Efficient wall drilling machine

A punching machine and wall technology, which is applied in the field of decoration and decoration, can solve the problems of low punching positioning accuracy, low work efficiency, and difficult operation, and achieve accurate and effective punching positioning, high punching accuracy and high punching quality , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

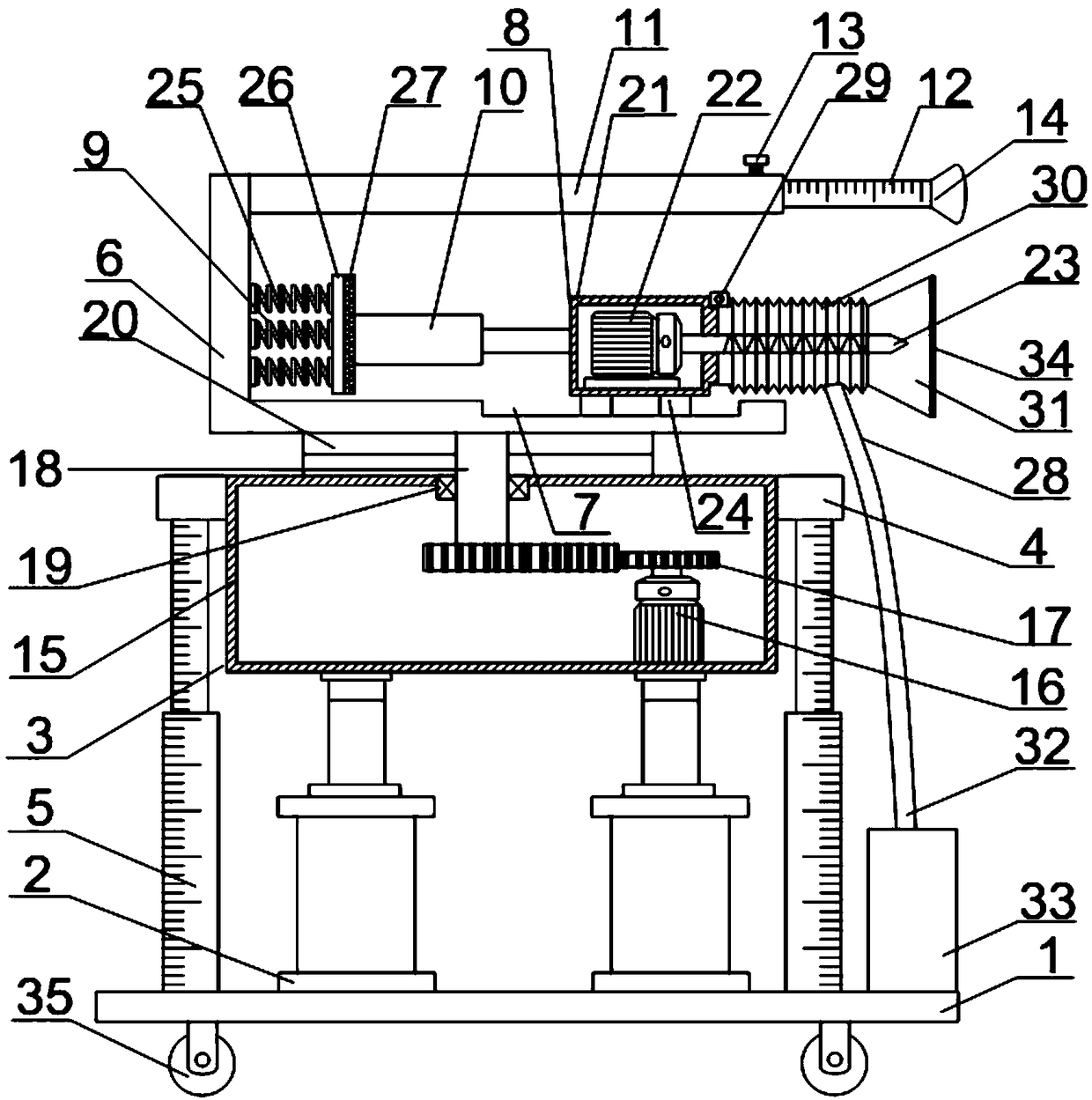

[0025] A high-efficiency wall punching machine includes a base 1, on which a first cylinder 2 is arranged, and the piston rod of the first cylinder 2 is fixedly connected to the lower side of a rotating device 3, and the rotating device 3 Both sides are provided with fixed mounts 4, and the fixed mounts 4 are fixedly connected with telescopic scale rods 5 between the bases 1, and the upper end of the rotating device 3 is connected with a fixed seat 6, and the fixed seat 6 is provided with A chute 7, a punching device 8 is slidably connected in the chute 7, a shock absorber 9 is connected to the fixed base 6 in the vertical direction, the shock absorber 9 is connected to a second cylinder 10, and the first cylinder 10 is connected to the shock absorber 9. The piston rod of the second cylinder 10 is connected to the punching device 8, and the upper end of the fixed seat 6 is fixedly connected with a hollow connecting pipe 11, and the front end of the connecting pipe 11 is inserte...

Embodiment 2

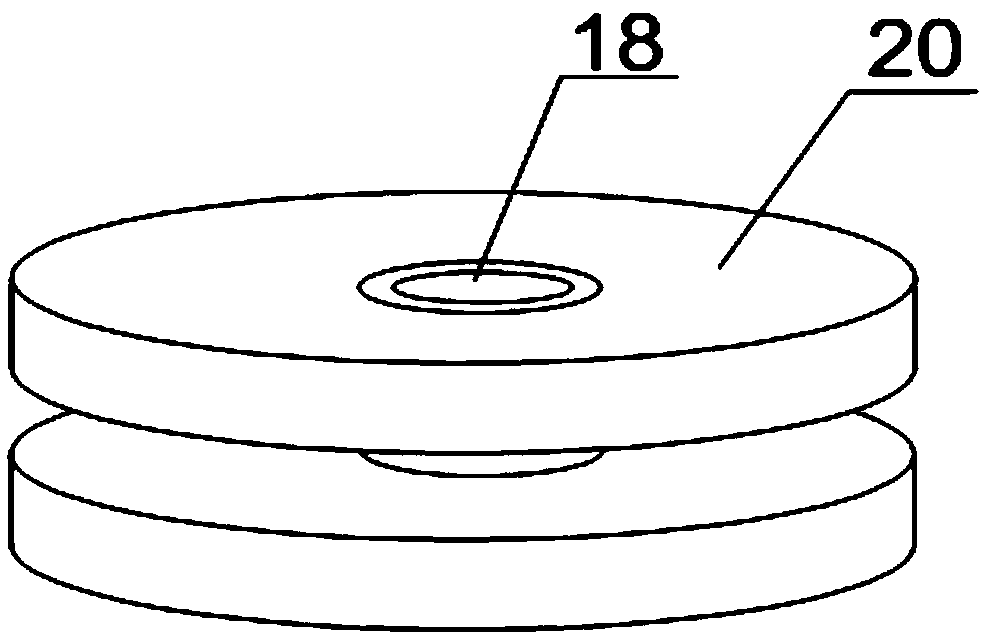

[0028] On the basis of Embodiment 1, the rotating device 3 includes a housing 15, a first motor 16 arranged at the inner bottom of the housing 15, a transmission gear 17 connected to the motor, and a transmission gear 17 connected to the transmission gear 17. The rotating shaft 18 and the rotating disc 20 connected with the rotating shaft 18 through a bearing 19 , the rotating disc 20 is arranged at the outer upper end of the housing 15 .

[0029] In this embodiment, when the direction of punching needs to be changed, the first motor 16 is started, and the transmission gear 17 connected to the first motor 16 drives the rotating shaft 18 to rotate, and the rotating shaft 18 drives the rotating disk 20 connected to it through the bearing 19 to rotate. , so as to drive the fixed seat 6 on the rotating disk 20 and the devices and equipment connected to the fixed seat 6 to rotate, so as to achieve the purpose of changing the punching direction without moving the punching machine, sa...

Embodiment 3

[0031] On the basis of Embodiment 1, the punching device 8 includes a mounting base 21, a second motor 22 fixed in the mounting base 21 and a drill bit 23 fixedly connected to the output end of the second motor 22, the mounting A slider 24 is fixedly connected to the lower end of the seat 21 , and the slider 24 is slidably connected to the chute 7 .

[0032] In this embodiment, when the punching machine is punching, the second motor 22 is started, and the drill bit 23 connected to the output end of the second motor 22 starts to rotate. The slide block 24 at its lower end slides forward in the chute 7, and the second motor 22 fixed in the mounting seat 21 and the drill bit 23 connected to the second motor 22 also carry out punching work forward thereupon, and the punching work does not need manpower. More automation improves the efficiency of drilling work, and the setting of the mounting base 21 can effectively protect the motor and prolong the service life of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com