Patents

Literature

156results about How to "Realize synchronized movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

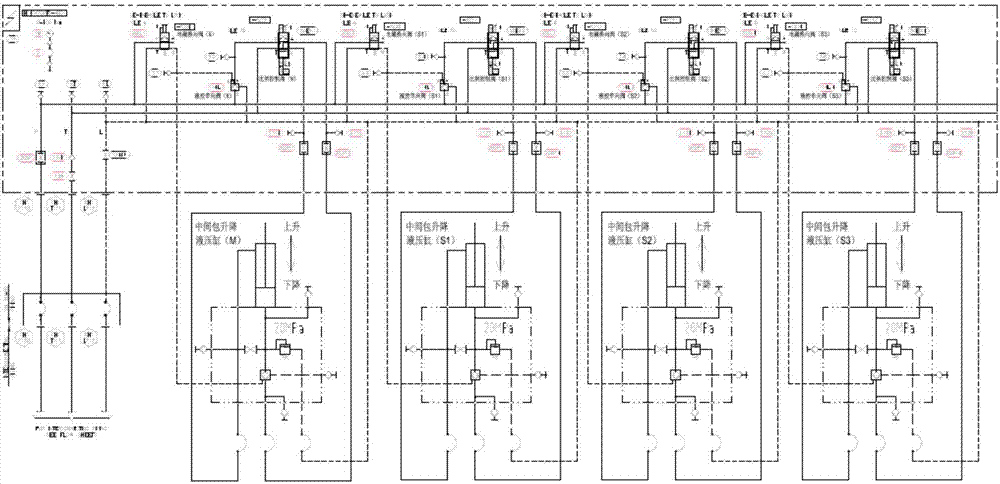

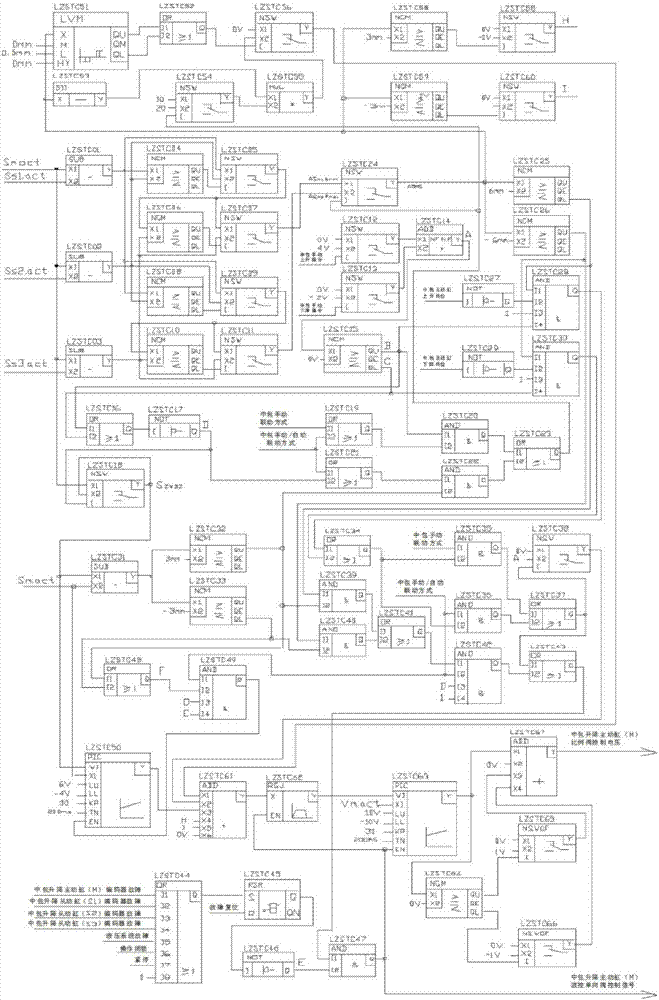

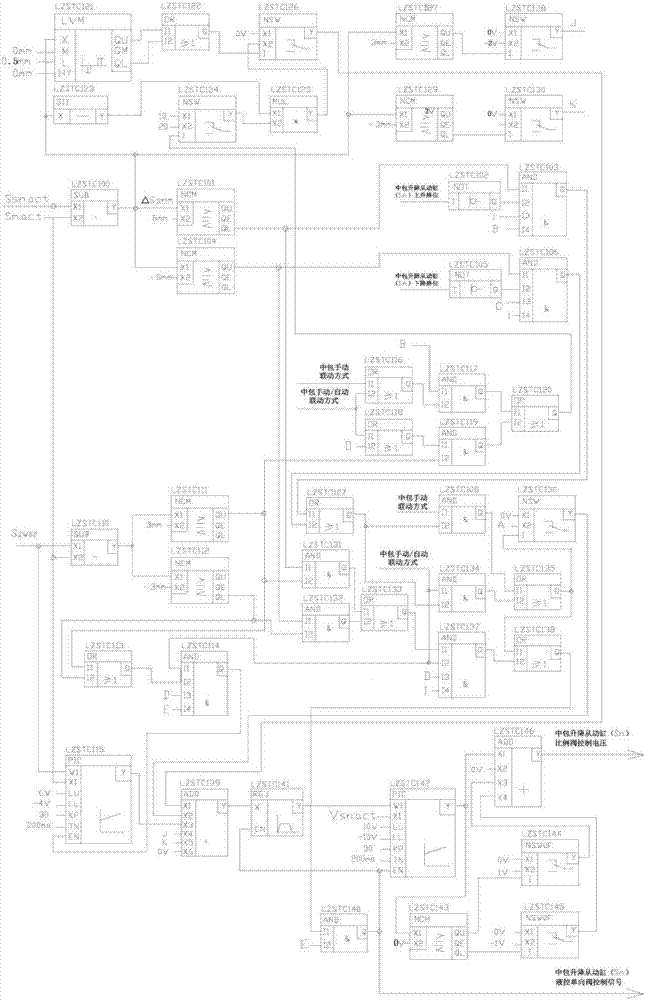

Synchronous control method based on continuous-casting tundish lifting hydraulic cylinder synchronous control system

InactiveCN107314000ARealize synchronized movementAvoid position shiftMelt-holding vesselsServomotorsHydraulic cylinderControl system

The invention belongs to the field of hydraulic transmission control, and provides a synchronous control method based on a continuous-casting tundish lifting hydraulic cylinder synchronous control system. According to the method, the position deviation, beyond a set range, between a driving hydraulic cylinder and a driven hydraulic cylinder is corrected through a driving and driven hydraulic cylinder synchronous position deviation speed correction unit; if the position deviation between the driving hydraulic cylinder and the driven hydraulic cylinder is beyond the set maximum allowable position deviation, the driving hydraulic cylinder at the higher speed or the driven hydraulic cylinder at the higher speed is controlled to stop moving through a driving and driven hydraulic cylinder synchronous position deviation overrun control unit and a driven hydraulic cylinder synchronous position deviation overrun control unit till the position deviation between the driving hydraulic cylinder and the driven hydraulic cylinder is smaller than the set maximum allowable position deviation again; and a driving and driven hydraulic cylinder automatic position holding and control unit is used for preventing position deviation of the driving hydraulic cylinder and the driven hydraulic cylinder in absence of manual instructions. In this way, by adoption of the synchronous control method, under the conditions that leakage of the hydraulic cylinders occurs, the manufacturing accuracy degrees of hydraulic elements are different and loads are nonuniform, synchronous movement of the driving hydraulic cylinder and the driven hydraulic cylinder can be achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

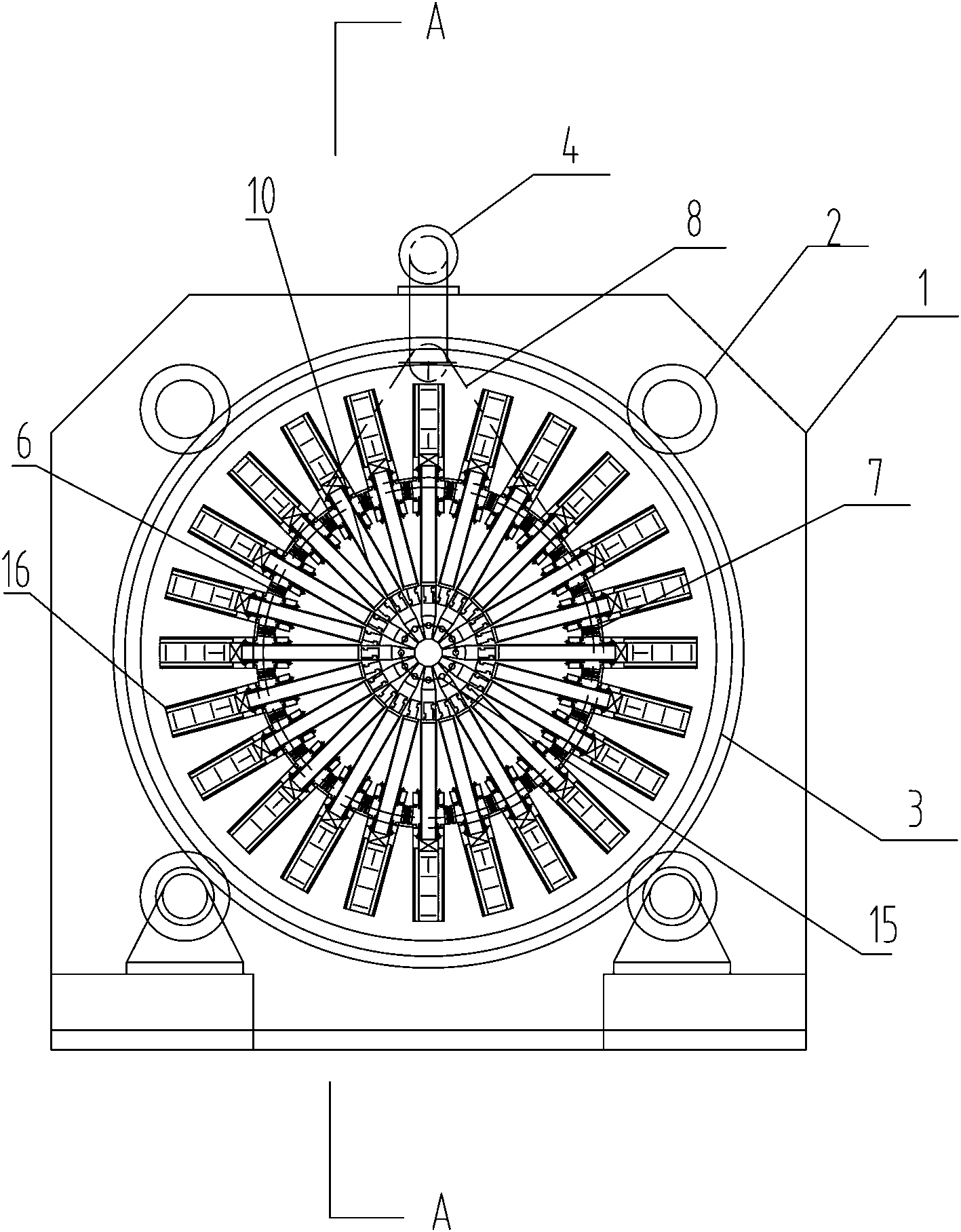

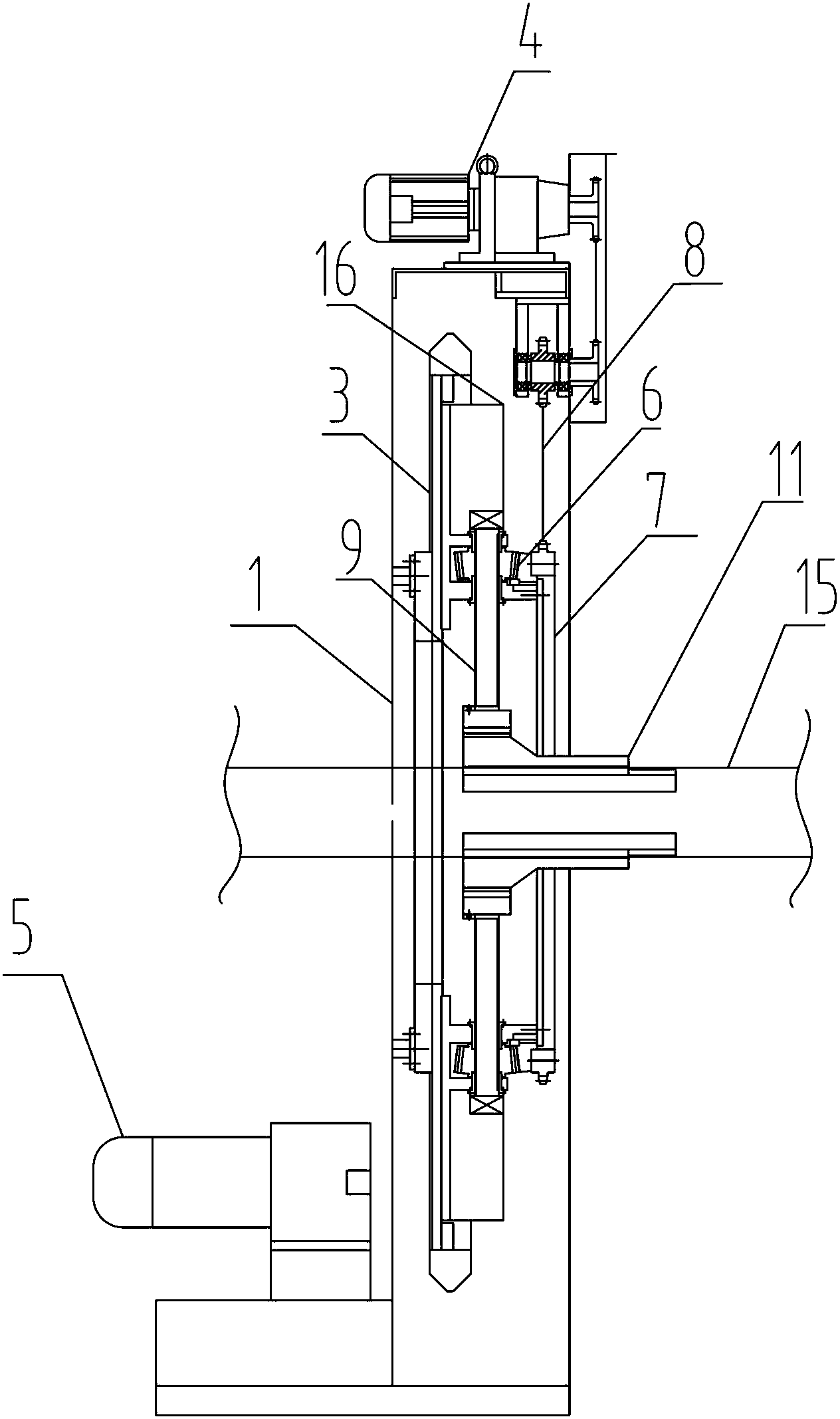

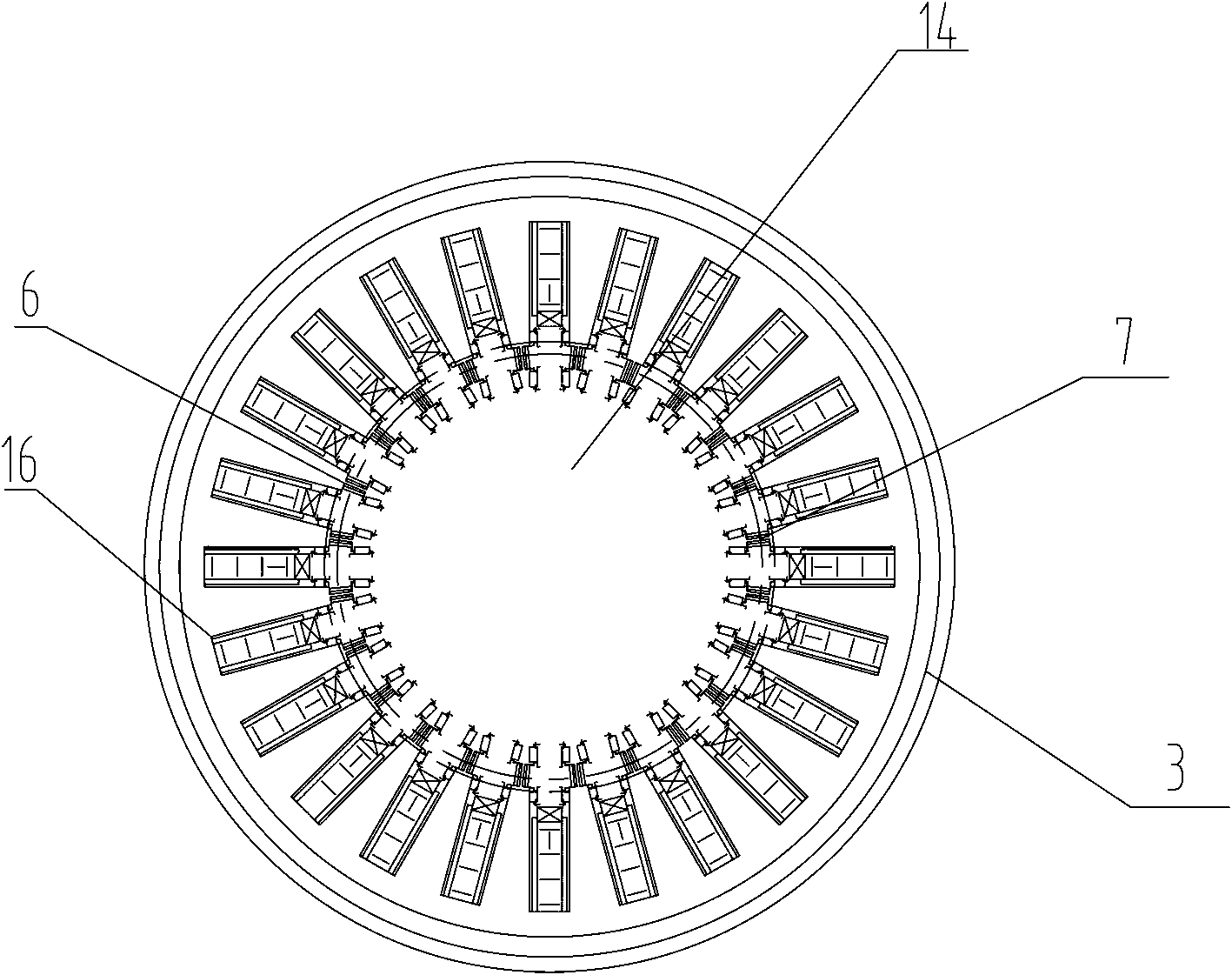

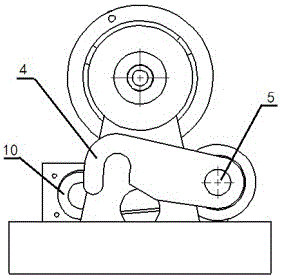

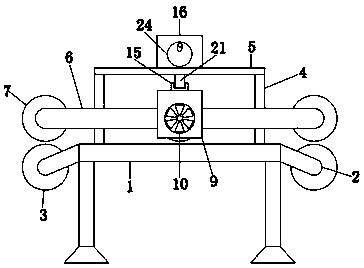

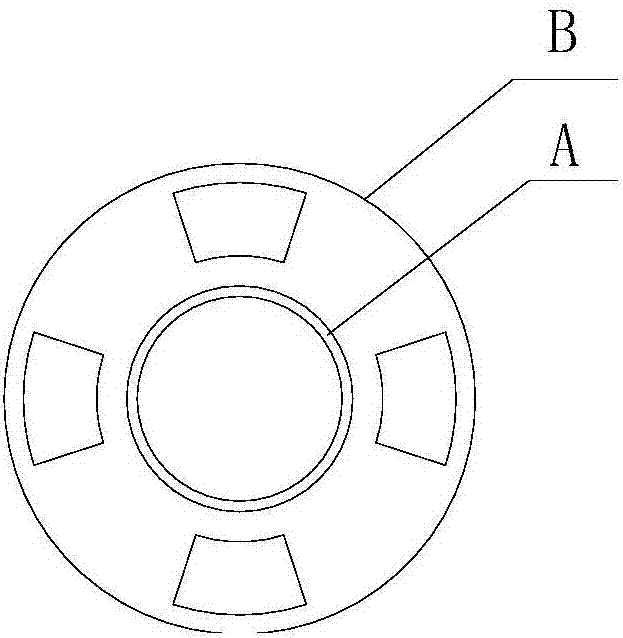

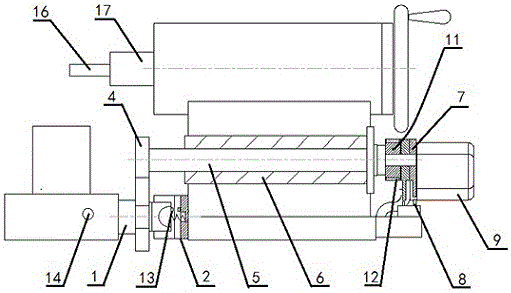

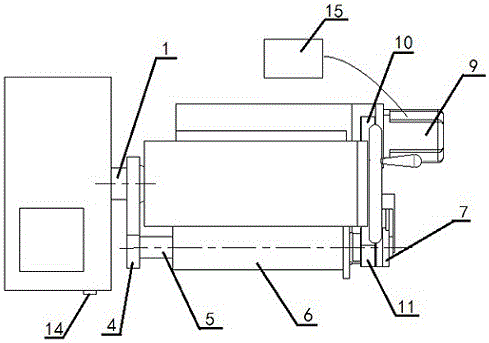

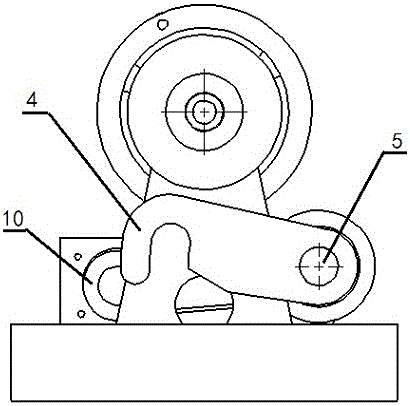

Diameter reducing device for electric pole reinforcing cage forming machine

InactiveCN103008509ARealize synchronized movementAutomatically shrinkMeshed-ring wire networkMolding machineSprocket

The invention provides a diameter reducing device for an electric pole reinforcing cage forming machine. The diameter reducing device comprises a main bracket, a guide wheel mechanism, a main rotating disk, a diameter reducing driving mechanism, a diameter reducing mechanism and a main rotating driving mechanism, wherein the guide wheel mechanism is arranged on the main bracket, the main rotating disk is arranged on the guide wheel mechanism, the diameter reducing mechanism and the diameter reducing driving mechanism are arranged on the main rotating disk, the main rotating driving mechanism can drive the main rotating disk to rotate, the diameter reducing mechanism consists of a pinion and a bevel gear wheel, the diameter reducing driving mechanism drives the bevel gear wheel to rotate by a chain wheel mechanism, the bevel gear wheel rotates to drive the pinion to rotate, a hole is arranged in the middle of the pinion, a thread is arranged in the inner wall of the hole, a thread is arranged at the outer surface of a lead screw mechanism, and the lead screw mechanism penetrates through the hole of the pinion and is connected with a reinforcement penetration mechanism. The diameter reducing device has the advantages that by adjusting the differential value of the rotating speed of the main rotating disk and the bevel gear wheel and automatically changing the diameter of an electric pole reinforcing cage, the forming device not only is applicable to equal-diameter electric pole reinforcing cages, but also is applicable to tapered electric pole reinforcing cages.

Owner:YICHANG HAITIAN ULTRASONIC TECH

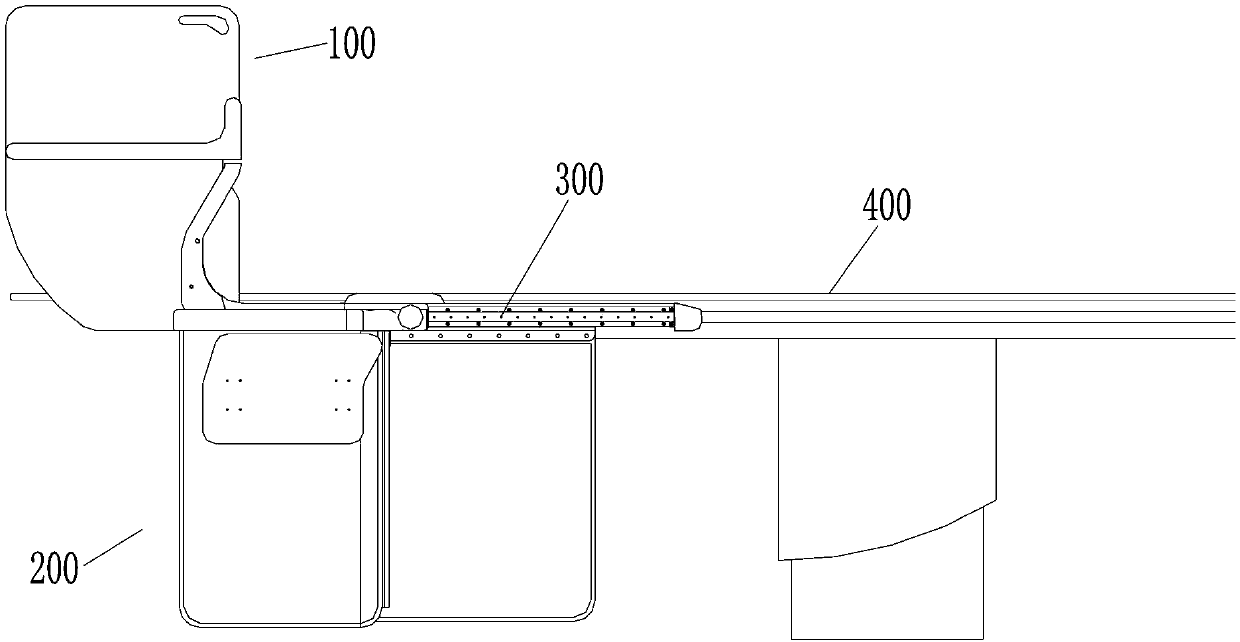

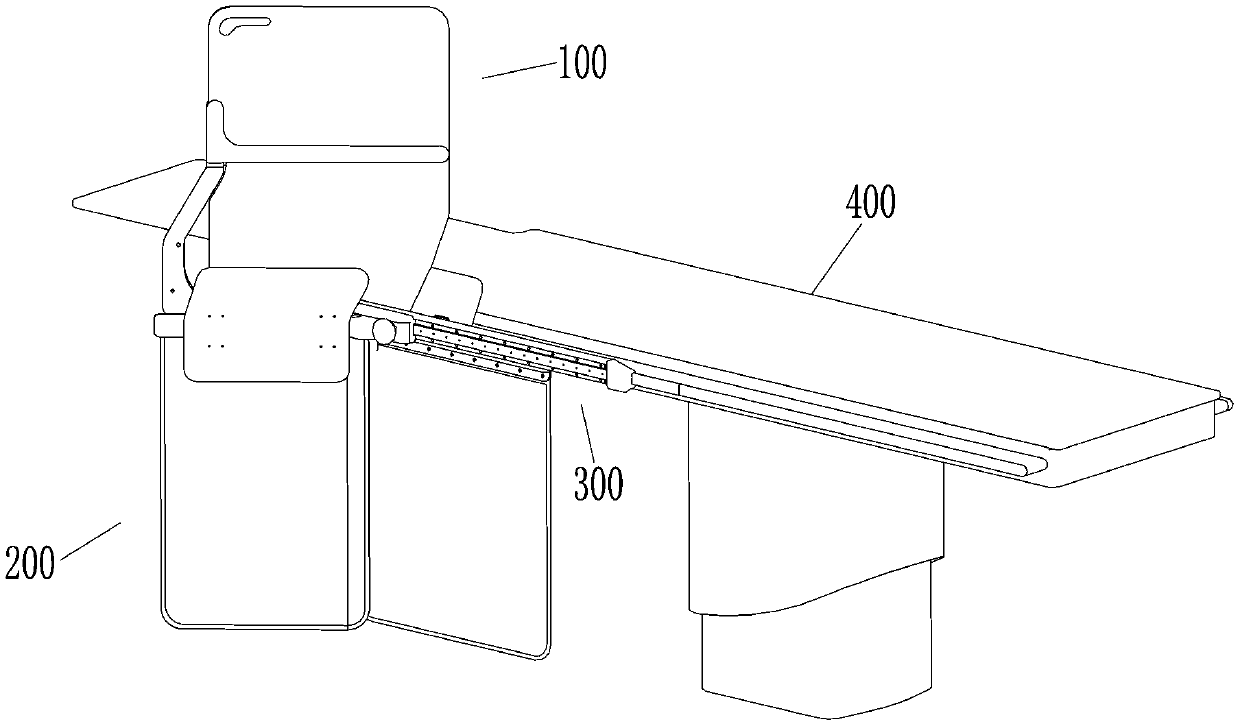

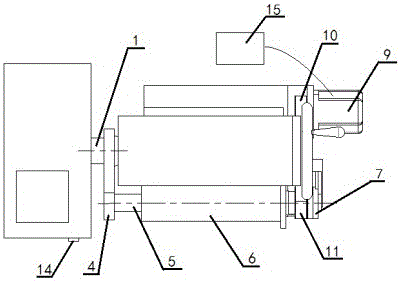

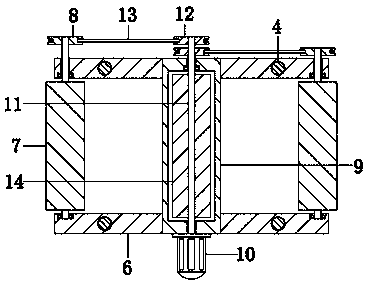

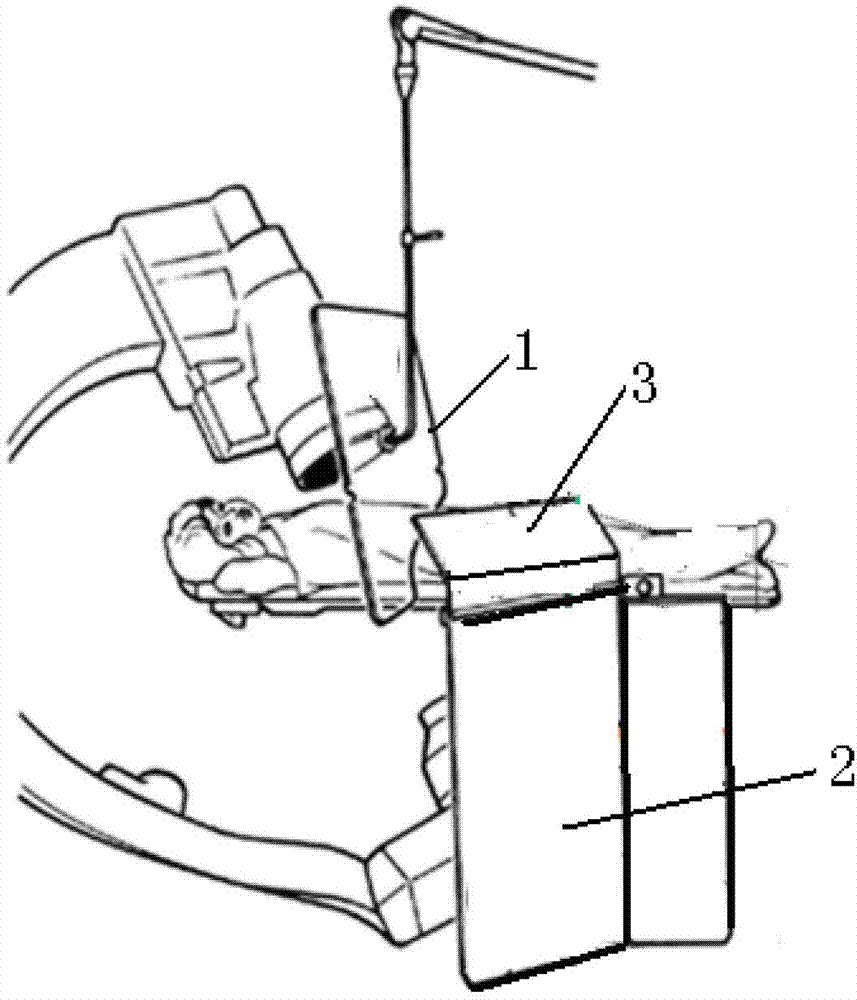

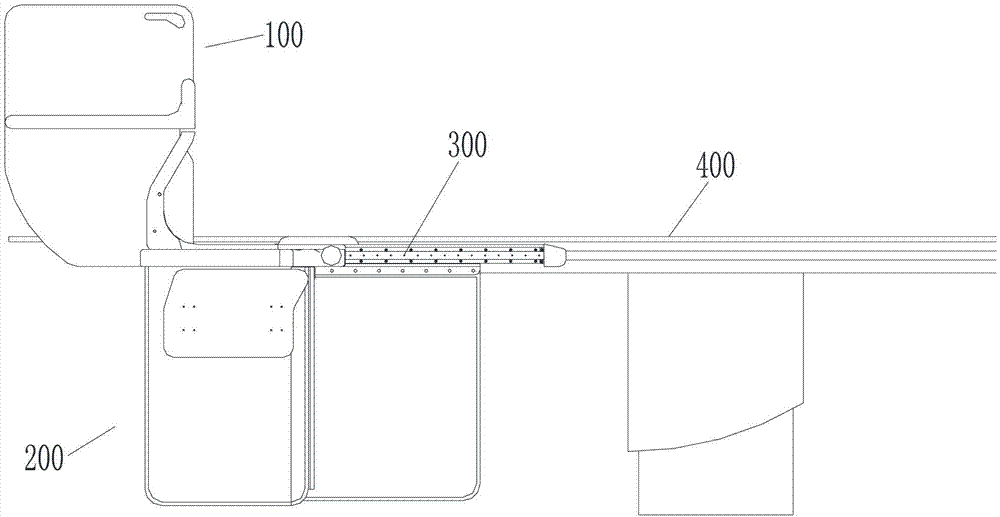

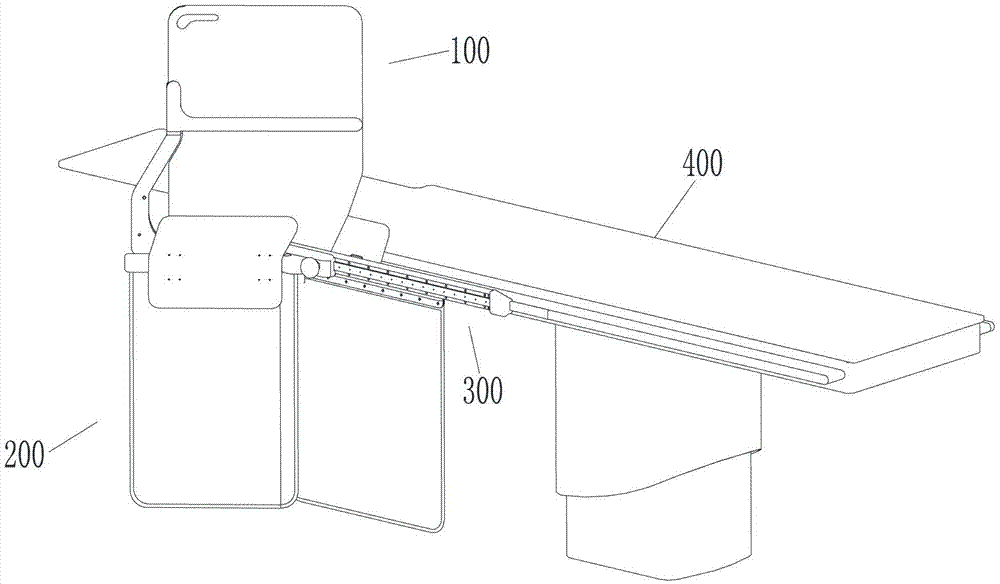

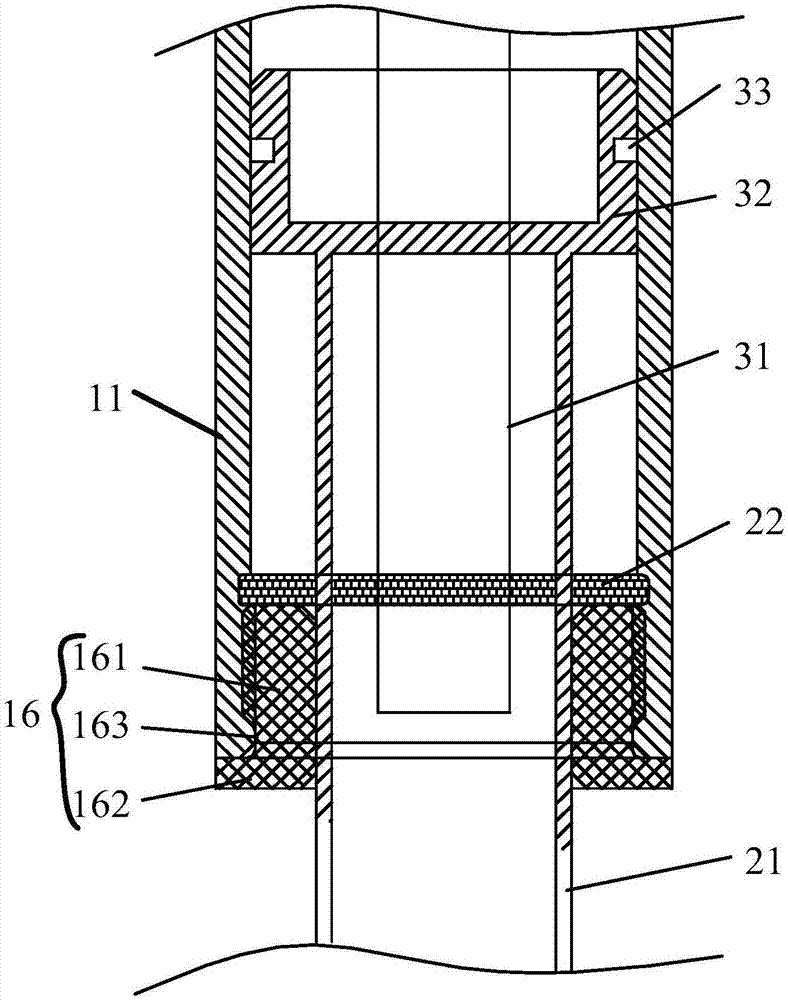

Integrated X-ray protection device on angiography machine

ActiveCN103385733ARealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

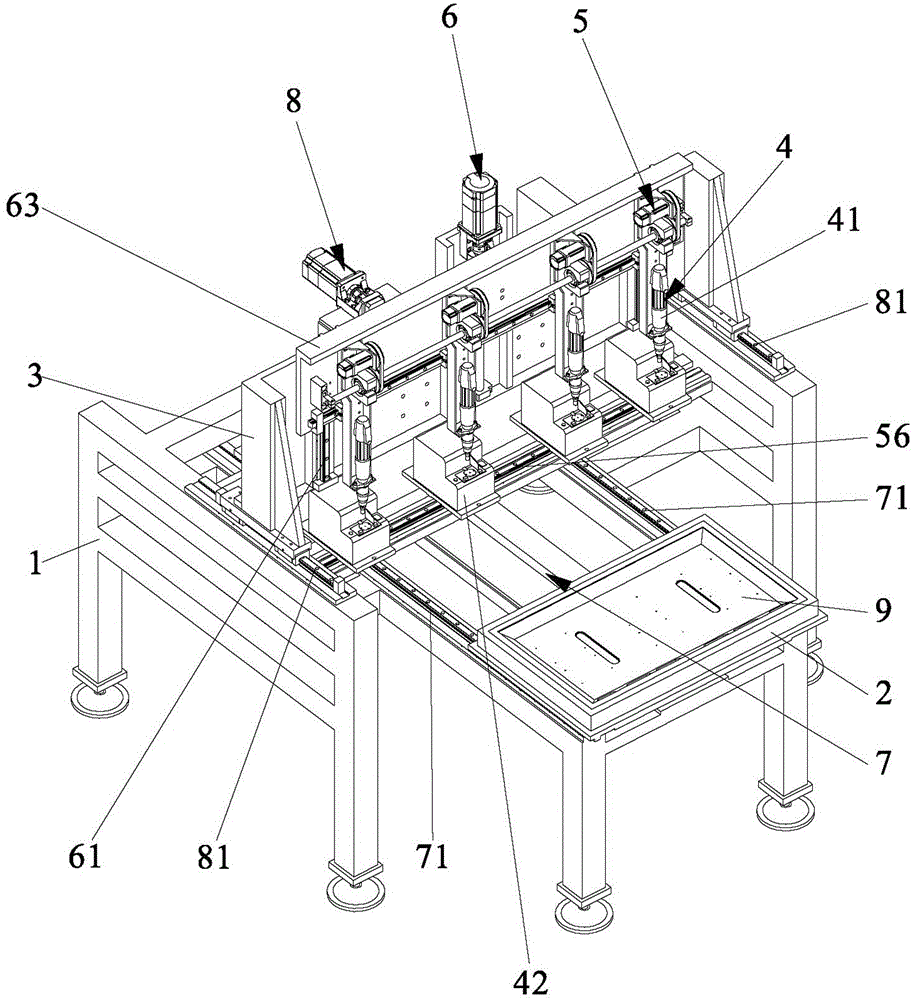

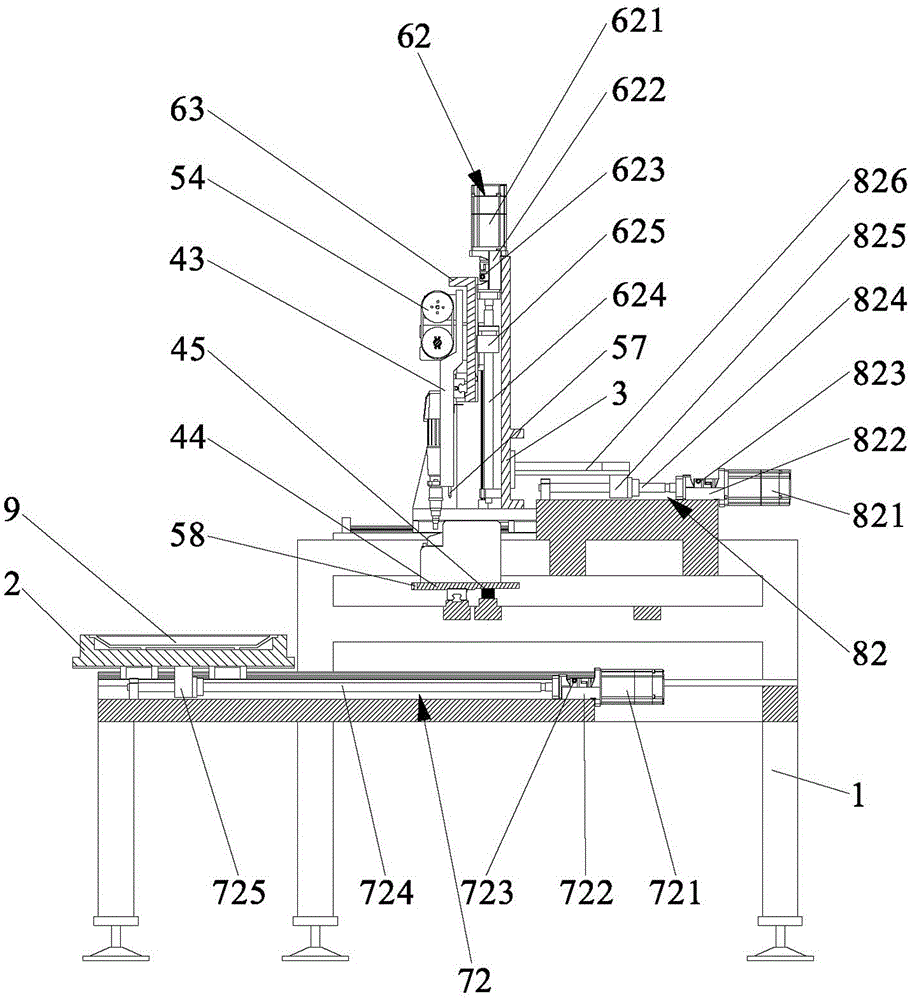

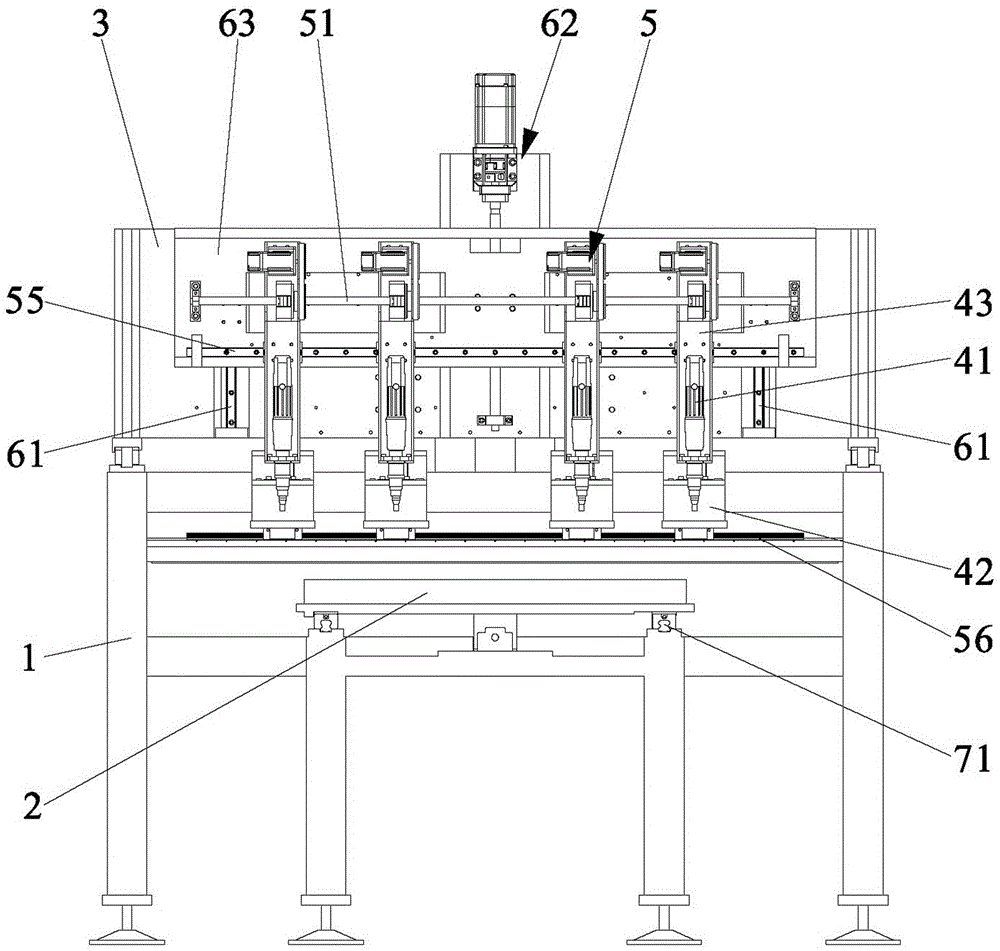

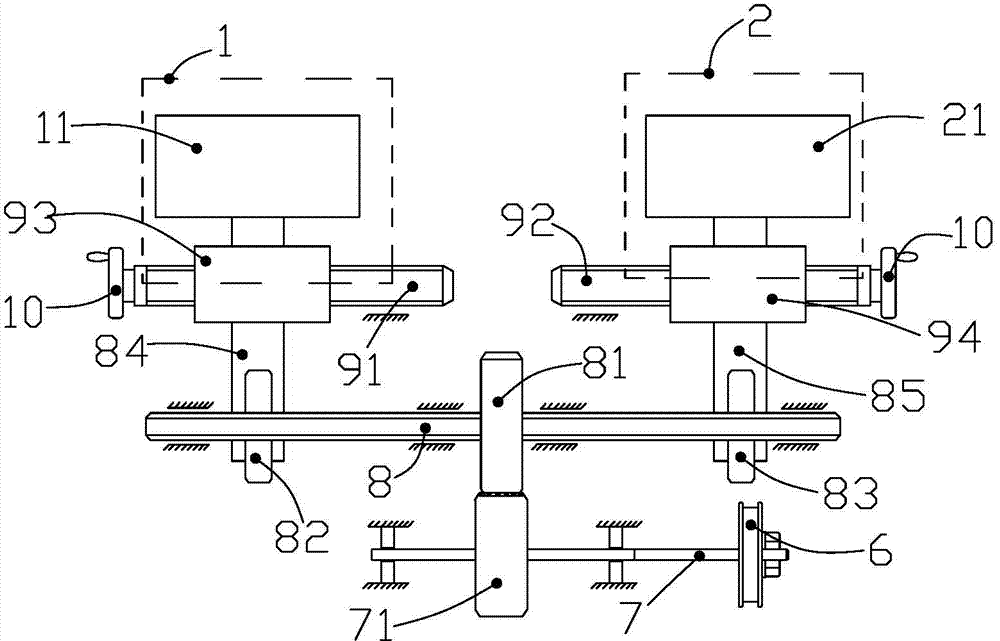

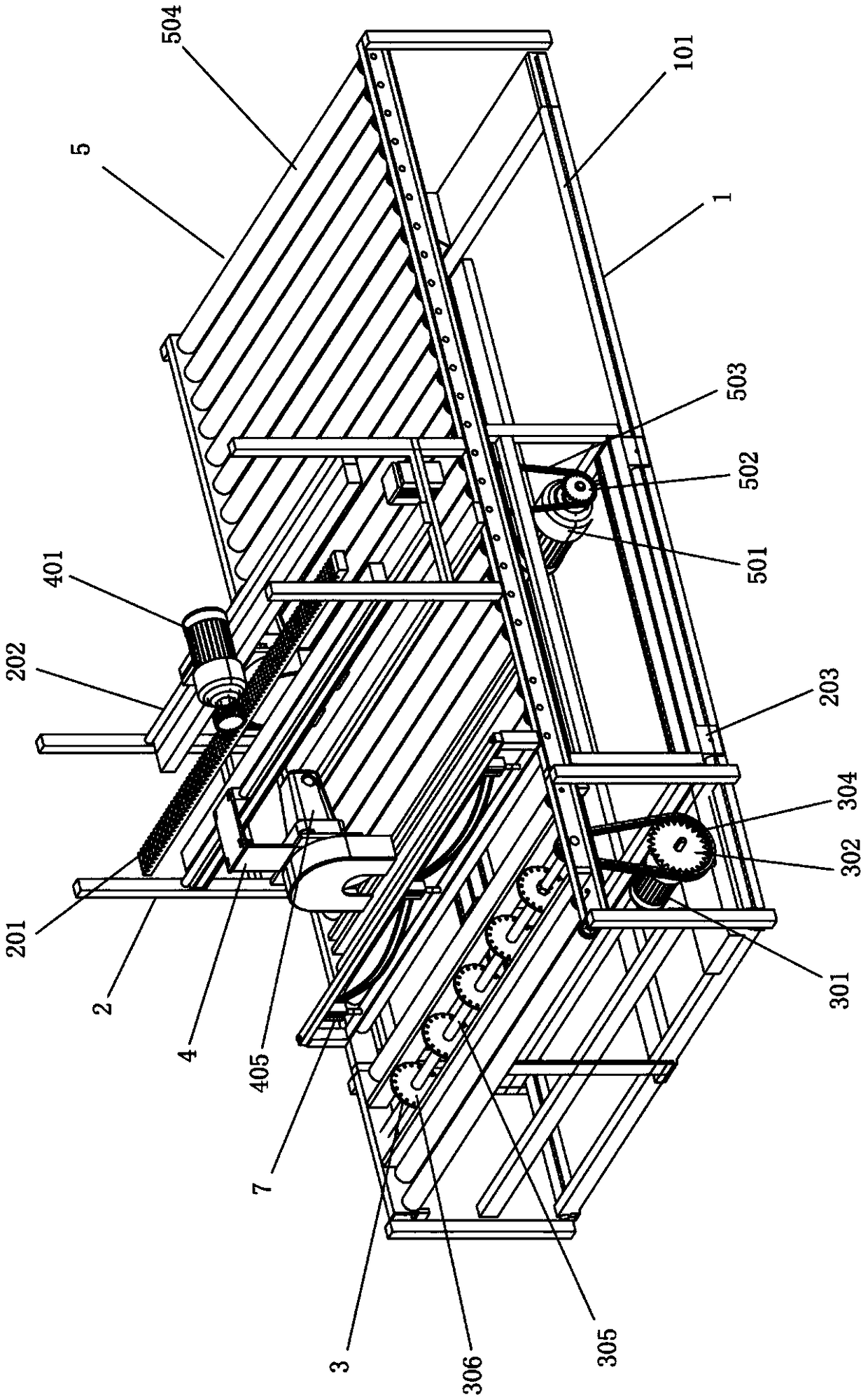

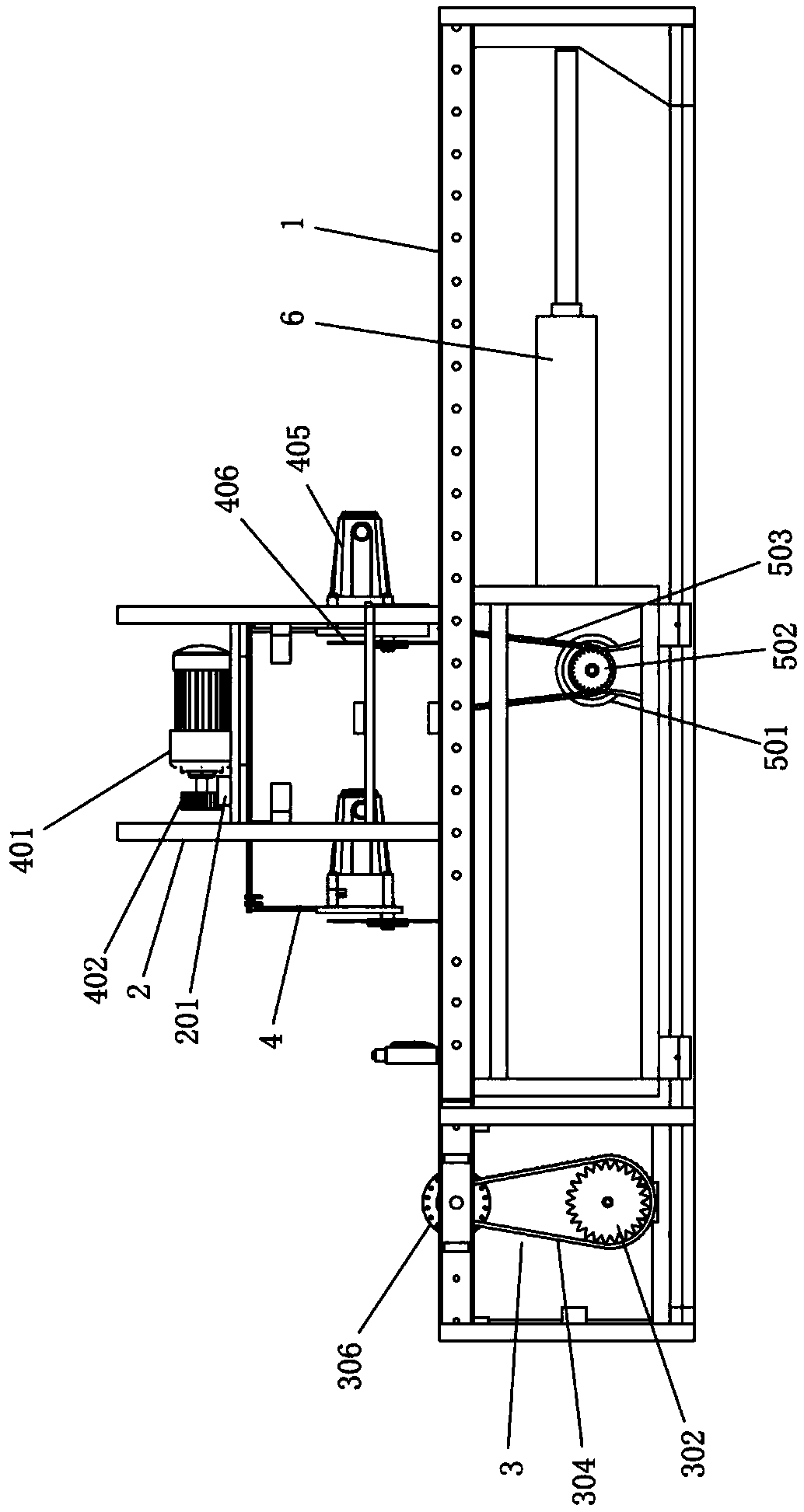

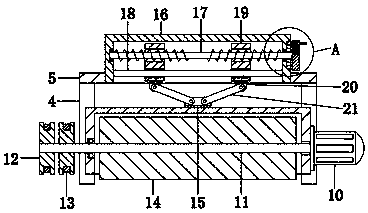

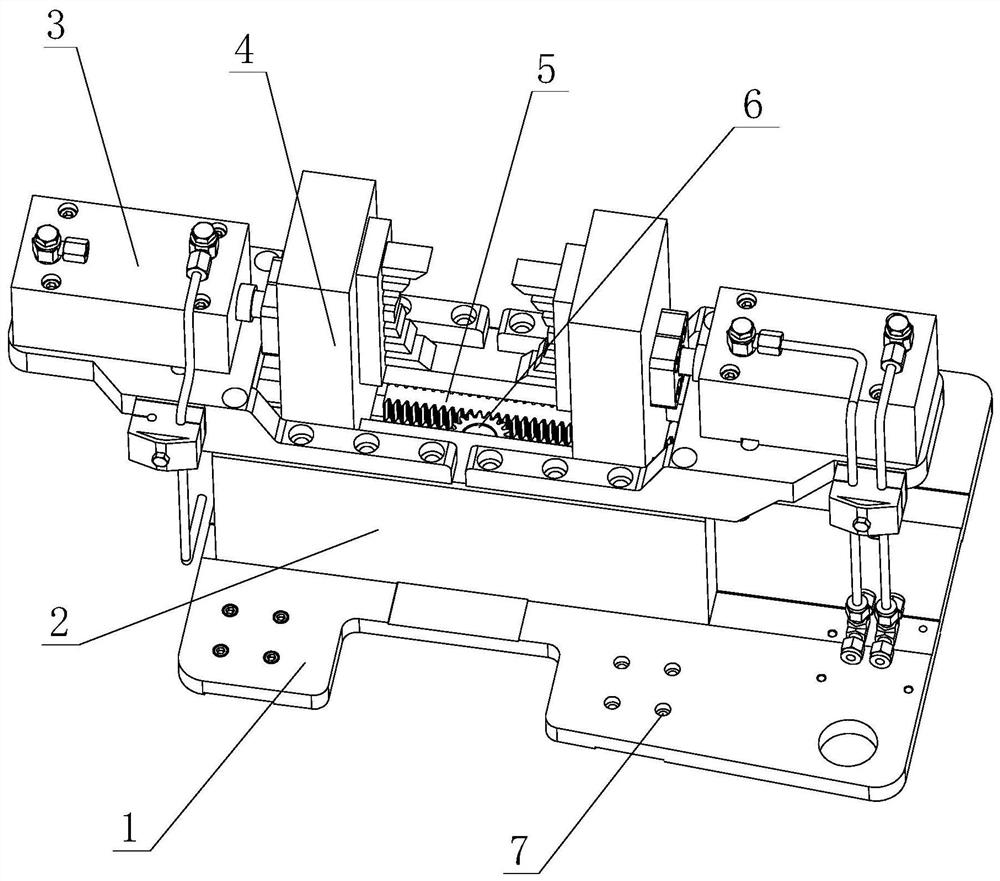

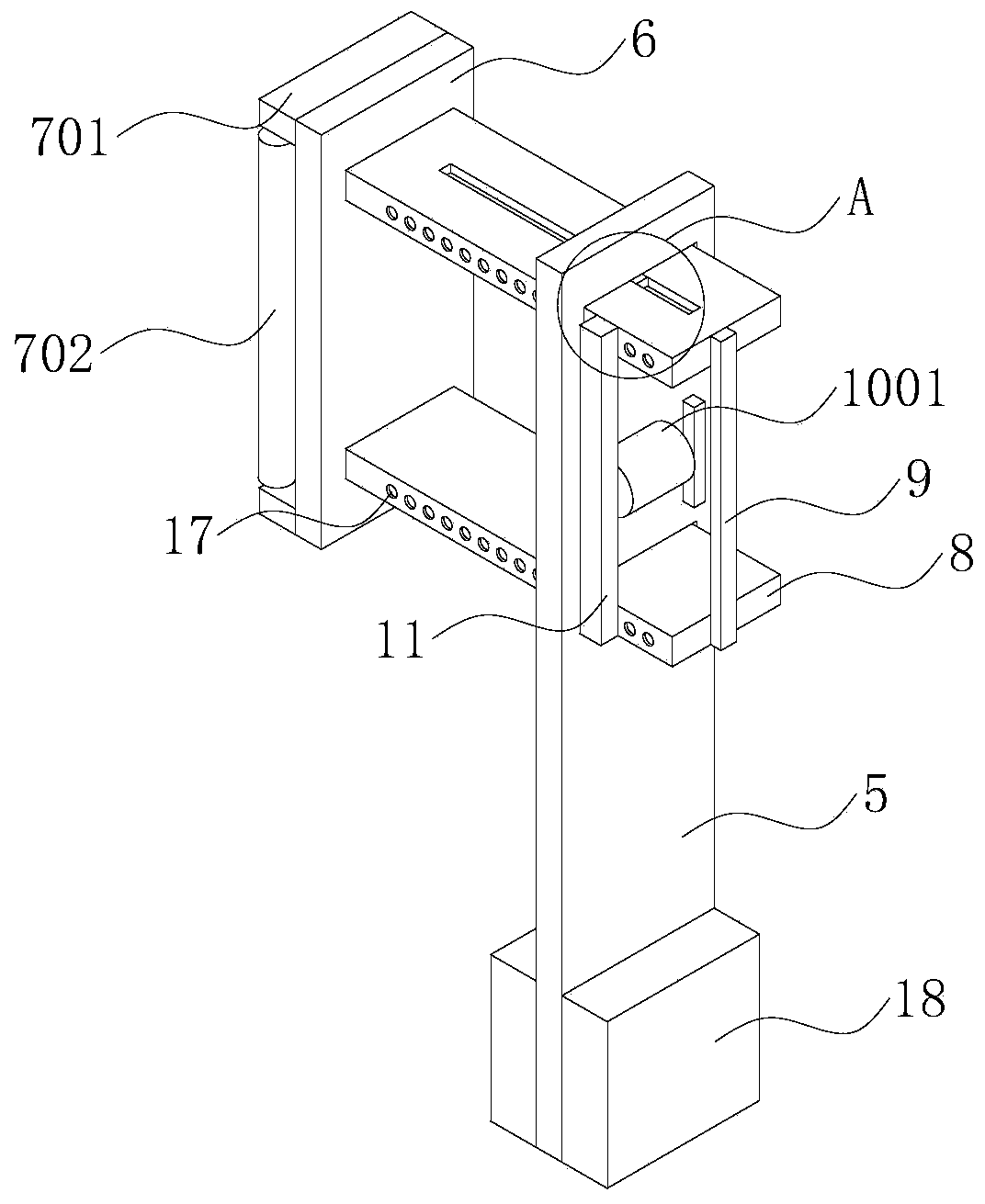

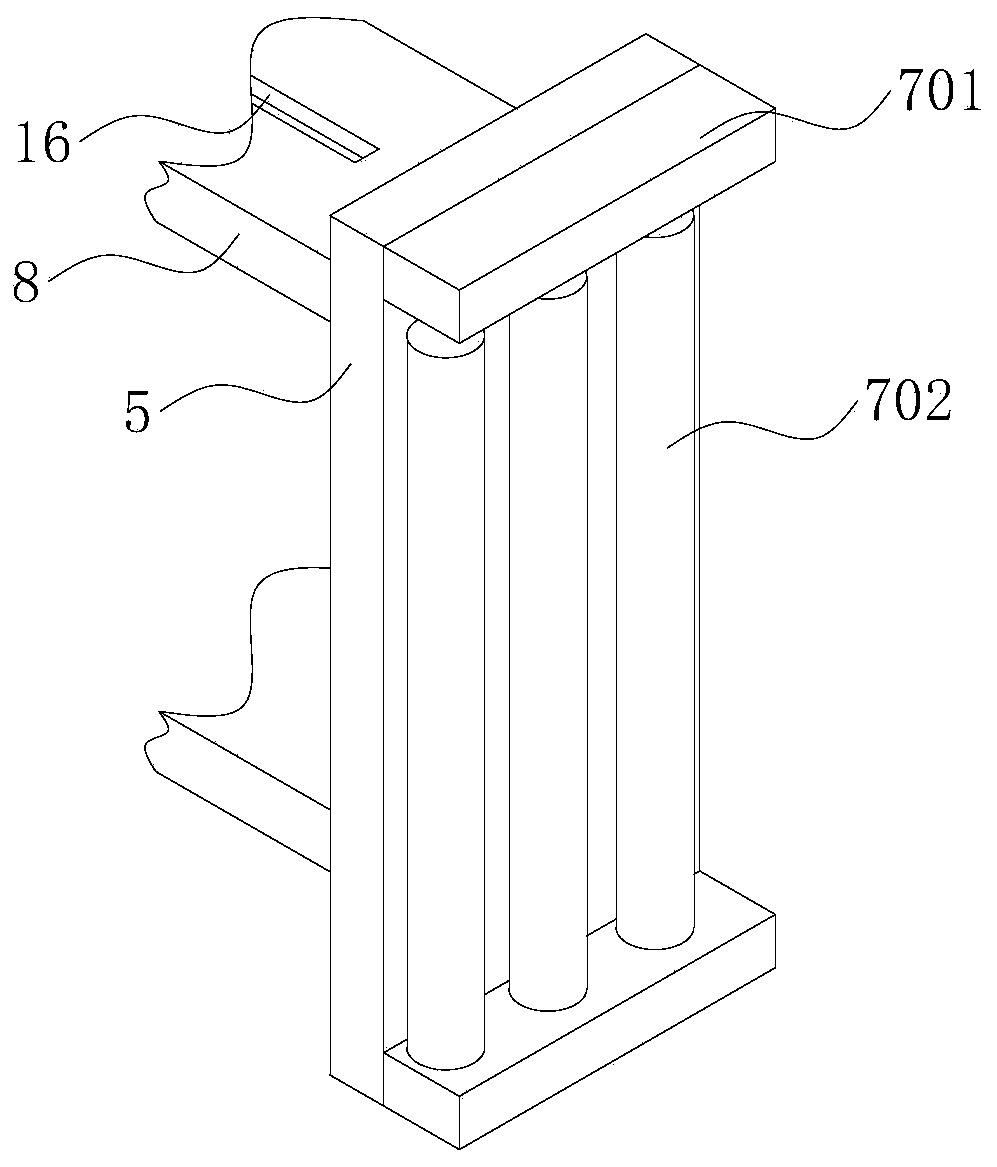

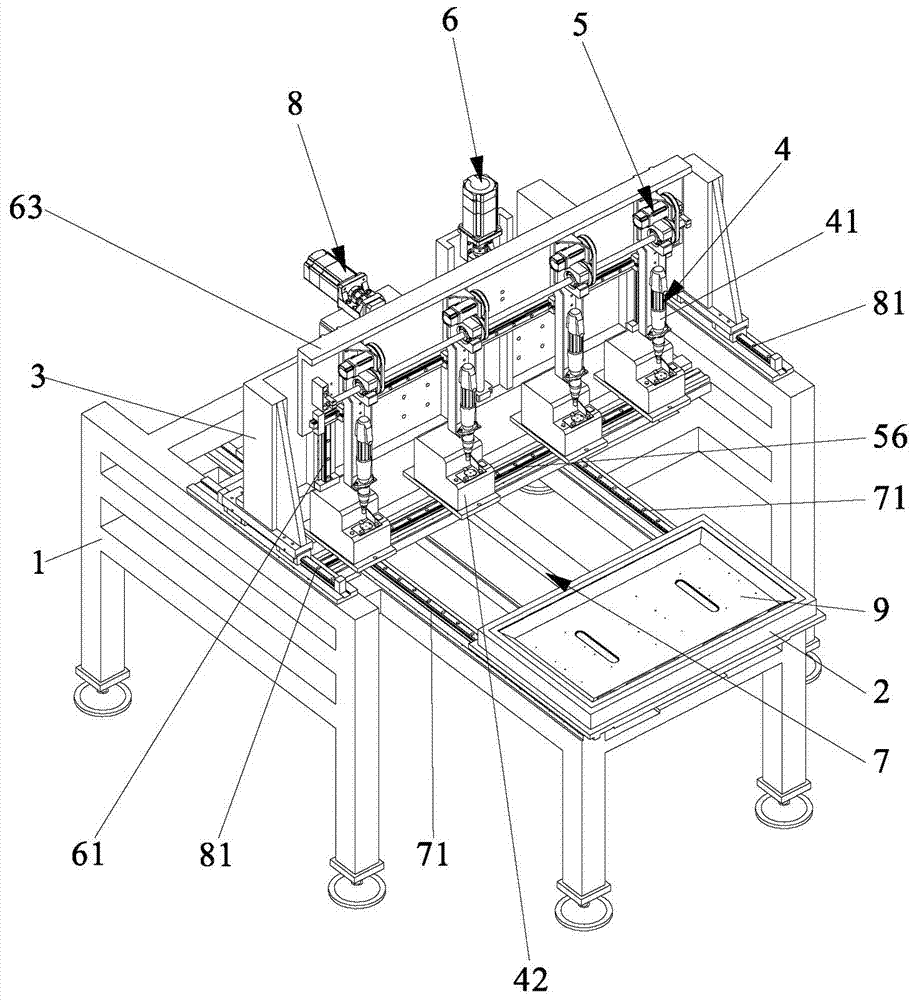

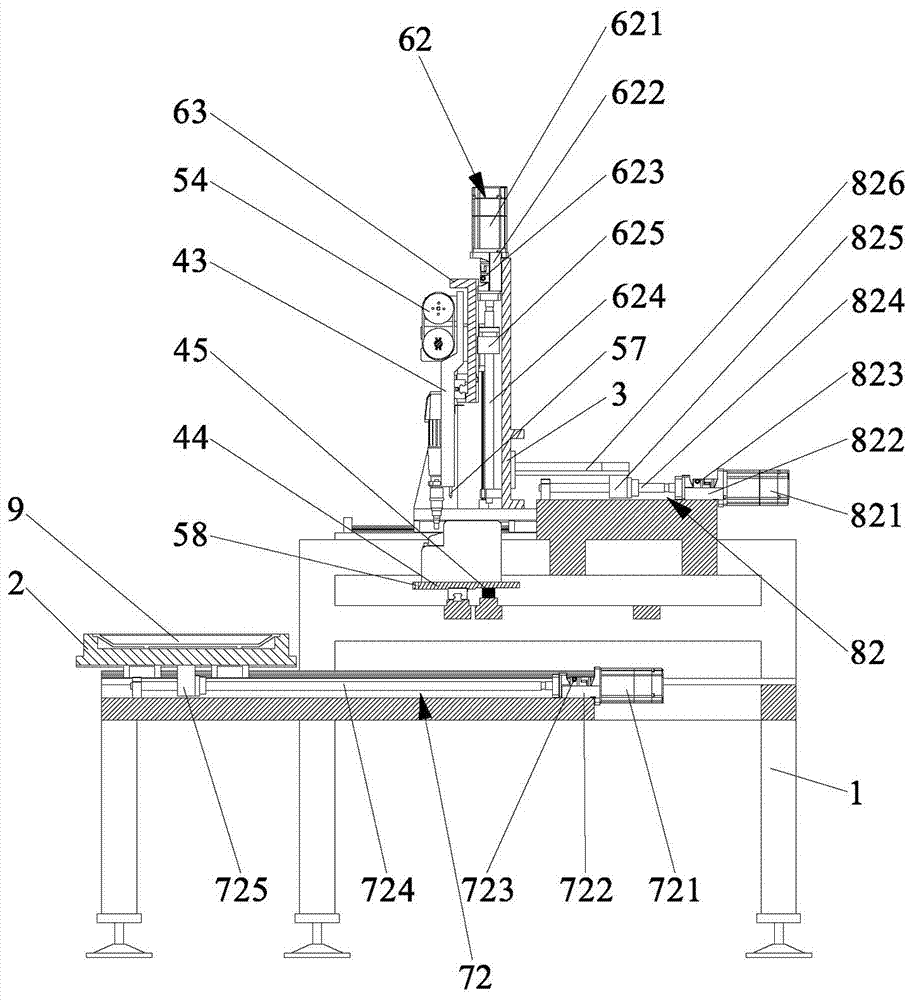

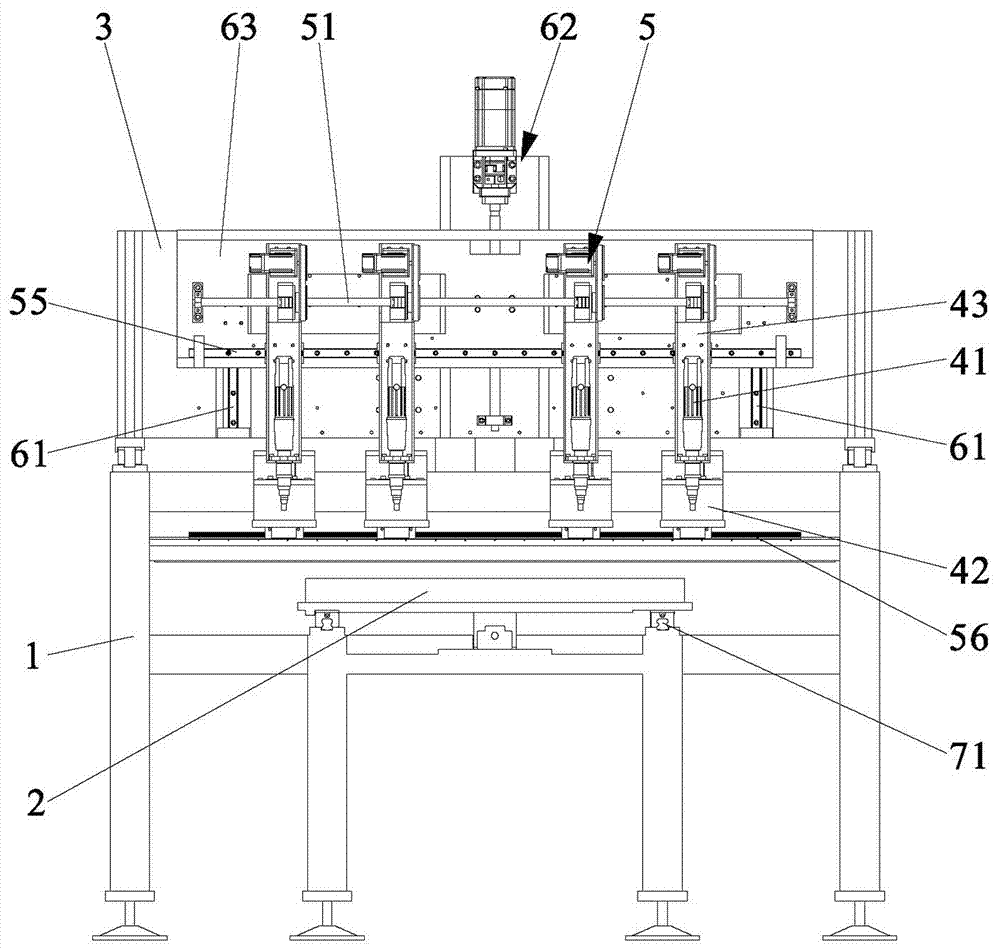

Adjustable multi-shaft automatic screwing machine and position adjustment method thereof

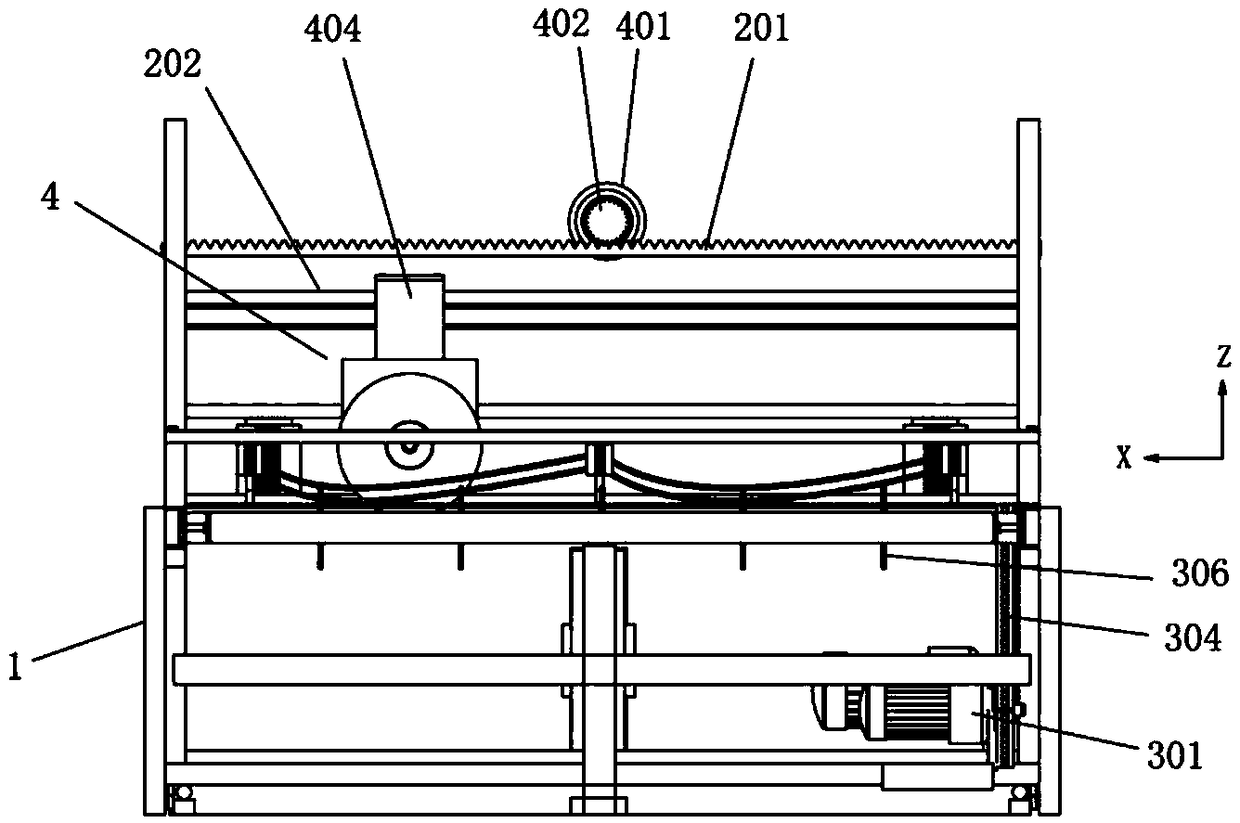

ActiveCN105014368ARealize synchronized movementEasy to adjustMetal working apparatusEngineeringMechanical engineering

The invention discloses an adjustable multi-shaft automatic screwing machine and a position adjustment method thereof. The screwing machine comprises a machine frame, an object containing table, a portal frame, a plurality of screwing mechanisms, a position adjustment mechanism capable of adjusting movement of the screwing mechanisms in the X axis direction, a Z-axis movement mechanism capable of driving the screwing mechanisms to vertically move, a Y-axis movement mechanism capable of driving the object containing table or the screwing mechanisms to move and a control mechanism. The position adjustment mechanism comprises a nut-rotating-type lead screw pair fixed to the portal frame. A plurality of nuts are arranged on the nut-rotating-type lead screw pair according to the number of the screwing mechanisms. Each nut is provided with an X-axis nut base which is fixedly linked with the corresponding screwing mechanism. Each screwing mechanism is provided with an X-axis motor to be connected with the corresponding nut in a transmission manner through a transmission mechanism. According to the adjustable multi-shaft automatic screwing machine and the position adjustment method, the relative positions among the screwing mechanisms can be adjusted to adapt to screw hole positions in a to-be-screwed workpiece, and therefore the multiple screw hole positions in a row in the workpiece can be screwed at the same time.

Owner:XIAMEN UNIV OF TECH

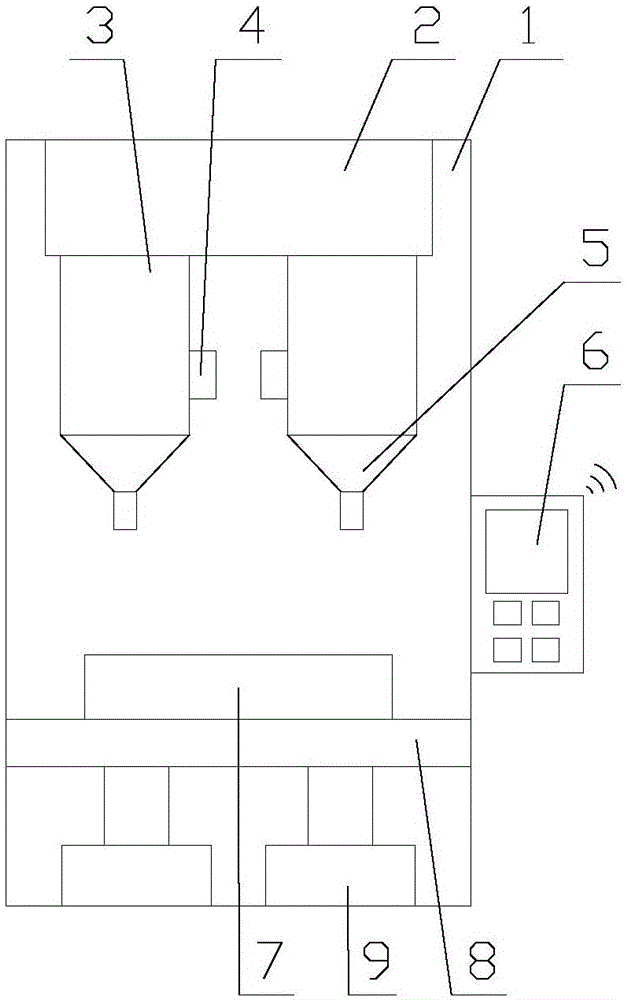

Fruit picking device

InactiveCN107241968ARealize synchronized movementAchieve fall outPicking devicesFruit treeEngineering

The invention discloses a fruit picking device. The fruit picking device comprises a moving seat, and moving wheels are arranged on one side of the moving seat. A collection tank is arranged on one side, away from the moving wheels, of the moving seat; a discharging hopper is arranged on one side, away from the moving seat, of the collection tank; a down-slide pipeline is arranged on one side, away from the collection tank, of the discharging hopper; a feeding hopper is arranged on one side, away from the discharging hopper, of the down-slide pipeline. A connection rod is arranged on the outer side of a fixing ring which is arranged on the outer side of the feeding hopper, and a supporting rod is in slidable connection with one end, away from the fixing ring, of the connection rod through a sleeve. The fruit picking device is simple in structure and convenient to operate, synchronous movement of a blade and the feeding hopper effectively guarantees picked fruits against falling out; the fruit picking device is convenient to adjust, suitable for fruit trees in different heights, wide in applicability and high in practicality, the defect of existing manual picking is overcome, and integration of picking and collection, reduction of manual workload and improvement of operating efficiency are realized.

Owner:合肥知亦嘉知识产权服务有限公司

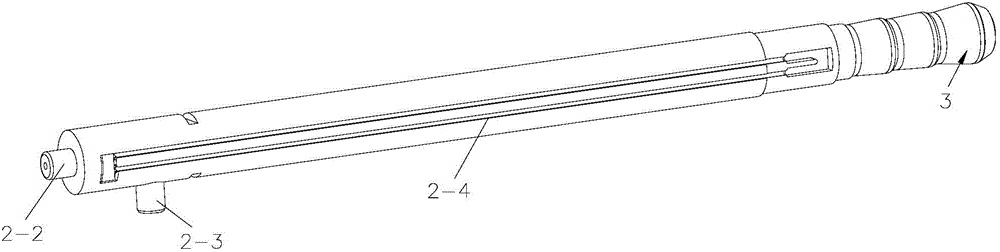

Ligation device of hemorrhoids

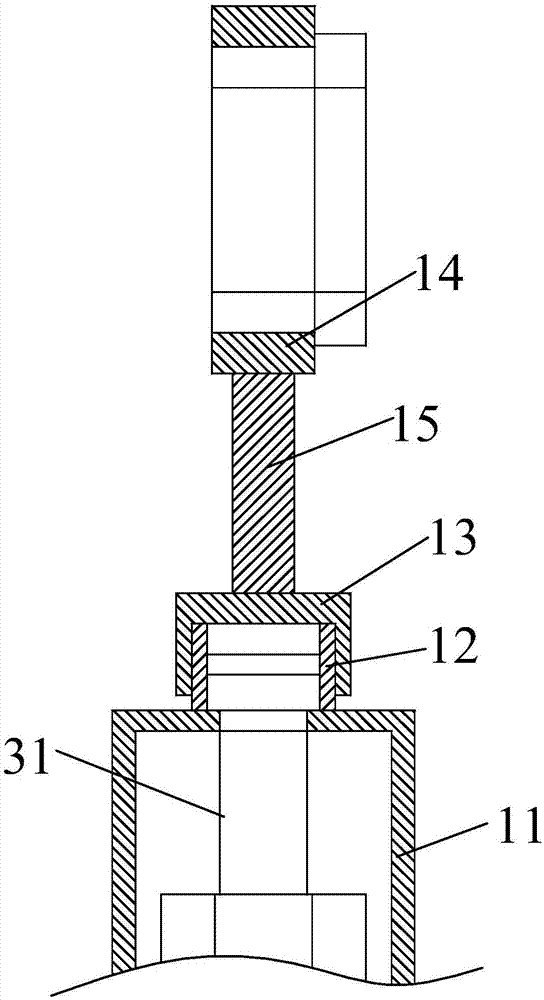

The invention discloses a ligation device of hemorrhoids. The device is provided with a power mechanism and a rubber gasket trigger mechanism. The power mechanism controls the rubber gasket trigger mechanism which includes an inner pipe and a sleeve, wherein the inner pipe is used for loading rubber gaskets, the sleeve sleeves the inner pipe, and the sleeve moves relative to the inner pipe or the rubber gaskets translate on the inner pipe when the inner pipe moves relative to the sleeve. The rubber gaskets of the ligation device provided by the invention are installed in real time in a surgery scene, i.e. the rubber gaskets are not installed in the normal state, therefore the problems that the rubber gaskets are easily aged and fatigued can be prevented; when the ligation device is in use, the rubber gaskets can be ligated on a progressive feeding mechanism in rows, and the movement ways of the rubber gaskets are synchronous and homodromous movement after the progressive feeding mechanism obtains power, therefore the continuous launching of the rubber gaskets and the uninterrupted ligation can be ensured, and the pain of patients can be alleviated.

Owner:JIANGSU ATE MEDICAL TECH

Synchronous control system for master and salve hydraulic cylinders with fixed potential difference and control method therefor

ActiveCN103742467AStatic positioning accuracy cannot be guaranteedRealize synchronized movementServomotorsHydraulic cylinderSynchronous motor

The invention discloses a synchronous control system for master and salve hydraulic cylinders with fixed potential difference. The synchronous control system for the master and salve hydraulic cylinders with fixed potential difference comprises a device body, a master hydraulic cylinder, n slave hydraulic cylinders, n+1 proportion adjusting valves and n+1 hydraulically controlled check valves, wherein the synchronous control system for the master and salve hydraulic cylinders further comprises three control programs, respectively are a synchronous control program for the master hydraulic cylinder with fixed potential difference, a synchronous control program for the slave hydraulic cylinders with fixed potential difference and a maximum potential difference protection control program for the master and slave hydraulic cylinders with fixed potential difference; According to the hydraulic cylinder synchronous control scheme provided by the invention, the high-accuracy synchronous movement of the plurality of hydraulic cylinders is achieved in the case of keeping certain distances among the hydraulic cylinders, and extremely strong robustness is provided. Therefore, the service life of the hydraulic cylinder is greatly prolonged, and the fault of stopping production to replace the leaked hydraulic cylinder is avoided.

Owner:MAGANG (GROUP) HOLDING CO LTD

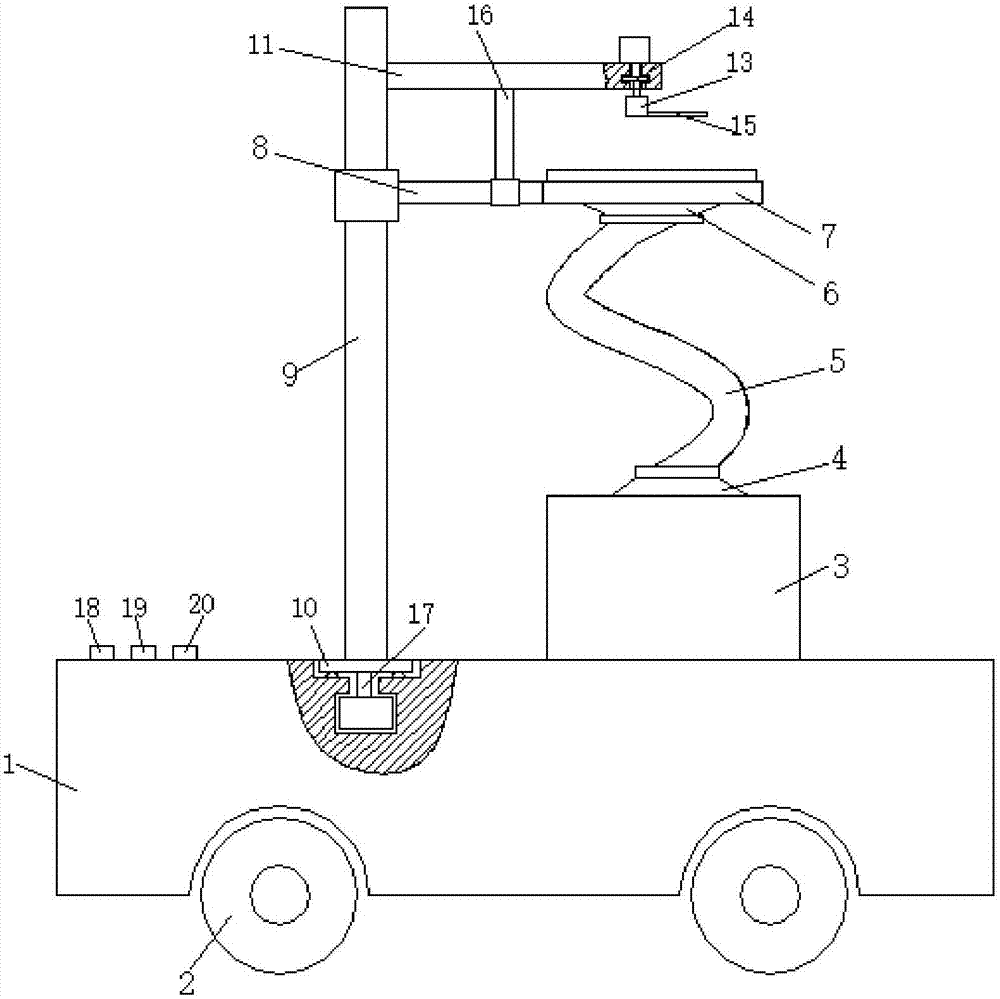

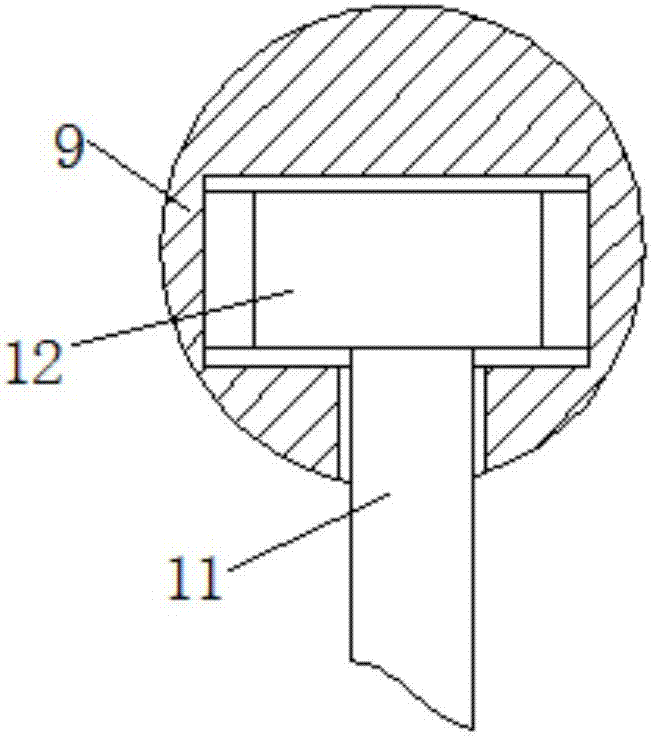

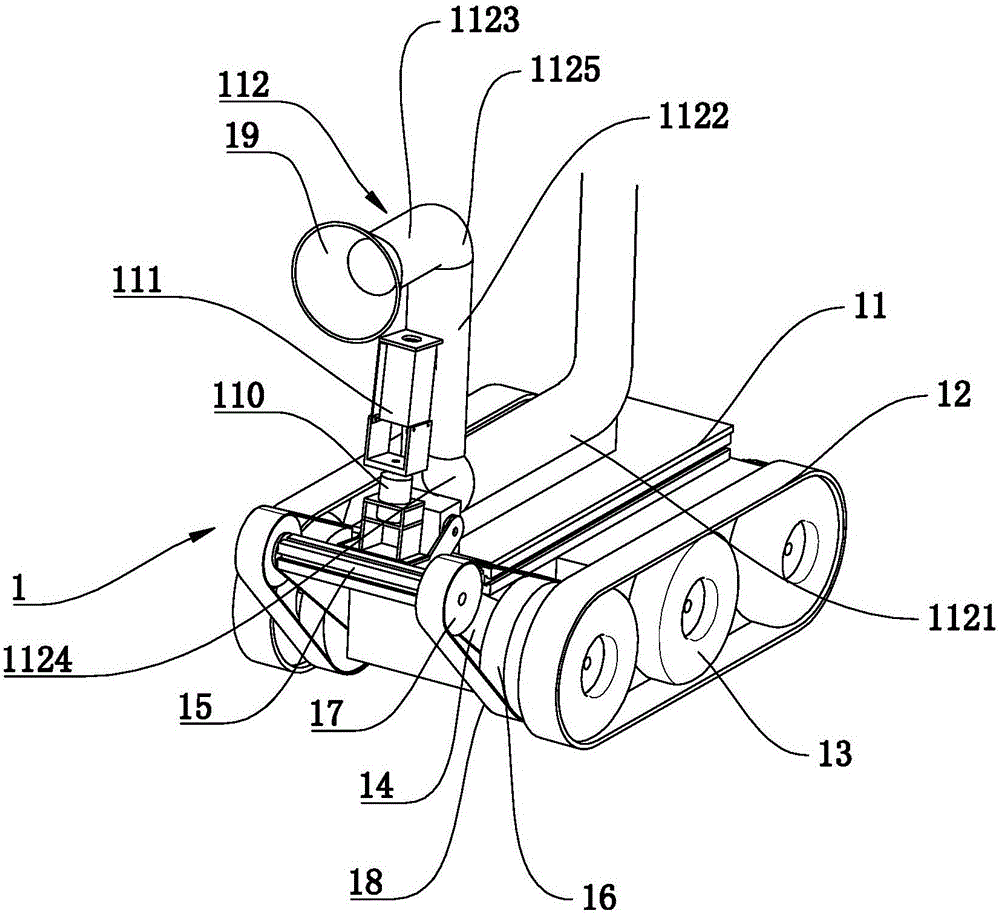

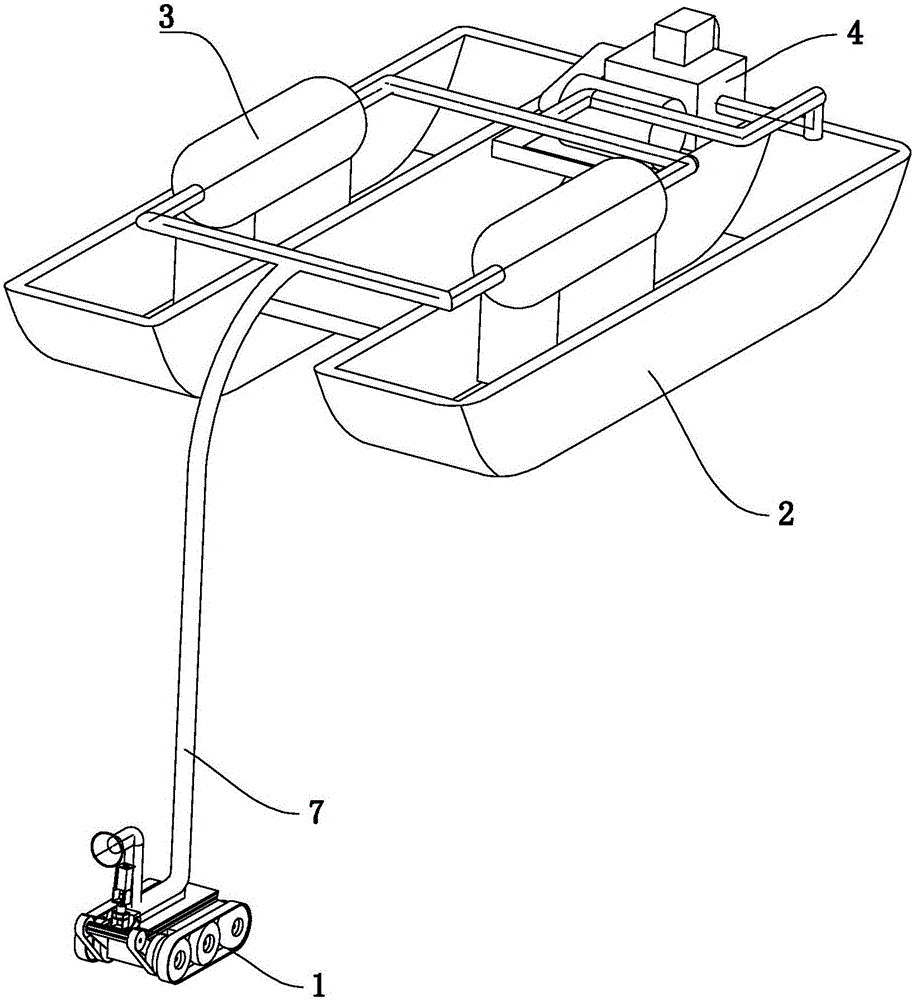

Fishing robot and automatic fishing system for aquatic products

PendingCN106826868AFull catchWon't affect homeworkPisciculture and aquariaManipulatorManipulatorEngineering

The invention discloses a fishing robot and an automatic fishing system for aquatic products. The fishing robot includes a base on which a suction head and a steering gear manipulator are arranged. The suction head is connected with a connecting pipe. The end is fixedly arranged on the base, and the moving end of the steering gear manipulator is fixedly connected to the connecting pipe; the two sides of the bottom of the base are provided with a running mechanism, and the running mechanism is connected with a driving device through transmission. The automatic fishing system for aquatic products of the present invention includes a mother ship and a fishing robot with this structure, which can realize automatic fishing of aquatic products, effectively replace labor, and have high fishing efficiency.

Owner:WEIFANG SHENGLI GASOLINEEUM MACHINERY

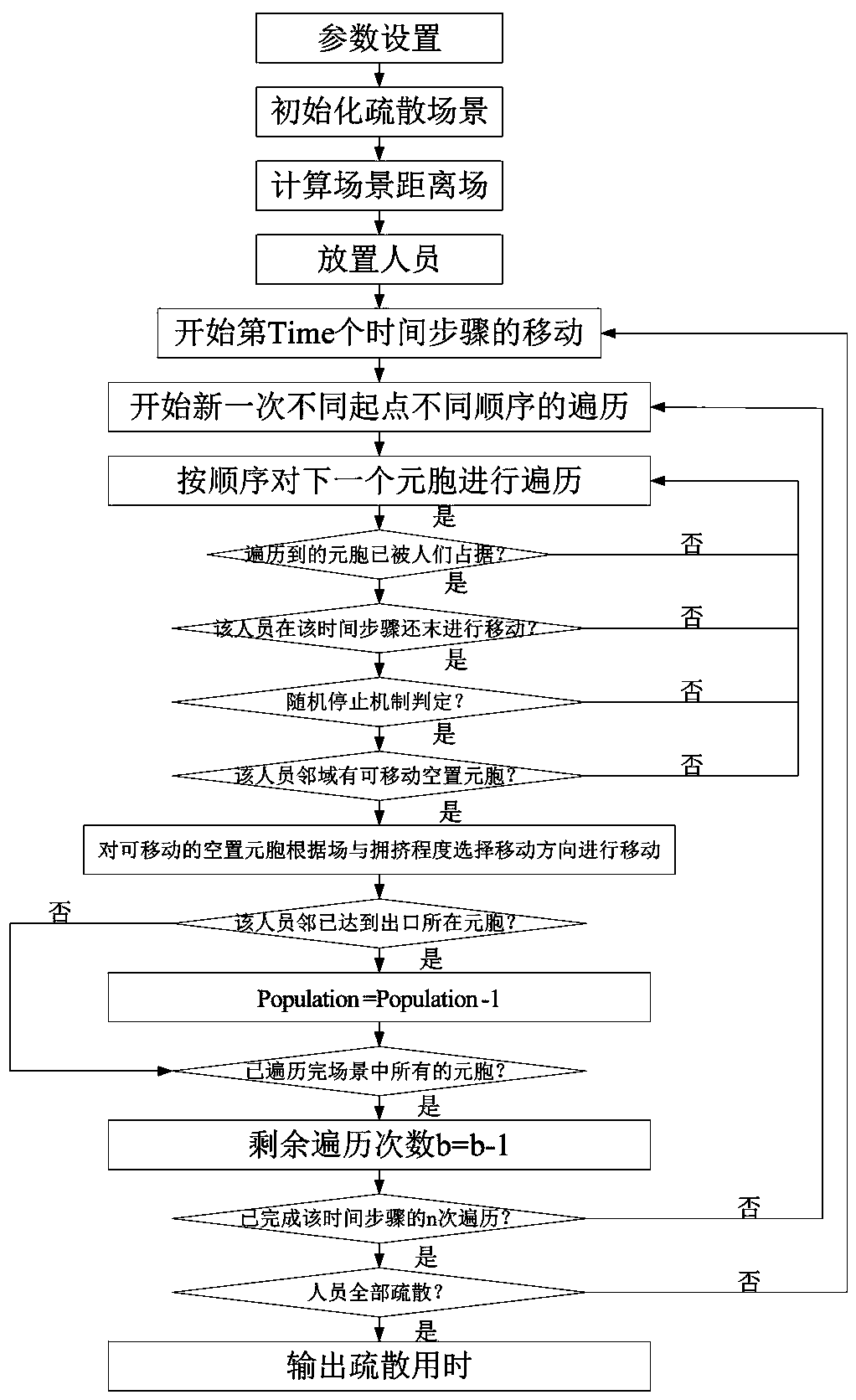

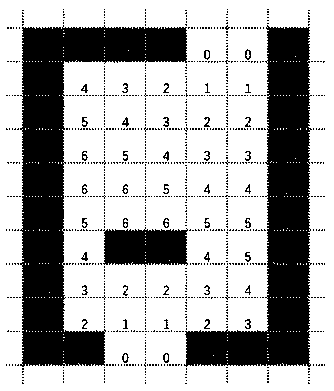

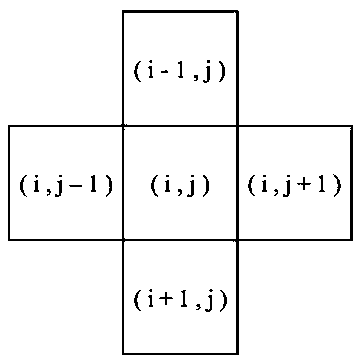

Personnel evacuation simulation method based on cellular automaton

ActiveCN110245403AEliminate sequence differencesRealize synchronized movementGeometric CADDesign optimisation/simulationCellular automationMathematical model

The invention discloses a personnel evacuation simulation method based on a cellular automaton. The method comprises the steps of discretizing a whole room into a plurality of finite cells with the same size, and building a two-dimensional cellular automaton mathematical model similar to an actual scene; after starting to move a time step, traversing different starting points and different sequences for multiple times in the same time step, wherein each person needs to be judged twice before moving, firstly, enabling each person to move for at most one time in one time step and the moved person not to move in the previous traversal in the time step, and secondly, judging a random stop mechanism before moving so as to simulate the occurrence of an accident in the evacuation process; for the people who can move by the vacant cells in the four neighborhoods, determining the moving direction of the people according to the distance field value and the crowding degree in front; and outputting the evacuation time after all people are evacuated. According to the invention, the evacuation process of the people in the specific scene can be simulated more truly.

Owner:SOUTHWEST PETROLEUM UNIV

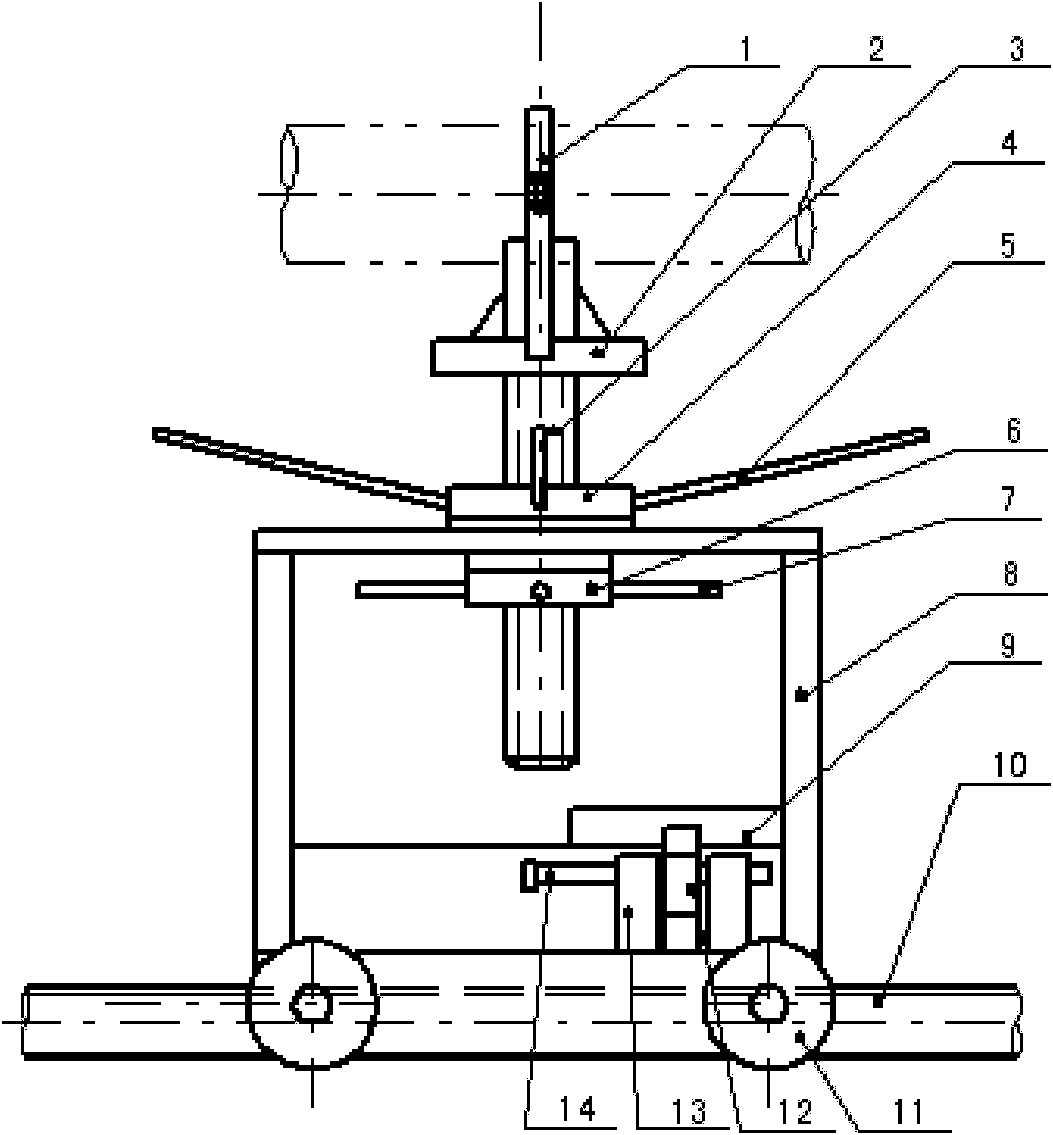

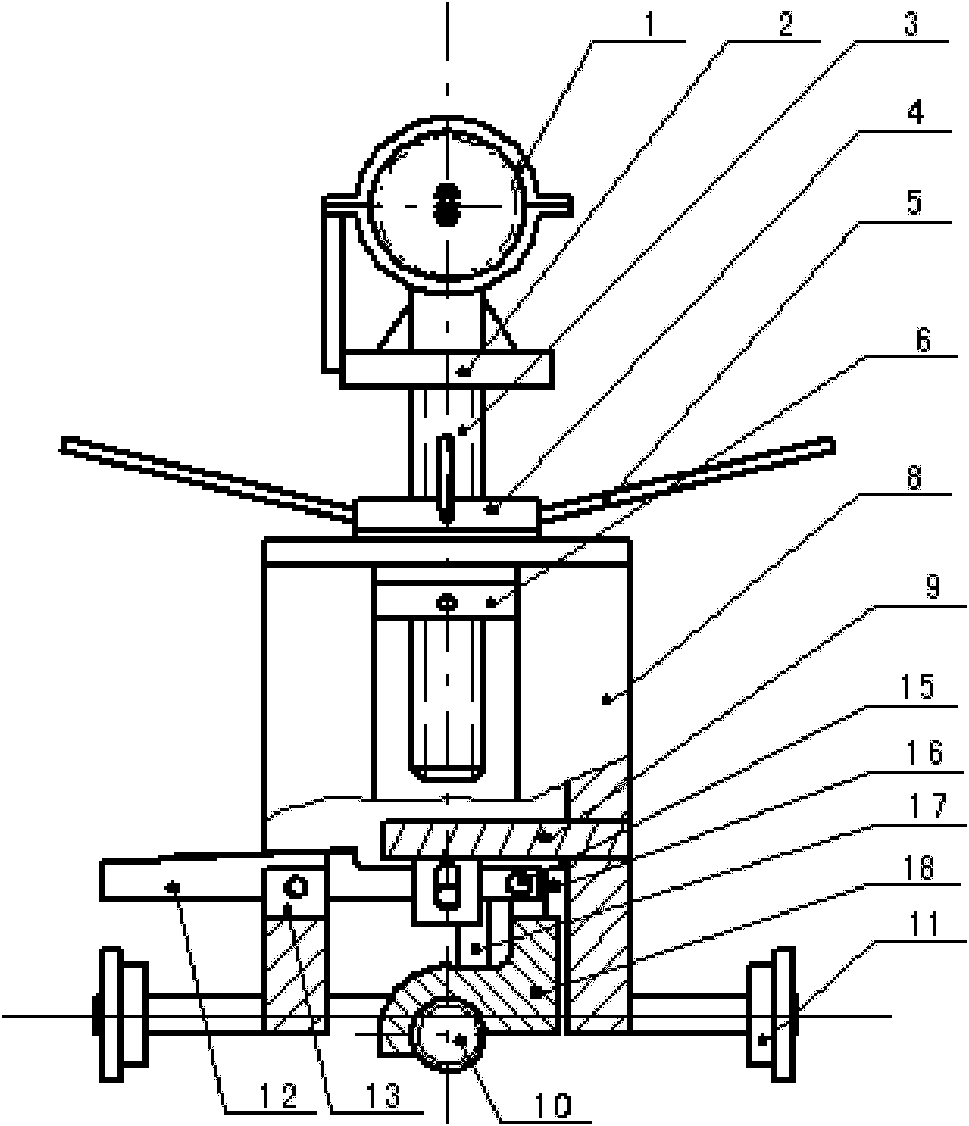

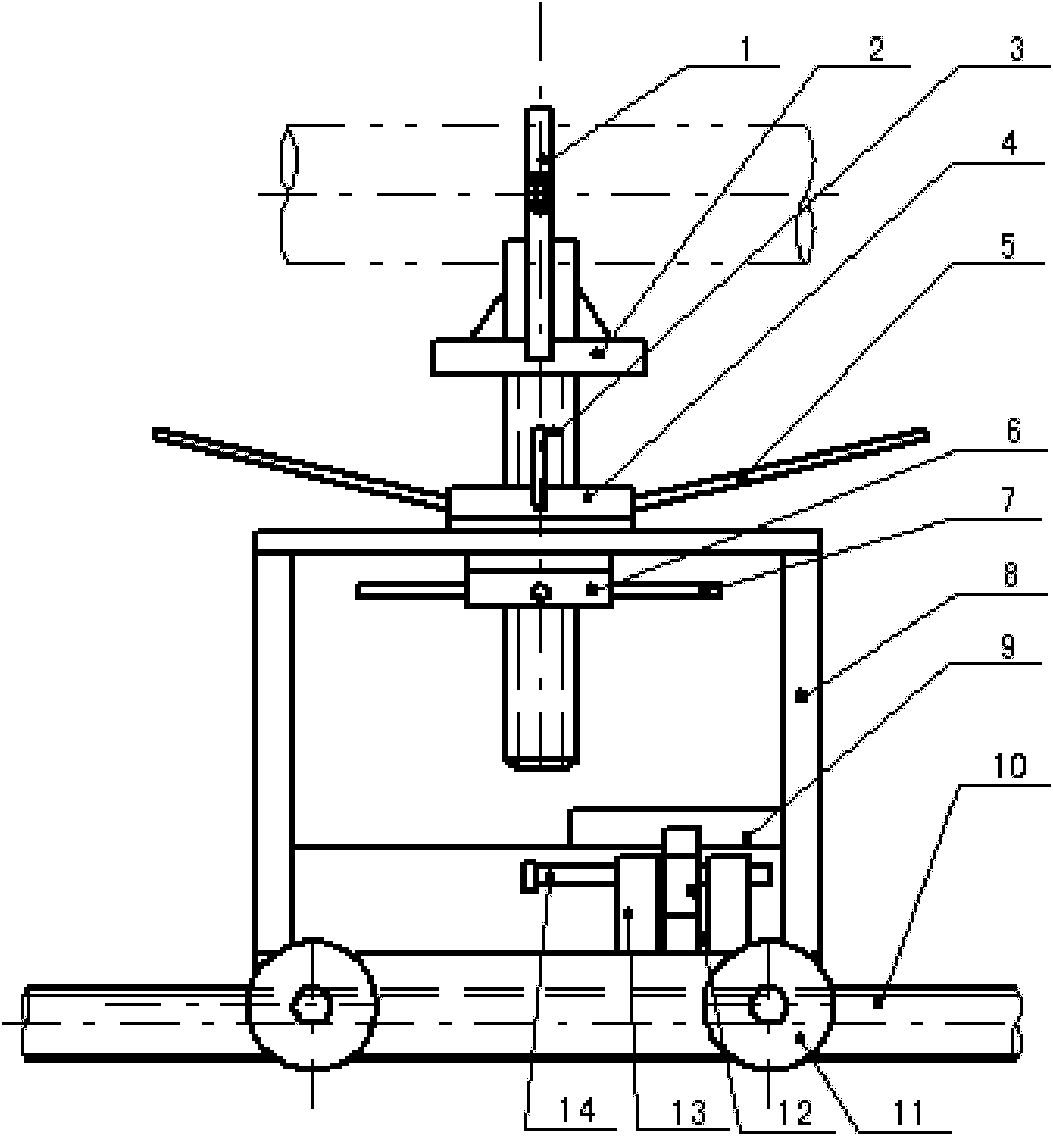

Track trailer for mandril workpiece during electroplating

ActiveCN101942685AGood stabilityWork reliablyElectrolysis componentsMandrelsEngineeringLocking plate

The invention relates to a track trailer for supporting a mandril workpiece during electroplating, comprising a support frame, track wheels and an erection loop of the mandril. The track trailer is characterized in that a vertical screw is vertically erected on the worktable of the support frame; the erection loop of the mandril is erected at the top end of the vertical screw; an adjusting plate and a locking plate are erected on screws on the upper and lower end faces of the worktable of the support frame through thread engagement; a half bearing engaged with a track screw is erected in the support frame; the half bearing carries out guide sliding in a vertical slide made in the support frame up and down and is fixedly erected with a brake rod by a connecting plate; and the inner end of the brake rod is hinged on a transverse plate fixedly erected with the support frame by an hinged shaft. The track trailer has simple structure and scientific design and can realize height adjustment according to the diameter of the mandril and stably support the mandril at the same time.

Owner:天津滨海龙泰科技发展有限公司

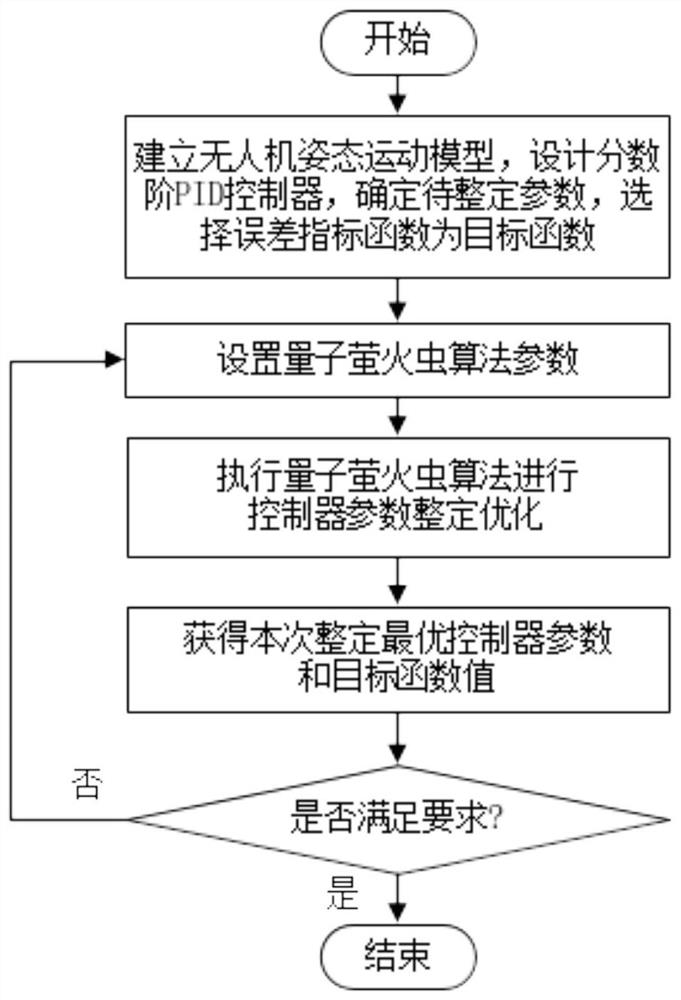

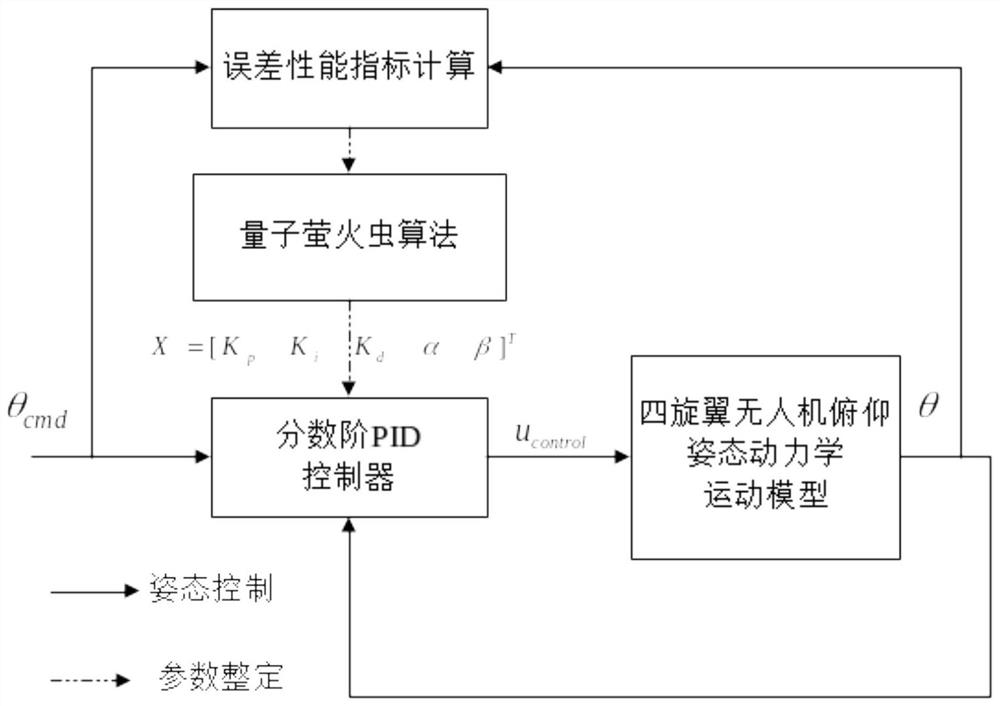

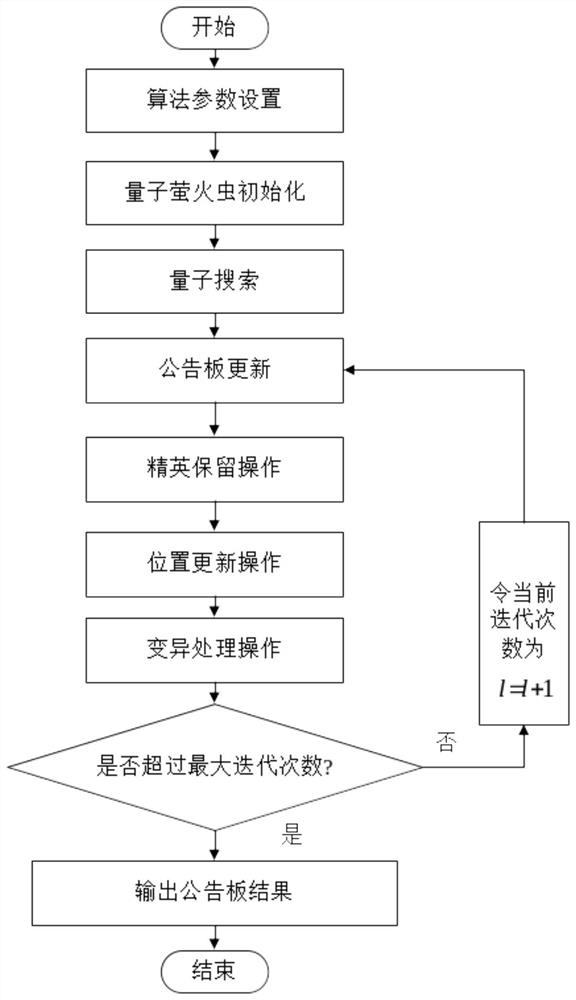

Intelligent setting method for unmanned aerial vehicle attitude control parameters based on quantum firefly algorithm

ActiveCN112596373AIncrease global convergence speedImprove traversalInternal combustion piston enginesArtificial lifeLocal optimumFractional-order control

The invention provides an intelligent setting method for unmanned aerial vehicle attitude control parameters based on a quantum firefly algorithm, and belongs to the field of automatic control. The method comprises the steps of building an unmanned aerial vehicle attitude motion model, designing a fractional order PID controller, determining a to-be-set parameter, and selecting an error index function as an objective function; setting parameters of the quantum firefly algorithm; executing the quantum firefly algorithm to perform controller parameter setting optimization, and obtaining the optimal controller parameter and the objective function value of the current setting; judging whether the objective function value meets requirements or not; if the objective function value meets the requirement, determining that the firefly position is the optimal attitude controller parameter, and ending the setting; otherwise, returning to the step 2, resetting the parameters of the quantum fireflyalgorithm, and executing the steps 2-4. According to the method, on the basis of a standard firefly algorithm, improvement is carried out by utilizing a quantum theory, elite retention and mutation behaviors, and the defects that the later convergence speed of the standard firefly algorithm is seriously reduced, the convergence precision is not high, and local optimum is likely to happen in the prior art are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

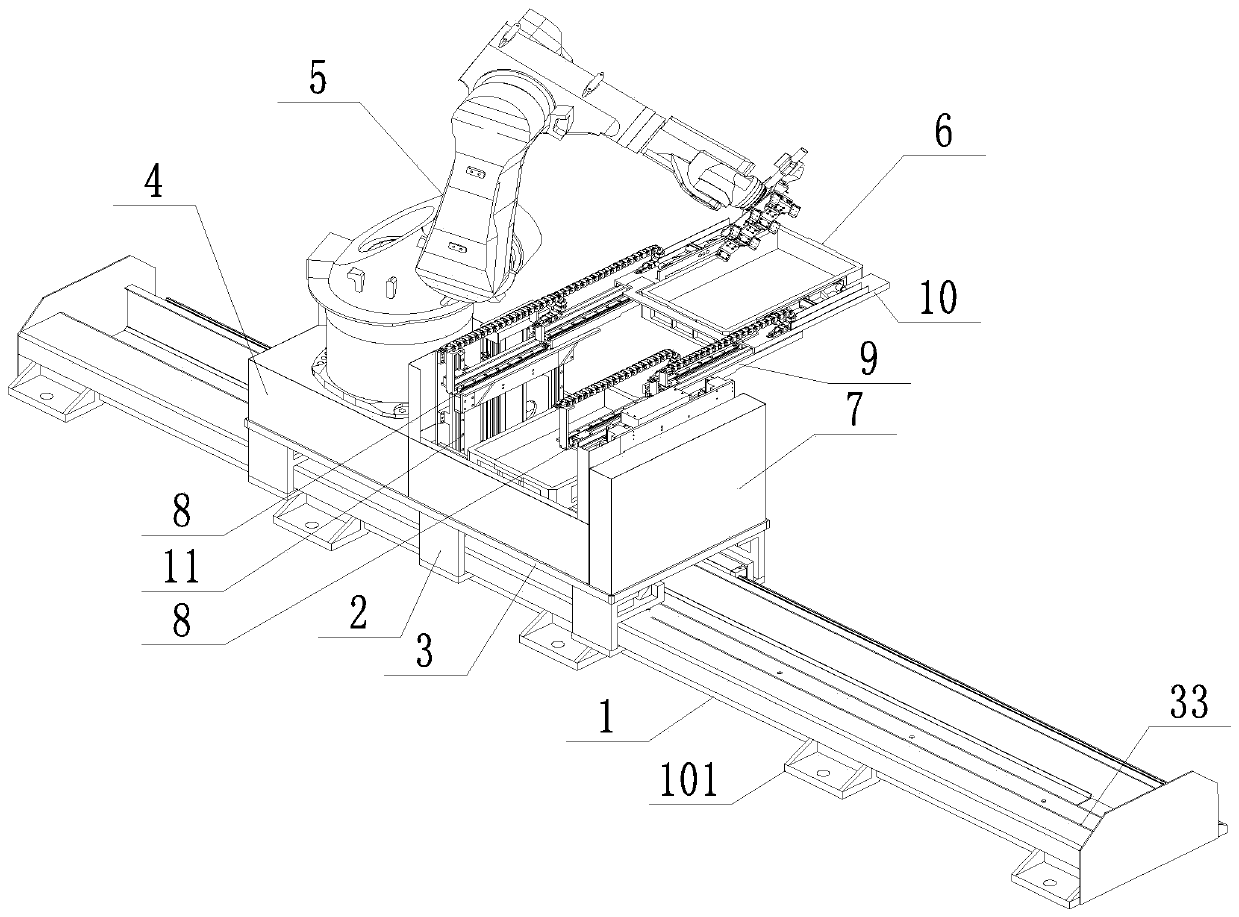

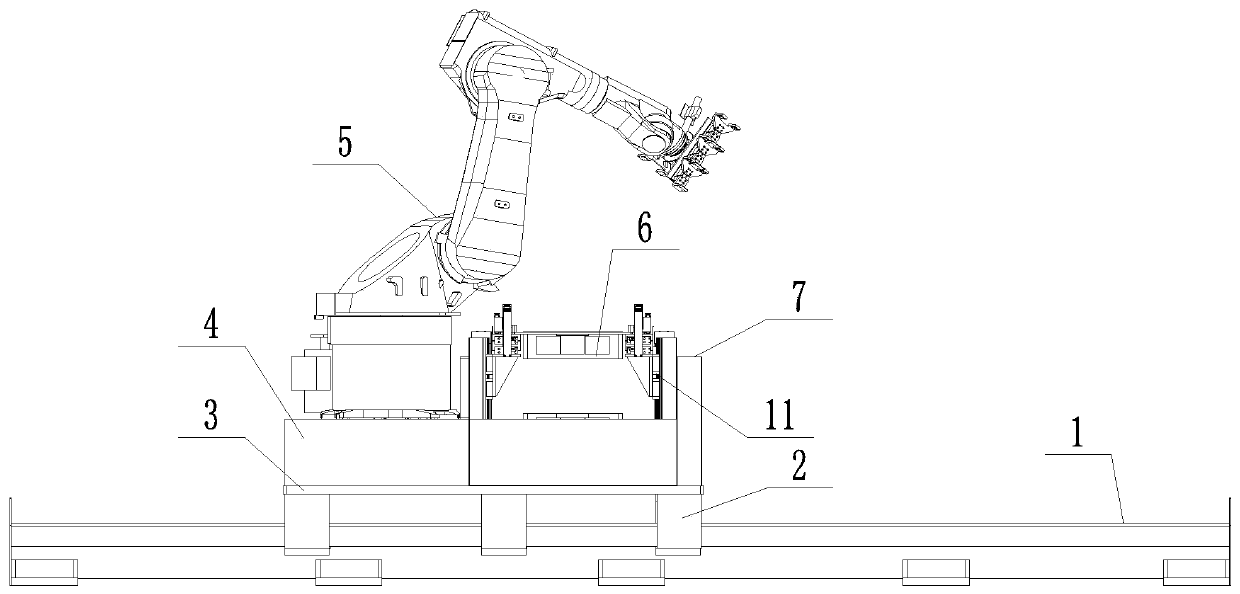

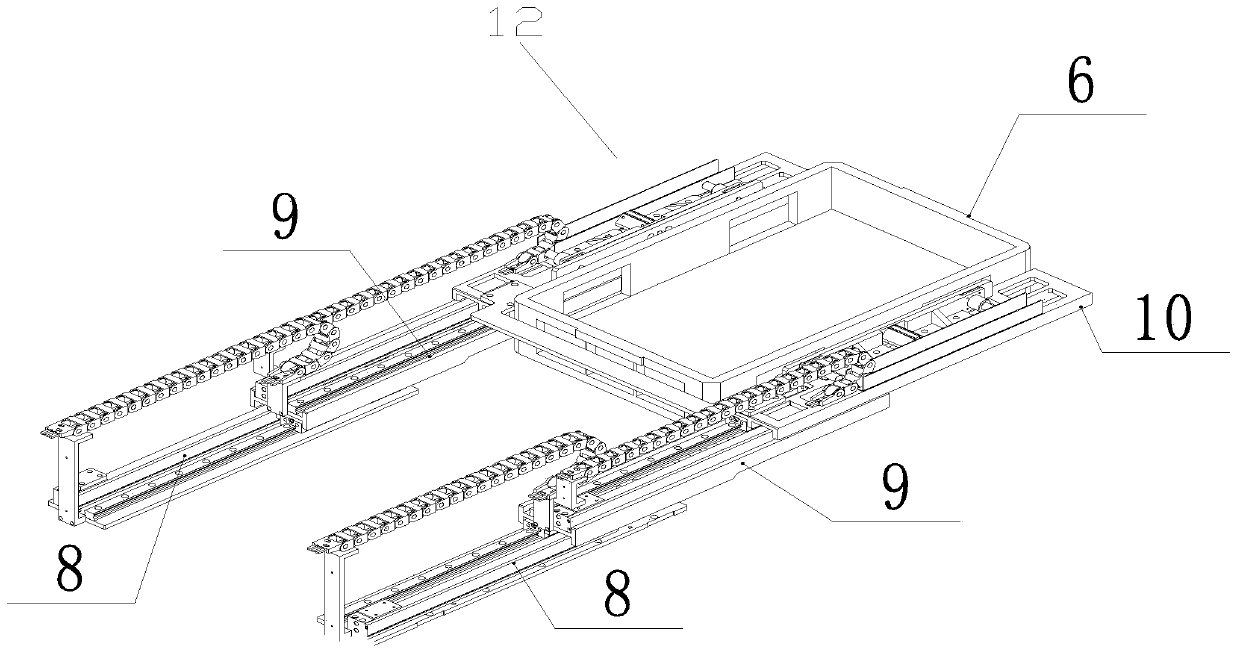

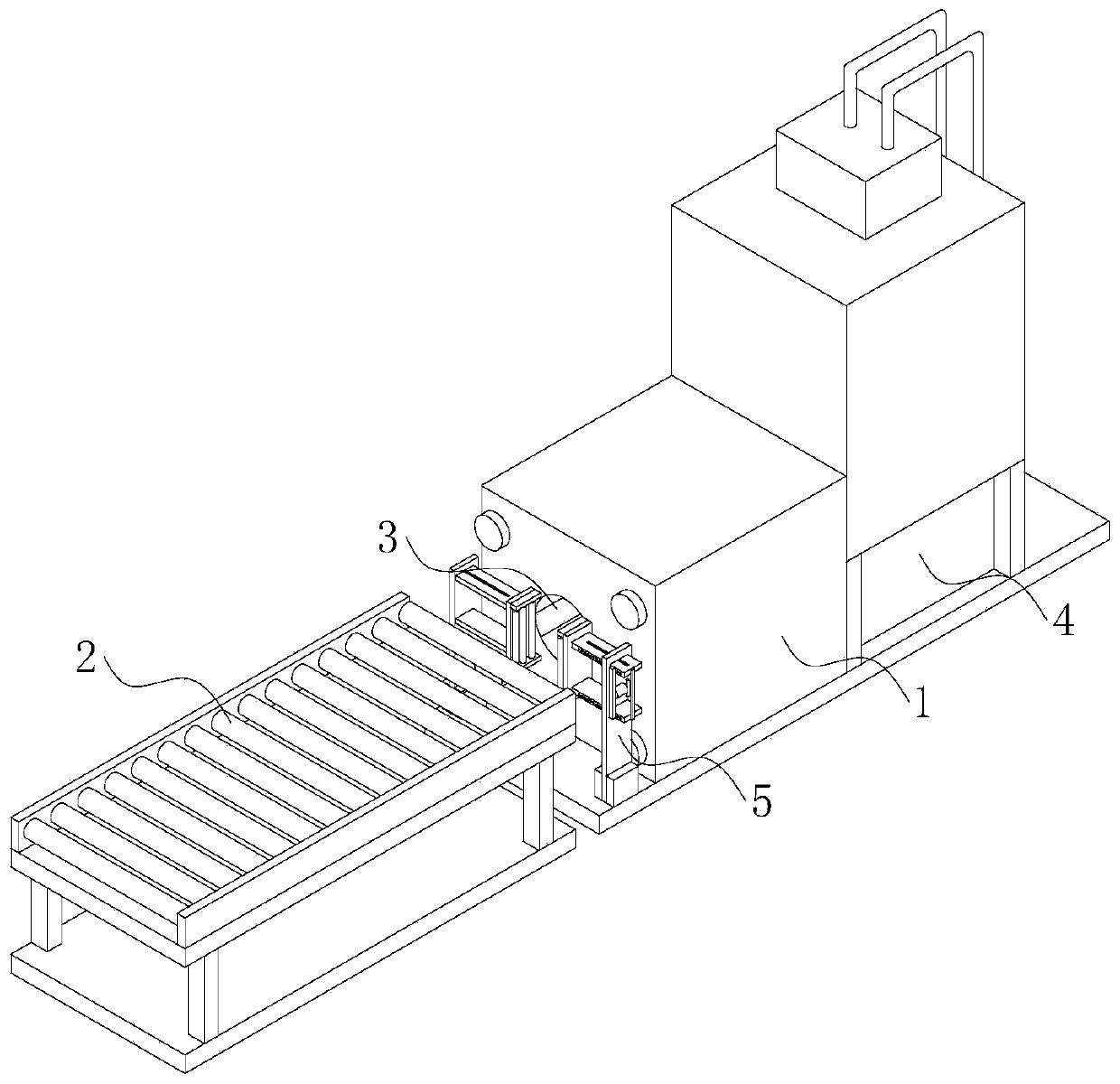

Feeding and blanking device and method for automatically conveying electric energy meters based on rail guided vehicle (RGV)

PendingCN110422620AImprove crawling efficiencyAccelerateConveyorsConveyor partsElectric energyGround track

The invention discloses feeding and blanking device and method for automatically conveying electric energy meters based on a rail guided vehicle (RGV). The device comprises a transfer box, a horizontally arranged walking device, a robot for grabbing the electric energy meters, and a carrier for supporting the transfer box, wherein the N electric energy meters are placed in the transfer box; the walking device comprises a ground track; a sliding seat is slidably connected above the ground track and is connected with a drive device; the robot is arranged above the sliding seat; and a linear module for driving the carrier to move up and down is arranged on the bottom part of the carrier, and is perpendicularly arranged on the sliding seat and located on one side of the robot. According to thefeeding and blanking device and the method for automatically conveying the electric energy meters based on the RGV provided by the invention, the robot can feed and blank at different positions, so that the defect of single feeding and blanking position of an original robot is overcome; by utilizing the carrier, the transfer box and the robot move synchronously, and meanwhile, the stacking of transfer boxes is realized; and the carrier is arranged in a secondary telescoping way, so that no space is occupied, the speed is fast, and the working efficiency is high.

Owner:ELECTRIC POWER RES INST STATE GRID JIBEI ELECTRIC POWER COMPANY +1

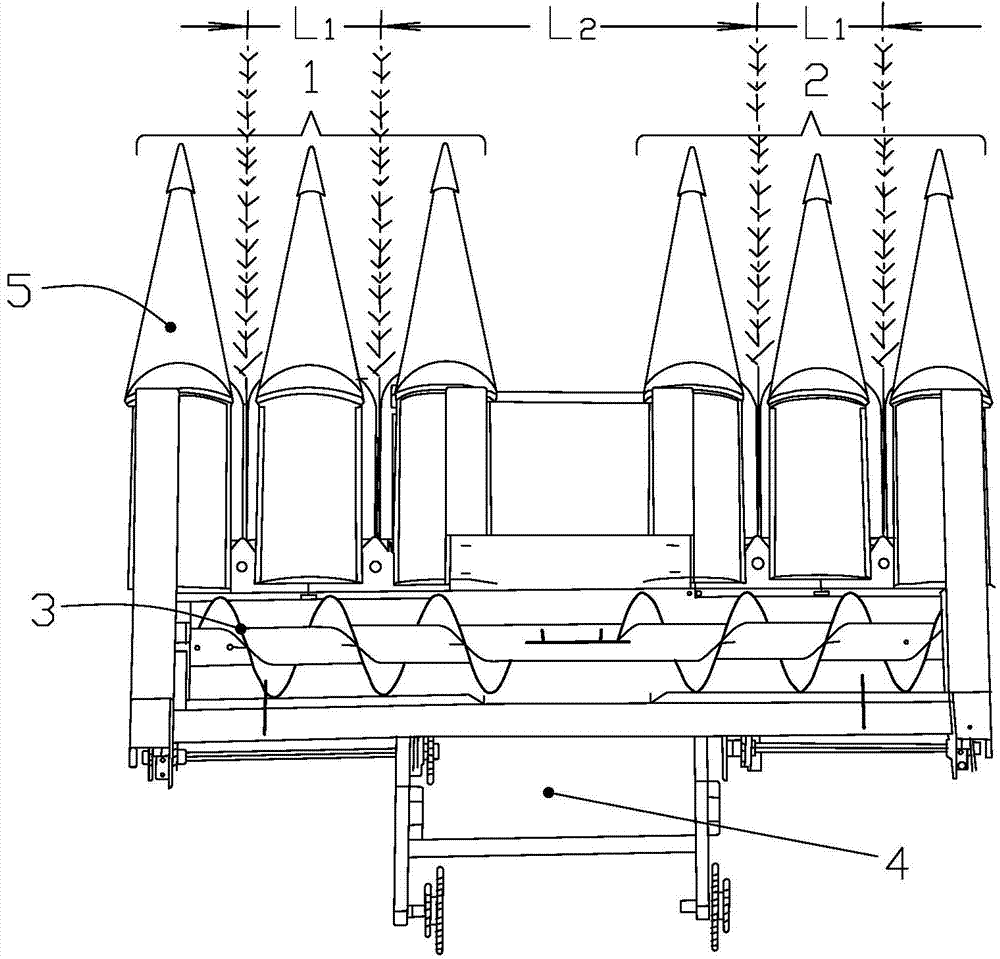

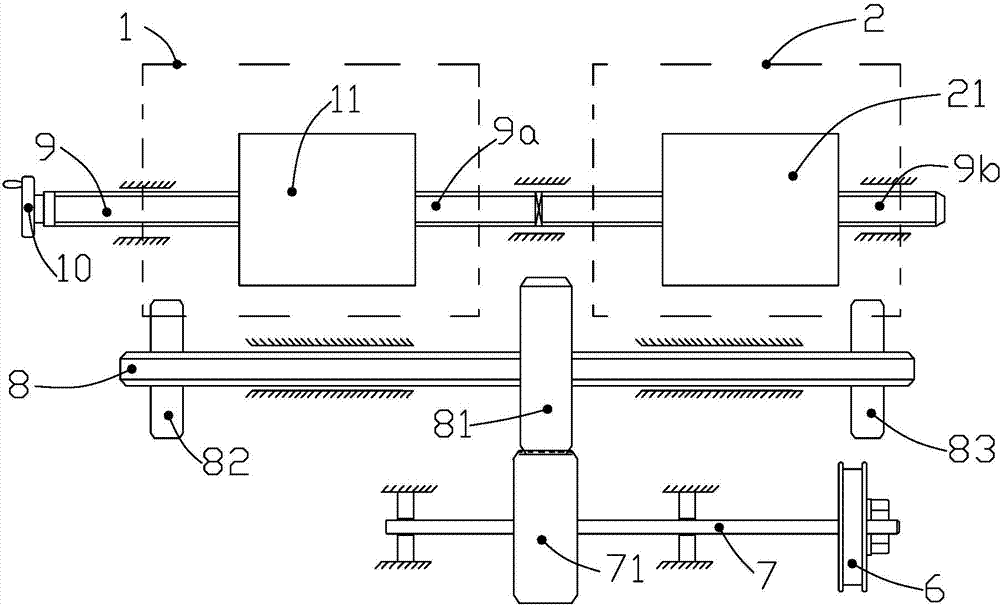

Adjustable double-row maize harvesting machine header

An adjustable double-row maize harvesting machine header comprises a transmission unit, a left header unit and a right header unit. The transmission unit comprises a power input wheel, a drive wheel, a driven wheel, a left header unit power input wheel and a right header unit power input wheel, the power input wheel and the drive wheel are arranged on a first transmission shaft, the driven wheel is arranged in the middle of a second transmission shaft, and the left header unit power input wheel and the right header unit power input wheel are arranged at the two ends of the second transmission shaft respectively. The drive wheel is matched with the driven wheel. The second transmission shaft is a hexagonal transmission shaft. The left header unit and the right header unit respectively comprise three millet dividing covers, the low portions of every two adjacent millet dividing covers are provided with harvesting units, and the left header unit and the right header unit are respectively and movably connected to a machine frame. The position, relative to the right header unit, of the left header unit can be adjusted, the adjustable double-row maize harvesting machine can adapt to the inter-group large space in a high photosynthetic efficiency planting method, the high efficiency mechanical harvesting is achieved, harvesting cost is reduced, and the application and popularization of the high photosynthetic efficiency planting method are facilitated.

Owner:SHANDONG RUNYUAN IND

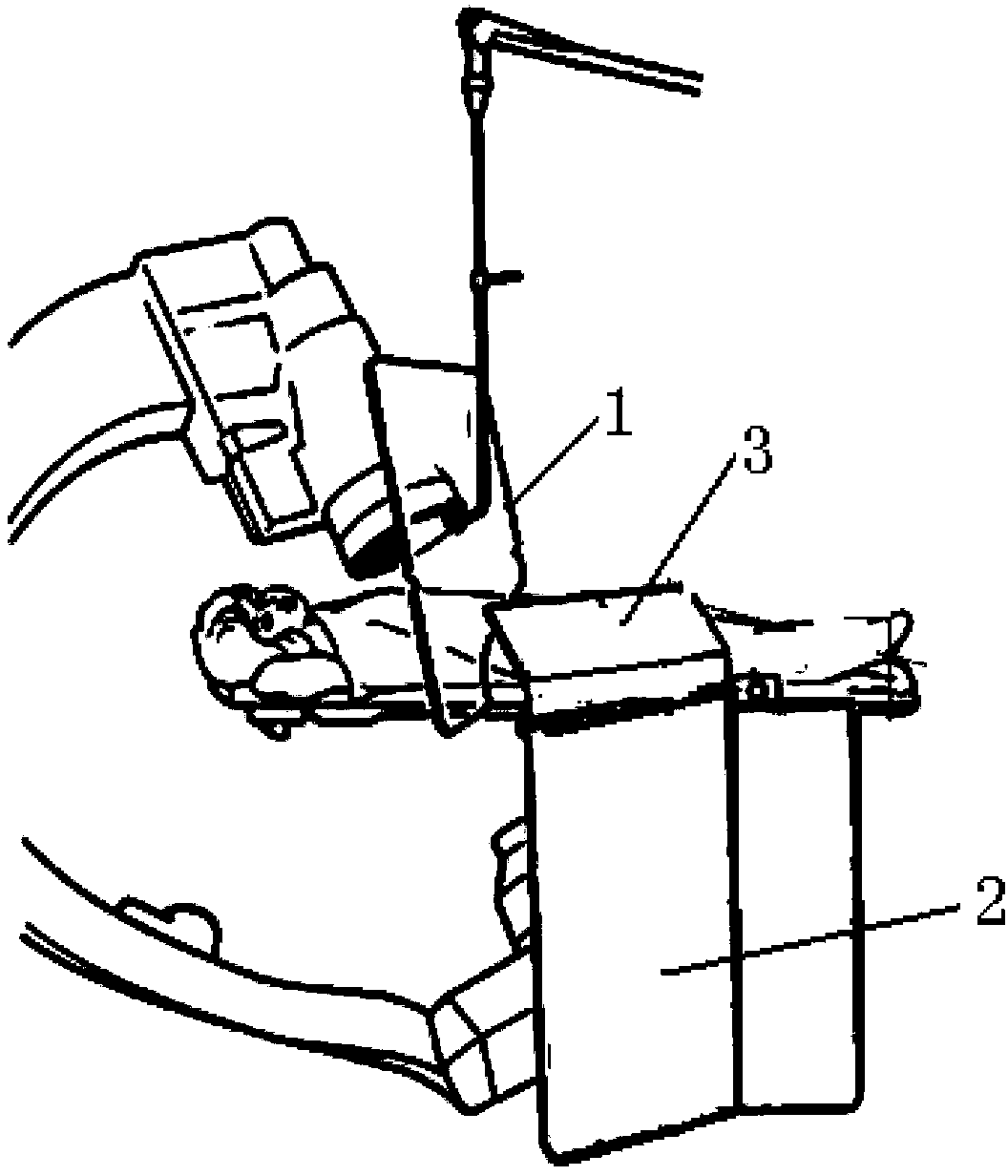

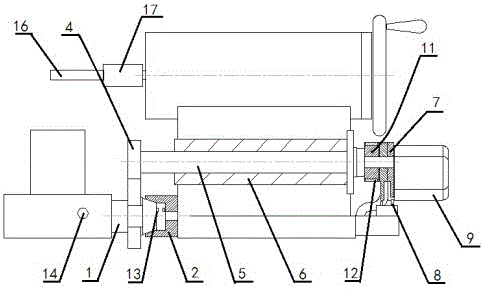

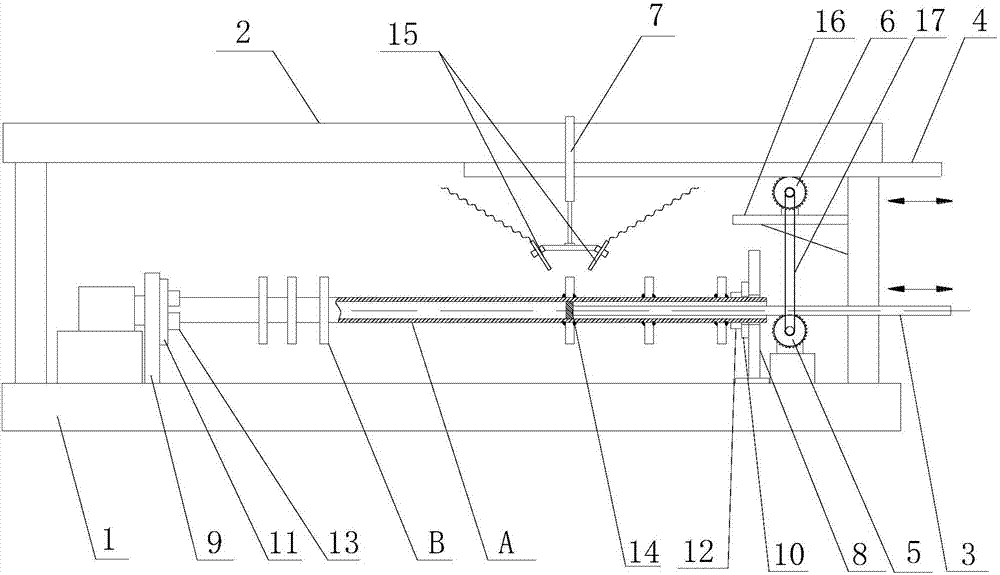

Numerical control lathe tailstock automatic control method capable of controlling drilling depth and finishing hole bottom

InactiveCN106001631ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlAutomatic control

The invention provides a numerical control lathe tailstock automatic control method capable of controlling the drilling depth and finishing a hole bottom. A connection device achieving connection and disconnection of a saddle and the tailstock of a numerical control lathe is adopted and comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is installed in a tube sleeve of the tailstock of the numerical control lathe. The centering assembly comprises a centering shaft and a centering sleeve with an inner cone hole. The shaft end of the centering shaft and the bottom of the cone hole of the centering sleeve are provided with a sensor. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting pressure blocks, the driving assembly comprises a pair of belt drivers, a driving motor, a reset switch and a controller, the controller is installed in a distribution cabinet of the lathe, the reset switch is installed on the front face of the saddle of the numerical control lathe, and the driving motor is fixedly connected with the tailstock of the numerical control lathe and electrically connected with the controller.

Owner:惠州市天力和丰精密五金有限公司

Tension detection mechanism for yarn strength

InactiveCN114047063ARealize compression and fixationEasy to installMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a tension detection mechanism for yarn strength. The mechanism comprises a base, a plurality of winding plates are fixedly mounted on the base, a sliding groove is formed in the base between adjacent winding plates, a pressing head is slidably clamped in the sliding groove, a pressure applying mechanism is mounted in the base, the pressure applying mechanism is connected with the pressing head, a tension sensor is fixedly mounted on the outer wall of one winding plate, clamping mechanisms are installed at the two ends of the tension sensor, a display screen is fixedly installed on the base, and a connecting line is installed between the display screen and the tension sensor. Yarn is wound on the multiple winding plates and sequentially penetrates through the multiple pressing heads, then the two ends of the yarn are fixedly clamped to the two ends of the tension sensor through the clamping mechanisms respectively, and the multiple pressing heads are driven by the pressure applying mechanism to synchronously move, so the multiple pressing heads evenly apply pressure to the yarn in a segmented mode till the yarn is broken; and the yarn tension strength can be detected through the tension sensor, the detection is convenient, the force application strength can be slowly applied, and the detection precision is high.

Owner:安徽汀州工程科技有限公司

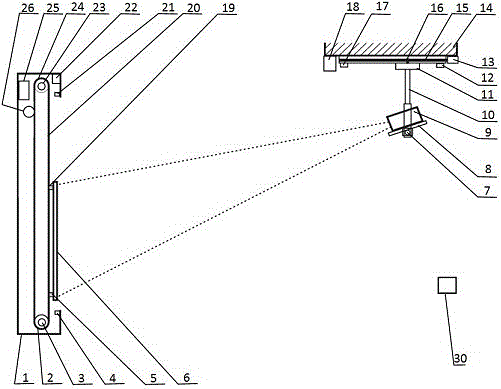

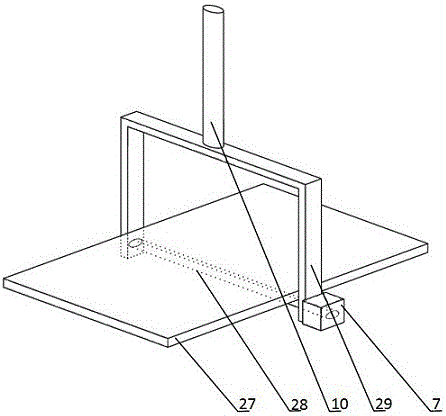

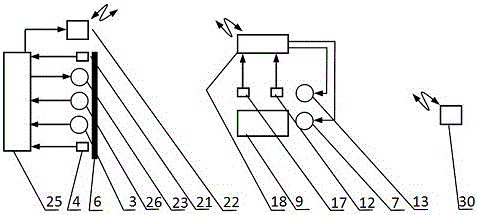

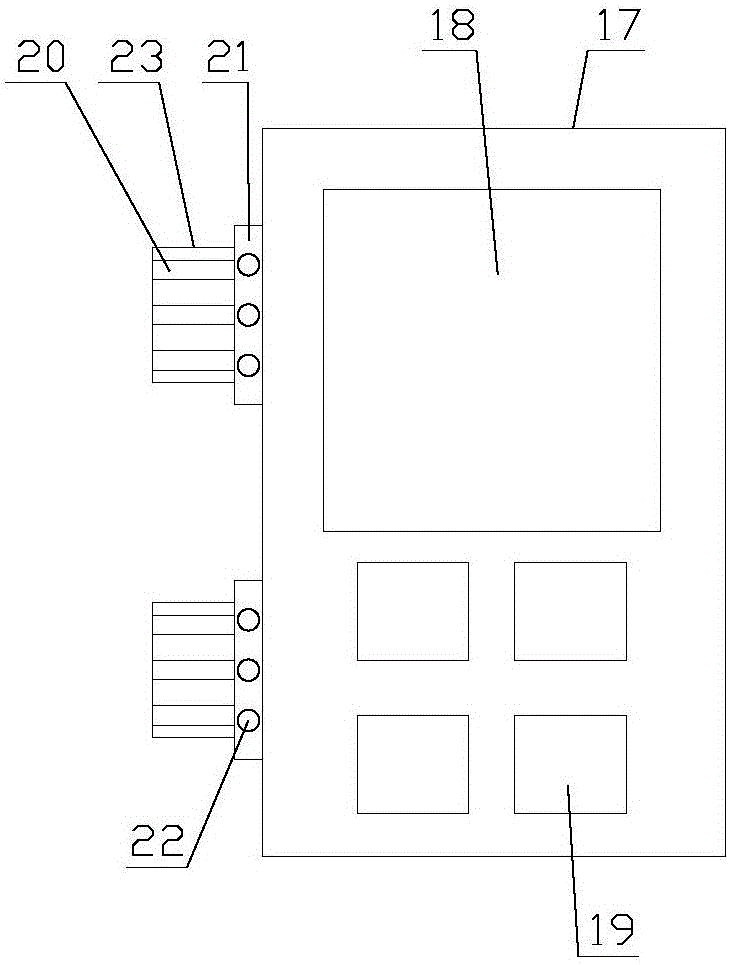

Device for achieving immersive display as well as synchronous moving of projection picture and blackboard of projector

ActiveCN106652588ARealize synchronized movementImprove teaching effectWriting boardsProjectorsComputer graphics (images)Motion control

The invention discloses a device for achieving immersive display as well as synchronous moving of a projection picture and a blackboard of a projector, and relates to the technical field of teaching aids, mainly aiming at solving the problem that the projection picture and blackboard content cannot be displayed in an immersive mode in the case that the projection picture cannot simultaneously move along with the blackboard in teaching. According to the device provided by the invention, positions of the blackboard and the projector are measured by virtue of a sensor; positions of the blackboard and the projector as well as a projection position of the projector are respectively controlled by virtue of a blackboard vertical motion and position location control device and a project motion control device, so that the projection picture of the projector is integrated with chalk words written on the blackboard, and subsequently the synchronous moving of the projection picture and the black board and the immersive display are achieved; and a classroom teaching effect is greatly enhanced.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

Intelligent cutting device for processing of MCM materials

PendingCN109366599AImprove efficiencyImprove cut qualityMetal working apparatusDrive shaftEngineering

The invention relates to an intelligent cutting device for processing of MCM materials. The intelligent cutting device comprises a longitudinal cutting assembly, a horizontal cutting assembly and a transporting assembly, wherein the longitudinal cutting assembly comprises a longitudinal cutting motor, a longitudinal cutting transmission shaft and longitudinal cutting saw blades; the longitudinal cutting motor is used for driving the longitudinal cutting saw blades to rotate and operate; a longitudinal transplanting bracket is arranged on a cutting machine frame; the horizontal cutting assemblyis arranged on the longitudinal transplanting bracket; a round power assembly is used for driving the longitudinal transplanting bracket to move; the horizontal cutting assembly comprises a horizontal transplanting bracket, a horizontal transplanting motor and horizontal cutting units, wherein a horizontal transplanting rack is arranged on the longitudinal transplanting bracket; a horizontal transplanting gear is arranged on the horizontal transplanting motor; the horizontal transplanting motor is used for driving the horizontal cutting units to horizontally move through the horizontal transplanting bracket; each horizontal cutting unit comprises a horizontal cutting motor and a horizontal cutting saw blade; and each horizontal cutting motor is used for driving the corresponding horizontal cutting saw blade to rotate and operate. The intelligent cutting device is reliable in performance, high in cutting efficiency and good in quality.

Owner:中山市创建机械设备有限公司

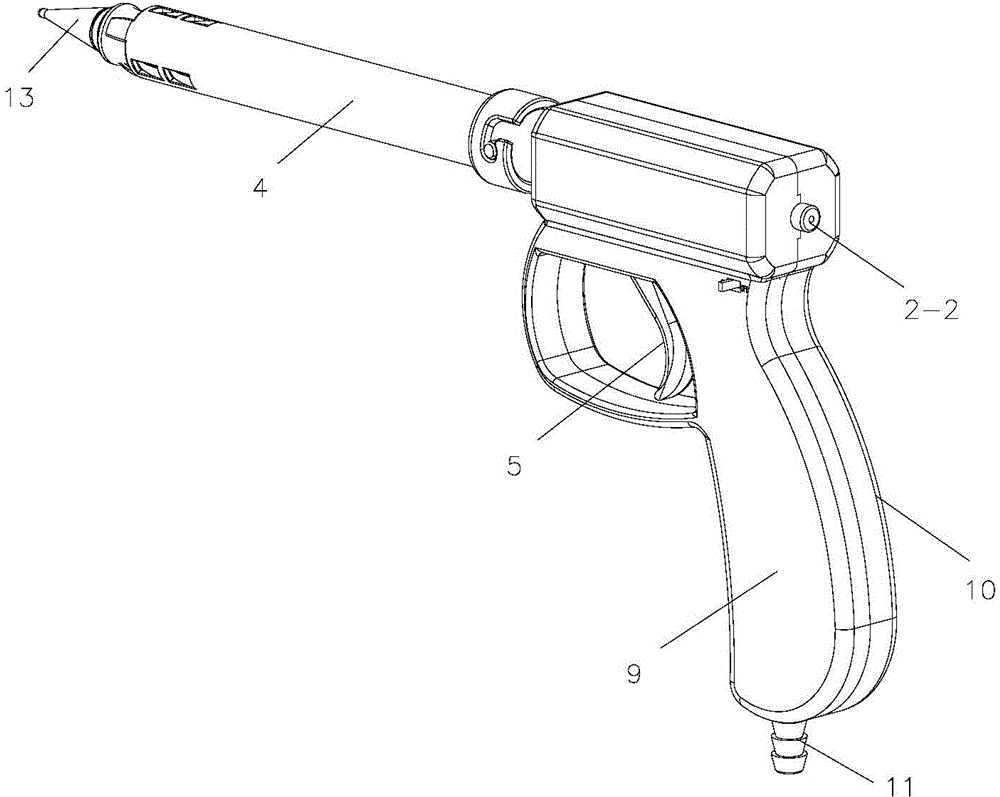

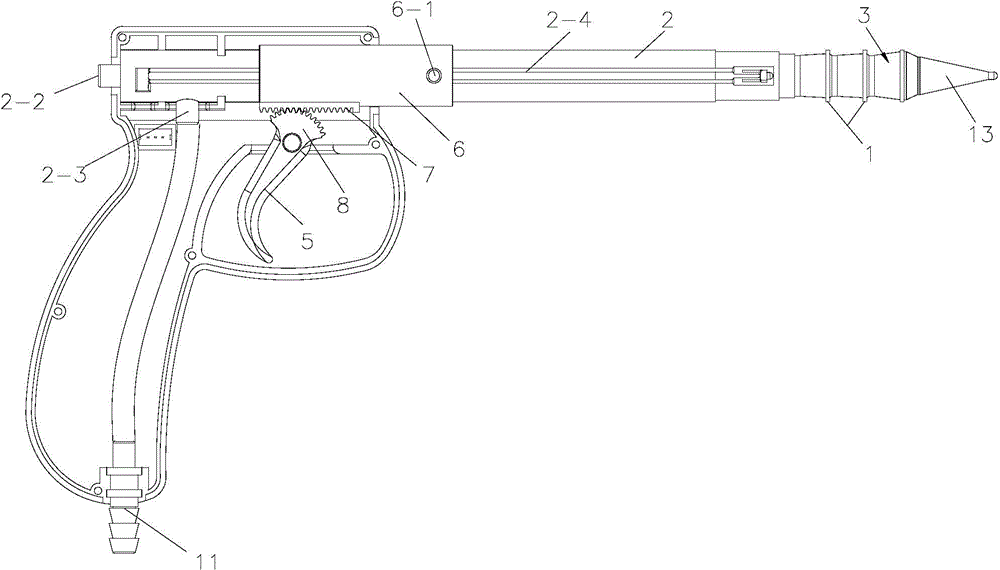

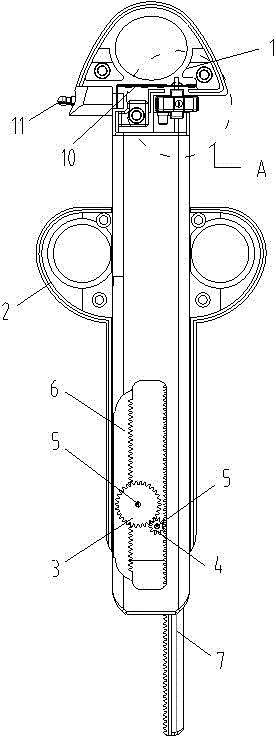

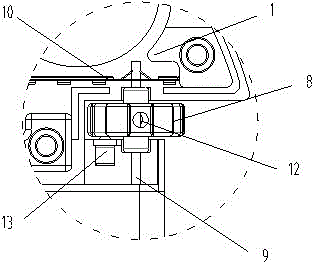

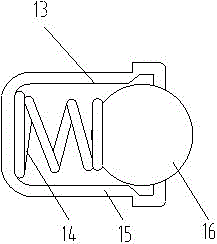

Rotatable and variable-speed electric snare handle

PendingCN105559878ASolving Gesture PuzzlesPrevent springbackSurgical instruments for heatingEngineeringElectrical and Electronics engineering

The invention discloses a rotatable and variable-speed electric snare handle. The rotatable and variable-speed electric snare handle comprises a handle main body, wherein the handle main body is sleeved by a ring sleeve in a sliding manner; a variable-speed gear and a transmission gear are respectively mounted on the ring sleeve and connected with the ring sleeve through locating pins; a first rack is arranged on the handle main body and in meshed connection with the variable-speed gear; the variable-speed gear is in meshed connection with the transmission gear; the transmission gear is in meshed connection with a second moveable rack; a turning wheel is mounted on the handle main body; a boosting rod is mounted in the turning wheel and connected with a copper sheet; the copper sheet is connected with a conductive column. The rotatable and variable-speed electric snare handle can reach the effect that an elastic metal wire can be rotated to enable a snare to snare a to-be-excised tissue, and the electric snare handle is convenient for a doctor to operate with a single hand.

Owner:ZHUJI PENGTIAN MEDICAL DEVICES

Embossing device for leather production

ActiveCN110129487ARealize synchronized movementAvoid distortionSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringMechanical engineering

The invention discloses an embossing device for leather production. The device comprises a working platform, supporting legs are welded to the four corners of the bottom of the working platform, oblique plates are installed at both front and rear ends of the left and right side walls of the working platform, the inner sides of the two oblique plates which are symmetric at front and back are rotatably connected with the first roller, both front and rear sides of the outer wall of the first roller are in clearance fit with inner rings of two bearings respectively, outer rings of the bearings arefixedly connected with the inner sides of the oblique plates, and an embossing mechanism is installed on the top of the working platform; four circular rods are included in the embossing mechanism, the four round rods are fixed to the four corners of the top of the working platform respectively, and the tops of the round rods are connected with the top plate through screws at the tops of the round rods. The embossing device has the advantages that the synchronous moving of an embossing roller and leather can be achieved to avoid the twisting deformation of leather embossing and improve the embossing quality, embossing on the leather with different thicknesses can be achieved, the practicability is high, and the demand of leather embossing is met to a great extent.

Owner:泰兴市平顺皮革制品有限公司

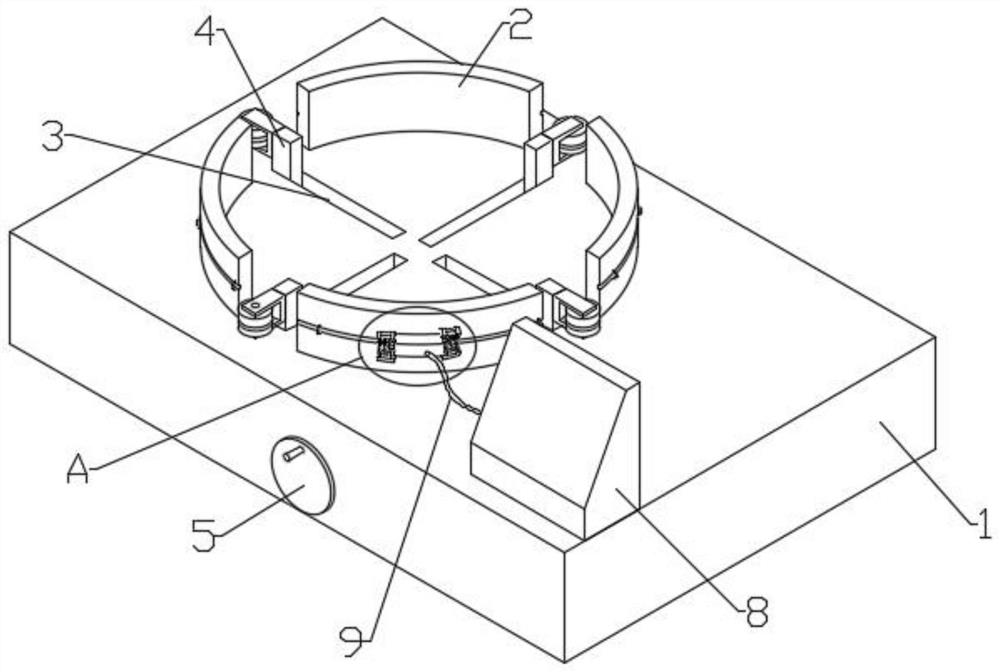

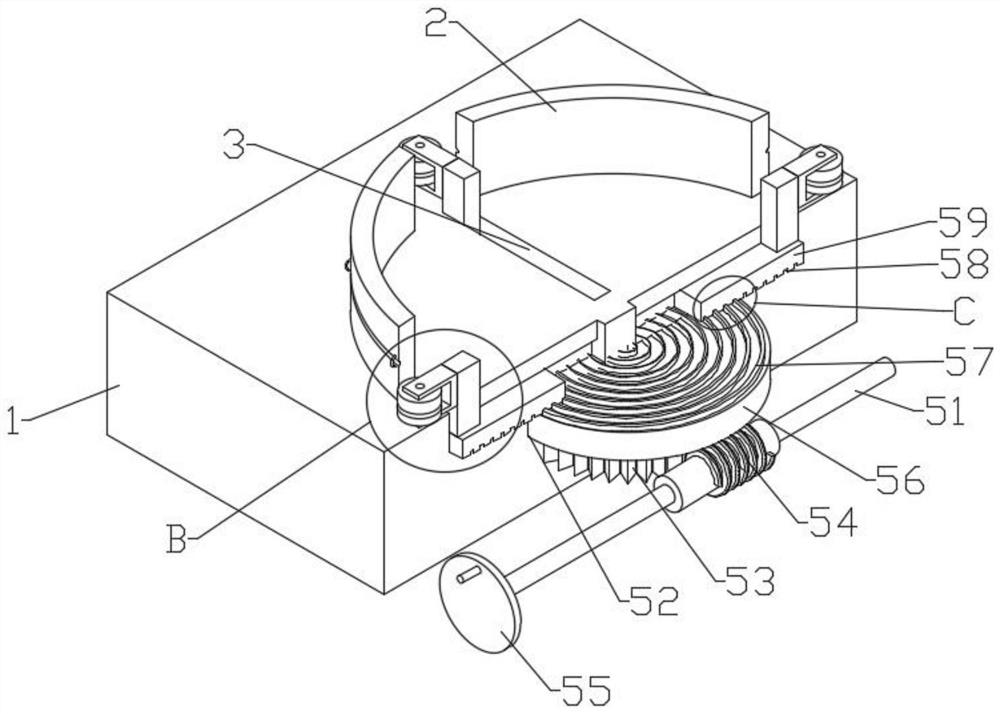

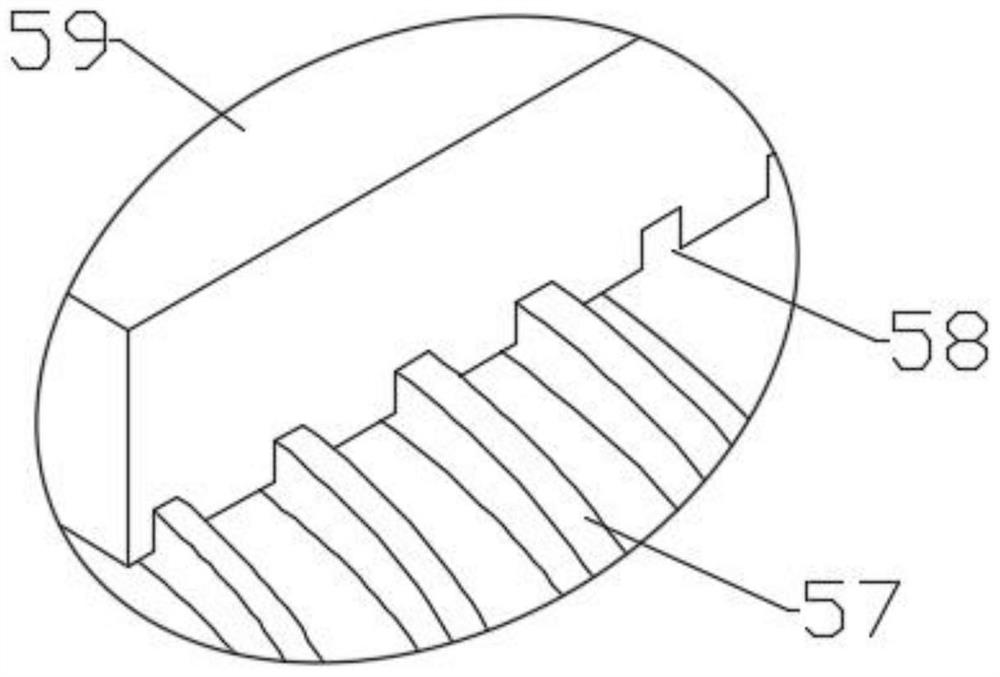

Efficient scaffold ringlock layered welding device

ActiveCN107030421ARealize synchronized movementSpeed up layered weldingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses an efficient scaffold ringlock layered welding device which comprises a pedestal, a cross beam, a pipe rack, a first transmission rod, a second transmission rod, a first transmission gear, a second transmission gear, a telescopic cylinder, a welding mechanism, a first driving mechanism and a second driving mechanism. By the arrangement of structures of all components in the device, due to cooperation of the first transmission rod with a magnetic block, layered arrangement of ringlocks in the length direction of a vertical pipe is achieved; by respective cooperation of the first transmission rod and the second transmission rod with the first transmission gear and the second transmission gear, synchronous movement of the welding mechanism and the magnetic block is realized, so that one driving mechanism can realize synchronous movement of welding guns in the welding mechanism and the ringlocks to be welded; and therefore, the speed of layered welding of the ringlocks can be greatly increased, the cost investment for equipment can be further effectively reduced, and energy can be saved.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

Integrated X-ray protection device on angiography machine

ActiveCN103385733BRealize simultaneous movement with the bedRealize synchronized movementRadiation safety meansAngiographyX-rayEngineering

The invention relates to the field of medical instruments, in particular to an X-ray protection device with an integrated structure for an angiography machine. The device comprises a protection screen unit, a protection curtain unit and a bedside sliding rail unit, wherein the protection screen unit is arranged on the protection curtain unit, and the protection curtain unit is fixed on the bedside sliding rail unit so as to enable the protection curtain unit and the protection screen unit to synchronously and horizontally move along a bedside. The protection device can synchronously move along with a bed, and in a moving process, the protection device is always in the best protecting state and close to a patient, so that the problem that the radiation, especially the secondary stray radiation caused by the rays reflected by the patient, can not be effectively shielded due to the movement of the bed surface of a conduit bed is effectively solved, and meanwhile, the problems of prolonged surgery time, increased surgery risk and the like that are caused by adjusting the protection screen unit during surgery in the prior art are effectively avoided.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

Intelligent twin riveting device for industrial production and control system thereof

The invention relates to an intelligent twin riveting device for industrial production and control system thereof. The intelligent twin riveting device for the industrial production comprises a rack, a rivet pressing mechanism, a working platform and a lifting adjusting mechanism. The control system of the intelligent twin riveting device for the industrial production comprises a central control module and a working power supply module. According to the intelligent twin riveting device for the industrial production and the control system thereof, a driving motor can synchronously control two transmission gears to rotate through a driving shaft, so that the distance between two first cylinders can be synchronously adjusted; mounting inserting blocks can be reliably positioned through positioning units after being inserted into inserting grooves, thus a central control mechanism can be reliably inserted and draw from the rack, and as a result, the equipment reliability is improved; an integrated circuit of a working power supply circuit can be used for accurately feeding back and acquiring output voltage, thus the stability of the output voltage can be ensured, and as a result, the equipment working reliability can be improved.

Owner:东莞市通博五金有限公司

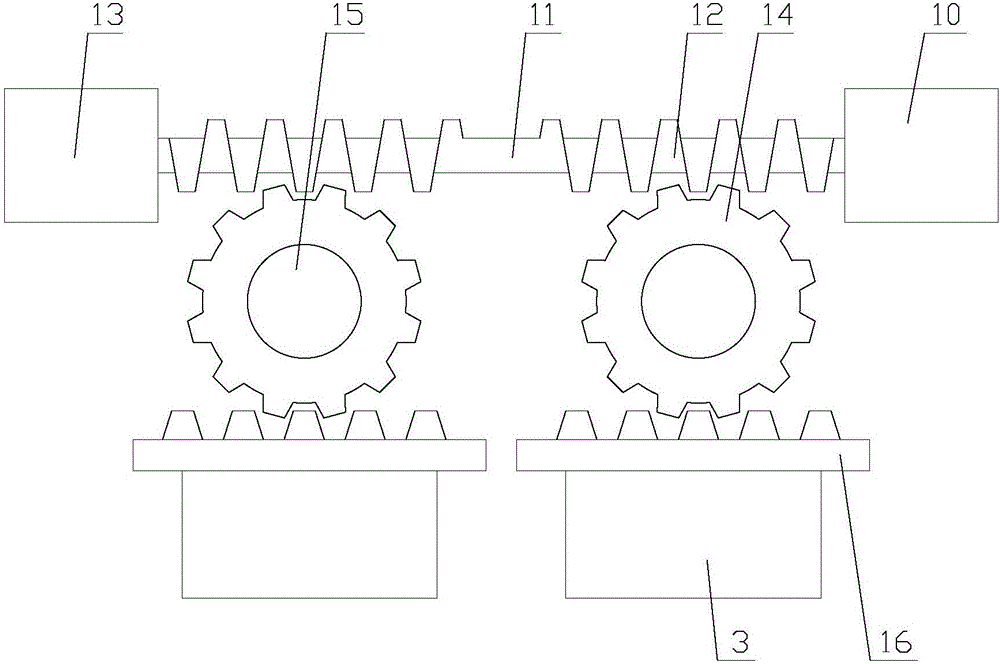

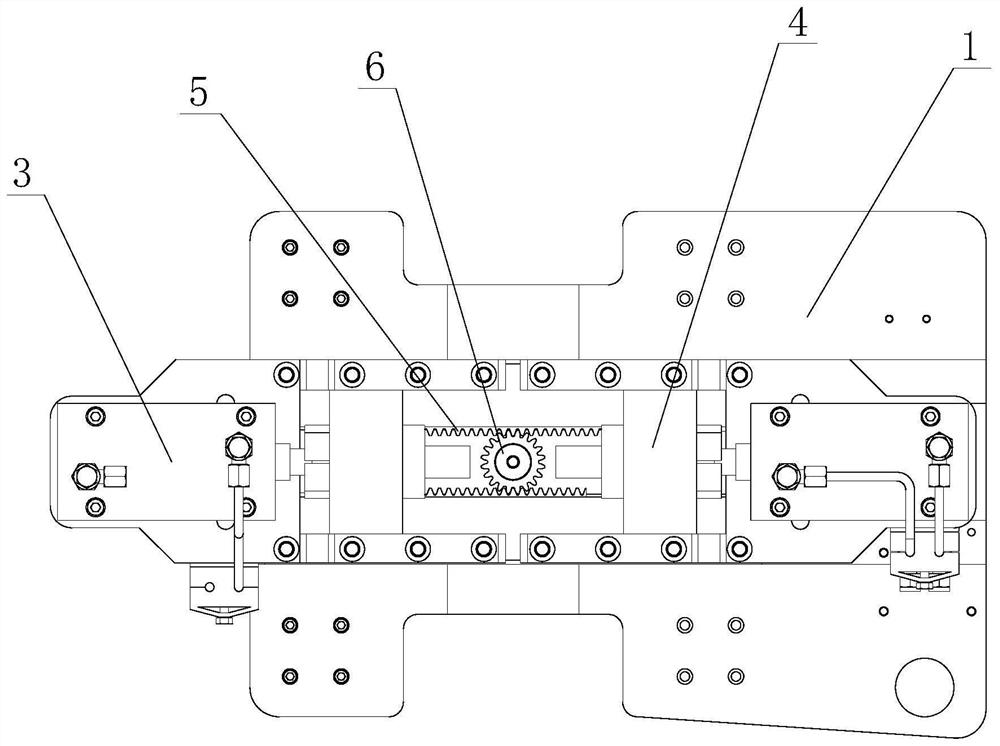

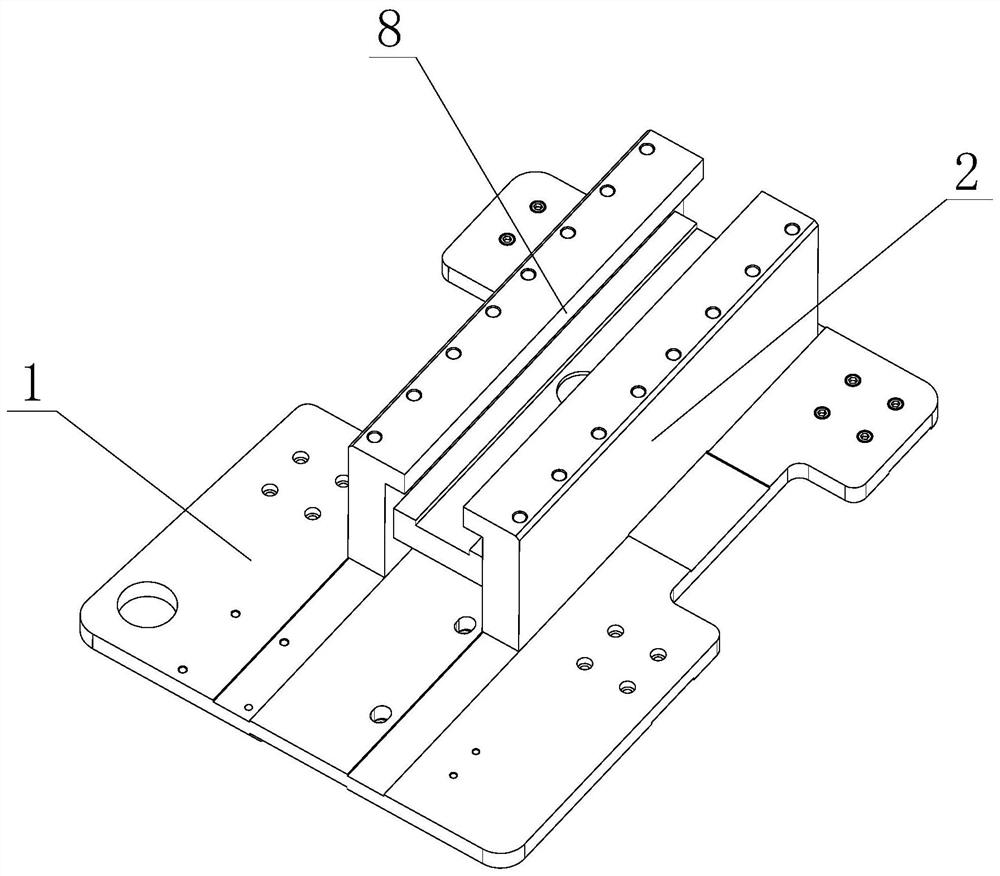

Steel pipe clamp for pipe thread machining equipment

ActiveCN113001220AEasy to moveRealize synchronized movementThread cutting machinesPositioning apparatusSteel tubeClassical mechanics

The invention discloses a steel pipe clamp for pipe thread machining equipment. The steel pipe clamp comprises a bottom plate, wherein a guide table is arranged on the bottom plate, two clamping components are connected to the guide table in a sliding mode, and the two ends of the guide table are provided with telescopic devices used for driving the two clamping components to move correspondingly; the two clamping components are each connected with a rack, the two racks are parallel to each other, a gear is rotationally connected to the guide table, and the two racks are engaged with the two sides of the gear correspondingly; and a mounting hole is formed in the bottom plate. According to the steel pipe clamp, the two racks restrain the movement of the two clamping components, so that the two clamping components move synchronously, the moving distances of the two clamping components are ensured to be the same, and then the two clamping components can clamp a pipe at a designated position.

Owner:杭州希纳博智能机电科技有限公司

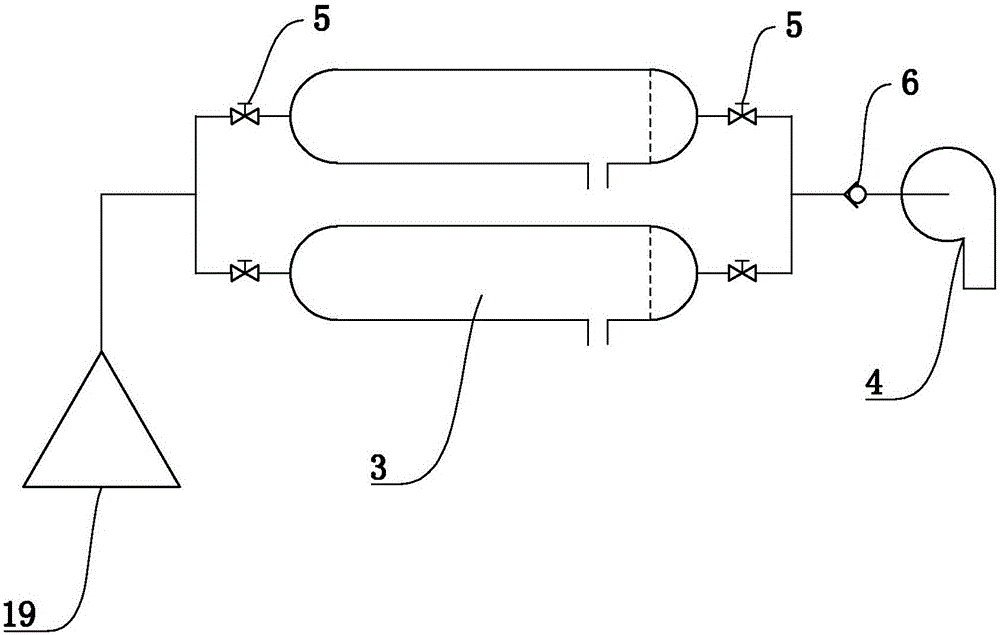

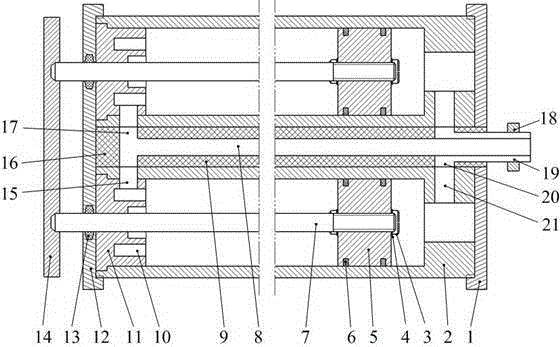

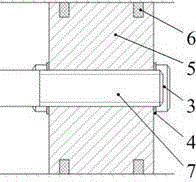

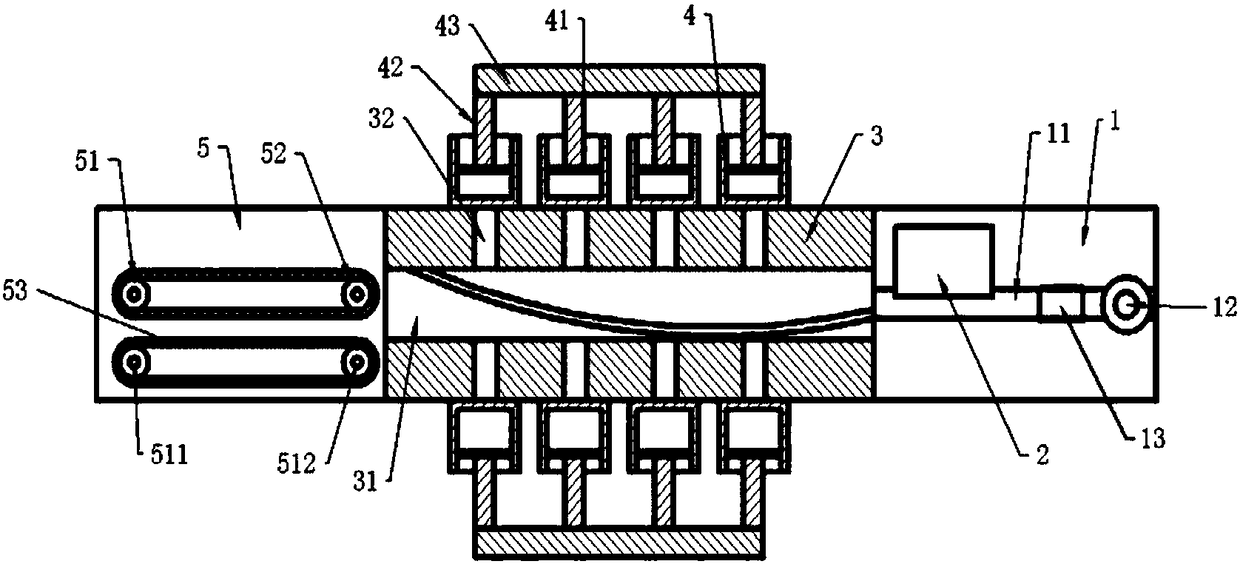

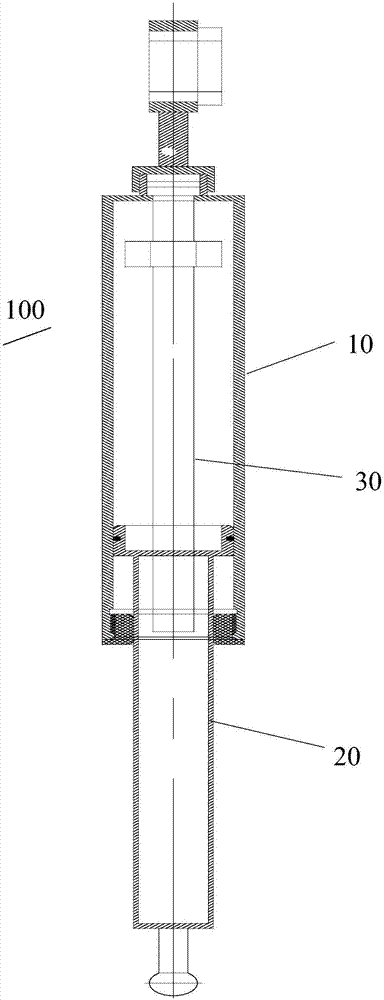

Combined hydraulic cylinder with adjustable power output angle

InactiveCN105179365ARealize oil supply switchingRealize synchronized movementFluid-pressure actuatorsEngineeringHydraulic cylinder

The invention provides a combined hydraulic cylinder with the adjustable power output angle. The combined hydraulic cylinder mainly comprises a hydraulic cylinder combined device, an adjustable oil conveying device and movable plates. The movable plates are installed on the hydraulic cylinder combined device. The adjustable oil conveying device is arranged in the middle of the hydraulic cylinder combined device. The combined hydraulic cylinder is characterized in that the angle of power output of the combined hydraulic cylinder can be adjusted. By means of double hydraulic cylinders, the adjustment on the two-dimensional output power angle is achieved. The oil supply switchover of the hydraulic cylinder combined device is achieved through the adjustable oil conveying device, the synchronous movement of the movable plates is achieved through an oil conveying port A1 and an oil conveying port B1, and inclination of the movable plates is achieved through an oil conveying port A2 and an oil conveying port B2.

Owner:UNIV OF JINAN

Fine copper pipe straightening device

InactiveCN108160756AAchieve alignmentStraightening lastsShaping toolsMetal-working feeding devicesEngineeringCopper

The invention belongs to the technical field of machining, and discloses a fine copper pipe straightening device. The fine copper pipe straightening device comprises a straightening mechanism and a shaping mechanism; the straightening mechanism comprises a straightening table and an air storage bin, a straightening groove is formed in the straightening table, a through hole is formed in the straightening table, a piston is in sliding connection into the air storage bin, a push rod is connected to the piston, an air inlet and an air outlet are formed in the air storage bin, the shaping mechanism comprises a supporting table and two sets of conveying belts, each conveying belt comprises a driving wheel, a driven wheel and a belt, a first rotaion shaft is arranged on each driving wheel, a second rotation shaft is arranged on each driven wheel, a rotation motor is arranged at the bottom of the supporting table, a moving mechanism is further included and comprises a first connection rod, asecond connection rod and a third connection rod, and the problems that in the prior art, a straightening roller is used for fixing the two ends of a fine copper pipe, when the straightening roller rotates, the fine copper pipe can be separated from the straightening roller, and the straightening effect is poor are solved.

Owner:宁波隆锐机械制造有限公司

Automatic feeding control method used for numerical control lathe tailstock and capable of controlling drilling depth

ActiveCN106180765ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlDrive motor

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

Protective device of displacement sensor and belt self-moving machine tail with displacement sensor

PendingCN107298281AAvoid influenceRealize synchronized movementConveyorsControl devices for conveyorsEngineeringClosed cavity

Disclosed is a protective device of a displacement sensor. The protective device comprises a fixed assembly, a sliding assembly and the displacement sensor; the fixed assembly is provided with a closed cavity for placing the displacement sensor; the opening in the bottom of the closed cavity of the fixed assembly is blocked by the sliding assembly, and the displacement sensor in the fixed assembly is connected with the sliding assembly, so that the sliding assembly drives the displacement sensor to slide up and down in the closed cavity of the fixed assembly, and displacement measurement is achieved. The protective device of the displacement sensor is fixed between a cylinder barrel of a leveling oil cylinder and a piston rod of the leveling oil cylinder by the fixed assembly and the sliding assembly, and the displacement sensor is arranged inside the fixed assembly and the sliding assembly, so that the displacement sensor is installed in a closed mode and prevented from being influenced by external environment, and meanwhile the synchronous movement and measurement of the displacement sensor and the piston rod of the leveling oil cylinder are achieved.

Owner:NINGXIA TIANDI BENNIU IND GRP

Anti-blocking aluminum profile extrusion molding device

PendingCN111389949ATo achieve the purpose of adjustmentReduce frictionEngineeringStructural engineering

The invention discloses an anti-blocking aluminum profile extrusion molding device which comprises an equipment body. A conveyor belt is arranged on the left side of the equipment body. Through the cooperative use of a moving plate, a movable plate, a sliding block, a sliding groove, a clamping plate, a clamping rod, a clamping groove, a rotating mechanism and a telescopic mechanism and the use ofa rotating mechanism, the friction of an aluminum profile during a conveying process can be reduced, through the use of the telescopic mechanism, the clamping plate can drive the clamping rod to be automatically inserted into the clamping slot to fix the position of the moving plate, so that the purpose of adjusting the position of the movable plate is achieved, and the problem of extrusion blockage phenomenon due to offset of one end of the aluminum profile at the time of extruding the aluminum profile due to the fact that existing aluminum profile extrusion molding equipment cannot guide and limit the extruded aluminum profile during the use process is solved. The anti-blocking aluminum profile extrusion molding device has the advantages of anti-blocking, guiding and limiting, and is worthy of promotion.

Owner:GUANGDONG XINGFA ALUMINUM HENAN

Adjustable multi-axis automatic locking screw machine and its position adjustment method

ActiveCN105014368BRealize synchronized movementEasy to adjustMetal working apparatusMulti axisPortal frame

The invention discloses an adjustable multi-shaft automatic screwing machine and a position adjustment method thereof. The screwing machine comprises a machine frame, an object containing table, a portal frame, a plurality of screwing mechanisms, a position adjustment mechanism capable of adjusting movement of the screwing mechanisms in the X axis direction, a Z-axis movement mechanism capable of driving the screwing mechanisms to vertically move, a Y-axis movement mechanism capable of driving the object containing table or the screwing mechanisms to move and a control mechanism. The position adjustment mechanism comprises a nut-rotating-type lead screw pair fixed to the portal frame. A plurality of nuts are arranged on the nut-rotating-type lead screw pair according to the number of the screwing mechanisms. Each nut is provided with an X-axis nut base which is fixedly linked with the corresponding screwing mechanism. Each screwing mechanism is provided with an X-axis motor to be connected with the corresponding nut in a transmission manner through a transmission mechanism. According to the adjustable multi-shaft automatic screwing machine and the position adjustment method, the relative positions among the screwing mechanisms can be adjusted to adapt to screw hole positions in a to-be-screwed workpiece, and therefore the multiple screw hole positions in a row in the workpiece can be screwed at the same time.

Owner:XIAMEN UNIV OF TECH

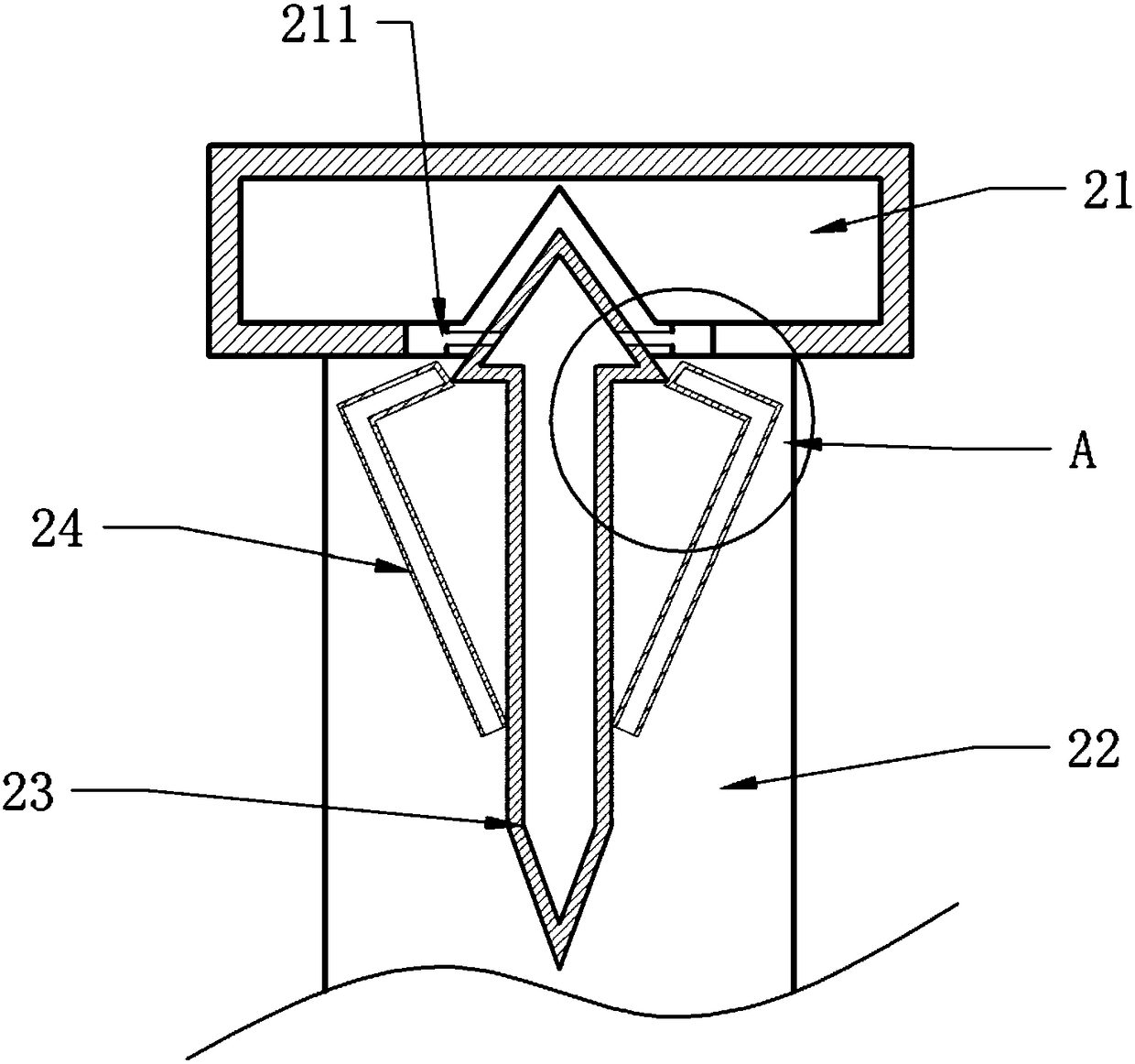

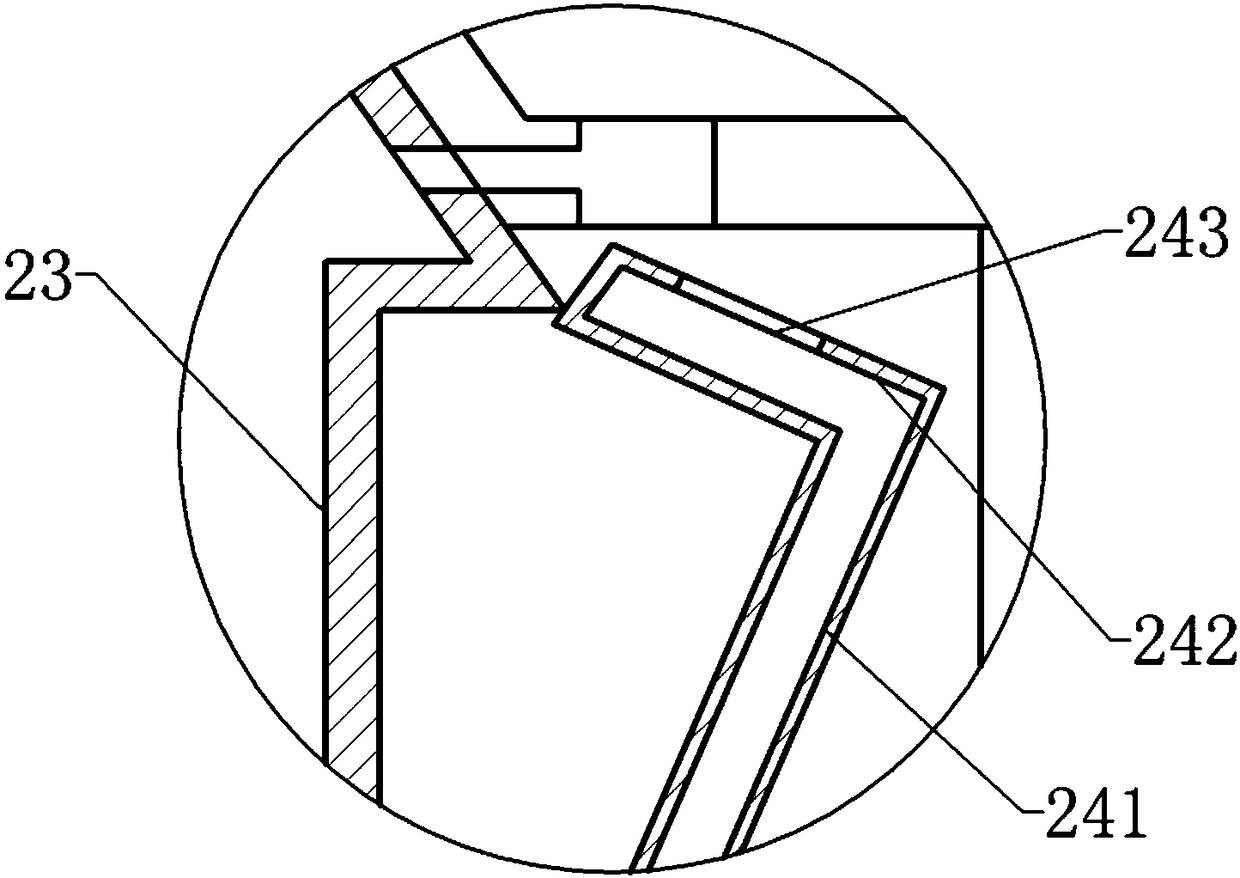

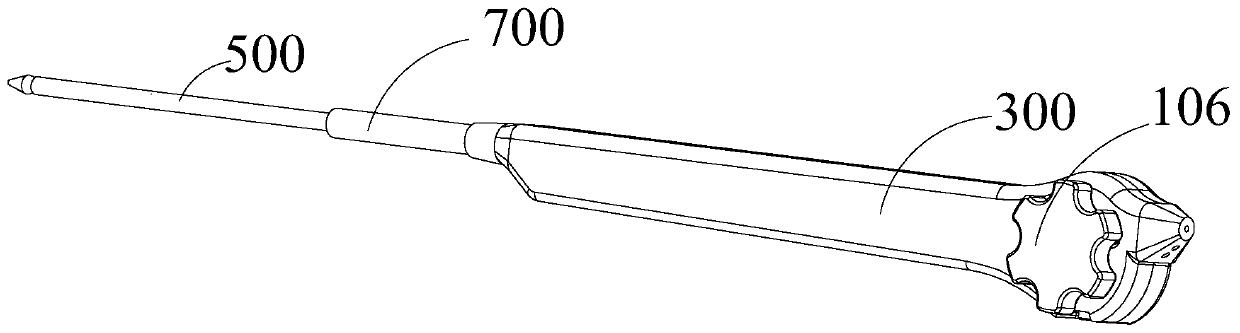

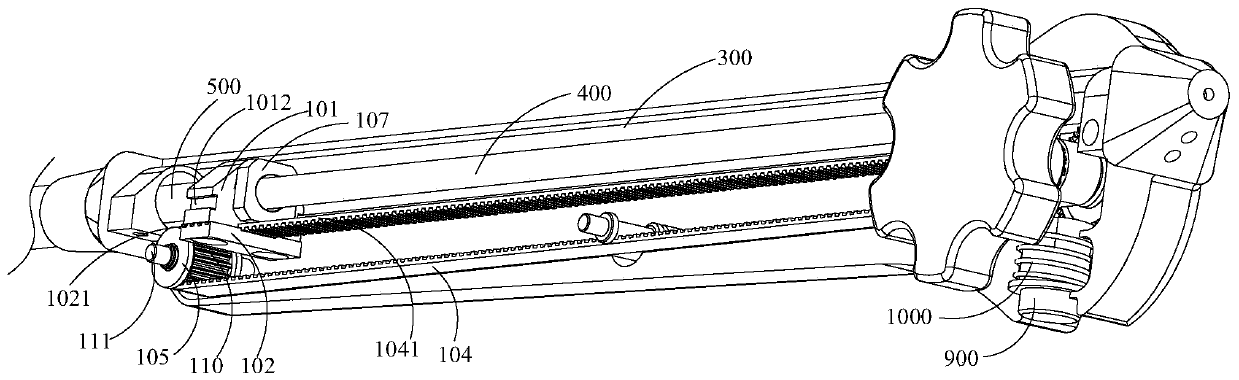

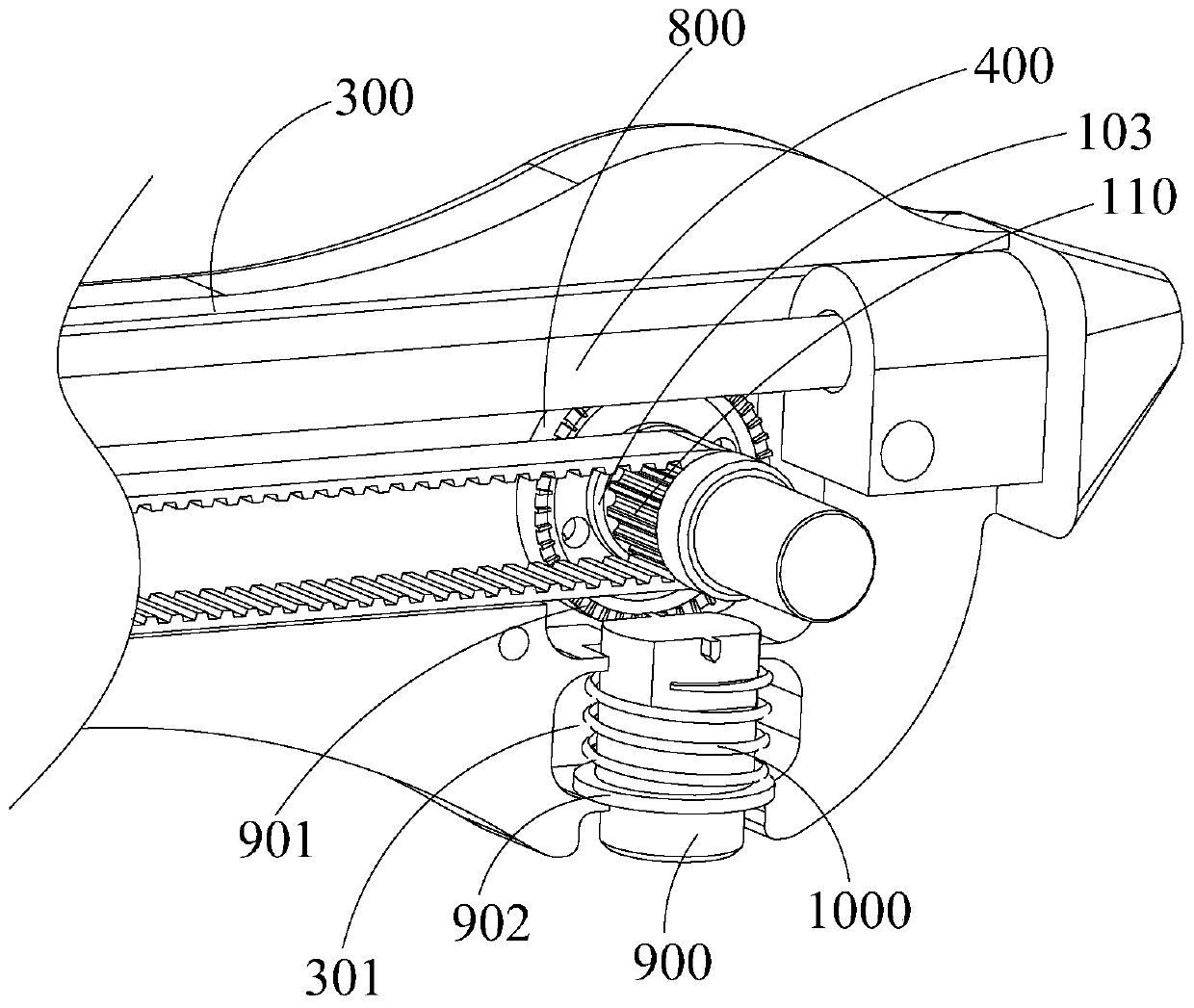

Stent implant driving mechanism and medical stent placement device

The invention discloses a stent implant driving mechanism and a medical stent placement device. The stent implant driving mechanism comprises an outer pipe clamping mechanism suitable for clamping anouter pipe and a shaft displacement driving mechanism suitable for driving the outer pipe to move, wherein the outer pipe clamping mechanism comprises an outer sleeve pipe fixedly arranged on the outer pipe in a sleeving manner, and a pressing block connected with the outer sleeve pipe; the shaft displacement driving mechanism comprises a transmission assembly which cooperates with the pressing block to be suitable for driving the pressing block to move, and a power part which is connected with the transmission assembly; the power part is suitable for driving the transmission assembly to drivethe pressing block to move, and besides, simultaneous movement of the outer pipe is realized; the transmission assembly comprises an annular simultaneous structure and a driven rotating wheel and a driving rotating wheel which are in adapting with the annular simultaneous structure; and the driving rotating wheel and the power part are in adapting to be suitable for the power part to drive the driving rotating wheel to rotate. According to the medical stent placement device, the flexibility of the stent placement operation process can be improved.

Owner:JIANGSU VEDKANG MEDICAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com