Car part machining equipment

A technology for auto parts and processing equipment, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of large space required for processing, high processing cost, and achieve higher processing efficiency , The effect of using less equipment and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

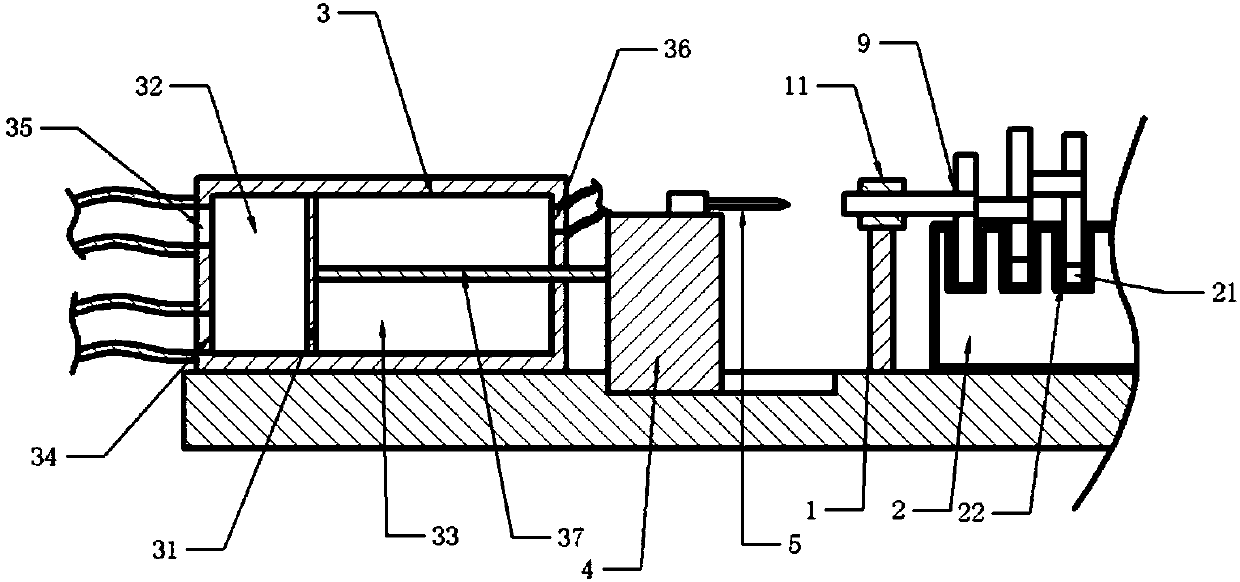

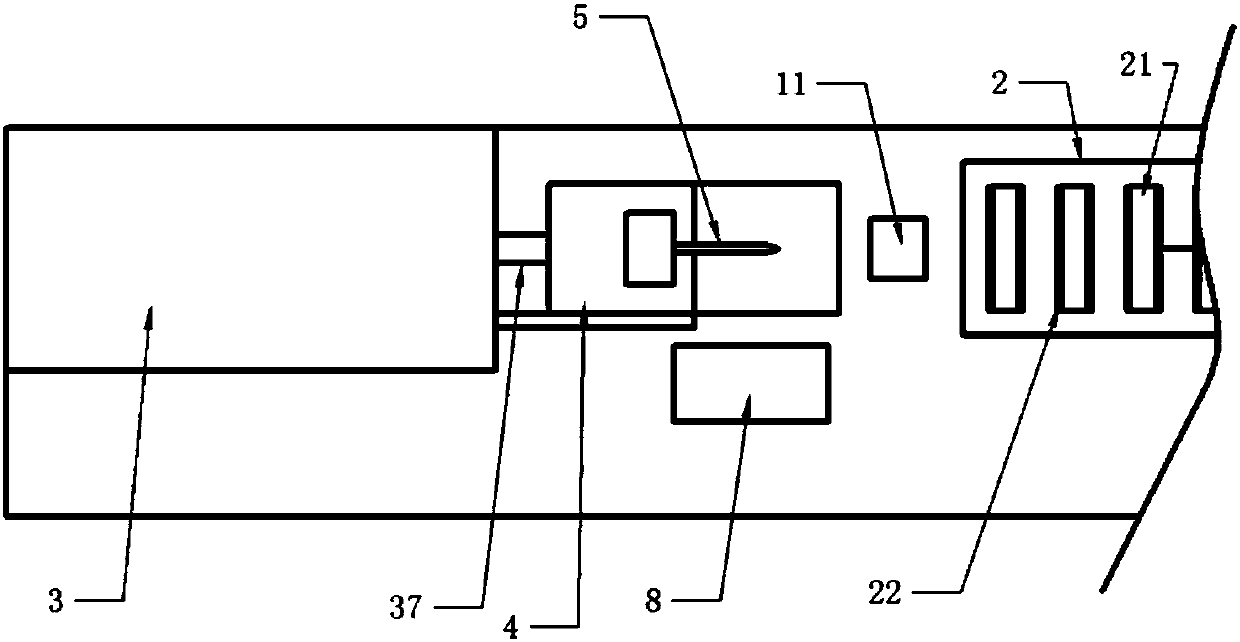

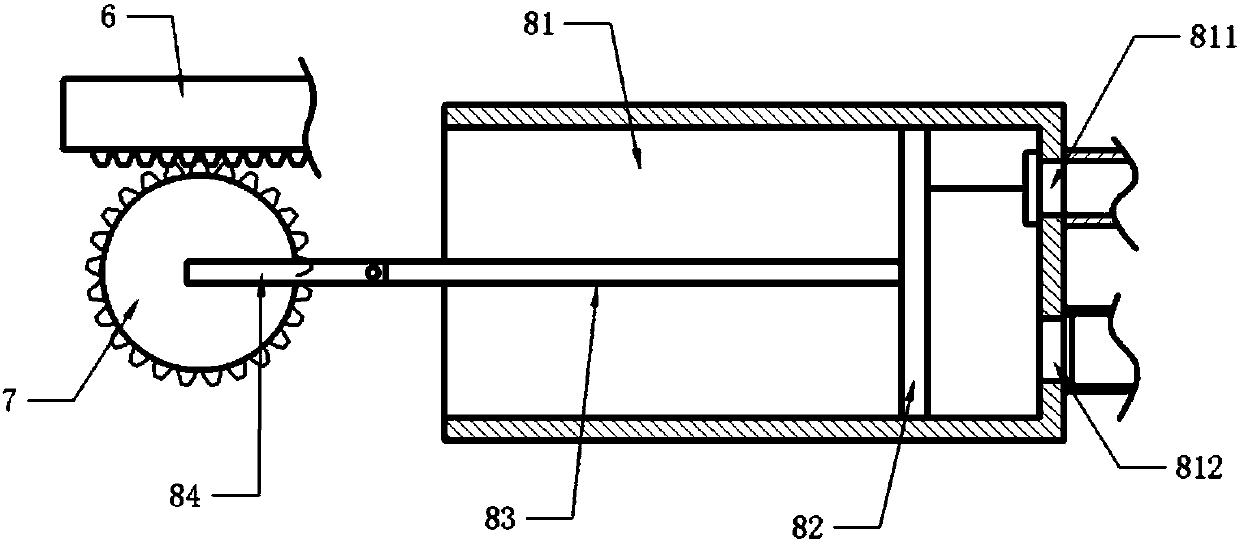

[0032] Further detailed explanation through specific implementation mode below:

[0033] The reference signs in the accompanying drawings of the description include: support column 1, support ring 11, air bag 2, installation groove 21, gasket 22, gas storage box 3, partition 31, drive chamber 32, pressure chamber 33, first air hole 34. Exhaust port 35, second air hole 36, push rod 37, mounting table 4, drill bit 5, rack 6, gear 7, dust removal part 8, dust removal box 81, air inlet 811, air outlet 812, slide plate 82, Linkage rod 83, fixed rod 84, crankshaft 9.

[0034] The embodiment is basically as attached figure 1 Shown:

[0035]Auto parts processing equipment includes a frame, a fixing mechanism is provided in the middle of the frame, a drilling mechanism is provided at both ends of the frame, and a dust removal mechanism is installed between the fixing mechanism and the drilling mechanism. The fixing mechanism includes two supporting columns 1 and an air bag 2 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com