Drilling clamp for reverse gear shaft

A technology for drilling jigs and gear shafts, which is applied in the direction of drilling templates, boring/drilling, drilling/drilling equipment for workpieces, etc., which can solve the problem of difficult alignment of reverse gear shafts and tools, and inability to reverse gears Shaft adjustment, affecting processing quality and other issues, to achieve the effect of reducing labor costs, convenient adjustment and fixing, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

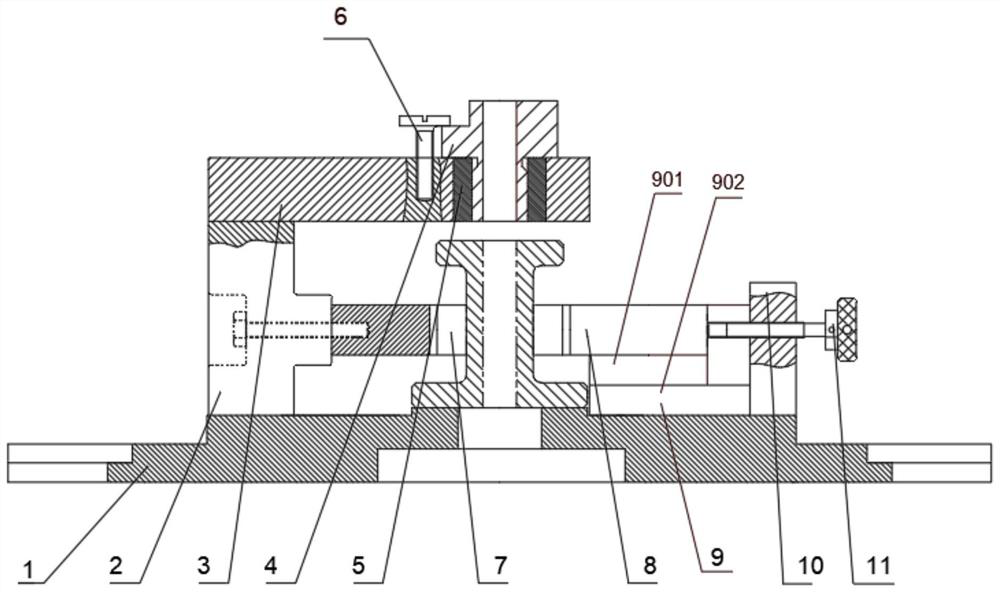

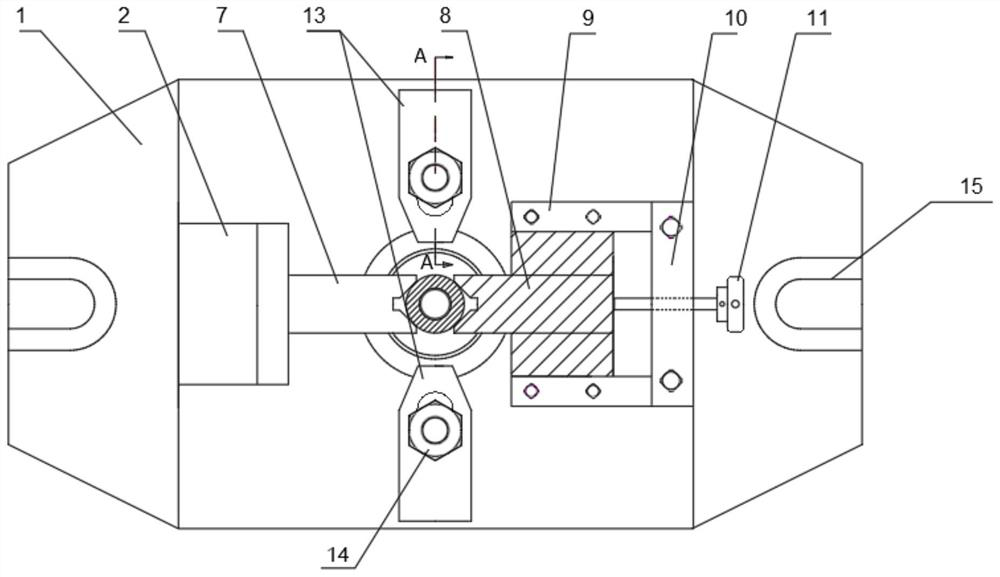

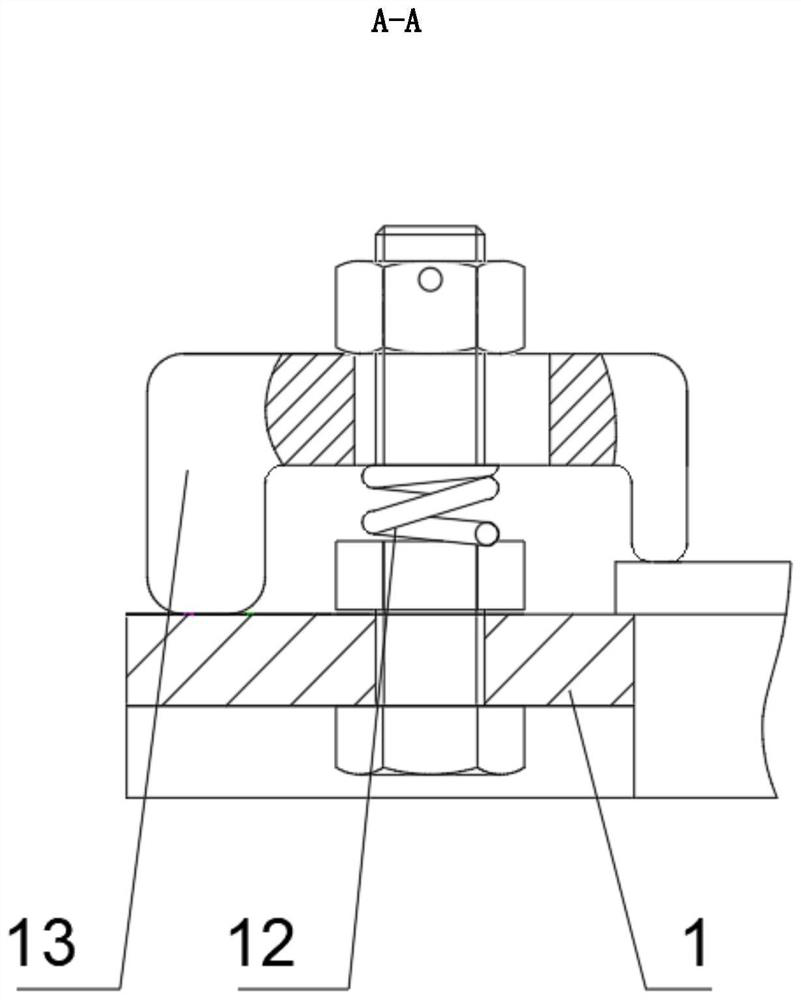

[0037] Such as Figure 1-3 As shown, the present invention provides a drilling jig for a reverse gear shaft, including a jig base (1) and a fixing device, and the fixing device includes clamping devices distributed on the left and right sides above the jig base (1) and distributed on the Clamping devices on the front and rear sides above the fixture base (1); the right side of the clamping device is adjustable.

[0038]The right side of the clamping device includes a fixed guide block (10) fixed on the right side of the clamp base (1), a slide rail guide block a (9) arranged on the left side of the fixed guide block (10), and a slide rail guide block a (9) The fixed block b (8) fixedly connected, the clamping bolt (11) installed on the fixed guide block (10) for adjusting the fixed block b (8); the slide rail guide block a (9) includes the guide block (901) and slide rail (902), the slide rail (902) is fixed on the fixture base (1), the guide block (901) is set to slide above...

Embodiment 2

[0050] Embodiment 2 On the basis of Embodiment 1, a slide rail guide block b (16) is provided at the fixed block a (7), as follows.

[0051] Such as Figure 1-3 As shown, the present invention provides a drilling jig for a reverse gear shaft, including a jig base (1) and a fixing device, and the fixing device includes clamping devices distributed on the left and right sides above the jig base (1) and distributed on Clamping devices on the front and rear sides above the fixture base (1); the right side of the clamping device is adjustable.

[0052] The right side of the clamping device includes a fixed guide block (10) fixed on the right side of the clamp base (1), a slide rail guide block a (9) arranged on the left side of the fixed guide block (10), and a slide rail guide block a (9) The fixed block b (8) fixedly connected, the clamping bolt (11) installed on the fixed guide block (10) for adjusting the fixed block b (8); the slide rail guide block a (9) includes the guide b...

Embodiment 3

[0064] Embodiment 3 On the basis of Embodiment 1, the fixed block a ( 7 ) and the fixed block b ( 8 ) are changed into U-shaped structures, and the rest of the structures are consistent with Embodiment 1.

[0065] In Embodiment 3, the fixed block a (7) and the fixed block b (8) are changed into a U-shaped structure. Although it is not as firm as a V-shaped structure, the fixed block is slightly loose during processing, but it does not affect the overall operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com