Diameter reducing device for electric pole reinforcing cage forming machine

A technology for steel cage forming machines and electric poles, which is applied to the manufacture of ring nets, other household appliances, and household appliances with wires, to achieve the effect of ensuring the accuracy of variable diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

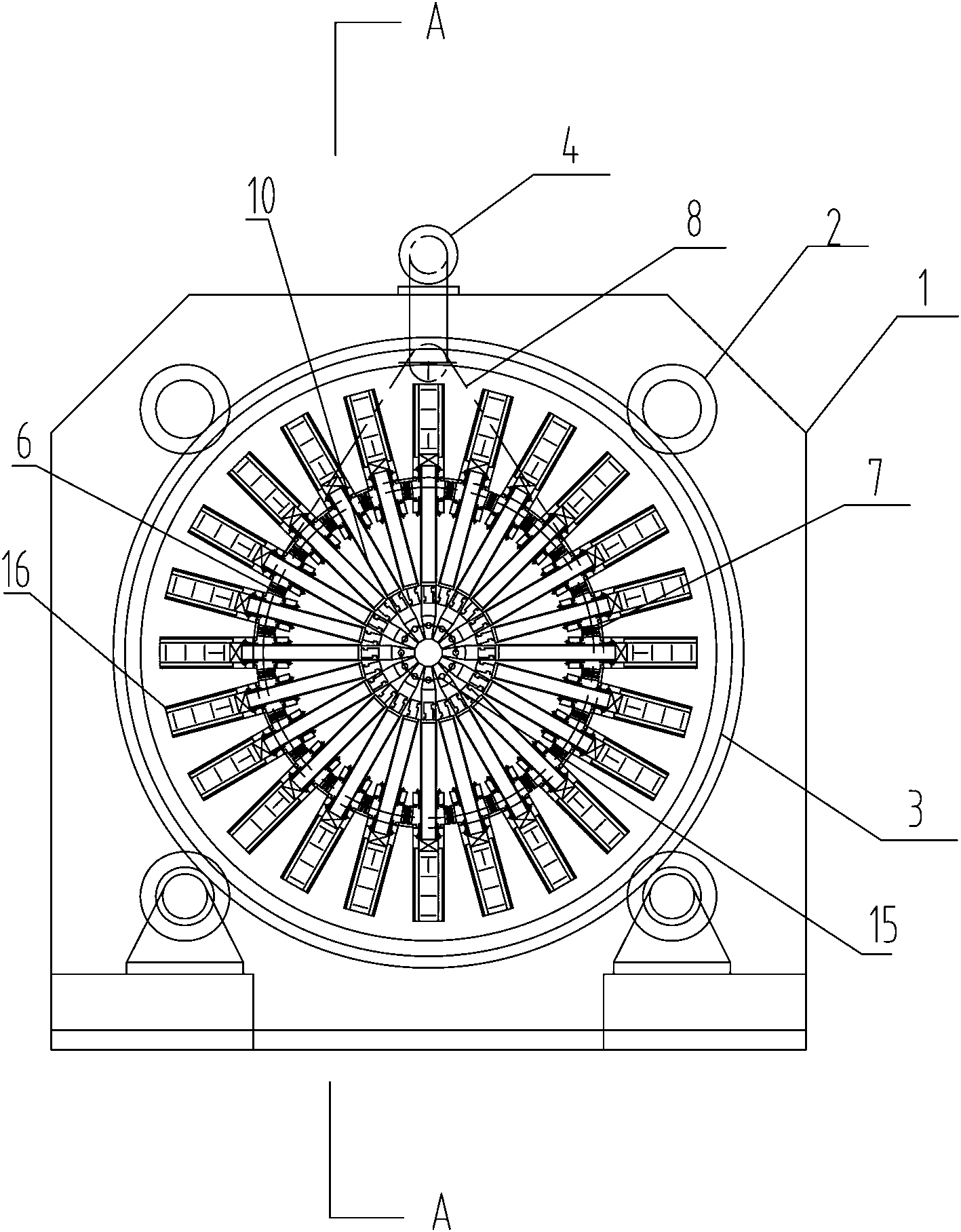

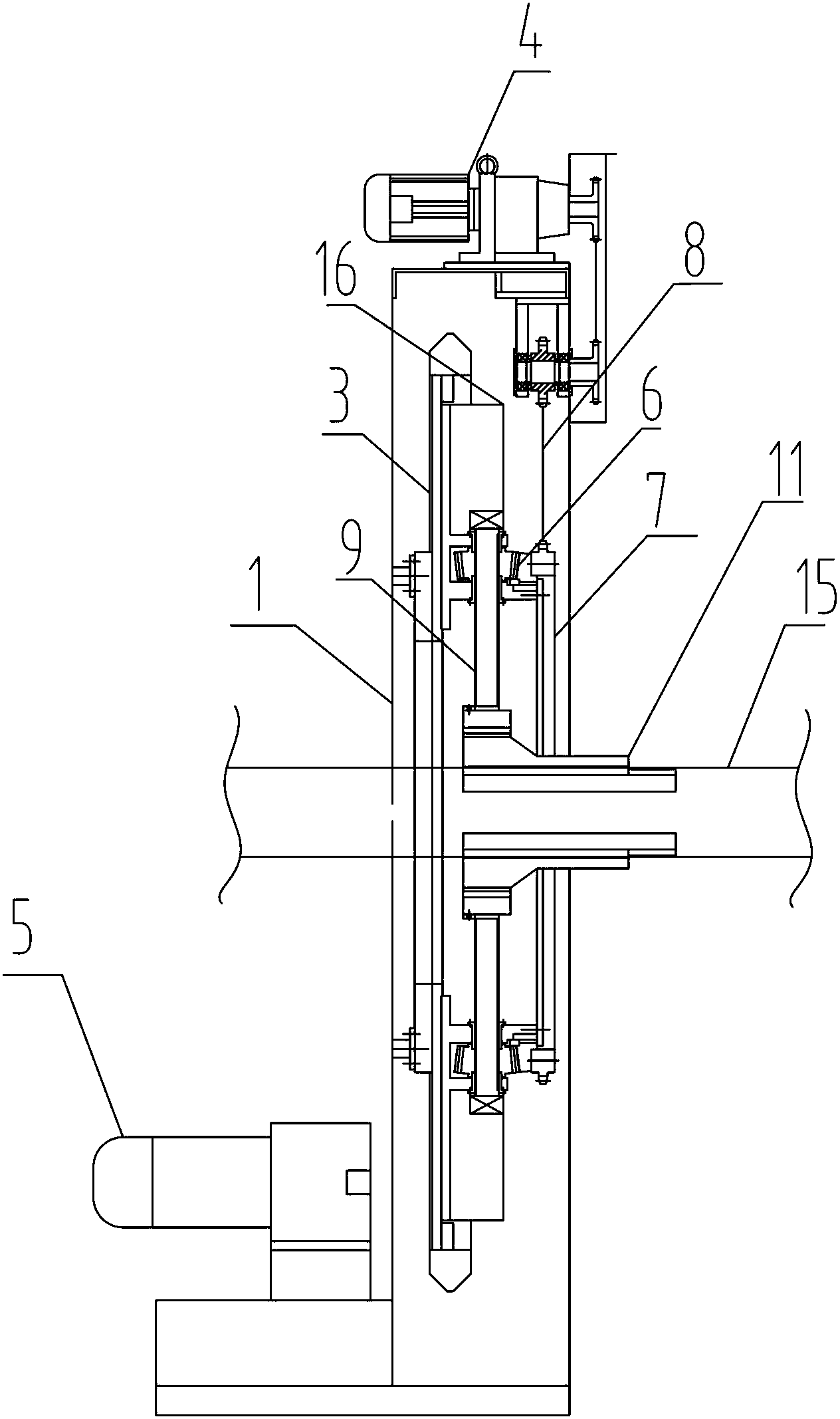

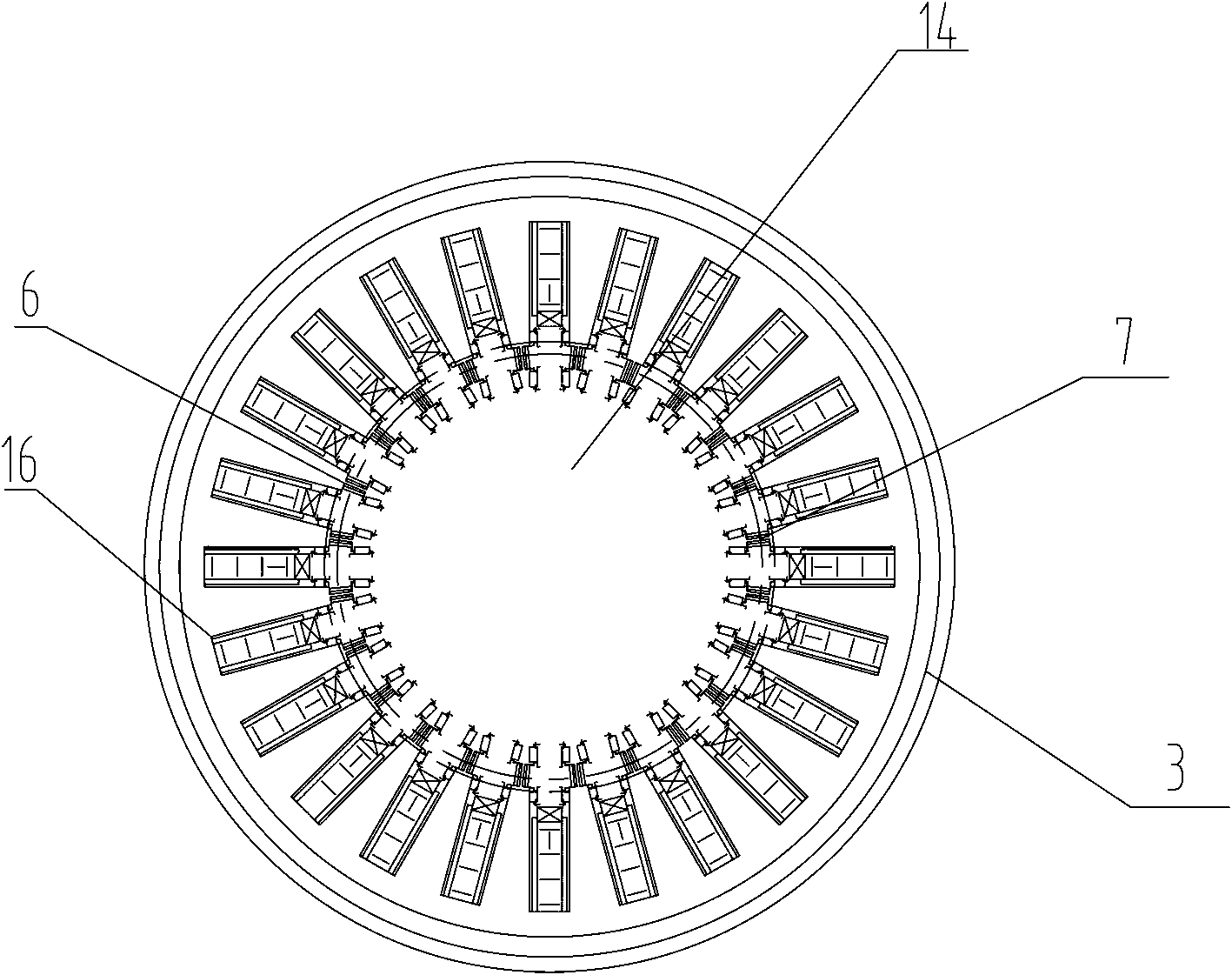

[0017] Such as figure 1 , figure 2 As shown, the variable diameter device includes a main support 1, a guide wheel mechanism 2, a main rotating disk 3, a variable diameter mechanism, a variable diameter drive mechanism 4, and a main rotation drive mechanism 5. The main support 1 is equipped with a guide wheel mechanism 2, and the main rotation Disk 3 is installed on the guide wheel mechanism 2, diameter reducing mechanism and variable diameter driving mechanism 4 are installed on the main rotating disk 3, main rotating driving mechanism 5 can drive the main rotating disk 3 to rotate, and the reducing mechanism is composed of pinion 6, large cone Gear 7 and screw mechanism 10 are made up of, variable-diameter driving mechanism 4 drives large bevel gear 7 to rotate through sprocket mechanism 8, and large bevel gear 7 rotates and drives pinion 6 to rotate, and pinion 6 middle is provided with hole 9, and hole 9 inner wall is provided with There are threads, the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com