Machining equipment for equipment part production

A technology for processing equipment and parts, which is applied in the field of processing equipment for the production of equipment parts, and can solve problems such as manual flipping of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

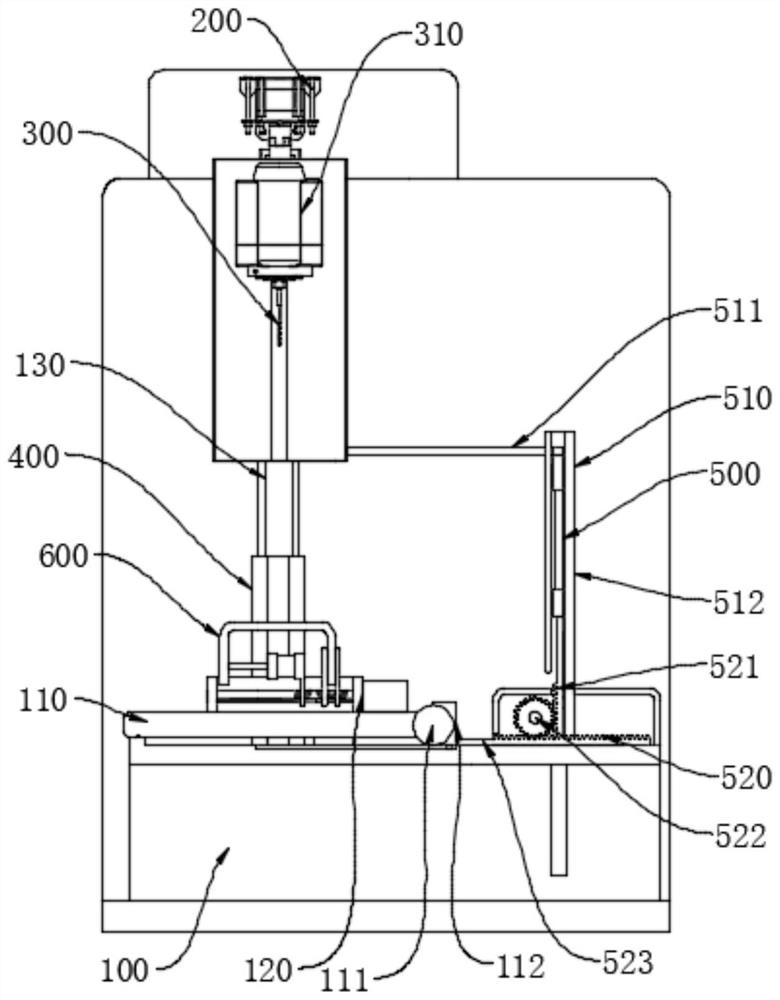

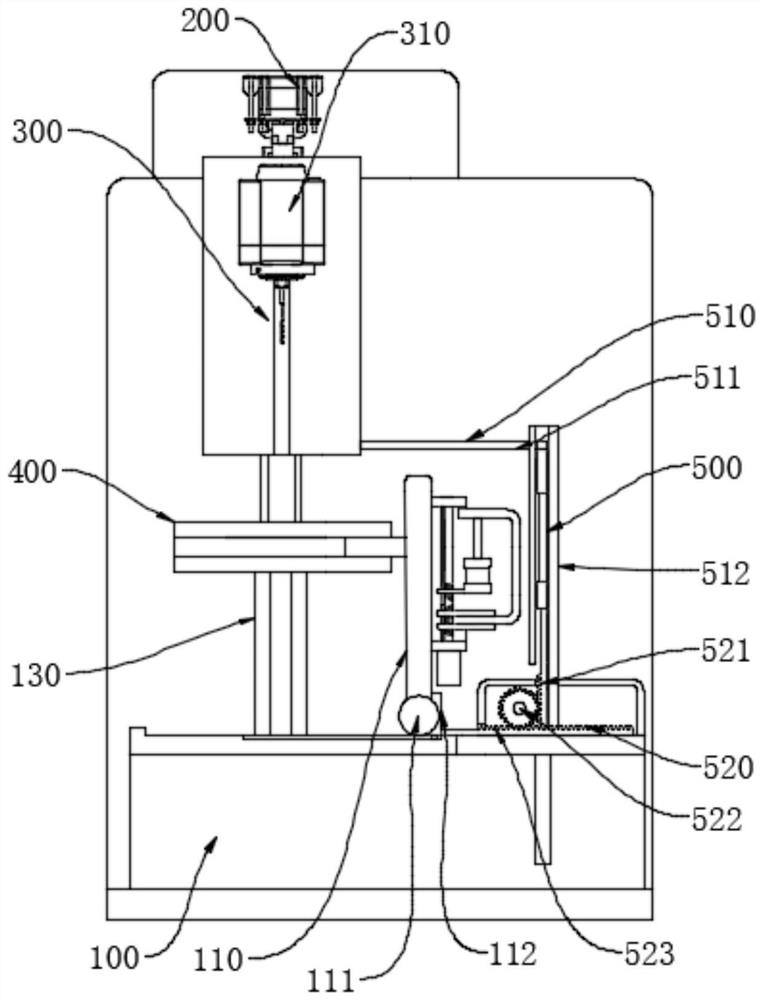

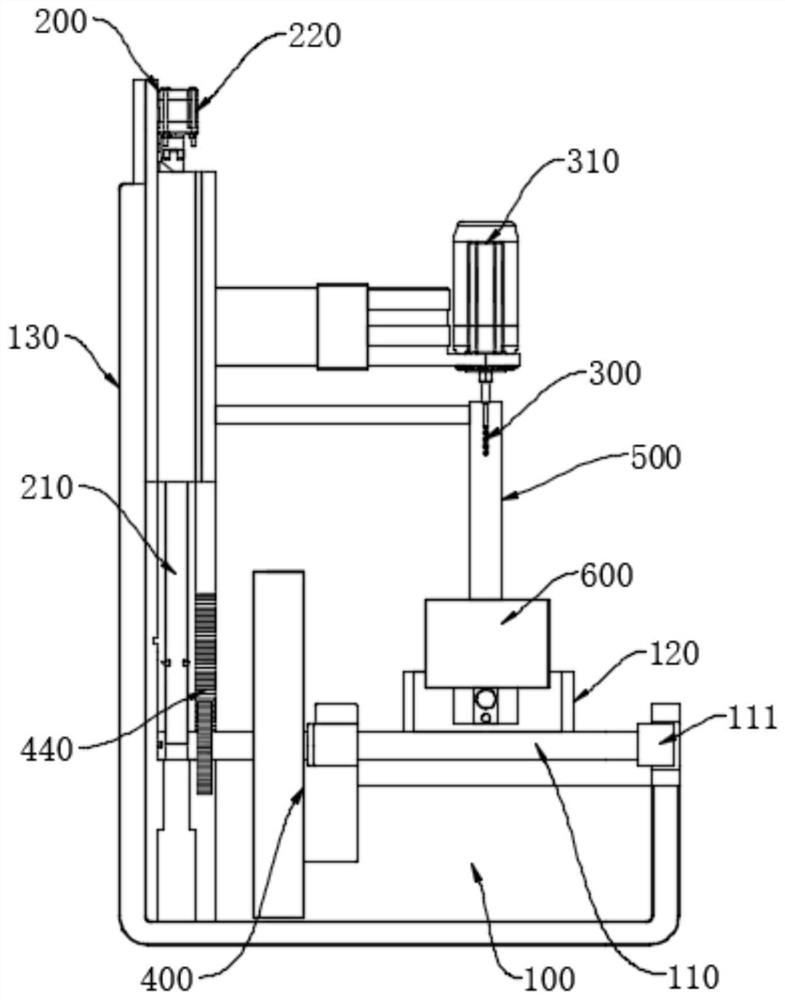

[0036] like Figure 1-Figure 11 As shown, a processing equipment for the production of equipment parts includes a worktable 100 and a fixture 120, the upper table surface of the worktable 100 is horizontal, and a turning table 110 is installed, and the fixture 120 clamps the workpiece 600 to the upper table surface of the turning table 110, The workpiece 600 has a U-shaped structure,

[0037] It also includes a lifting assembly 200, a drill bit 300, a turning assembly 400 and an adjusting assembly 500. The drilling head 300 is arranged above the worktable 100 and corresponds to the position of the workpiece 600. The lifting assembly 200 is used to drive the drilling head 300 to rise and fall, and the turning assembly 400 is connected to the lifting assembly. 200 is matched to drive the turning assembly 400 to drive the turning table 110 to turn from the horizontal state to the vertical state by ninety degrees during the ascending process. The turning table 110 moves horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com