Patents

Literature

31results about How to "Realize drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

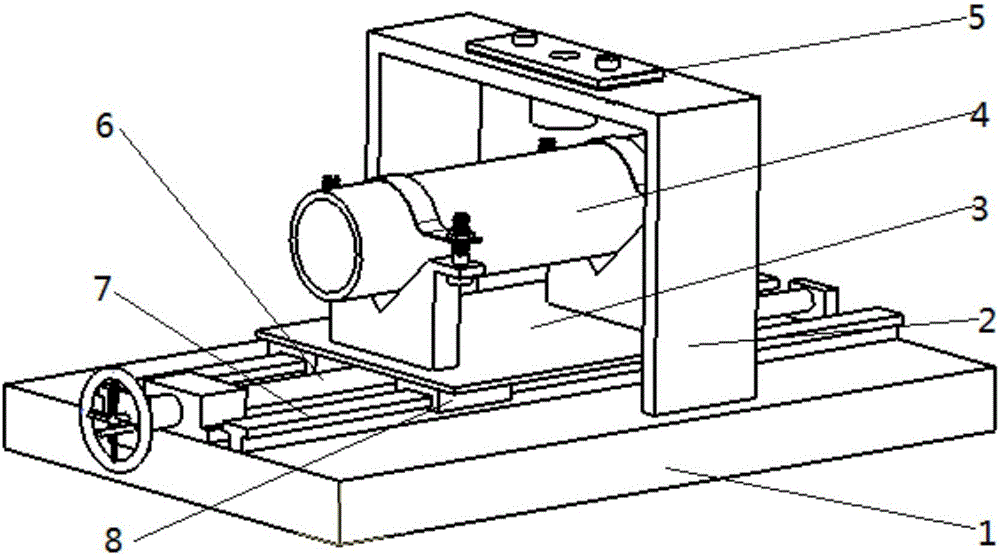

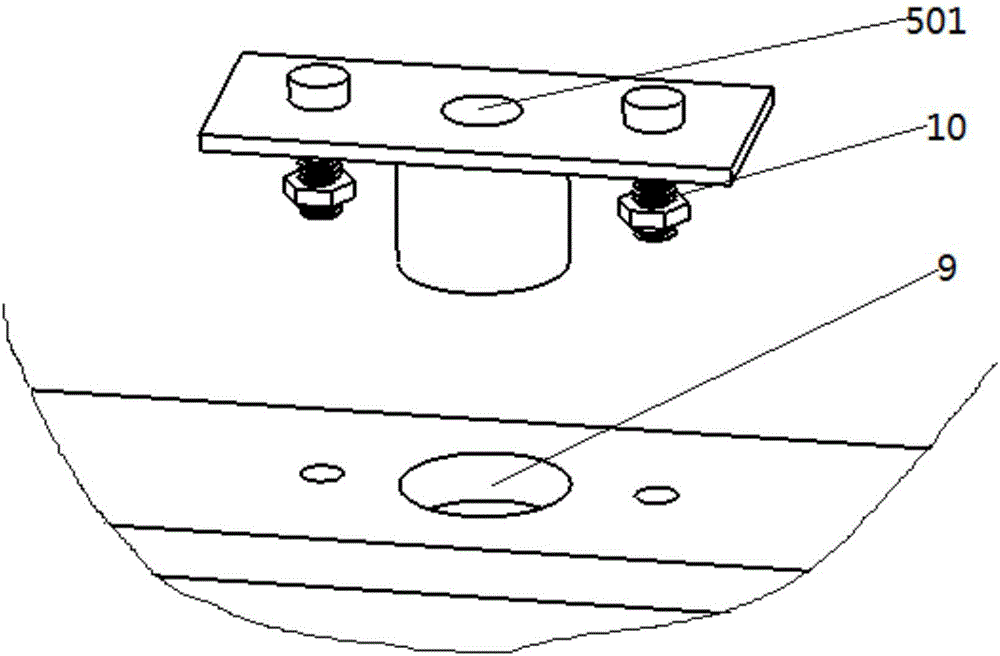

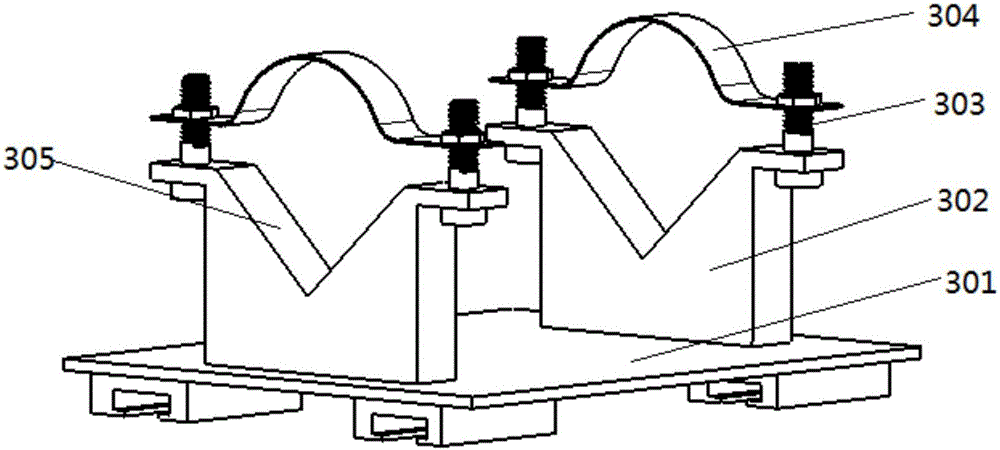

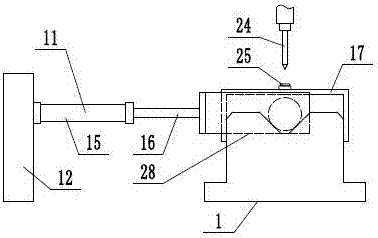

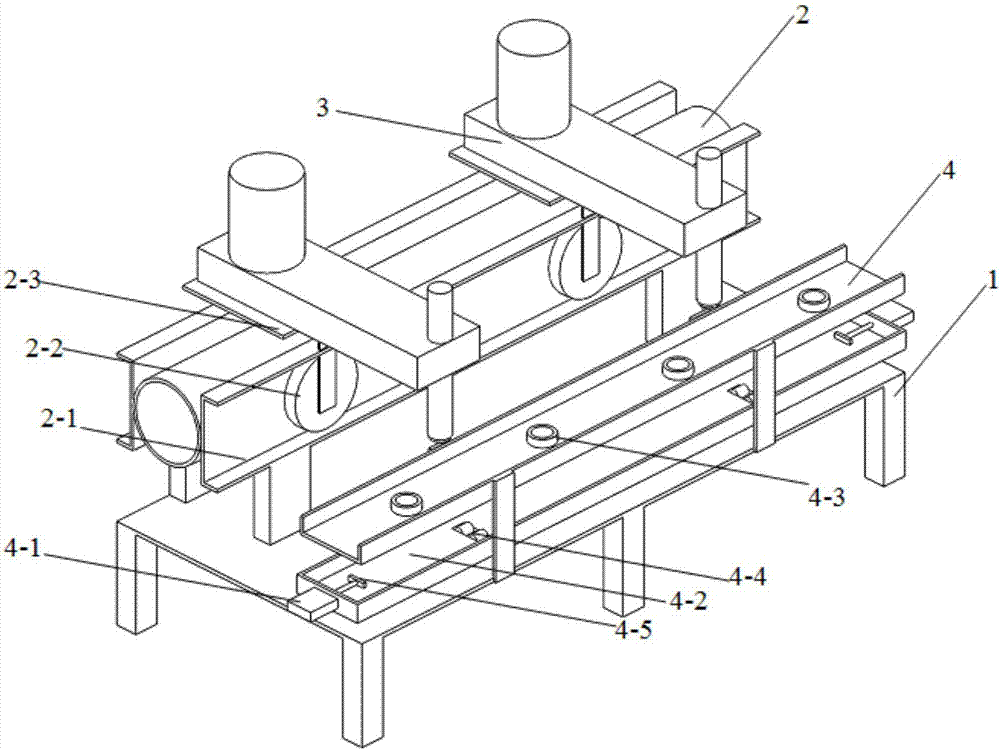

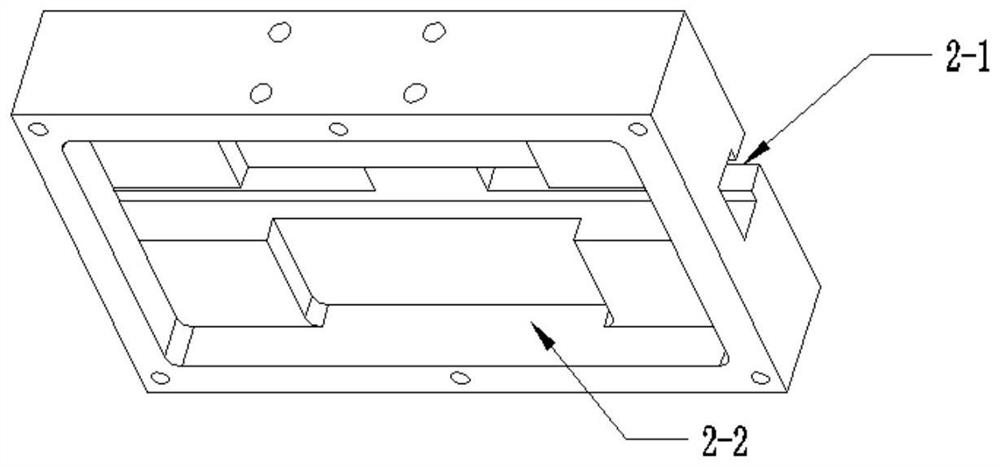

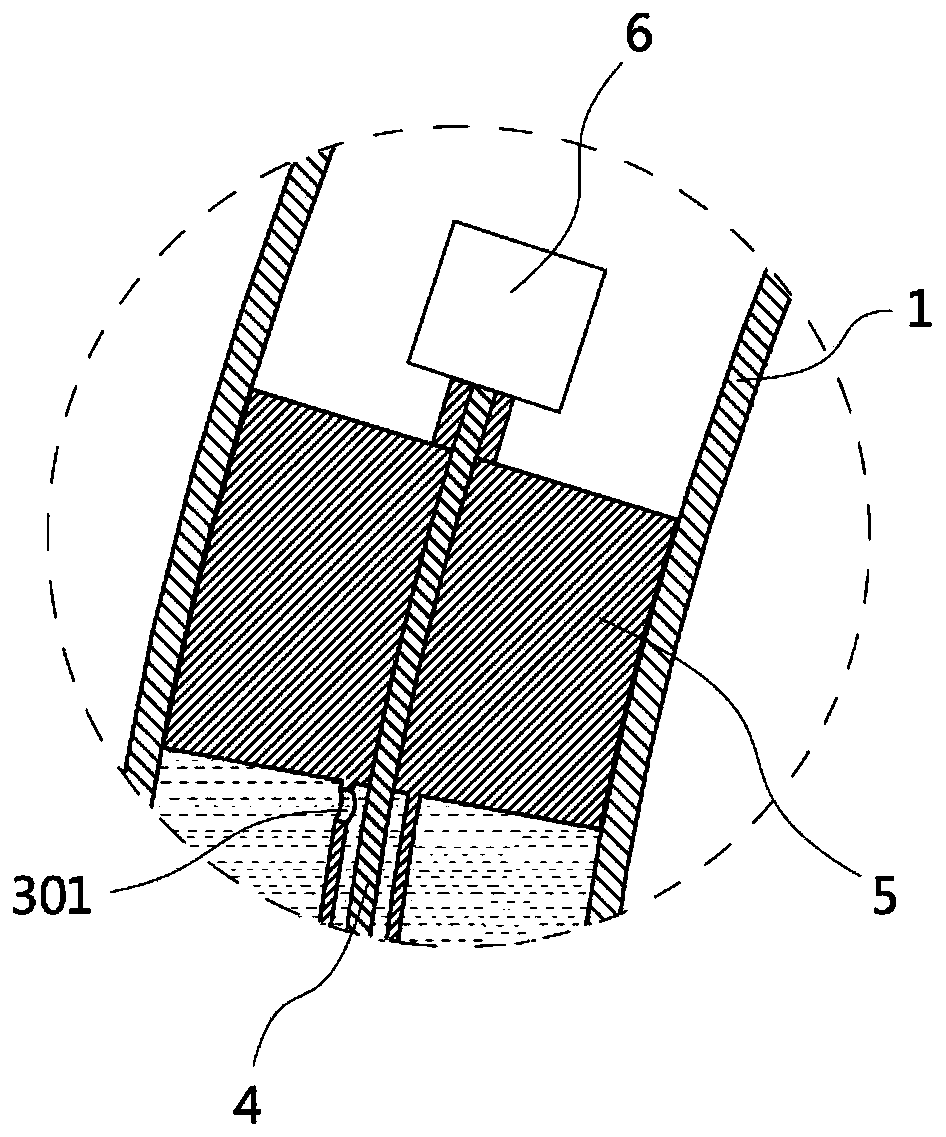

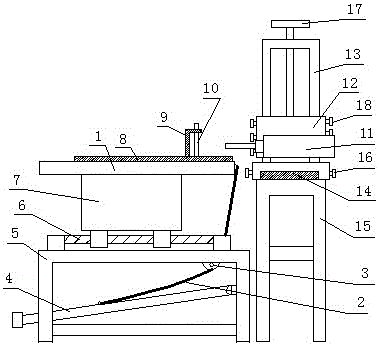

Drilling fixture for plastic pipe

InactiveCN105922342ARealize drillingHigh precisionMetal working apparatusMechanical engineeringDrilling machines

The invention provides a drilling fixture for a plastic pipe. The drilling fixture comprises a base and a clamping mechanism which are in sliding connection with each other through cooperation of guide rails and sliding blocks, wherein a straight-line motion mechanism is arranged between the base and the clamping mechanism, and comprises a lead screw nut pair of which the axis is parallel to the sliding direction of the sliding blocks; the top of a nut on the lead screw nut pair is fixedly connected with the bottom of the clamping mechanism; a support is fixed on the base; a drilling die is arranged on the support; a first through hole capable of accommodating the drilling die is formed in the support; the clamping mechanism comprises a baseplate and brackets; a V-shaped groove is formed in the cross section of each bracket; and a flexible steel belt is connected with the two sides of each bracket through locking bolts. The drilling fixture provided by the invention has the advantages that through the regulation of pipe diameters and drilling positions, relatively-high-precision drilling on plastic pipes of different specifications on a common drilling machine can be achieved; the structure is simple; and the operation is easy.

Owner:TIANJIN RUILING TECH DEV CO LTD

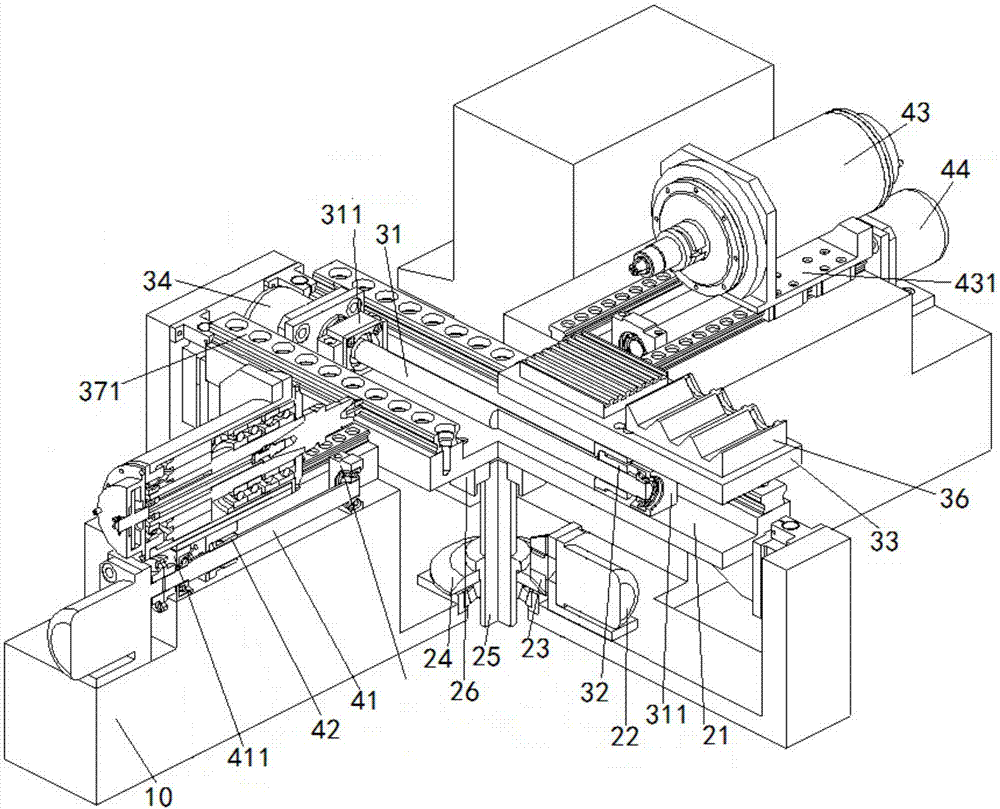

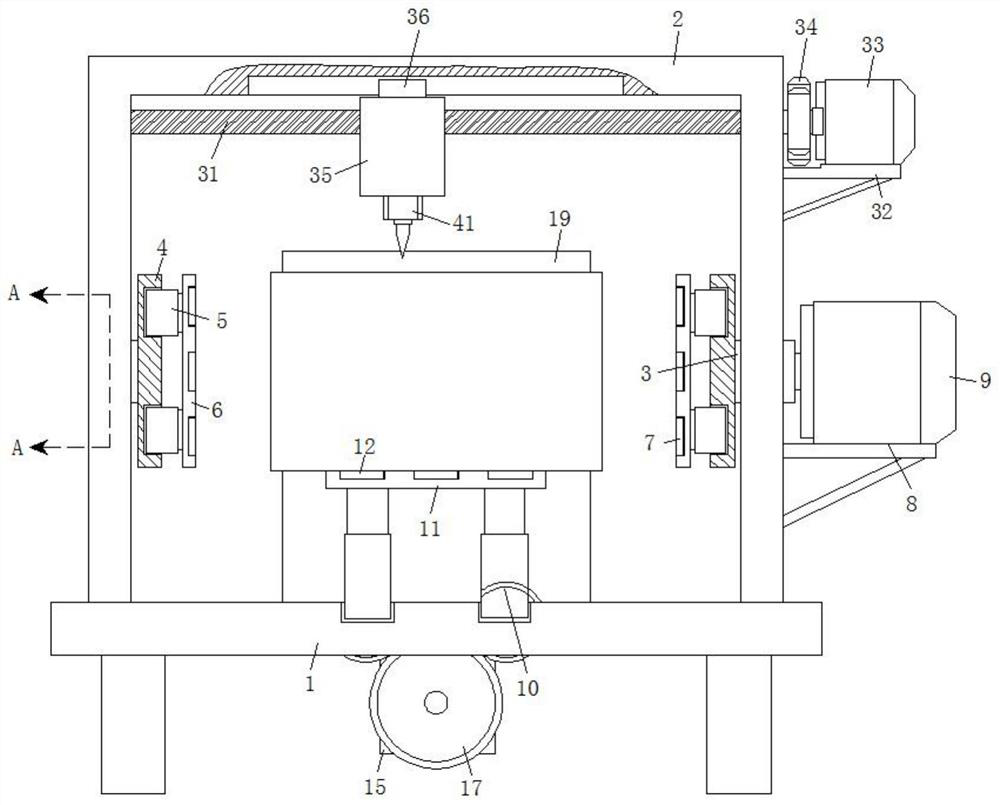

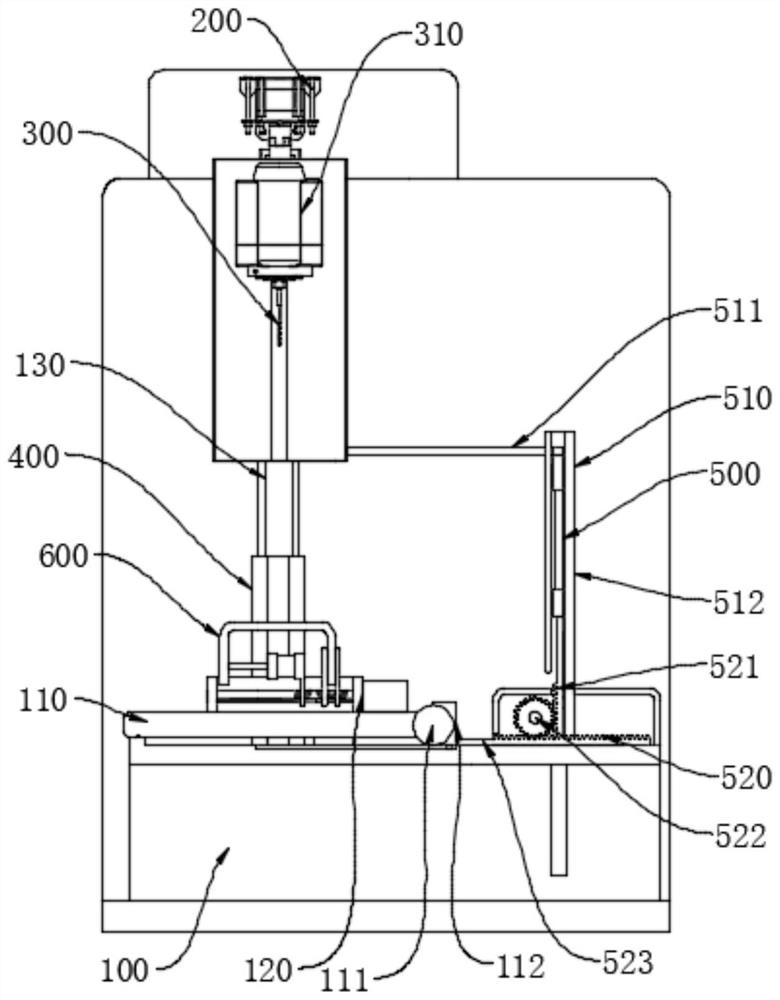

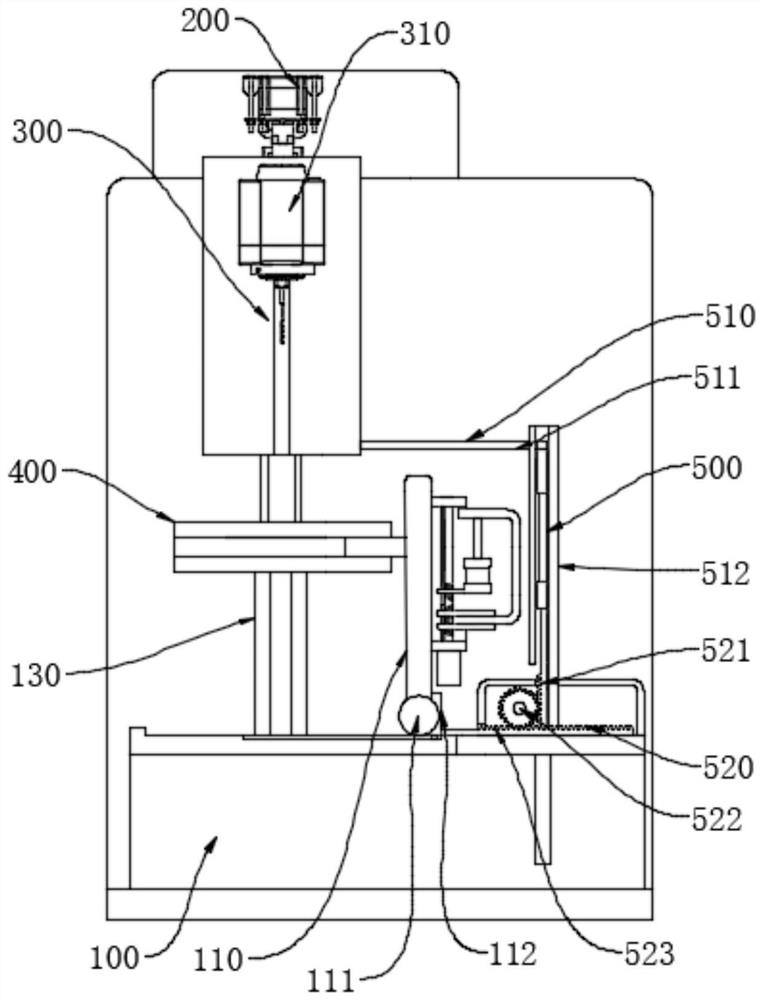

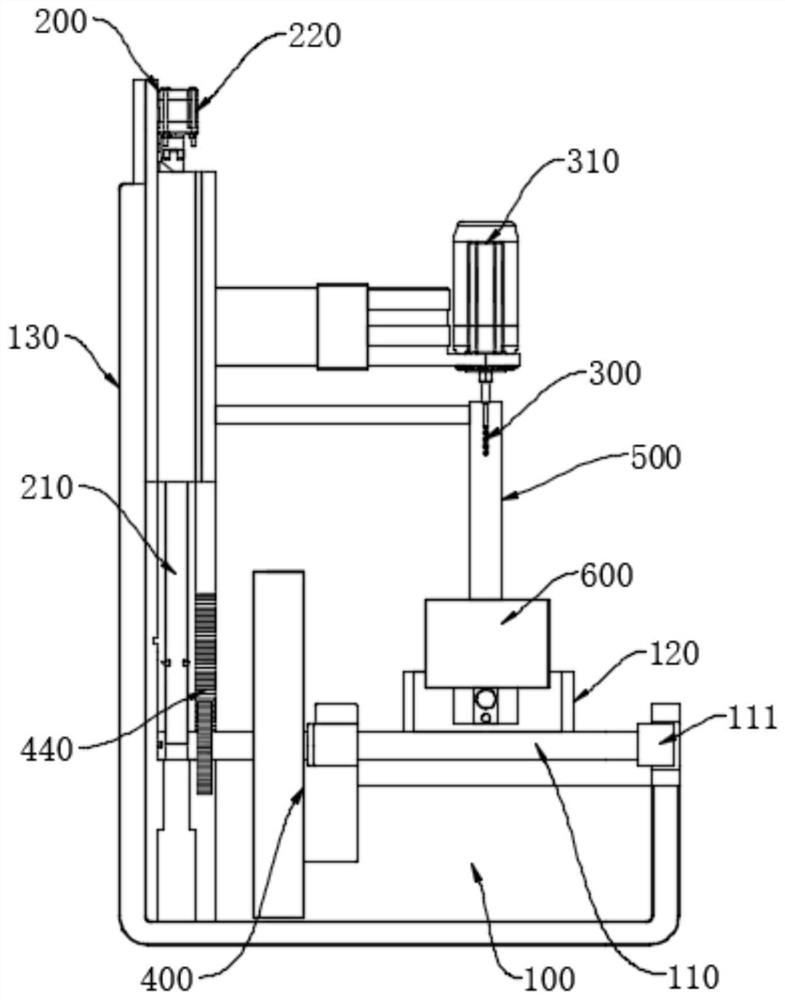

Special numerical control machine tool for machining small part

InactiveCN107971750ASolve processing problemsRealize processing automationFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a special numerical control machine tool for machining a small part. The special numerical control machine tool comprises a machine tool body, a control mechanism and a three-axis machining mechanism; the Y-axis machining mechanism comprises a liftable large slide carriage; an X-axis machining mechanism comprises an X-axis ball screw; an X-axis stepping motor is used for driving the X-axis ball screw so that a small slide carriage can be driven to move horizontally by an X-axis nut; two groups of worktables and a row tool type tool magazine are detachably installed on the small slide carriage; two Z-axis machining mechanisms are arranged; each Z-axis machining mechanism comprises a Z-axis ball screw; and each Z-axis stepping motor is used for driving the corresponding Z-axis ball screw so that an electric spindle can be driven to move horizontally by a Z-axis nut. The special numerical control machine tool disclosed by the invention improves the part machining efficiency, increases the percent of pass of products, guarantees the machining quality and the stability of the machining quality, can be provided with different cutting tools according to the machining content of different types of work pieces so as to implement various machining of milling, drilling, chamfering, deburring and the like, realizes procedure centralization and machining automation of the small part, and alleviates the labor intensity of a worker.

Owner:SHANGHAI DIANJI UNIV

Dead-corner-free efficient drilling equipment for power distribution cabinet production

PendingCN112139542AImprove work efficiencyGuaranteed uptimeFeeding apparatusPositioning apparatusRolling-element bearingStructural engineering

The invention discloses dead-corner-free efficient drilling equipment for power distribution cabinet production. The equipment comprises a working table. An installing frame is fixed to the middle ofthe top face of the working table through screws. First installing columns are connected to the inner walls of the two sides of the installing frame through rolling bearings correspondingly. First installing plates are fixed to the ends of the first installing columns correspondingly. First grooves are formed in the upper sides and the lower sides of the ends, away from the first installing columns, of the first installing plates. First electric telescopic rods are fixedly connected to the inner walls of the first grooves through screws. First adsorption plates are fixedly connected to the output ends of the first electric telescopic rods through screws. First electromagnetic blocks are fixed in the other ends of the first adsorption plates correspondingly. First horizontal frames are fixedly connected to the sides of the first installing frames through screws. First servo motors are fixedly connected to the top faces of the first horizontal frames through screws. The equipment is stable in operation, reasonable in design and high in automation degree, dead-corner-free drilling operation on the six faces of an electric control cabinet can be achieved after one-time feeding, and theworking efficiency of drilling of the electric control cabinet is greatly improved.

Owner:ANHUI LANRUN AUTOMATION INSTR

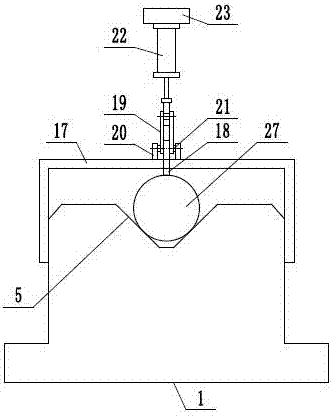

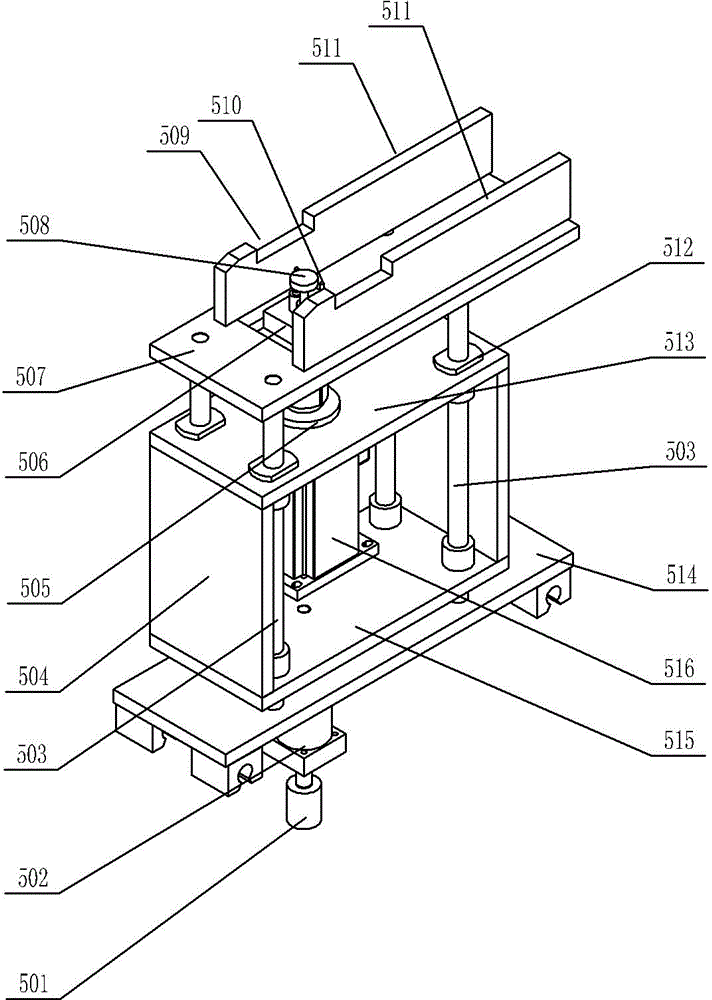

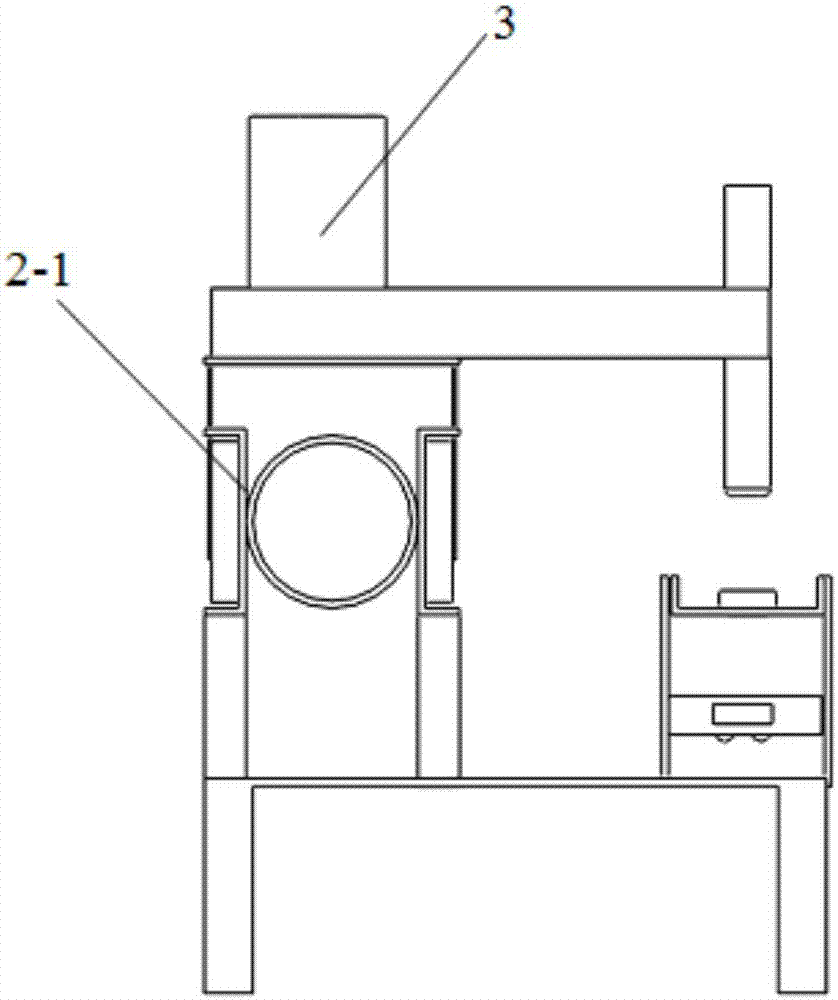

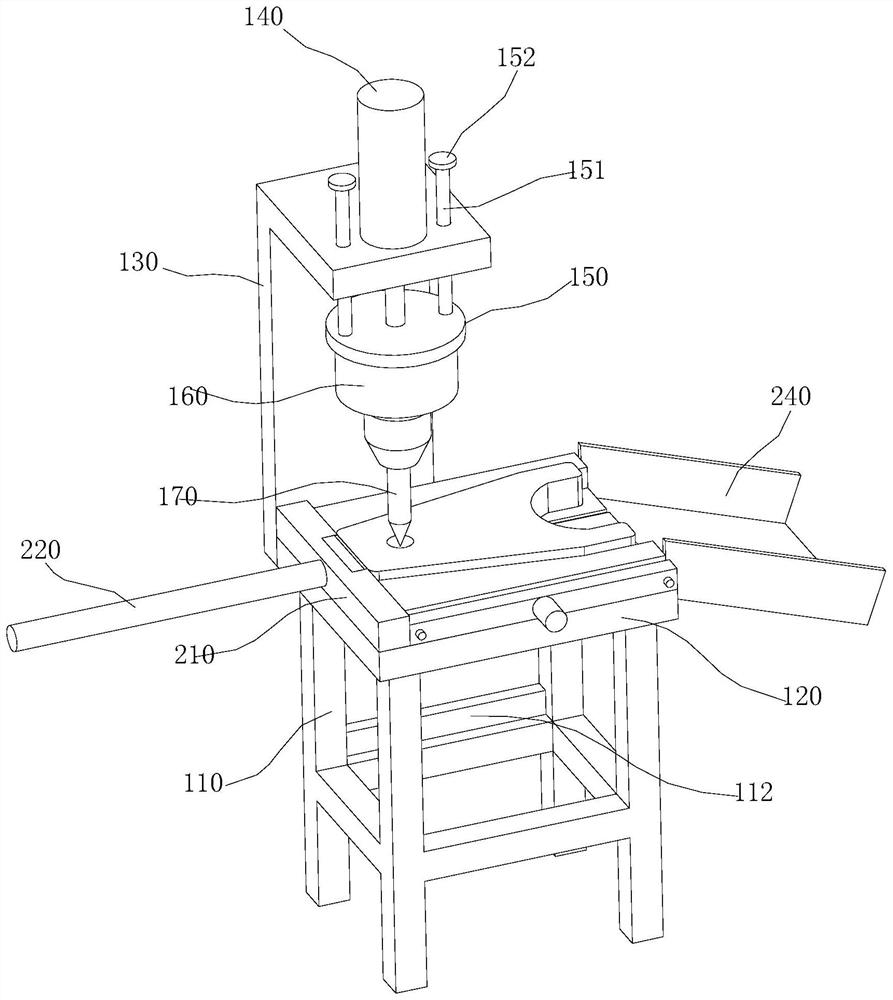

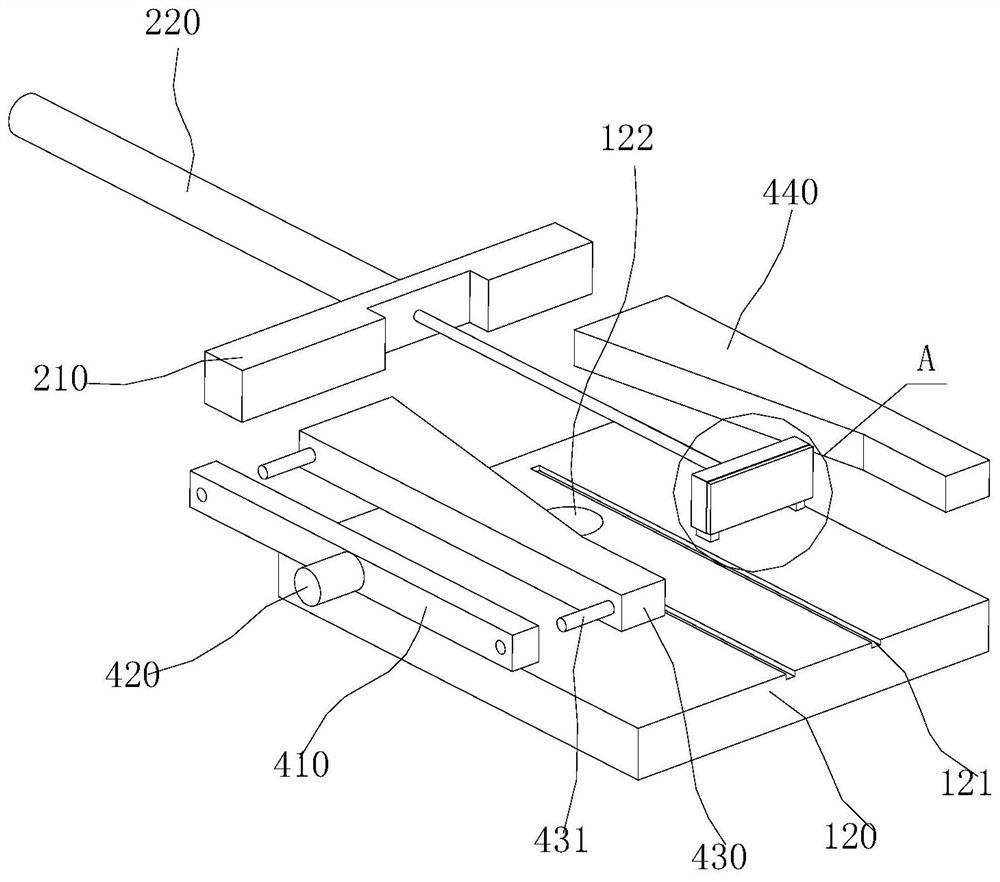

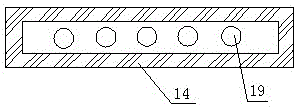

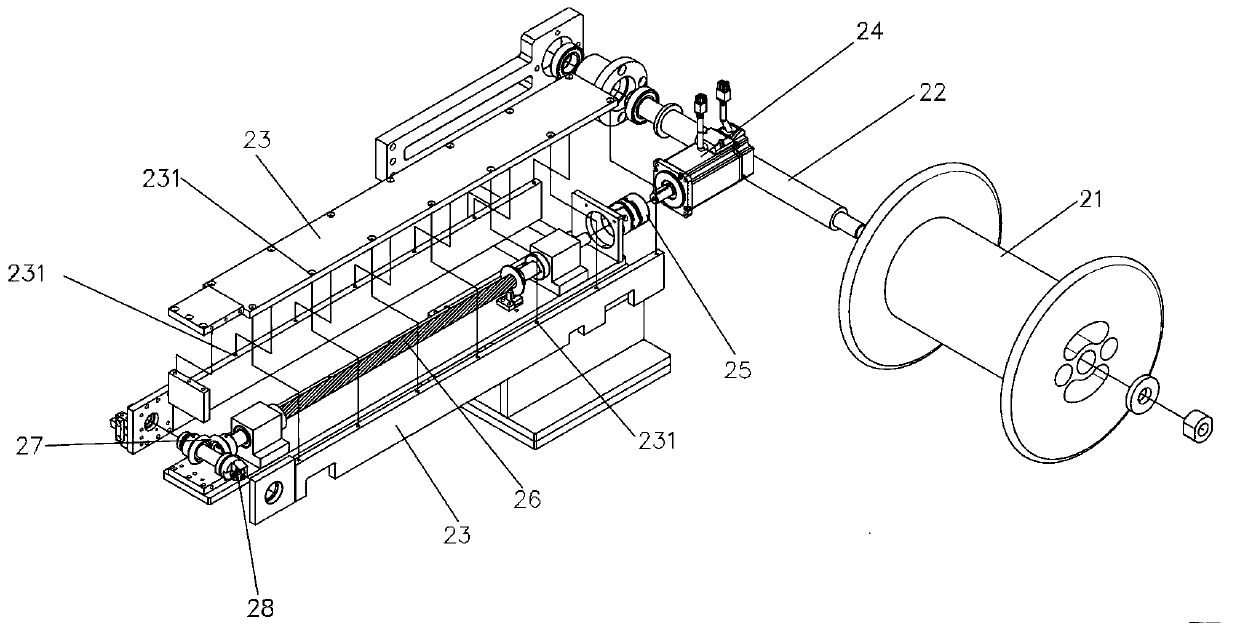

Continuous drilling device for producing cylindrical hardware fittings

ActiveCN110394474AImprove stabilityImprove reliabilityPositioning apparatusMetal working apparatusEngineeringAssembly line

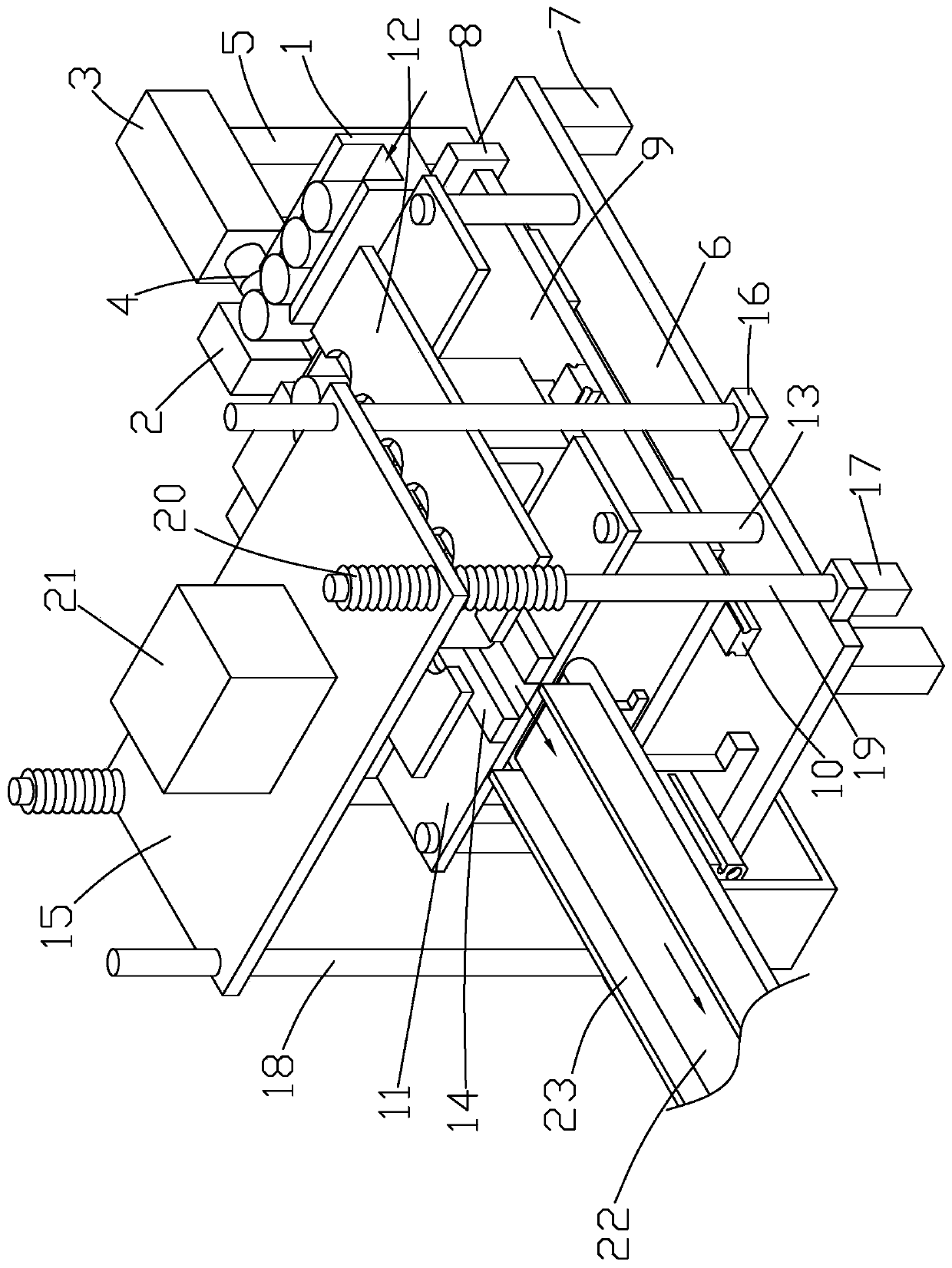

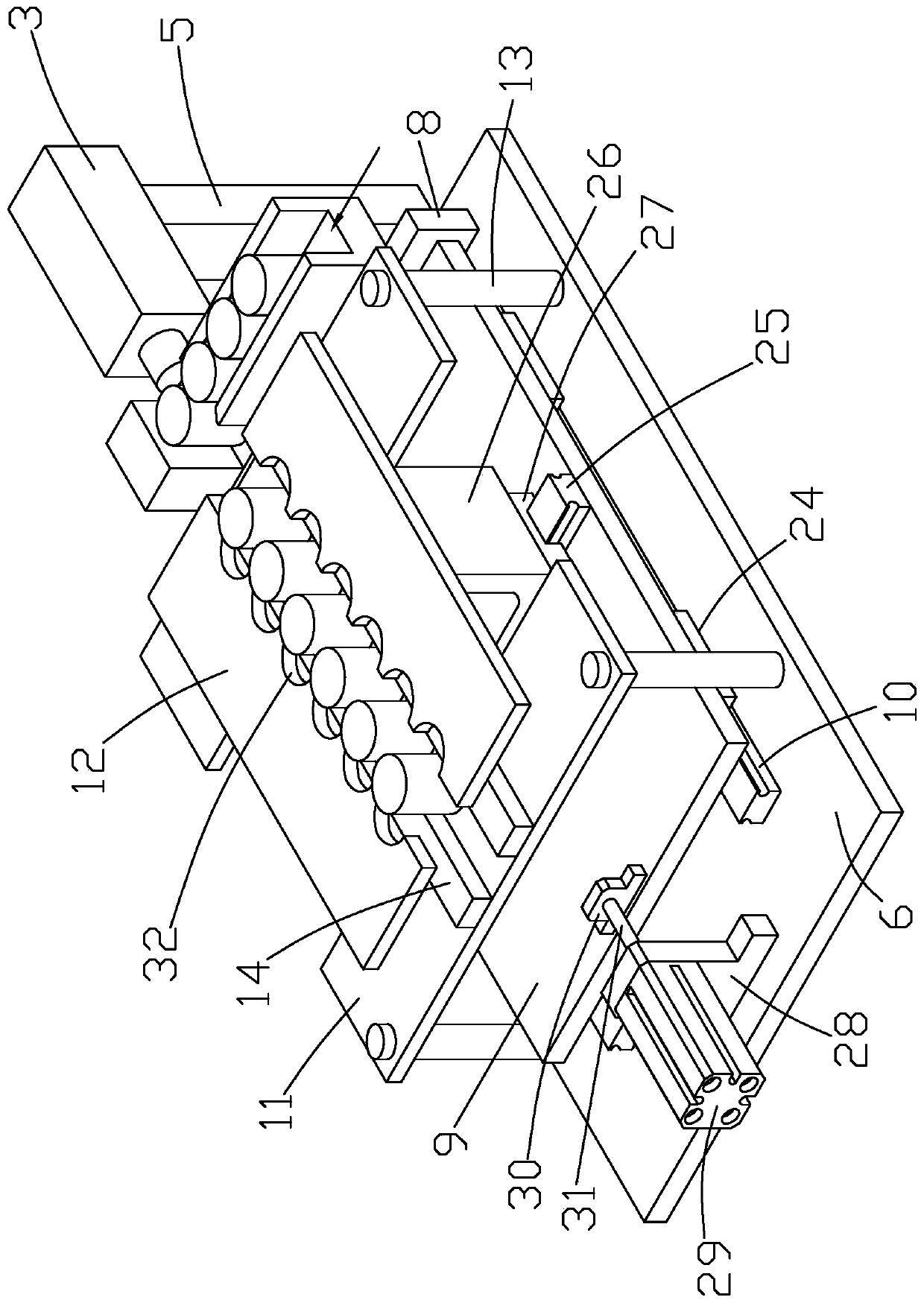

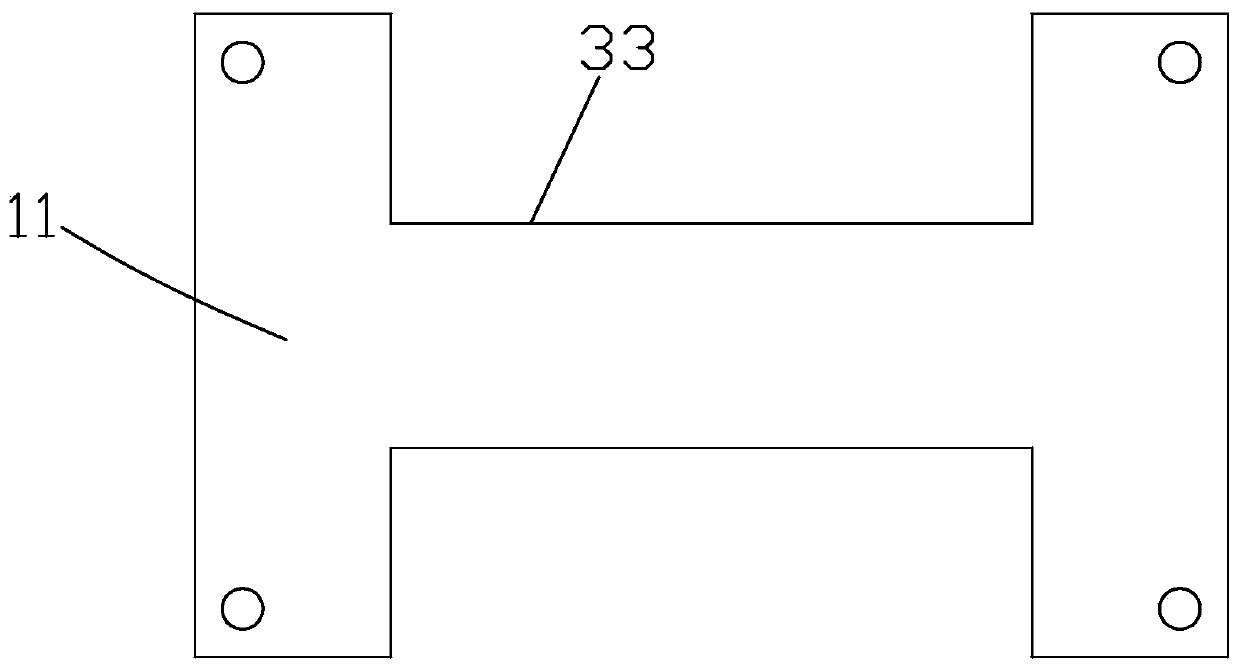

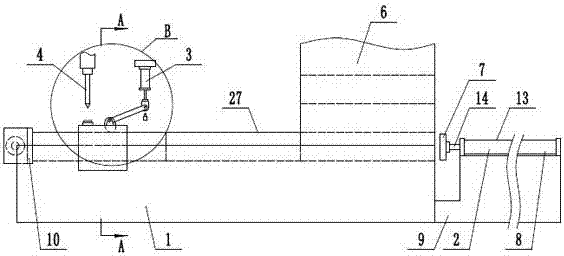

The invention discloses a continuous drilling device for producing cylindrical hardware fittings. The continuous drilling device comprises a base plate, a feeding mechanism and a discharging mechanism, and further comprises a continuous drilling component, wherein the bottom surface of the base plate is symmetrically provided with support feet; the feeding mechanism and the discharging mechanism are separately arranged on both sides of the continuous drilling component; the continuous drilling component includes a horizontal moving mechanism, a clamping mechanism, an I-shaped support plate anda drilling mechanism; the I-shaped support plate is fixedly connected to the upper portion of the base plate through a first column, and is parallel to the base plate; the horizontal moving mechanismis arranged between the I-shaped support plate and the base plate; the clamping mechanism is connected to the top surface of the horizontal moving mechanism; and the drilling mechanism is connected to the upper portion of the I-shaped support plate through a lifting mechanism. The continuous drilling device for producing the cylindrical hardware fittings has the advantages of simple structure andhigh practicability; and the continuous transportation and drilling of the cylindrical hardware fittings are achieved, the clamping accuracy of the cylindrical hardware fittings is improved at the same time, and then the accuracy and quality of drilling machining are improved so as to meet the needs of assembly line production.

Owner:湖南兴天机械股份有限公司

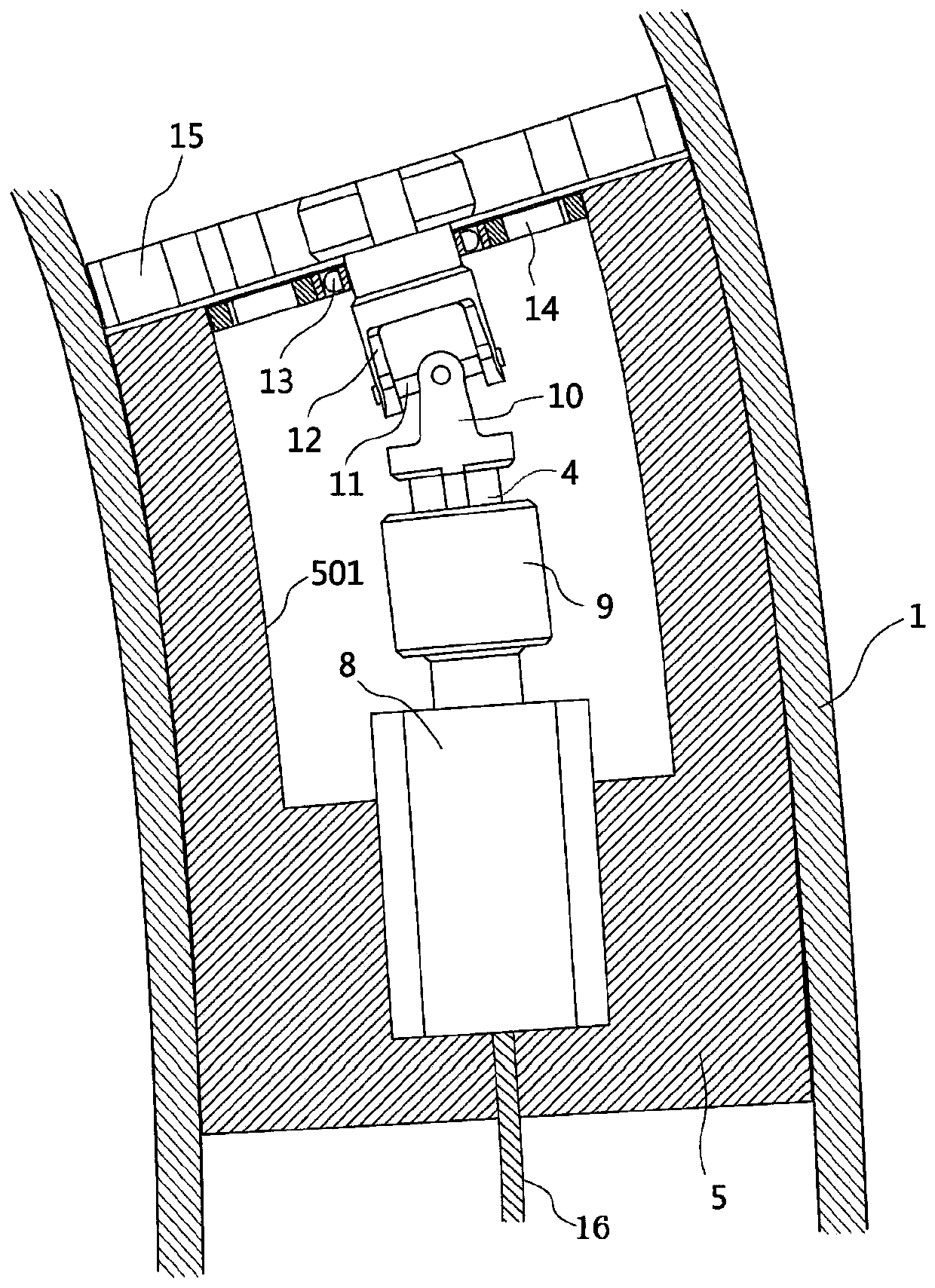

Shaft body drilling device

InactiveCN107116248AWith drillingWith automatic feedingWork clamping meansMetal working apparatusEngineeringCam

The invention provides a shaft body drilling device, and belongs to the technical field of mechanical processing. The shaft body drilling device comprises an loading and unloading mechanism, a pressing mechanism and a drilling mechanism, wherein a material bin of the loading and unloading mechanism is arranged above the right end of a bearing support base; a top plate is mounted at the left end of a top plate piston rod; a positioning baffle plate can be arranged in a slide slot in the left end of the bearing support base in a front-rear sliding mode; a baffle plate piston rod is connected with the positioning baffle plate; a bearing pin roll of the pressing mechanism can be rotatably arranged on the fixed supporting lug; the lower end of a connecting rod is fixedly arranged on the bearing pin roll; a pressing cam is fixedly arranged on the bearing pin roll in the eccentric mode; the lower end of the pressing air cylinder is hinged with the upper end of the connecting rod; and a drill bit of the drilling mechanism is arranged above a guide drilling sleeve. The shaft body drilling device realizes automatic loading and unloading of the shaft body, greatly reduces labor intensity of a worker, realizes continuous and quick drilling and processing on a shaft body, is reasonable in structure, is good in reliability and is low in cost.

Owner:赵锋

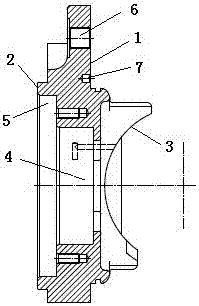

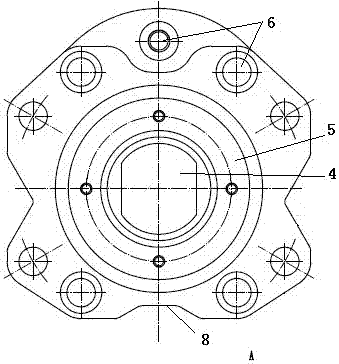

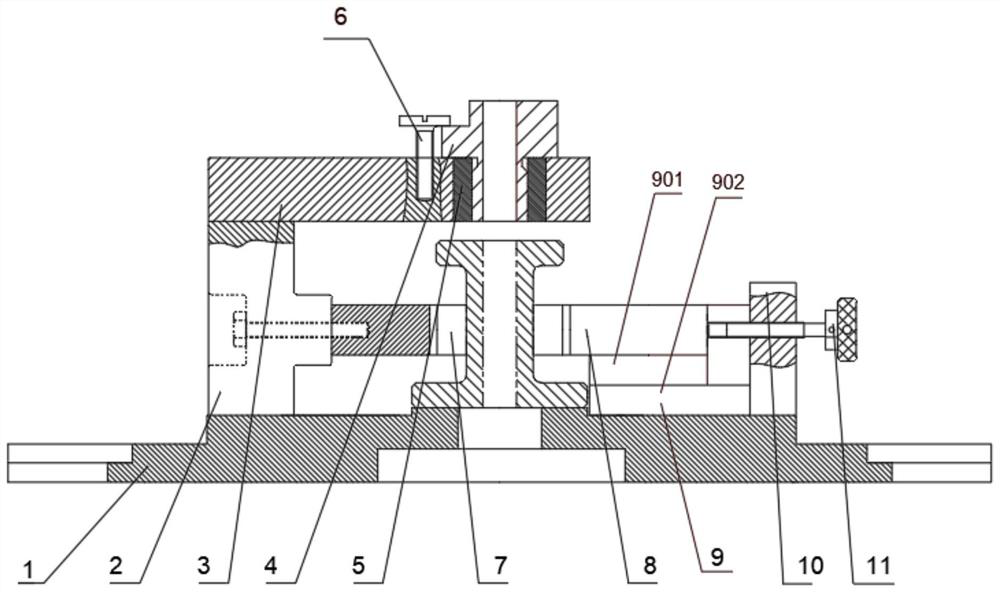

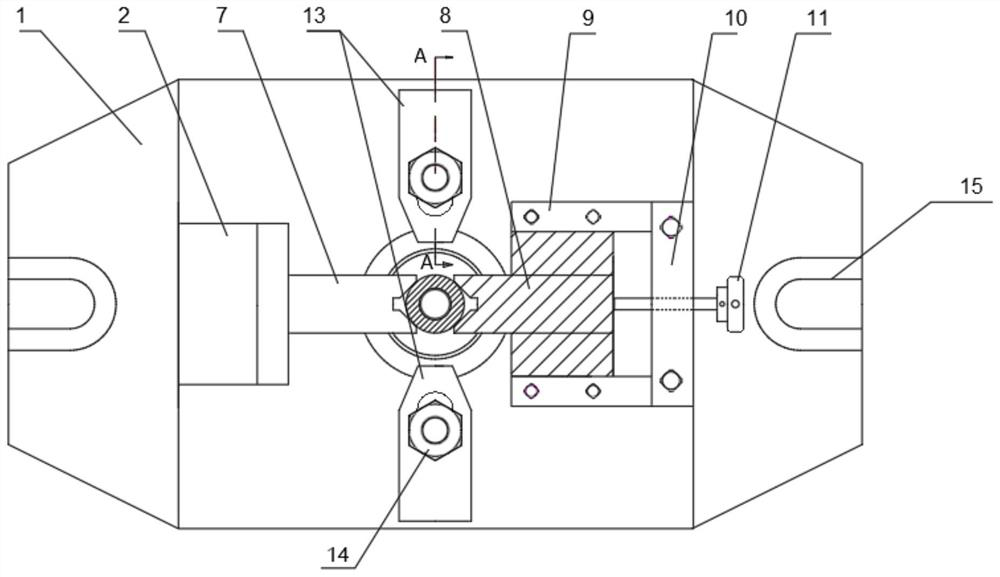

Pull rod type positioning and clamping device

InactiveCN107081613AHave looseWith positioning clampPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention provides a pull rod type positioning and clamping device and belongs to the technical field of machining. The pull rod type positioning and clamping device comprises a pull rod, a rotation stopping flat key, a key sliding groove, a pressing rotary sleeve and a swing rod. The pull rod is slidably arranged on a pull rod supporting seat in a left-and-right mode, the rotation stopping flat key is located in the key sliding groove in the pull rod supporting seat, and the pressing rotary sleeve is connected to a threaded section at the right end of the pull rod in a threaded mode; a rotary sleeve handle is installed on one side of the pressing rotary sleeve, the left end of a supporting spring is attached to the right end surface of the pull rod supporting seat, and the right end of the supporting spring is attached to the left end surface pressing rotary sleeve; the lower end of a disc-shaped workpiece is installed on a lower supporting seat of the workpiece, and the right end of the disc-shaped workpiece is attached to a side supporting seat which is provided with a drilling guide sleeve; and one end of the swing rod is hinged to a fixed supporting seat through a swing rod pin shaft, and the other end of the swing rod is provided with a swing rod handle. According to the pull rod type positioning and clamping device, positioning and clamping of the disc-shaped workpiece are achieved, the structure is reasonable, and the pull rod type positioning and clamping device has the characteristic that the disc-shaped workpiece can be quickly approached and loosened, and reliability is good.

Owner:赵锋

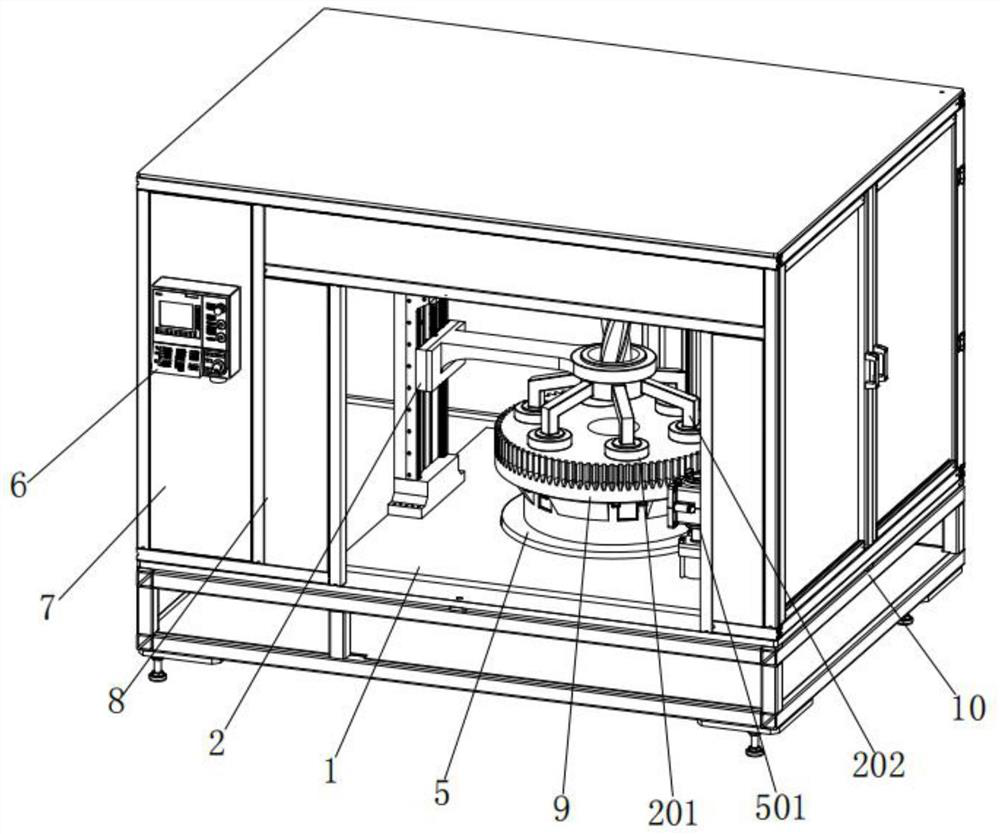

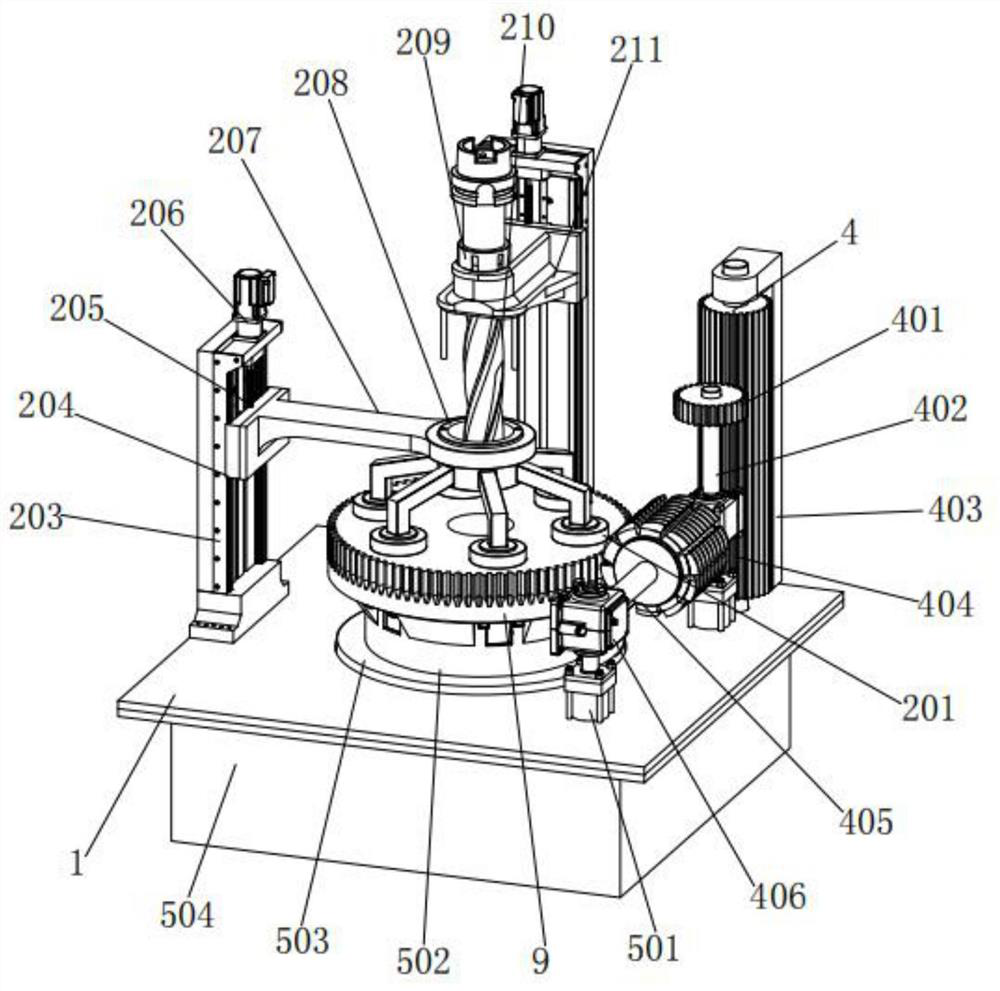

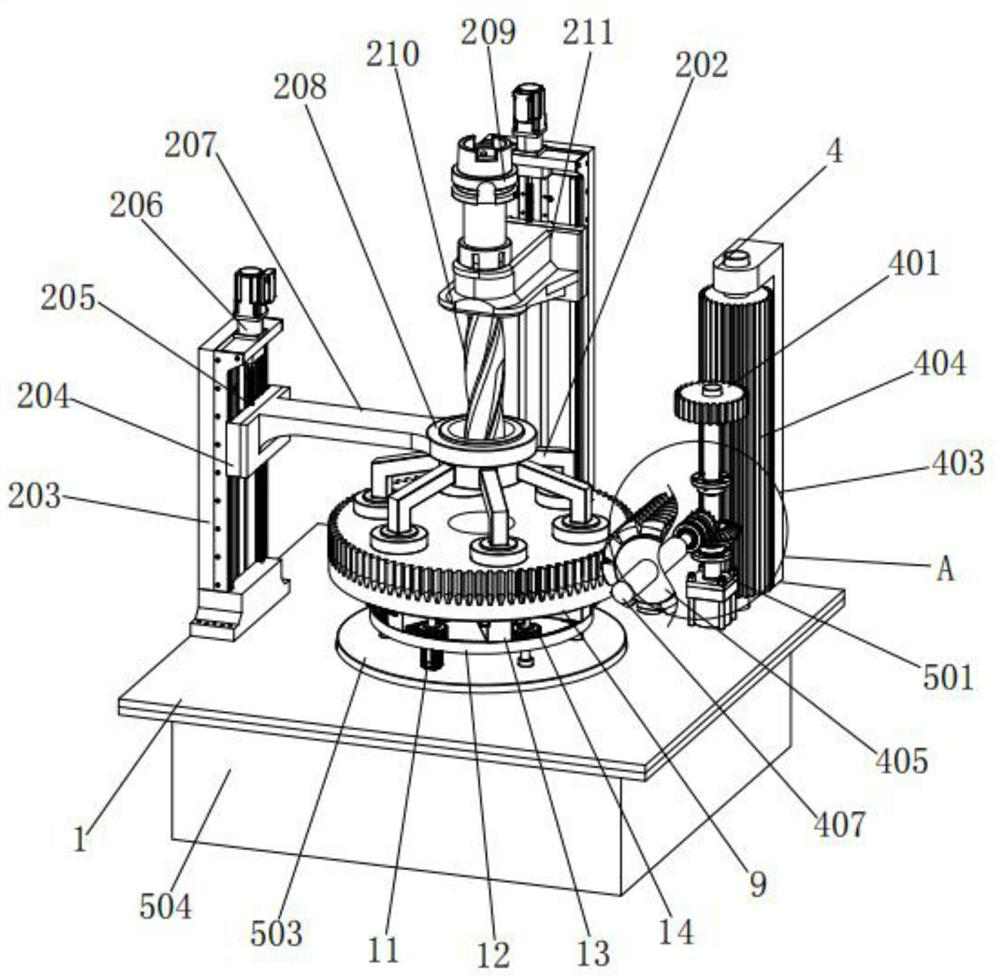

Multi-station gear machining and manufacturing platform

ActiveCN113275886ARealize drillingAvoid the problem of poor processing efficiencyOther manufacturing equipments/toolsBoring/drilling machinesGear wheelElectric machinery

The invention discloses a multi-station gear machining and manufacturing platform. The multi-station gear machining and manufacturing platform comprises a machining platform and a gear workpiece; the gear workpiece is arranged in the center of the upper portion of the machining platform; a base plate is attached to the lower portion of the gear workpiece; and the lower end of the base plate is fixedly connected with a plurality of end plates; the lower end of a vertical shaft on the left side of the front end is fixedly connected with an output shaft of an adjusting motor; a driving assembly is installed in the lower portion of the machining platform; a drilling assembly and a tooth cutting assembly are installed on the upper portion and the right side of the machining platform correspondingly; the multi-station gear machining and manufacturing platform is scientific and reasonable in structure and safe and convenient to use; corresponding teeth can be machined on the outer wall of the gear workpiece through cooperation of a second supporting plate, a drill bit, the gear workpiece, an air cylinder, a first gear, a hob and the machining platform; and the problem of poor machining efficiency caused by the processes of carrying, secondary clamping and the like due to the fact that drilling and tooth cutting of gears need to be carried out on different machining platforms is solved.

Owner:SHAOXING GLOBAL MACHINERY MFG

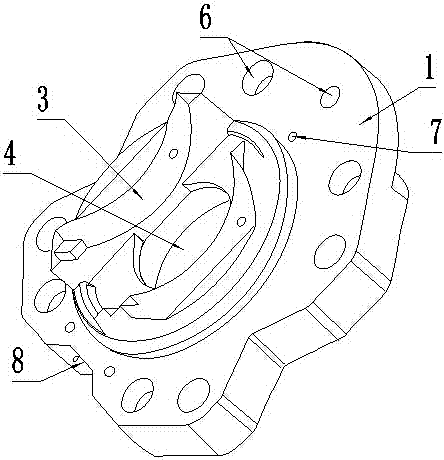

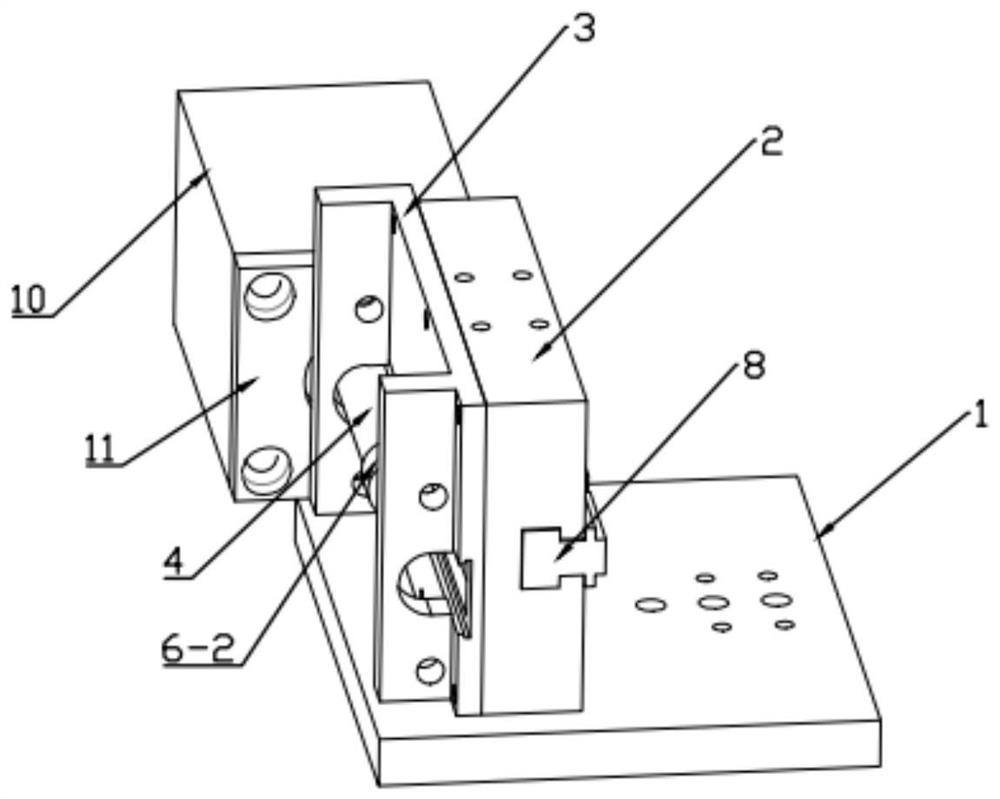

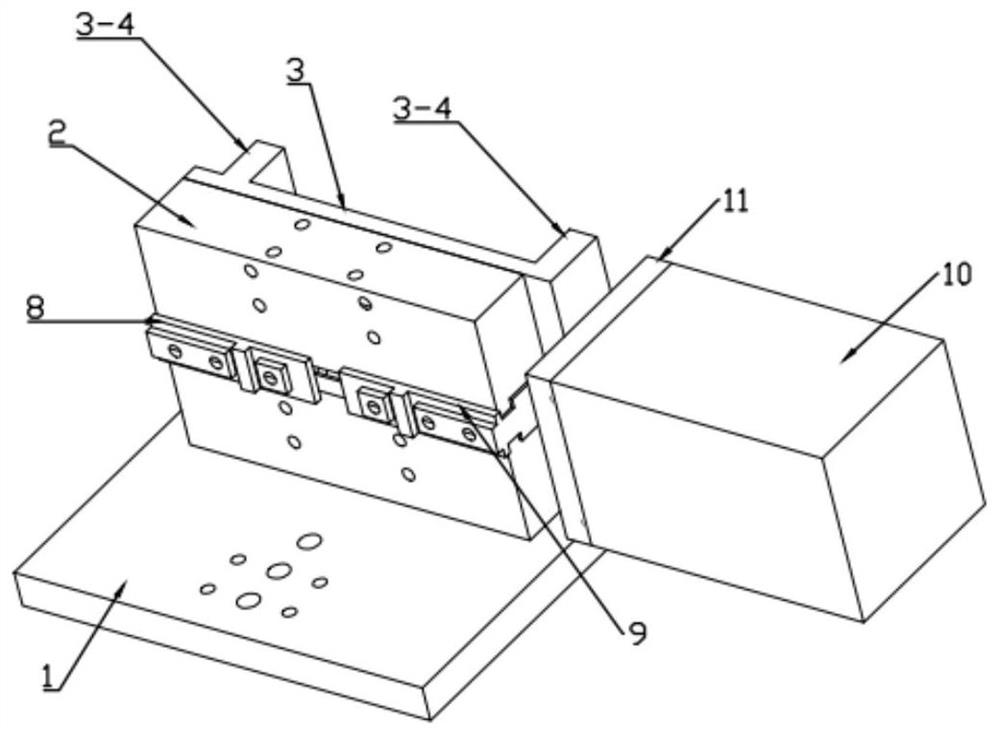

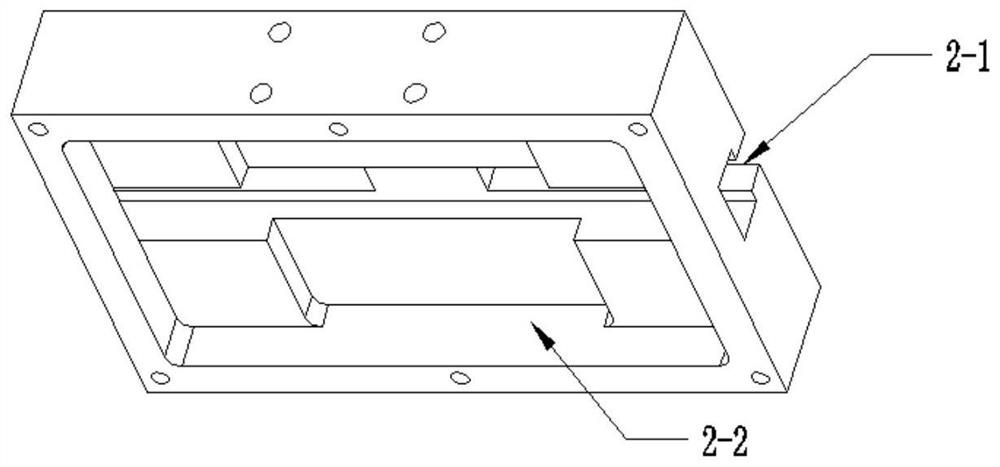

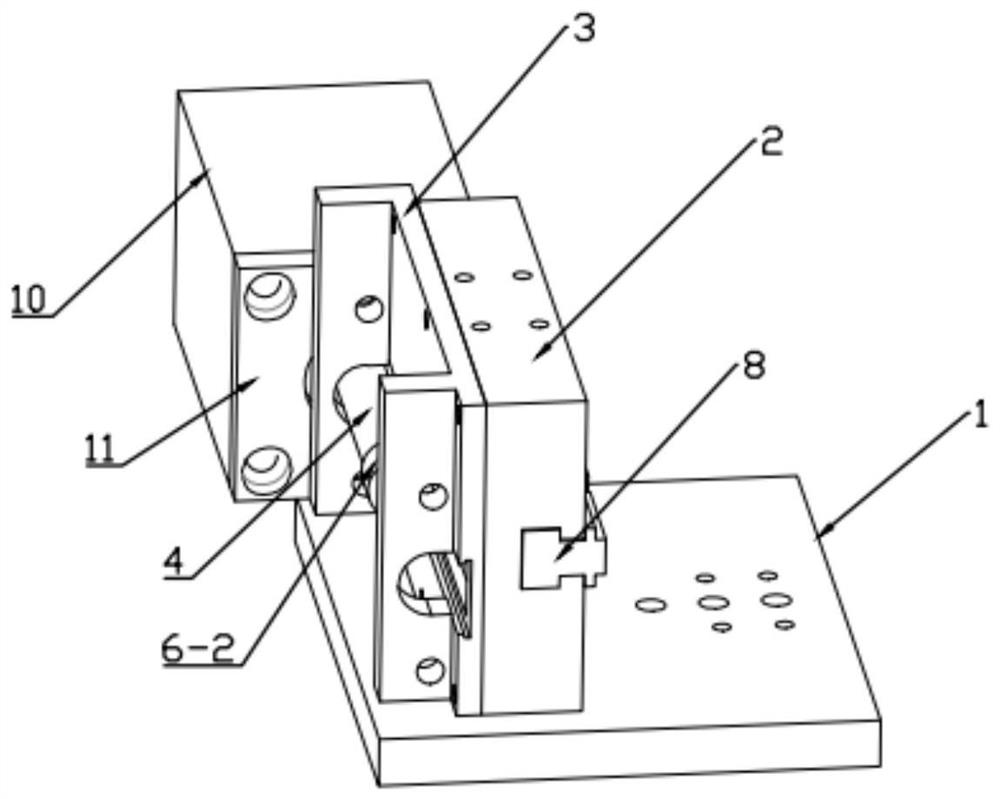

Swinging seat drilling tool

ActiveCN107160207ARealize drillingReduce processing stepsPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a swinging seat drilling tool and relates to the technical field of cold machining process equipment. The swinging seat drilling tool comprises a base, a right surface machining position and a reverse surface machining position. The right surface machining position comprises a first positioning device and compressing mechanisms. The first positioning device can be matched with an external table circle of the inner arc surface on the reverse surface of a swinging seat and the planes around the swinging seat, the periphery of the swinging seat is compressed by means of the compressing mechanisms to achieve machining of hole openings of thread holes and connecting holes in the right surface of the swinging seat. The reverse surface machining position comprises a second positioning device and compressing mechanisms. The second positioning device is matched with a stop opening of the right surface of the swinging seat and the planes around the swinging seat. The compressing mechanisms are arranged around the first positioning device and the second positioning device correspondingly. The planes around the swinging seat can be compressed through the compressing mechanisms to achieve machining of pin holes and connecting holes in the reverse surface of the swinging seat. By adopting the swinging seat drilling tool, drilling machining on the right surface and the reverse surface of the swinging seat is achieved, a machine tool and the tool do not need to be replaced, the machining procedures of the swinging seat are simplified, the labor intensity of operators is reduced, and machining efficiency is improved.

Owner:邢台中伟卓特液压科技有限公司

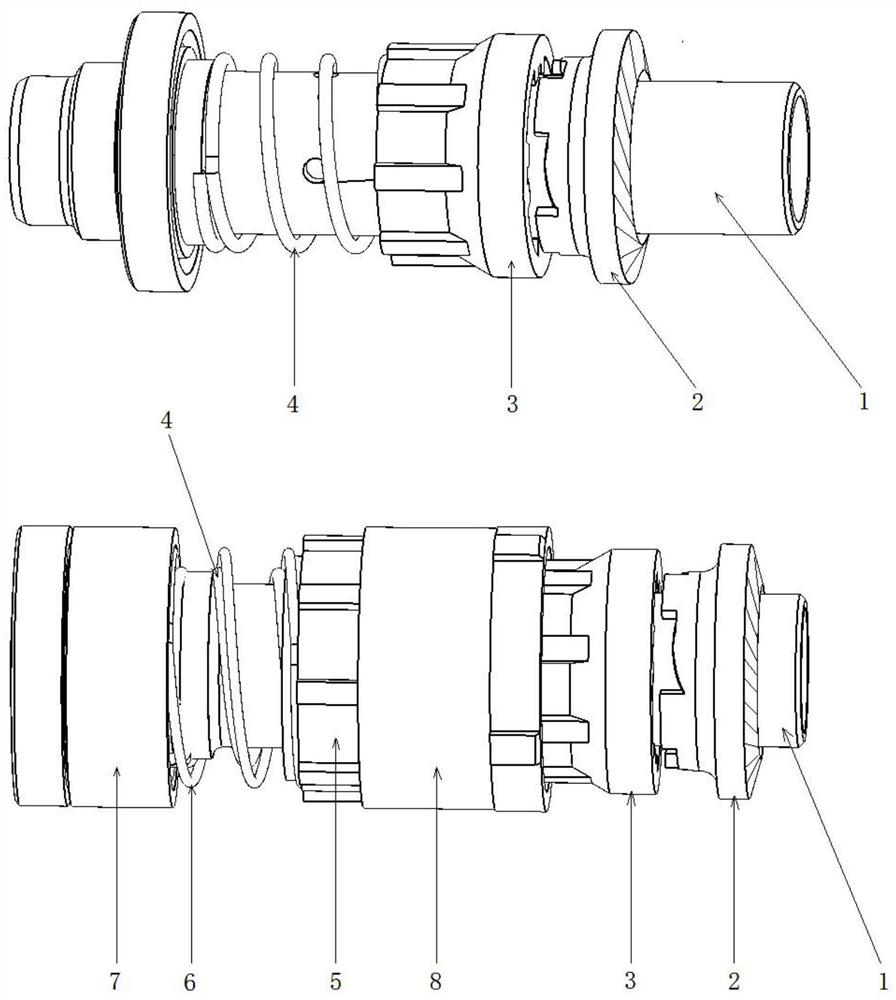

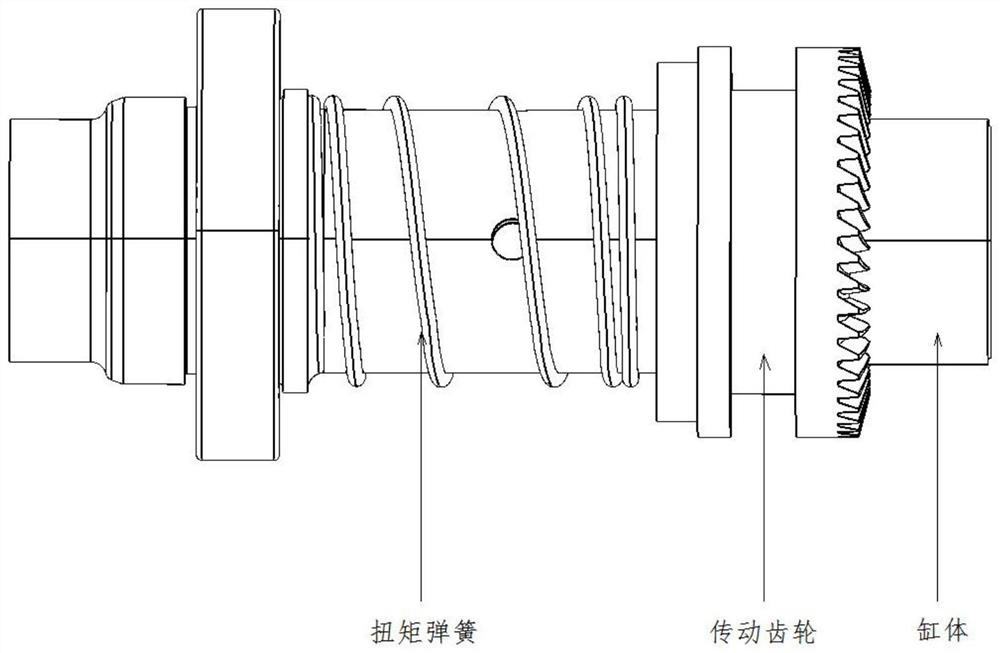

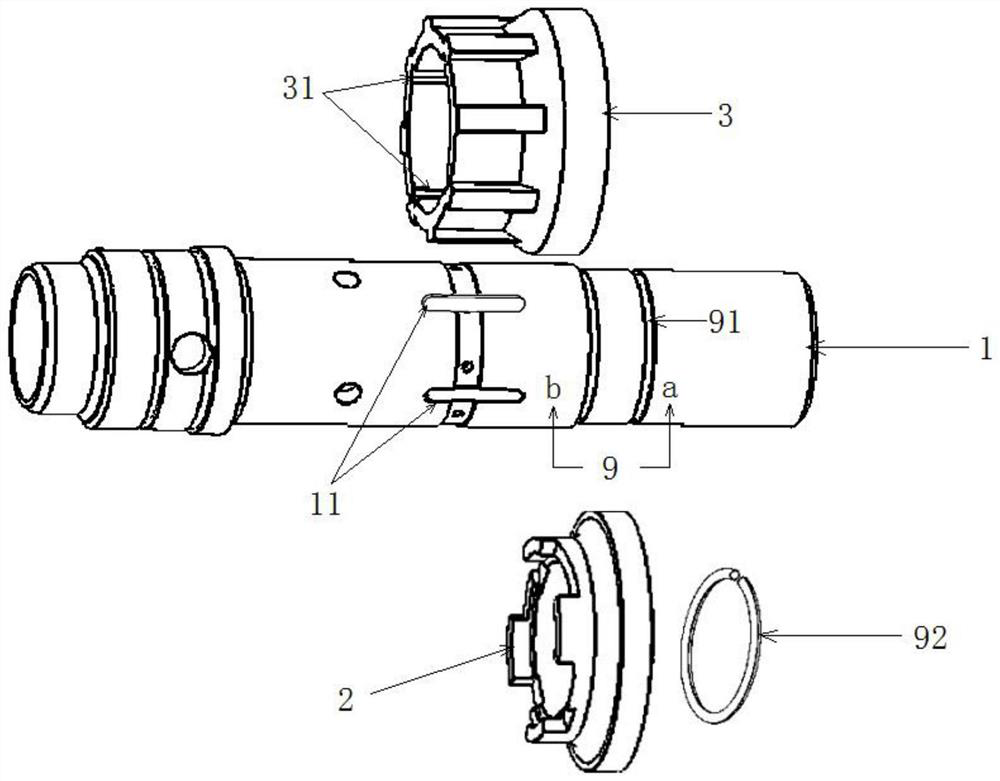

Air cylinder assembly for electric hammer

The invention discloses an air cylinder assembly for an electric hammer. The air cylinder assembly comprises a cylinder body, wherein one end of the cylinder body is provided with a transmission gearin a sleeved mode, one end of the transmission gear is provided with a gear face, and the gear face is meshed with a motor transmission mechanism; the portion, close to the transmission gear, of the cylinder body is provided with a clutch sleeve in a sleeved mode, and the side, close to the clutch sleeve, of the cylinder body is provided with a torque spring in a sleeved mode; and the other end, far away from the transmission gear, of the clutch sleeve is provided with a limiting sleeve in a sleeved mode, the other end, far away from the clutch sleeve, of the limiting sleeve is provided with areset spring, the other end, far away from the limiting sleeve, of the reset spring is provided with a fixing sleeve, and a locking sleeve is arranged on peripheries of the clutch sleeve and the limiting sleeve in sleeving mode. According to the air cylinder assembly for the electric hammer, the transmission gear is limited on a transmission gear fixing part, and therefore the transmission gear cannot axially slide; the clutch sleeve is arranged, the torque spring abuts against the clutch sleeve, the limiting sleeve is arranged, and the arranged reset spring abuts against the limiting sleeve,so that the friction force among the transmission gear, the clutch sleeve and the cylinder body is reduced, and the disassembly convenience is improved; and the locking sleeve is arranged, so that the working state of the electric hammer is adjusted more conveniently and efficiently.

Owner:浙江金可曼电器有限公司

Drilling and tapping equipment

InactiveCN114589495ALow efficiencyEasy to installWork clamping meansAutomatic workpiece supply/removalProcess engineeringDrill hole

The invention provides drilling and tapping equipment. The drilling and tapping equipment comprises a rack, a drilling device and a tapping device. The rack is provided with a conveying device for conveying profiles; the drilling device comprises a drilling assembly and a first driving assembly erected on the rack; the drilling assembly is provided with a drilling tool located above the conveying device, and the first driving assembly is used for controlling lifting motion and rotation of the drilling tool; the tapping device is located on the lower station of the drilling device and comprises a tapping assembly and a second driving assembly erected on the rack. The tapping assembly is provided with a tapping tool located above the conveying device, and the second driving assembly is used for controlling lifting motion and rotation of the tapping tool. The automatic drilling and tapping equipment solves the problems that traditional drilling and tapping equipment is large in error and low in efficiency, and has the advantages of replacing manual labor and being high in automation degree.

Owner:佛山市信新瀚家居科技有限公司

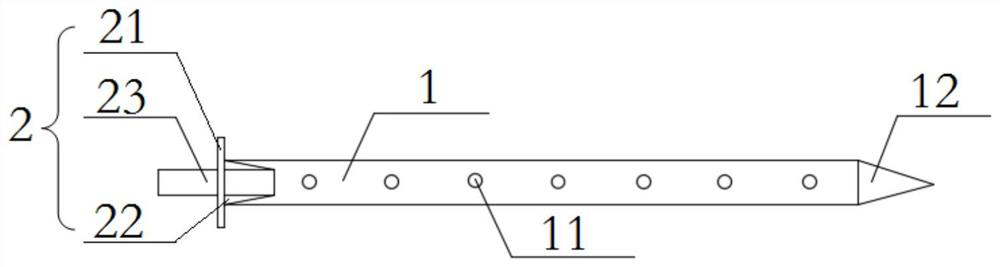

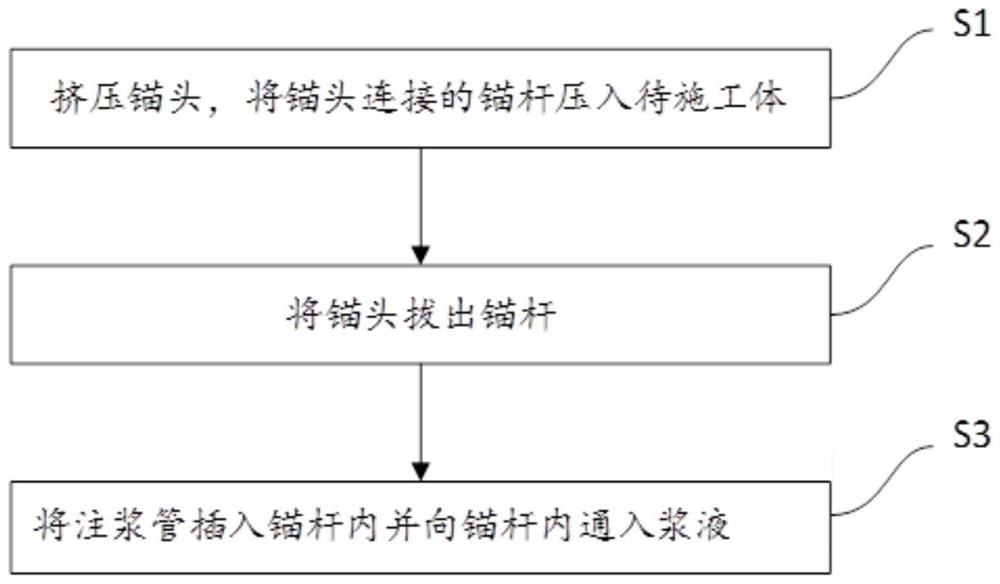

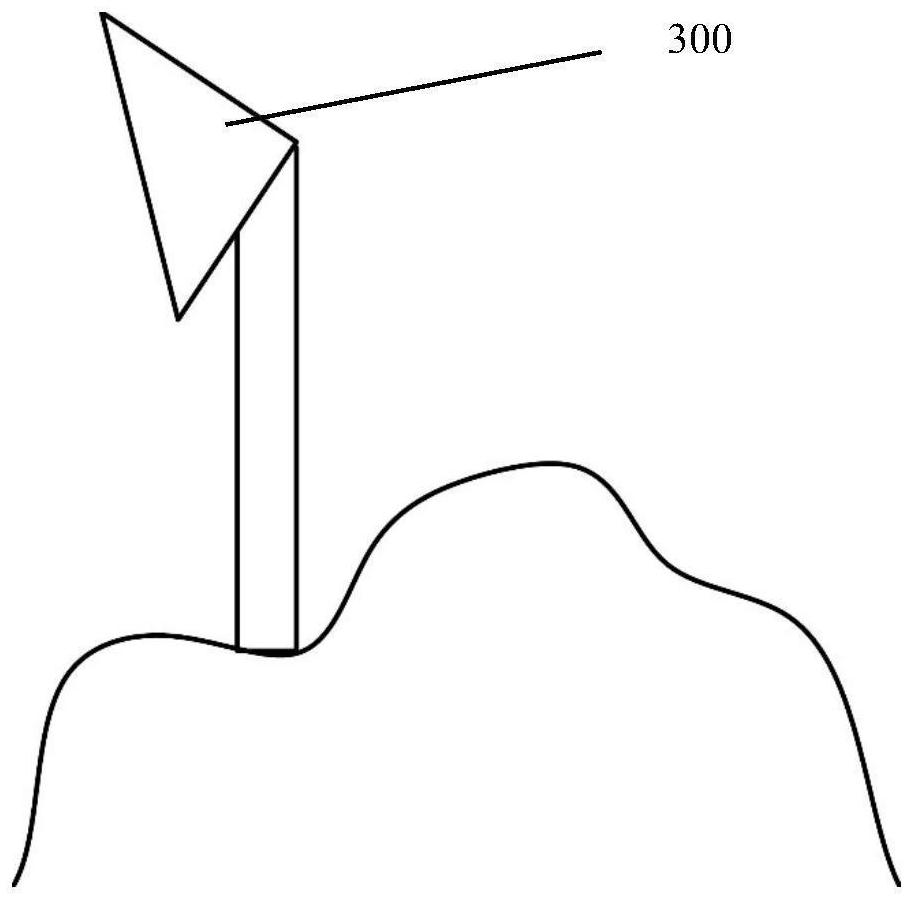

Grouting method and press-in type hollow grouting anchor pipe

PendingCN111636910ARealize drillingFast realization of grouting constructionExcavationsBulkheads/pilesSlagRock bolt

The invention discloses a grouting method and a press-in type hollow grouting anchor pipe. The press-in type hollow grouting anchor pipe comprises a hollow anchor rod, wherein grouting holes are formed in the peripheral side of a rod body of the hollow anchor rod, one end of the hollow anchor rod is in a pointed tail shape, the other end of the hollow anchor rod is detachably connected with an anchor head, and one end of the anchor head is inserted into the hollow anchor rod. The invention further discloses the grouting method, which is applied to the press-in type hollow grouting anchor pipeand is characterized in that the hollow anchor rod provided with the anchor head is mechanically pressed into a rock-soil foundation to be constructed, then the anchor head is taken down, grout is injected into the hollow anchor rod from the position, provided with the anchor head, of the hollow anchor rod, and the grout is enabled to flow out of the grouting holes and fill the periphery of a rodbody and a rock-soil foundation hole drilled by the hollow anchor rod. In conclusion, by the adoption of the press-in type hollow grouting anchor pipe, two steps of hole forming and anchor pipe press-in can be combined into a whole, the construction process is simplified, the construction period is shortened, the press-in type hollow grouting anchor pipe is particularly suitable for construction of loose and soft layers such as blast furnace slag, soil layers and sand layers, in addition, the anchor head can be repeatedly used, and the construction cost is reduced.

Owner:PANGANG GRP ENG TECH

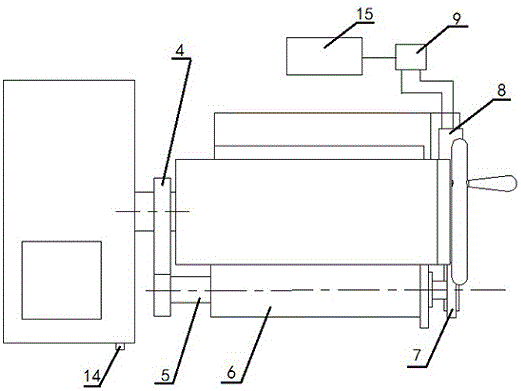

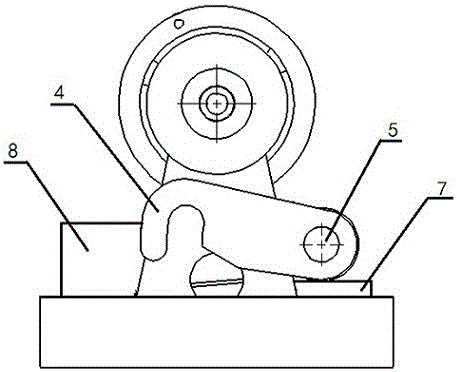

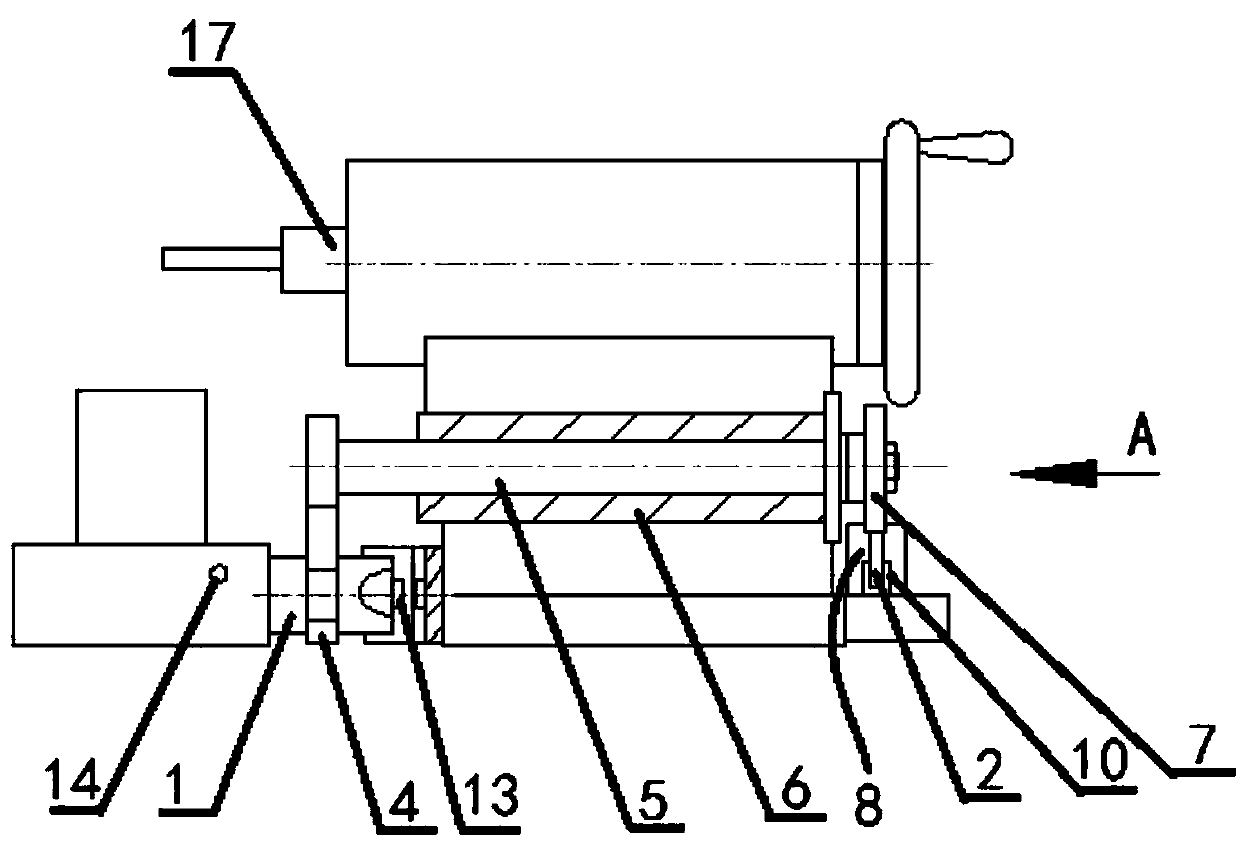

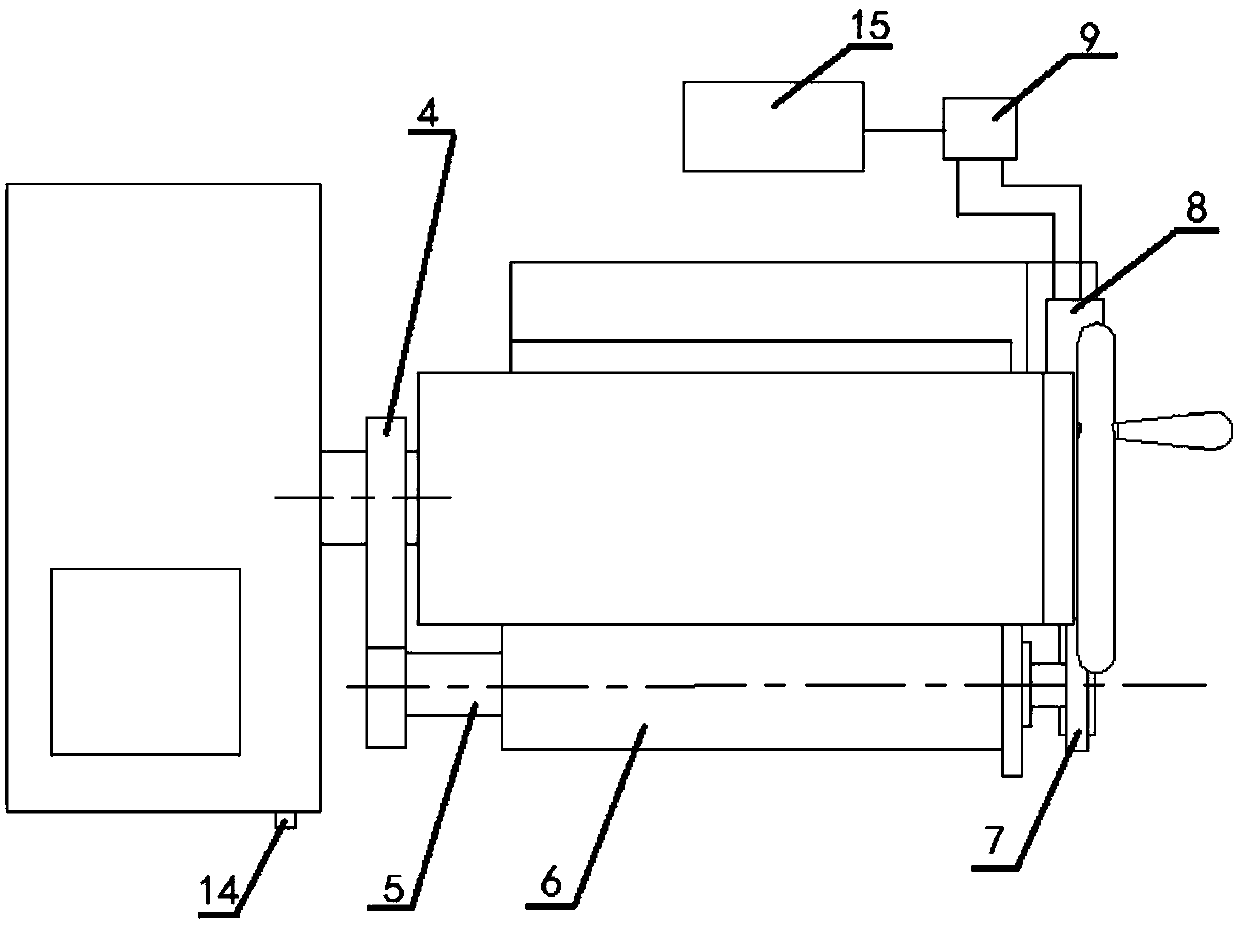

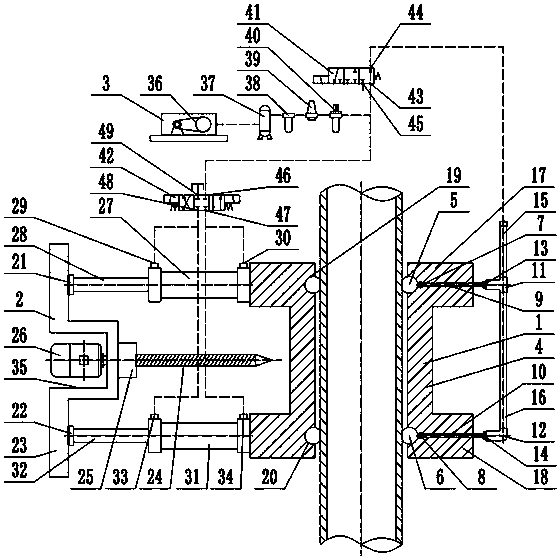

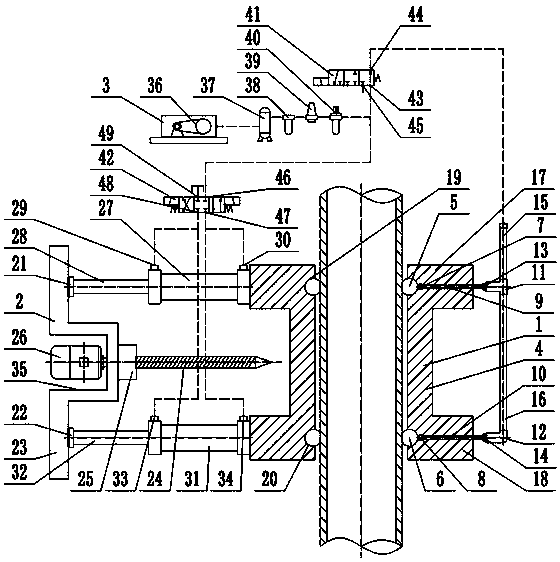

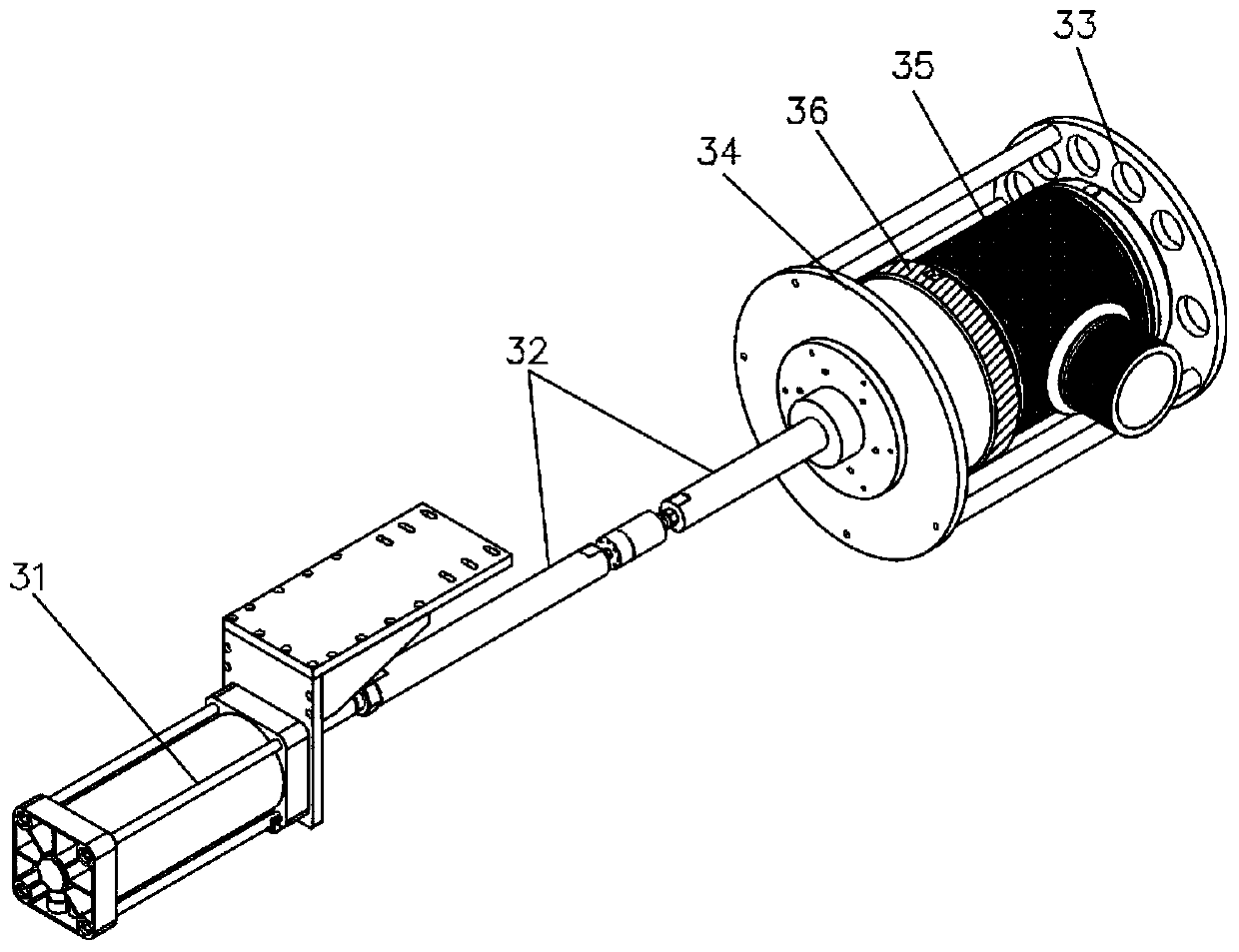

Power head of timber door drilling device

InactiveCN105619536AAdjust the amount of stretchPrecise shiftStationary drilling machinesEngineeringPiston rod

The invention provides a power head of a timber door drilling device. The power head comprises a power head bottom plate, wherein four corners of a guide rod fixing plate are supported on the power head bottom plate through guide rods, a cylinder and a slider are fixed on the lower end surface of the power head bottom plate, an end of a piston rod of the cylinder penetrates the power head bottom plate and is then connected with a motor base, the motor base is a rectangular frame and comprises a motor base top plate, a motor base bottom plate and motor base side plates, linear bearings are symmetrically arranged at four corners of the motor base top plate and four corners of the motor base bottom plate, the guide rods sequentially penetrate the linear bearings on the motor base top plate and the motor base bottom plate, a motor is fixed on the lower end surface of the motor base top plate, a drill plane connecting seat is fixed on the upper end surface of the motor base top plate, a drill plane is supported on the drill plane connecting seat and connected with an output shaft of the motor, a hole allowing the drill plane to penetrate is formed in the guide rod fixing plate, and a drill bit is arranged on the drill plane. The power head of the timber door drilling device has the advantages of simple structure, convenience in maintenance and low manufacture cost.

Owner:WUXI FORMEN TECHN

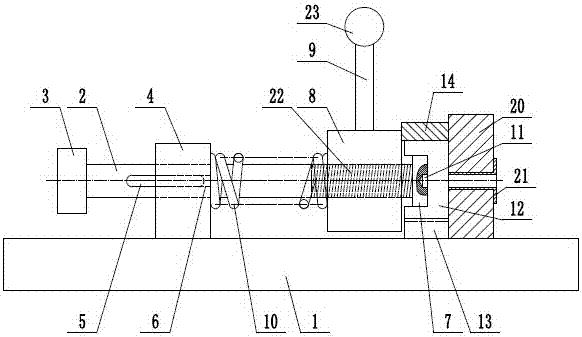

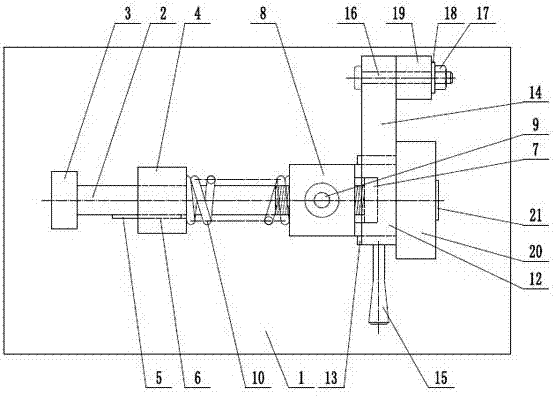

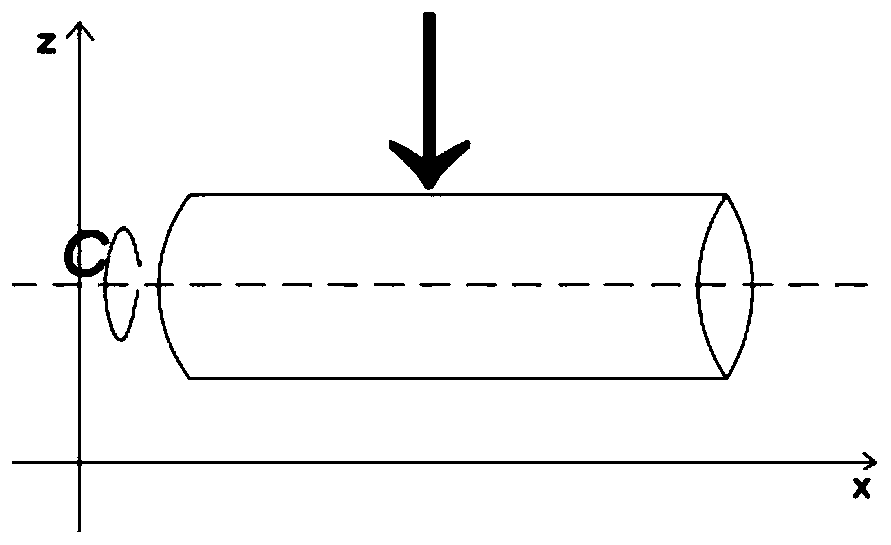

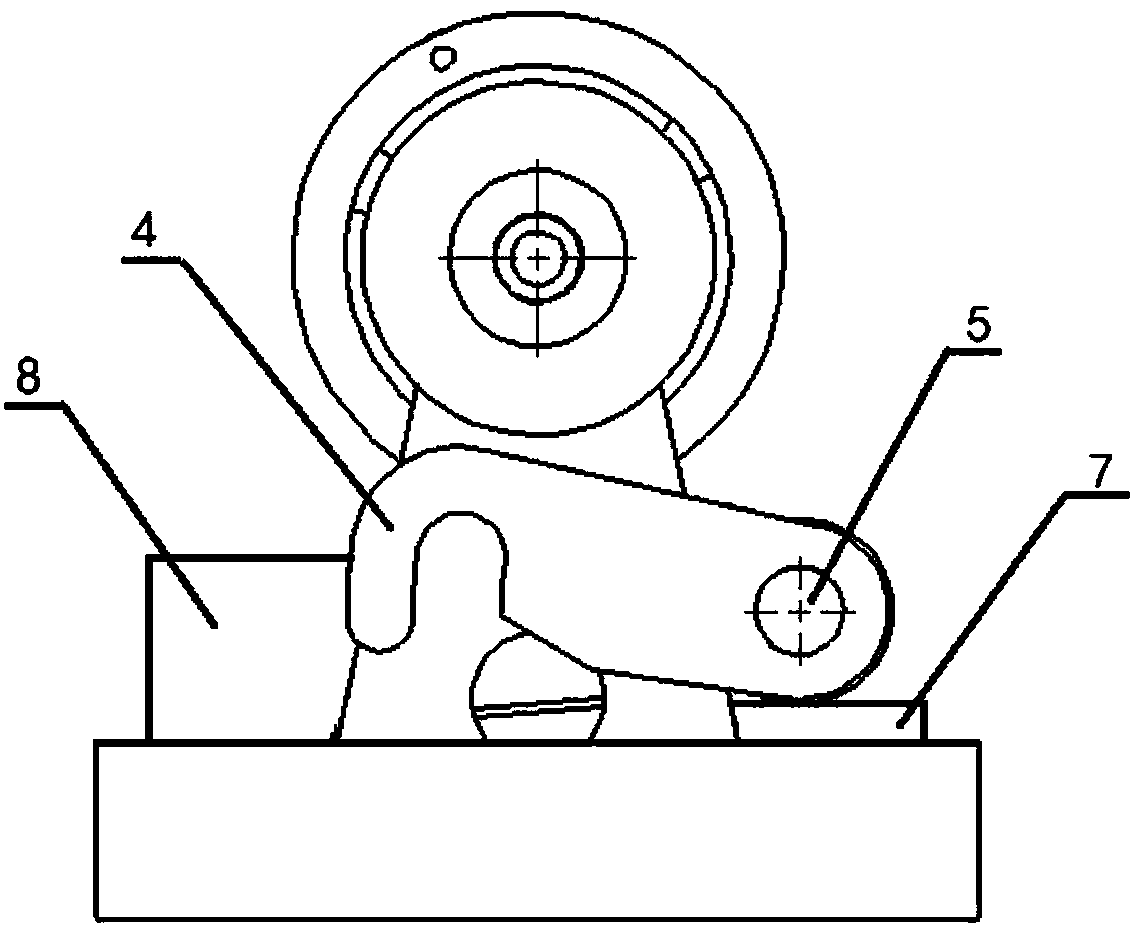

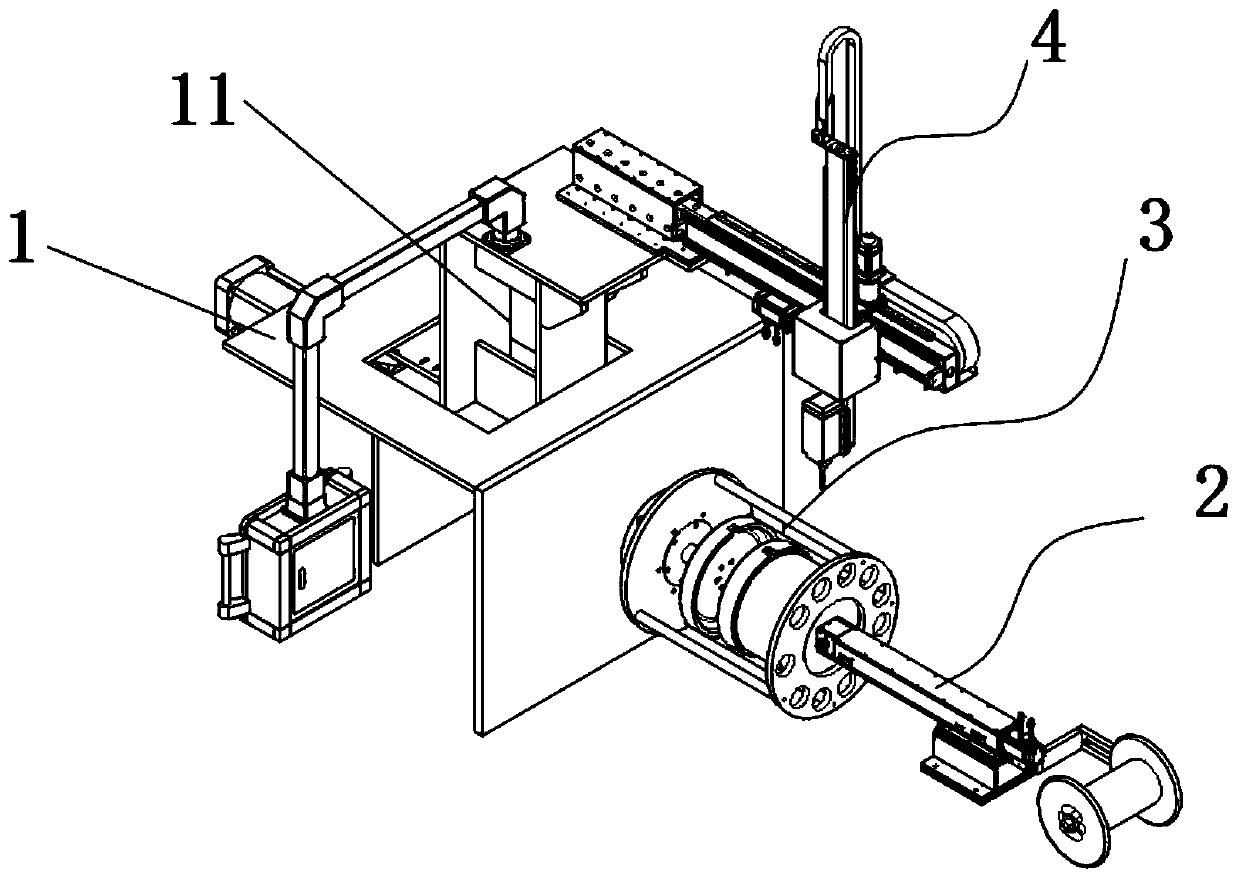

Numerically-controlled lathe tailstock automatic feeding control method capable of controlling finishing of hole bottoms

ActiveCN106112024ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

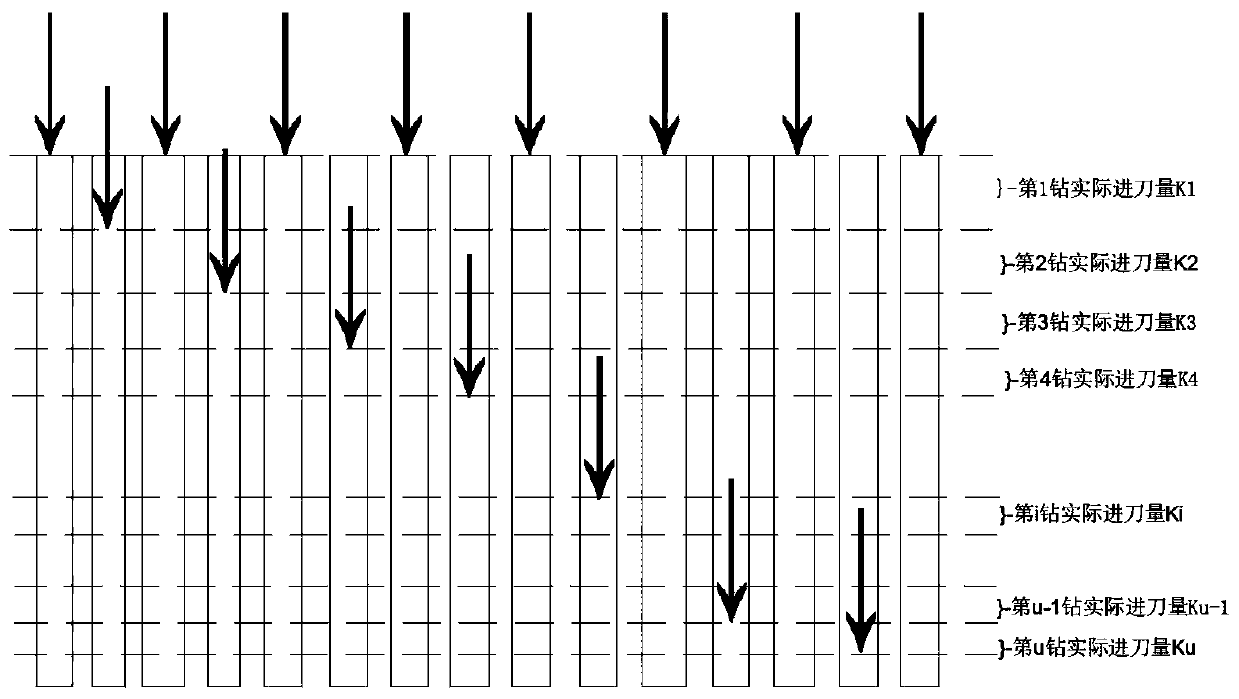

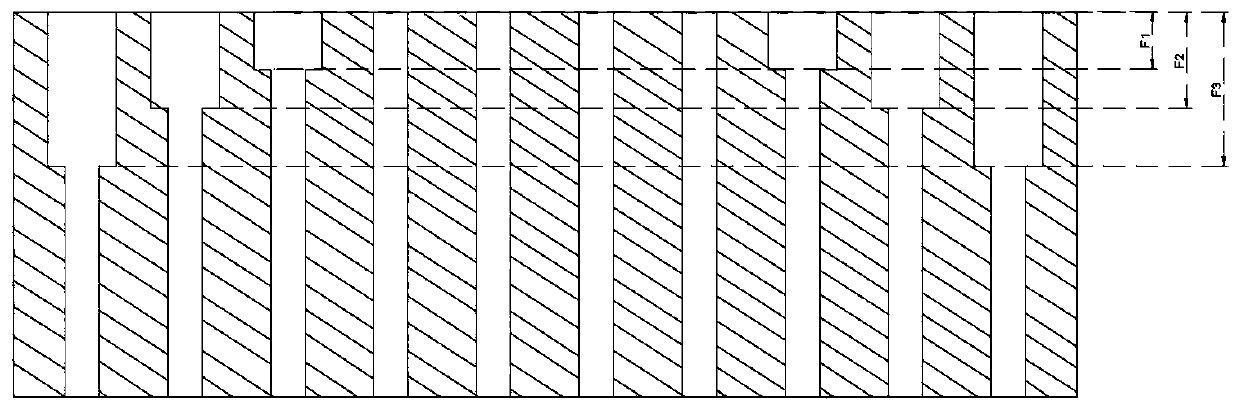

High-efficiency mesh drilling new method

The invention discloses a high-efficiency mesh drilling new method. A workpiece to be processed is cylindrical, the method has the specific steps that S1, drill bits are aligned with each row of holeson the cylinder workpiece; S2, location holes are drilled: a hole with a certain depth is drilled on the surface of an unmachined cylinder workpiece by using a drill bit; S3, a main hole is drilled:according to the machining requirements, the drill bit in line with the hole diameter is selected, and the required hole depth is machined at the position of each location hole on the cylinder workpiece; when a certain amount of feed is drilled, the drill bits need to be retired for chip removal, reception is conducted, and the drilling of the hole is completed; and S4, pressure-relief holes are drilled: the pressure-relief holes with a certain depth are drilled at both ends of the cylinder workpiece by using the drill bit that is thicker than the drill bit drilling the main hole, when the workpiece with thousands of holes needs to be machined for several days in a row, once shut down or unexpected power off happens, run and machine directly as long as restarted, and the hole machined lasttime is continued to be machined.

Owner:DALIAN UNIV

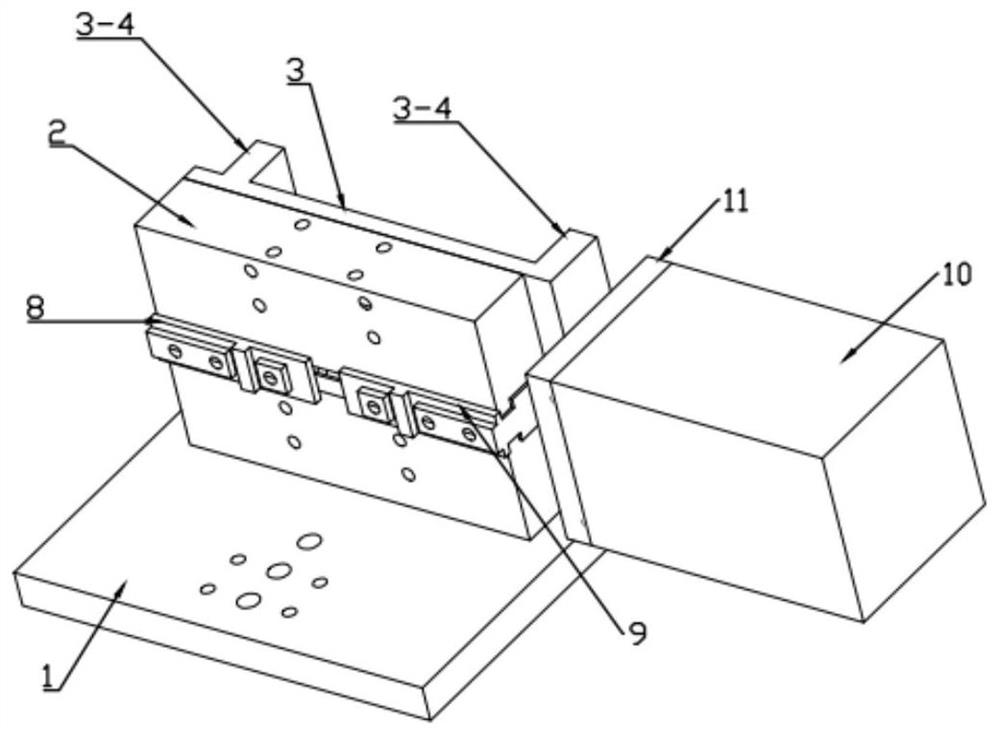

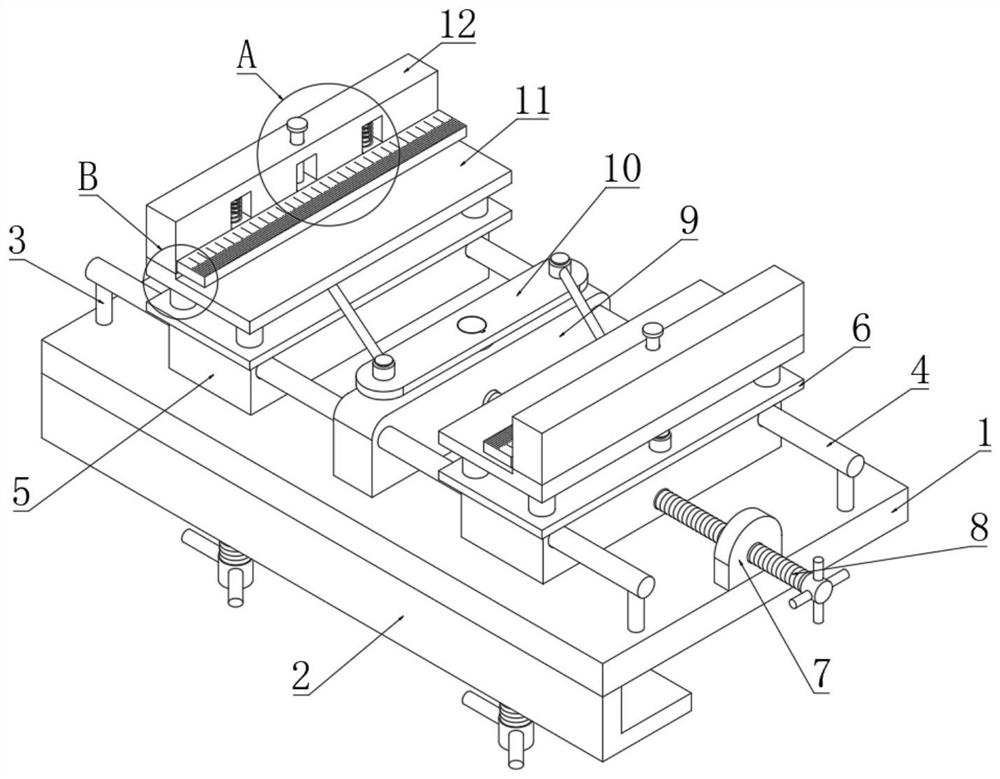

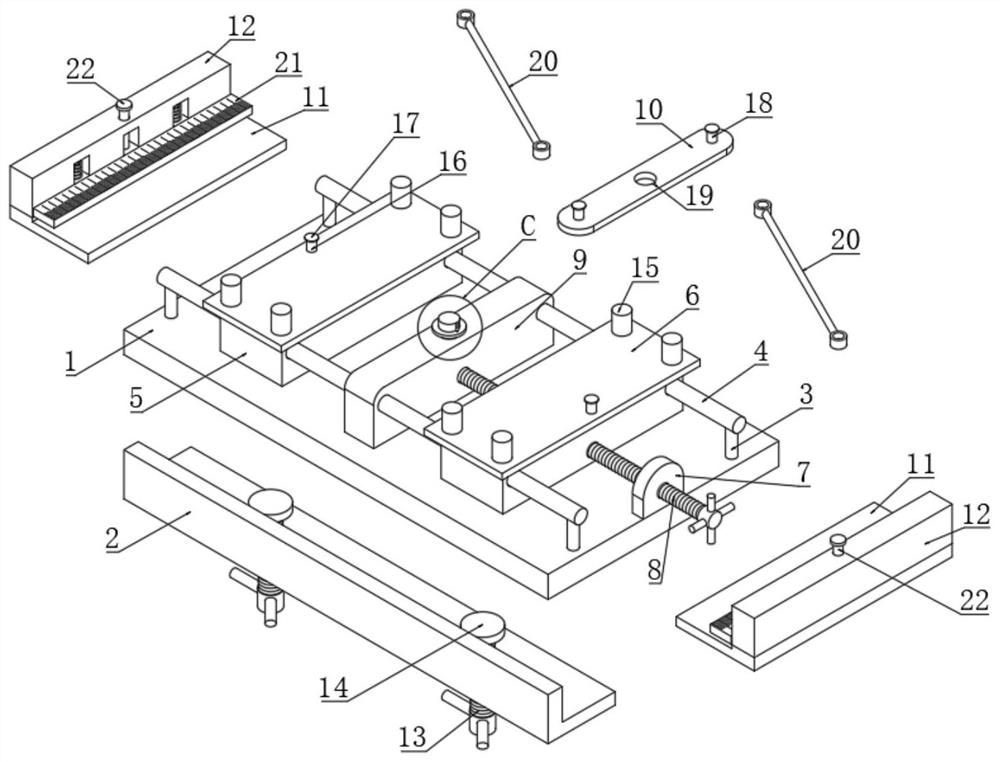

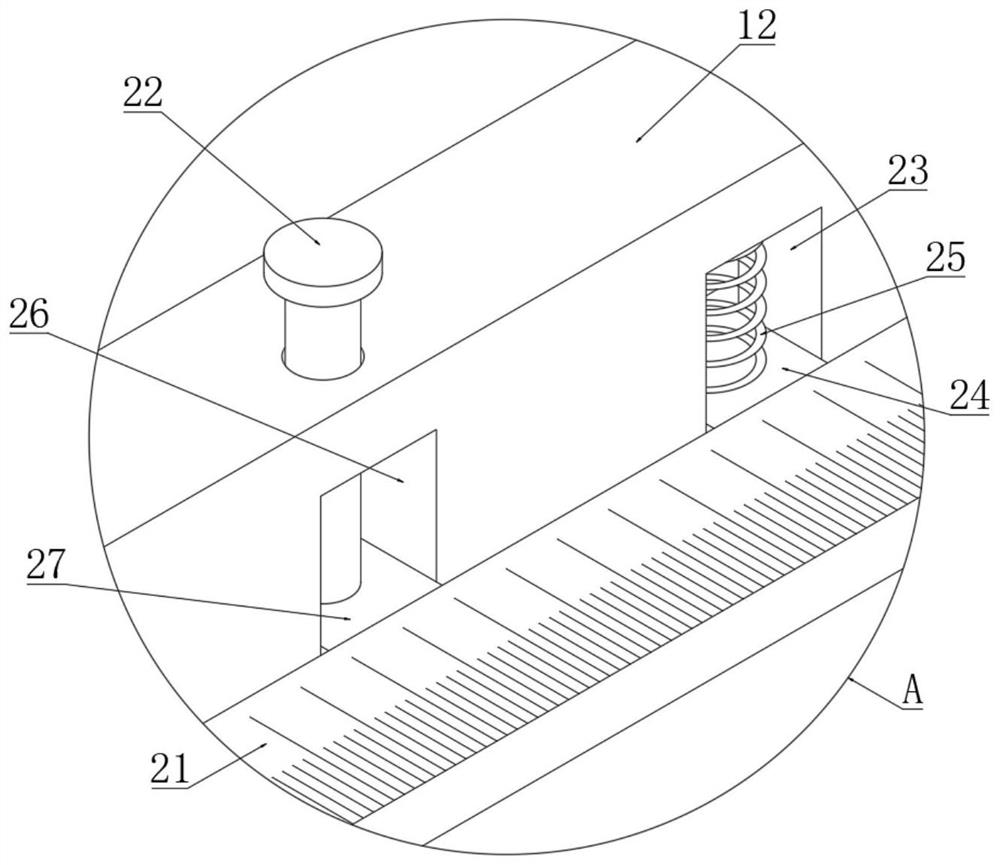

Bidirectional bench clamp

ActiveCN113275923ARealize drillingPositioning apparatusMetal-working holdersClassical mechanicsSlide plate

The invention relates to the technical field of clamps. In order to solve the problem that the clamping precision of an existing bench clamp cannot meet the requirement for machining of round or circular arc and square products with the high symmetry degree requirement, the invention provides a bidirectional bench clamp. A clamp body and a support are fixedly arranged on a base, the support is fixedly arranged on the rear end face of the clamp body, a left sliding block and a right sliding block are symmetrically arranged on a first sliding groove, a positioning plate is arranged in an installation groove between the clamp body and the support, protruding blocks on the left sliding block and the right sliding block are arranged in two second sliding grooves of the positioning plate respectively, the protruding blocks of the positioning plate are arranged in a third sliding groove in a sliding plate, the protruding part of the sliding plate penetrates out of a fourth sliding groove, a spacer bush is fixedly arranged on the protruding part, one end of a pull rod is fixedly connected with the spacer bush, and the other end is fixedly connected with a telescopic shaft of a linear reciprocating mechanism. According to the bidirectional bench clamp, the reciprocating action of the linear reciprocating mechanism is converted into co-advancing and co-retreating actions of the left sliding block and the right sliding block through the sliding plate and the positioning plate, and bidirectional clamping and loosening of a workpiece are achieved.

Owner:青岛海德锻造有限公司

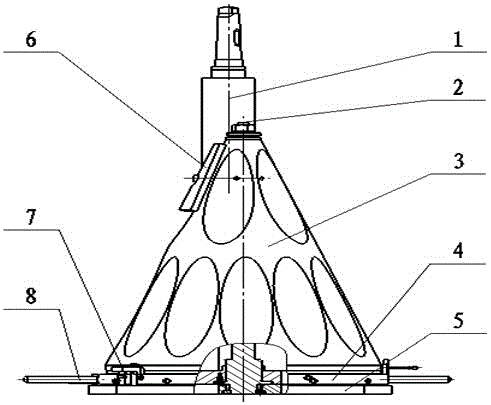

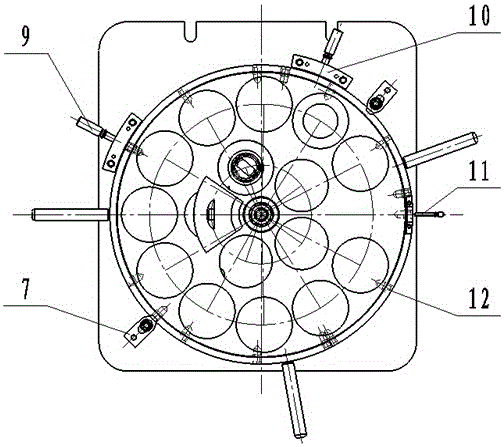

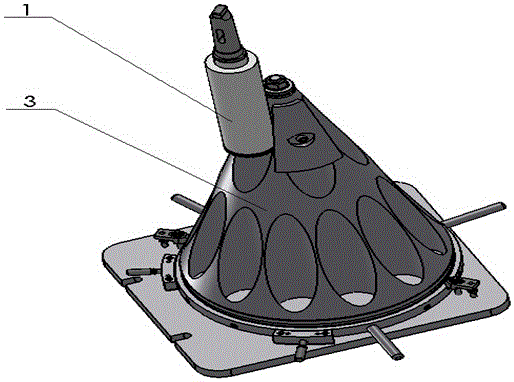

A Method for Machining Axial Hole of Thin-walled Cone

ActiveCN103447567BImprove machining accuracyNot easily deformedPrecision positioning equipmentPositioning apparatusThin walledComputer science

The invention discloses a method for processing axial holes of a thin-wall cone and relates to a processing method for holes. The method comprises the following steps: a, manufacturing an auxiliary jig; b, installing the jig and parts; c, performing tool setting and tool changing; d, processing one hole; e, processing another hole; f, processing a first layer of holes; g, performing the tool setting again; h, processing a second layer of holes; i, processing all holes. According to the method disclosed by the invention, under the condition that a drilling tool is unchanged in position, a rotary turnplate is positioned by utilizing indexing holes to realize drilling of the thin-wall cone. The method is higher in processing precision, and the holes are not easy to deform. According to the method disclosed by the invention, a process that repositioning needs to be performed every time when one hole is processed is also saved, and therefore, the work efficiency can be greatly improved. Moreover, the used jig is simple in structure, and convenient to operate. In consideration of reasons, the method for processing the axial holes of the thin-wall cone disclosed by the invention is higher in promotion value.

Owner:GUIZHOU FENGLEI AVIATION ORDNANCE CO LTD

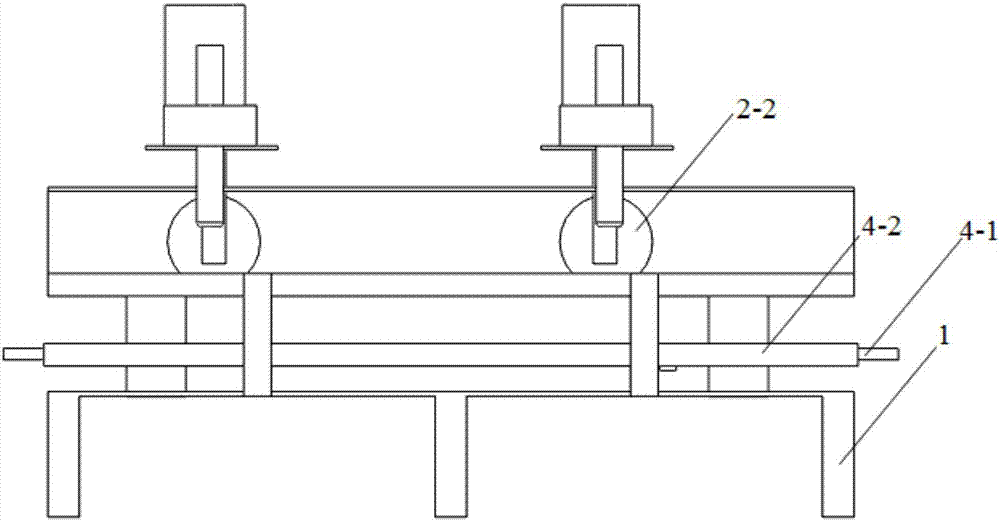

Double-station aluminum plate sliding type drilling device

InactiveCN107159927ARealize drillingHigh precisionBoring/drilling machinesSlide plateMutual position

The invention relates to drilling equipment, in particular to a double-station aluminum plate sliding type drilling device. The double-station aluminum plate sliding type drilling device comprises a rack, a sliding mechanism, drilling equipment and a hole positioning device, wherein the sliding mechanism, the drilling equipment and the hole positioning device are arranged on the rack. The sliding mechanism is composed of a sliding way, sliding wheels and a sliding plate. The sliding wheels are arranged on the two sides of the sliding plate and arranged in the sliding way. The two pieces of drilling equipment are arranged on the sliding plate. The hole positioning device is composed of air cylinders, a material shelf and drilling dies. The air cylinders are arranged on the two sides of the material shelf. The drilling dies are arranged at the upper end of the material shelf. The double-station aluminum plate sliding type drilling device aims at achieving drilling on ultralong workpieces; and the two pieces of drilling equipment are adopted in the device, so that the production efficiency is greatly improved, and the positional precision of all holes is greatly improved through the sliding way and the drilling dies.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

Two-way vise

ActiveCN113275923BRealize drillingPositioning apparatusMetal-working holdersSlide plateIndustrial engineering

Owner:青岛海德锻造有限公司

An automatic feed control method for the tailstock of a CNC lathe that can control the finishing of the bottom of the hole

ActiveCN106112024BRealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

Clamp assembly for plate drilling and application method thereof

PendingCN112959104ARealization of drillingRealize clamping workPositioning apparatusMetal-working holdersClassical mechanicsEngineering

The invention discloses a clamp assembly for plate drilling and an application method thereof. The clamp assembly for plate drilling comprises a fixed base, wherein four first supporting rods are fixedly connected to the side of the top end of the fixed base; a connecting rod is fixedly connected to the top ends of each two first supporting rods; movable blocks are connected to the two sides of the connecting rods in a sliding and penetrating mode; the top ends of the two movable blocks are both fixedly connected with bearing plates; the sides of the top end of each bearing plate are fixedly connected with four second supporting rods; the top ends of each four second supporting rods are fixedly connected with a supporting plate; the top end of each supporting plate is provided with a clamping mechanism; the middle of the top end of the fixed base is fixedly connected with a fixed block; and the top end of the fixed block is provided with a reciprocating mechanism. The clamp assembly for plate drilling and the application method thereof provided by the invention have the beneficial effects that through the design of the reciprocating mechanism, the two clamping mechanisms move away from each other or close to each other under the operation of the reciprocating mechanism, so that the clamping work of plates with different sizes is realized, and the practicability of the device is improved.

Owner:浙江优冠力魔汽车配件有限公司

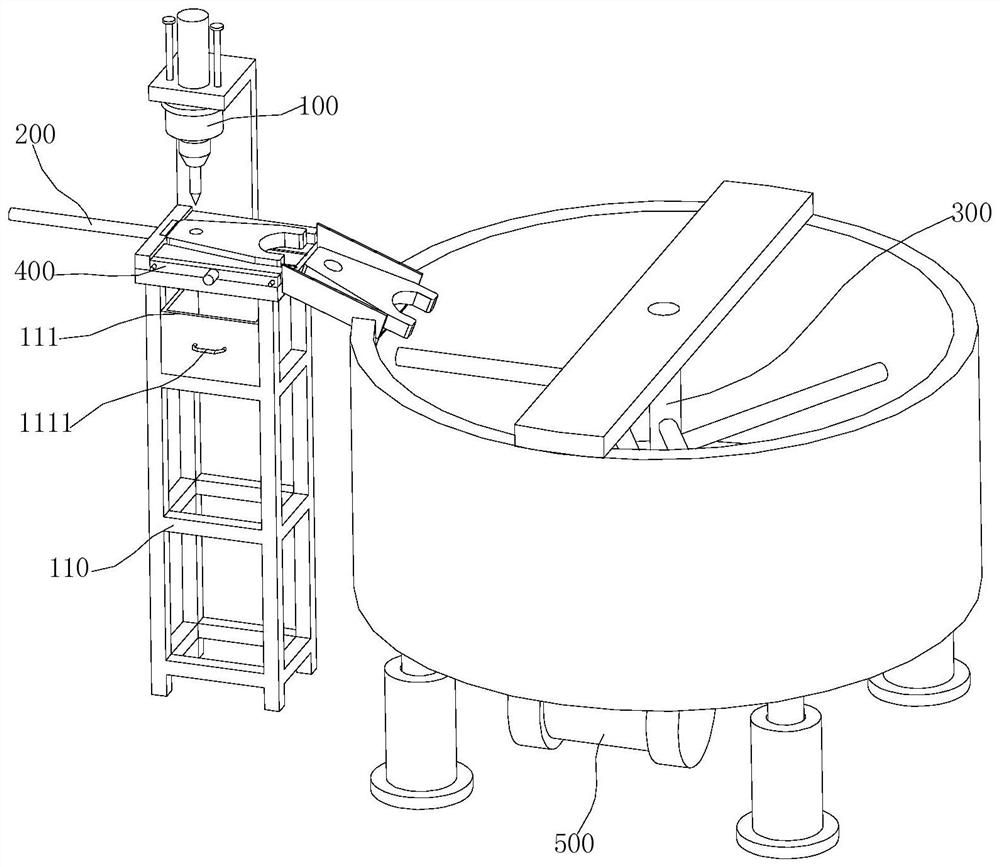

An all-in-one machine for deburring and drilling transmission shift fork castings

ActiveCN111922724BRealize drillingReduce workloadEdge grinding machinesPolishing machinesElectric machineryEngineering

The invention provides a deburring and drilling integrated machine for transmission shift fork castings, which belongs to the technical field of mechanical processing and includes a drilling mechanism, a material pushing mechanism and a burr removal mechanism, wherein the workbench in the drilling mechanism is fixed on a support frame, The mounting frame is fixed on the workbench, the first driving element is fixed on the mounting frame, the mounting plate is fixed on the first driving element, the first motor is fixed on the mounting plate, and the drill bit is fixed on the first motor. The first fixed block in the pushing mechanism is fixed on the worktable, the second driving part is fixed on the first fixed block, the pushing block is fixed on the second driving part, and the sliding material plate is fixed on the working table. The second motor in the deburring mechanism is fixed to the processing barrel, one end of the rotating shaft is fixed to the second motor, the other end rotates to the support plate, the support plate is fixed to the processing barrel, and the stirring rod is fixed to the rotating shaft. Through the device, the drilling and deburring process of the shift fork casting is realized, the work efficiency is improved, the workload of workers is reduced, and the equipment cost investment is low.

Owner:江苏万基传动科技有限公司

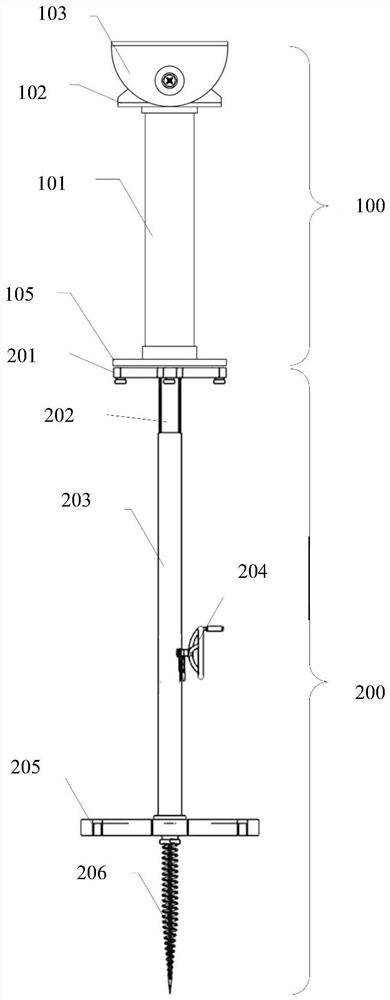

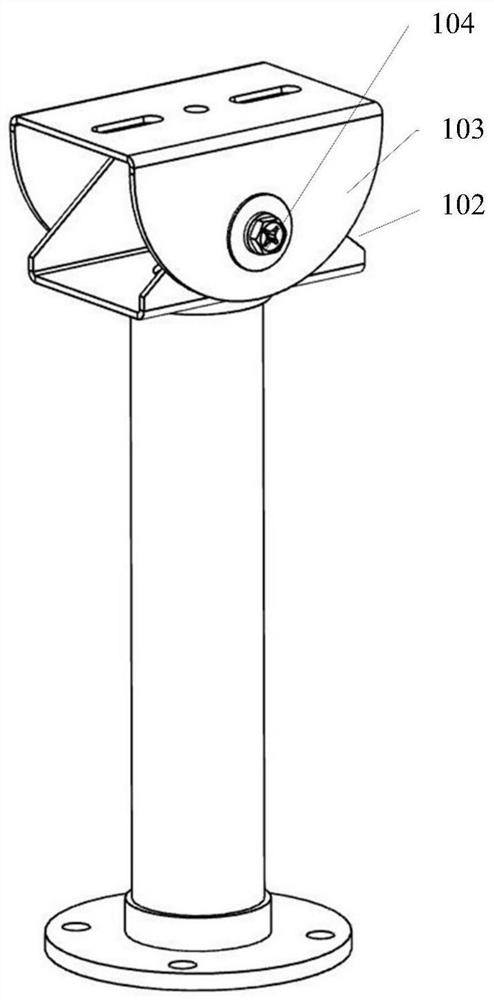

Angle-adjustable reflector device

PendingCN114690126AHeight adjustableEasy to fixWave based measurement systemsStands/trestlesEngineeringMechanical engineering

The invention discloses an adjustable corner reflector device which comprises a corner reflector and a fixed adjusting device, and the fixed adjusting device comprises a first part which comprises a first supporting rod and an adjustable top seat arranged at the upper end of the first supporting rod; the second part comprises a second supporting rod, a third supporting rod, a base and a drill bit; an adjusting device is arranged on the third supporting rod and used for enabling the second supporting rod to stretch out and draw back relative to the third supporting rod or enabling the drill bit to rotate to drive the third supporting rod to move up and down. In the corner reflector device, an adjusting device comprises a driving part, a first driven part and a second driven part; the second supporting rod can move up and down under the action of the first driven component through the driving component, so that the height of the corner reflector is adjusted, the drill bit moves downwards to fix the corner reflector under the action of the second driven component, and the device can adapt to soil of various hardness.

Owner:四川数字交通科技股份有限公司

Glass tube clamping and drilling device

ActiveCN108214939AAchieve clampingEasy to holdWorking accessoriesStone-like material working toolsEngineeringAtmospheric pressure

The invention provides a glass tube clamping and drilling device, and belongs to the technical field of glass tube machining. The device comprises a clamping mechanism, a drilling mechanism and an airpressure system, wherein the clamping mechanism comprise a first clamping hose, the first clamping hose is installed in a first hose groove, and a second clamping hose is arranged in a second hose groove; one end of a first horizontal hard tube is connected with a first tube joint, and the other end of the first horizontal hard tube is connected with one end of a three-way joint; one end of a second horizontal hard tube is connected with a second tube joint, and the other end of the second horizontal hard tube is connected with one end of a two-way elbow; the two ends of a second vertical hard tube are correspondingly connected with one end of the three-way joint and the other end of the two-way elbow; one end of a first vertical hard tube is connected with the other end of the three-wayjoint, and a first piston rod and a second piston rod of the drilling mechanism are connected with a supporting plate; and a drill bit is coaxially arranged on a drill bit support, and a drilling motor and the drill bit support are coaxially connected. The glass tube clamping and drilling device has the advantages that the clamping stability is good, a glass tube is effectively prevented from being broken when clamped, and drilling machining of the glass tube is facilitated.

Owner:ZHEJIANG ZHUOYI TEXTILE

A glass tube clamping drilling device

ActiveCN108214939BAchieve clampingEasy to holdWorking accessoriesStone-like material working toolsEngineeringAtmospheric pressure

Owner:ZHEJIANG ZHUOYI TEXTILE

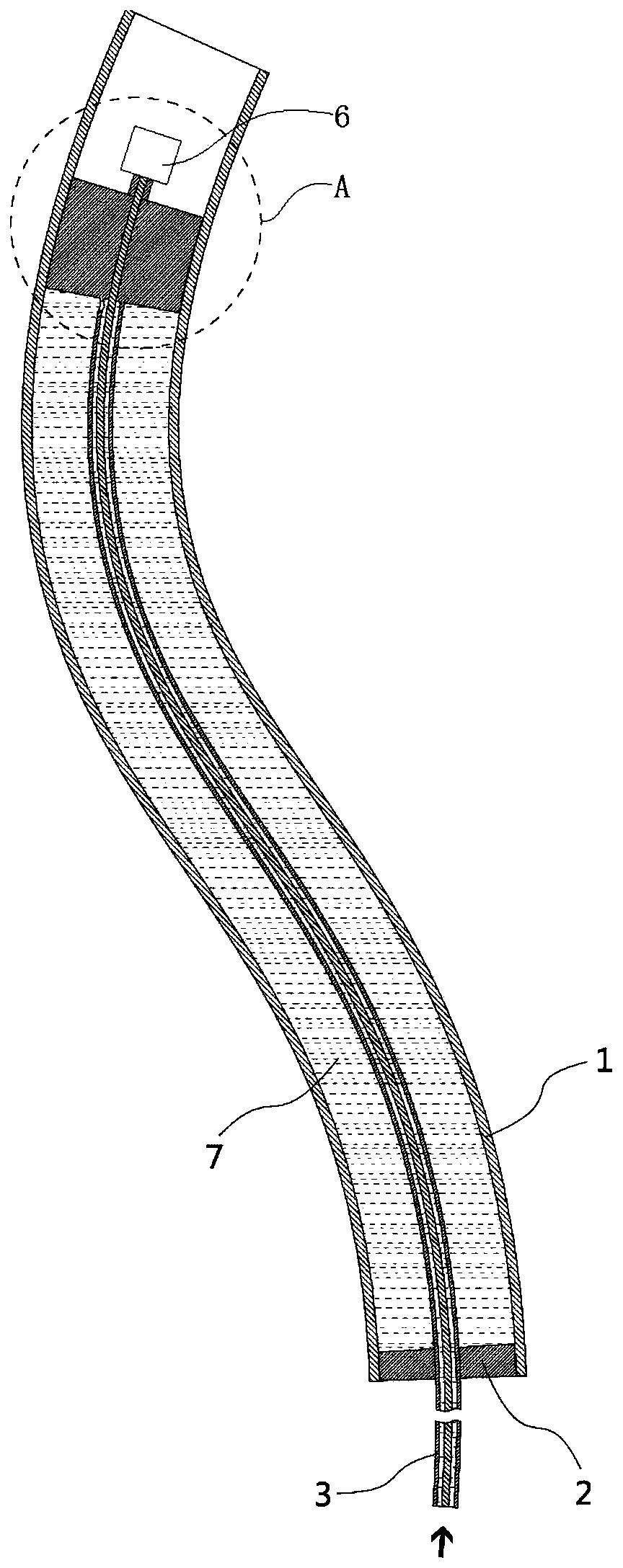

In-pipeline working body transporting and positioning device, transporting method and positioning method

The invention discloses an in-pipeline working body transporting and positioning device, a transporting method and a positioning method. The in-pipeline working body transporting and positioning device comprises a first rubber stopper, a flexible pipe and a second rubber stopper. One end of the flexible pipe penetrates through the first rubber stopper and the second rubber stopper to be connectedwith a working body, and the other end of the flexible pipe is connected with a hydraulic pump. The outer wall of the part, between the first rubber stopper and the second rubber stopper, of the flexible pipe is provided with a pipe wall hole. A device for pipeline machining or overhauling can be fed into a pipeline. The working body can be successfully transported into the pipeline, drilling machining, overhauling, finishing and the like can be carried out in the pipeline, and the in-pipeline working body transporting and positioning device, the transporting method and the positioning methodare suitable for various types of straight pipes and elbow pipes.

Owner:XIAN UNIV OF TECH

Machining equipment for equipment part production

The invention relates to the field of part machining, in particular to machining equipment for equipment part production, which comprises a workbench, a clamp, a lifting assembly, a drill bit, an overturning assembly and an adjusting assembly, the upper table surface of the workbench is horizontal and is provided with an overturning table, and the machining equipment further comprises the lifting assembly, the drill bit, the overturning assembly and the adjusting assembly. The lifting assembly is used for driving a drill bit to ascend and descend, the overturning assembly is matched with the lifting assembly and used for driving the overturning assembly to drive the overturning table to be overturned by 90 degrees from the horizontal state to the vertical state in the ascending process, and the adjusting assembly is matched with the lifting assembly. After the workpiece is installed on the overturning table, a drill bit descends for the first time to drill one side face of the workpiece, the overturning table is driven to overturn in the ascending process, the other side face of the workpiece corresponds to the drill bit, and then the drill bit descends for the second time to drill the other side face of the workpiece. And then drilling machining of different side faces of the workpiece can be achieved through a single-shaft drilling machine.

Owner:佛山市景丰号机械配件有限公司

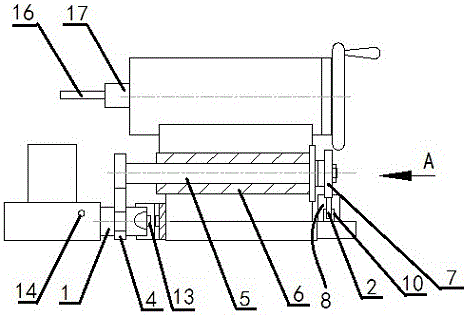

Pedal Feeding Drilling Machine

ActiveCN104690779BHeight adjustableAvoid accumulationStationary drilling machinesEngineeringDrilling machines

The invention provides a foot-operated feeding drilling machine, which comprises a rack, a foot-operated feeding device and a shifter for adjusting the position of an electric drill. The foot-operated feeding device is arranged on the rack, and the shifter is arranged at the discharge end of the foot-operated feeding device. The foot-operated feeding device consists of a feeding table, a chain, a gear and a pedal plate. The shifter includes the electric drill, a base plate for fixing the electric drill, a vertical rail for vertical movement of the base plate, a horizontal rail for lateral movement of the vertical rail and a bearer for fixing the horizontal rail. The foot-operated feeding drilling machine realizes accurate and convenient feeding through the foot-operated feeding device, and achieves horizontal or vertical adjustment of the electric drill through the shifter during drilling at different positions, thus meeting production requirements.

Owner:朱玉静

Drilling clamp for reverse gear shaft

PendingCN113211121APrecise positioningEasy to operatePositioning apparatusDrill jigsEngineeringStructural engineering

The invention relates to the field of clamps, in particular to a drilling clamp for a reverse gear shaft. The drilling clamp for the reverse gear shaft comprises a clamp base and a fixing device, the fixing device comprises clamping devices distributed on the left side and the right side of the upper part of the clamp base and pressing devices distributed on the front side and the rear side of the upper part of the clamp base, and the right sides of the clamping devices are adjustable. During working, the reverse gear shaft is placed between a fixing block a and a fixing block b, a clamping bolt is adjusted to enable the fixing block a and the fixing block b to clamp the reverse gear shaft, pressing plates and the pressing springs are adjusted to implement pressing action, the reverse gear shaft is accurately and firmly fixed to the drilling clamp, and a bushing is connected to a quick-change drill bushing in a sleeving mode, which as a whole is mounted on a drill plate, so that a drill bit can accurately enter to perform drilling action.

Owner:青岛国邦智能科技有限公司

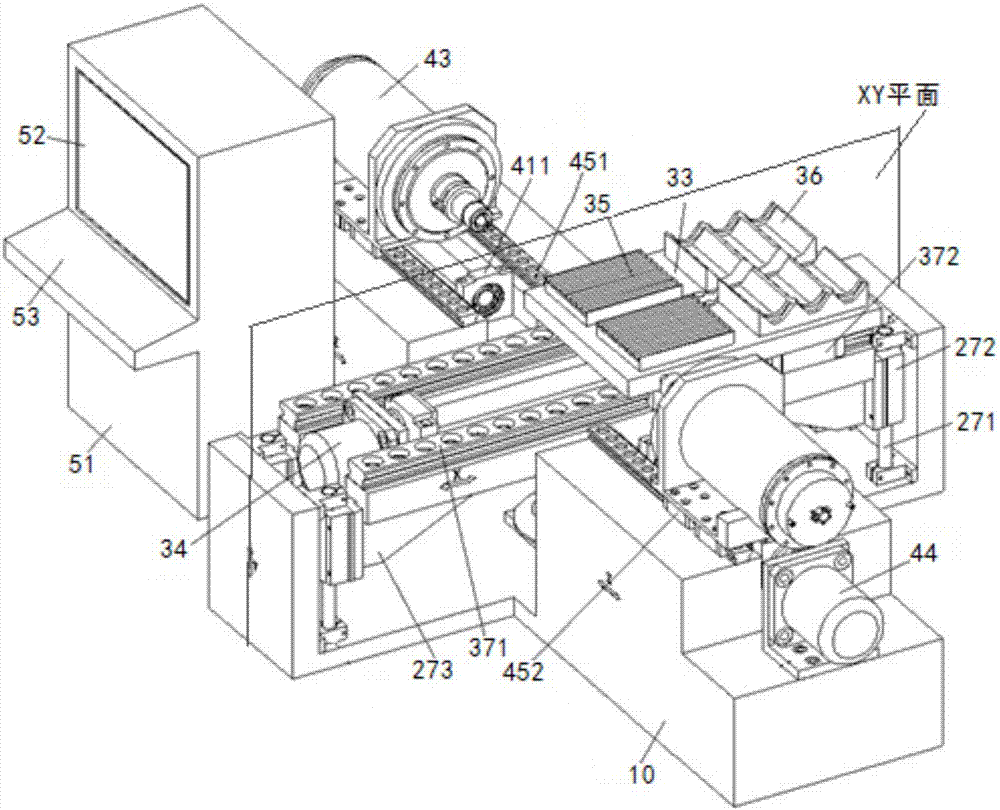

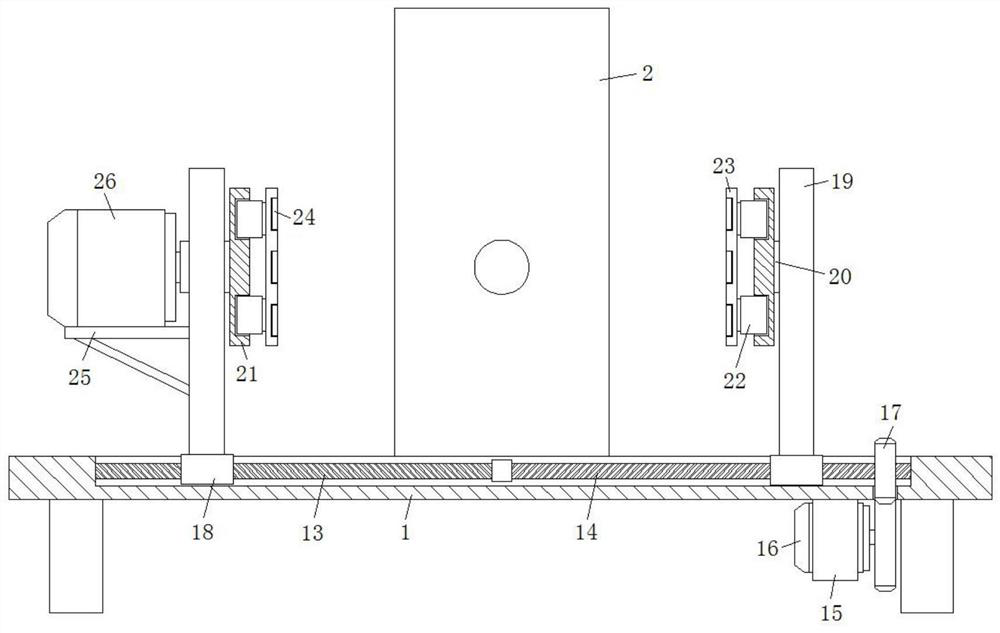

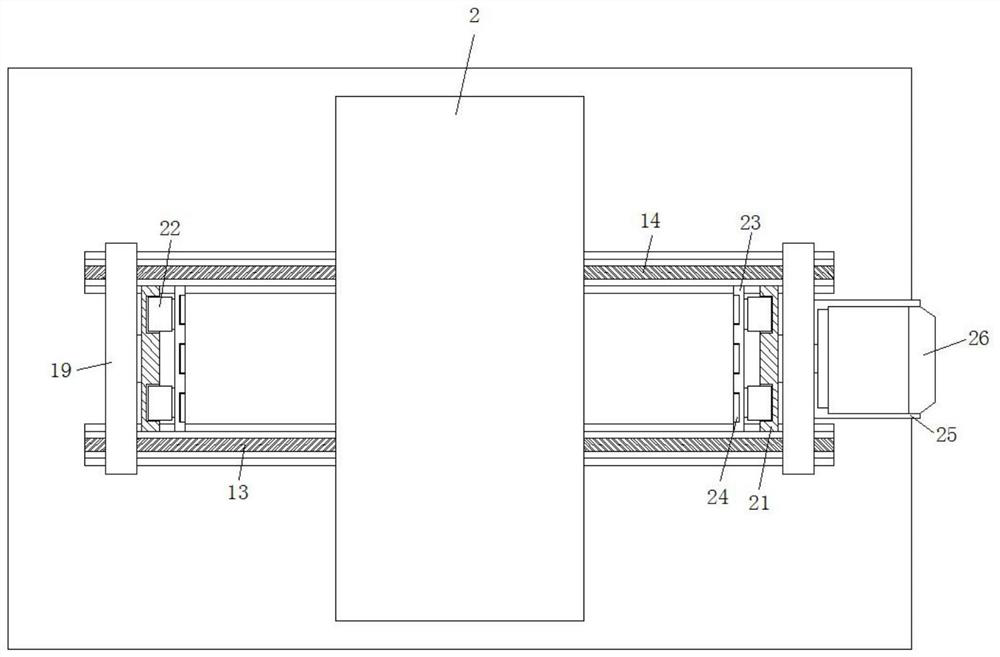

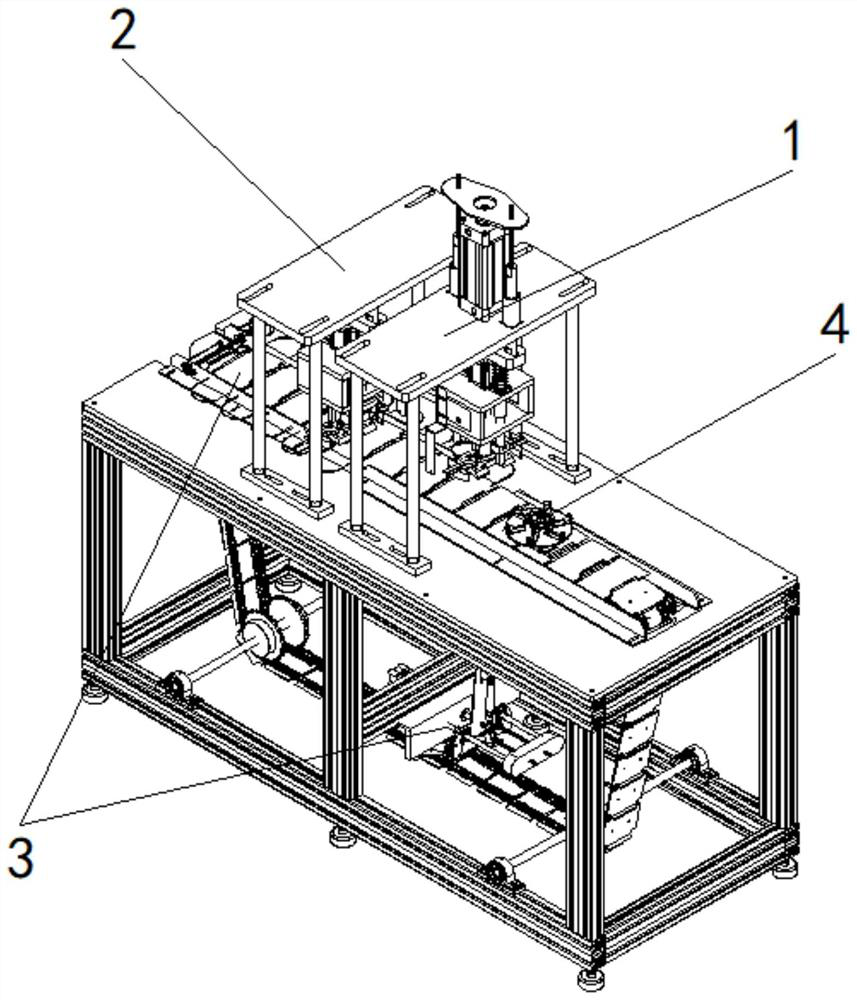

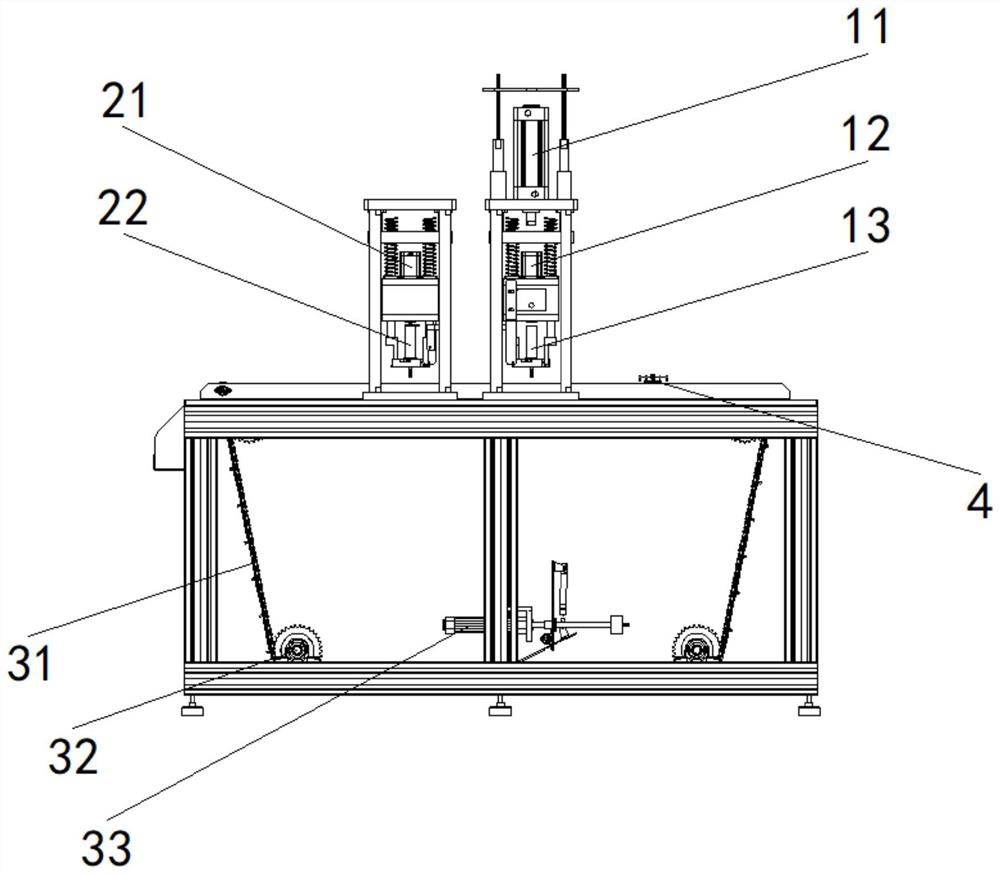

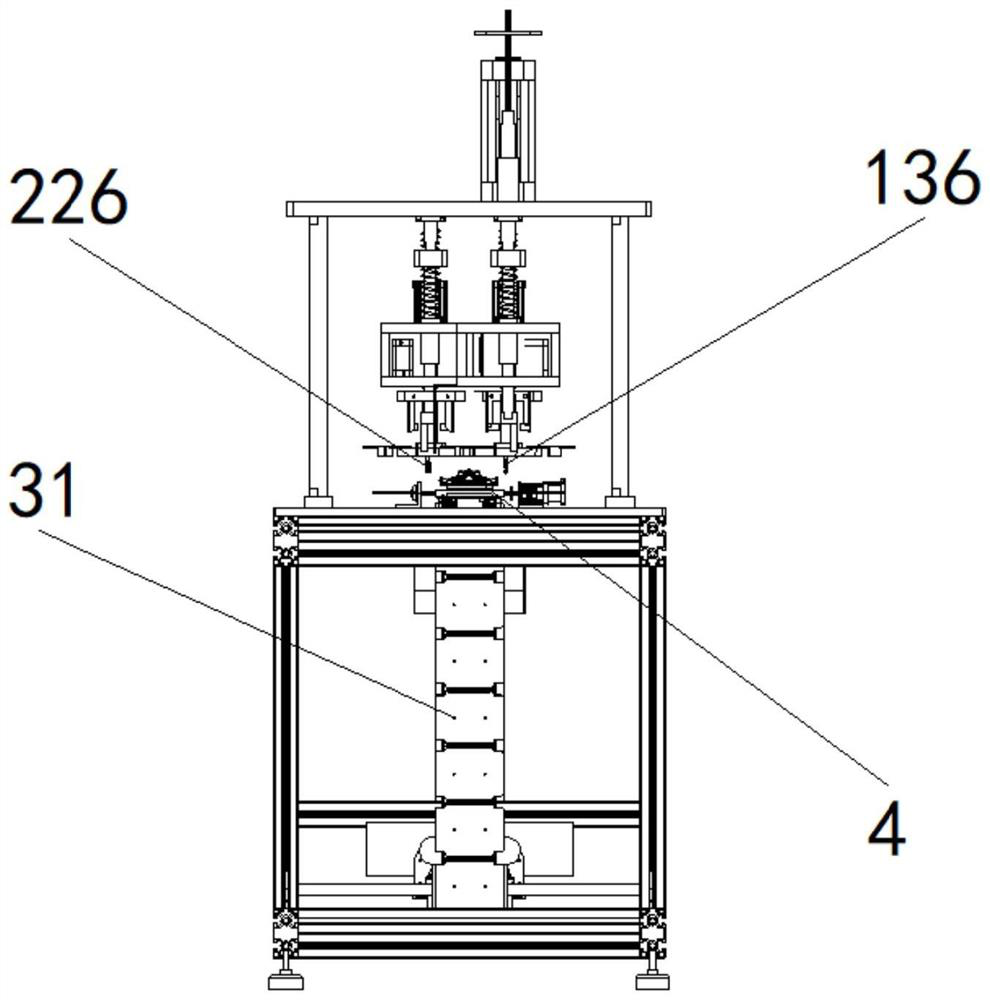

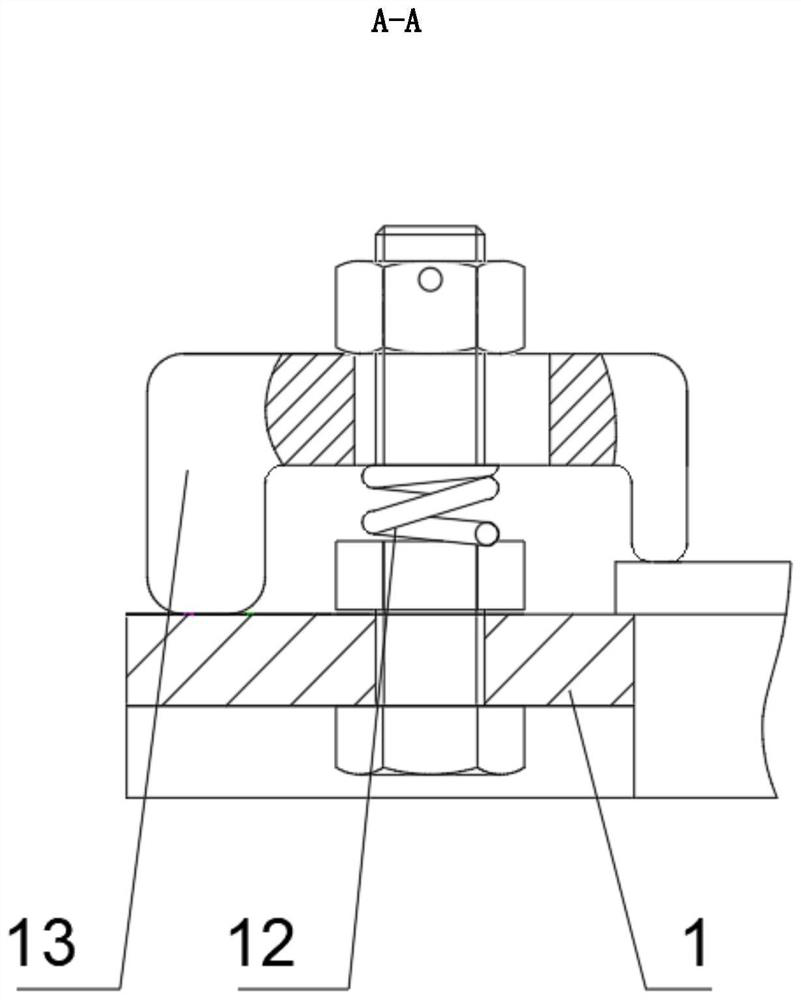

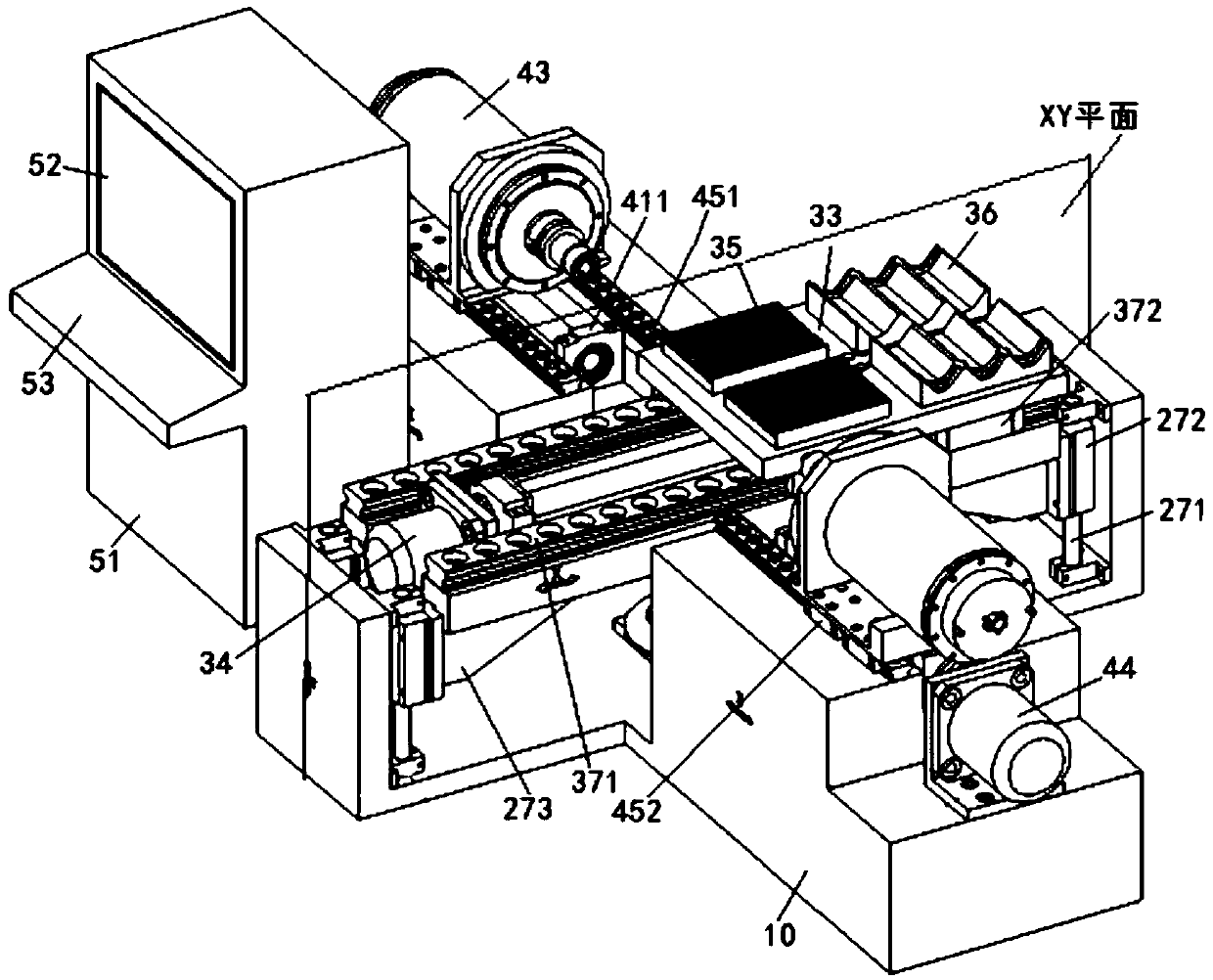

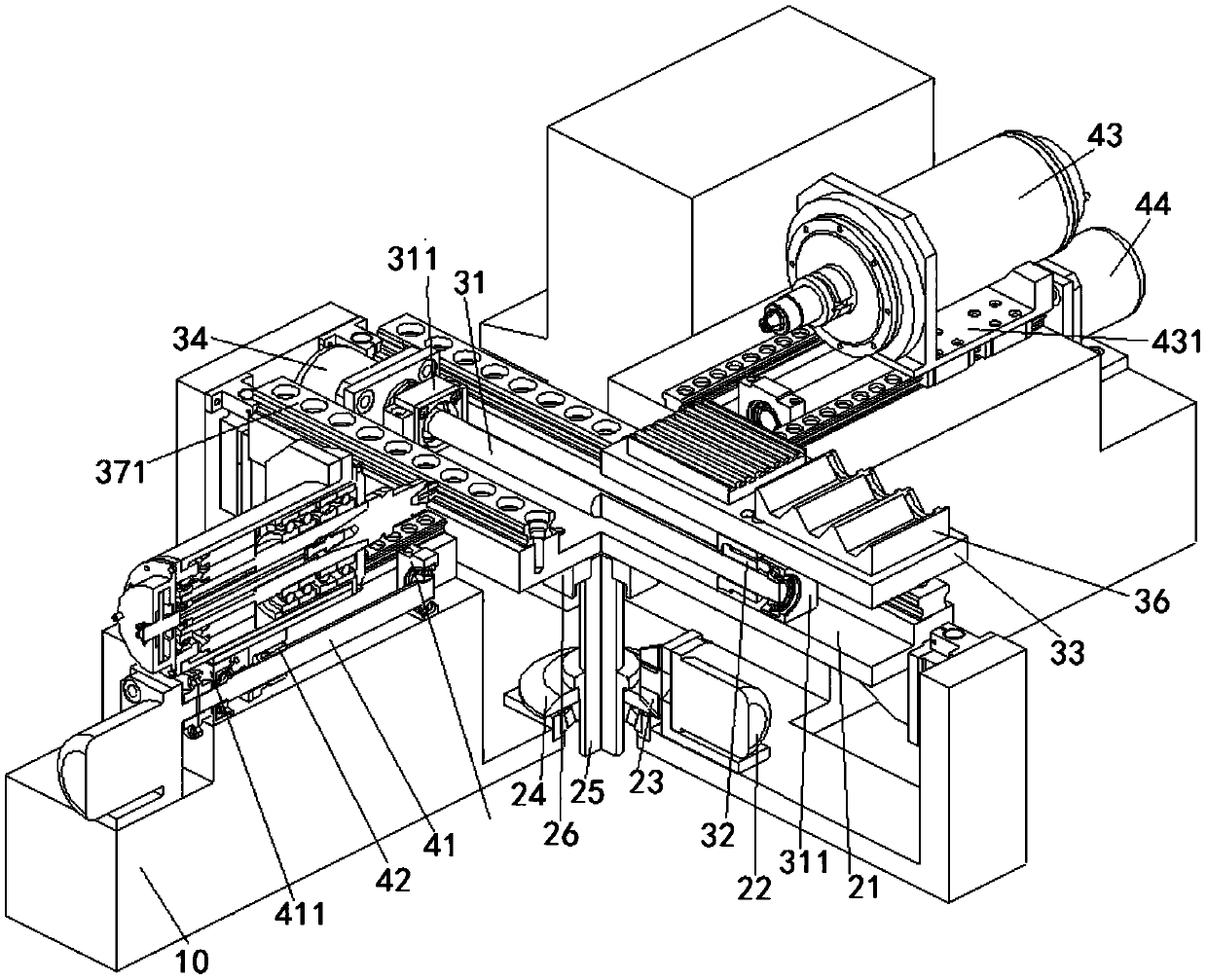

Numerical control machine tool automatic wiring device

PendingCN110052843ARealize drillingFeeding apparatusOther manufacturing equipments/toolsNumerical controlElectric machine

The invention discloses a numerical control machine tool automatic wiring device comprising a machine body (1), a tool rest module (2) arranged on the machine body (1), a clamp module (3) connected with the tool rest module (2), a gear box (11) arranged in the machine body (1), and a hole drilling module (4) externally connected to the gear box (11). According to the numerical control machine toolautomatic wiring device, a pipe fitting to be subjected to wiring is clamped on the clamp module, a servo motor in the tool rest module drives tool bits to move, and an enameled wire is driven by thetool bits to conduct reciprocating automatic wiring on the inner wall of the pipe fitting; and meanwhile the hole drilling module can conduct hole drilling machining on the pipe fitting. Due to the adoption of the numerical control machine tool automatic wiring device, double-layer or multi-layer wiring can be conducted on the inner wall of the pipe fitting, and hole drilling machining can be further conducted on the pipe fitting synchronously through the hole drilling module.

Owner:海力士五金机电(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com