A Method for Machining Axial Hole of Thin-walled Cone

A technology of axial hole and hole processing, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of out-of-round processed holes, unstable workpiece positioning, and hole-to-hole deformation, and achieve improved Work efficiency, high promotional value, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

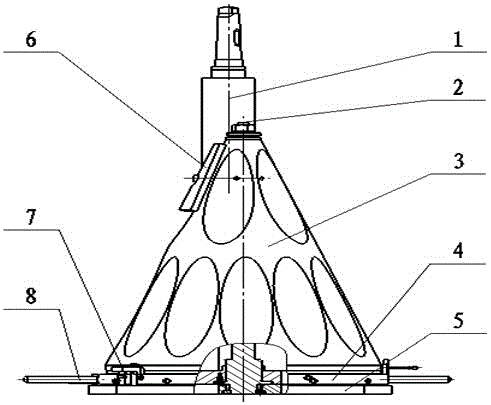

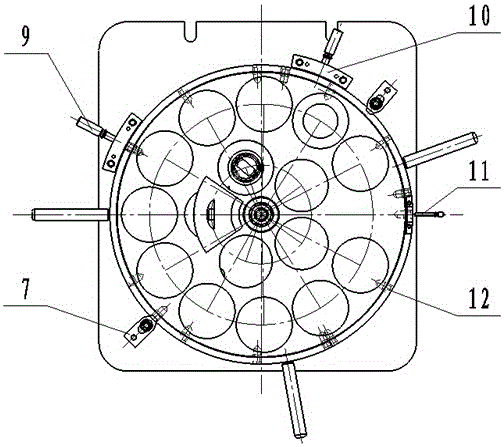

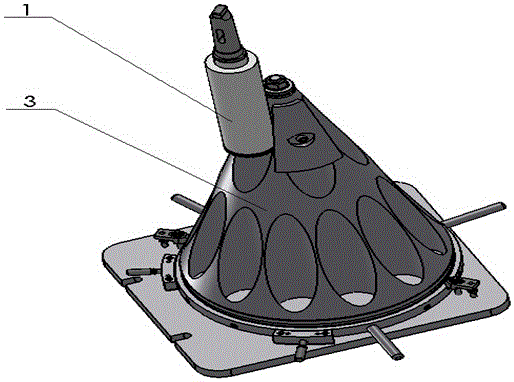

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] A method for machining the axial hole of a thin-walled cone, comprising the following steps:

[0023] a. Making auxiliary fixtures: the specific structure of the fixtures is as follows, including a base 5, a turntable 4, a rotating central axis 2, and a conical positioning body 3. The conical positioning body 3 matches the thin-walled cone 14 to be processed, The thin-walled cone 14 can be set on the conical positioning body 3 and the two are concentric and coaxial; the conical positioning body 3 is processed with a through hole at the position of the central axis, and is processed in the axial direction around the through hole of the conical positioning body 3 There are limited holes, and the circles and quantity of the limited holes are consistent with the circles and quantity of the holes to be processed on the thin-walled cone 14. The limited holes are formed du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com