High-efficiency mesh drilling new method

A new method and drilling technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the difficulty of tool cooling, the chip blocking the drill chip flute, the easy skew of the drilling axis, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

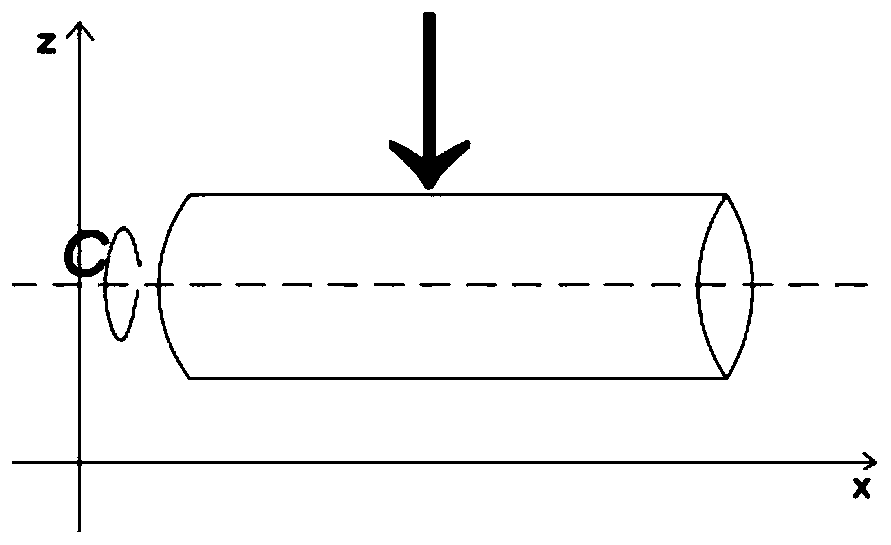

[0069] like Figure 1-3 As shown, this embodiment provides a new method for high-efficiency mesh drilling, the workpiece to be processed is cylindrical, and the specific steps include:

[0070] S1. The drill bit moves along the x-axis direction, the workpiece rotates around the central axis C-axis, the drill bit can be aligned with any hole in the same row on the workpiece; the drill bit moves along the z-axis, the workpiece can be drilled, or the drill bit can be withdrawn.

[0071] S2. Drill positioning hole: Drilling the positioning hole is to use a thinner drill bit to drill a hole with a depth of about 2mm at the position to be drilled on the surface of the unprocessed workpiece. The purpose of the positioning hole is to guide the main drill bit into the drilling position.

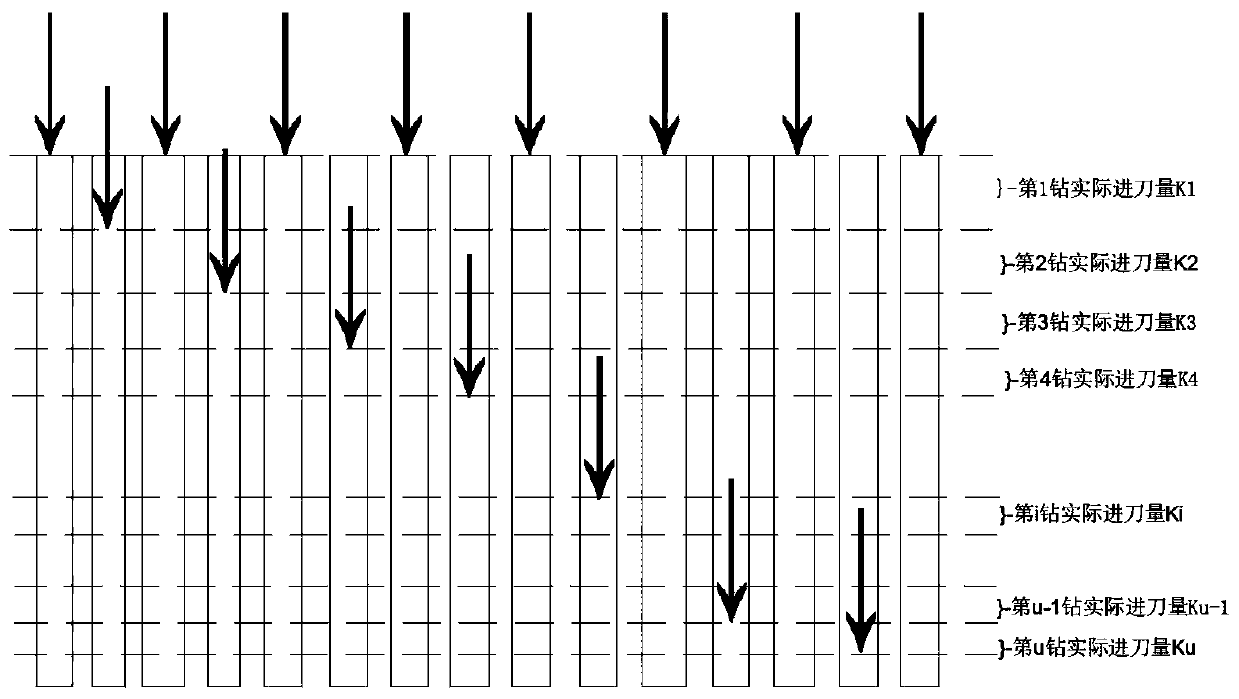

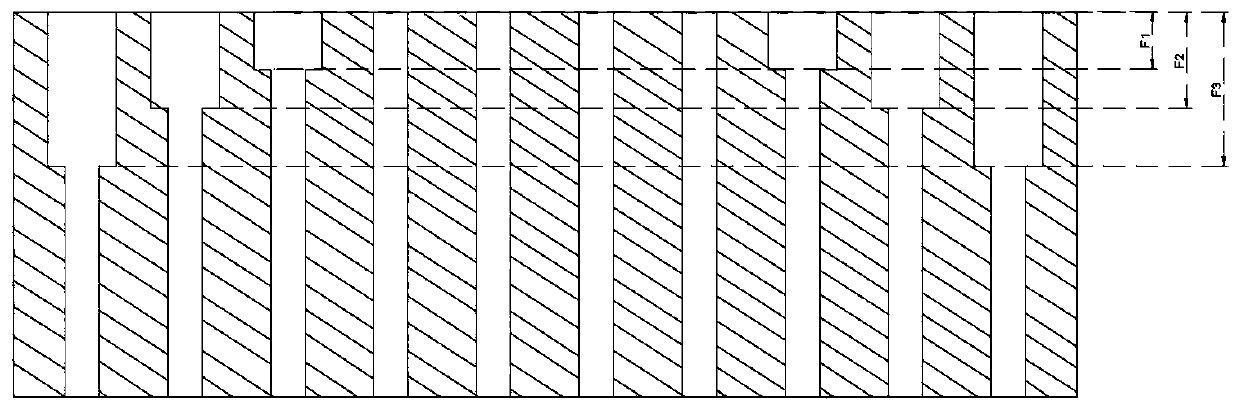

[0072] S3. Drilling the main hole: refers to the depth of the hole that needs to be drilled at each positioning hole position on the cylindrical workpiece by selecting a drill bit that meets the hole di...

Embodiment 2

[0110] The present embodiment provides a kind of algorithm step that runs in the machine when drilling the positioning hole as follows:

[0111] (1) The user presses the cycle start button;

[0112] (2) Move the x-axis, the C rotation axis and the z-axis, so that the drill bit starts to row the surface position of the starting hole;

[0113] (3) Prompt the user to adjust the drill fixture so that the user can accurately adjust the position of the drill after installing a new drill;

[0114] (4) The user presses the cycle start button, and the drill starts to rotate;

[0115] (5) The user confirms that the drill speed is normal, presses the cycle start button to start processing;

[0116] (6) If the number of initial rows is less than the number of terminated rows, or the number of initial rows is equal to the number of terminated rows and the number of initial holes is less than or equal to the number of terminated holes, then continue to step 7; otherwise, go to step 12; ...

Embodiment 3

[0125] The algorithm steps that run in the machine when drilling the main hole are as follows:

[0126] (1) The user presses the cycle start button;

[0127] (2) Move the x-axis, the C rotation axis and the z-axis, so that the drill bit starts to row the surface position of the starting hole;

[0128] (3) Prompt the user to adjust the drill fixture so that the user can accurately adjust the position of the drill after installing a new drill;

[0129] (4) The user presses the cycle start button, and the drill starts to rotate;

[0130] (5) The user confirms that the drill speed is normal, and presses the cycle start button to start processing;

[0131] (6) If the number of initial rows is less than the number of terminated rows, or the number of initial rows is equal to the number of terminated rows and the number of initial holes is less than or equal to the number of terminated holes, then continue to step 7; otherwise, go to step 14;

[0132] (7) Determine the z coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com