Drilling method of a pcb board drilling machine

A technology of PCB board and processing method, applied in the field of PCB processing of printed circuit board, can solve the problems of unstable Z-axis processing process, inconsistent position of front and back holes of PCB, Z-axis vibration and high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

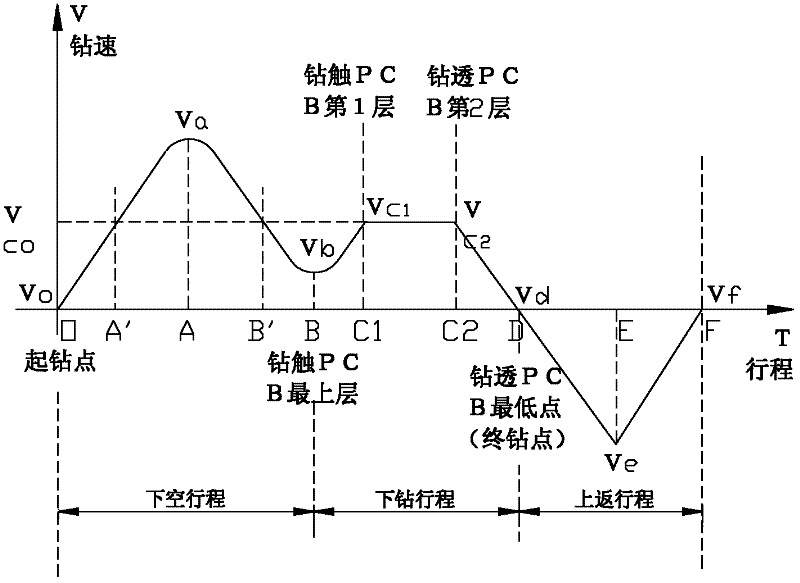

[0024] Such as figure 2 , is a schematic block diagram of an embodiment of the drilling method of the present invention for a PCB board drilling machine. The PCB board is clamped on the platform of the PCB board drilling machine, and the PCB board includes the uppermost protective layer, the middle circuit board layer, and the lower backing board layer successively. The processing method is based on having PLC function and It is implemented on the PCB CNC drilling machine with UMAC motion control card.

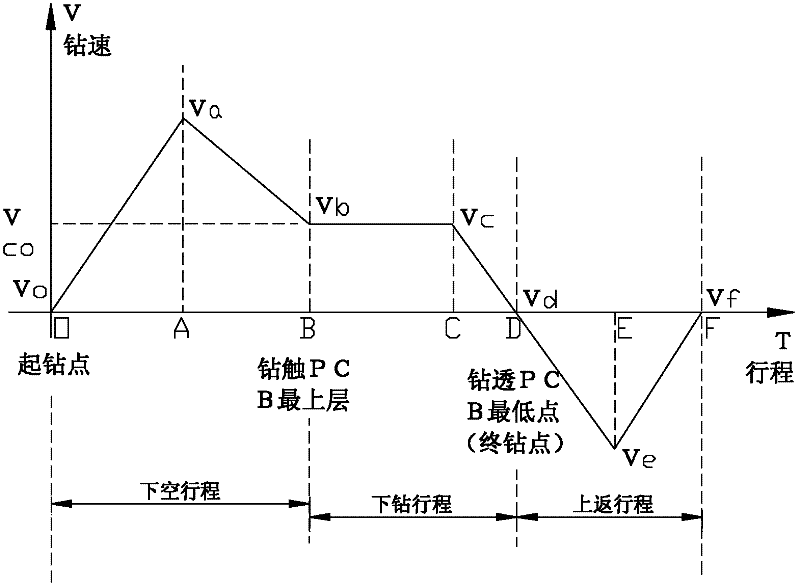

[0025] The processing method includes controlling the drill shaft of the drilling rig to perform a downward stroke O-D segment for forward rotation, and an upper return stroke D-F segment for reverse rotation; the downward stroke O-D segment includes an idling lower stroke O-B segment, drilling Drilling stroke section B-D; the downstroke O-B section includes: the speed-up section O-A section increasing from zero speed Vo, the deceleration section A-B section starting from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com