Turning method for thin and long threaded shaft

A threaded shaft and slender technology, which is applied in the field of turning slender threaded shafts, can solve problems such as difficult clamping of workpieces, irregular thread tooth profiles, and unstable thread cutting, etc., to achieve fast and convenient operation, ensure processing quality, reduce deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

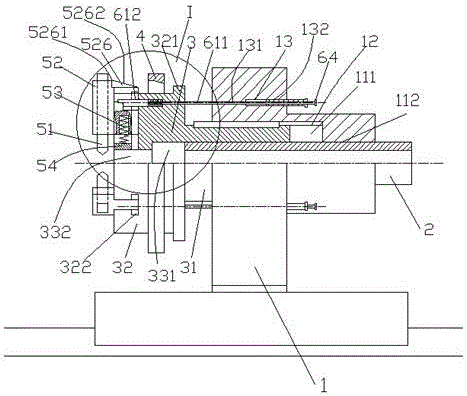

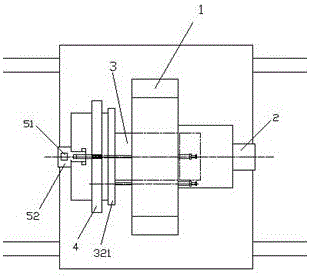

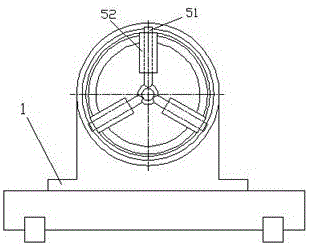

[0029] A device for turning an elongated threaded shaft on a lathe, which uses a device for turning an elongated threaded shaft, the device for turning an elongated threaded shaft is installed on a large carriage of a lathe, which includes a base 1, Guide sleeve 2, telescopic sleeve 3, tool reset ring 4, thread length control mechanism and tool assembly;

[0030] The base 1 is installed on the large carriage of the lathe, and a cylinder is arranged on the right side of the base 1, and three uniformly distributed light holes 131 and diameters suddenly become larger and are provided with an inner cylinder around the cylinder. The first step hole 13 formed by threaded deep holes 132, the middle part of the base 1 is provided with a second step hole consisting of a hole A111 with a larger diameter and a hole B112 with a smaller diameter on the cylinder, and the hole A111 is set There is a long groove 12 with a rectangular cross-section in the left and right directions;

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com