Patents

Literature

39results about How to "Realize finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

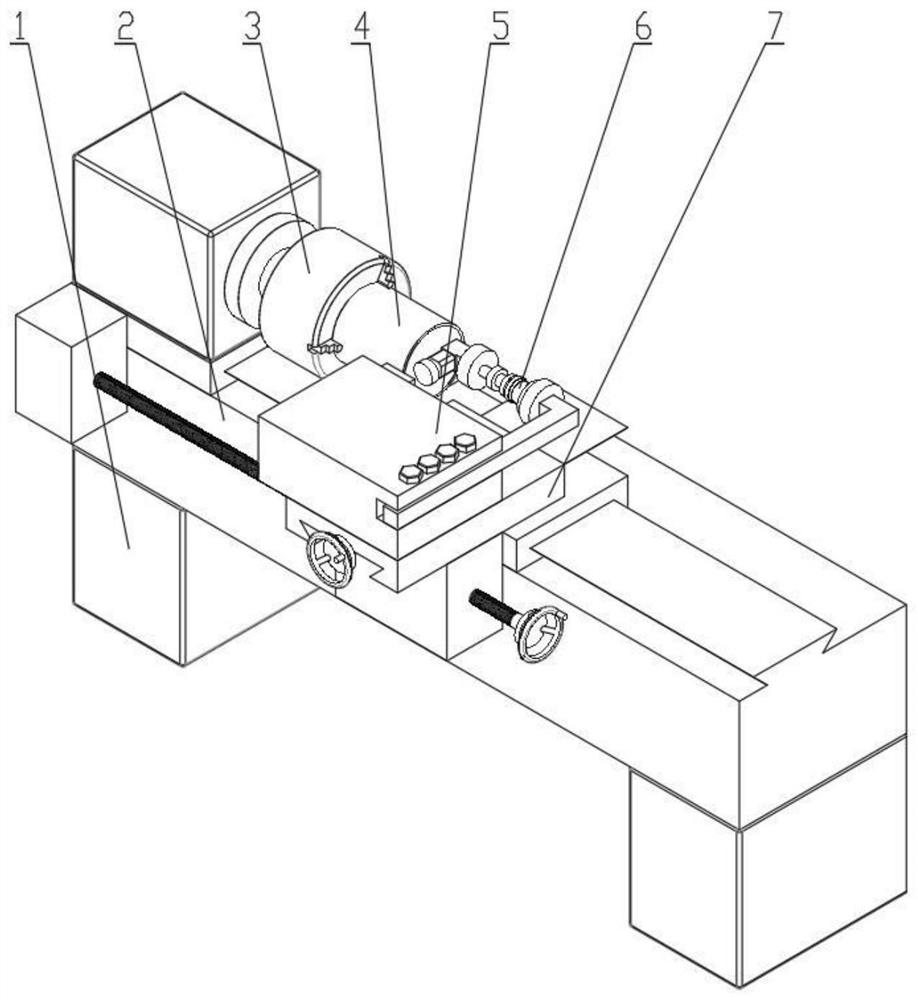

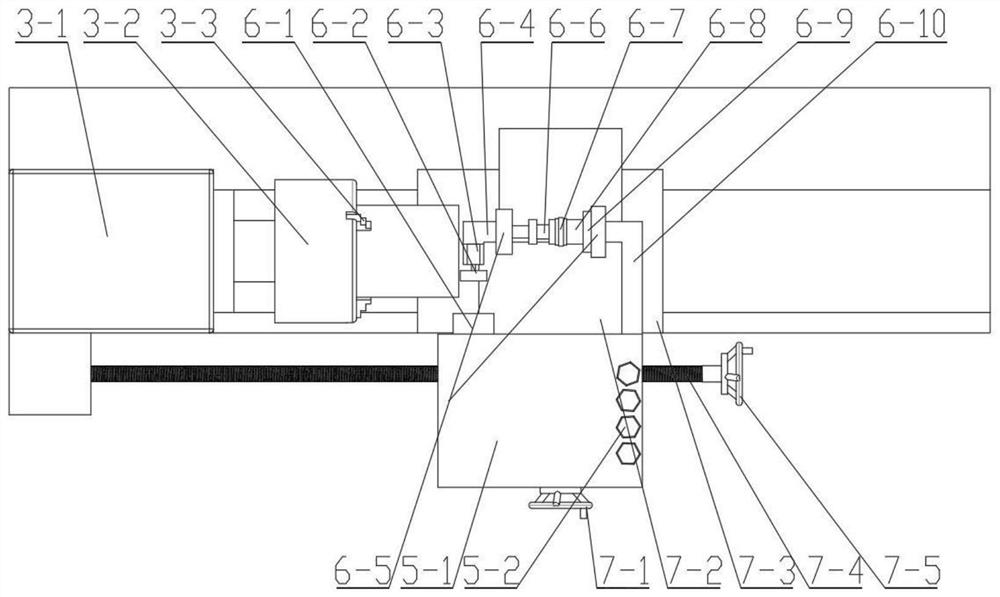

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

PendingCN108857605AHigh degree of automationImprove processing efficiencyEdge grinding machinesPolishing machinesMotor driveMachining

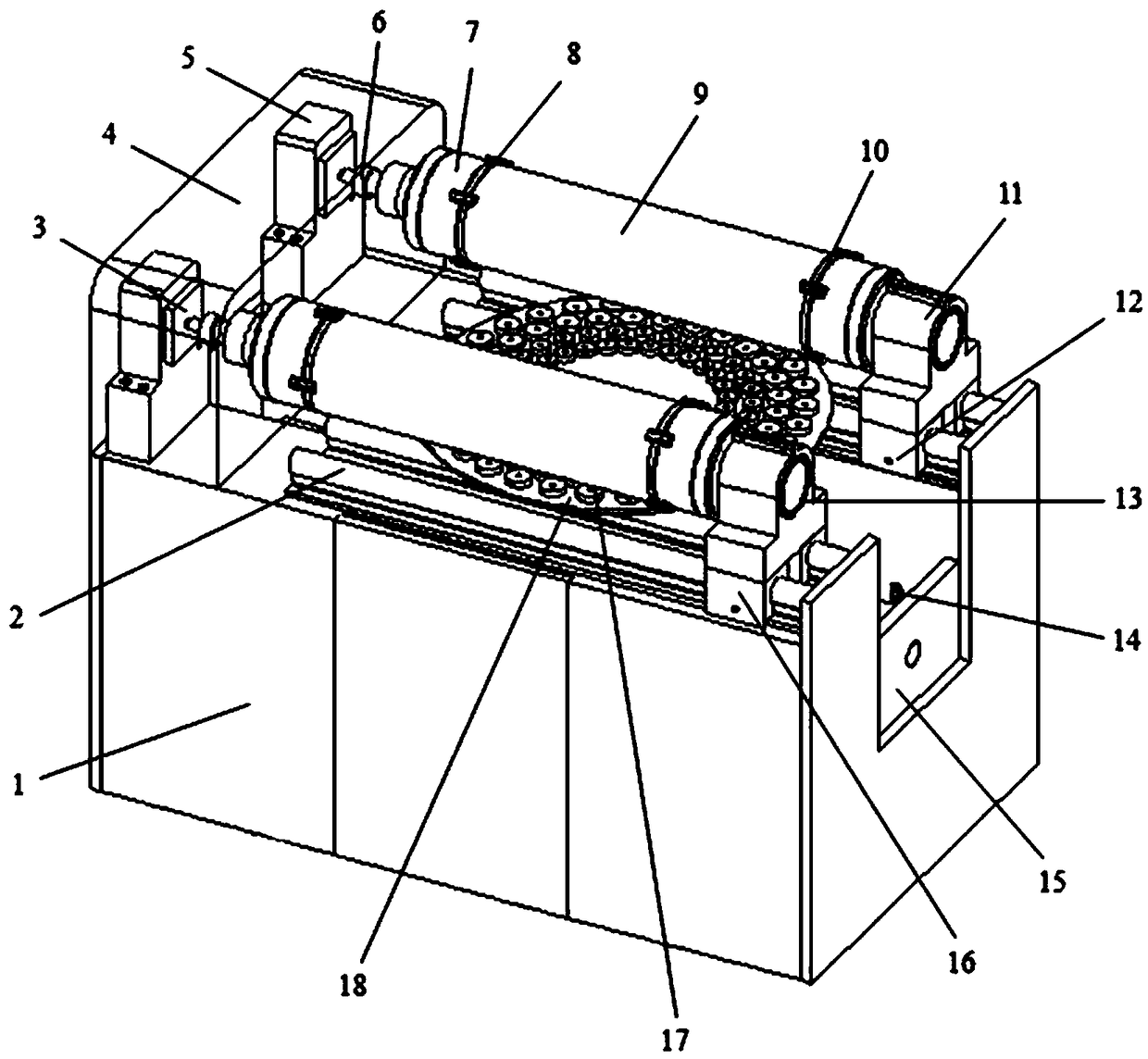

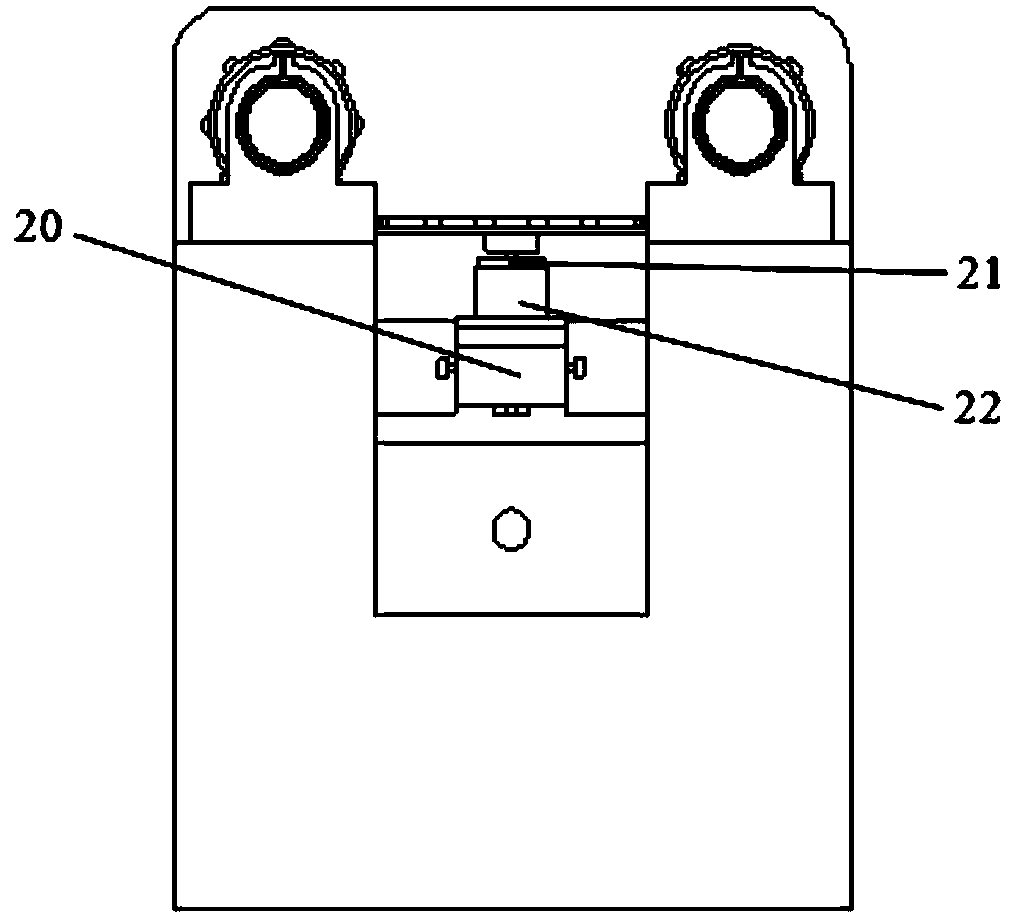

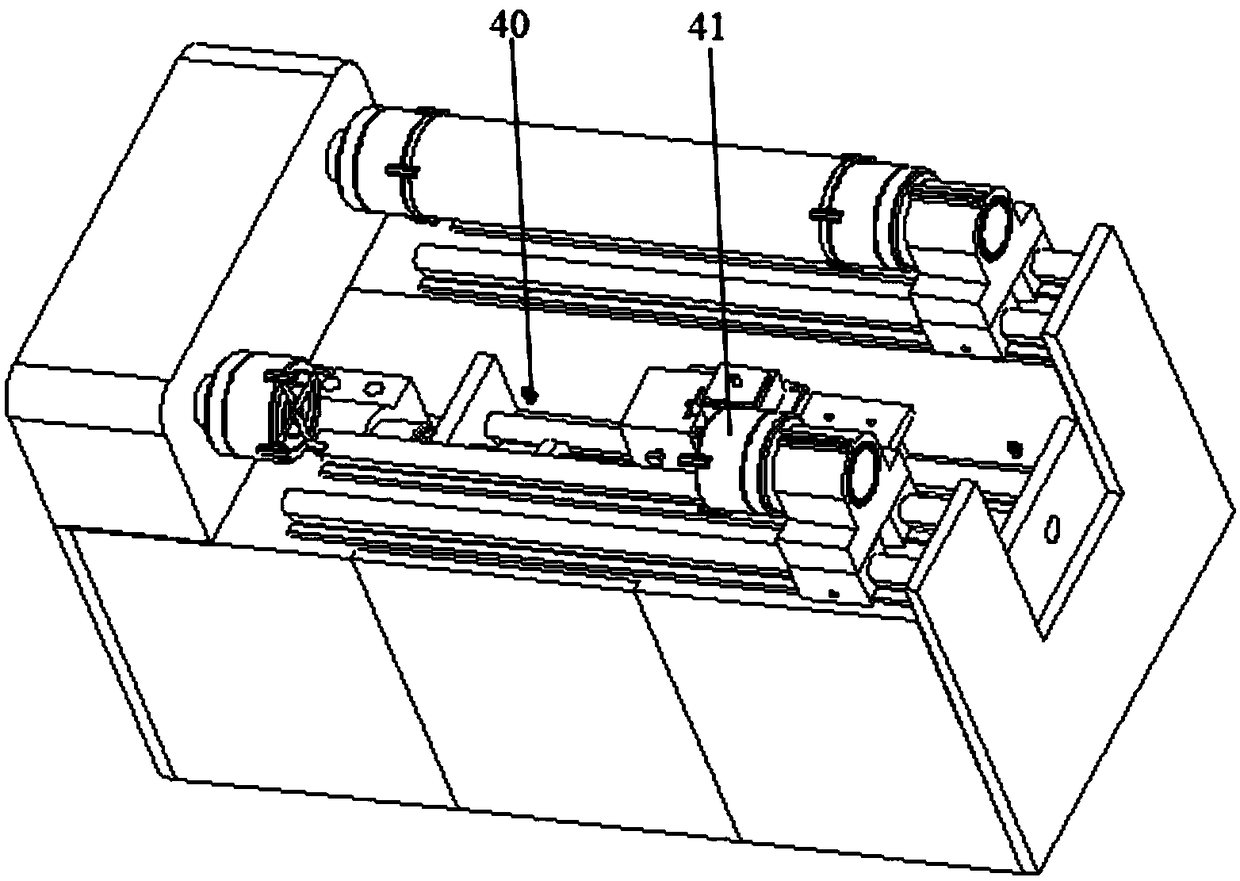

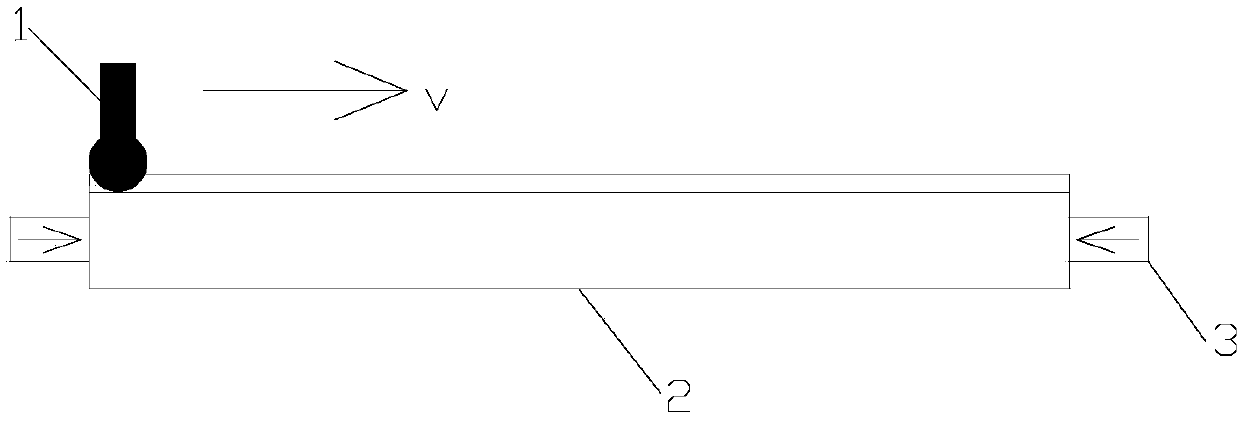

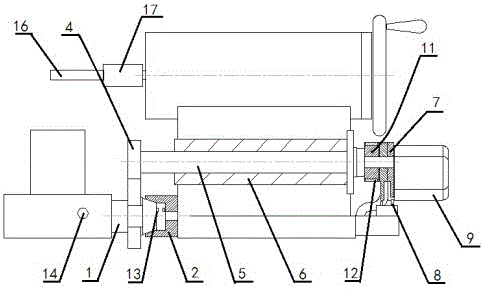

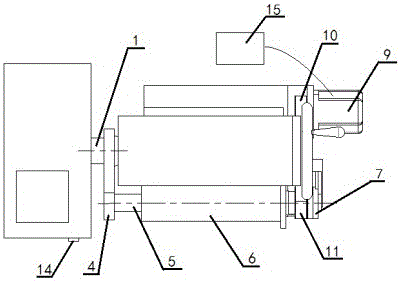

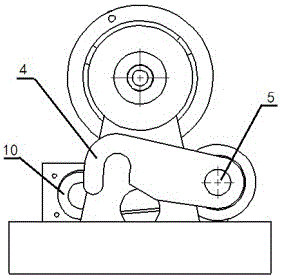

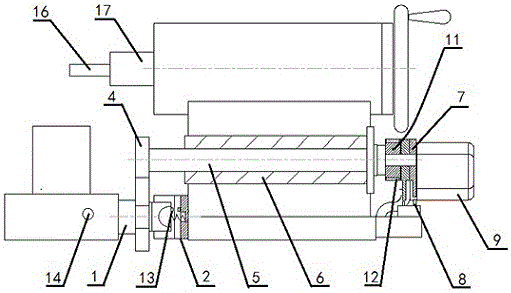

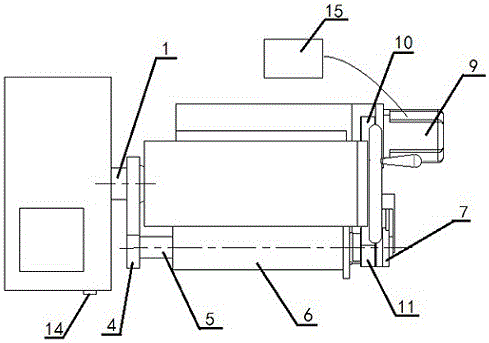

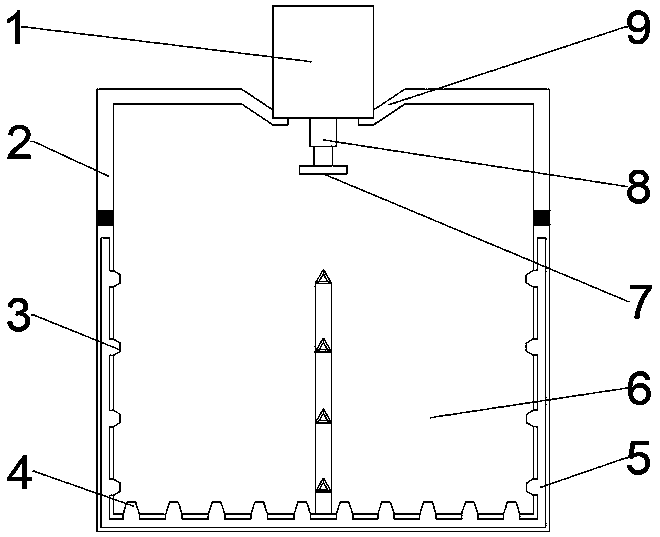

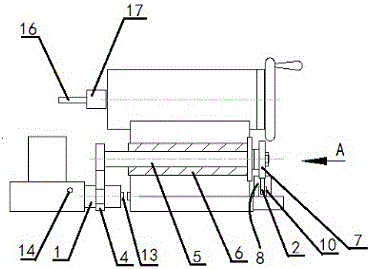

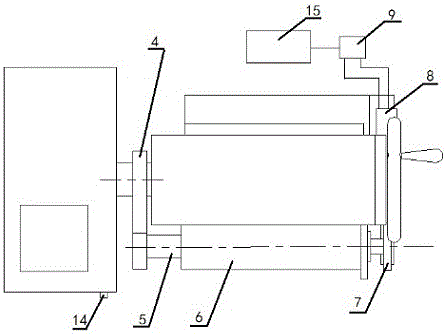

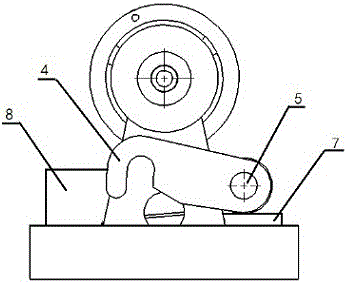

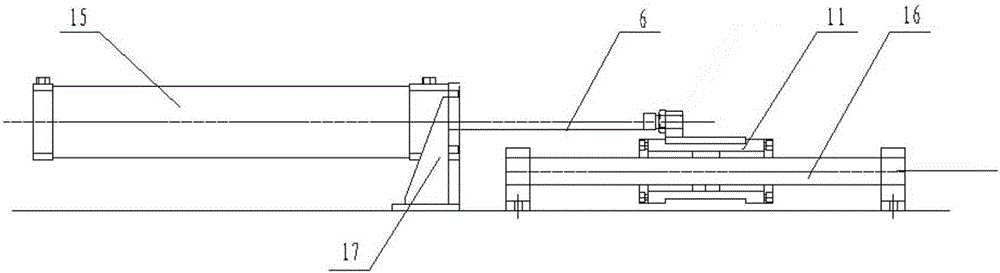

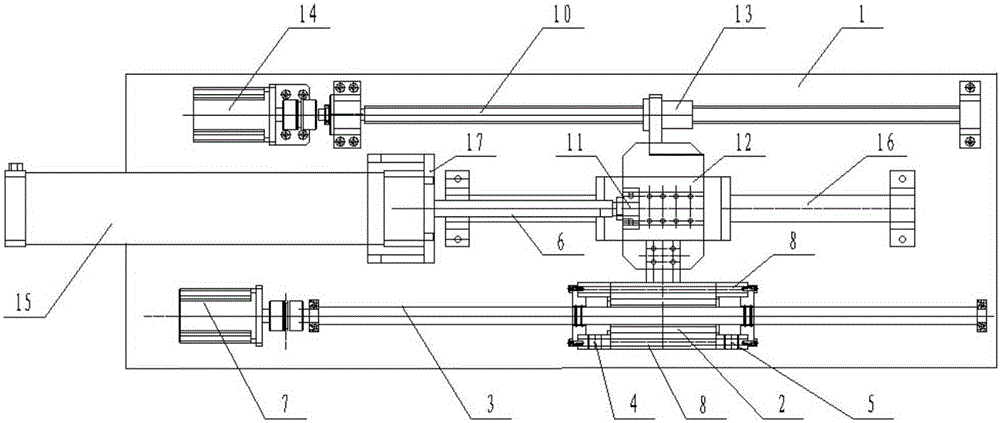

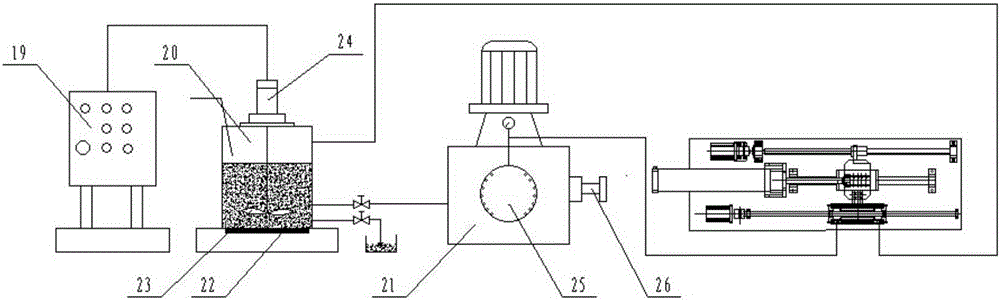

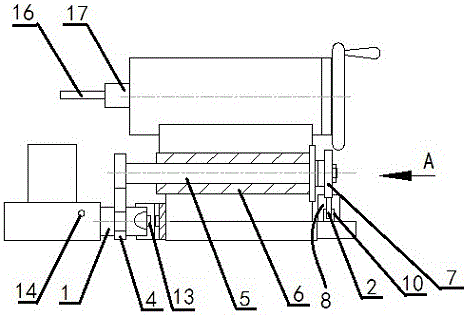

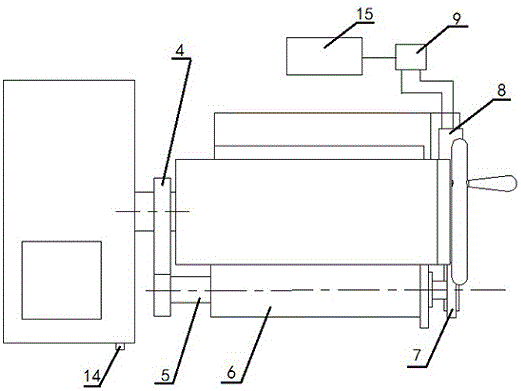

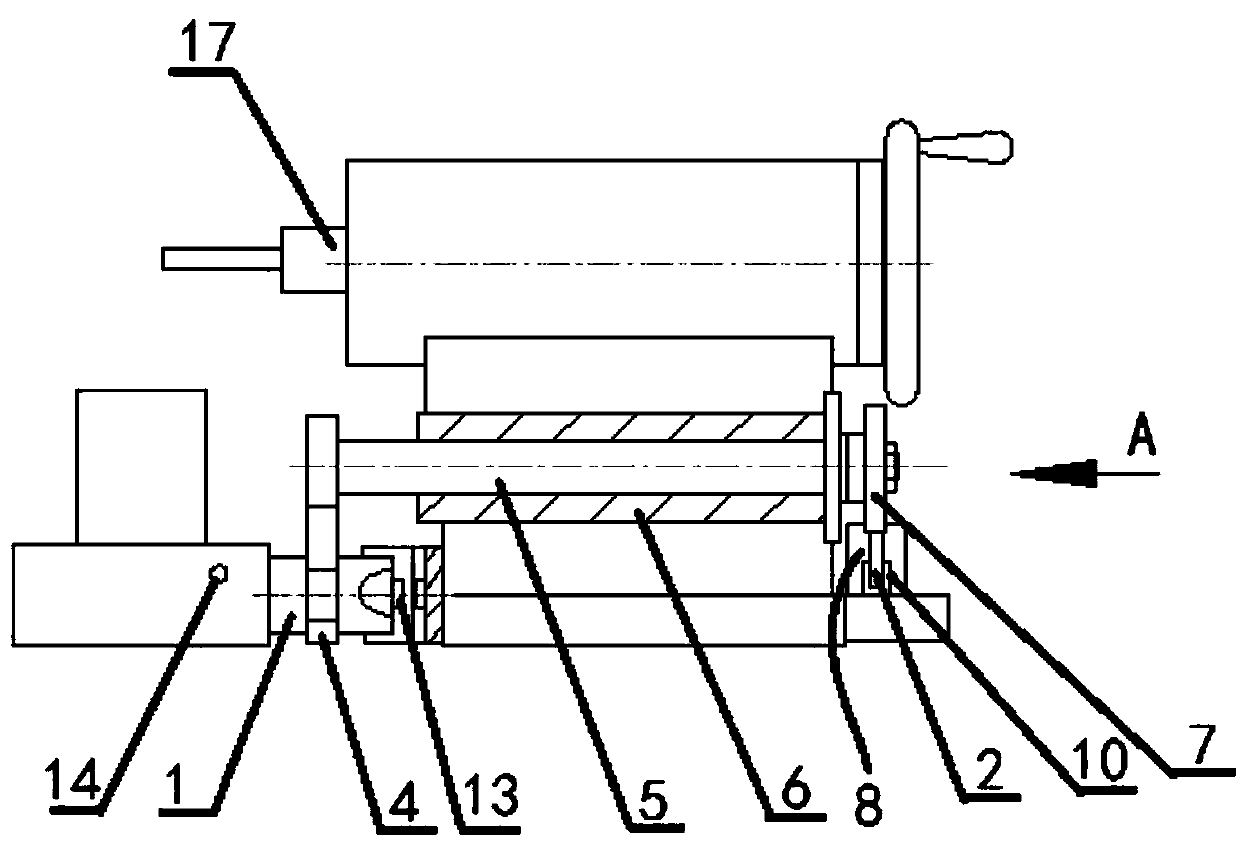

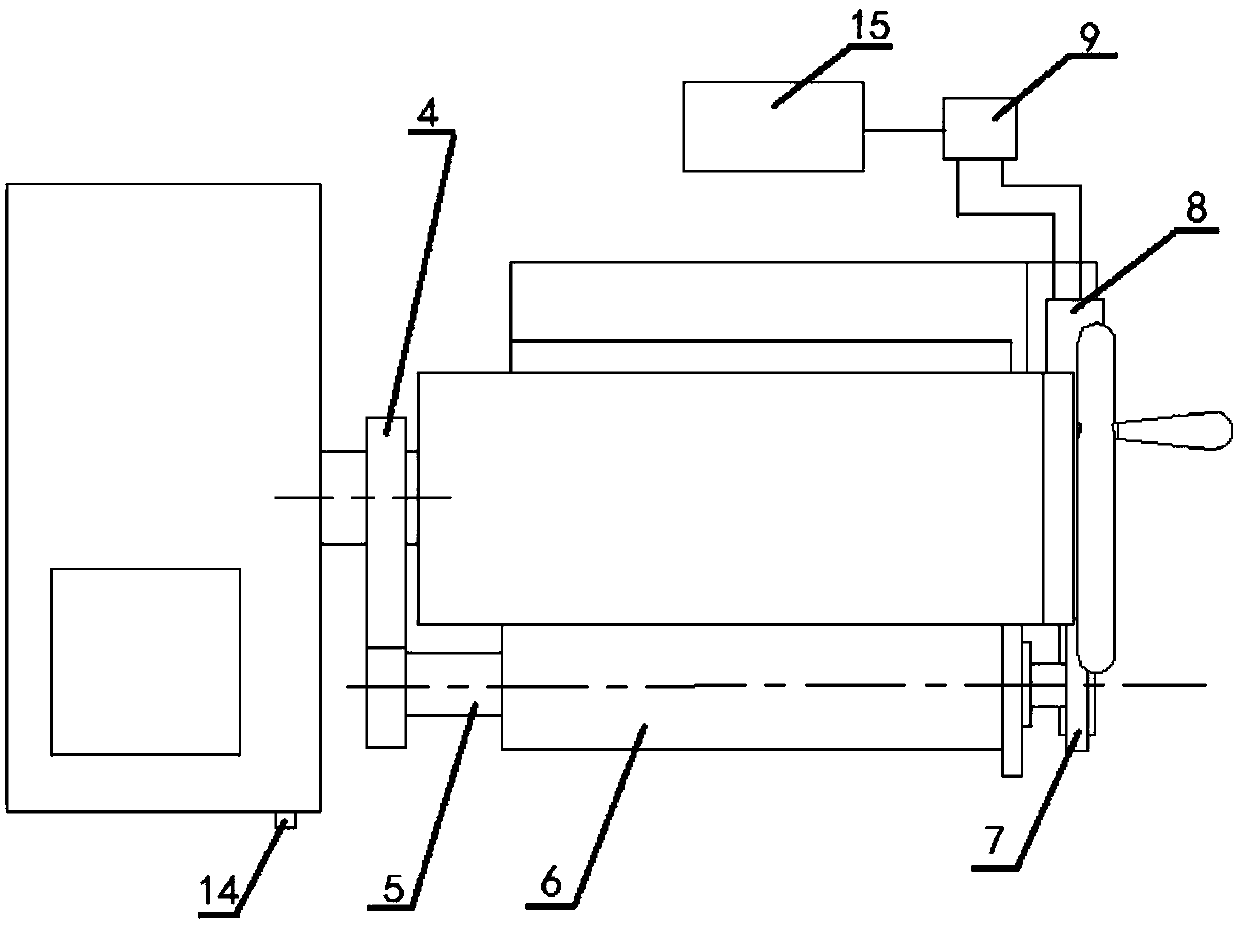

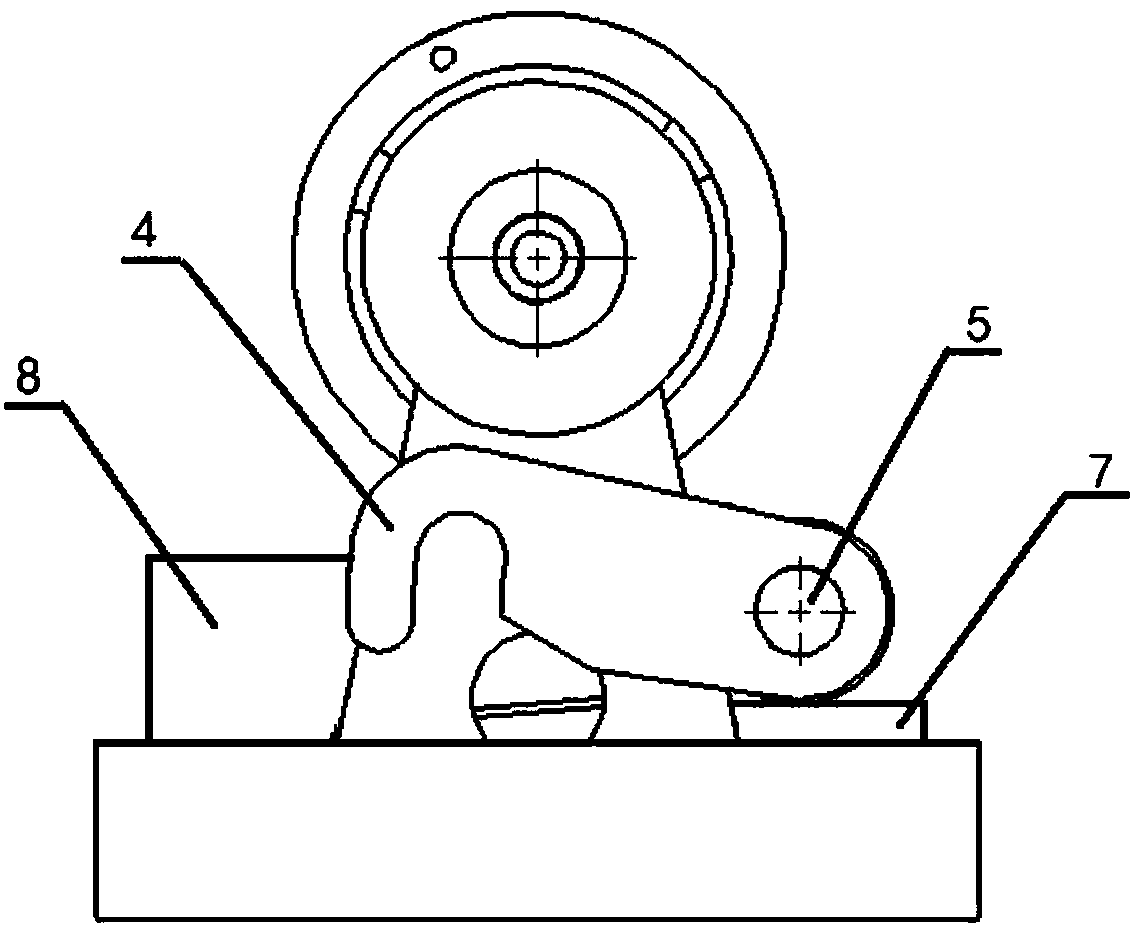

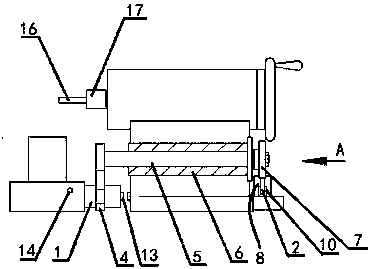

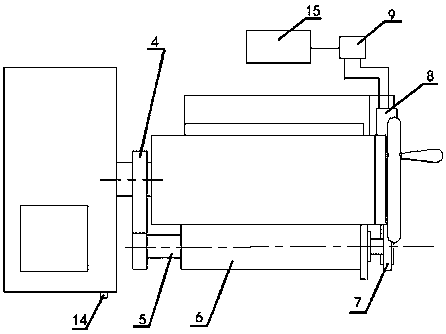

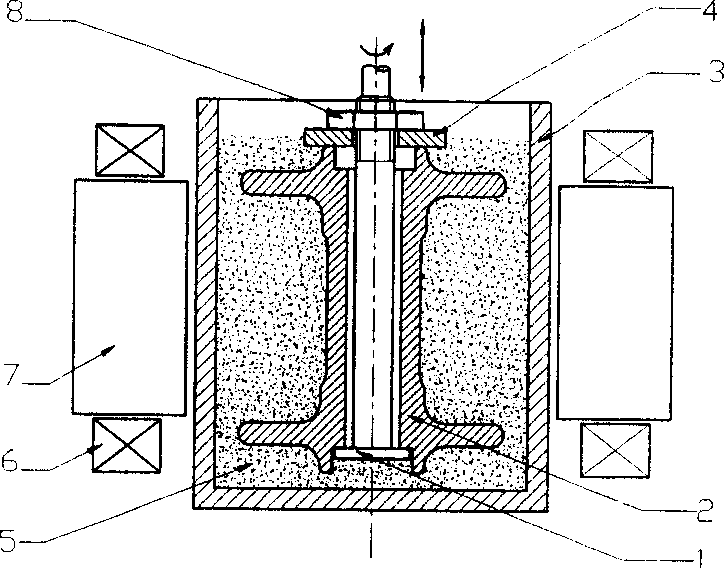

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

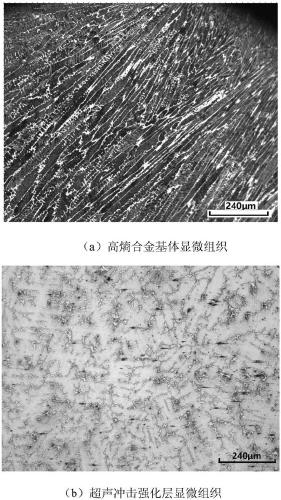

Method for improving surface performance of single-phase high-entropy alloy

The invention discloses a method for improving surface performance of a single-phase high-entropy alloy, and belongs to the technical field of high-entropy alloy surface strengthening. The single-phase high-entropy alloy is an Al<x>CrCoFeMnNi alloy, wherein x represents the mole number, and is equal to 0-0.5; after the single-phase high-entropy alloy is subjected to solution treatment and surfacepretreatment, the surface of the high-entropy alloy is strengthened through ultrasonic impact equipment; and the high-entropy alloy is of a single-phase face-centered cubic structure, a certain depthof plastic deformation layer is formed on the surface of the high-entropy alloy after ultrasonic impact, grains are obviously refined, a gradient structure is formed from the surface to the core, andhardness and abrasion resistance are significantly improved. According to the method, a fine structure and a large number of microscopic defects can be obtained on the surface of the high-entropy alloy while the chemical composition of the surface of the high-entropy alloy is ensured to be unchanged and the toughness of the core is ensured, thus the hardness of the surface of the high-entropy alloy is increased by 1.8-2.5 times, the abrasion resistance is increased by 1.3-2.5 times, the method is simple, easy to operate, safe, reliable, small in energy consumption, economical and practical.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

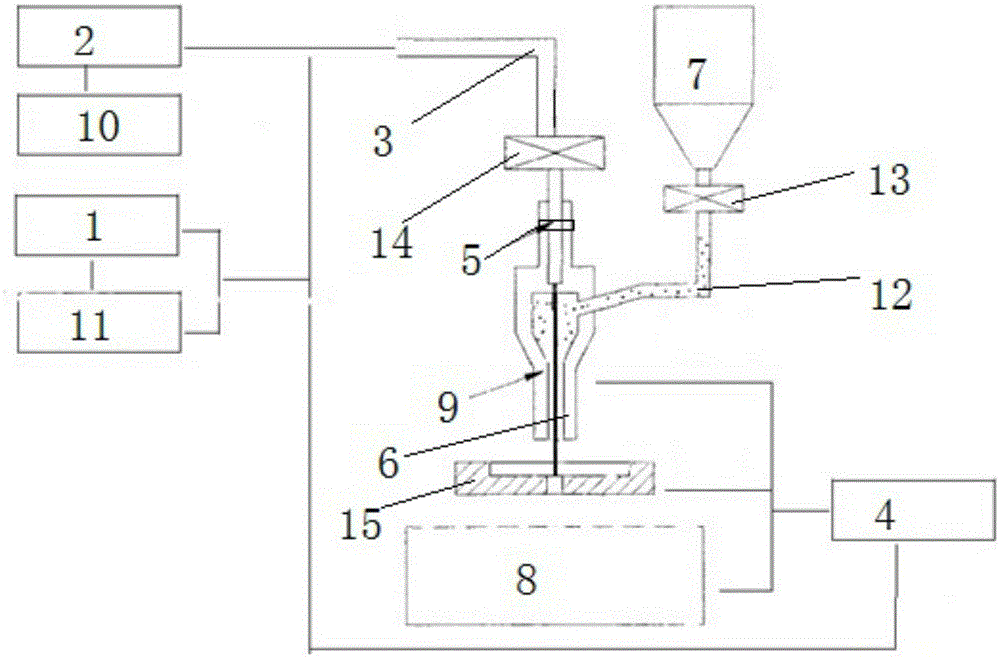

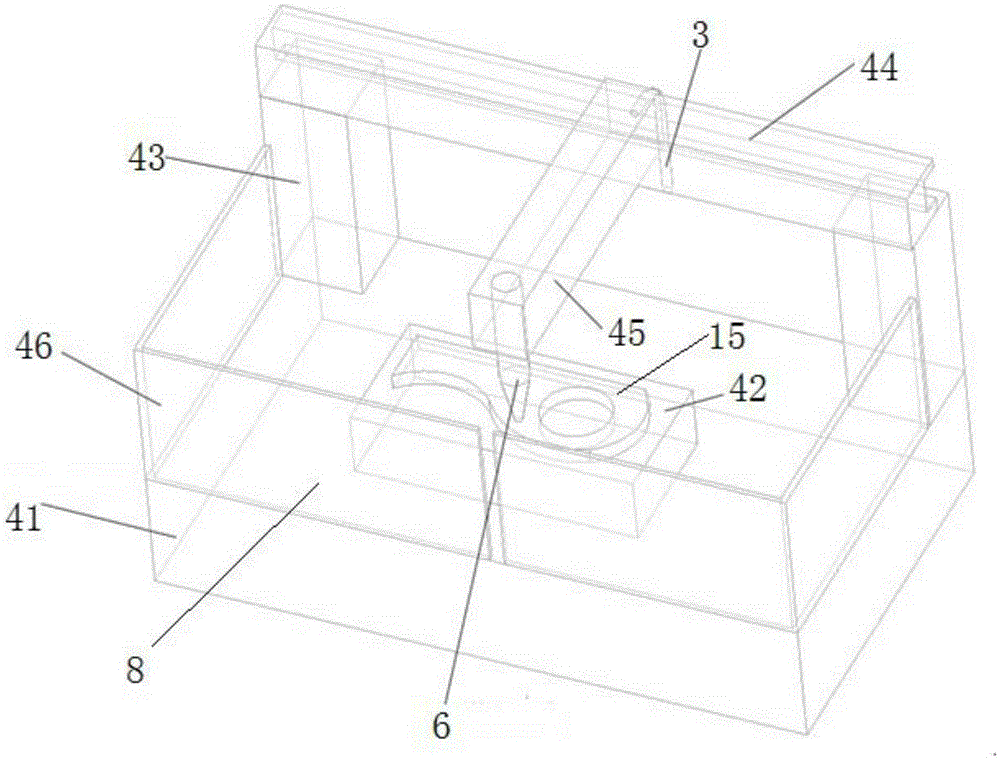

Fluid magnetic abrasive hole finishing processing device

The invention discloses a fluid magnetic abrasive hole finishing processing device. The device comprises a driving cylinder and a storage cylinder which are connected into a whole through a middle connecting cover, a front end cover is arranged at the upper end of the driving cylinder, a rear end cover is arranged at the lower end of the storage cylinder, a driving cylinder piston is arranged in the driving cylinder, the lower end of the driving cylinder piston is connected with a piston rod, the other end of the piston rod penetrates the middle connecting cover to extend into the storage cylinder and is provided with a storage cylinder piston, and an oil return port communicating with the inside of the driving cylinder is arranged on a driving cylinder shell and adjacent to the middle connecting cover. After a magnetic field is applied, viscosity is increased rapidly under the action of the external magnetic field, so that grinding media with certain shear yield stress are formed along the hole wall surfaces, further processing such as finishing, grinding and deburring of inner walls of various holes is achieved, and surface adaptability and universality are high.

Owner:TAIYUAN UNIV OF TECH

Electrorheological assisted ultrasonic tracking deburring device

PendingCN107775457ARealize finishingEdge grinding machinesGrinding carriagesNumerical controlImaging processing

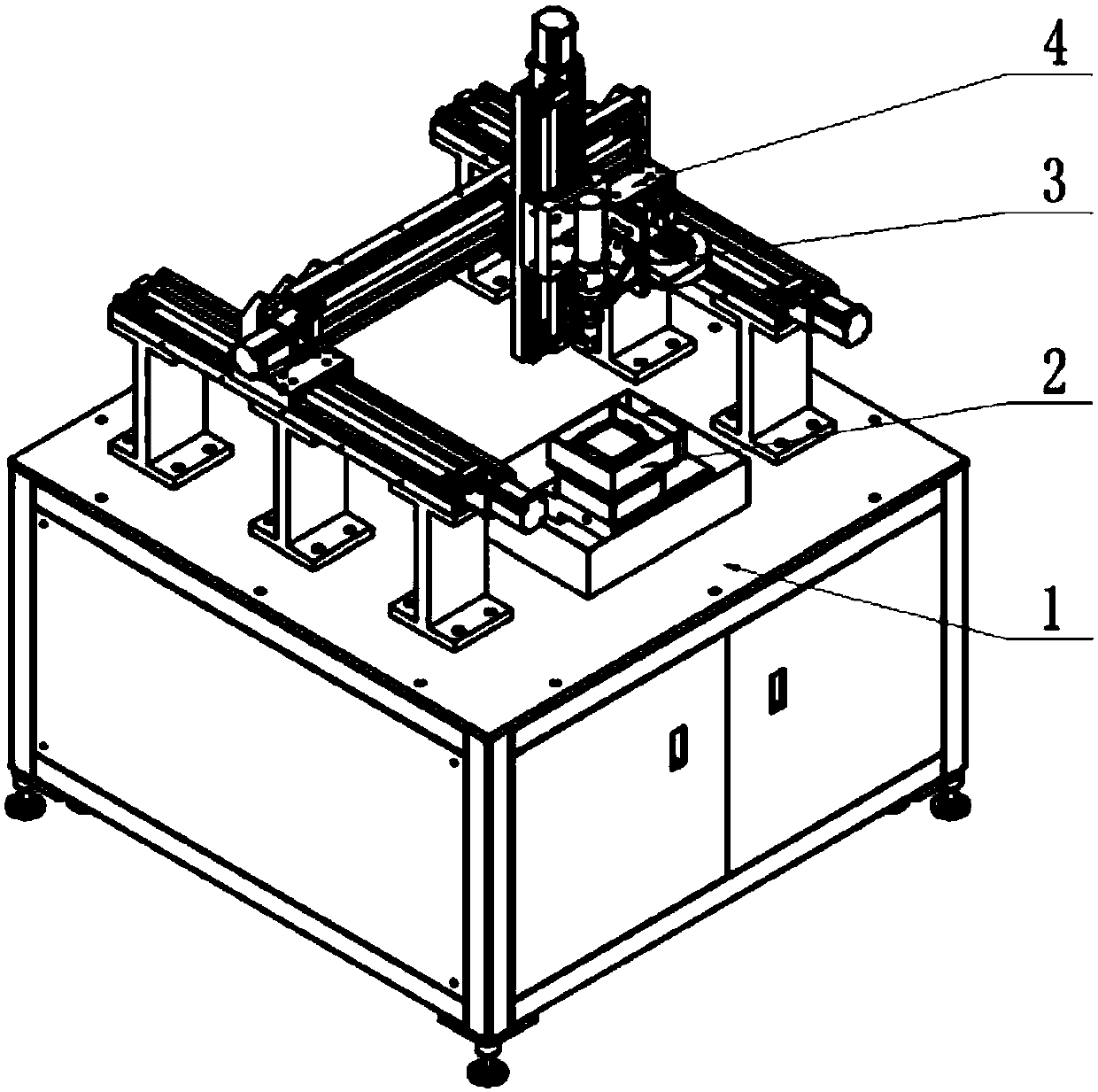

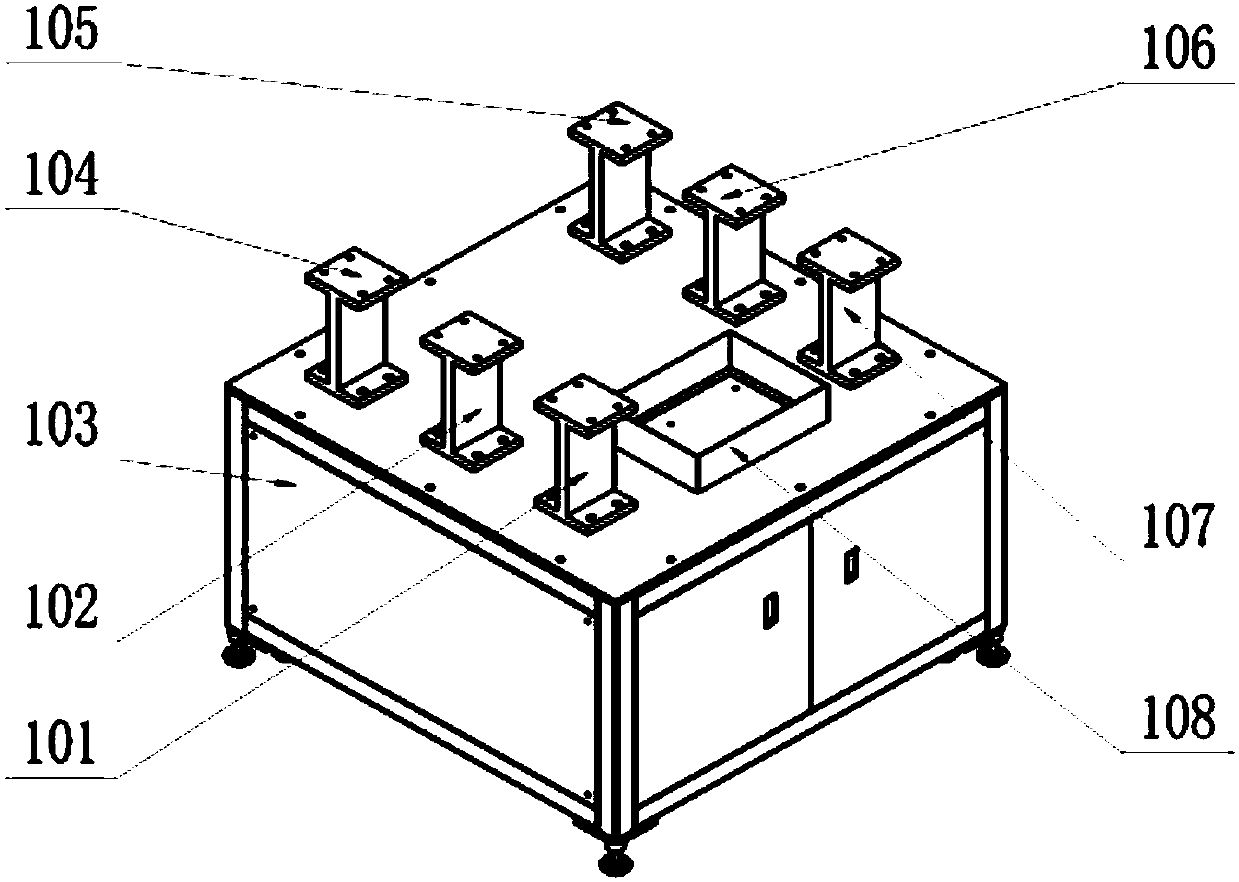

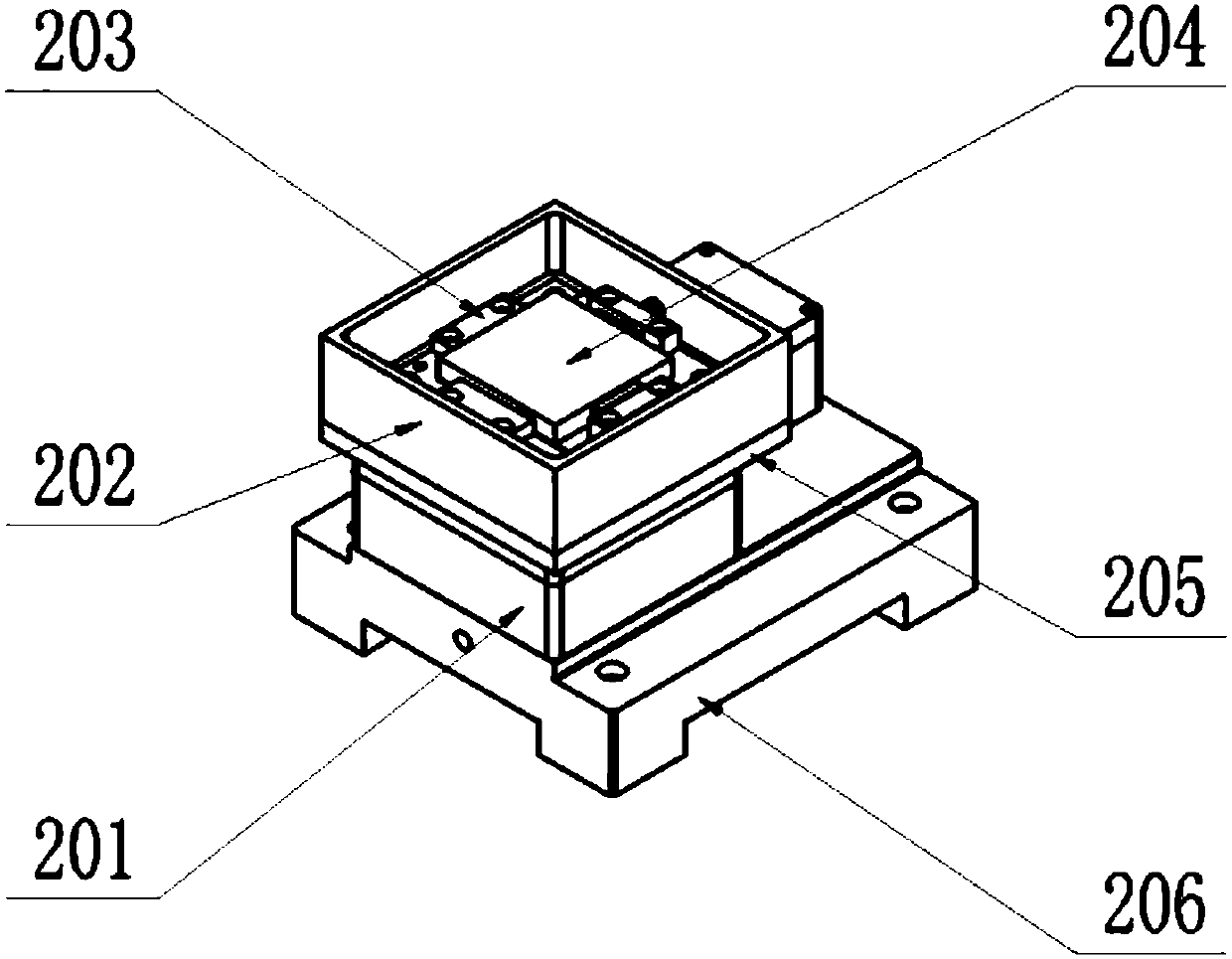

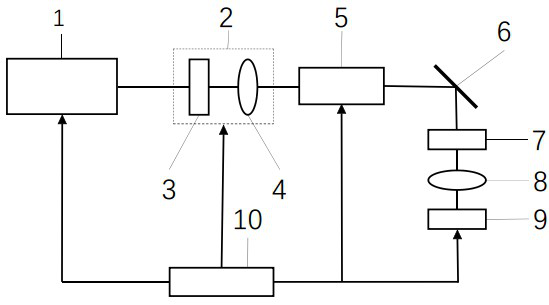

The invention relates to an electrorheological assisted ultrasonic tracking deburring device and belongs to the field of ultraprecision machining and manufacturing. A rotating fixture working table and a servo movement mechanism are mounted on a table board of an equipment support seat of an equipment base, and a tool head is mounted on a slider of a Z-axis module of the servo movement mechanism.The electrorheological assisted ultrasonic tracking deburring device has the beneficial effects as follows: the tool head with ultrasonic vibrators and electrorheological assisting effect is loaded bya numerical control four-axis machine tool, surface defects such as microstructural burrs, tool marks, bulges and the like of a metal test piece are removed by abrasive grains under driving of recombination actions of supersonic vibration and electrorheological effect, submillimeter-scale microstructural finish machining of the metal test piece is realized, structural guarantee is provided for tracking machining of positioning and tracing for the surface defects such as burrs and the like by the aid of visual image processing, and the device can be widely applied to submillimeter-scale microstructural tracking finish machining of a metal mold.

Owner:JILIN UNIV

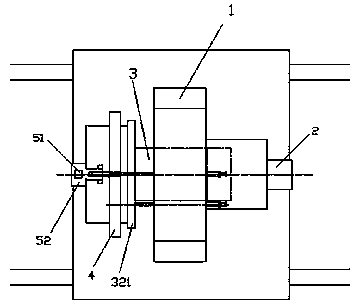

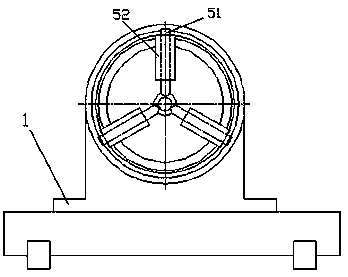

Magnetic grinding device suitable for spherical surfaces and irregular solid surfaces and method thereof

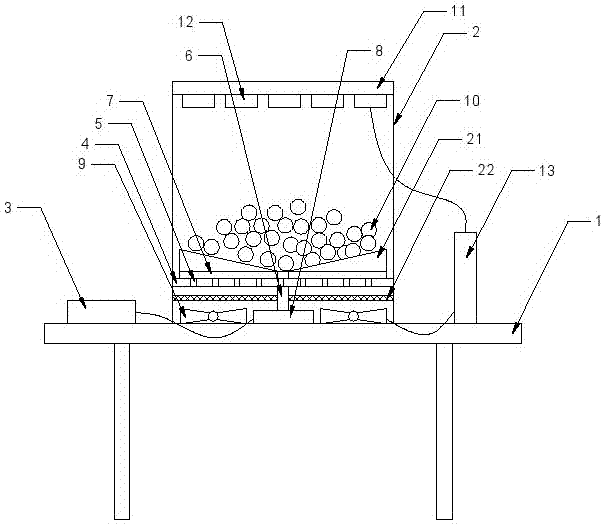

ActiveCN111216032AImprove tumbling effectRealize finishingEdge grinding machinesPolishing machinesMagnetic tension forceLaundry washing machine

The invention relates to the technical field of magnetic grinding, in particular to a magnetic grinding device suitable for spherical surfaces and irregular solid surfaces and a method thereof. The magnetic grinding device comprises a driving device and a magnetic grinding roller, wherein the driving device is connected with the magnetic grinding roller; a magnetic pole is arranged in the magneticgrinding roller to form a magnetic field, and a magnetic grinding material and parts to be processed are placed in the magnetic grinding roller; and the driving device drives the magnetic grinding roller to rotate, and the magnetic grinding material moves under the action of magnetic force and centrifugal force, so that the parts to be processed are processed. The magnetic grinding device is simple and is easy to operate, a principle of simulating a roller washing machine is adopted, the magnetic grinding material is rolled in a container with high fluidity and irregularity, and the polishingeffect on the parts placed in the container is realized; and the magnetic grinding device can be widely applied to the parts with various shapes, has good adaptability and can greatly improve the processing efficiency.

Owner:UNIV OF SCI & TECH LIAONING

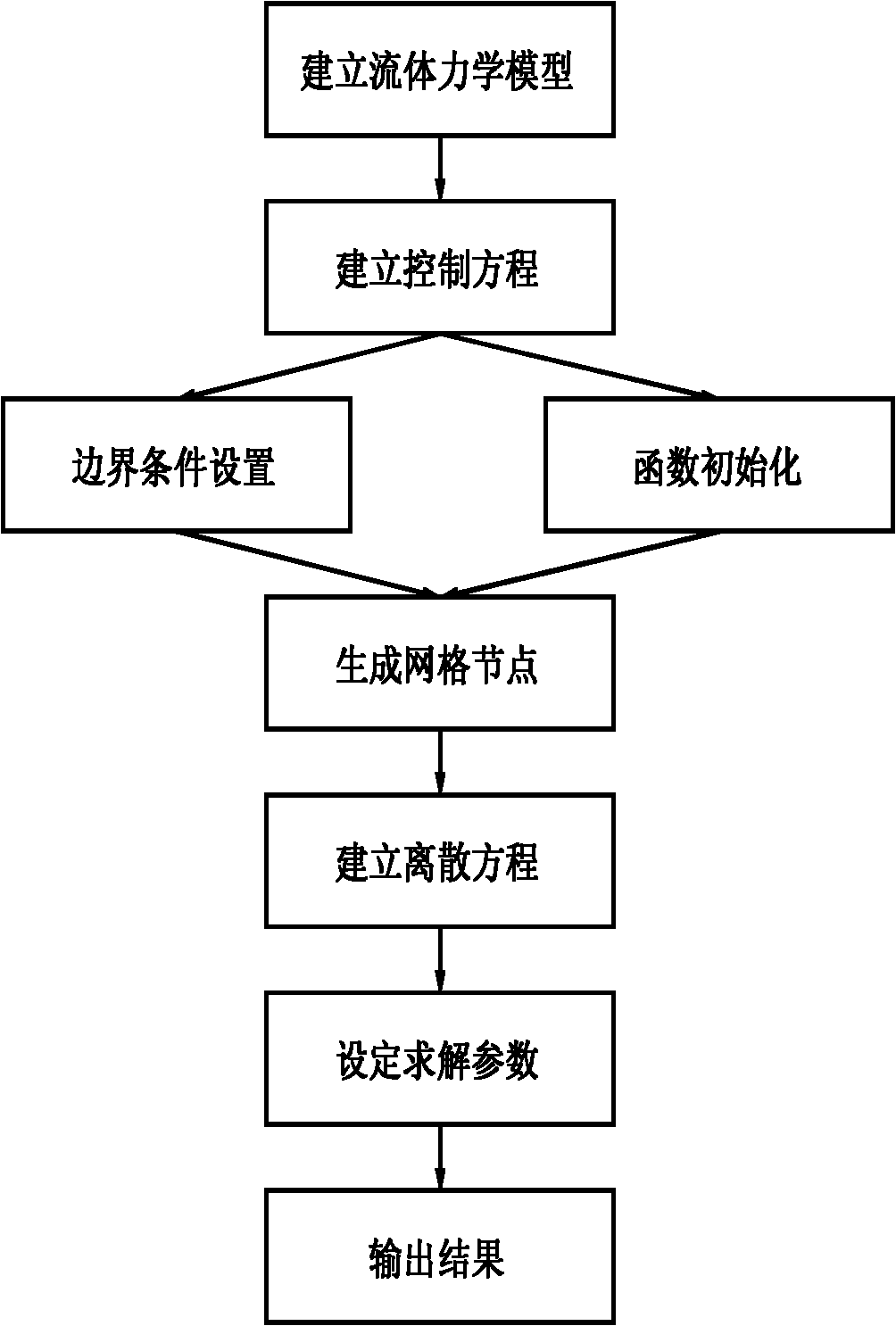

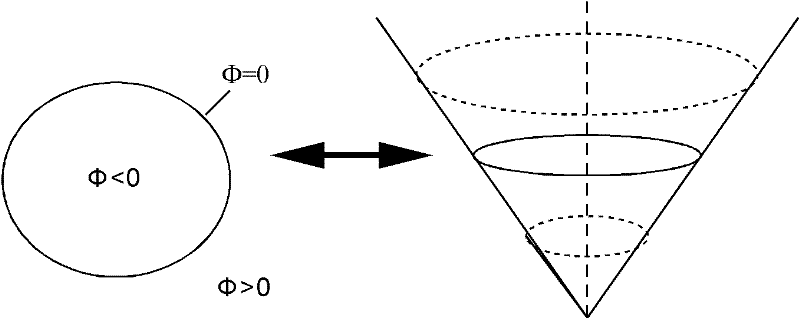

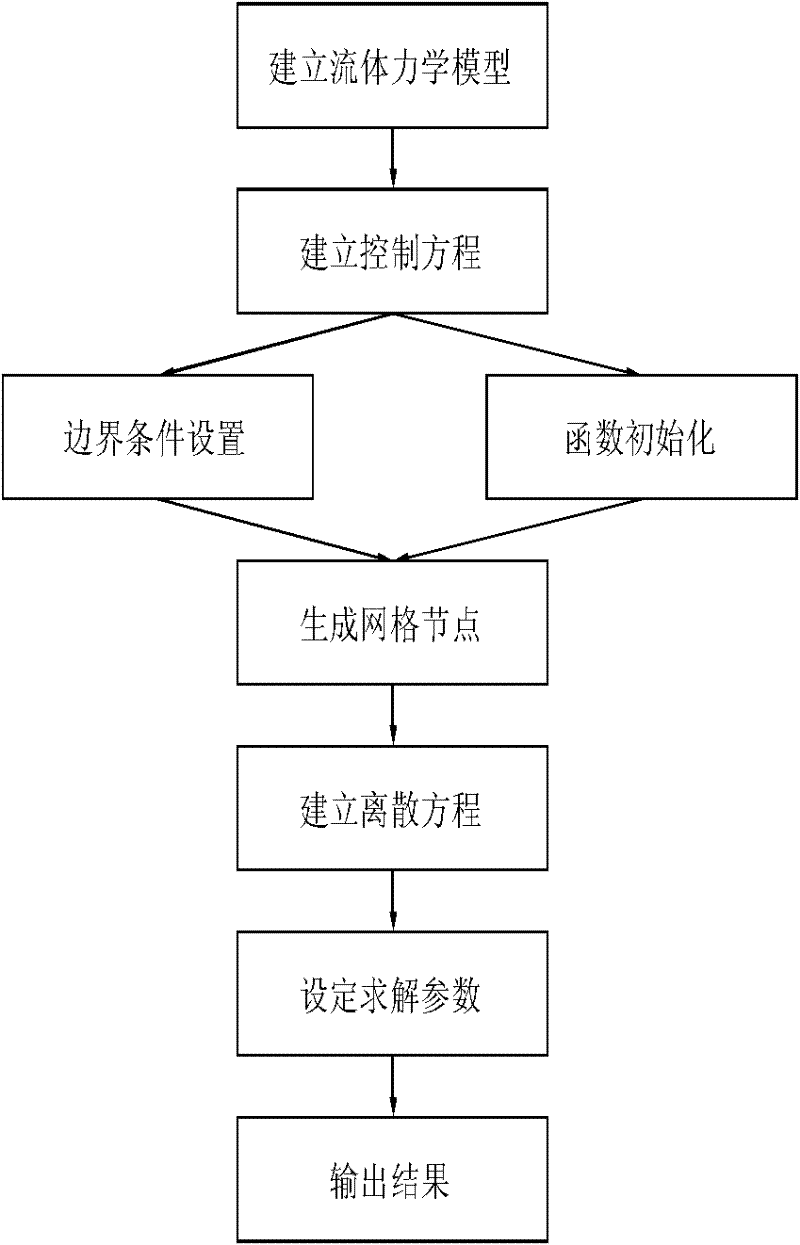

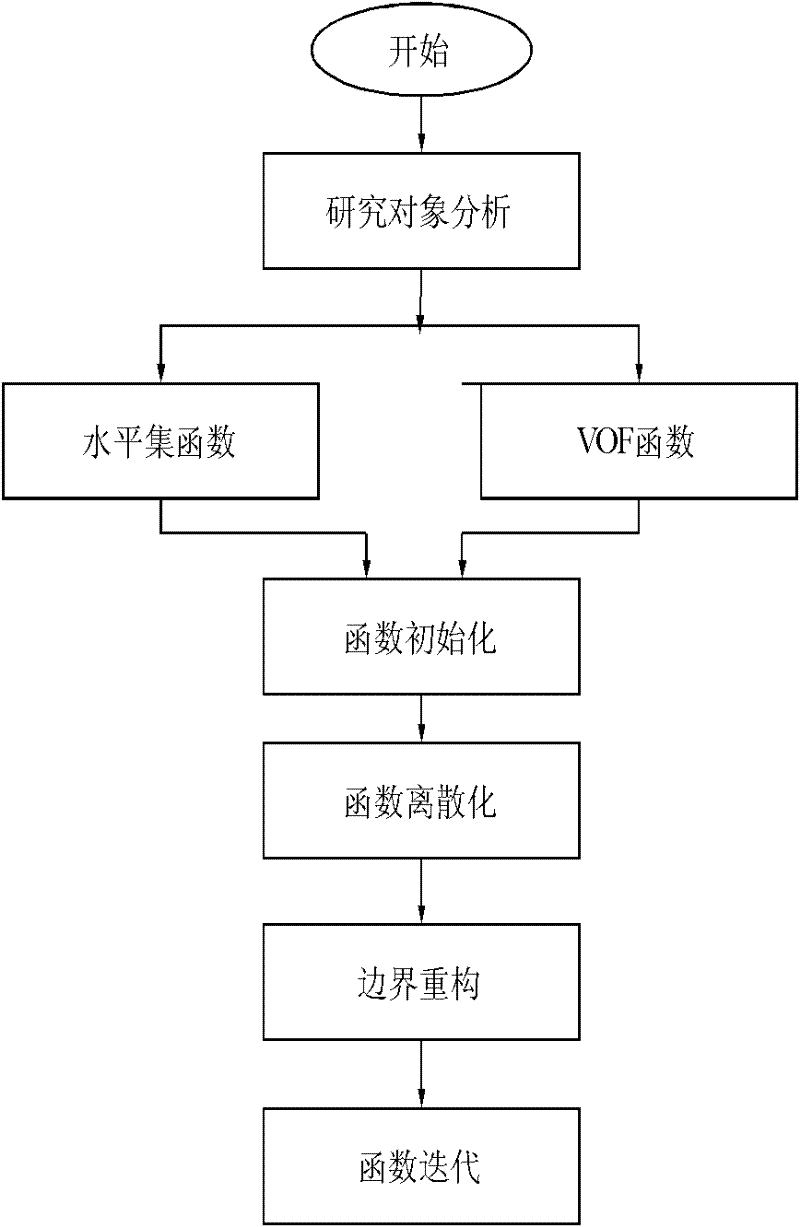

Soft abrasive flow field testing method based on level set

ActiveCN101813555AAccurate descriptionRealize finishingHydrodynamic testingSpecial data processing applicationsEquations of motionVolumetric model

A soft abrasive flow field testing method based on a level set comprises the following steps: 1) establishing an equation of motion of the level set function of the soft abrasive flow by combining a fluid Navier-Stokes equation; 2) discretizing and projecting space; 3) discretizing time; 4) iterating combination of the level set function and function of volume of fluid model; 5) reconstructing the distance function; and 6) testing the soft abrasive flow field: better analyzing the flow field characteristics to find the best machining state by adopting the principle of the level set method, namely effectively capturing topological variation of the interface. The testing method improves the computational accuracy and accurately finds the best machining state.

Owner:ZHEJIANG UNIV OF TECH

Numerical control lathe tailstock automatic control method capable of controlling drilling depth and finishing hole bottom

InactiveCN106001631ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlAutomatic control

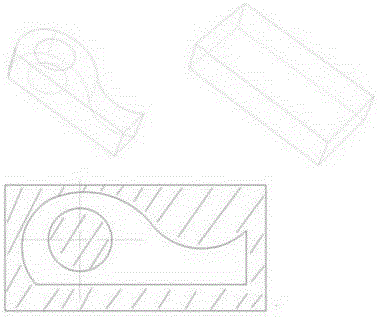

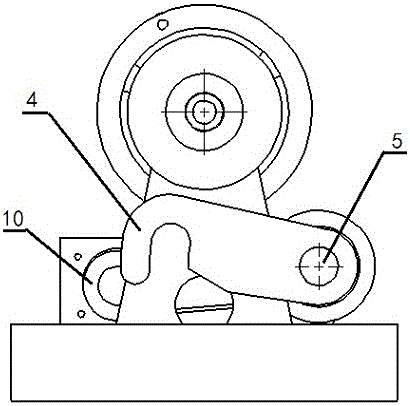

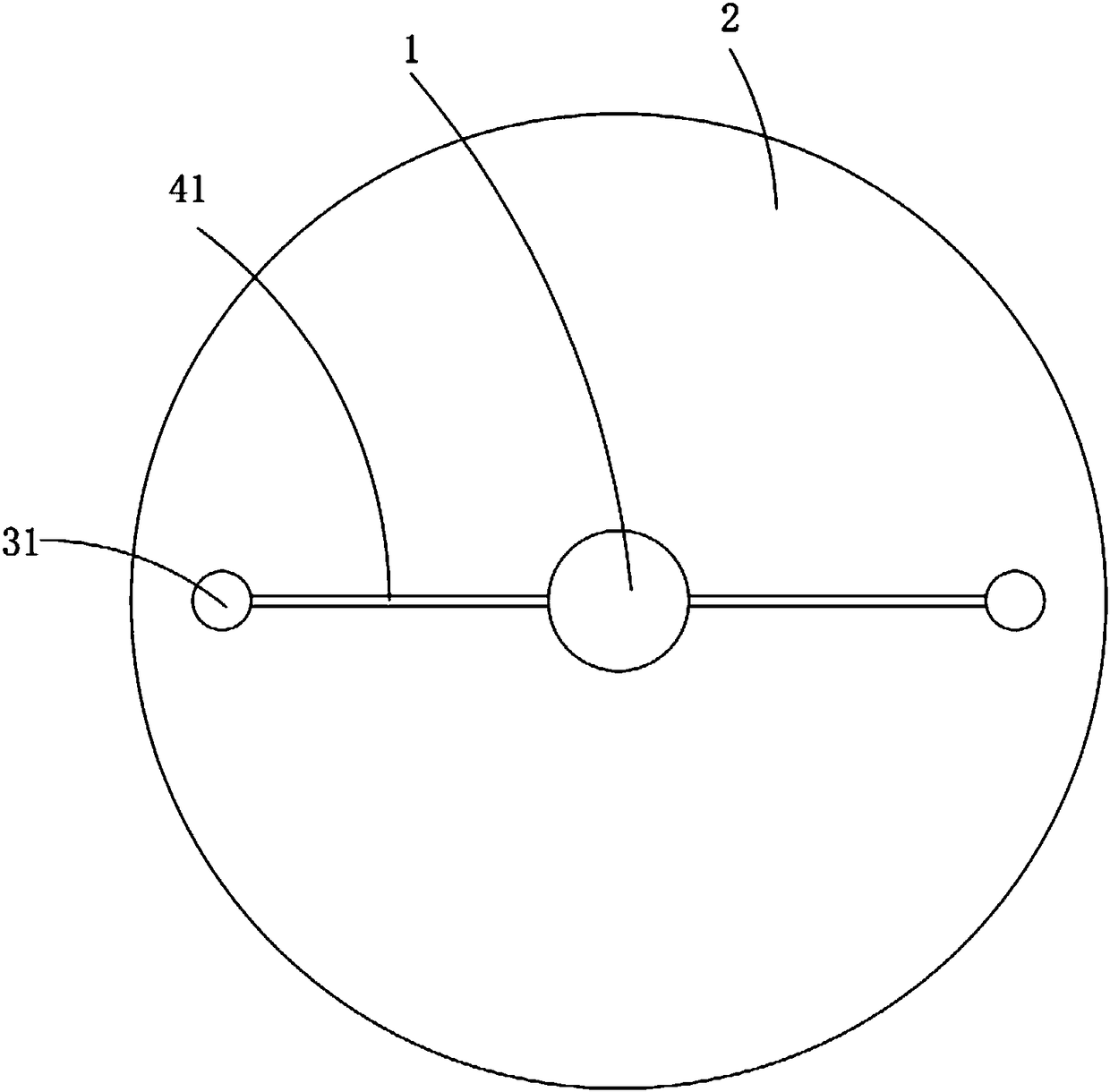

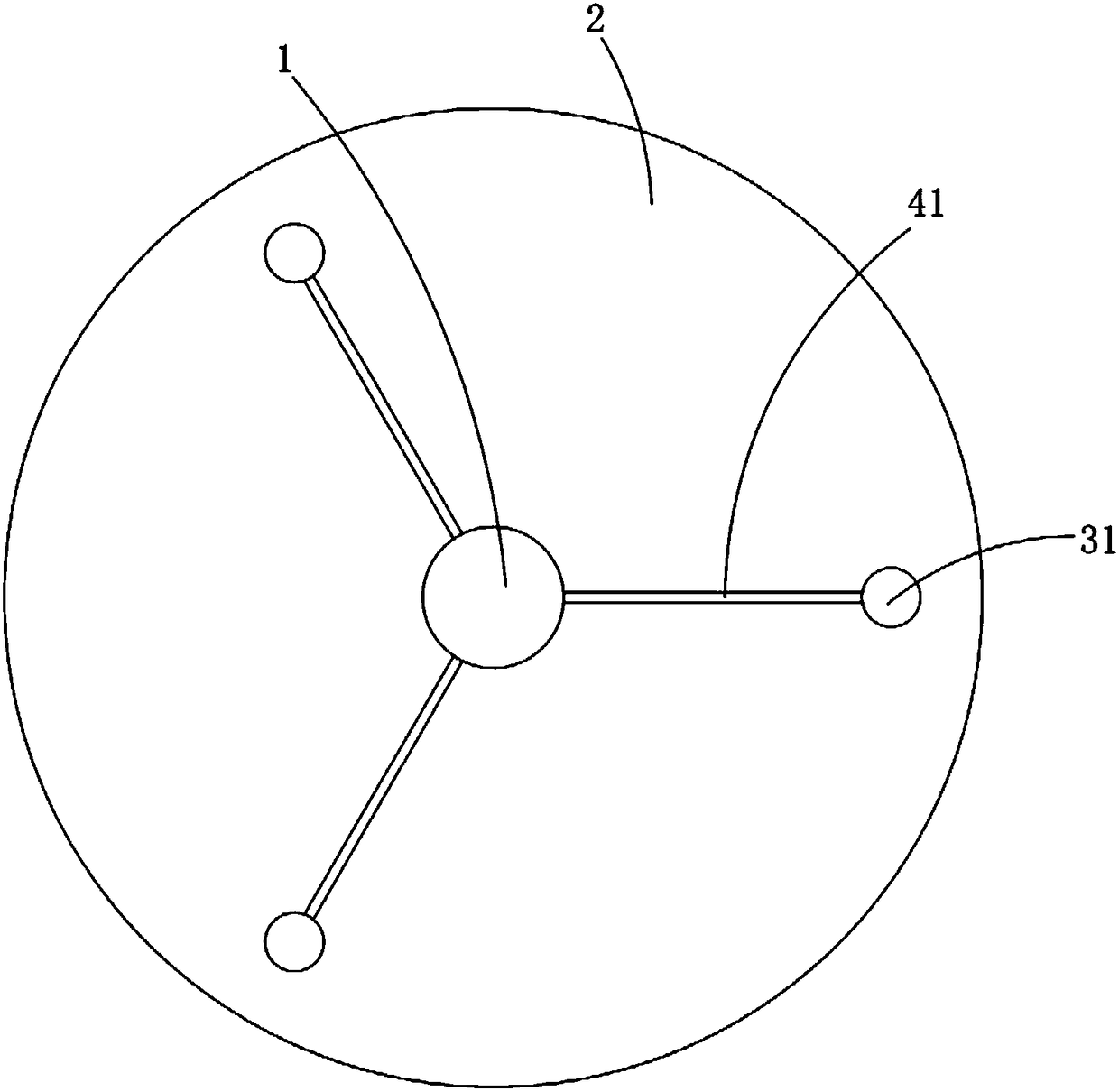

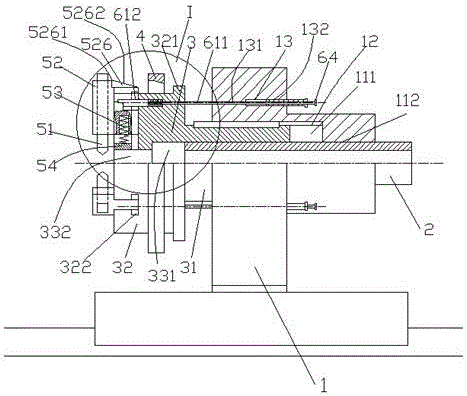

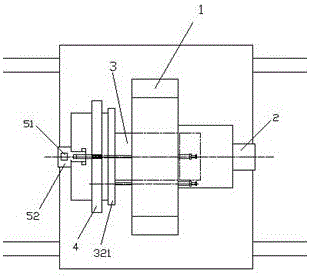

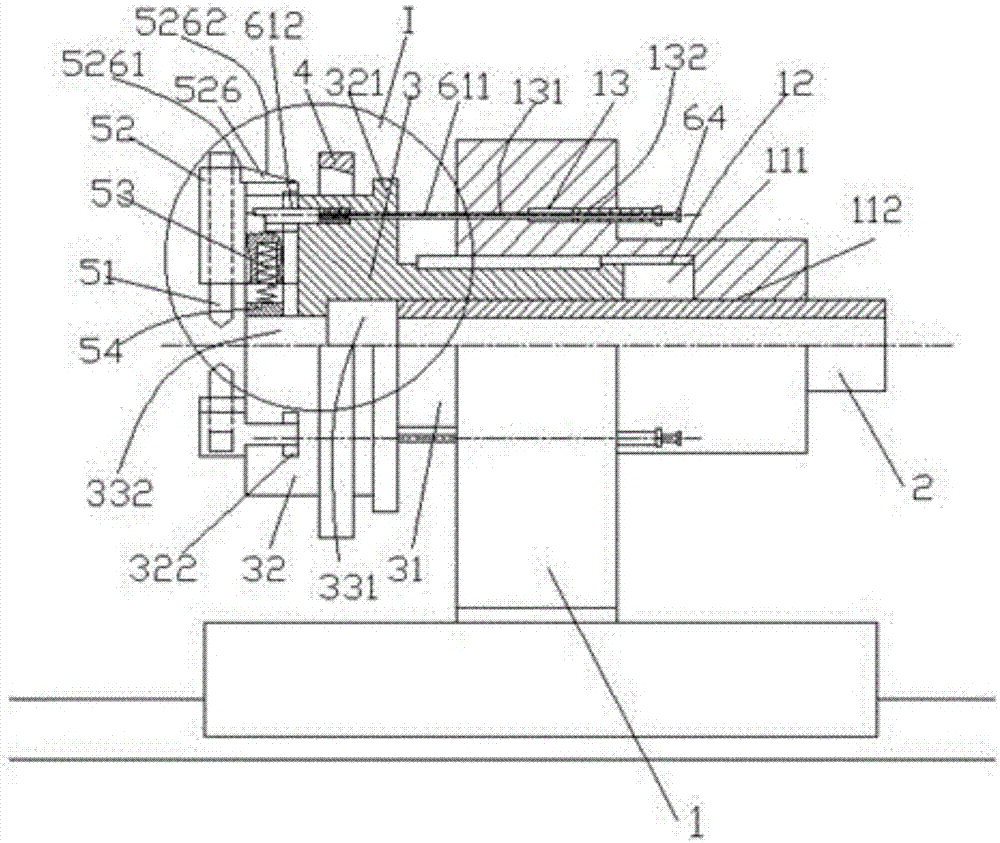

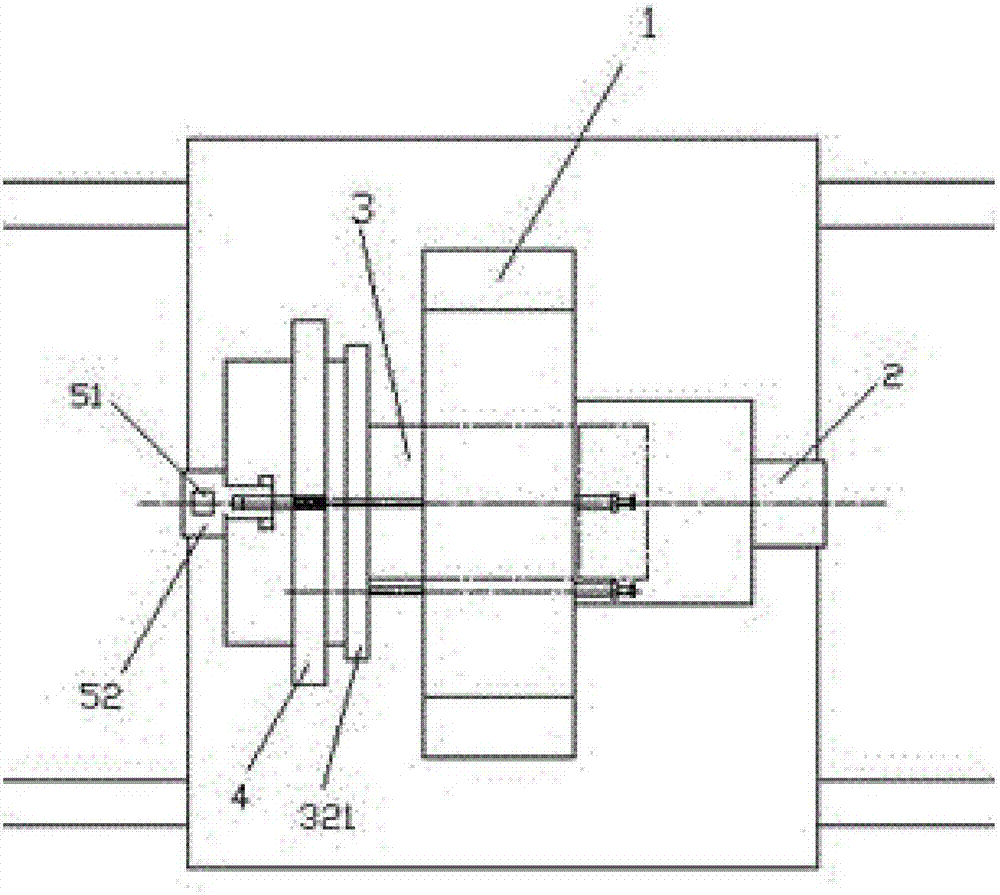

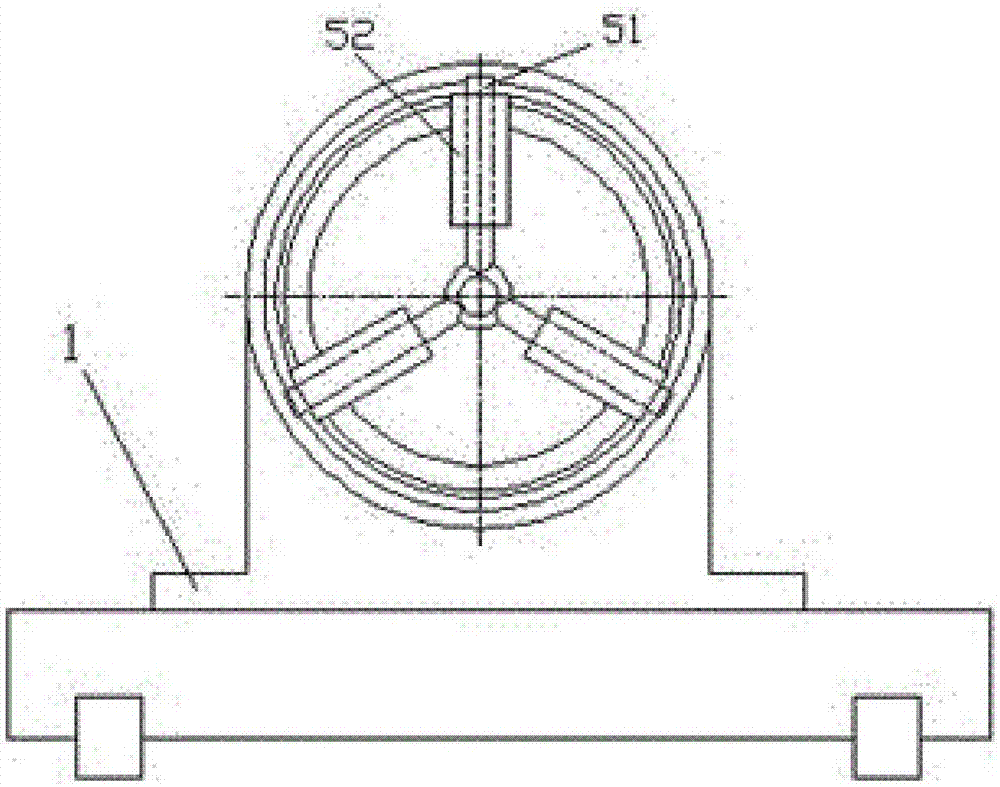

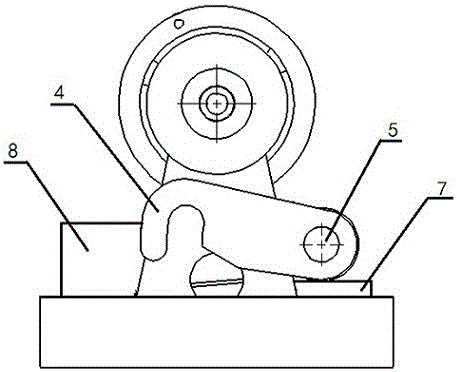

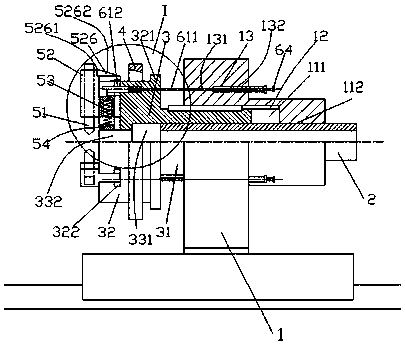

The invention provides a numerical control lathe tailstock automatic control method capable of controlling the drilling depth and finishing a hole bottom. A connection device achieving connection and disconnection of a saddle and the tailstock of a numerical control lathe is adopted and comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is installed in a tube sleeve of the tailstock of the numerical control lathe. The centering assembly comprises a centering shaft and a centering sleeve with an inner cone hole. The shaft end of the centering shaft and the bottom of the cone hole of the centering sleeve are provided with a sensor. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting pressure blocks, the driving assembly comprises a pair of belt drivers, a driving motor, a reset switch and a controller, the controller is installed in a distribution cabinet of the lathe, the reset switch is installed on the front face of the saddle of the numerical control lathe, and the driving motor is fixedly connected with the tailstock of the numerical control lathe and electrically connected with the controller.

Owner:惠州市天力和丰精密五金有限公司

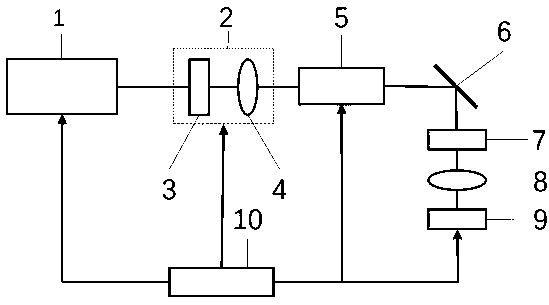

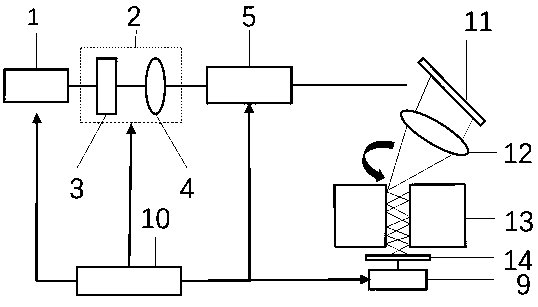

Laser machining center

ActiveCN105414769AEfficient processingRealize finishingLaser beam welding apparatusControl systemEngineering

The invention discloses a laser machining center which comprises a control system, a laser device, an optical path system, a machining tool, a concentrator system, a laser cutter bit, a gas source and a waste receiving device. The laser cutter bit is movably mounted on the machining tool. The optical path system is connected between the laser device and the laser cutter bit. A protective gas nozzle is arranged in the laser cutter bit and communicated with the gas source. The concentrator system is located between the optical path system and the laser cutter bit. The waste receiving device is located below the laser cutter bit, and the laser device and the machining tool are both in communication connection with the control system. The laser machining center is high in working efficiency and machining precision, capable of saving energy and environmentally friendly.

Owner:唐山胜钰机械制造有限公司

Automatic feeding control method used for numerical control lathe tailstock and capable of controlling drilling depth

ActiveCN106180765ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlDrive motor

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

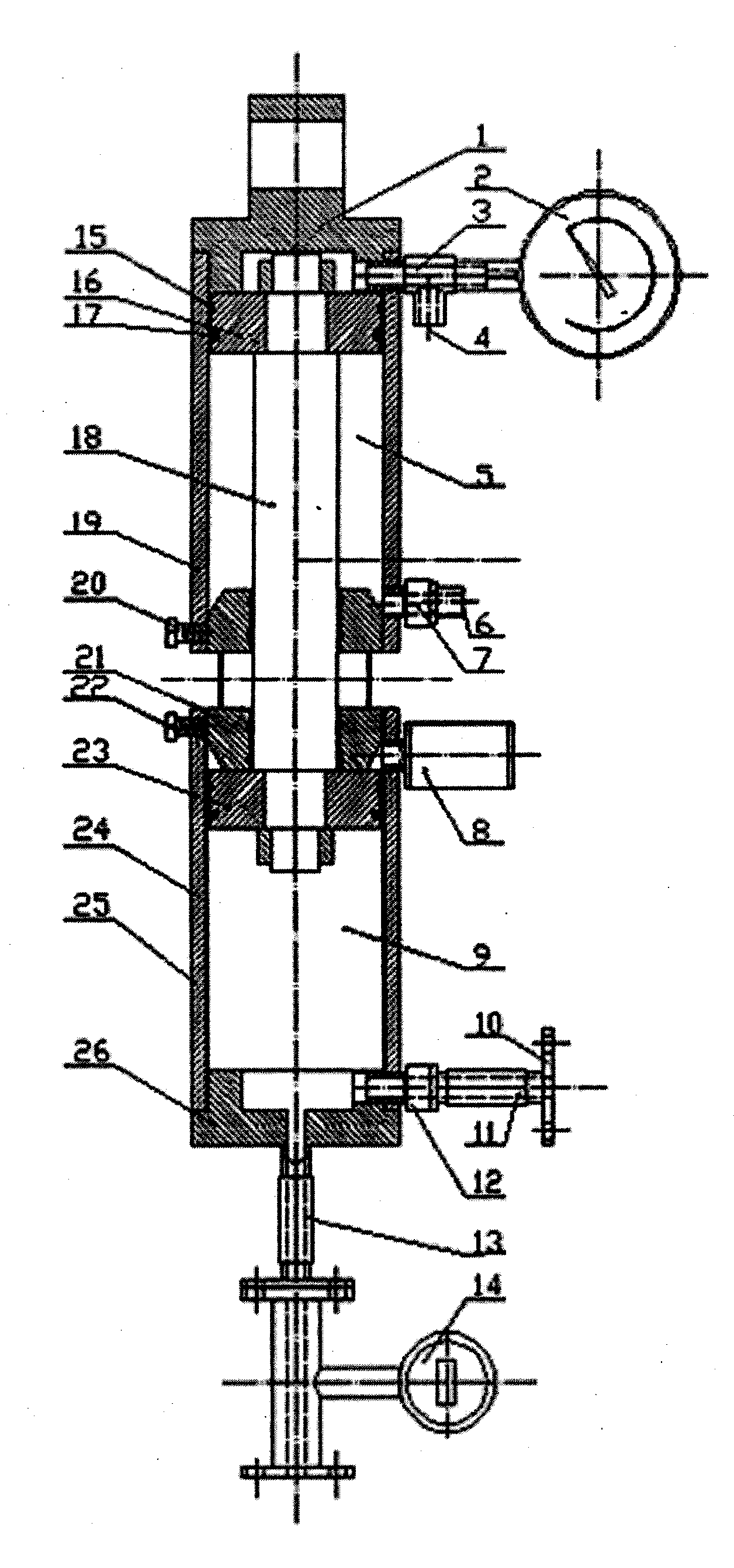

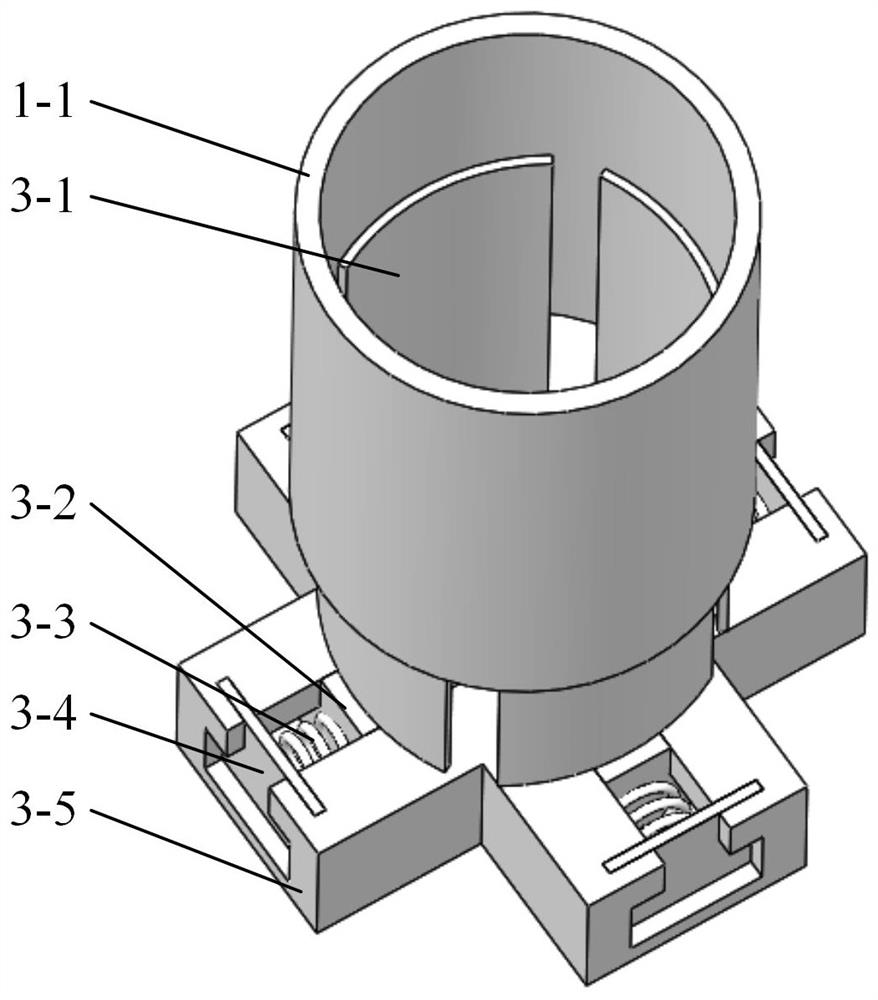

Radial ultrasonic honing device

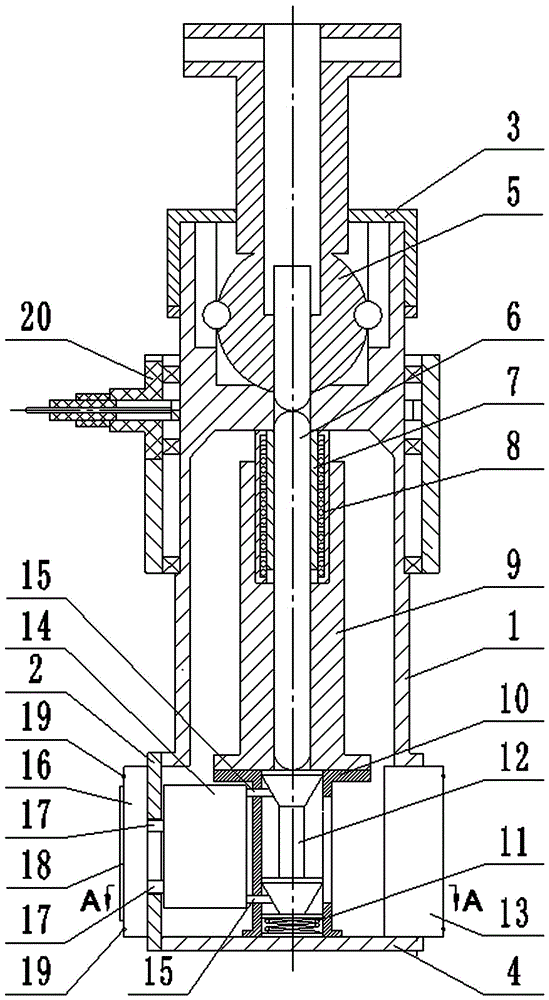

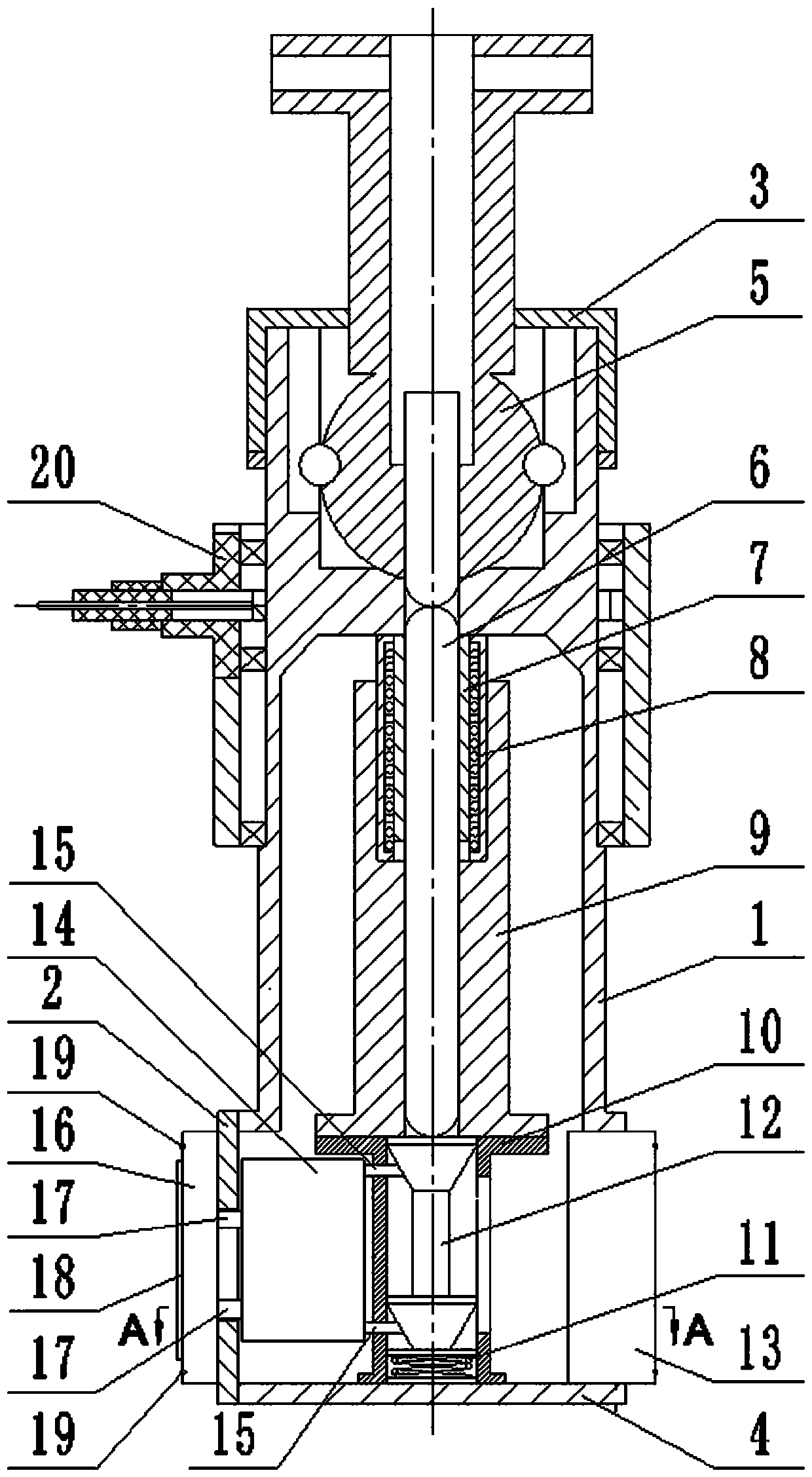

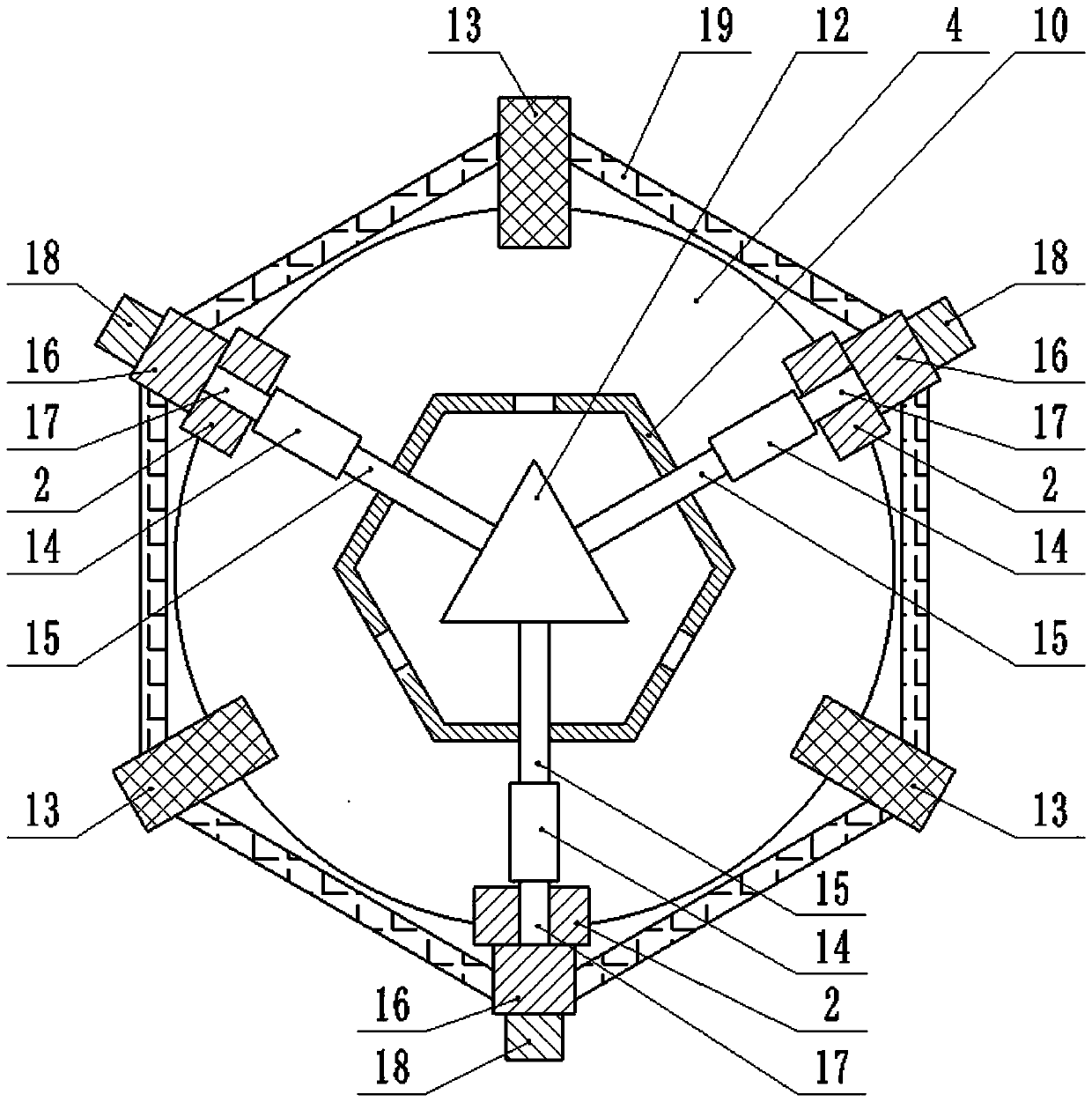

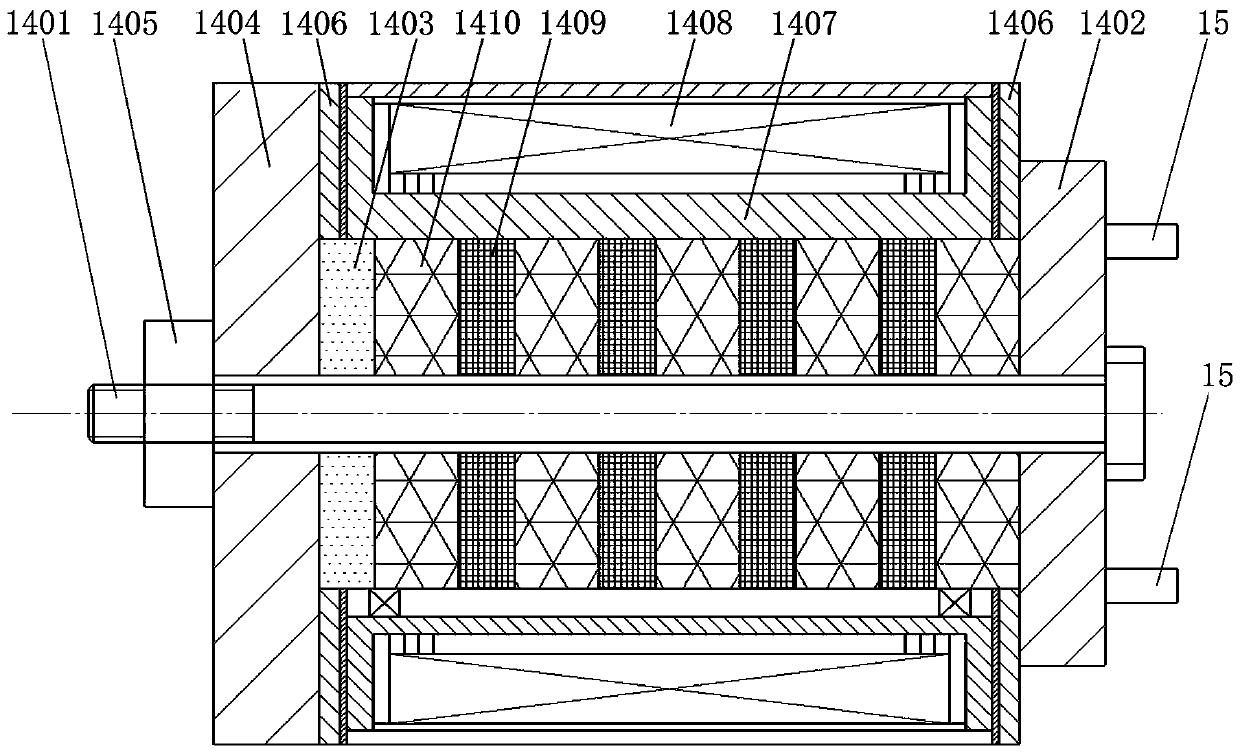

The invention relates to an ultrasonic vibration honing technique, in particular to a radial ultrasonic honing device. By adoption of the radial ultrasonic honing device, the problems that an existing ultrasonic vibration honing device is complicated in overall structure, high power and high energy are difficult to obtain, the storage oil lubrication performance of a workpiece is prone to being affected, and transducer operation desynchrony is prone to being caused are solved. The radial ultrasonic honing device comprises an outer barrel, supporting rods, an upper cover, a lower cover, a floating mechanism, an ejector rod, a limiting barrel, a linear bearing, an inner barrel, a supporting barrel, a reset spring, an expand mandrel, guide bars, rare-earth super-magnetostriction transducers, inner pin rods, oilstone bases, outer pin rods, oilstone, annular springs and a collecting ring. The radial ultrasonic honing device is applicable to ultrasonic vibration honing.

Owner:ZHONGBEI UNIV

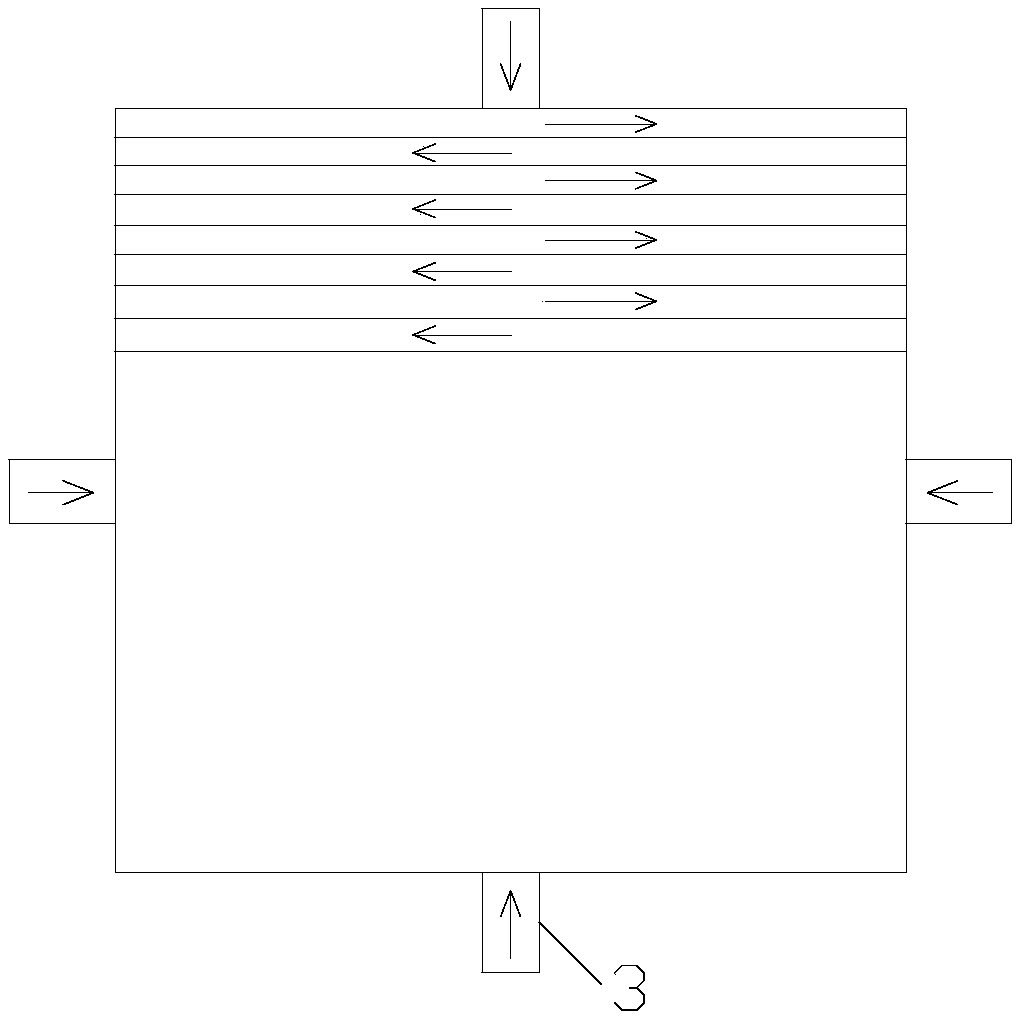

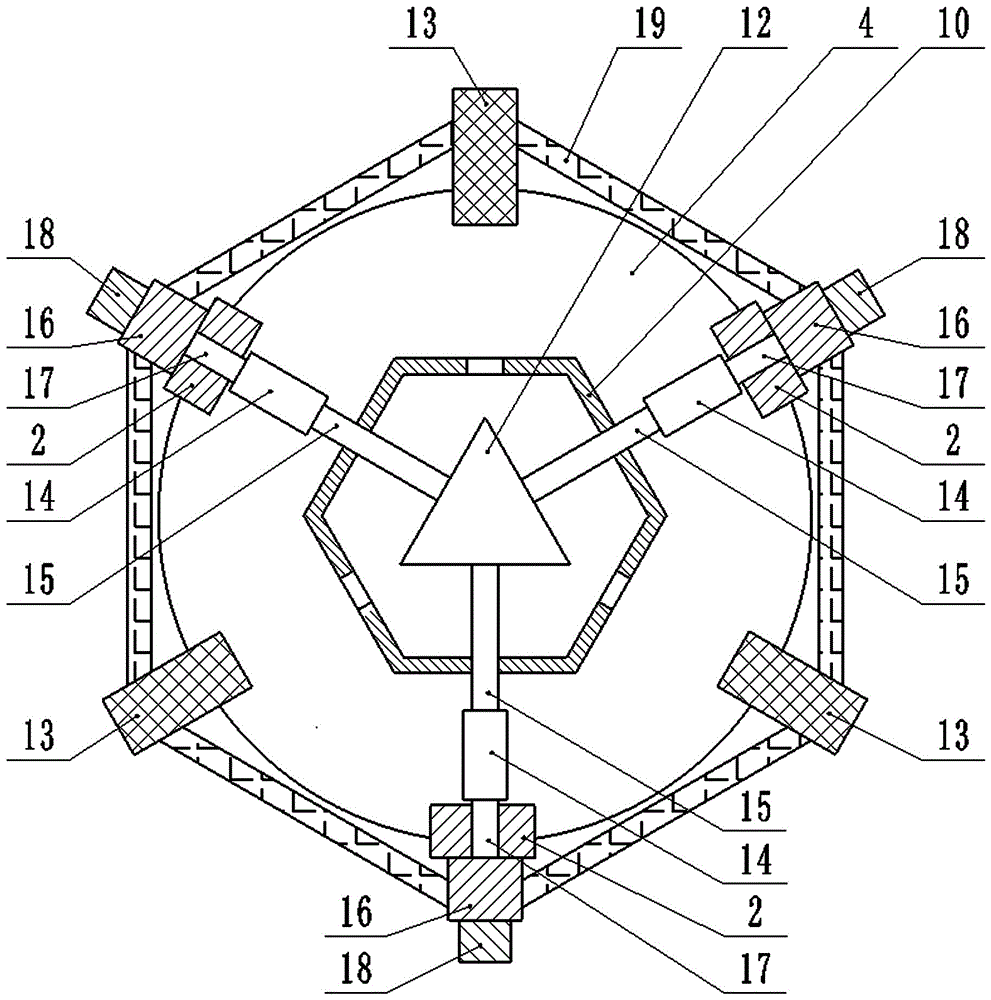

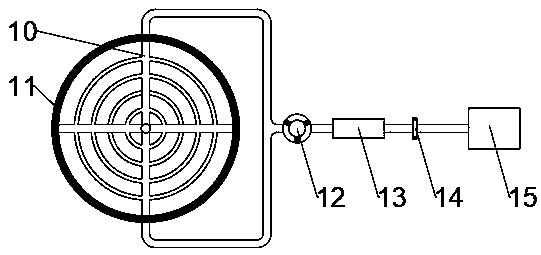

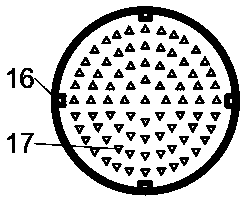

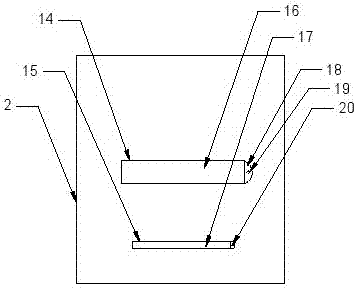

Device and method for finishing suspended abrasive pool through triangular frustum air pressure jet holes

InactiveCN110421485ARealize finishingRealize no dead angle finishingEdge grinding machinesPolishing machinesEngineeringEnergy consumption

The invention discloses a device and method for finishing a suspended abrasive pool through triangular frustum air pressure jet holes. Thedevice and method capable of efficiently finishing complex curved surfaces, irregular holes and ultra-precision parts are researched and designed. The device comprises a frame, the abrasive pool, an air pressure power system, an air injection system and a workpiece rotating system. According to the device, a fluidized bed principle is utilized, and finishing at different degrees on different workpieces is implemented by changing air flow velocity and abrasive particles. According to the device, the triangular frustum jet holes are adopted to further gather and pressurize high-speed air flow, so that energy consumption of the air pressure power system isreduced. The device is simple to operate and low in cost, is not harmful to the environment, is not influenced by other factors, and works stably and efficiently.

Owner:SHANDONG UNIV OF TECH

Metal casting ultrasonic finishing batch production method and equipment

PendingCN108544306AImplement batch processingSimple methodEdge grinding machinesPolishing machinesMachining processMetal

The invention discloses a metal casting ultrasonic finishing batch production method. A grinding material and metal castings are freely placed in a finishing machining chamber, ultrasonic waves are provided by an ultrasonic tool head rotating relative to the grinding material, meanwhile, a rotating magnetic field with the magnetic field direction changing periodically is provided by a magnetic field generator rotating relative to the grinding material, and metal casting ultrasonic finishing batch production is completed. According to ultrasonic finishing batch production equipment, the ultrasonic tool head is rotationally mounted on the lower portion of a containing body, the magnetic field generator is fixed to the ultrasonic tool head, and the ultrasonic tool head and the magnetic fieldgenerator are driven to rotate at high speeds in the ultrasonic finishing machining process. The metal castings in any shape can be subjected to finishing machining and do not need to be clamped and fixed, an operator needs to put the magnetic conductive grinding material into the containing body only, the type range of the metal castings is further enlarged, and meanwhile, batch machining of themetal castings is achieved.

Owner:东莞市新玛博创超声波科技有限公司

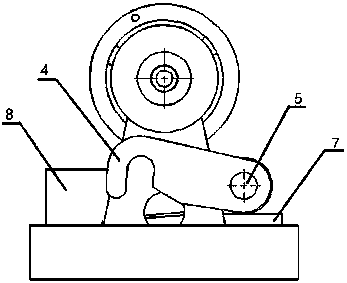

Turning method for thin and long threaded shaft

ActiveCN106363254AReduce distortionGuarantee processing qualityThread cutting feeding devicesThread cutting machinesEngineeringScrew thread

The invention discloses a turning method for a thin and long threaded shaft. A turning device for the thin and long threaded shaft is used in the method and is installed on a carriage of a lathe. The turning device comprises a base, a guiding sleeve, a telescopic sleeve, a tool reset ring, a thread length control mechanism and a tool assembly. The turning device has the beneficial effects that due to the fact that scale marks are arranged on the surface of the outer circle of the part, close to a shaft ring, of the thin and long shaft, the length value of a to-be-turned thread can be accurately adjusted by adjusting the axial position of a screw sleeve; due to the fact that three sets of turning tools are distributed evenly in the circumferential direction, deformation of the threaded shaft in the turning process is reduced, and the machining quality is ensured; due to the fact that a slope A and a slope C which can be in contact or be separated are arranged, ending machining of the thread can be accurately achieved, and the phenomenon of tool crashing is effectively avoided; and due to the fact that the tool reset ring is arranged, the three sets of turning tools can contract towards the center at the same time, and operation is fast and convenient.

Owner:嘉兴大力精密紧固件股份有限公司

Turning device for long and thin threaded shaft

ActiveCN107262844AReduce distortionGuarantee processing qualityThread cutting feeding devicesThread cutting machinesEngineeringScrew thread

Owner:SHANGYU SNAKE HOT RUNNER

Automatic numerical control lathe tailstock control method

ActiveCN106001633ARealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

The invention provides an automatic numerical control lathe tailstock control method. A connection device for achieving automatic connection and disconnection between a lathe saddle and a tailstock of a numerical control lathe through an air cylinder is utilized. The connection device comprises a connection pillar, a rotating arm assembly, a drive assembly and a drill bit assembly, the middle of the connection pillar is provided with an annular groove, the shaft end of the connection pillar and the side face of the tailstock are provided with a pair of sensors, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and a big gear, the shaft sleeve is fixed to the front side face of the tailstock of the numerical control lathe, the rotating shaft penetrates through the shaft sleeve, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the big gear, the front end of the rotating arm is provided with a hook portion capable of being clamped into an annular groove, the drive assembly comprises a rack, an air cylinder, a magnetic exchange valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the magnetic exchange valve, and the rest switch is mounted in front of the lathe saddle of the numerical control lathe and electrically connected with the controller.

Owner:三星智能科技盐城有限公司

Air-floating shaft rotating soft abrasive flow polishing device

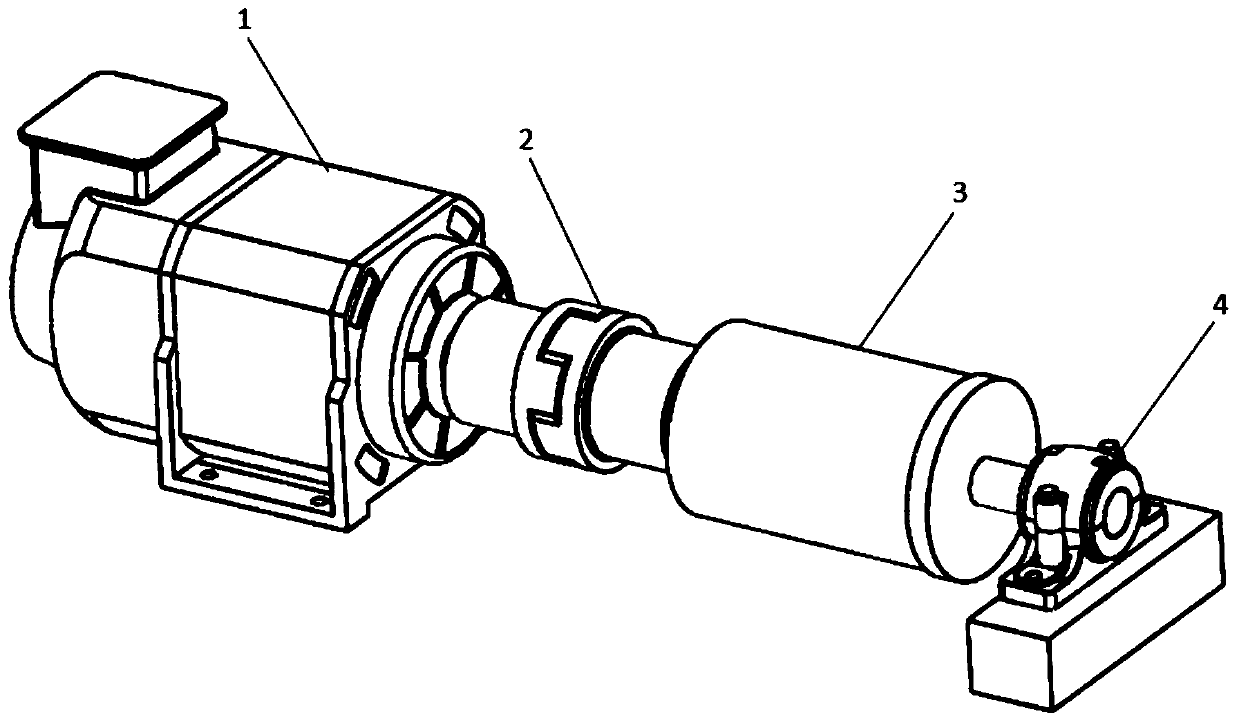

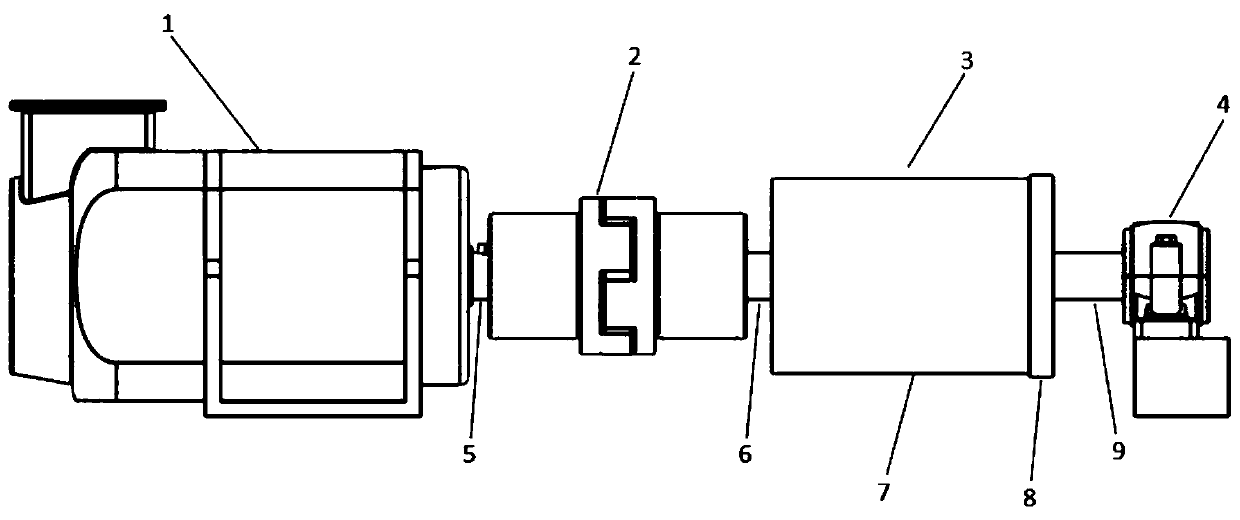

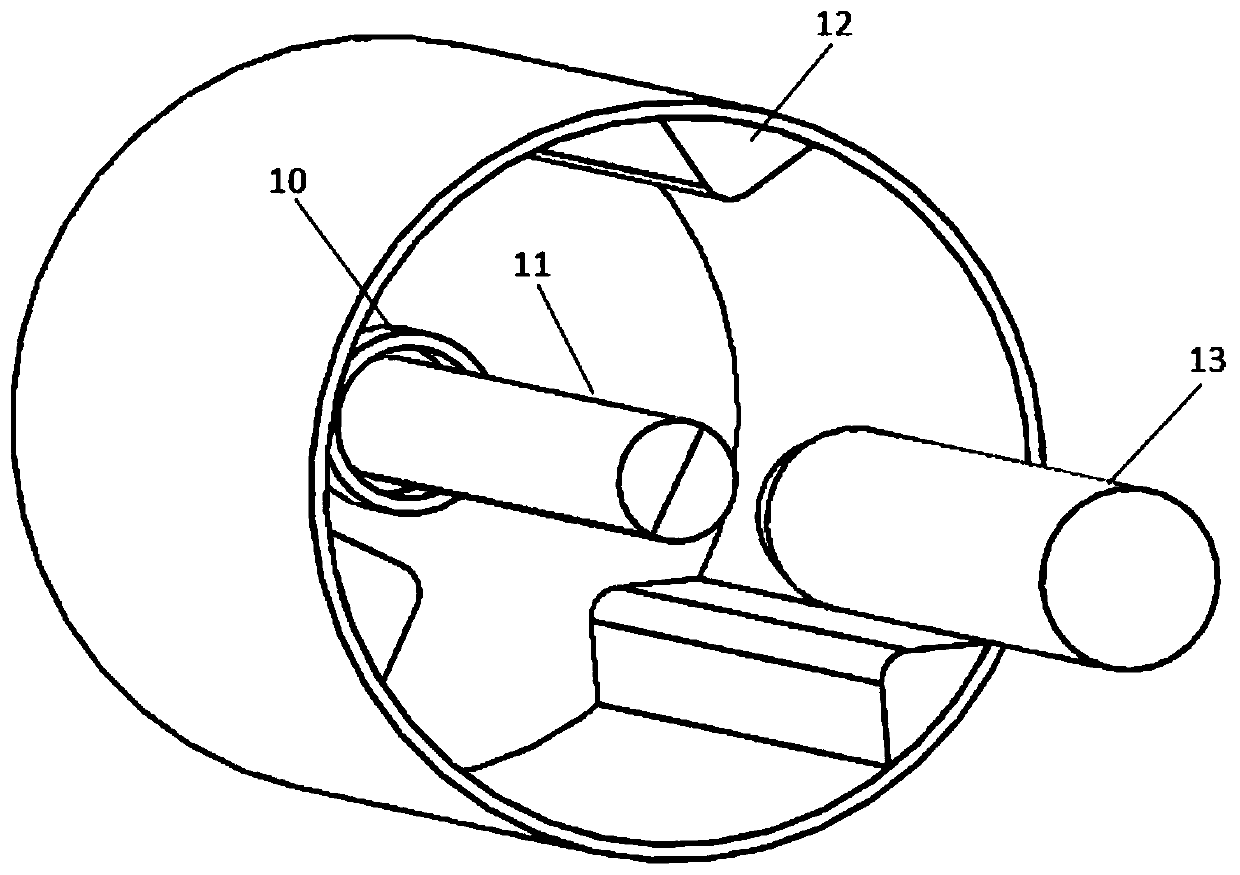

ActiveCN104325412BRealize finishingMeet high speed requirementsAbrasive machine appurtenancesAbrasive blasting machinesCouplingEngineering

The invention discloses an air-floating shaft rotating soft abrasive flow polishing device, which is used for grinding a slender rod to be processed, comprising a fixed plate, a core polishing device for a slender rod, a workpiece feeding device and a buffer device; the slender The rod core polishing device, the workpiece feeding device, and the buffer device are all fixedly installed on the fixed plate; the workpiece feeding device is used for axial feeding of the slender rod core polishing device, and the buffer device is used for buffering the slender rod core polishing device Axial feed; the slender rod core polishing device includes an internal screw type constraint module, a constraint module mounting seat, a sealing cover, a clamping end cover, an O-ring and a screw rod, and the slender rod to be processed passes through one end of the constraint module mounting seat It is connected with the servo motor through a coupling, and the other end is matched with a rolling bearing. The inside of the constraining module mounting seat forms a constrained flow channel through a sealing cover and a clamping end cover. The invention has high polishing efficiency and good polishing effect, and is extremely suitable for ultra-precision machining of the inner wall.

Owner:ZHEJIANG UNIV OF TECH

Automatic polishing separator

The invention discloses an automatic polishing-separating machine which comprises a base, a machining box and a power switch, wherein the machining box is positioned at the middle of the base; the power switch is arranged on one side of the base; a separating plate is arranged in the machining box; a plurality of vent holes are formed in the separating plate; a rotating shaft is arranged at the middle of the separating plate, and rotationally connected with the bottoms of the separating plate and the machining box; a plurality of stirring rods are circumferentially arranged at one end of the rotating shaft in the machining box; a motor is arranged at the other end of the rotating shaft; a plurality of draught fans are arranged between the bottoms of the separating plate and the machining box; a plurality of hollow steel balls are arranged on the separating plate; the ball diameter of each steel ball is greater than the hole diameter of each vent hole; a top plate is hinged with the top of the machining box; a plurality of electromagnets used for adsorbing the steel balls are arranged on the top plate, and connected with a control switch; the draught fans and the control switch are electrically connected with each other; and the motor and the power switch are electrically connected with each other. By adoption of the automatic polishing-separating machine disclosed by the invention, the problem that a conventional oil switch polishing device is complex in operation procedure can be mainly solved.

Owner:EAST SEALING TECH (JIANGSU) CO LTD

Method for modulating high-aspect-ratio hole inner surface features by using laser

ActiveCN110587141AAchieve productionHigh precisionLaser beam welding apparatusLaser processingLight beam

The invention discloses a method for modulating high-aspect-ratio hole inner surface features by using a laser, and belongs to the technical field of laser processing. The method is characterized by comprising the following steps of (1), cleaning the inner surface of a hole; (2), clamping to enable the axis of the hole to be coincided with the normal incidence direction of the laser; (3), deflecting the incident angle of the laser and circularly scanning along the inner surface of the hole periodically; (4), adjusting the distance between the light beam relative to the surface of a workpiece;and (5), enabling the light beam to cover the whole inner surface of the hole. According to the method, based on the laser remelting technology, the high-aspect ratio hole is reprocessed by adopting the laser, local lines and local micro-cracks are efficiently eliminated by laser melting a thin layer of material, the surface roughness is greatly reduced, surface microcracks are eliminated, and themethod has the characteristics of high precision and high efficiency, and can realize assembly line production.

Owner:SHANDONG UNIV OF TECH

Numerically-controlled lathe tailstock automatic feeding control method capable of controlling finishing of hole bottoms

ActiveCN106112024ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

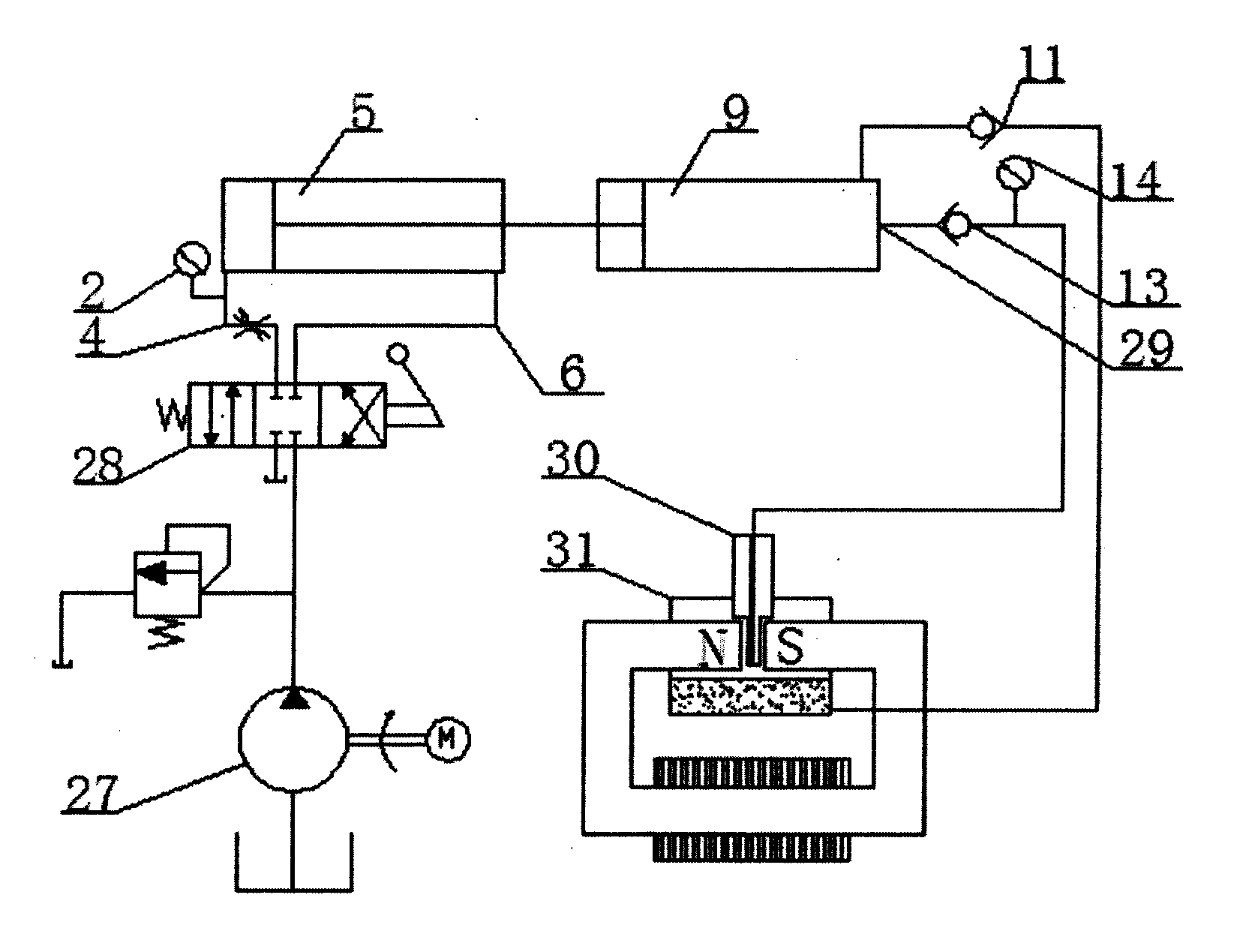

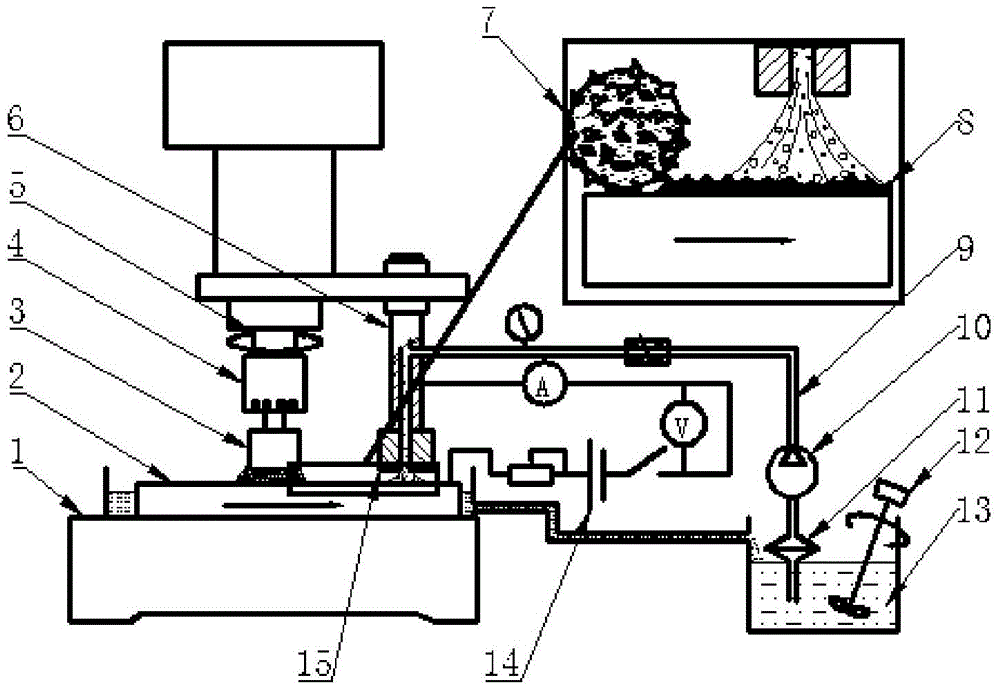

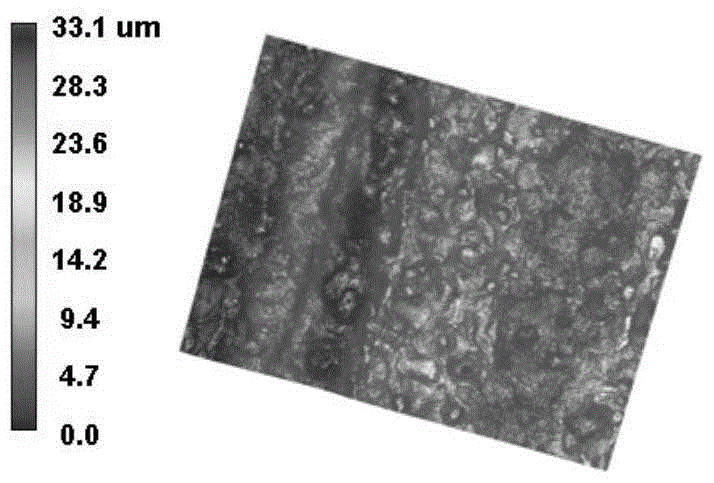

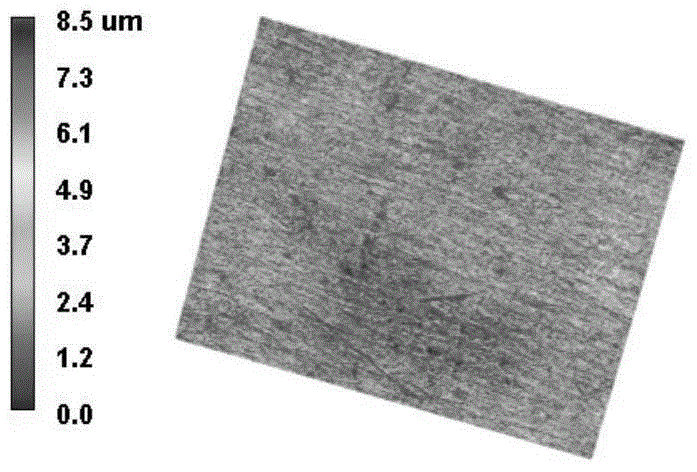

A method and device for electrolytic-magnetic grinding composite smoothing hard materials

The invention discloses a method and a device thereof for electrolytic-magnetic grinding composite smoothing of hard materials. The steps of the method include: setting the DC power supply voltage of the electrolytic-magnetic composite grinding device to be 8-20V, and the electrolyte solution to be a sodium nitrate solution with a concentration of 12-20%; installing the electrodes and magnetic poles on the machine tool, turning on the DC power supply and the machine tool Fine grinding; replace the sintered magnetic abrasive for ultra-fine grinding. The device adopted in the method includes an electrolytic-magnetic grinding composite mechanism and an electrolyte supply mechanism, and the electrolytic-magnetic grinding composite mechanism includes: a workbench, a workpiece, a magnetic pole, a fixture, a machine tool, a connecting rod, magnetic abrasive particles, a passivation film, and a DC power supply and electrodes; the electrolyte supply mechanism includes: delivery pipe, peristaltic pump, filter, stirrer and electrolyte. The invention combines the electrolytic polishing process and the magnetic grinding process, exerts their respective advantages, and remarkably improves the grinding process efficiency and the surface quality of the workpiece.

Owner:UNIV OF SCI & TECH LIAONING

A kind of viscoelastic magnetic abrasive tool with silicon rubber as matrix and preparation method thereof

The invention provides a viscoelastic magnetic grinding tool with silicone rubber as the matrix and a preparation method thereof, and belongs to the field of mechanical part precision surface polishing. The grinding tool can solve the problems that in the prior art, a grinding tool is high in use cost, complex-surface workpieces are difficult to machine, and after machining, the metal surface layer is subjected to plastic deformation, the surface hardness is increased, and residual compressive stress exists. A composite grinding material is formed by mixing a matrix, a ferromagnetic phase, a grinding grain phase and a surface modifier, is in a semi-solid shape and has viscoelasticity, plasticity, mobility and magnetism. The matrix of the viscoelastic magnetic grinding tool is made of a semi-solid compound which is composed of 107 silicone rubber, a chemical agent, nano silicon dioxide, silicon oil and naphthenic oil. The prepared novel magnetic grinding tool is high in grinding capability, good in self-sharpening performance small in temperature rise and free of residual stress in machining, and complex surfaces with inner holes, grooves and the like can be subjected to finish machining.

Owner:TAIYUAN UNIV OF TECH

An automatic feed control method for the tailstock of a CNC lathe that can control the finishing of the bottom of the hole

ActiveCN106112024BRealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

A method of laser modulation of inner surface features of high aspect ratio holes

ActiveCN110587141BAchieve productionHigh precisionLaser beam welding apparatusLaser processingAngle of incidence

The invention relates to a method for modulating inner surface features of a hole with a high depth-to-diameter ratio by using a laser, belonging to the technical field of laser processing. It is characterized in that it includes the following steps: (1) cleaning the inner surface of the hole; (2) clamping so that the axis of the hole coincides with the normal incident direction of the laser; (3) deflecting the incident angle of the laser and periodically scanning along the inner surface of the hole; (4) Adjust the distance of the beam relative to the surface of the workpiece; (5) Make the beam cover the entire inner surface of the hole. The invention is based on laser remelting technology, and adopts laser to reprocess holes with high depth-to-diameter ratio. Efficiently eliminate local lines and local microcracks by laser melting a thin layer of material. Greatly reduces surface roughness and eliminates surface microcracks. It has the characteristics of high precision and high efficiency, and can realize assembly line production.

Owner:SHANDONG UNIV OF TECH

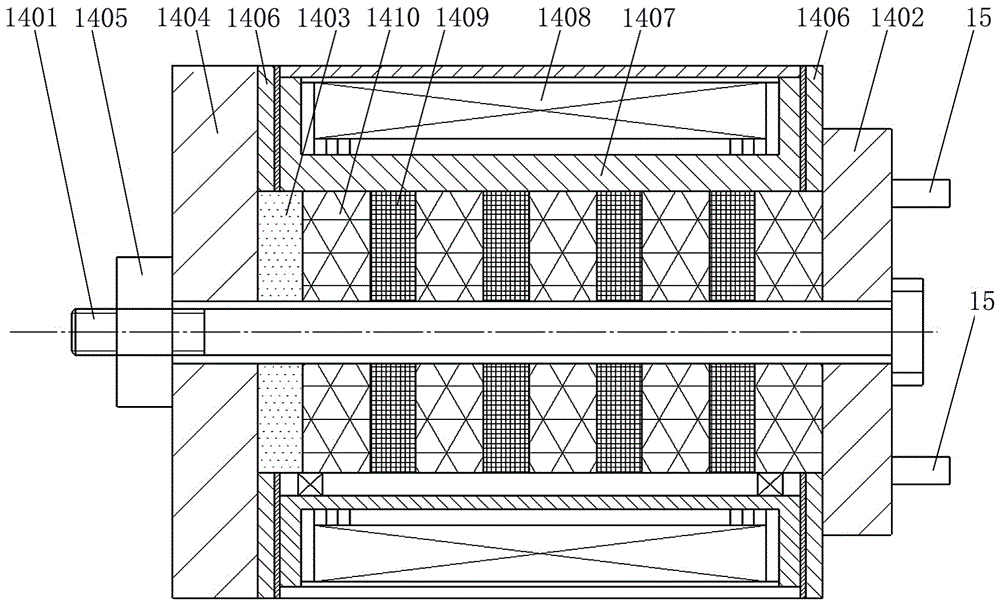

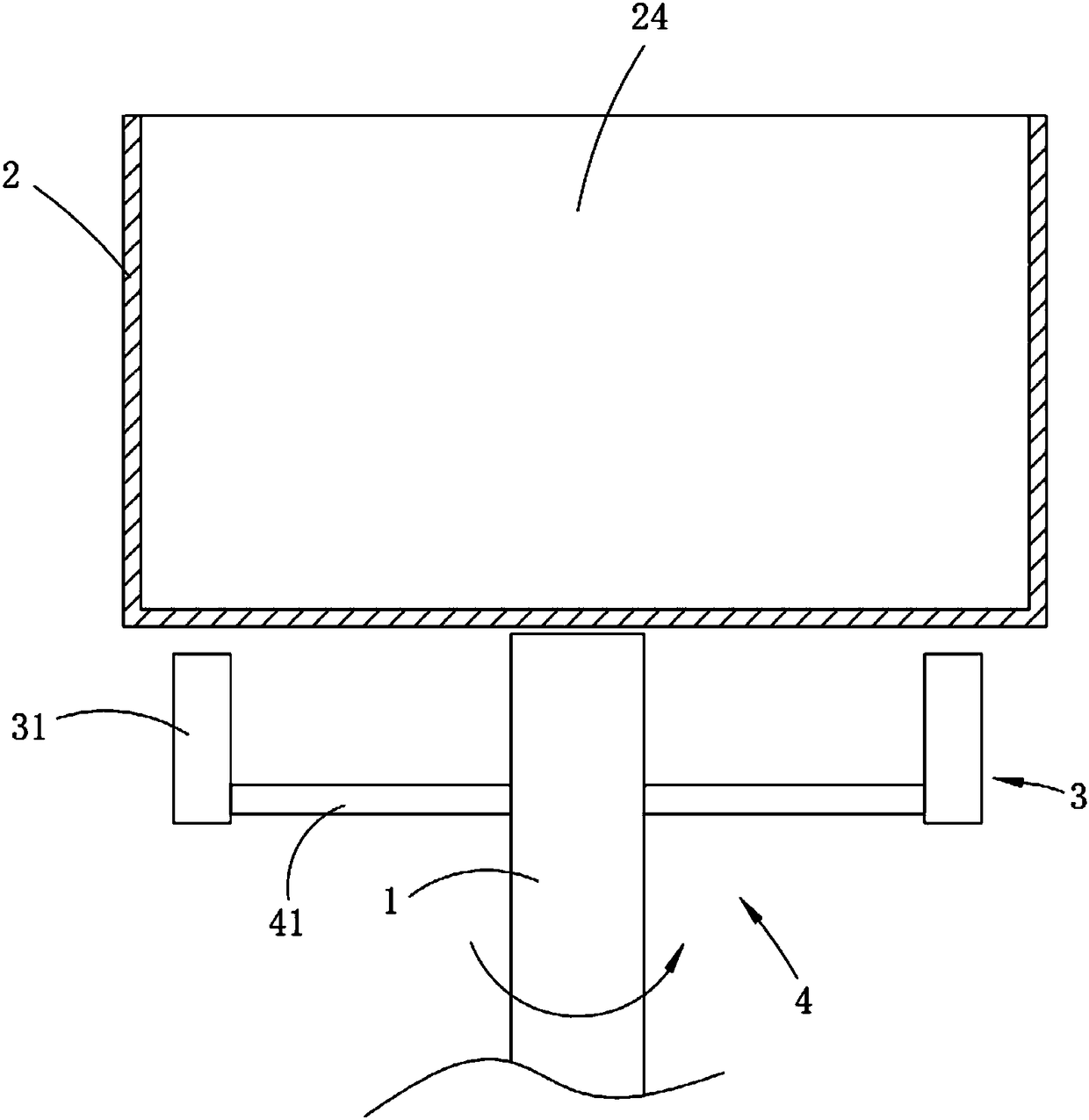

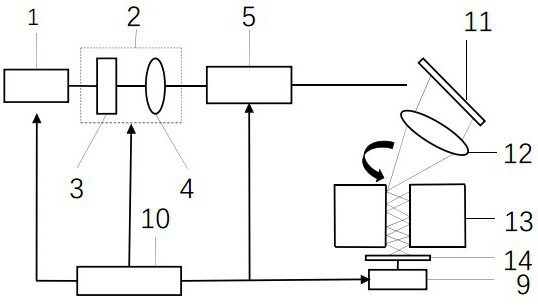

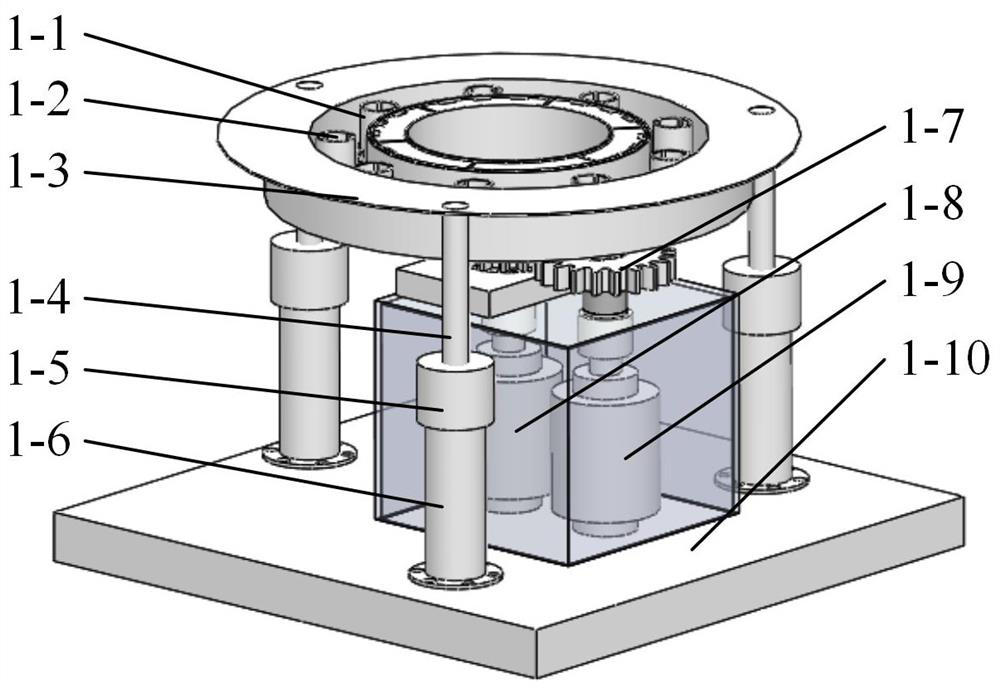

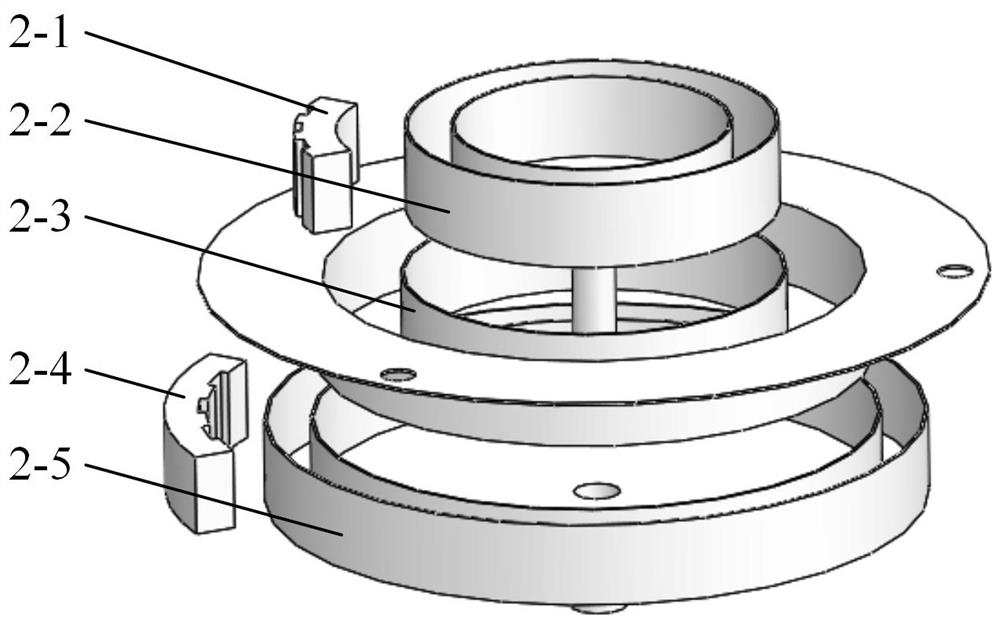

A magnetic field-assisted lightening device and method for complex curved surfaces based on alternating magnetic field

ActiveCN112658817BAchieve relative movementEfficient and high-quality finishingGrinding drivesGrinding work supportsGear driveElectric machine

Aiming at the technical problems of high-efficiency, high-quality finishing and flexible control of complex curved surfaces, a magnetic field-assisted finishing device and method for complex curved surfaces based on alternating magnetic fields were invented. The device includes a workpiece clamping device, a magnetic field generating device, a vibrating connecting rod, a vibrating motor, a supporting connecting rod, a gear transmission mechanism, an inner annular magnetic pole groove driving motor, an outer annular magnetic pole groove driving motor and a base, and the magnetic field generating device includes Inner annular magnetic poles, inner annular magnetic pole slots, annular baffles, outer annular magnetic poles and outer annular magnetic pole slots. Among them, the workpiece clamping device can realize the clamping of different surfaces of the parts to be processed; adjust the rotation direction and speed of the inner and outer ring magnetic poles, generate an alternating magnetic field, and drive the magnetic finishing medium to carry out finishing processing; the three vibration motors Vibration composite action further improves the finishing efficiency. The invention can break through the limitation of the traditional method on complex curved surface finishing, so as to realize efficient flexible automatic finishing.

Owner:SHANDONG UNIV OF TECH

A method for automatic control of tailstock of CNC lathe

ActiveCN106001633BRealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

Owner:三星智能科技盐城有限公司

Radial ultrasonic honing device

Owner:ZHONGBEI UNIV

Soft abrasive flow field testing method based on level set

ActiveCN101813555BAccurate descriptionSports state is accurateHydrodynamic testingSpecial data processing applicationsDiscretizationComputer science

A soft abrasive flow field testing method based on a level set comprises the following steps: 1) establishing an equation of motion of the level set function of the soft abrasive flow by combining a fluid Navier-Stokes equation; 2) discretizing and projecting space; 3) discretizing time; 4) iterating combination of the level set function and function of volume of fluid model; 5) reconstructing the distance function; and 6) testing the soft abrasive flow field: better analyzing the flow field characteristics to find the best machining state by adopting the principle of the level set method, namely effectively capturing topological variation of the interface. The testing method improves the computational accuracy and accurately finds the best machining state.

Owner:ZHEJIANG UNIV OF TECH

Magnetic particle grinding device and method for grinding inner and outer surfaces of different tube diameters through ultrasonic waves

The invention discloses a magnetic particle grinding device and method for grinding inner and outer surfaces of different tube diameters through ultrasonic waves. The magnetic particle grinding devicecomprises a working platform, a main shaft rotating drive device, a fixed device, a reciprocating motion device and an ultrasonic vibration grinding device, wherein the main shaft rotating drive device is mounted on the working platform; a rail is arranged on the working platform in the axial direction of the main shaft; the reciprocating motion device can move along the rail; the fixed device can move on the reciprocating motion device in the radial direction of the main shaft; the ultrasonic vibration grinding device is mounted on the fixed device; a tubular workpiece is mounted on a triangular chuck of the main shaft rotating drive device; an auxiliary magnetic pole of the ultrasonic vibrating device is mounted outside the tubular workpiece; and an inner magnetic pole of the ultrasonicvibrating device is arranged in the radial direction of the tubular workpiece. The magnetic particle grinding device can realize compounding motion of magnetic poles, can perform magnetic particle grinding on inner and outer tubes of straight tubes with different tube diameters, improves grinding and polishing quality of inner and outer surfaces of the tubes, improves processing efficiency, and reduces processing cost.

Owner:UNIV OF SCI & TECH LIAONING

Liquid magnetic grinding and it preparation method

InactiveCN100384590CImprove liquidityStrong shape adaptabilityMetal working apparatusMagnetic liquidsRelative motion

A magnetic liquid grinder for polishing the surface of metallic or non-metal work-piece features that when there is no action of magnetic, its magnetic liquid can flow freely and when a magnetic field is applied to it, it can become a visco-plastic substance with a certain rigidity to form a flexible grinding layer on the surface of work-piece. The surface of work-piece can be polished by the relative movement between work-piece and said flexible grinding layer.

Owner:TAIYUAN UNIV OF TECH

A device for turning slender threaded shafts on a lathe

ActiveCN106670594BControl lengthRealize finishingThread cutting machinesThread cutting auxillary apparatusEngineeringScrew thread

The invention discloses a device for long and thin threaded shaft turning of a lathe. The device for long and thin threaded shaft turning of the lathe is mounted on a large carriage of the lathe and comprises a base, a guide sleeve, a telescopic sleeve, a tool reset ring, thread length control mechanisms and tool assemblies. The device has the beneficial effects that due to the arrangement of three sets of threaded tools distributed circumferentially and evenly, threaded shaft deformation in the turning process is reduced, and machining quality is guaranteed; due to arranged adjusting sleeves, the length of a thread on each to-be-turned long and thin shaft can be controlled precisely; due to the arrangement of first inclined faces and third inclined faces capable of being in contact with each other or being separated from each other, thread ending machining can be achieved precisely, and the tool collapse situation is effectively avoided; and due to the arranged tool reset ring, the three sets of threaded tools can contract towards the center at the same time, and operation is fast and convenient.

Owner:徐州力达缝纫设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com