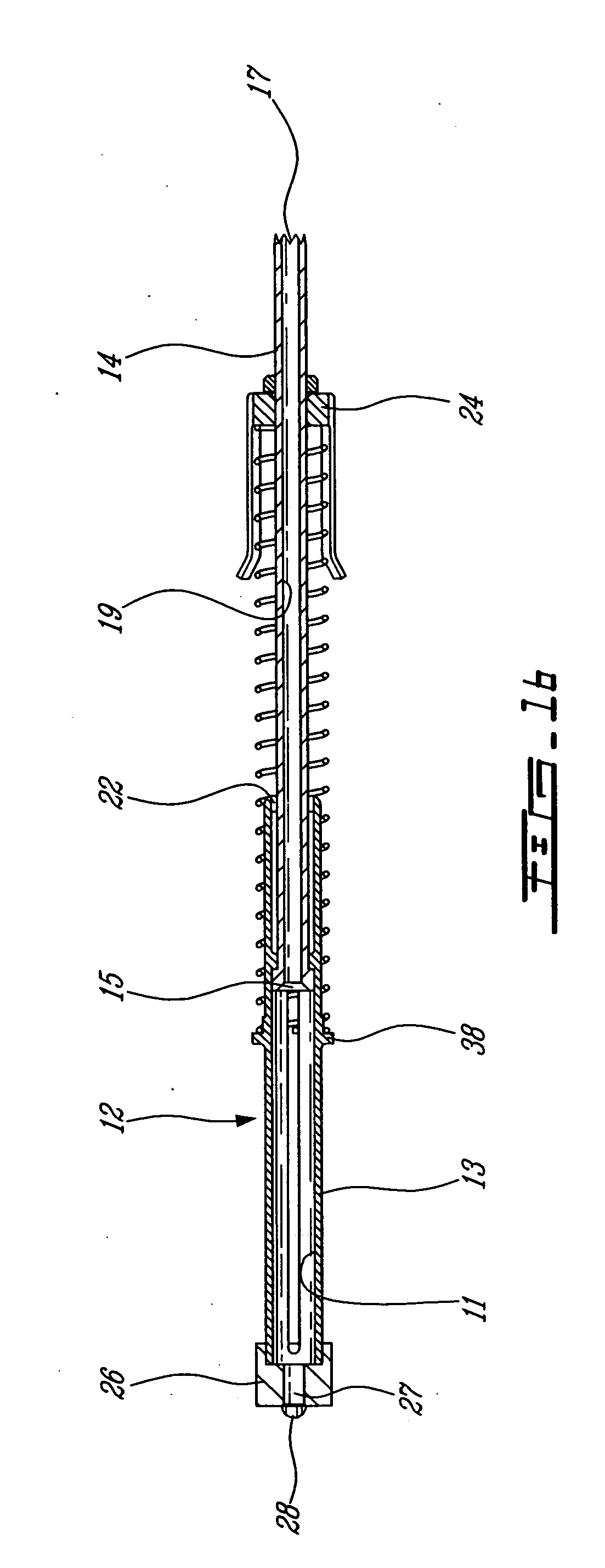

CAS drill guide and drill tracking system

InactiveUS6887247B1Accurate representationDepth accurateDrilling/boring measurement devicesThread cutting machinesThree-dimensional spaceEngineering

A drill guide assembly for a drilling tool having a chuck engaging a bit portion comprising a tip and a length extending from the chuck, the drill guide assembly comprising a first member, a second member and a trackable member. The first member is adapted to abut a workpiece surface and defines a central aperture therethrough adapted to receive the bit portion of the drilling tool. The second member is adapted to be axially displaced with respect to the first member and is axially biased therefrom, and defines a central aperture therethrough adapted to receive the bit portion of the drilling tool. The trackable member, fastened to the second member, comprises a detectable element adapted to be located and tracked in three dimensional space, thereby defining the position and movement of the second member and therefore that of the bit portion of the drilling tool.

Owner:ORTHOSOFT ULC

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

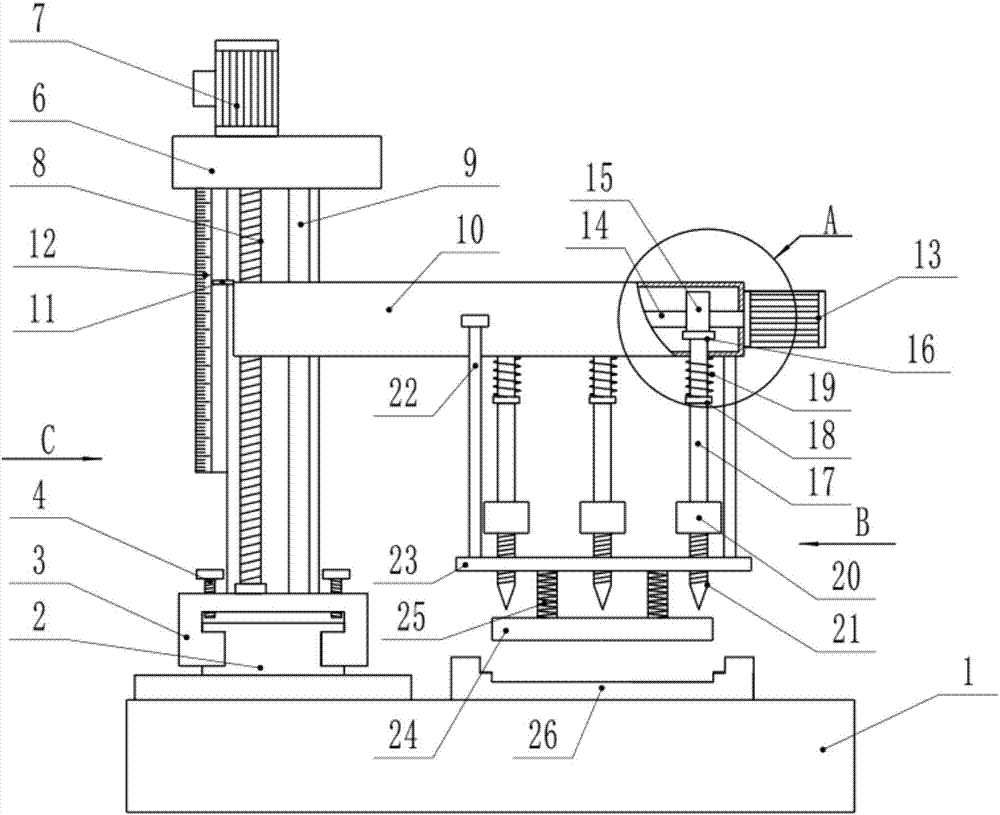

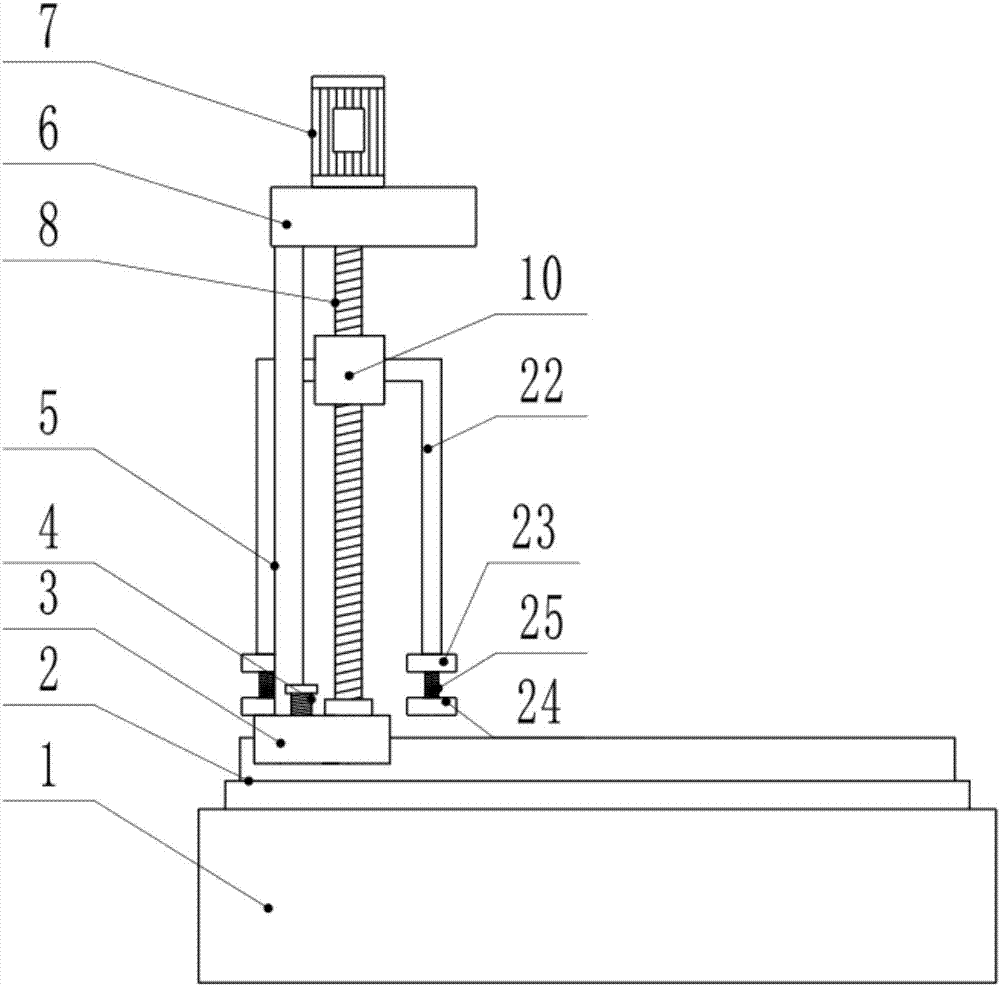

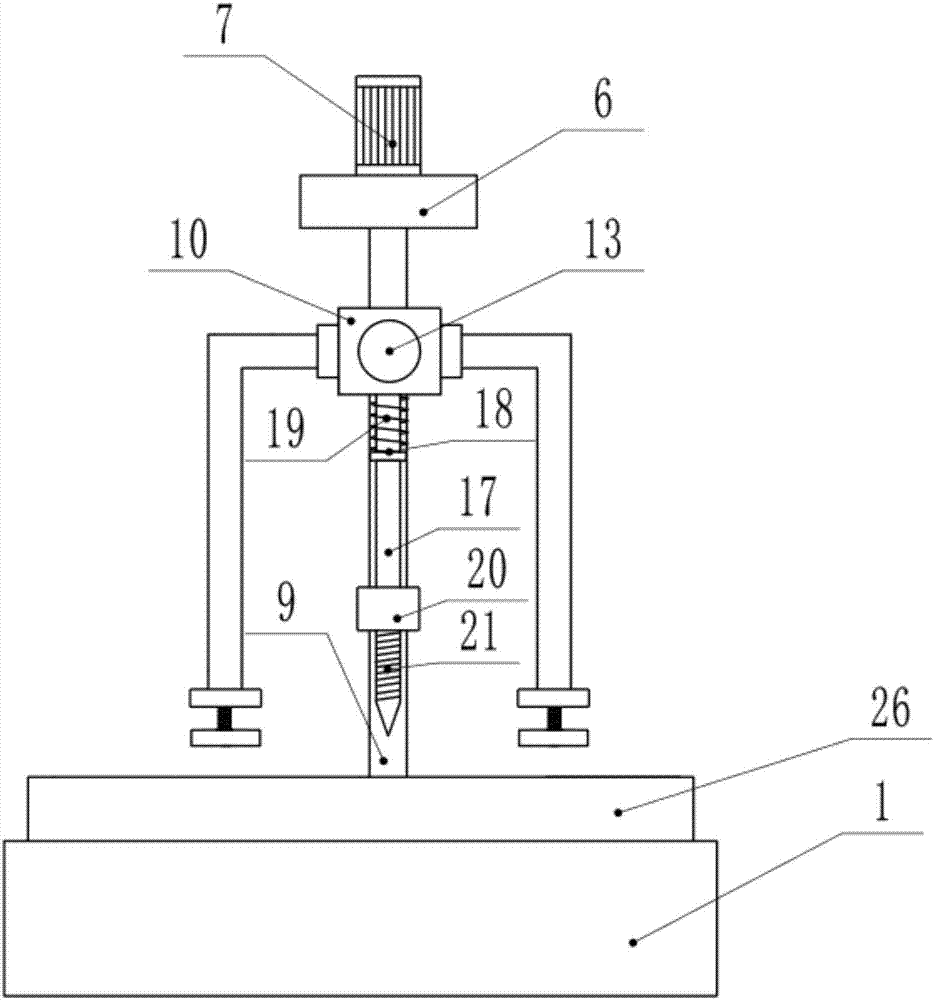

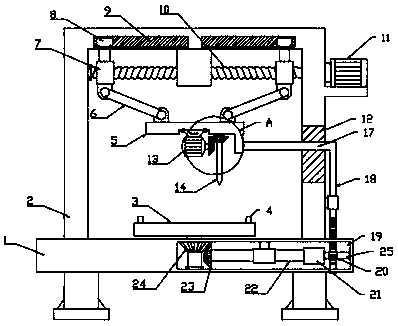

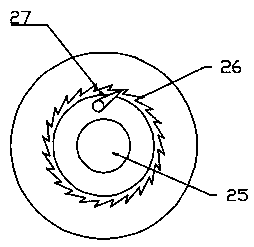

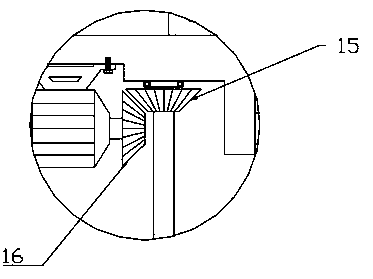

Building wood drilling device with porous continuously-punching function

The invention discloses a construction wood drilling device with multi-hole continuous punching function, comprising a platform, a slide rail, a slider, a lifting motor, a screw rod, a lifting platform, a driving motor, a cam, a drilling motor, a drill bit and a drilling platform , a lifting motor is fixedly installed on the cover plate, the output shaft of the lifting motor is vertically downward and is connected with a screw rod, several groups of cams are fixedly installed on the rotating shaft, the top block is matched with the cam, and the connecting A drilling motor is fixedly installed at the lower end of the rod, and a drill bit is fixedly installed on the output shaft of the drilling motor; the lifting work of the lifting platform is realized through the threaded cooperation between the screw rod and the lifting platform, and the working of the lifting motor, so as to meet the needs of different thicknesses of wood. Drilling work improves the versatility of the drilling machine; multiple sets of drill bits are set in the device, which can perform multi-hole continuous punching work at the same time. Compared with manual drilling in sequence, the work efficiency is high and the distance between holes can be effectively controlled, improving Drilling accuracy.

Owner:张志航

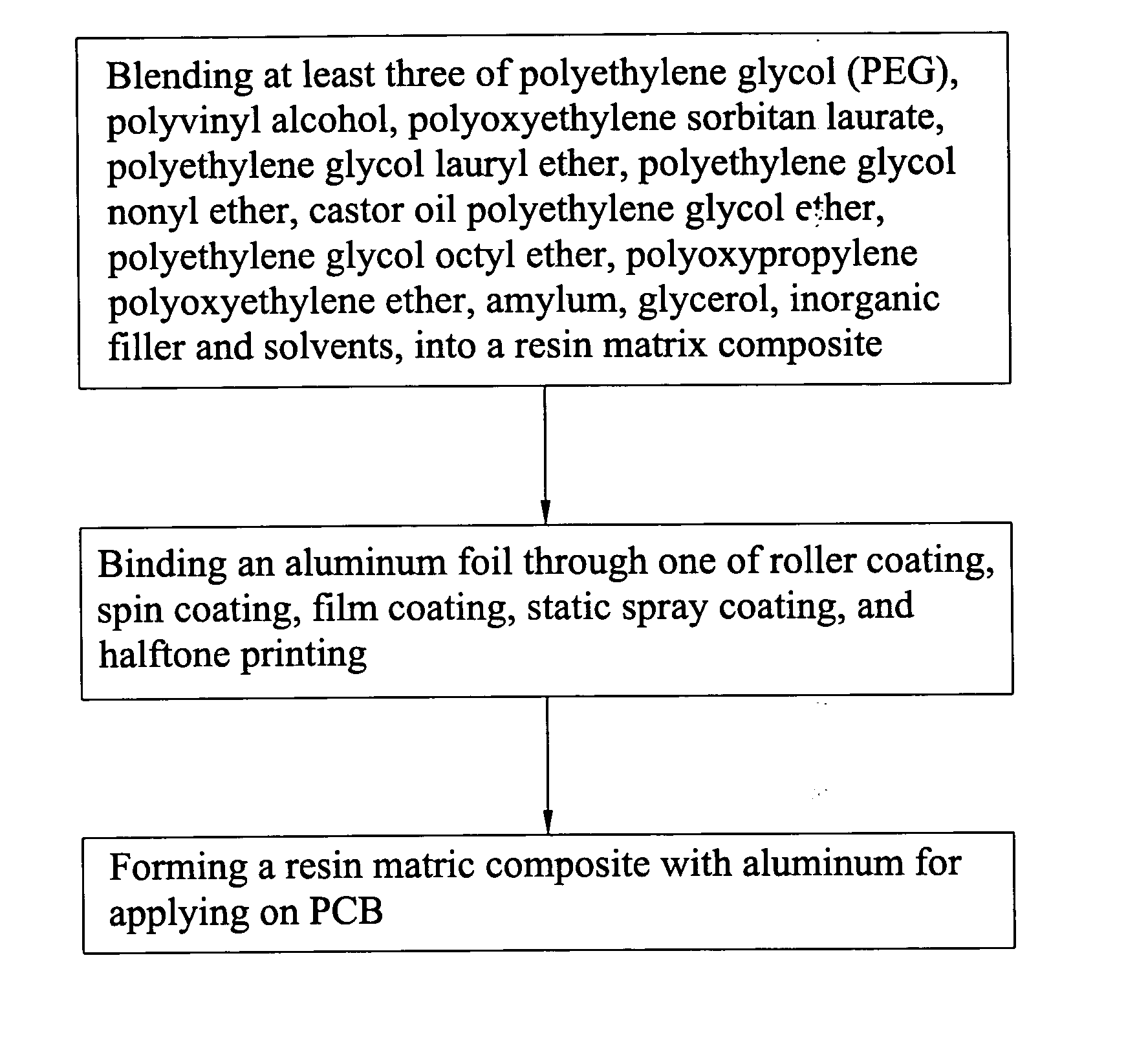

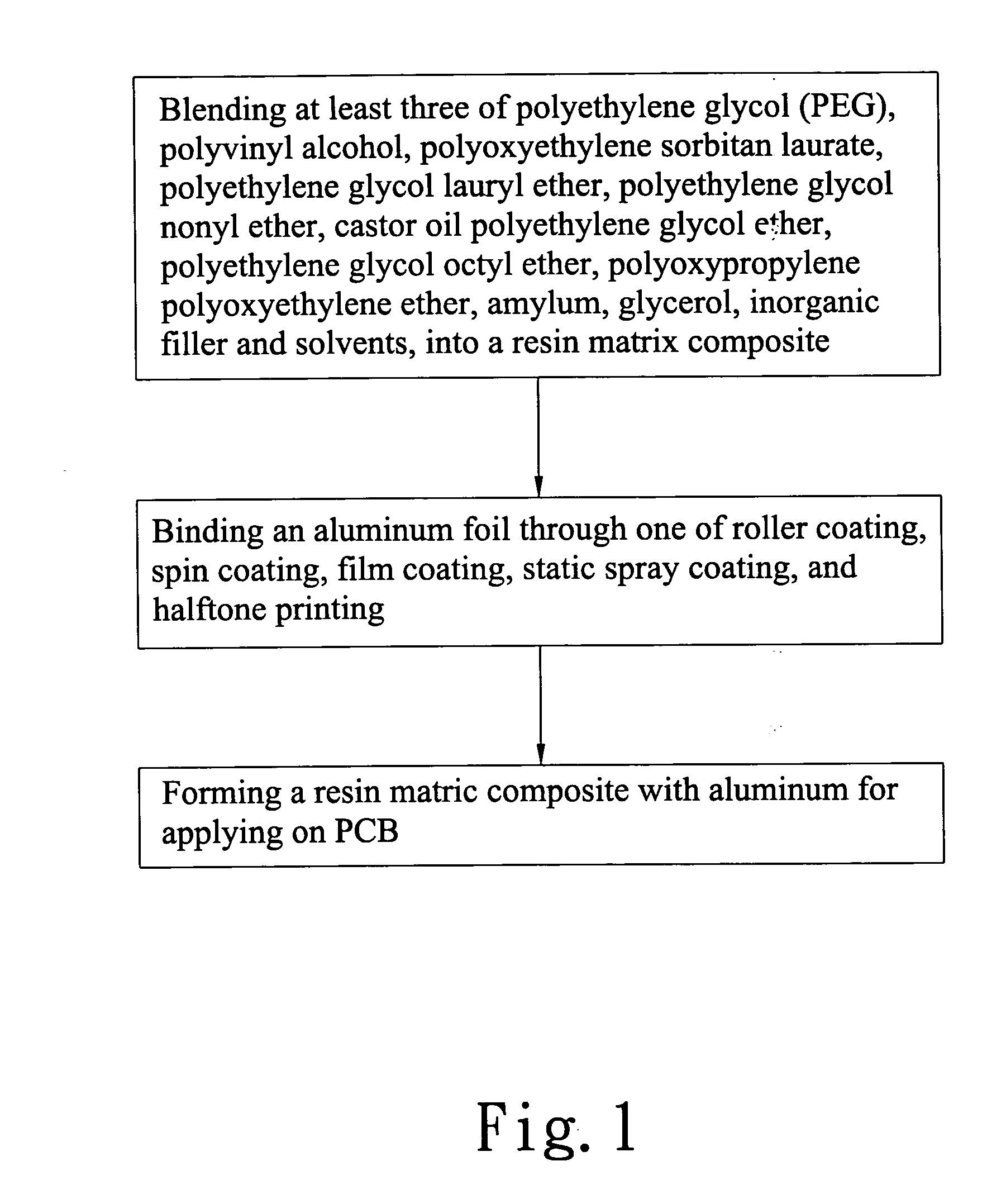

Resin matrix composite with aluminum for lubrication in drilling

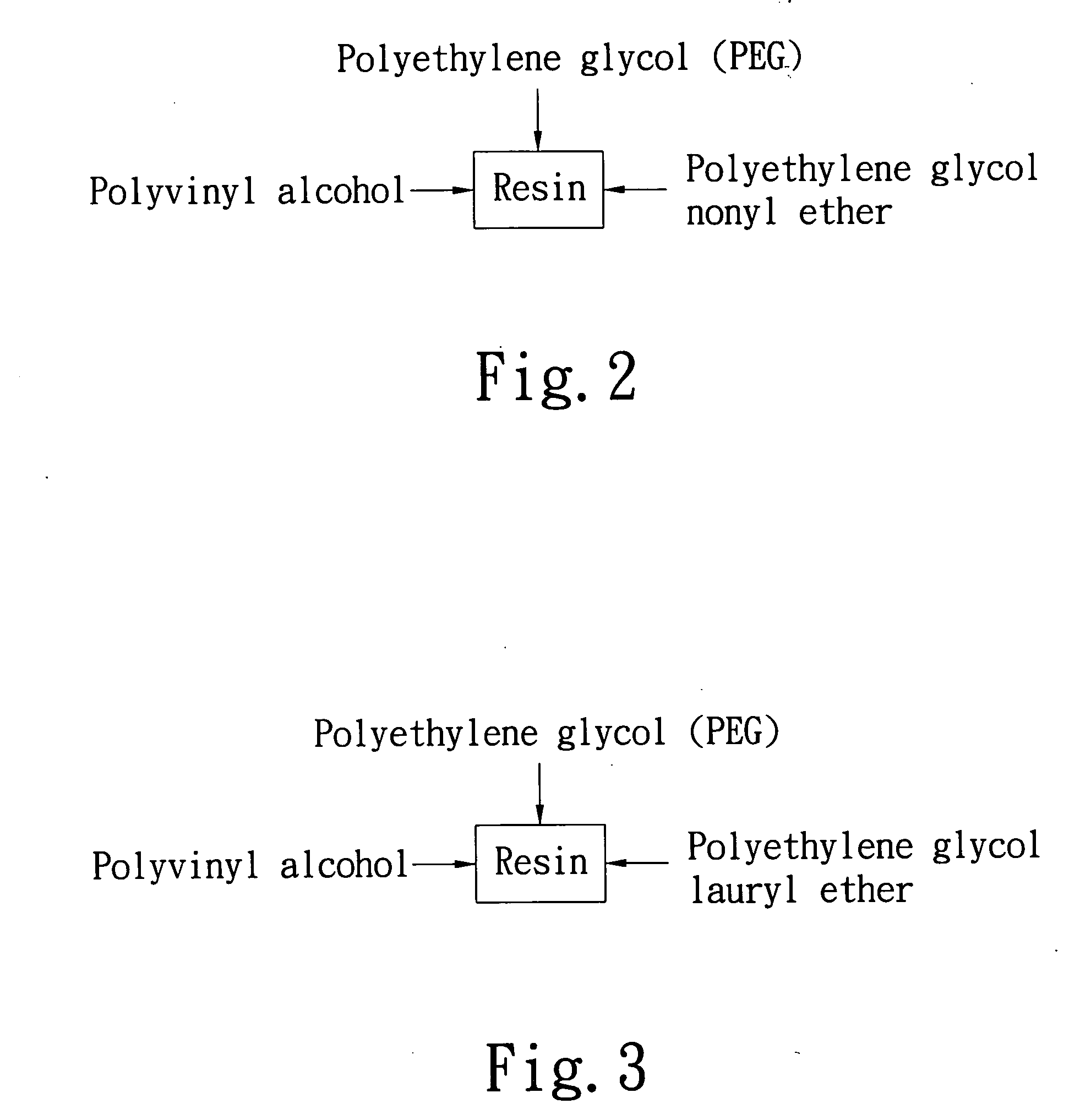

InactiveUS20060062996A1Simplified typesIncrease ratingsSynthetic resin layered productsPrinted circuit manufacturePolyvinyl alcoholPolyethylene glycol

A resin matrix composite with aluminum for lubrication in drilling comprises a resin matrix composite and an aluminum foil. The resin matrix composite is consisting of at least three of the following materials: PEG (polyethylene glycol), polyvinyl alcohol (PVA), polyoxyethylene sorbitan laurate, coconut alcohol polyethylene glycol ether, polyethylene glycol nonyl ether, castor oil polyethylene glycol ether, polyoxypropylene polyoxyethylene ether, amylum, glycerol, inorganic filler, and solvents. By one of roller coating, spin coating, film coating, static spray coating, or halftone printing, the resin matrix composite can bind the aluminum foil to form a resin matrix composite with aluminum foil for applying on PCB (printed circuit board) to function as lubricating in drilling.

Owner:YEH YUN CHAO

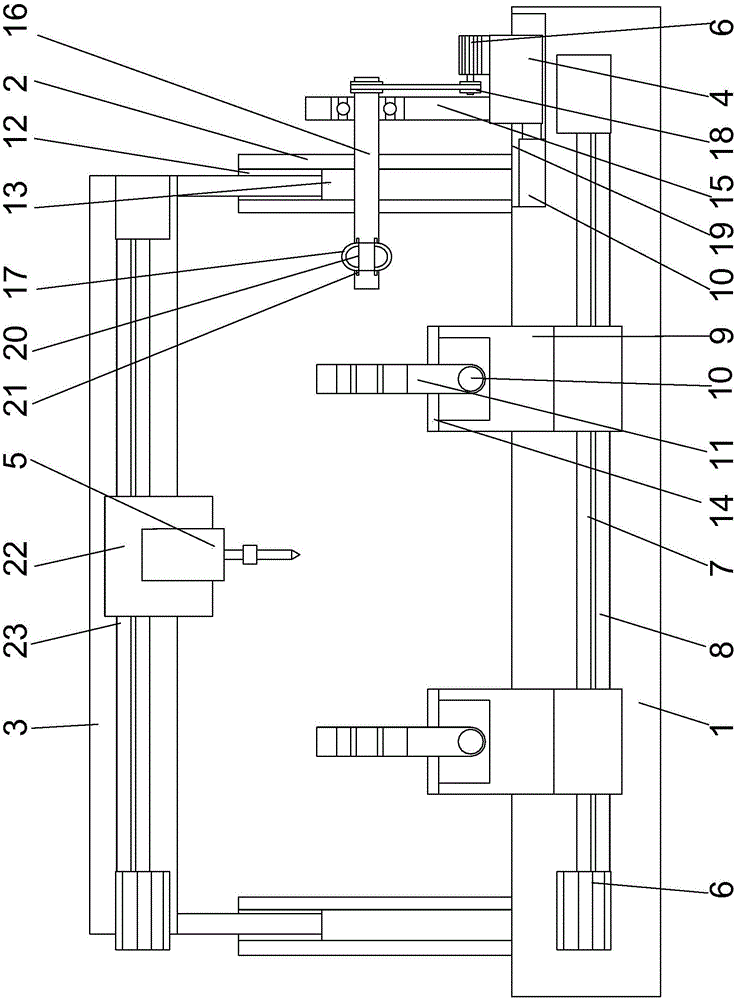

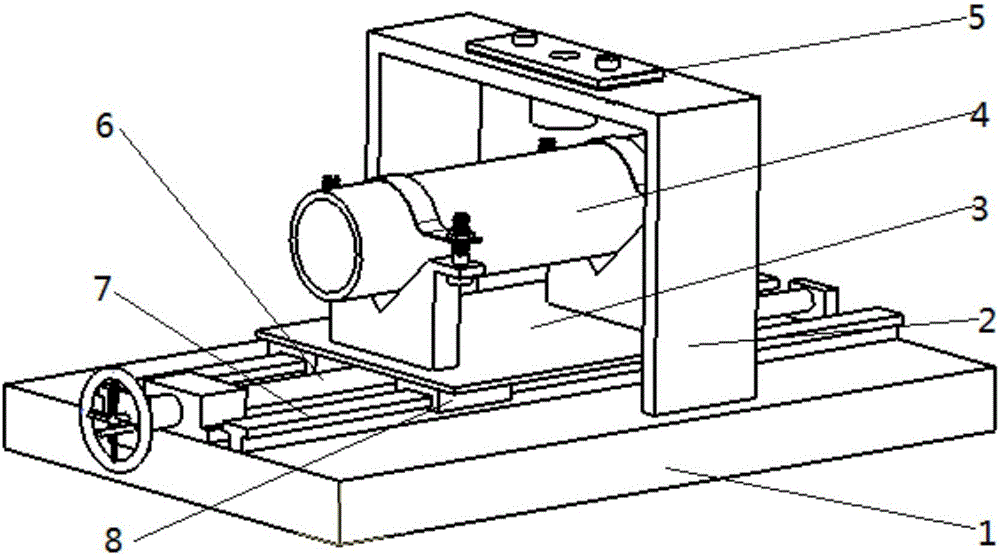

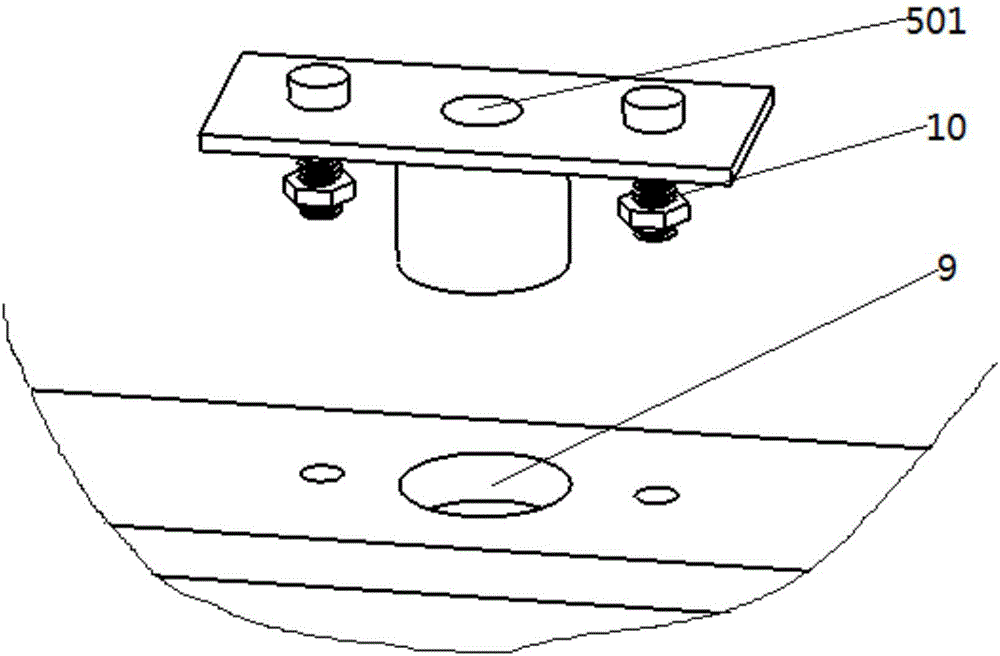

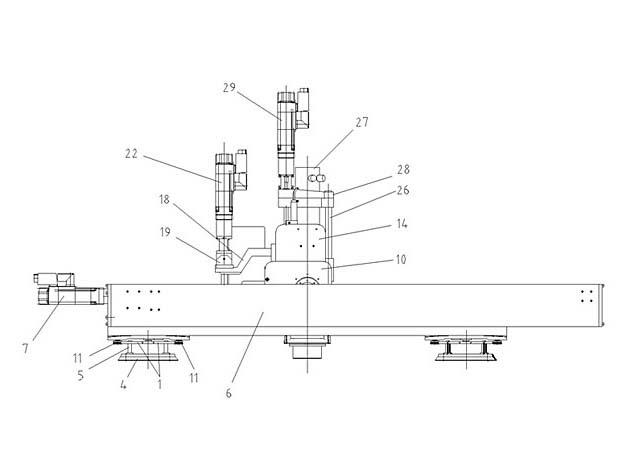

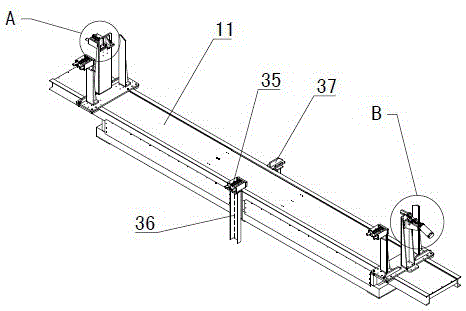

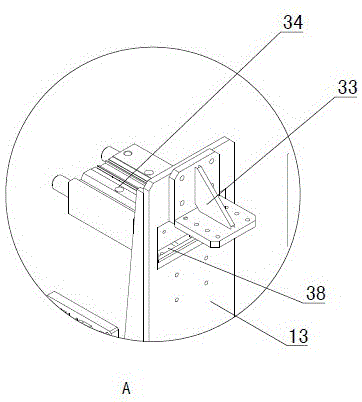

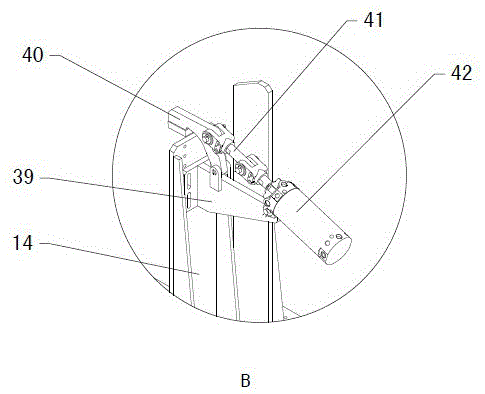

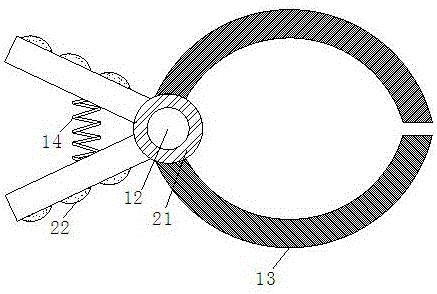

Multi-angle drilling device for pipe

ActiveCN105750937ARealize multi-angle drillingEasy to controlFeeding apparatusLarge fixed membersEngineeringPosition-sensing hydraulic cylinder

The invention discloses a multi-angle drilling device for a pipe.The multi-angle drilling device comprises a base and a transverse beam arranged on the base.A drilling device body is arranged on the transverse beam, a pipe rotating device is arranged on the base, a motor is arranged on the base, a lead screw is arranged on a rotating shaft of the motor, a fixing shaft matched with the lead screw is arranged below the lead screw, a supporting platform is arranged on the lead screw and arranged on the lead screw and the fixing shaft in a sleeving mode, two opposite hydraulic cylinders are arranged on the supporting platform, positioning buckles are arranged on stretchable rods of the two hydraulic cylinders, and the lower ends of the positioning buckles are fixedly connected to the hydraulic cylinders.According to the multi-angle drilling device, a transverse rod is driven by the motor to rotate, the pipe is rotated, and multi-angle and multidirectional drilling operation can be conveniently carried out on the pipe in the radial direction; as the pipe is moved through the lead screw, the drilling accuracy can be improved in the axial direction of the pipe.

Owner:江苏净傲机电科技有限公司

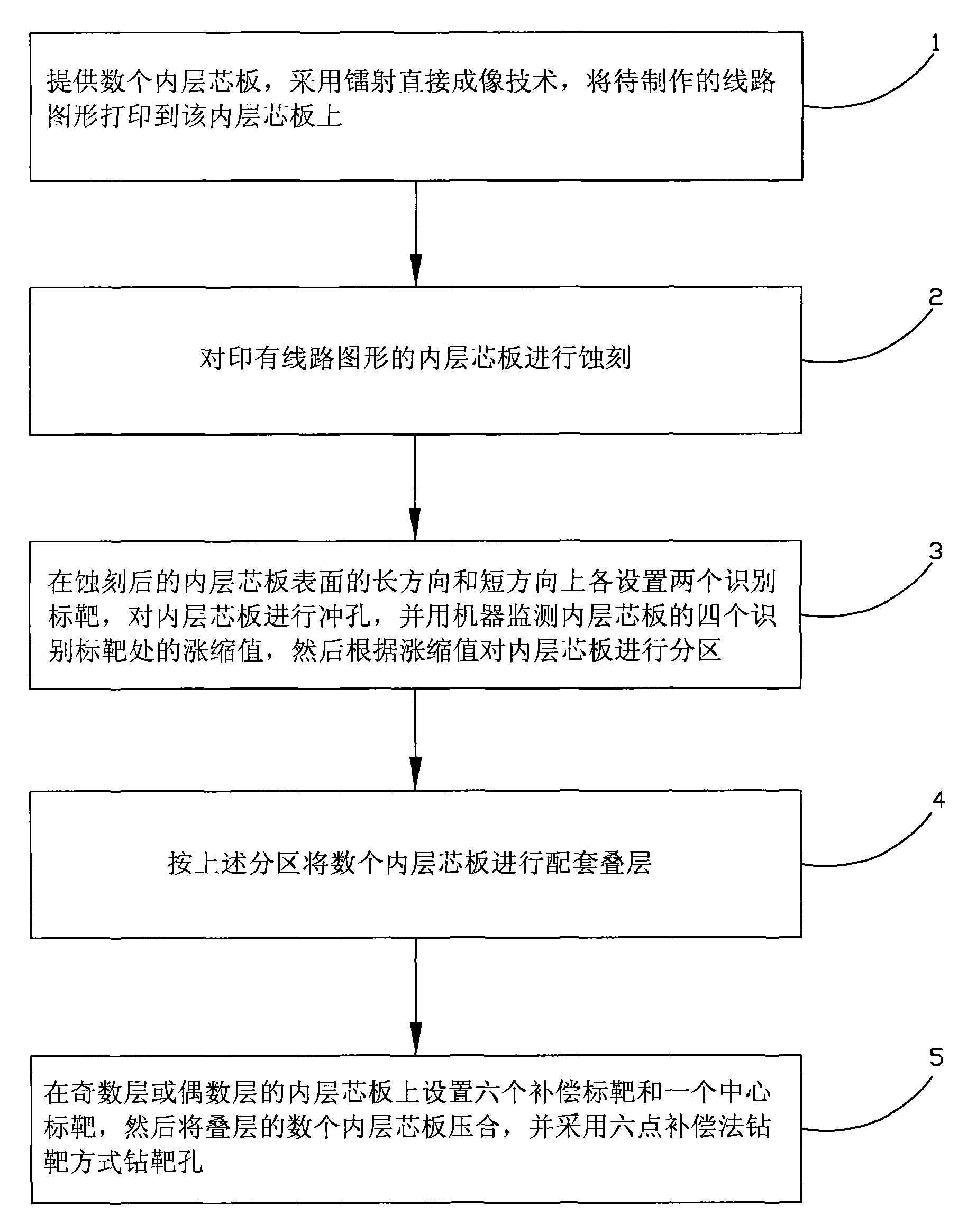

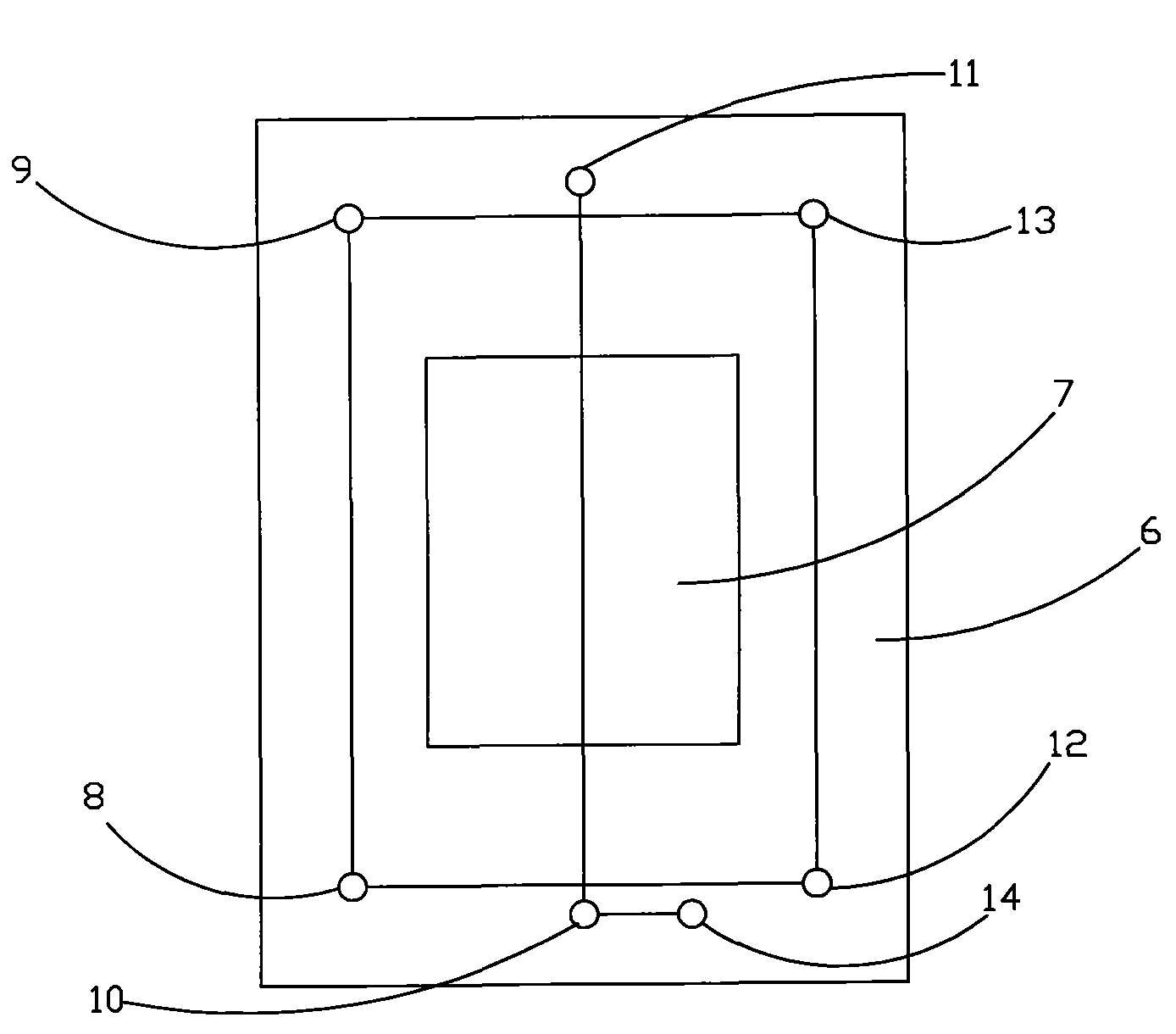

Method for making high alignment printed circuit board

ActiveCN101668389AHigh control precisionEasy alignmentConductive material chemical/electrolytical removalMultilayer circuit manufactureDirect imagingEngineering

The invention relates to a method for making a high collimation printed circuit board, comprising the following steps: step 1. providing a plurality of internal layer core plates, and printing circuitpatterns to be made onto the internal layer core plates by adopting a laser direct imaging technique; step 2. etching the internal layer core plates printed with the circuit patterns; step 3. respectively arranging two identifying targets for punching holes on the internal layer core plates in the long direction and short direction of the surfaces of the etched internal layer core plates, monitoring the expansion and shrinkage values of four identifying targets of the internal layer core plates by using a machine, and then partitioning the internal layer core plates according to the expansionand shrinkage values; step 4. matching and overlaying the plurality of internal layer core plates according to the partitions; and step 5. arranging six compensation targets and a central target on the internal layer core plates of odd layers or even layers, then pressing the plurality of overlaid internal layer core plates and drilling target holes by adopting a target drilling mode of six-pointcompensation method. With the method, the quality of the printed circuit board products can be effectively monitored, so that the invention is propitious to the improvement of the alignment of the printed circuit boards.

Owner:DONGGUAN MEADVILLE CIRCUITS

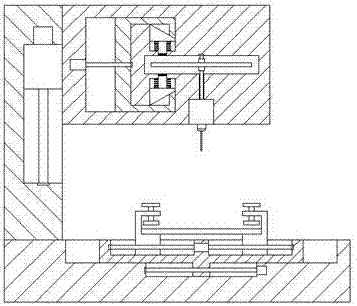

Automatic punching device for processing parts

InactiveCN109570548AHigh degree of automationImprove drilling accuracyFeeding apparatusPositioning apparatusAutomationThreaded rod

The invention discloses an automatic punching device for processing parts. The automatic punching device comprises a bottom plate, a bracket, a placing table, a bidirectional threaded rod and a transmission cavity; the right end of a working table is provided with a transmission cavity, a bevel gear D is arranged on the inner side of the transmission cavity, a rotating shaft of the bevel gear D penetrates through the transmission cavity to reach the upper end of the working table and to be fixedly connected with the lower end of the placing table, and the upper end of the placing table is provided with a fixing mechanism. The automatic punching device is novel in design, when a push plate moves downwards, a rack plate is driven by a connecting rod to move downwards, when the rack plate moves downwards, an annular gear on a third rotating rod drives ratchet teeth to rotate, the ratchet teeth cannot drive a second rotating rod to rotate under the effect of pawls, after punching is completed, a positive and negative rotation motor rotates reversely, at the time, the push plate moves upwards, rotation of the second rotating rod is achieved, the placing table is driven to be rotated under the effects of a bevel gear C and the bevel gear D, rotation of part plates is achieved, automatic transposition and punching are achieved, and the automation degree is high.

Owner:泰州市津专知识产权服务有限公司

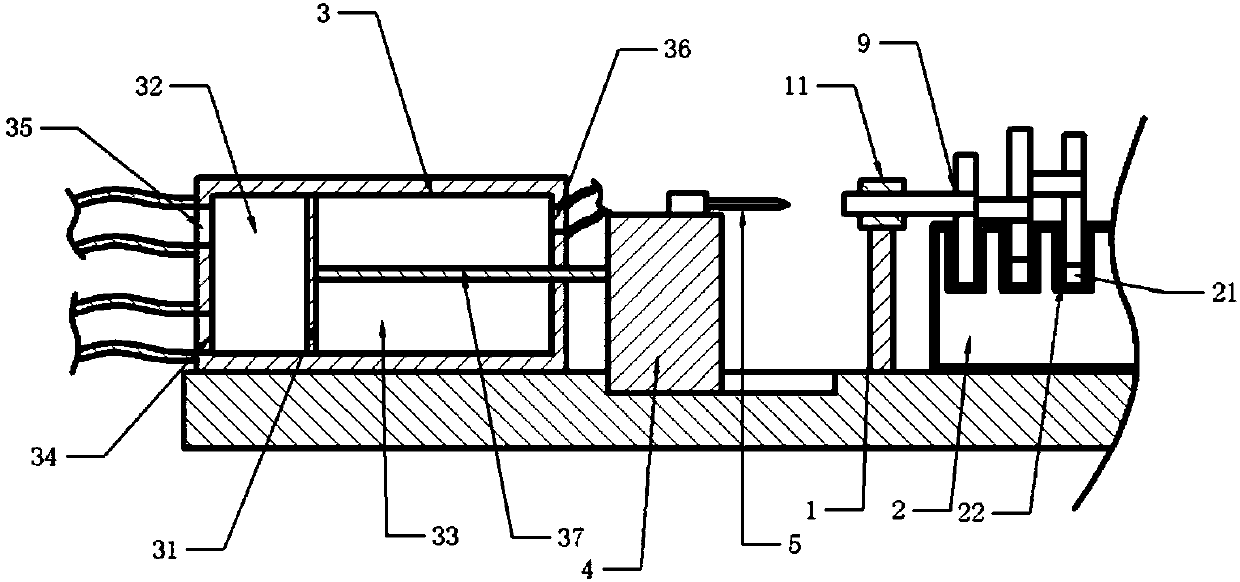

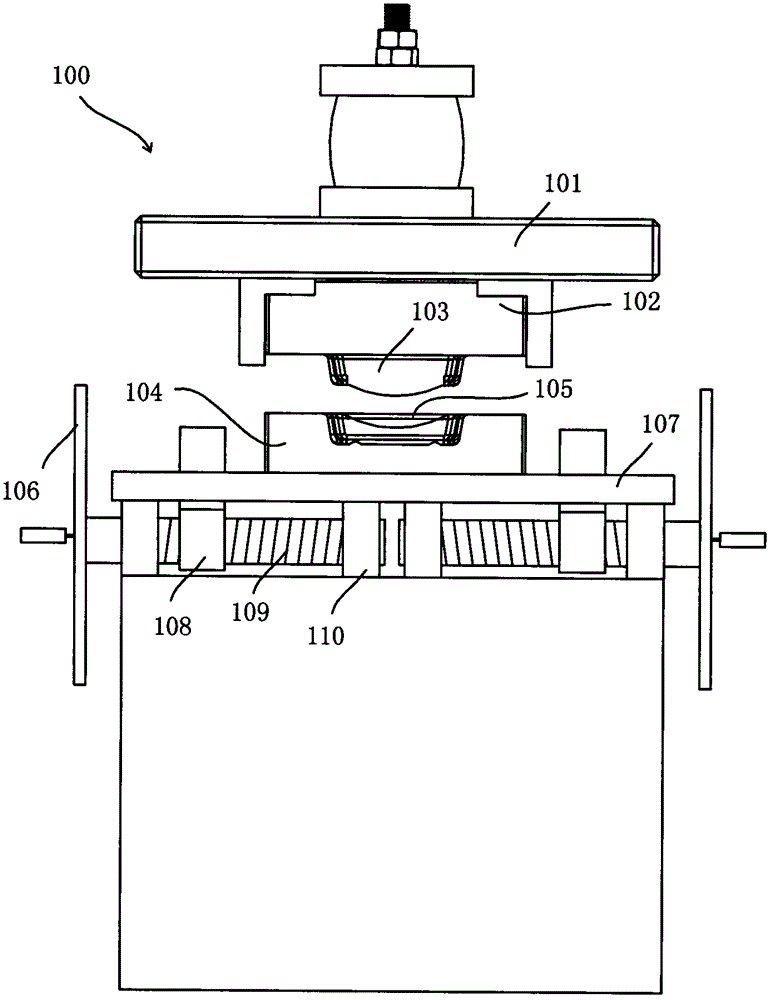

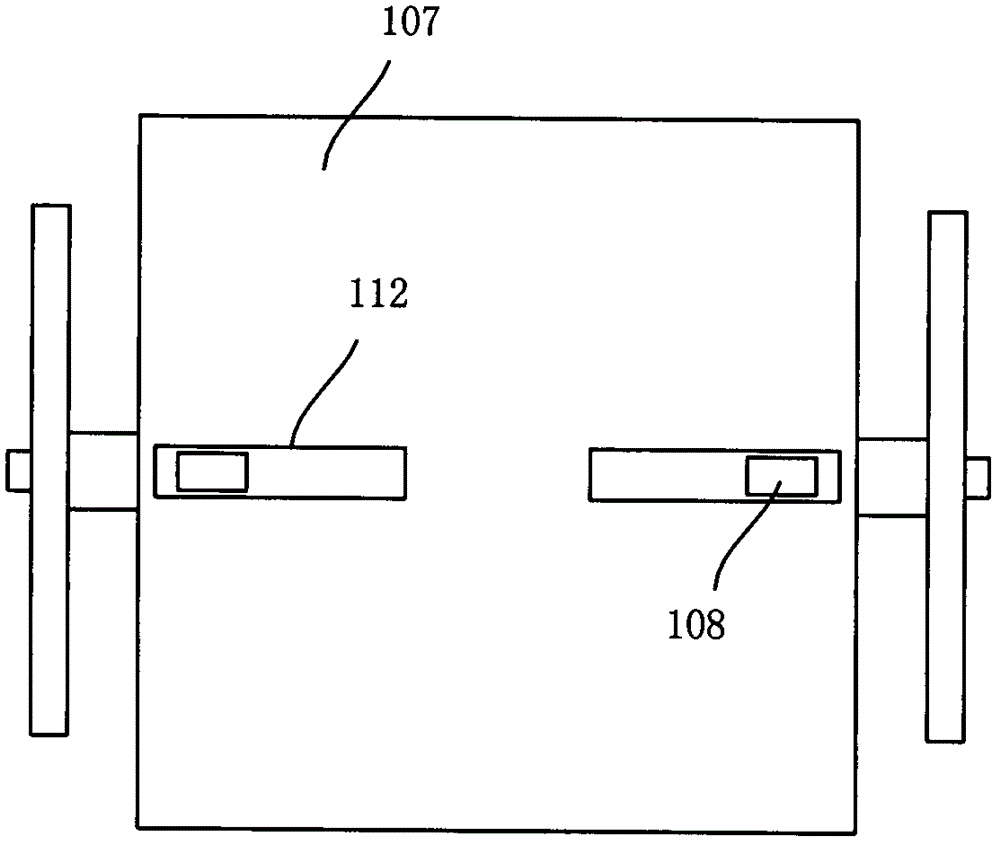

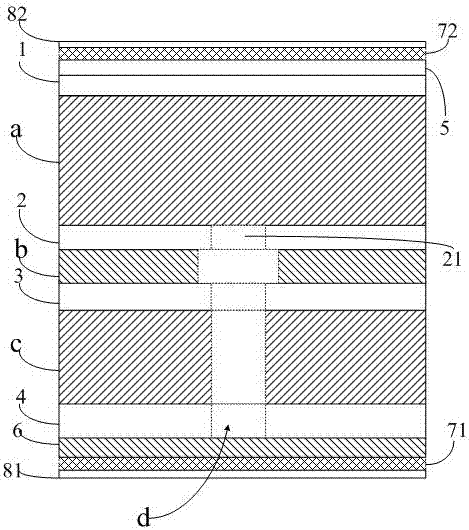

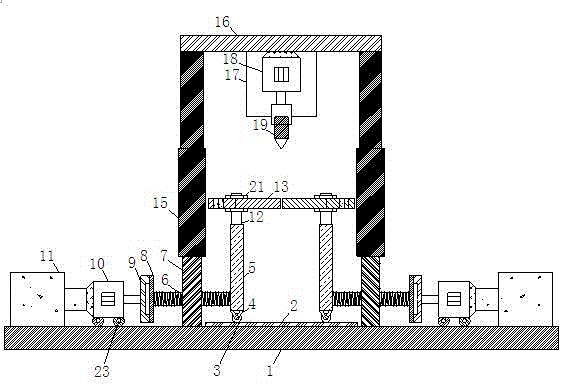

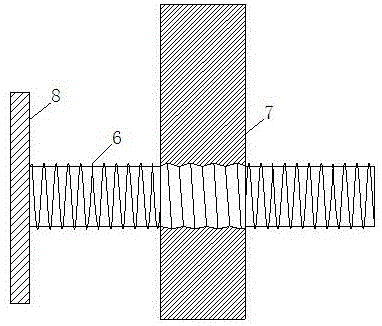

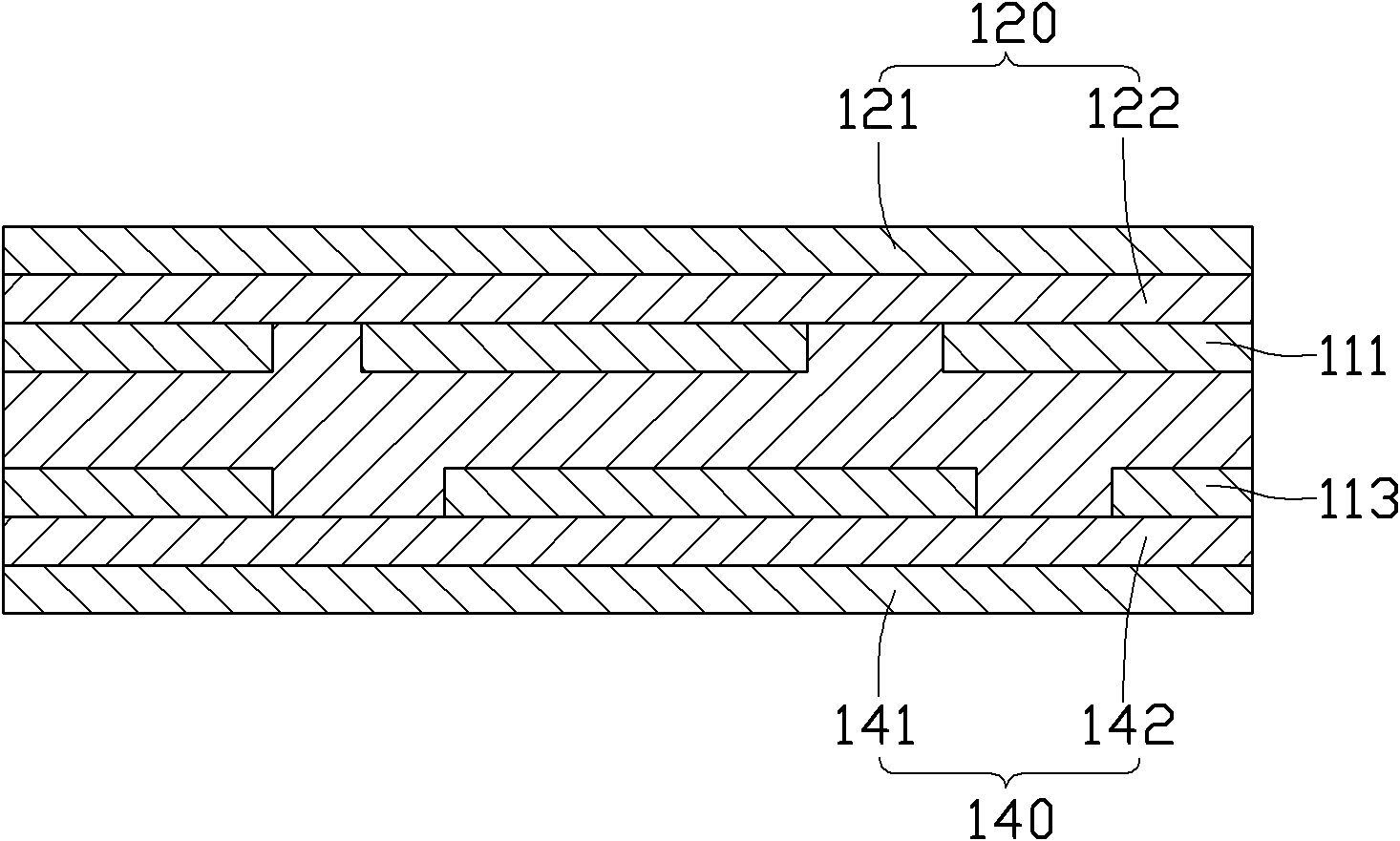

Damping structure of drilling machine supporting seat

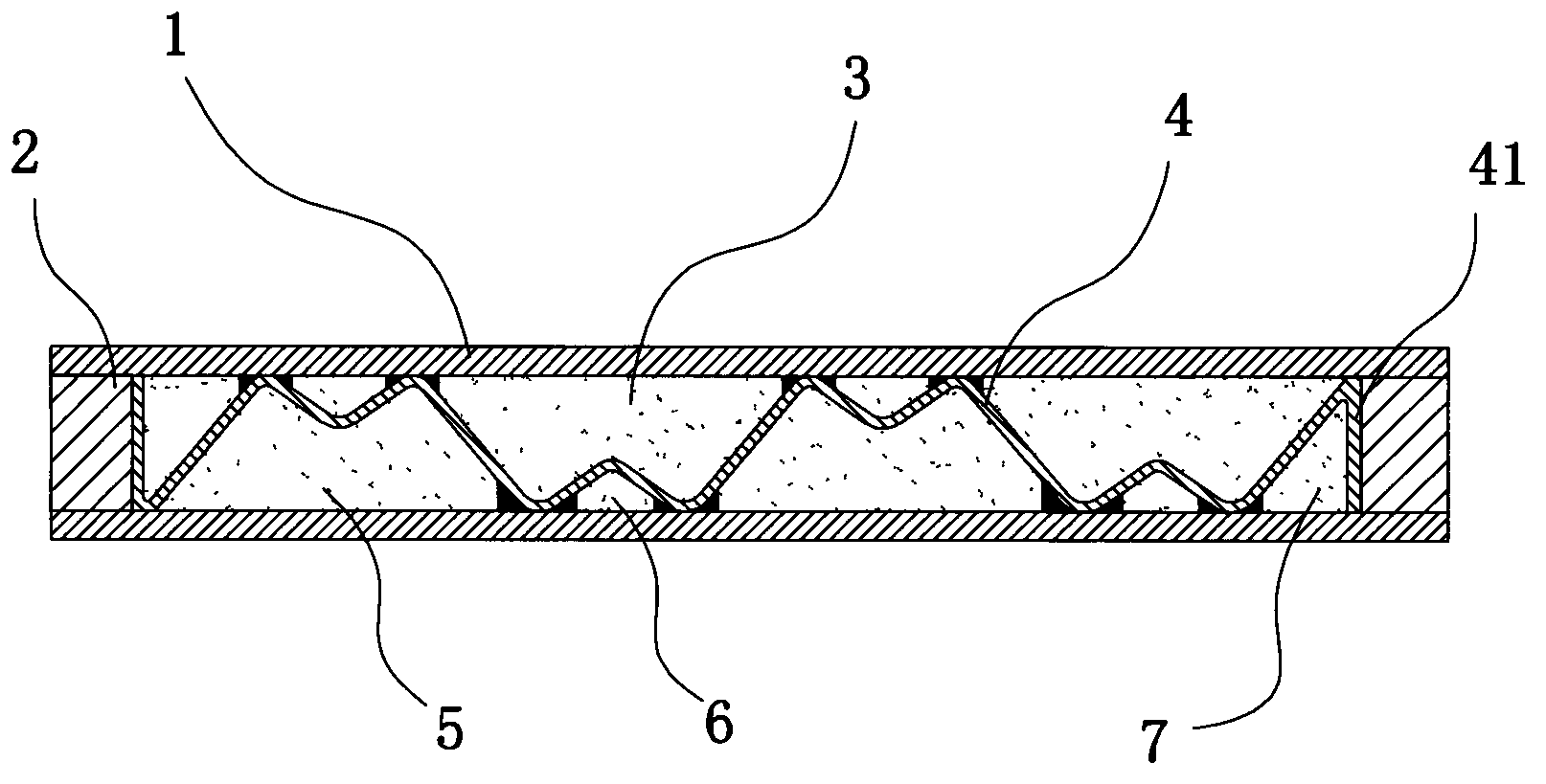

InactiveCN103317353AReduce vibrationImprove drilling accuracyNon-rotating vibration suppressionLarge fixed membersWall plateEngineering

The invention relates to a damping structure of a drilling machine supporting seat. The damping structure comprises the supporting seat which comprises wall plates of two-layer structures, retaining plates are fixedly connected at two ends of the wall plates, a damping rib is welded between the wall plates, the wall plates and the damping rib are not completely welded and can slide mutually, the section of the damping rib is of a curved structure, a first filling cavity and a second filling cavity are formed between the damping rib and the wall plate, two ends of the damping rib are provided with vertical plates respectively, the vertical plates are fixedly connected with the retaining plates, a third filling cavity is formed between the two ends of the damping rib and the wall plates by the aid of the vertical plates, and buffering padding is arranged in the first filling cavity, the second filling cavity and the third filling cavity respectively. A two-layer wall plate structure and a welding structure with high damping performance are adopted, so that vibration of a drilling machine is effectively reduced, drilling accuracy is improved. The damping structure has the advantages of simple structure and good damping effect.

Owner:SUZHOU BIANFENG ELECTRONICS TECH

Method of processing geological data

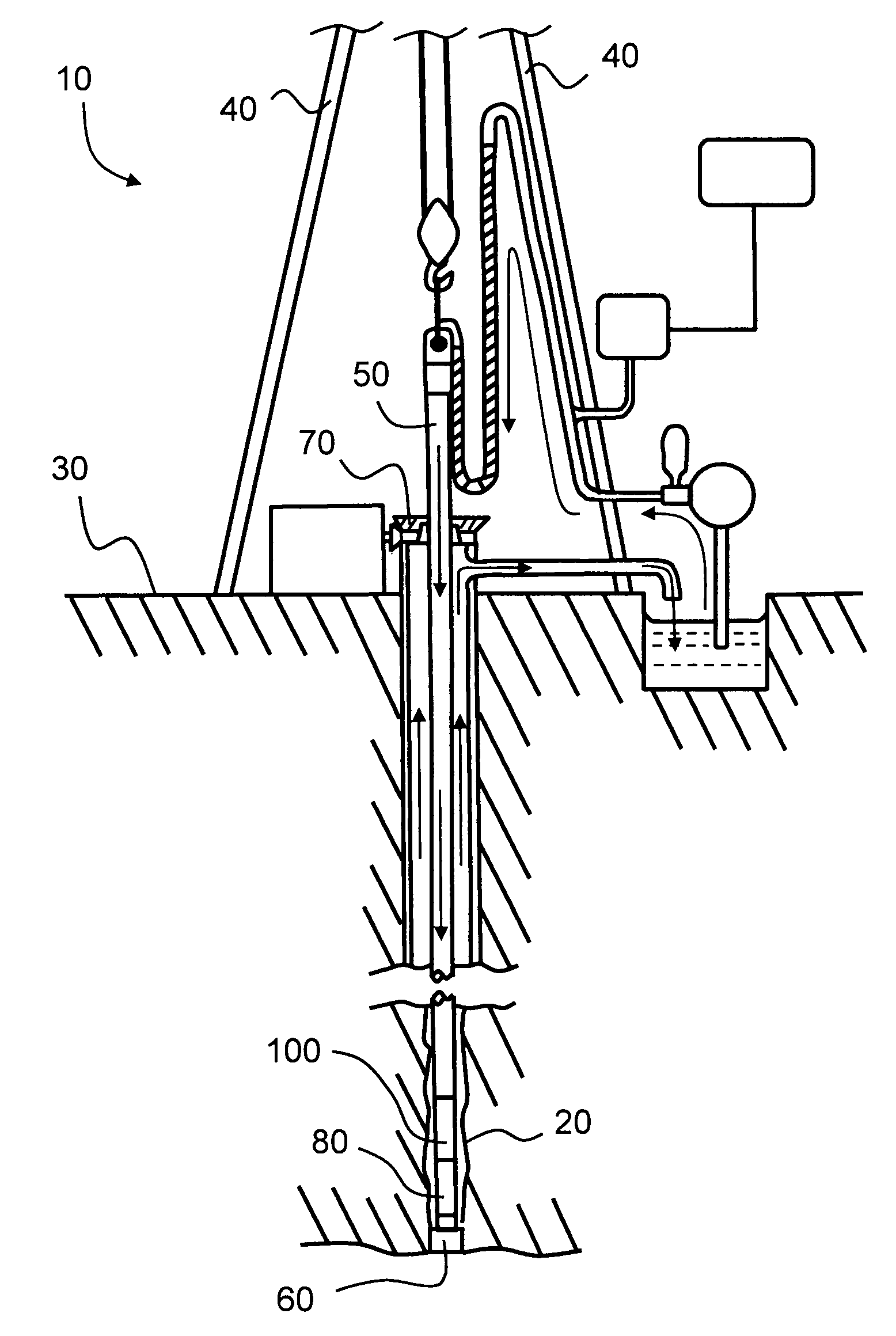

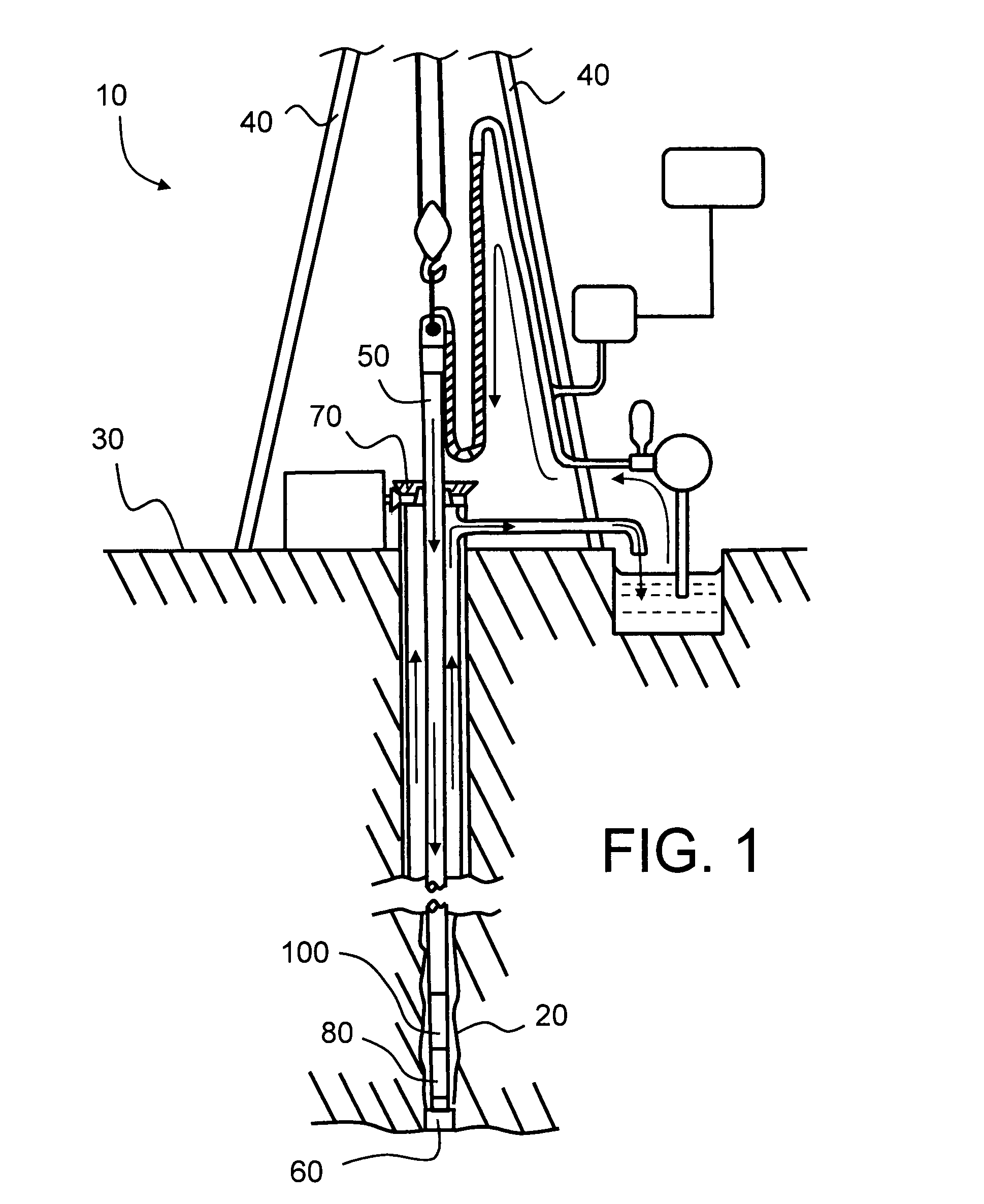

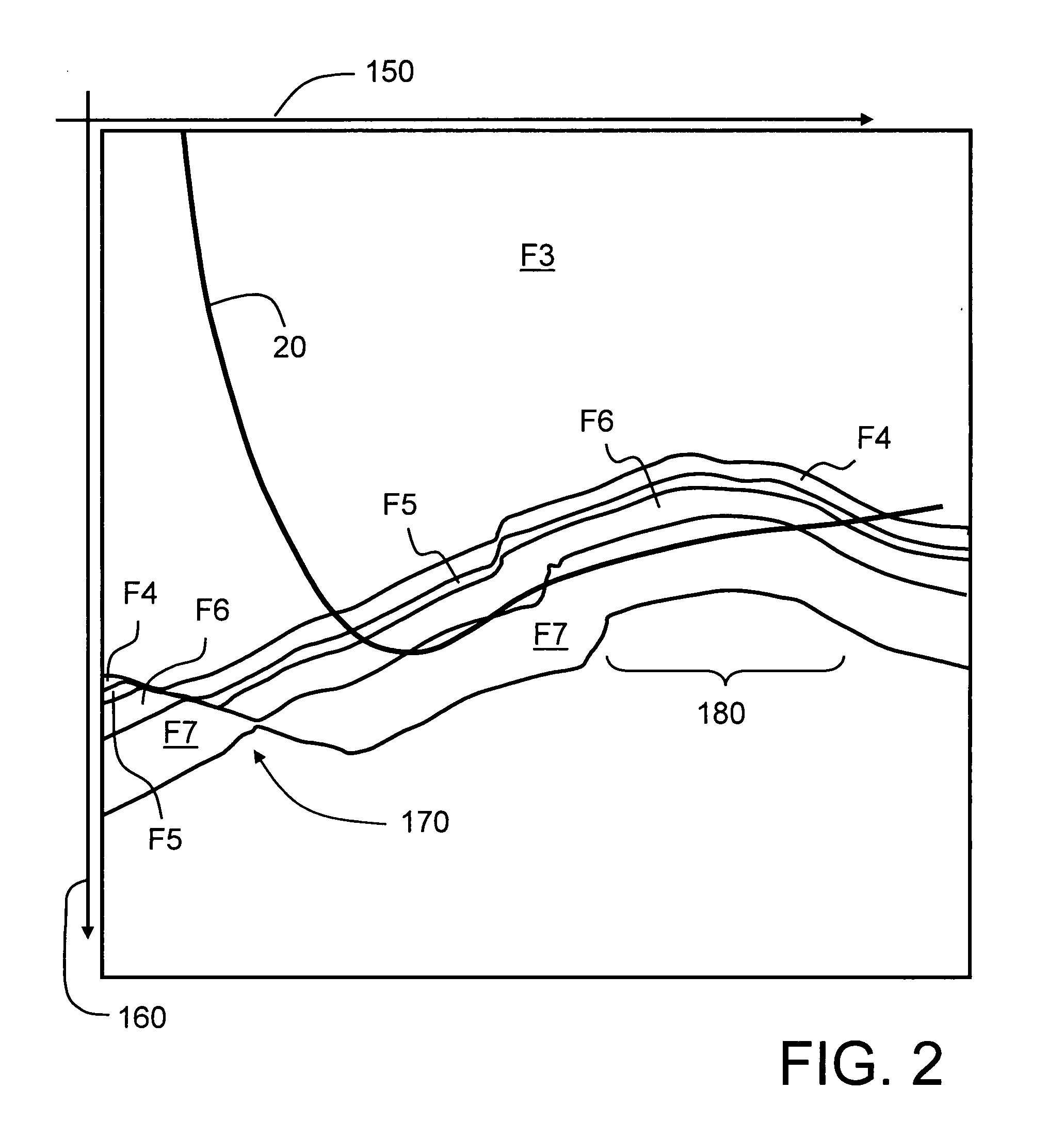

ActiveUS20080239871A1Accurate and reliable processAccurate and reliable representationElectric/magnetic detection for well-loggingSurveyGeophysicsDrill pipe

There is provided a method of processing geological data during drilling of a borehole for improving accuracy of the geological data. The method includes a first step of determining from instrumentation (100) associated with a string (50) of drilling pipes a spatial trajectory of a borehole (20, 200) in a subterranean region. A second step of the method involves determining from the spatial trajectory one or more points (P1, P2, P3) with reference to the geological data whereat the trajectory changes direction in one or more layers of strata (F) of the subterranean region. A third step of the method involves subdividing an offset log generated by the instrumentation (100) in response to the one or more points (P1, P2, P3) to generate corresponding sections of offset log. A fourth step involves mutually comparing the subdivided sections of offset log to find a condition of best comparison therebetween and thereby generate one or more error terms (E). A fifth step involves, in response to the one or more error terms (E), updating the geological data to improve its accuracy. Beneficially, the method includes a sixth of repeating the second to fifth steps until the one or more error terms (E) are minimized. The method is relevant for a drilling rig (40) to enhance its drilling accuracy into the subterranean region.

Owner:ROXAR SOFTWARE SOLUTIONS

CAS drill guide and drill tracking system

ActiveUS20050074304A1Accurate representationDepth accurateDrilling/boring measurement devicesThread cutting machinesTool bitAxial displacement

A drill guide assembly (10) for a drilling tool (50) having a chuck engaging a bit portion (54) comprising a tip (62) and a length extending from the chuck, the drill guide assembly comprising a first member (14), a second member (12) and a trackable member (16). The first member (14) is adapted to abut a workpiece surface and defines a central aperture (19) therethrough adapted to receive the bit portion. The second member (12) is adapted to be axially displaced with respect to the first member and is axially biased therefrom, and defines a central aperture (11) therethrough adapted to receive the bit portion. The trackable member (16), fastened to the second member, comprises a detectable element (35) adapted to be located and tracked in three dimensional space, thereby defining the position and movement of the second member and therefore that of the drilling tool bit portion.

Owner:ORTHOSOFT ULC

Car part machining equipment

ActiveCN108032114AEasy to placeAchieve fixationWork clamping meansLarge fixed membersEngineeringAirbag

The invention belongs to the technical field of car element machining equipment and discloses car part machining equipment comprising a rack, a fixing mechanism and a drilling mechanism. The fixing mechanism comprises two support columns and an airbag, a mounting groove is formed in the upper surface of the airbag, and a gasket is arranged on the side wall of the mounting groove. The drilling mechanism comprises a driving part and a drilling part, the driving part comprises an air storing box, and a partition plate is slidably connected to the interior of the air storing box. A pushing rod isarranged on the partition plate, the air storing box comprises a driving cavity and a press-moving cavity, and a first air hole, a second air hole and an exhaust hole are formed in the air storing box. The drilling part comprises a mounting table slidably connected to the rack, a drill bit mounted on the mounting table and a motor for driving the drill bit to rotate, and the end, away from the airstoring box, of the pushing rod is fixed to the mounting table. According to the car part machining equipment, the problems that in the prior art, when a crankshaft is punched, punching equipment andequipment for fixing the crankshaft are needed for use, thus the space needed by machining is large, and the machining cost is high are solved.

Owner:宁波江北珂达汽车技术有限公司

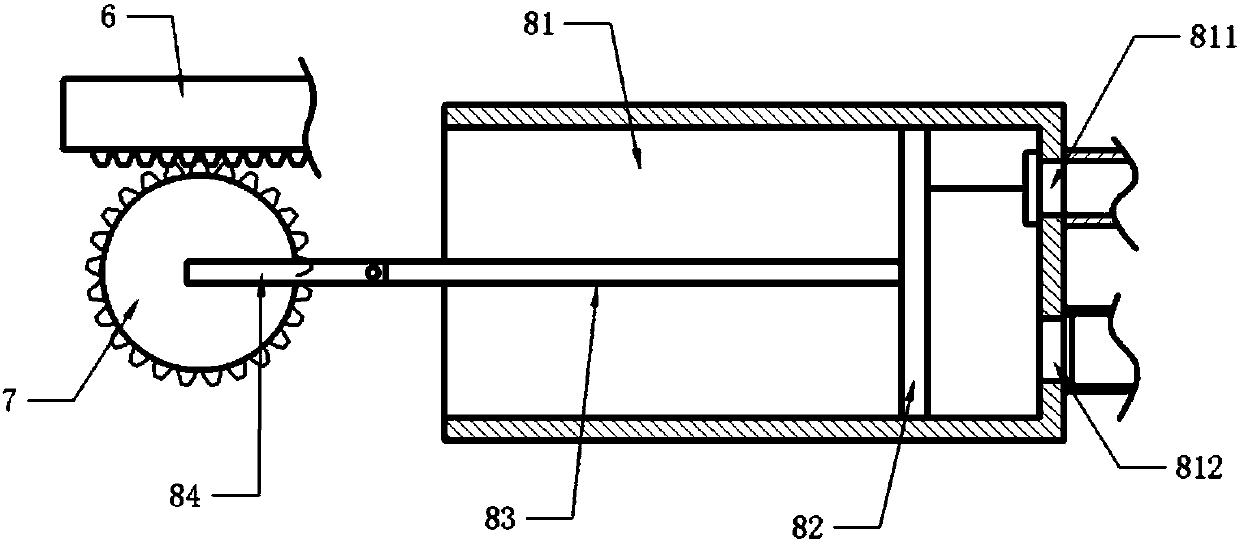

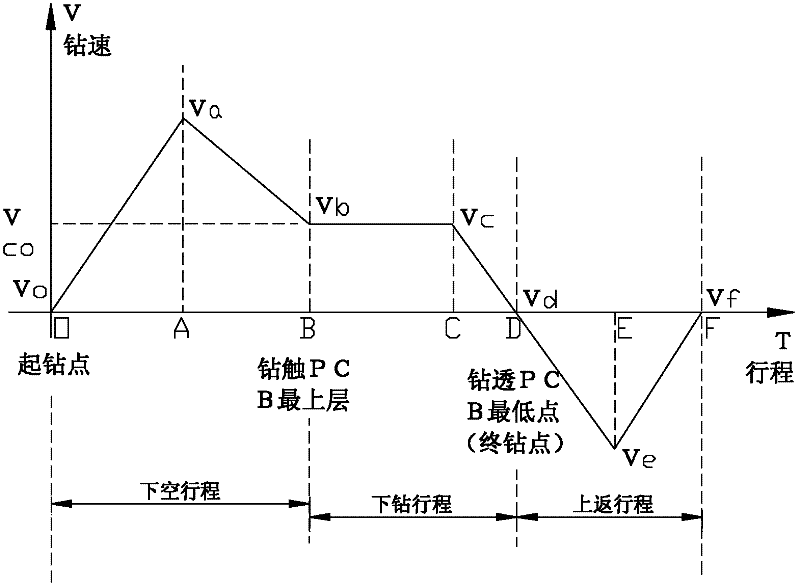

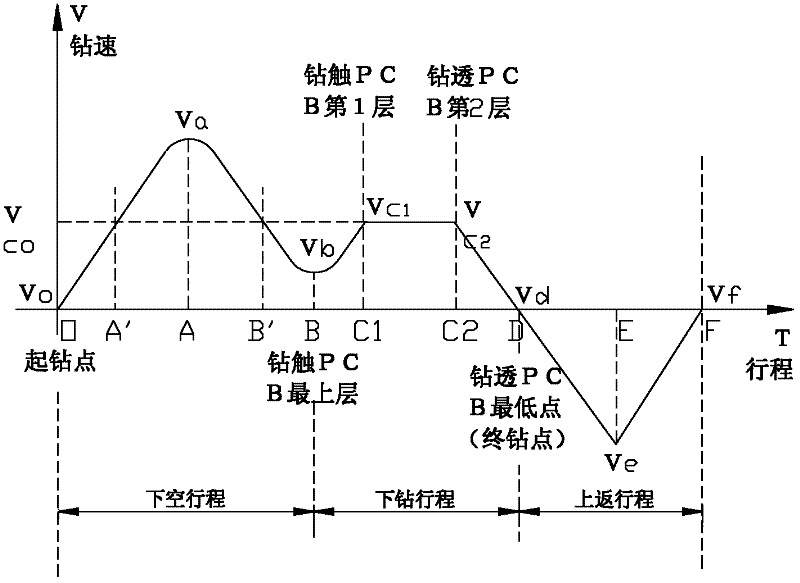

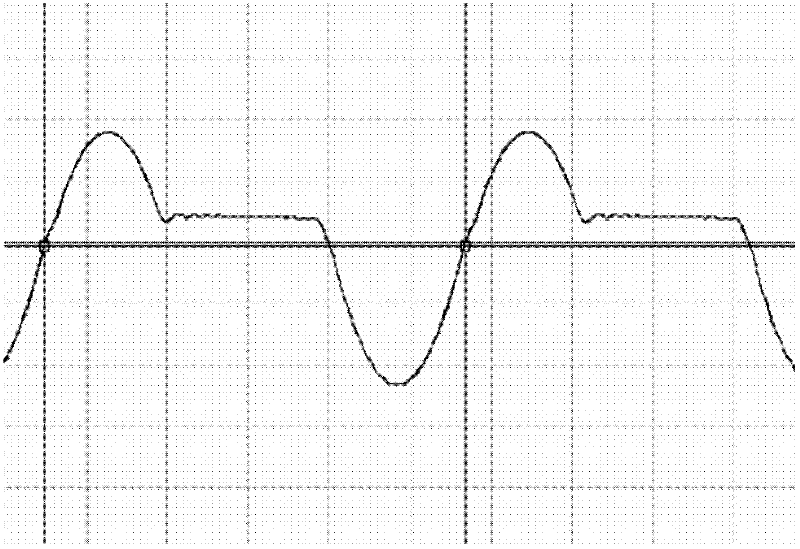

Drilling method of a pcb board drilling machine

The invention relates to a drilling processing method of a PCB (printed circuit board) board drilling machine, which comprises a downward stroke controlling a drill spindle of the drilling machine to rotate forwards, and an upward return stroke controlling the drill spindle of the drilling machine to rotate reversely, wherein the downward stroke comprises a downward noncutting stroke and a downward drilling stroke; the downward noncutting stroke comprises an acceleration section and a deceleration section, the deceleration section keeps until a touch pad rotation speed Vb is achieved when a drill cutter touches a protective layer; the downward drilling stroke comprises a constant speed section in which drilling is carried out at a constant rotary speed Vco, and a deceleration section for reducing the rotary speed after the drill cutter touches a base plate layer; and the upward return stroke starts when the base plate layer is drilled through, the constant rotary speed Vco starts whenthe drill cutter touches a circuit board layer and ends when the circuit board layer is drilled through by the drill cutter, the deceleration section is adjusted in the processing method to make the touch pad rotary speed Vb lower than the constant rotary speed Vco, and an acceleration section in which the rotary speed increases gradually also exists between the reduced touch pad rotary speed Vb and the constant rotary speed Vco. In the processing method provided by the invention, simple and effective steps can be adopted, and vibration noise of the drilling spindle and PCB front and back surface hole site deviation are further reduced through reducing drilling entering rotary speed.

Owner:HANS CNC SCI & TECH

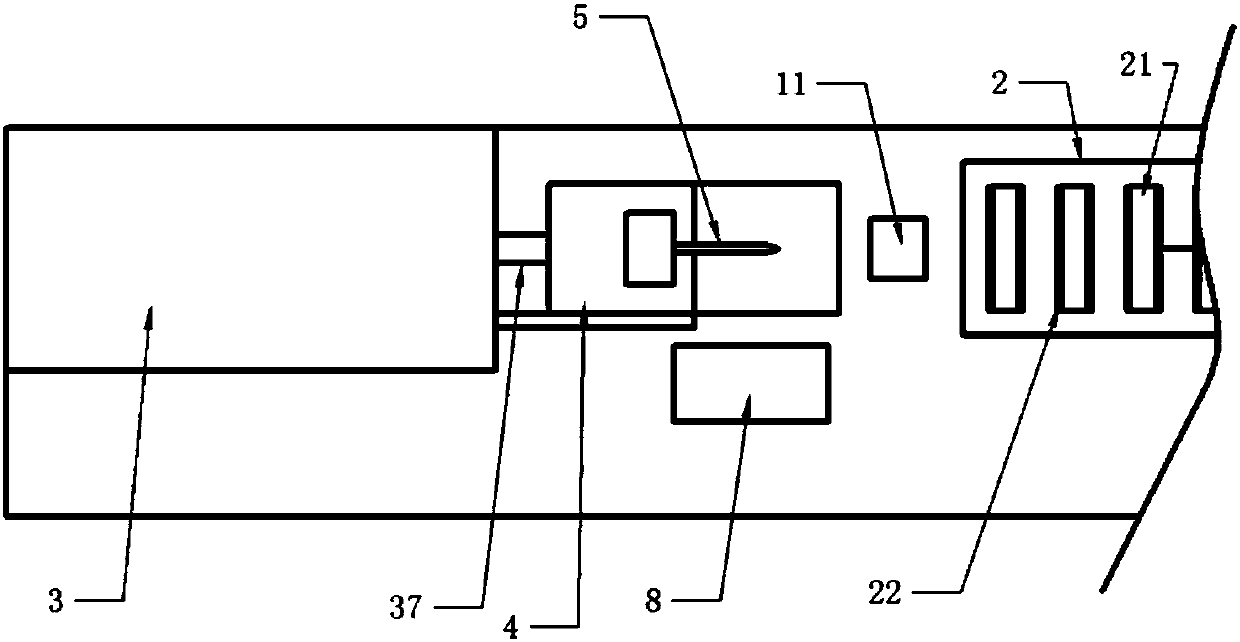

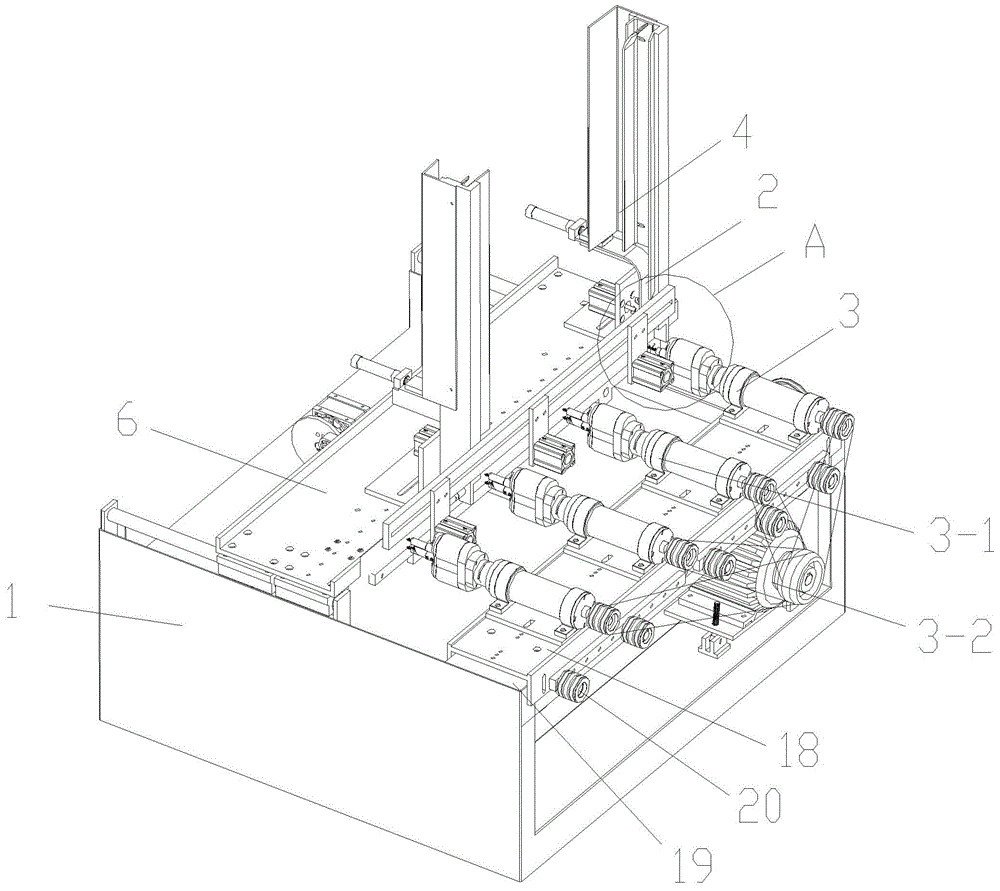

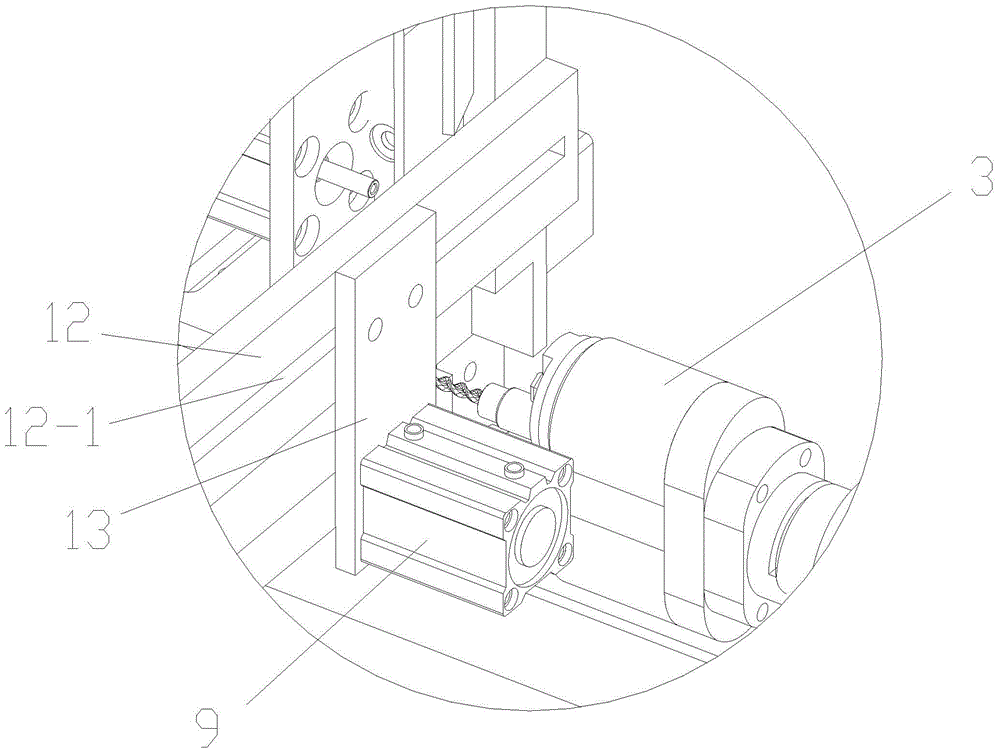

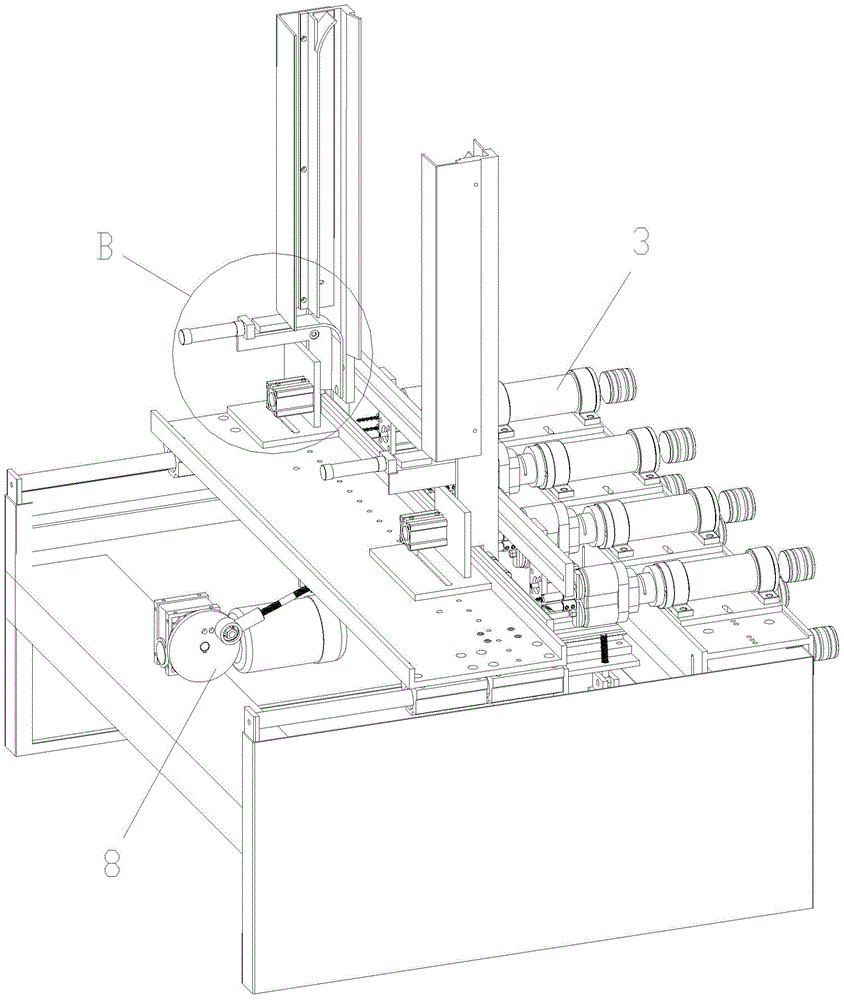

Full-automatic plate material drilling machine

A full-automatic plate material drilling machine comprises a machine frame, the machine frame is provided with a positioning frame for fixing a plate material and a drilling machine for drilling the plate material, the positioning frame is provided with a positioning groove for making the plate material placed longitudinally and positioned, the bottom of the positioning groove is provided with discharge ports, each discharge port is provided with a supporting limit block, and each supporting limit block is arranged on a first gas cylinder; the top of the positioning groove is connected with a feeding device, the feeding device comprises a placing frame, the placing frame is provided with a groove body for making the plate material transversely placed, the groove body is vertically arranged, the bottom of the groove body is provided with a supporting seat, the side edge of the bottom of the groove body is provided with a plate material outlet, and the supporting seat is provided with a second gas cylinder for pushing the plate material out of the plate material outlet; a guide channel is arranged between the plate material outlet and the top of the positioning groove.

Owner:恒达传动禹城有限公司

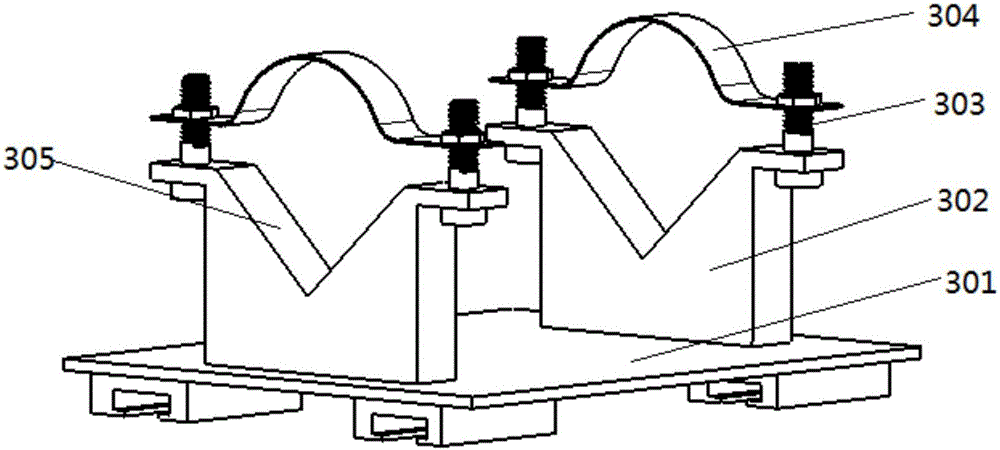

Drilling fixture for plastic pipe

InactiveCN105922342ARealize drillingHigh precisionMetal working apparatusMechanical engineeringDrilling machines

The invention provides a drilling fixture for a plastic pipe. The drilling fixture comprises a base and a clamping mechanism which are in sliding connection with each other through cooperation of guide rails and sliding blocks, wherein a straight-line motion mechanism is arranged between the base and the clamping mechanism, and comprises a lead screw nut pair of which the axis is parallel to the sliding direction of the sliding blocks; the top of a nut on the lead screw nut pair is fixedly connected with the bottom of the clamping mechanism; a support is fixed on the base; a drilling die is arranged on the support; a first through hole capable of accommodating the drilling die is formed in the support; the clamping mechanism comprises a baseplate and brackets; a V-shaped groove is formed in the cross section of each bracket; and a flexible steel belt is connected with the two sides of each bracket through locking bolts. The drilling fixture provided by the invention has the advantages that through the regulation of pipe diameters and drilling positions, relatively-high-precision drilling on plastic pipes of different specifications on a common drilling machine can be achieved; the structure is simple; and the operation is easy.

Owner:TIANJIN RUILING TECH DEV CO LTD

Method for part curve surface hole site drilling line drawing with three-dimensional model

InactiveCN103170660AShorten the processing cycleSave marking timeDrilling/boring measurement devicesOther workshop equipmentNumerical controlPolyester

The invention relates to a method for part curve surface hole site drilling line drawing with a three-dimensional model. The method for the part curve surface hole site drilling line drawing with the three-dimensional model includes the following steps: (1) unfolding a curve surface of a part and correspondingly unfolding a hole site on the curve surface under the condition of a three-dimensional mathematical model, (2) conducting projection on two-dimensional model lines of the unfolded part and the unfolded hole site, and using a numerical controlled plotter to draw the two-dimensional model lines on a polyester film, (3) attaching the polyester film to the curve surface of the part, aligning the model lines with the edge of the part, and using a punch to make a round hole central point on the surface of the part, and (4) taking down the polyester film, and using a drilling tool to drill in the dotting position. The method for the part curve surface hole site drilling line drawing with the three-dimensional model can not only improve machining accuracy and machining efficiency of the hole site on the curve surface, but also reduce machining cost.

Owner:SHENYANG AIRCRAFT CORP

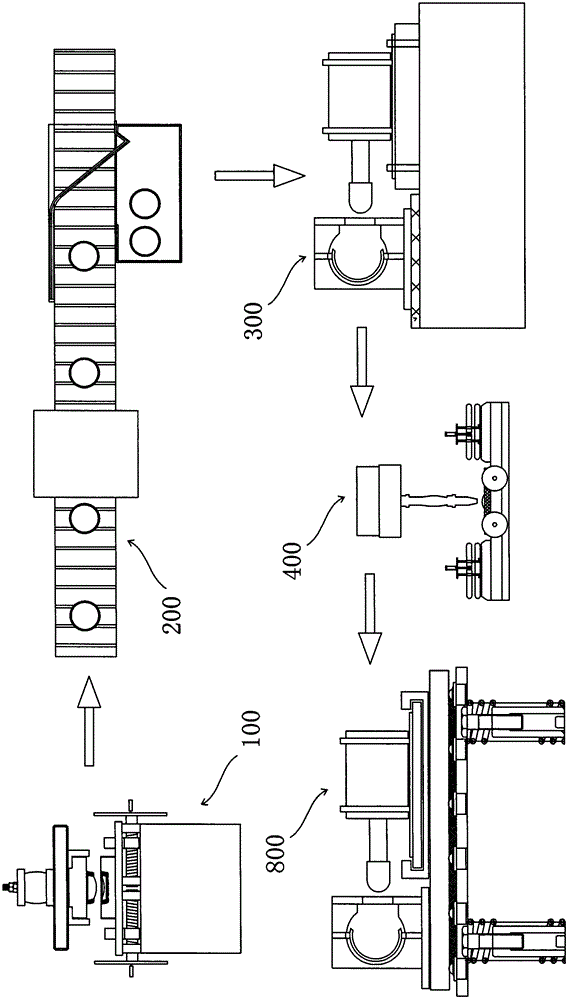

Automotive brake pad production line

ActiveCN104476200AHigh precisionImprove processing efficiencyOther manufacturing equipments/toolsProduction lineHeat transfer efficiency

The invention relates to an automotive brake pad production line which comprises a tabletting device, a thermal treatment device, a grinding device, a drilling device, a code spraying device and a conveying device connected among the former. Through the tabletting device, a concave die can be closely clamped, so that position of the concave die can be adjusted accurately; through the thermal treatment device, an automotive brake pad storage shelf after being subjected to thermal treatment can be automatically conveyed to a goods storage area, and heat transfer efficiency of a drum brake pad is improved; through the grinding device, an automotive brake pad is closely clamped, and position of an automotive brake pad clamp can be adjusted accurately, so that grinding accuracy is improved remarkably; through the drilling device, the automotive brake pad is closely clamped, the position of the automotive brake pad can be adjusted accurately, and a clamping clamp can be accurately positioned, so that drilling accuracy is improved remarkably; through the code spraying device, the brake pad is clamped closely, code spraying accuracy is improved, and one-step code spraying forming of multiple batches of brake pads is realized.

Owner:HUANGSHAN FEIYING AUTO PARTS

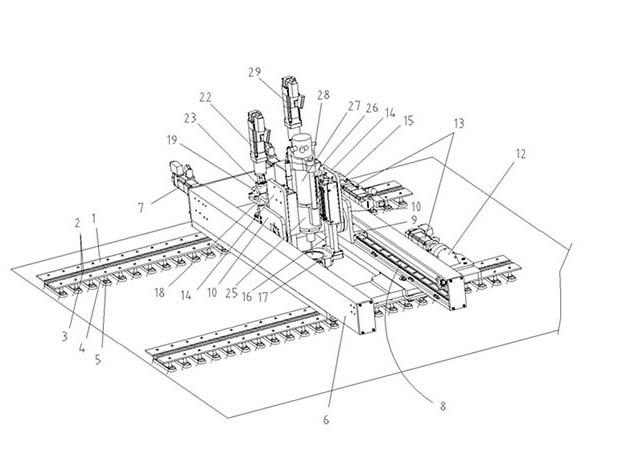

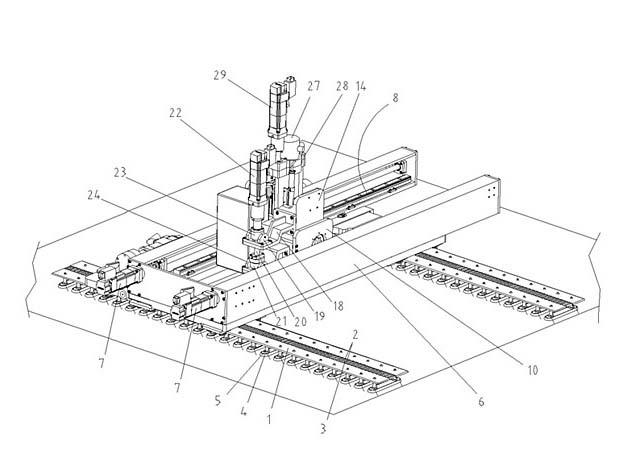

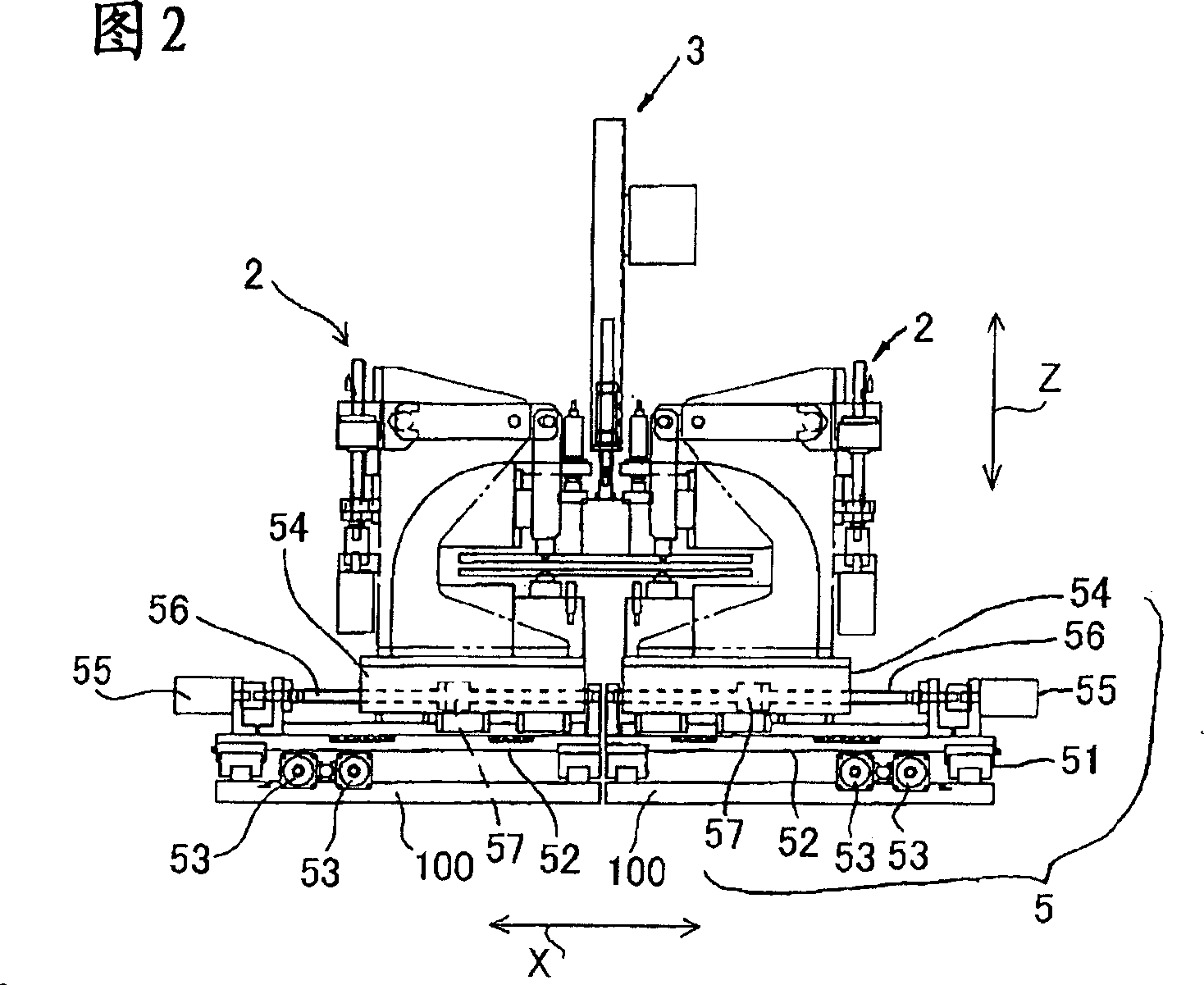

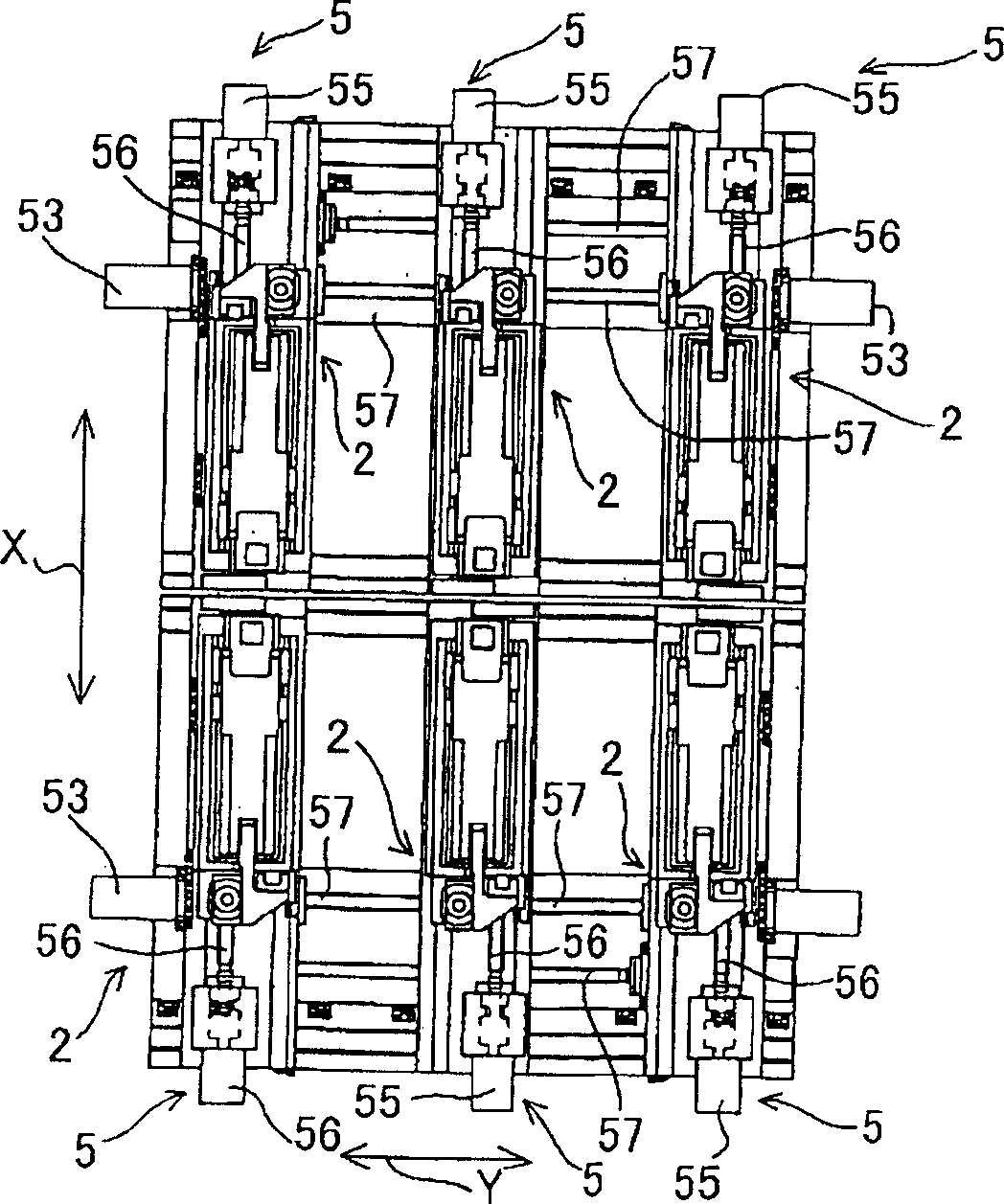

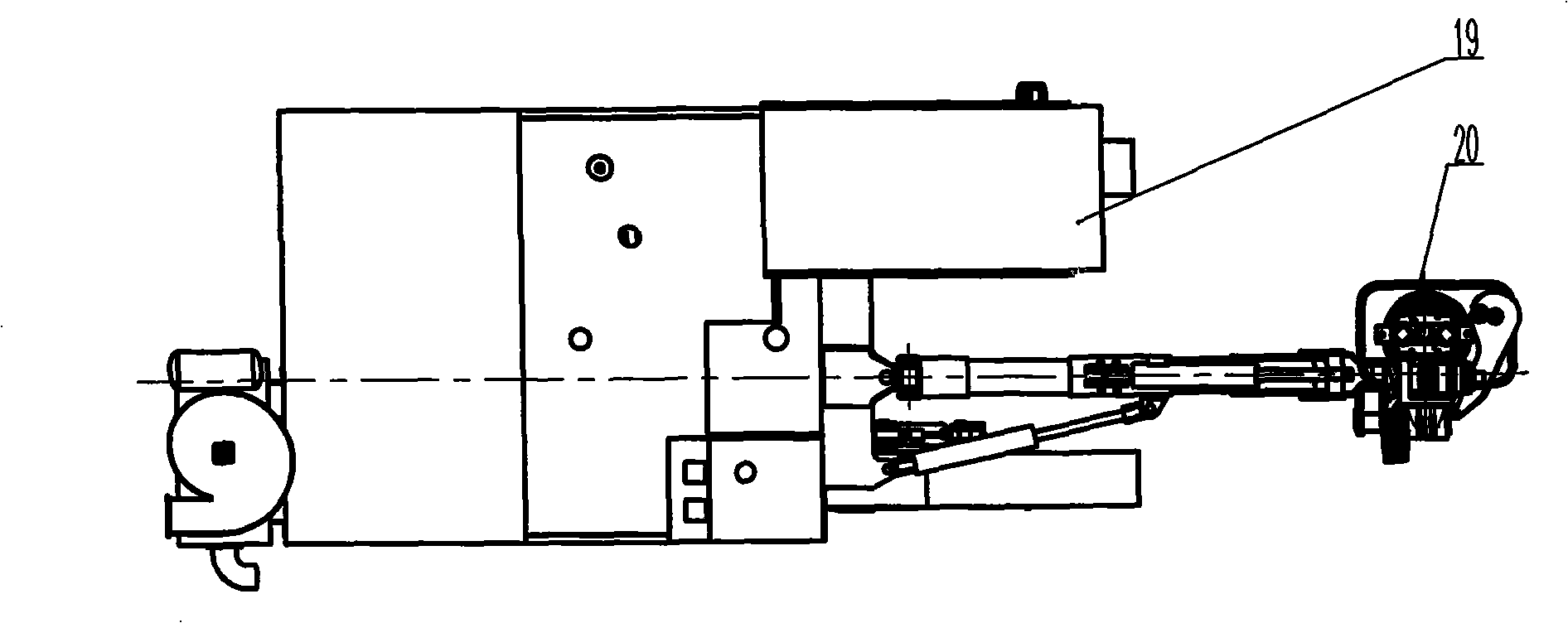

Arc surface drilling equipment

ActiveCN102198531AImprove drilling accuracyExtended drilling rangePortable drilling machinesBoring/drilling machinesElectricityEngineering

The invention discloses arc surface drilling equipment, which comprises two flexible tracks. A movable framework is arranged on the flexible tracks; a vertical plate is mounted on the movable framework via a linear guide rail; the vertical plate is rotatably connected with a swing plate; and an electric main shaft is mounted on the swing plate. The electric main shaft is slidably connected with the swing plate via a hoop, and the swing plate is connected with a swing driving mechanism. The electric main shaft can move longitudinally, transversely and vertically on the drilling equipment, and can swing and rotate, so a drilling range of the electric main shaft is expanded, absorption positions of the flexible tracks on the surface of a workpiece are not needed to be frequently changed, theworking intensity is reduced, the working efficiency is improved, and the processing cost is lowered; meanwhile, the drilling equipment is more stable, and the drilling precision is improved.

Owner:大连四达高技术发展有限公司

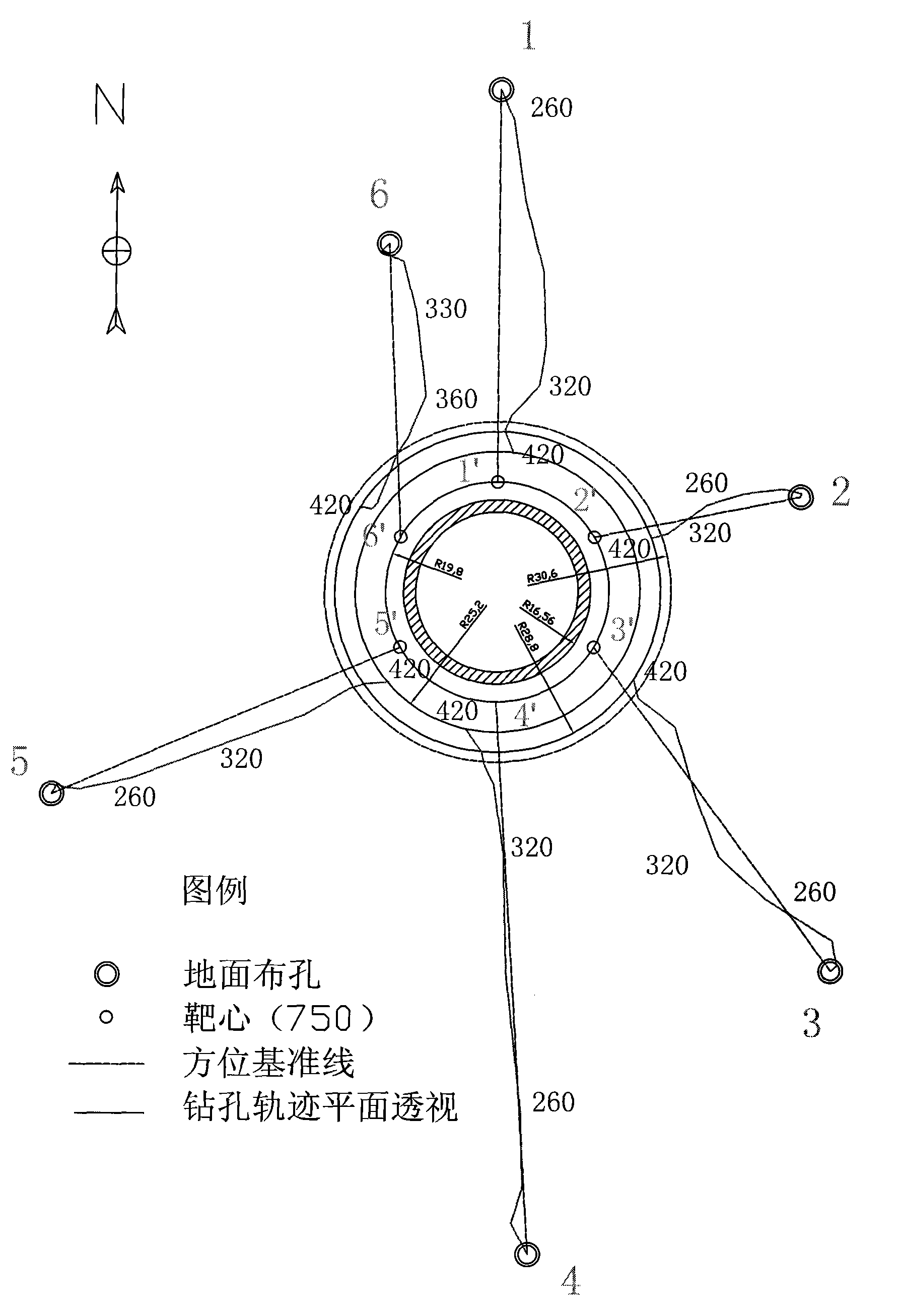

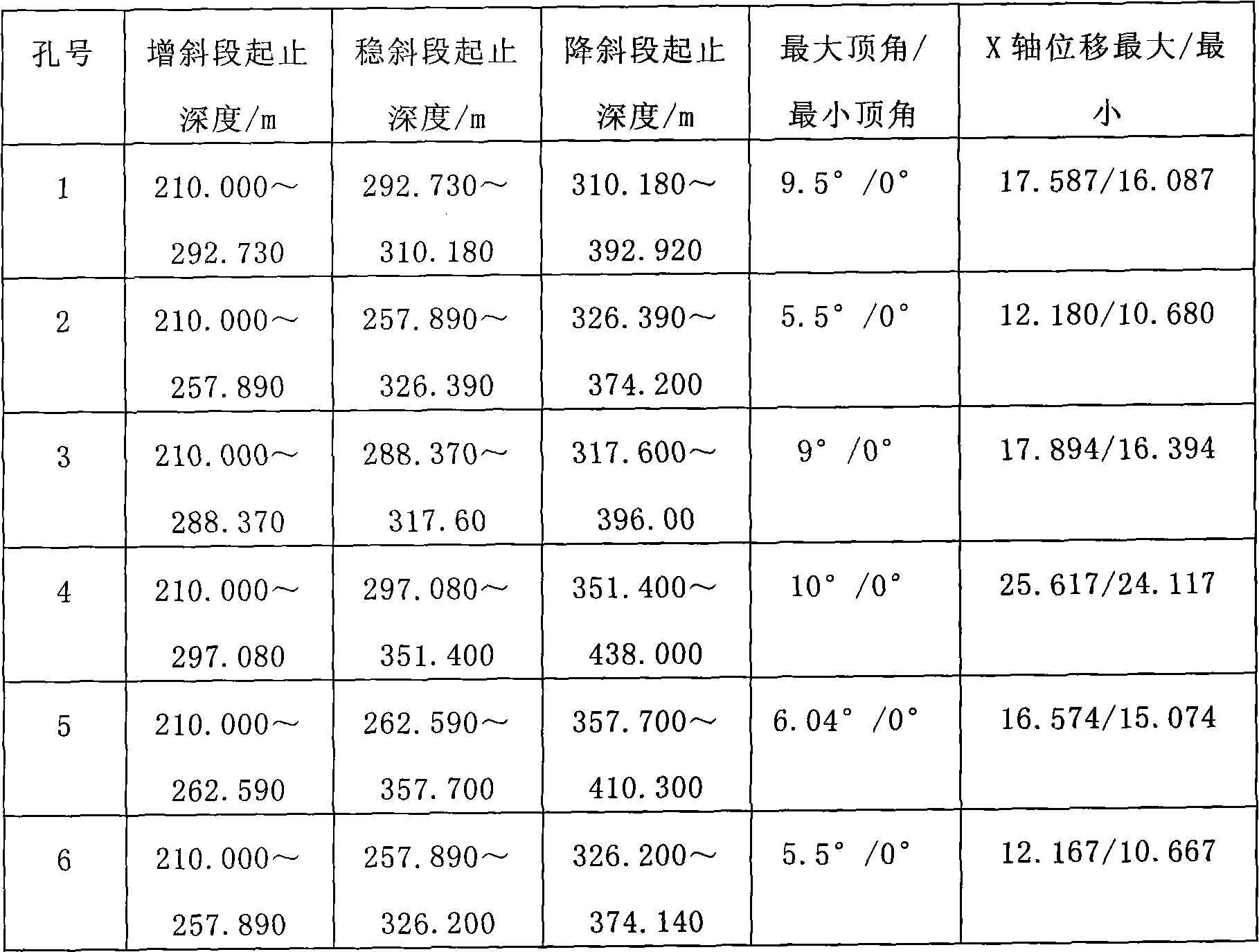

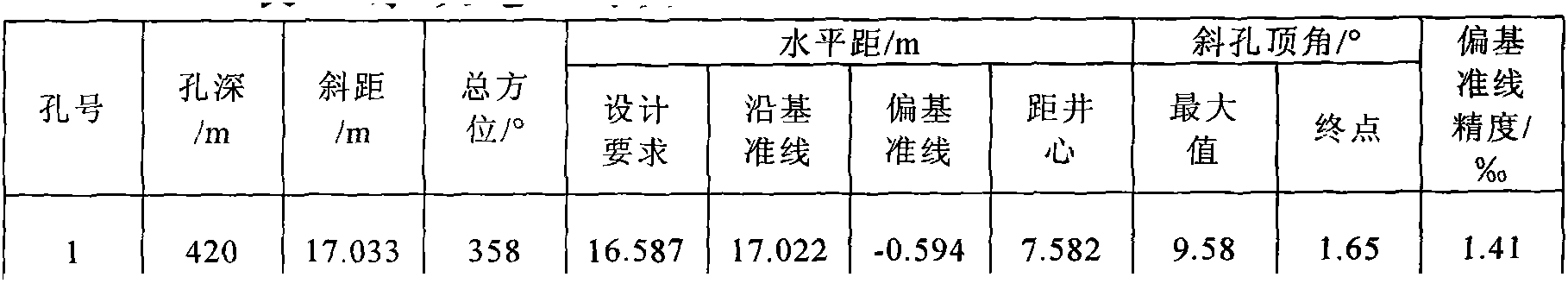

Coal engineering hole directional drilling method

InactiveCN102094580AWon't breakImprove drilling accuracyDirectional drillingCoalDirectional drilling

The invention provides a coal engineering hole directional drilling method, which mainly solves the problems of low drilling precision and complex procedure of the conventional directional drilling method. The directional drilling method is characterized by comprising the following steps of: 1, designing a drilling trace: designing the drilling trace and drilling parameters according to the requirement of engineering drilling; 2, determining special equipment, machines and devices which are required by the engineering, and combining the drilling equipment according to the requirements of all drilling stages; 3, constructing according to the trace and the parameters which are designed in the step 1, measuring the finished drilling trace by using an inclinometer after one stage is finished, analyzing whether data is the same as the designed trace, and expecting the next trace tendency; and 4, performing error correction design if error correction is needed to be performed in the step 3, repeating the content in the step 2, and cycling until the drilling is finished; and if error correction is not needed in the step 3, continuing to drill the next hole section until the drilling is finished. The coal engineering hole directional drilling method has the characteristics of high drilling precision, simple procedure, smooth drilled holes and contribution to the next work of drilling.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Curved plate tool and curved plate drilling equipment and drilling method thereof

ActiveCN105108540AAvoid mutual interferenceSimple structureWork clamping meansMeasurement/indication equipmentsHole drilling methodWorkbench

The invention discloses a curved plate tool and curved plate drilling equipment and a drilling method thereof, and belongs to the field of special-shaped plate machining equipment. A to-be-machined workpiece fixed on a back-face fixing workbench adopts an arc-shaped plate with two ends bending upwards, the to-be-machined workpiece is located between a first support and a second support, the upper end of the first support is provided with a back-face pressing mechanism used for pressing one end of the to-be-machined workpiece, the upper end of the second support is provided with a clamping fixture with the height adjustable, and the clamping fixture is used for clamping the other end of the to-be-machined workpiece; a back-face transverse positioning mechanism performs transverse positioning on the to-be-machined workpiece. The curved plate drilling equipment detects the vertical distance between a drilling mechanism and the to-be-machined workpiece in real time through a drilling positioning device, the drilling equipment on a mechanical arm automatically drills the to-be-machined workpiece in the shape of the special-shaped plate, therefore, the working intensity is lowered, the working efficiency is improved, the machining cost is lowered, and the drilling precision is improved. According to the curved plate drilling method, the working mode of a drill bit can be adjusted according to the resistance borne by the drill bit, the life of the drill bit is prolonged, and the working efficiency is improved.

Owner:淄博纽氏达特机器人系统技术有限公司

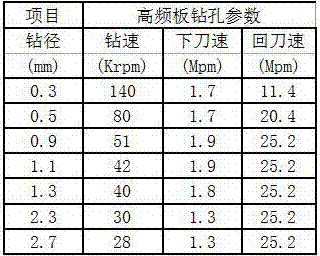

Hybrid different board material high-frequency board manufacturing method

ActiveCN107278062AAvoid bendingSolve the problem of overflow glueMultilayer circuit manufactureEpoxyProcess quality

The invention provides a hybrid different board material high-frequency board manufacturing method. A double-face copper-plated high-frequency board material and an epoxy resin board are employed for manufacturing, a non-flowing glue PP plate is utilized as a stitching medium of the high-frequency board material and the epoxy resin board, dimensions of a groove hole on the non-flowing glue PP plate are specially designed to solve a groove hole glue spilling problem, processing quality of products is improved, moreover, the overlapping process for drilling is further specially designed for the high-frequency board material, for a board material sinking problem of the high-frequency board material during stitching after grooving, a stitching overlapped structure is especially designed, a three-in-one buffer pad is employed to solve the grooving-side board material sinking problem, a hot pressing program is designed according to the stitching overlapped structure, the cold press time is further prolonged to further reduce a board bending problem caused by different expansion coefficients of different board materials, the high-frequency board material contains fillers which are not easily removed in a chemical glue removal mode, before electroplating, plasma glue removal is firstly carried out, chemical glue removal is then carried out, and complete cleaning is carried out to effectively improve electroplating quality.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Efficient wall drilling machine

ActiveCN109227965AControl altitudeImprove stabilityWorking accessoriesStone-like material working toolsFixed frameEngineering

An efficient wall drilling machine comprises a base, a first cylinder is arranged on the base, and a piston rod of the first air cylinder is fixedly connected to the lower side of a rotating device; fixing frames are arranged on the two sides of the rotating device, and a telescopic scale rod is fixedly connected between each fixing frame and the base; the upper end of the rotating device is connected with a fixing base, and a sliding groove is formed in the horizontal direction of the fixing base; a drilling device is slidably connected with the interior of the sliding groove, and a damping device is connected to the vertical direction of the fixing base; the damping device is connected with a second cylinder, and a piston rod of the second cylinder is connected with the drilling device;a hollow connecting pipe is fixedly connected to the upper end of the fixing base, and a scale rod is inserted into the front end of the connecting pipe; the scale rod is fixed into the connecting pipe through a locking bolt, and a vacuum suction cup is arranged at the front end of the scale rod. The drilling machine is reasonable in design, the working efficiency can be effectively improved, thedrilling positioning precision and quality are improved, and the flexibility and the safety are achieved.

Owner:王勇

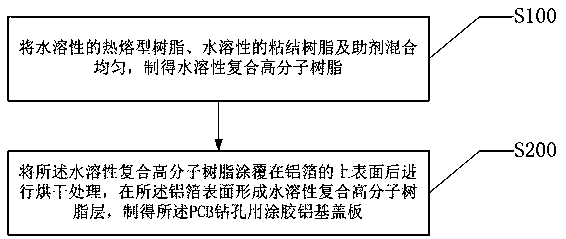

Coated aluminum substrate for drilling PCB (Printed Circuit Board) and preparation method of coated aluminum substrate

The invention discloses a coated aluminum substrate for drilling a PCB (Printed Circuit Board) and a preparation method of the coated aluminum substrate. The method comprises the following steps: taking 40-50 parts by weight of two or more of polyurethane, acrylic ester, aqueous phenolic resin and aqueous epoxy resin to form a component A1, then taking 40-55 parts by weight of two or more of polyoxyethylene, polyethylene glycol, glycerin, vinyl acetate and polyving akohol to form a component A2, taking 5-8 parts by weight of accessory ingredient, mixing the component A1, the component A2 and the accessory ingredient to obtain emulsion, coating the surface of an aluminum foil with the emulsion in a roller coating manner to prepare finished product. By using the characteristics of the surface layer resin of the aluminum foil of low hardness, low melting point, strong cohesive property and excellent water solubility, the coated aluminum substrate for drilling the PCB is capable of improving the drilling precision of a drill point in the drilling process, effectively reducing the working temperature of the drill point, prolonging the service life of the drill point and improving the hole wall quality of the drill hole.

Owner:烟台柳鑫新材料科技有限公司

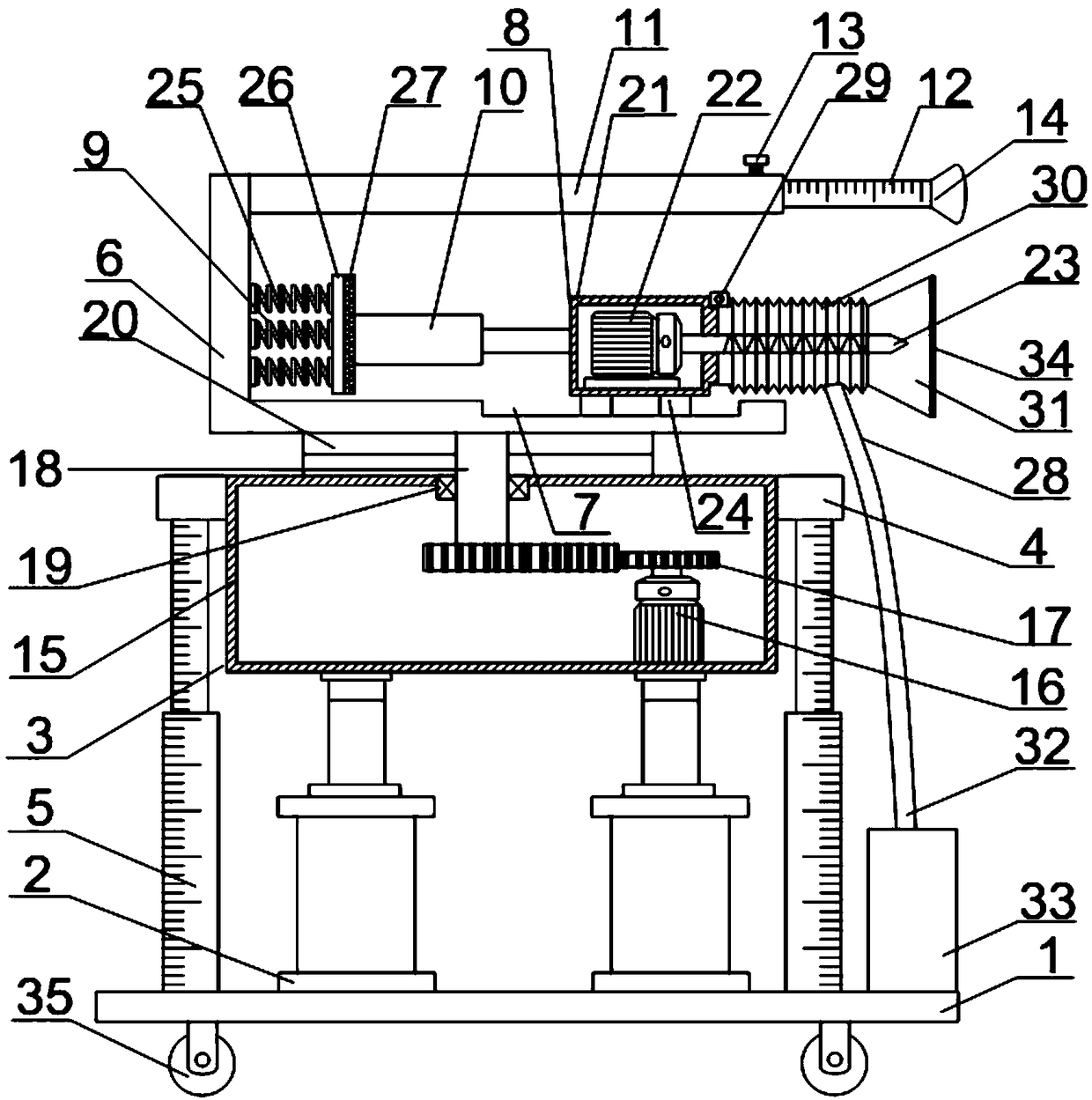

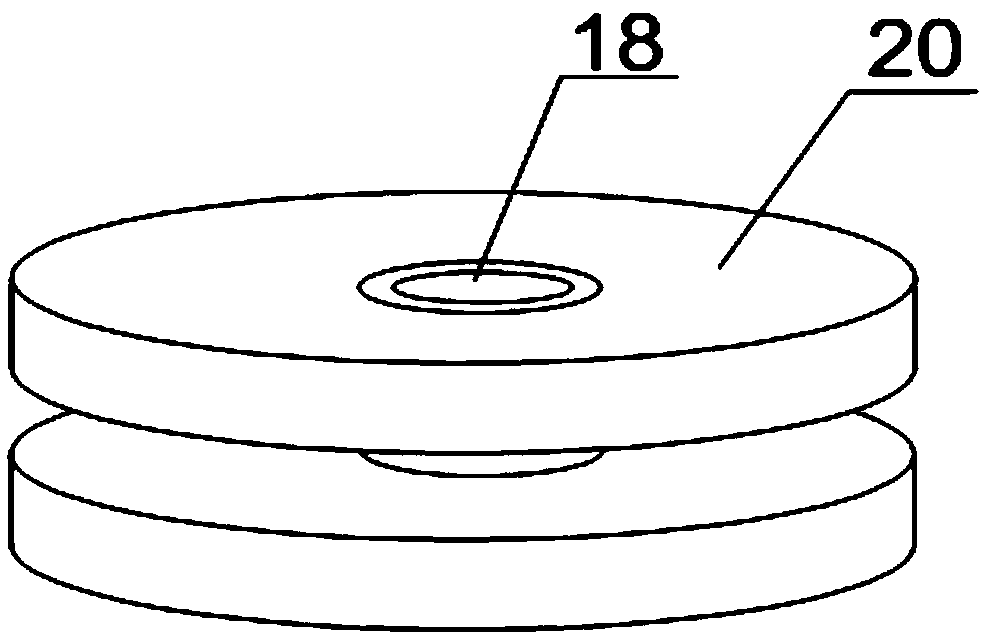

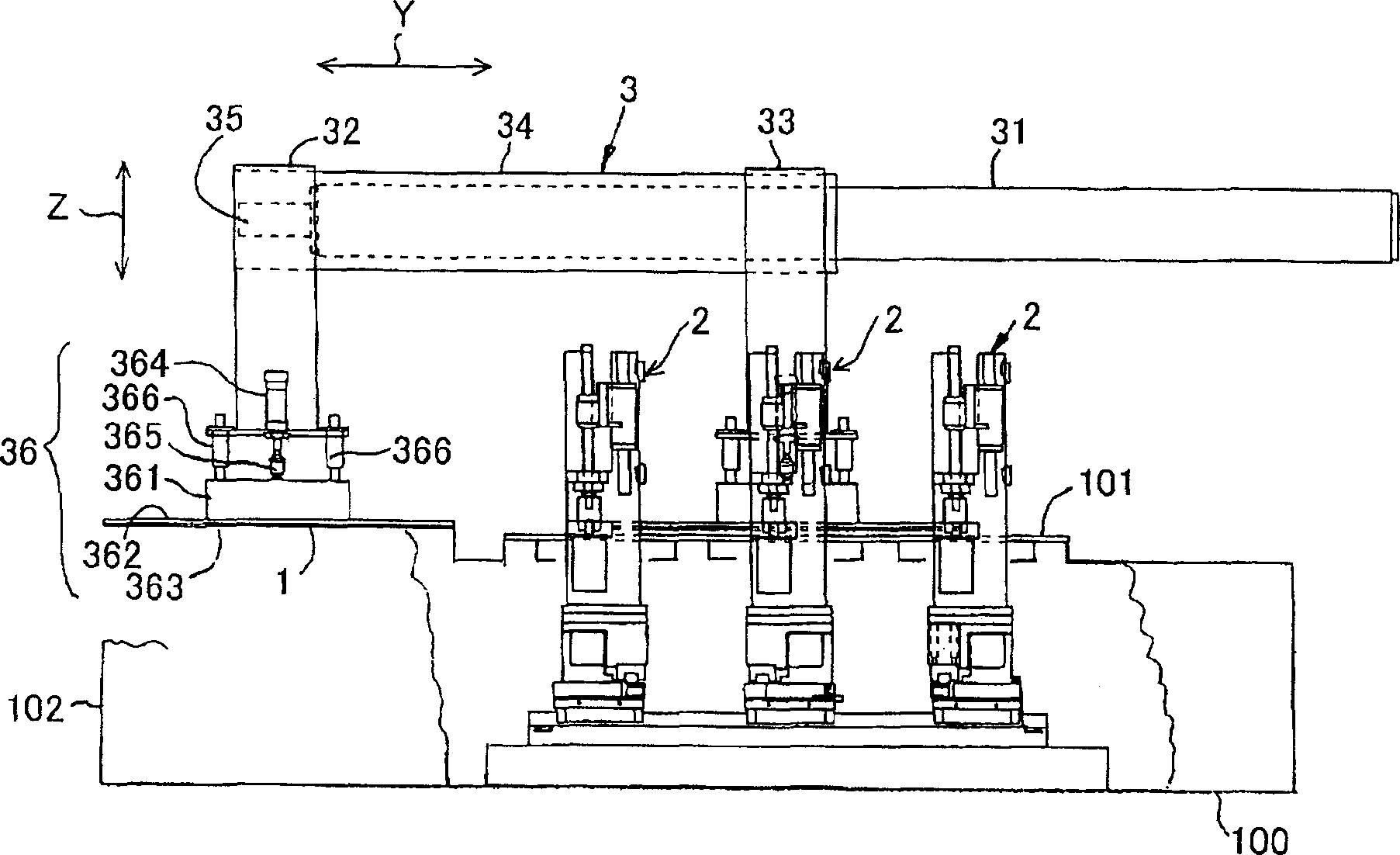

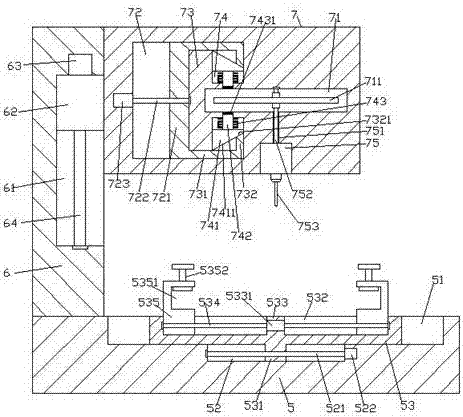

Perforating apparatus and method for slab workpiece

InactiveCN1526524ADoes not affect replacement operationsEasy and fast replacement workAutomatic control devicesMeasurement/indication equipmentsIndustrial engineering

Owner:SEIKO PRECISION CO LTD

Safe and adjustable plate drilling equipment

ActiveCN107088663AAutomatic locking controlAchieve cooperationFeeding apparatusDriving apparatusEngineeringThreaded rod

The invention discloses safe and adjustable plate drilling equipment which comprises a base and a drilling mechanism arranged above the top of the base, wherein a vertical column is arranged on the end surface at the top of the left side of the base; two first sliding grooves are formed in the end surface at the top of the left side of the base in a manner of being symmetric in the front-back direction; a second sliding groove is formed in the middle of the inner bottom wall of each of the first sliding grooves; a first threaded rod arranged in a manner of extending in the left-right direction is arranged in each of the second sliding grooves; an adjusting sliding block is in sliding fit connection with the interior of each of the first sliding grooves; a manipulating sliding cavity is formed in the drilling mechanism; a convex block is arranged in the right side of the manipulating sliding cavity; a locking cavity arranged in a manner of extending towards the right side is formed in the convex block; a drilling motor is fixedly arranged in the end surface at the bottom of the drilling mechanism; a drilling bit is connected to the bottom of the drilling motor in a matched manner; a through hole is formed between the middle of the top of the drilling motor and the middle of the bottom of the locking cavity; and a rotating shaft arranged in a manner of extending in the up-down direction is in transition fit connection with the interior of the through hole. According to the safe and adjustable plate drilling equipment, the structure is simple, the safety is high, and both the drilling efficiency and the drilling precision are improved.

Owner:CHONGQING DONGKE MOLD MFG

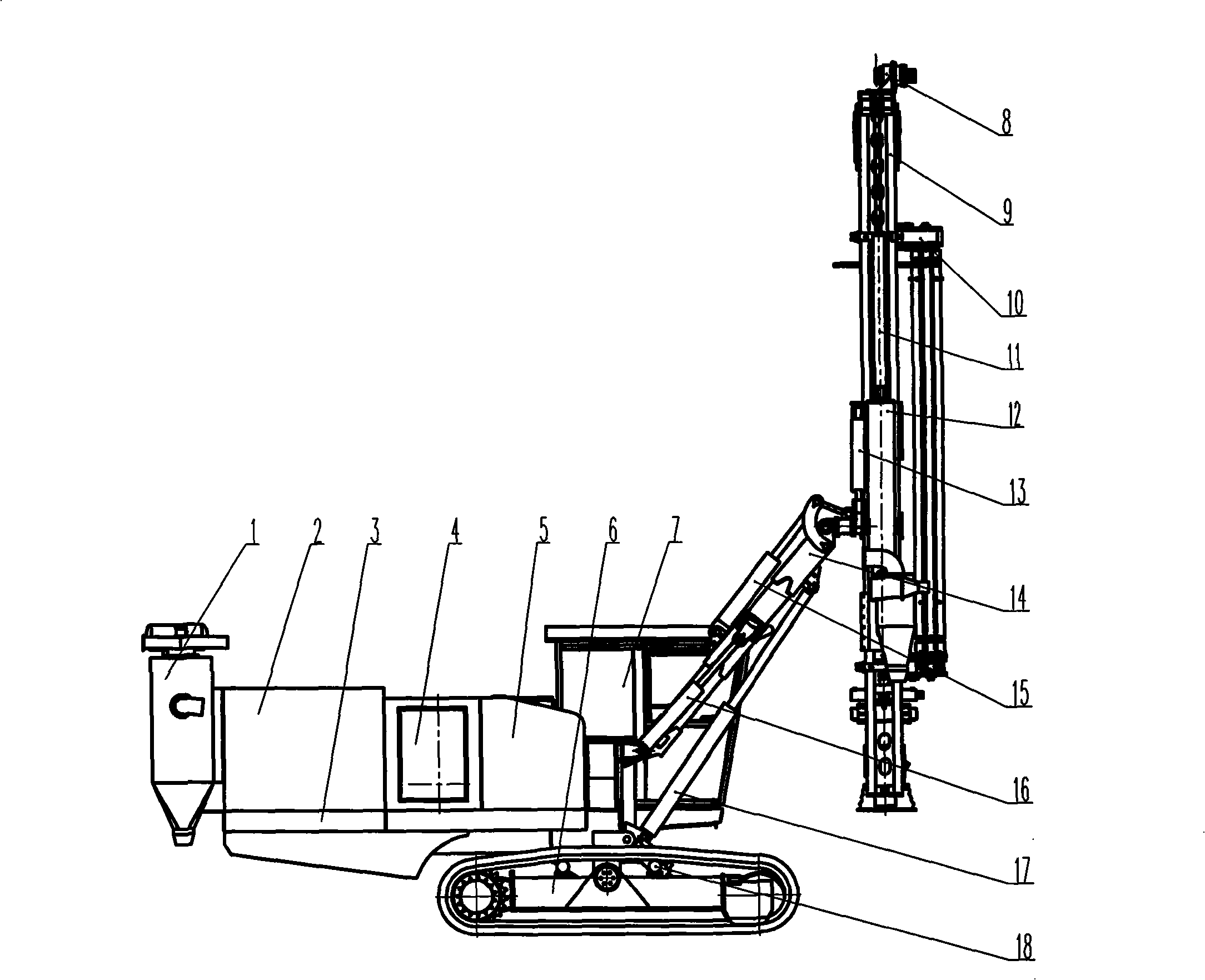

Integrated arm type in-hole perforator

InactiveCN101343979AWide range of operationsReduce auxiliary work timeDrilling machines and methodsControl systemEngineering

The invention discloses an integrated arm type down-the-hole drilling machine, which comprises a traveling chassis, a machine frame (3), a drill arm (14), a drill tower (9), a drilling system, a power system (4), a hydraulic system (5), a control system (19) and a cab (7), wherein, the traveling chassis which adopts a pedrail floating type traveling chassis (6) is arranged below the machine frame (3), an air compressor (2) and a dust removing system (1) are arranged on the machine frame (3), a drill arm lifting cylinder (17) and a drill arm deflecting cylinder (16) are installed between the drill arm (14) and the machine frame (3), and a drill tower lifting cylinder (15) and a drill tower deflecting cylinder (13) are arranged between the drill arm (14) and the drill tower (9). A compensation cylinder (11) is arranged between a sliding carriage (12) of the drilling system and the drill tower (9). The invention provides the integrated arm type down-the-hole drilling machine which has the advantages that the structure is compact, the maneuverability is good, the integrated arm type down-the-hole drilling machine can meet the requirements of multiple direction drilling, the operation range is wide, the energy consumption is low, the efficiency is high, the control is convenient and flexible, the maintenance is convenient, and the operation cost is low.

Owner:CENT SOUTH UNIV +1

Gluing aluminum-based cover plate for PCB drilling and preparing method thereof

InactiveCN110281308AReduce the temperatureExtended service lifePretreated surfacesCoatingsSolubilityWater soluble

The invention provides a gluing aluminum-based cover plate for PCB drilling and a preparing method thereof. The gluing aluminum-based cover plate for PCB drilling comprises aluminum foil and a water-soluble composite molecular resin layer arranged on the upper surface of the aluminum foil. The water-soluble composite molecular resin layer material comprises water-soluble hot melting resin, water-soluble bonding resin and an assistant. According to the invention, the toughness of the water-soluble composite molecular resin layer is proper, in the drill needle falling process, the guide effect is achieved, and the drilling precision is improved; meanwhile, the hot melting resin in the water-soluble composite molecular resin layer achieves the effect of lubricating a drill bit and cooling the drill needle during drilling, the hole wall roughness is effectively improved, wire winding is reduced, the drill bit temperature is reduced, the service life of the drill needle is prolonged, and in addition, the water-soluble composite molecular resin layer is good in water solubility, easy to treat after drilling, not prone to being attached into holes of a PCB and capable of ensuring drilling quality.

Owner:烟台柳鑫新材料科技有限公司

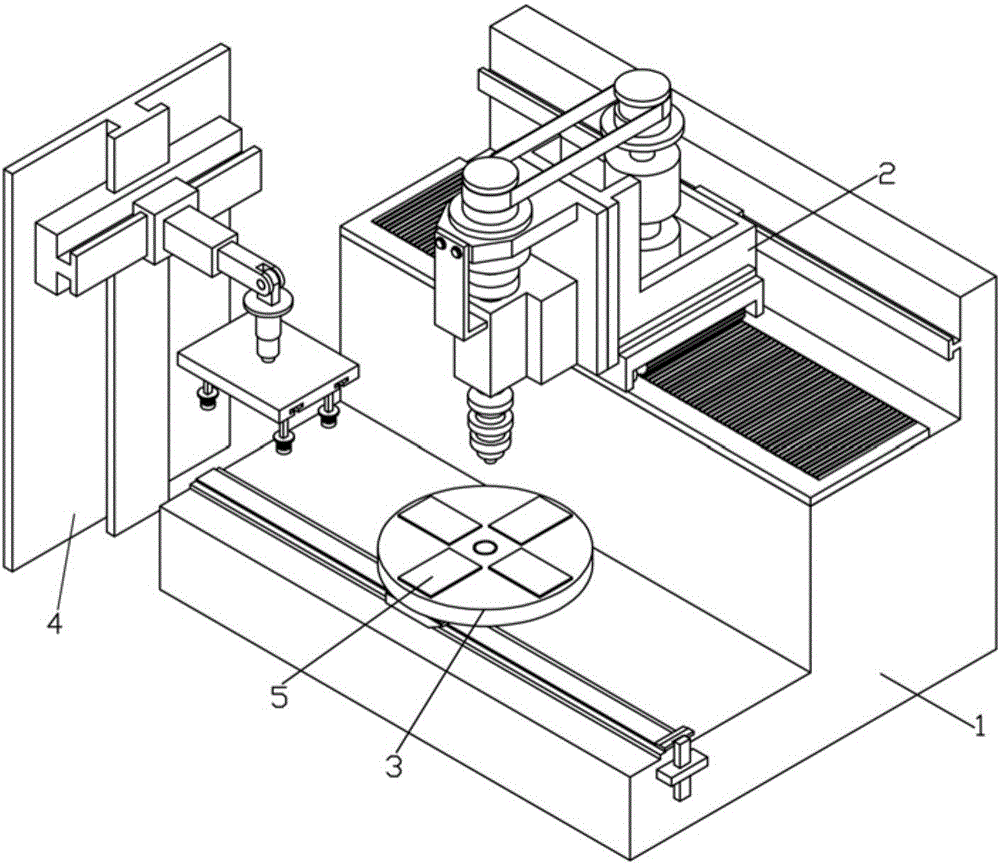

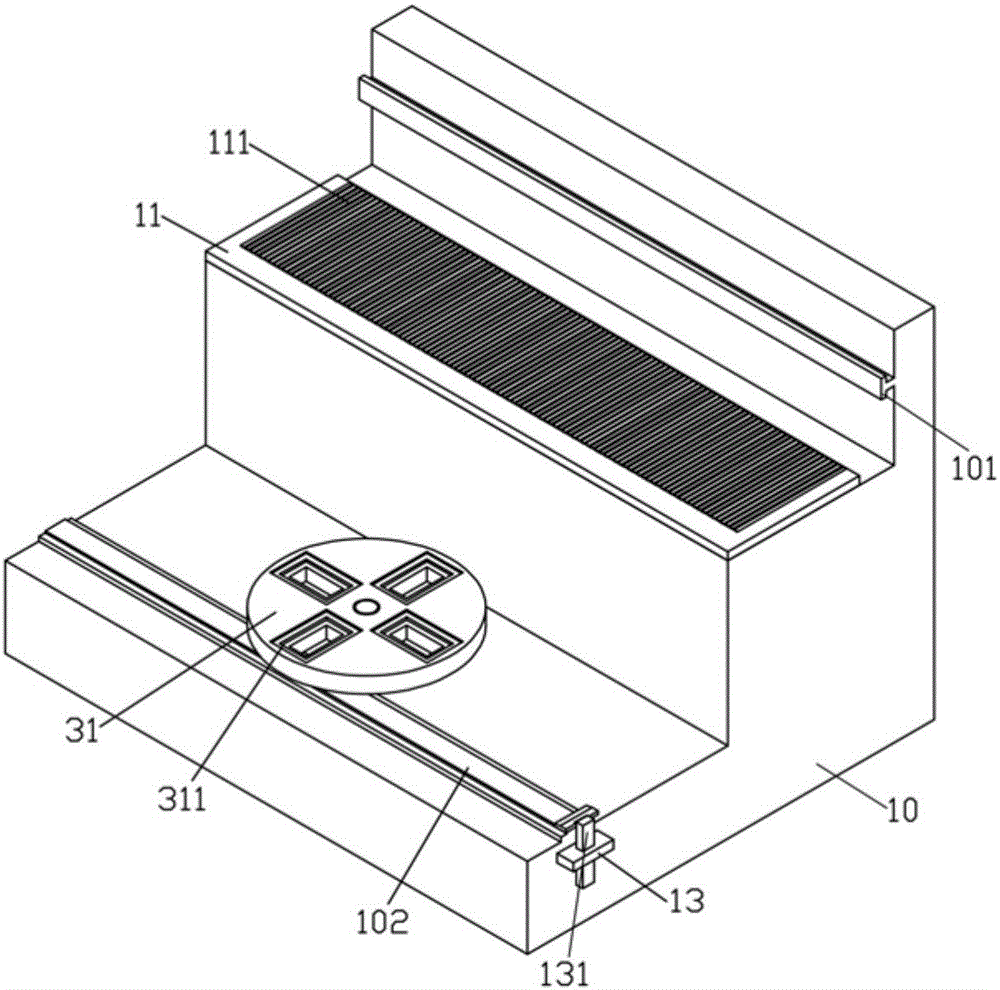

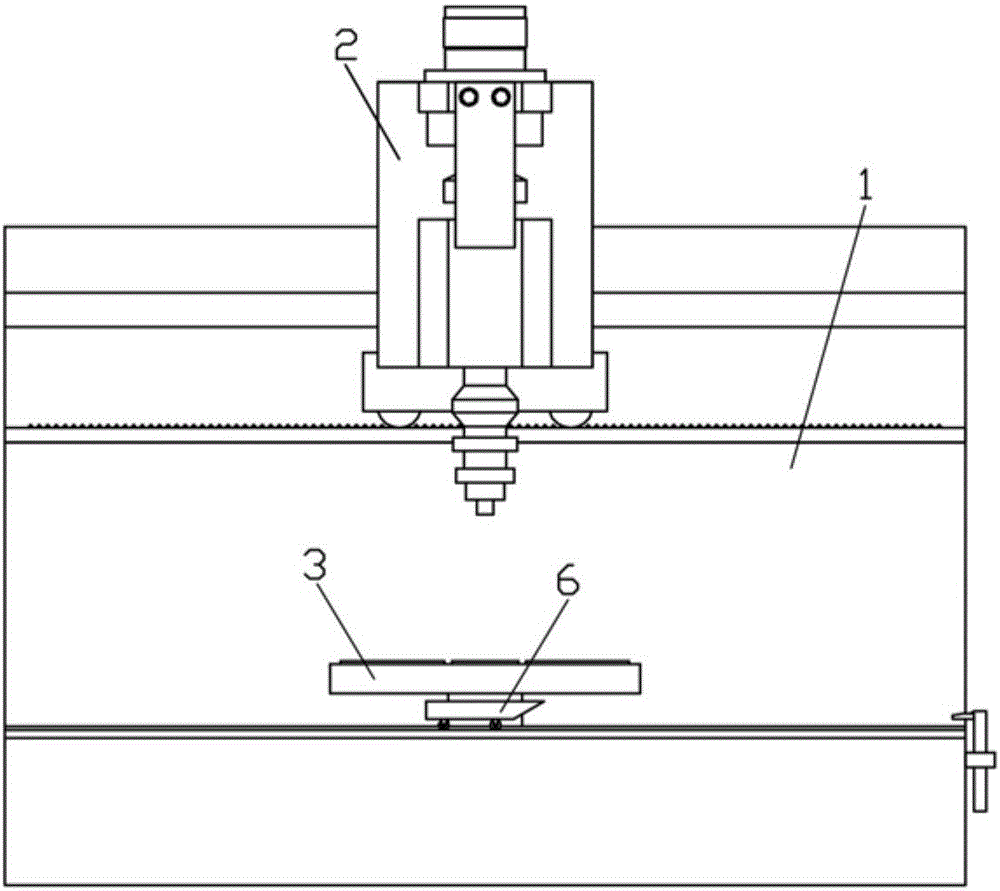

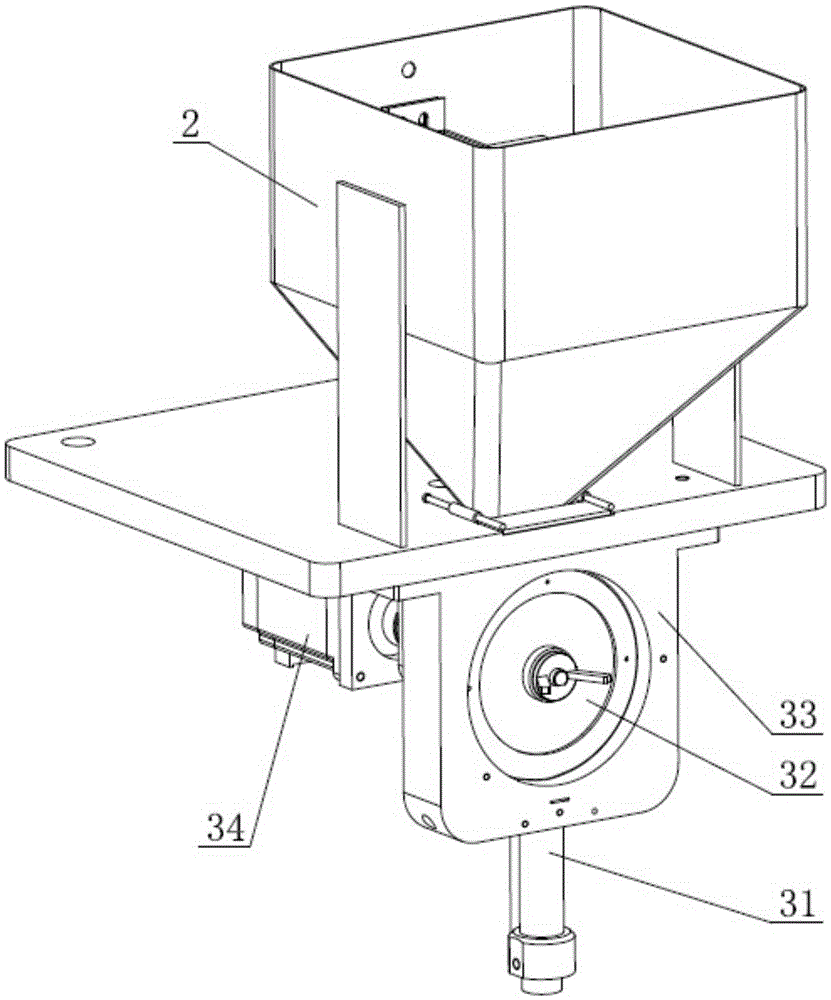

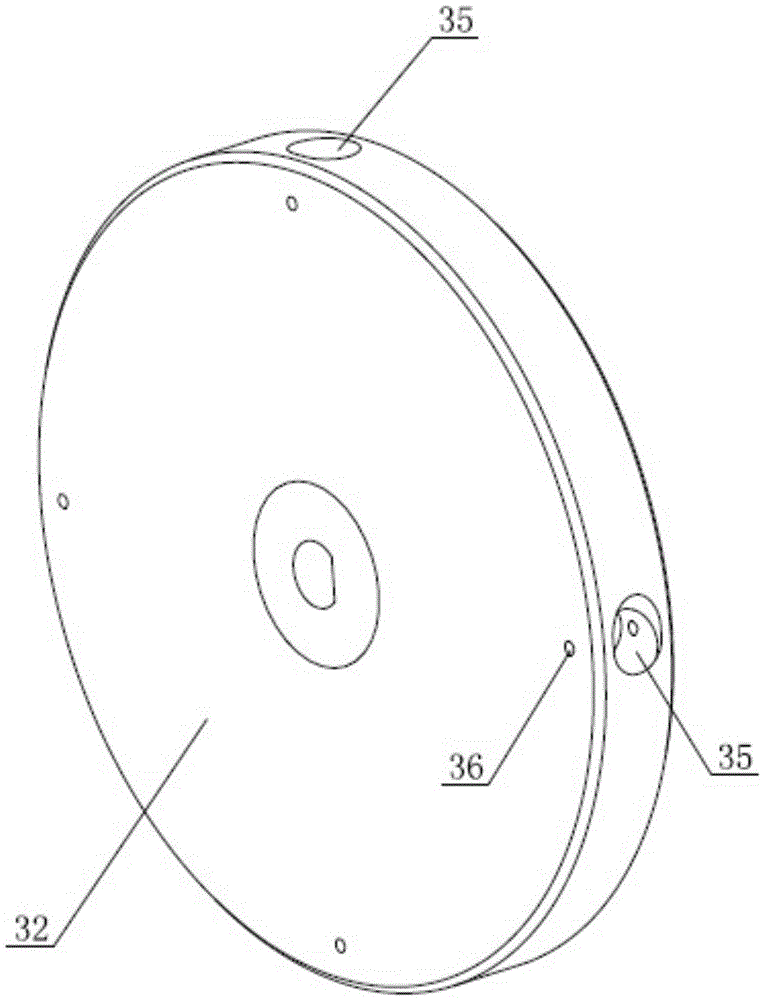

Drilling apparatus for integrated circuit board

ActiveCN106413260AHigh degree of automationImprove drilling accuracyPrinted circuit manufactureEngineeringPrinted circuit board

The invention discloses a drilling apparatus for an integrated circuit board. The drilling apparatus comprises an integrated circuit board drilling unit and an integrated circuit board transfer unit, wherein the integrated circuit board transfer unit is positioned on one side of the integrated circuit board drilling unit and used for attracting and transferring to-be-machined or machined integrated circuit boards; the integrated circuit board drilling unit comprises an integrated circuit board drilling control console, an integrated circuit board drilling head part module and a rotary type circuit board fixing platform, wherein the integrated circuit board drilling control console is step-shaped; the integrated circuit board drilling head part module is positioned on the upper part of the integrated circuit board drilling control console for performing a drilling operation on the integrated circuit boards; and the rotary type circuit board fixing platform is positioned on the lower part of the integrated circuit board drilling control console for supporting and positioning the integrated circuit boards. By virtue of the cooperating operation between the integrated circuit board transfer unit and the integrated circuit board drilling unit, the automatic degree of the drilling apparatus can be improved; and in addition, the drilling apparatus is simple in structure and easy to operate, so that the drilling precision is greatly improved.

Owner:惠州市惠展电子有限公司

Clamping device of drilling machine

InactiveCN106002392APrevent missFully lockedPositioning apparatusMetal-working holdersMachine partsEngineering

The invention discloses a clamping device of a drilling machine. The clamping device comprises a base. A sliding rail is fixedly installed at the top of the base, rolling wheels are connected to the top of the sliding rail in a sliding mode, supports are movably connected to the axis parts of the rolling wheels, fixing seats are fixedly connected to the ends, away from the rolling wheels, of the supports, a screw rod is movably connected to one side of each fixing seat, penetrates through a supporting column and extends out of the supporting column, the end, outside the corresponding supporting column, of each screw rod is fixedly connected to a rotary handle, and a rotating block is fixedly connected to one side of each rotary handle. According to the clamping device of the drilling machine, the fixing seats are used for fixing a machined part through electric telescopic rods, motors, the rotary handles, the screw rods, the sliding rail and the rolling wheels; fixing clamps are used for clamping the machined part through fixing shafts, fixing clamps and springs, and thus the machined part is fully locked to prevent machined part deviation caused by vibration of a drill bit; thus, deviation of a drill hole is avoided, the drilling precision is improved, the yield is increased, and the machining efficiency is improved.

Owner:无锡博成洋超声设备有限公司

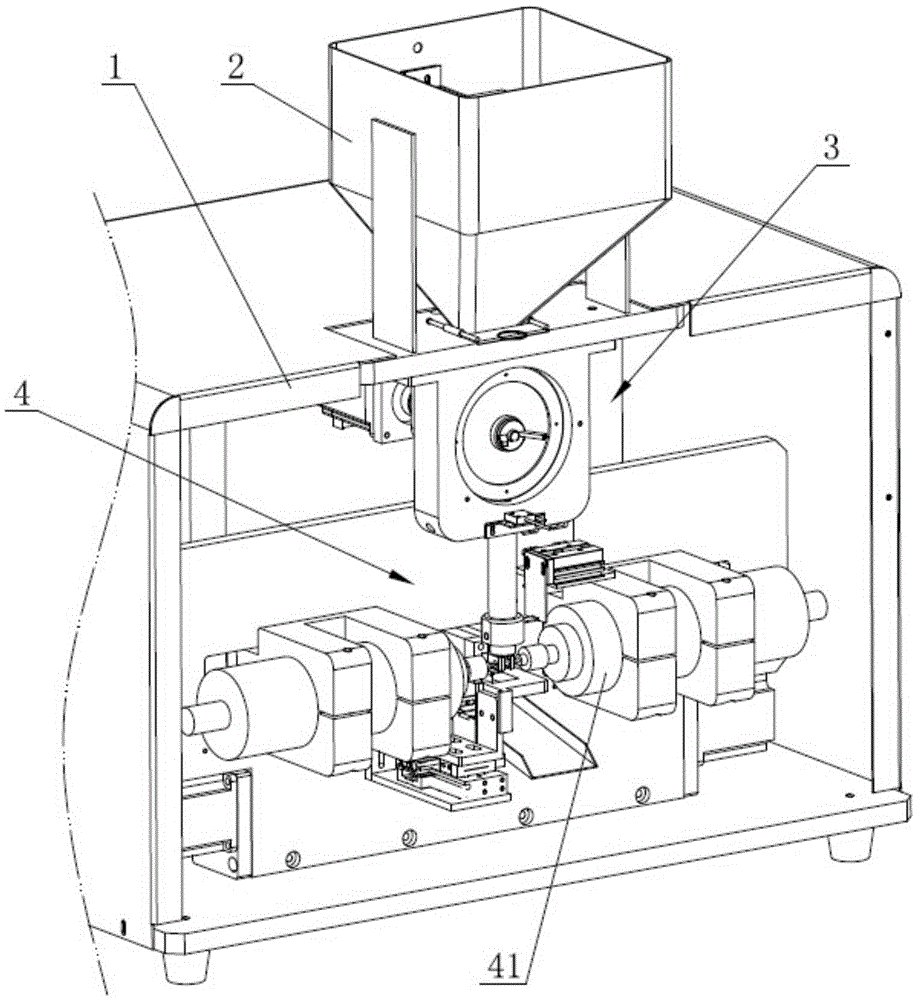

Full-automatic spherical material perforating machine

InactiveCN105476202AImprove drilling efficiencyImprove drilling accuracyFine working devicesJewelleryDrill bitEngineering

The invention relates to the technical field of automatic feeding devices and in particular relates to a full-automatic spherical material perforating machine comprising a rack, and a storing part, a distribution assembly and a perforating assembly which are arranged on the rack. The full-automatic spherical material perforating machine is characterized in that the distribution assembly comprises a material pipe for conveying spherical materials in the storing part to the perforating assembly one by one; the perforating assembly comprises a clamp, and two drilling devices which are positioned at two sides of the clamp; the drill of one drilling device and the drill of the other drilling device are in the same axis. The full-automatic spherical material perforating machine can be used for achieving full-automatic batch perforating processing of the spherical materials, so that the perforating efficiency of the spherical materials is greatly improved; the perforating precision is high; the double-direction perforating can be performed once; no burr is generated; the manual contact of the materials in the perforating process is avoided; the safety is relatively high; the practicability is high.

Owner:山东云途信息科技有限公司

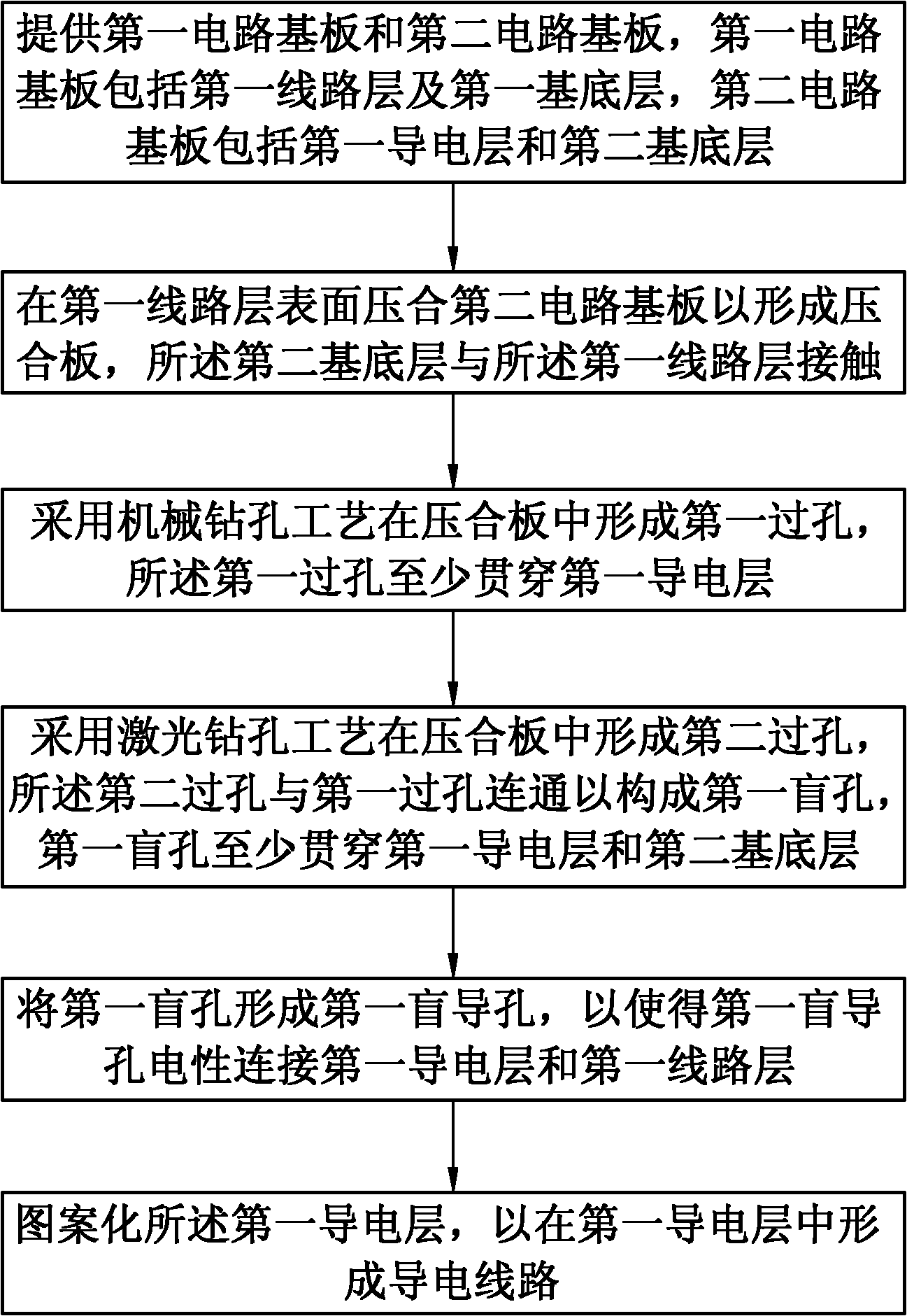

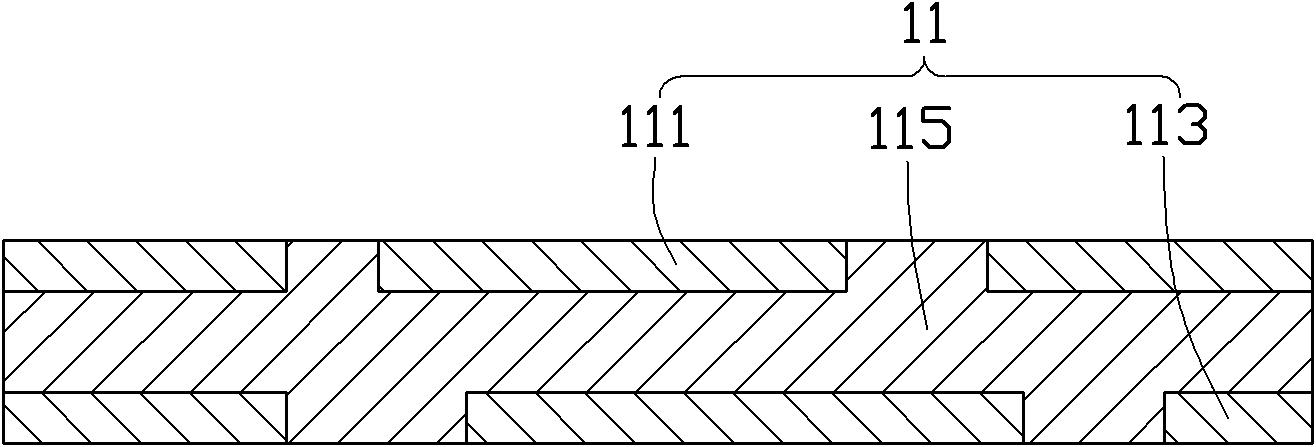

Method for manufacturing multilayer circuit board

ActiveCN102387672ASimplify the manufacturing processImprove production efficiencyMultilayer circuit manufactureEngineeringLaser drilling

The invention provides a method for manufacturing a multilayer circuit board, which comprises the following steps of: providing a first circuit substrate and a second circuit substrate, wherein the first circuit substrate comprises a first circuit layer and a first substrate layer, and the second circuit substrate comprises a first conductive layer and a second substrate layer; laminating the second circuit substrate on the surface of the first circuit layer so as to form a laminated board, wherein the second substrate layer is in contact with the first circuit layer; forming a first via holein the laminated board by adopting a mechanical drilling process, wherein the first via hole at least penetrates through the first conductive layer; forming a second via hole in the laminated board by adopting a laser drilling process, wherein the second via hole is communicated with the first via hole so as to compose a first blind hole, and the first blind hole at least penetrates through the first conductive layer and the second substrate layer; making a first blind guide hole from the first blind hole, so that the first blind guide hole is electrically connected with the first conductive layer and the first circuit layer; and patterning the first conductive layer so as to form a conductive circuit in the first conductive layer.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com