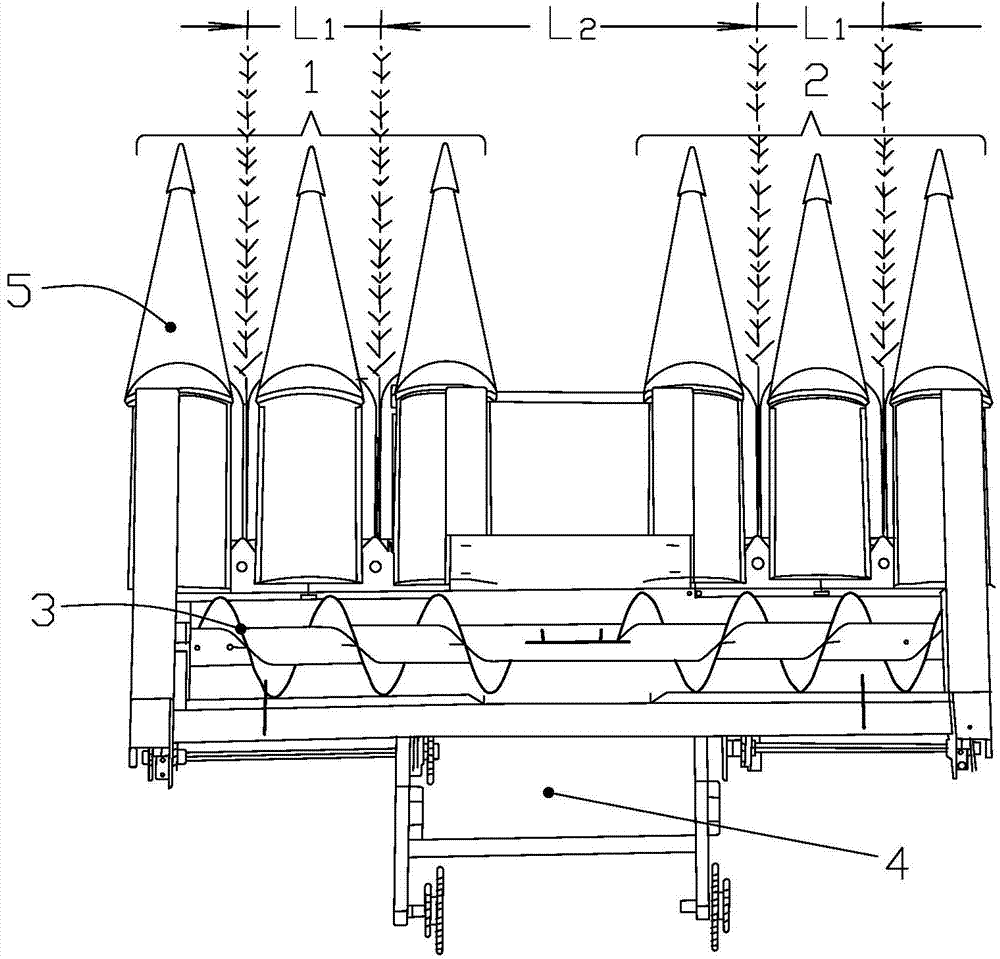

Adjustable double-row maize harvesting machine header

A corn harvester, adjustable technology, applied in harvesting platforms, harvesters, agricultural machinery and implements, etc., can solve the problems of restricting the development of corn crops, high harvesting costs, and low machine harvesting efficiency, so as to reduce the number of labor force and improve The effect of high-quality and high-efficiency harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

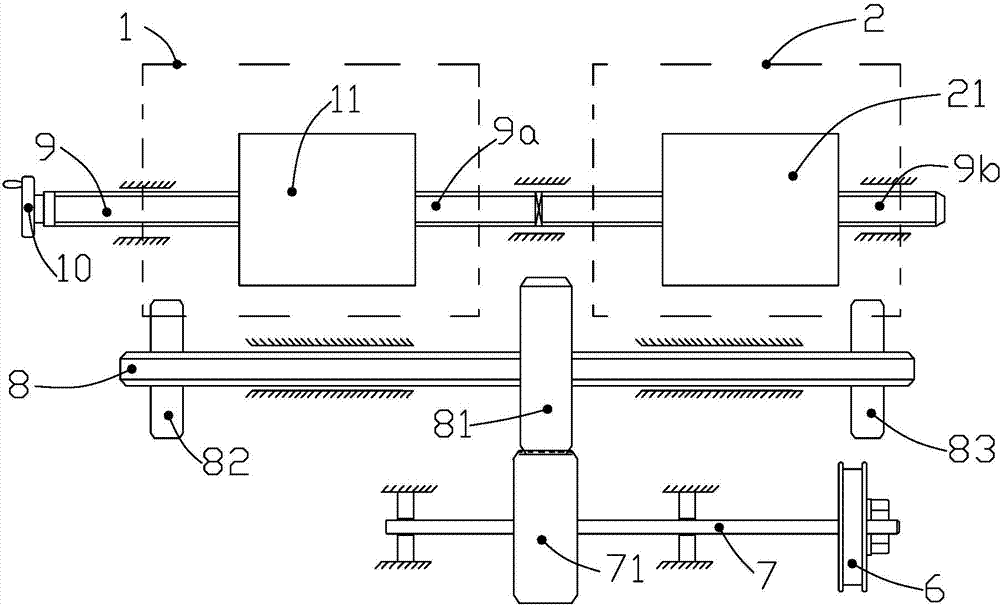

[0026] Such as figure 2 As shown, as an embodiment of the present invention, a set of screw nut units are used to drive and adjust the left header unit 1 and the right header unit 2 . Specifically, the left header unit 1 is fixedly installed on the movable fixed base 11 of the left header, and the movable fixed base 11 of the left header is connected with the frame of the header by slide rails; The right header unit 2 is fixedly installed on the movable fixed base 21 of the right header, and the movable fixed base 21 of the right header is connected with the frame of the header by using slide rails.

[0027] The lower ends of the movable fixed base 11 of the left header and the movable fixed base 21 of the right header are respectively fixed with screw nuts. Adjusting lead screw 9 is divided into lead screw left section 9a and lead screw right section 9b, described lead screw left section 9a and described lead screw right section 9b have the opposite direction of rotation, a...

Embodiment 2

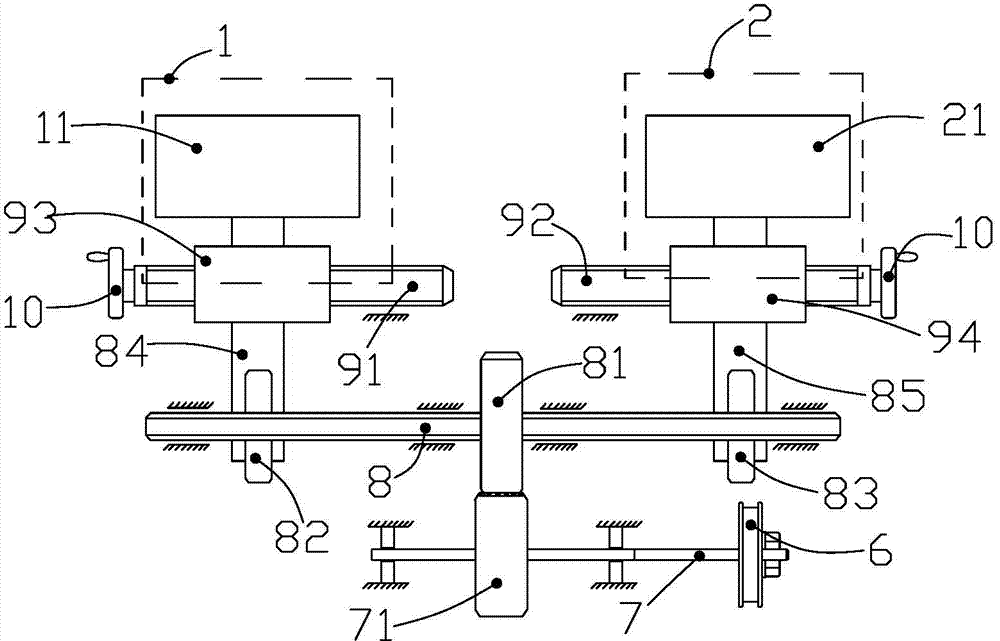

[0030] As another embodiment of the present invention, such as image 3 As shown, two groups of screw nut units are used to separately drive and adjust the left header unit 1 and the right header unit 2 . Specifically, it includes a left adjusting lead screw 91 and a right adjusting lead screw 92 , a movable fixed base 84 of the left power input wheel, and a movable fixed base 85 of the right power input wheel. The left header unit 1 is fixedly installed on the movable fixed base 11 of the left header, and the movable fixed base 11 of the left header is connected with the frame of the header by a slide rail; the right header unit 2 It is fixedly installed on the movable fixed base 21 of the right header, and the movable fixed base 21 of the right header is connected with the frame of the header by slide rails. The power input wheel 82 of the left header unit is fixedly installed on the movable fixed base 84 of the left power input wheel, and the movable fixed base 84 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com