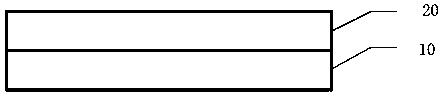

Gluing aluminum-based cover plate for PCB drilling and preparing method thereof

A glue-coating, aluminum-based technology, used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc. The effect of reducing wire wrapping, improving hole wall roughness and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

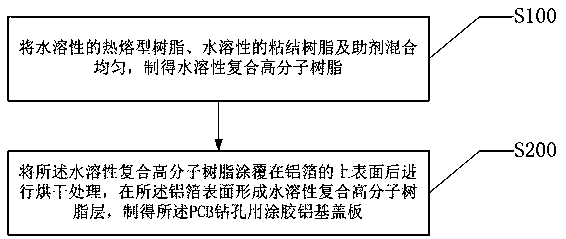

Method used

Image

Examples

Embodiment 1

[0041] Take 0.3 parts of carboxymethyl cellulose, 5 parts of polyvinylpyrrolidone (PVP-K30), 6 parts of polyvinyl alcohol, 8 parts of polyethylene glycol, and 2 parts of polyoxyethylene polypropylene ether, and add them to 40 parts of distilled water in sequence, Under the condition of 25°C, it was fully dissolved by mechanical stirring, and then 30 parts of water-based polyurethane resin, 4 parts of water-based soybean oil-rosin-based hyperbranched polyester solution, 3 parts of polypropylene glycol (PPG-400), and 1 part of leveling agent were added. part, 0.7 part of silane coupling agent, after stirring evenly, filter and stand for defoaming for later use.

[0042] The above-mentioned water-based composite polymer resin is coated on the surface of aluminum foil with a thickness of 0.10mm by a roller coating machine, the coating thickness is 0.04mm, and the speed is 6m / min. Baking line drying, the drying temperature is 100 ° C, that is, the glue-coated aluminum-based cover p...

Embodiment 2

[0044] Take 0.3 parts of carboxymethyl inulin, 6 parts of polymethacrylic acid, 9 parts of polyethylene oxide, 9 parts of polyvinyl alcohol, and 2 parts of polyoxyethylene polypropylene ether, and add them to 45 parts of distilled water in sequence. Under mechanical stirring to fully dissolve, then add 20 parts of water-based epoxy resin, 4 parts of water-based soybean oil-rosin-based hyperbranched polyester solution, 3 parts of polypropylene glycol (PPG-400), 1 part of leveling agent, silane coupling 0.7 parts of the joint agent, after stirring evenly, filter and stand for defoaming for later use.

[0045] The above-mentioned water-based composite polymer resin is coated on the surface of aluminum foil with a thickness of 0.10mm by a roller coating machine, the coating thickness is 0.04mm, and the speed is 6m / min. Baking line drying, the drying temperature is 95 ° C, that is, the glue-coated aluminum-based cover plate for PCB drilling.

Embodiment 3

[0047] Take 0.3 parts of carboxymethyl starch, 2 parts of polyvinylpyrrolidone (PVP-K90), 12 parts of polyethylene glycol, 5 parts of polyacrylamide, and 3 parts of polyoxyethylene polypropylene ether, and add them to 40 parts of distilled water in turn. Under the condition of 25°C, it was fully dissolved by mechanical stirring, and then 30 parts of acrylic modified water-based alkyd resin, 4 parts of water-based soybean oil-rosin-based hyperbranched polyester solution, and 2 parts of polypropylene glycol (PPG-400) were added. 1 part of leveling agent, 0.7 part of silane coupling agent, after stirring evenly, filter and stand for defoaming for later use.

[0048] The above-mentioned water-based composite polymer resin is coated on the surface of aluminum foil with a thickness of 0.10mm by a roller coating machine, the coating thickness is 0.04mm, and the speed is 6m / min. Baking line drying, the drying temperature is 105 ° C, that is, the glue-coated aluminum-based cover plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com