Magnetic particle grinding device and method for grinding inner and outer surfaces of different tube diameters through ultrasonic waves

A grinding device, internal and external surface technology, applied in the field of magnetic particle grinding and finishing, can solve the problems of increased processing cost, low processing efficiency, low efficiency, etc., and achieve improved performance and service life, processing efficiency and processing accuracy. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

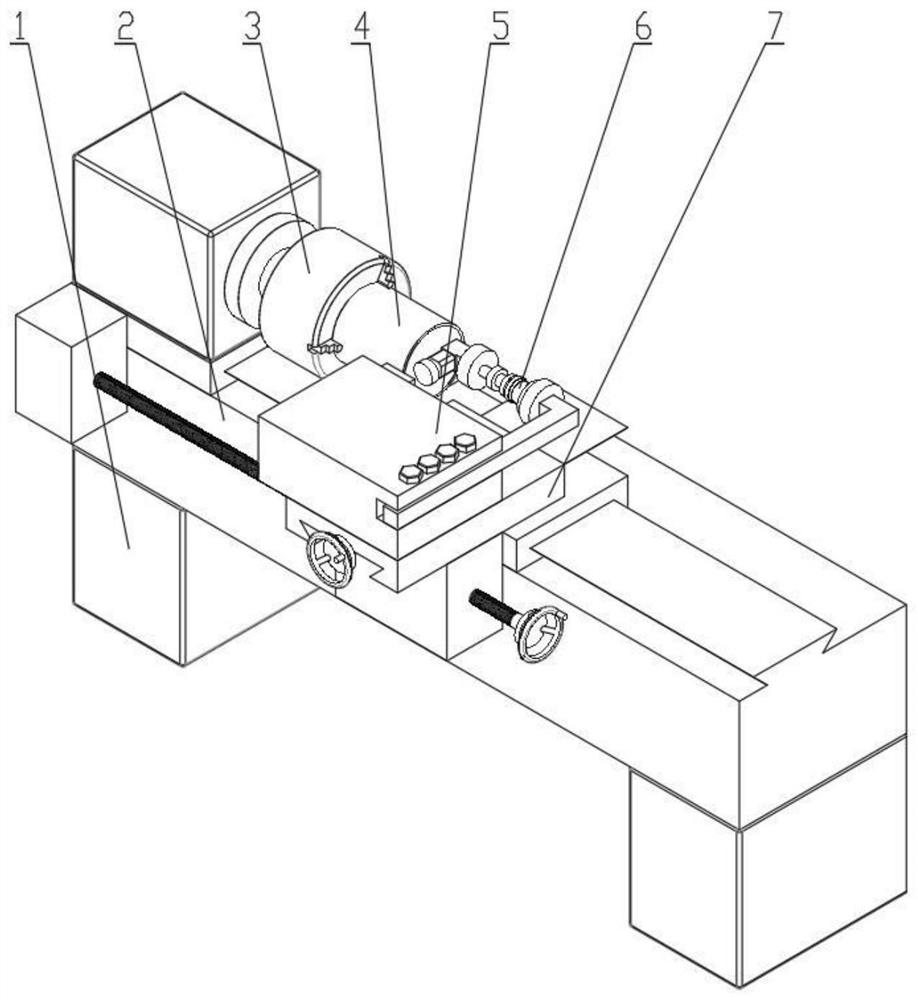

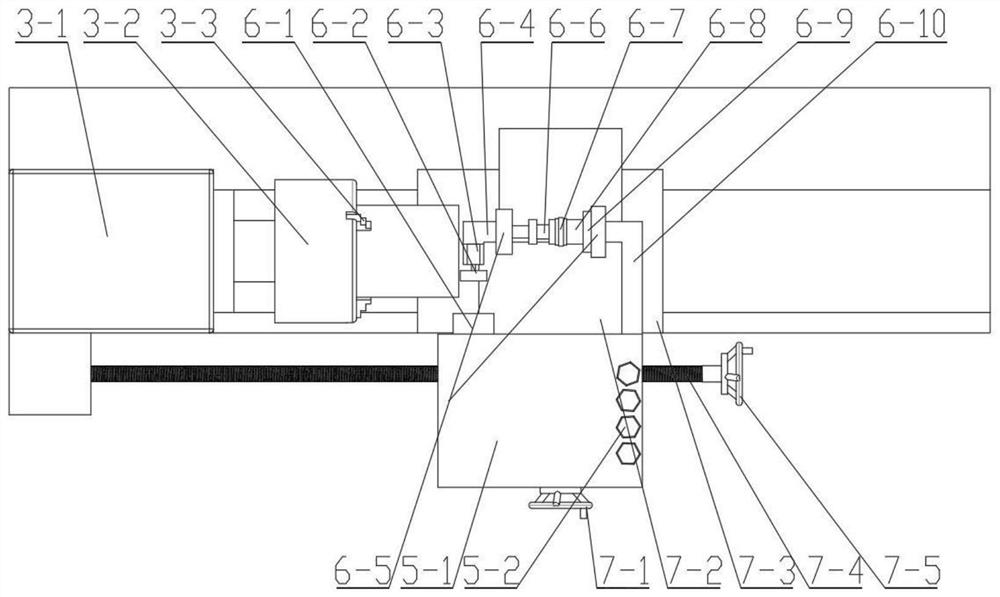

[0028] like Figure 1-Figure 2 As shown, a magnetic particle grinding device for ultrasonically grinding the inner and outer surfaces of different pipe diameters, including a working platform 2, a spindle rotation drive device 3, a fixing device 5, a reciprocating movement device 7, and an ultrasonic vibration grinding device 6, the spindle rotation drive device 3 is installed on the working platform 2, on which a track is arranged axially along the main shaft 3-2, the reciprocating device 7 can move along the track, and the fixing device 5 can be mounted on the reciprocating device 7 Move radially along the main shaft 3-2, the ultrasonic vibration grinding device 6 is installed on the fixture 5, the tubular workpiece 4 is installed on the triangular chuck 3-3 of the main shaft rotation drive device 3, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com