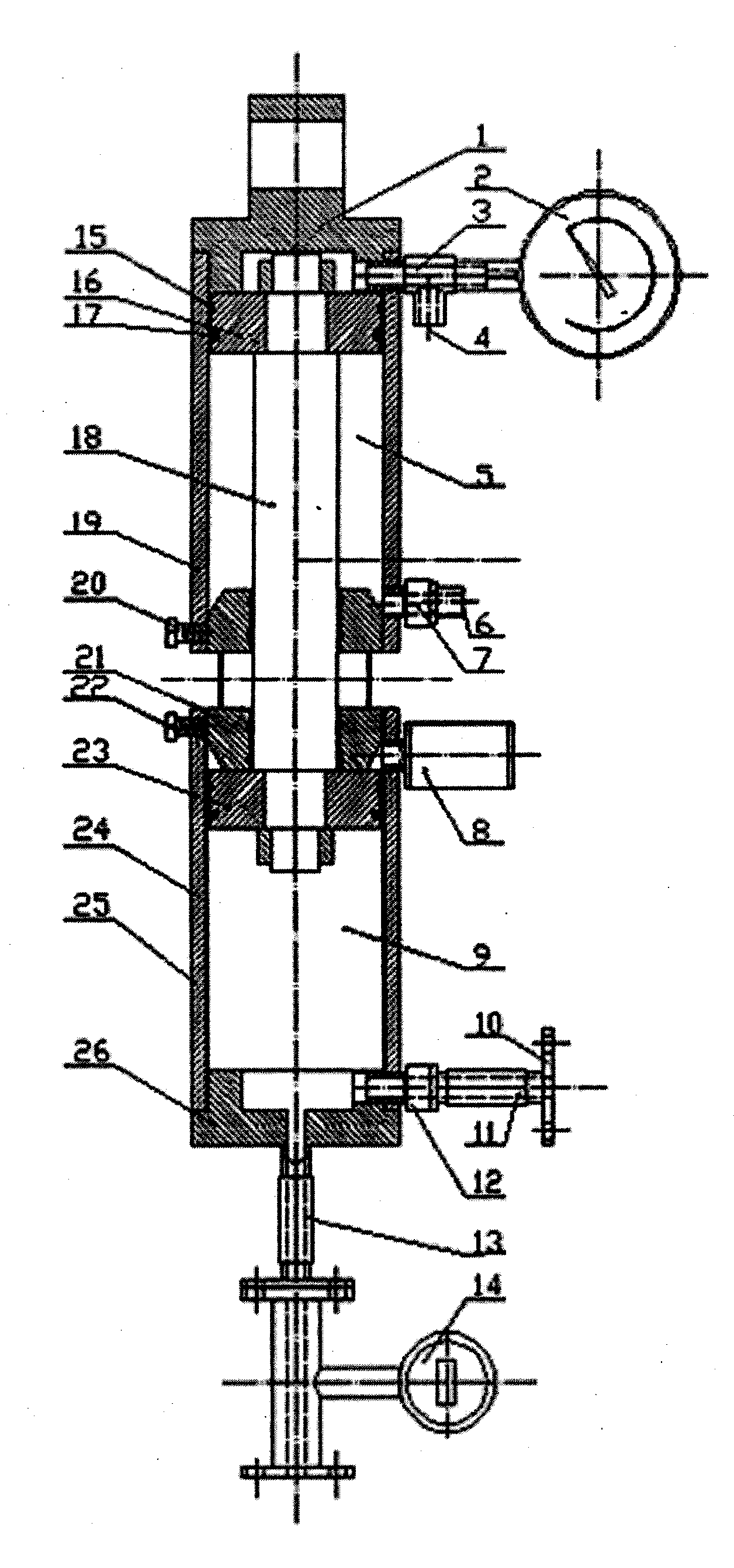

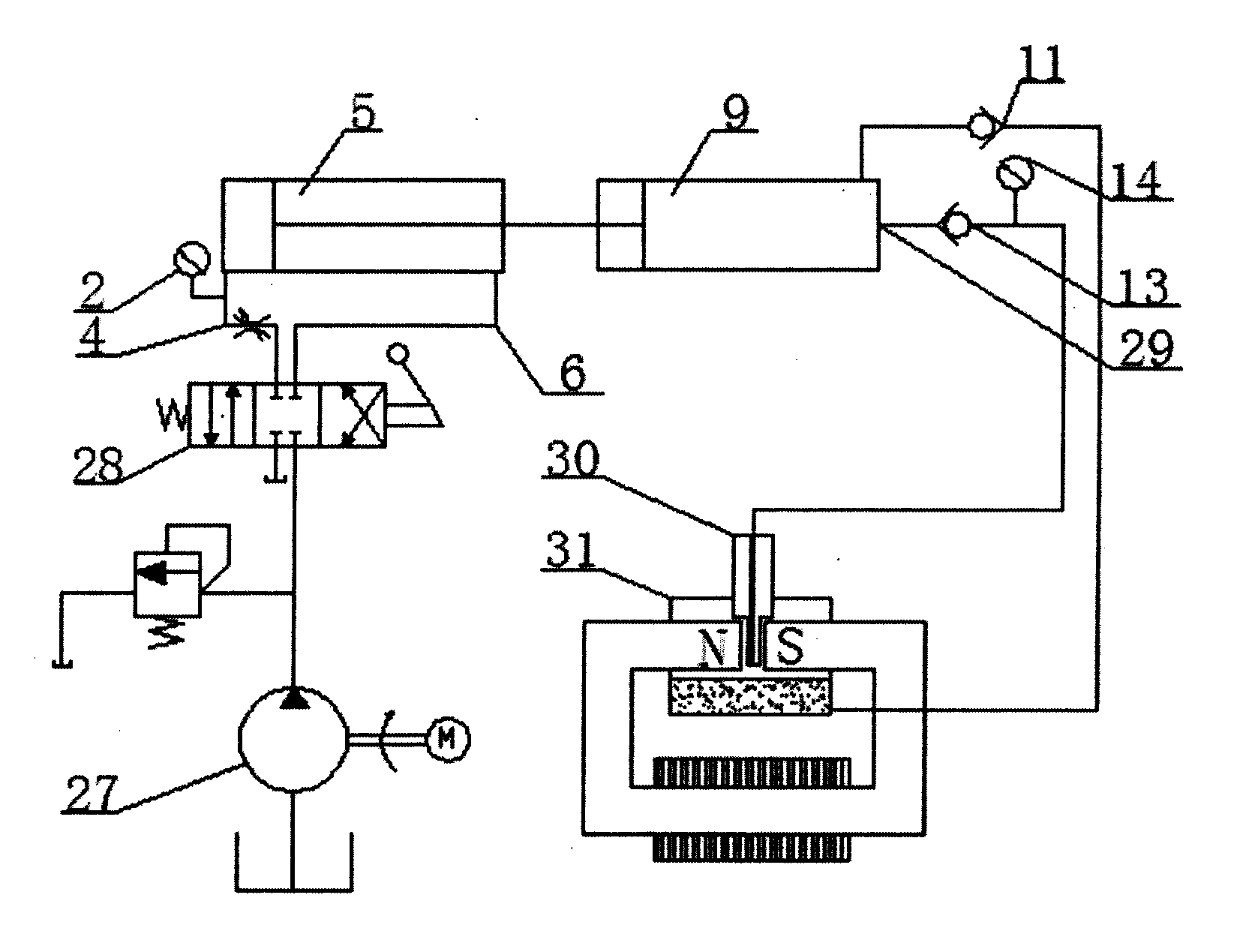

Fluid magnetic abrasive hole finishing processing device

A technology of liquid magnetism and processing equipment, which is applied in the field of finishing of mechanical products, can solve the problems of difficult electrode production, inability to process, and difficult cleaning, and achieve the effects of small harmful residual stress, convenient removal rate, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Development of brand 1030# liquid magnetic abrasive tool

[0042] Add 5.9g of sodium dodecylsulfonate to 195ml of deionized water, heat and stir until completely dissolved, then add 197g of carbonyl iron powder with the brand name RXe (3um) at a low speed (500rpm), green silicon carbide (600 #) 200 grams, increase the rotating speed to 1000rpm, stir on an electronic stirrer for 6 hours, let stand for 24 hours after stirring, and the sedimentation rate is less than 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com