Patents

Literature

87results about How to "Reduce labor force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

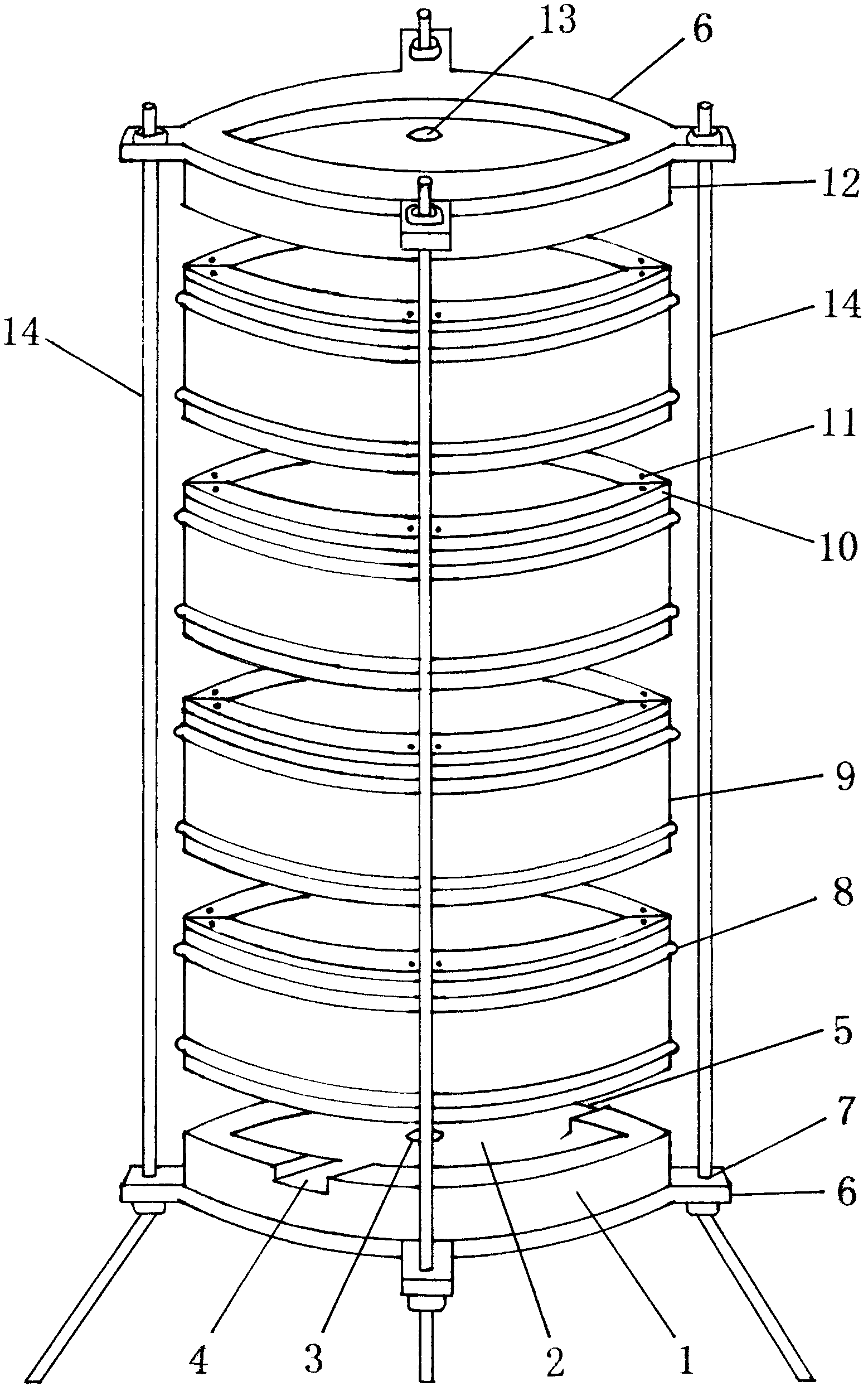

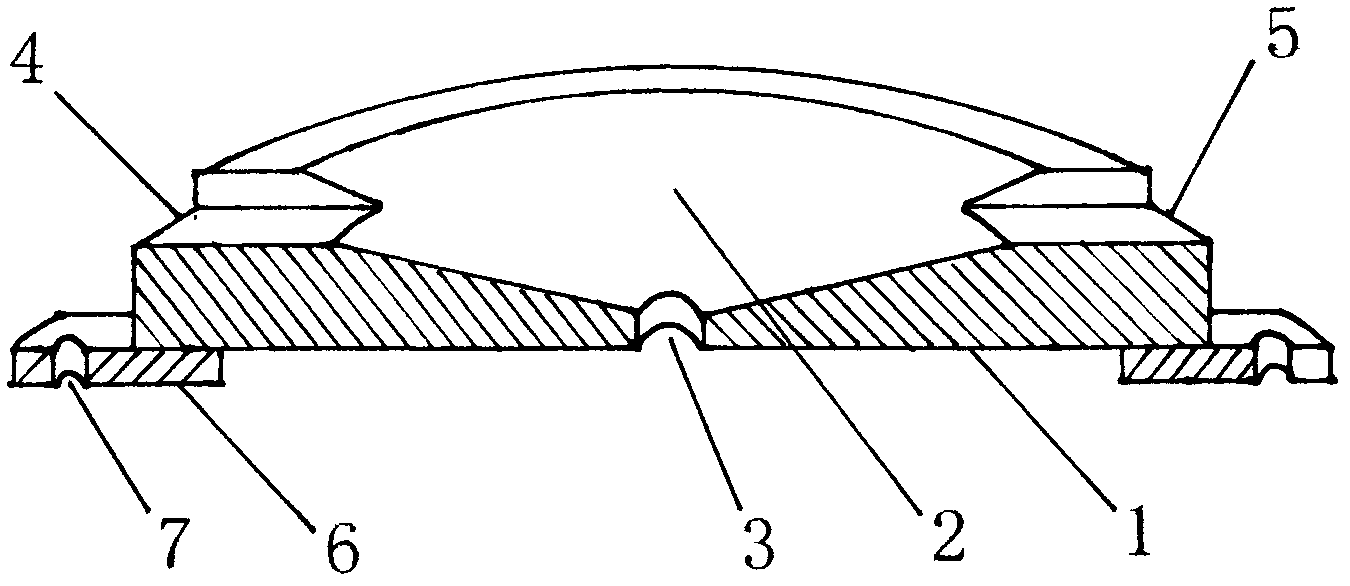

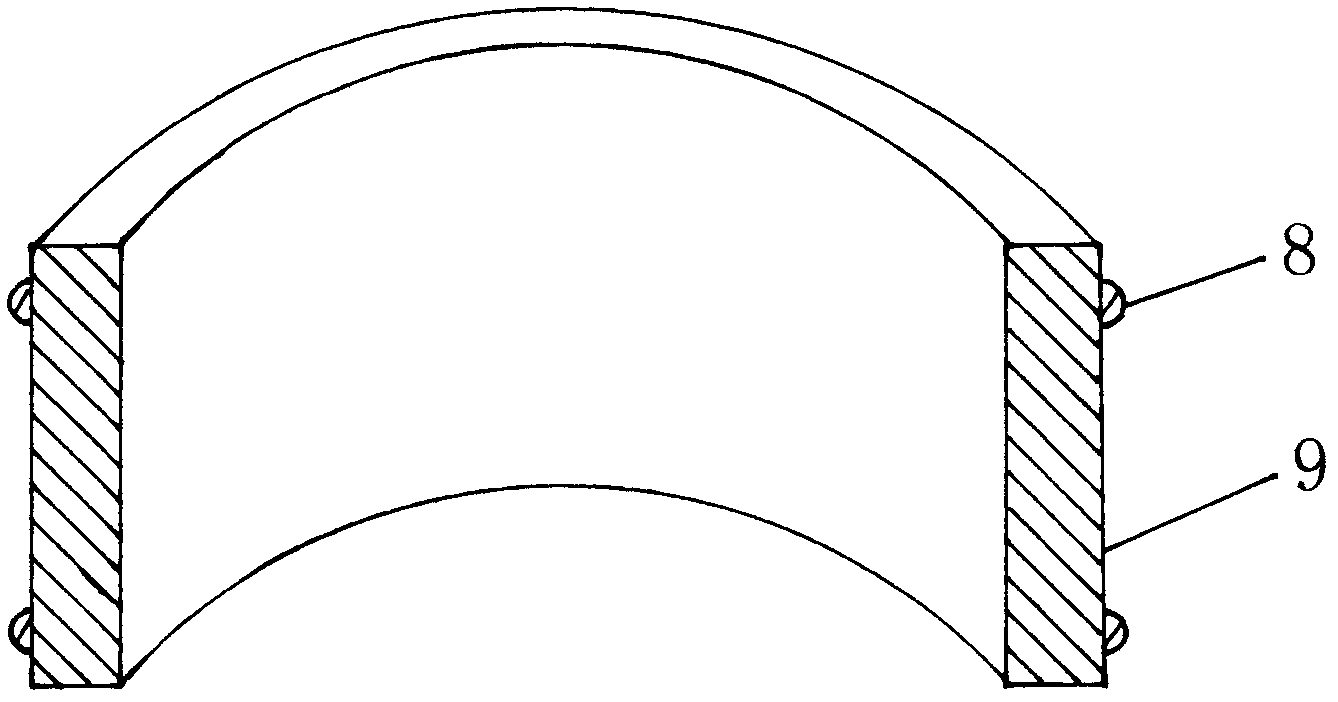

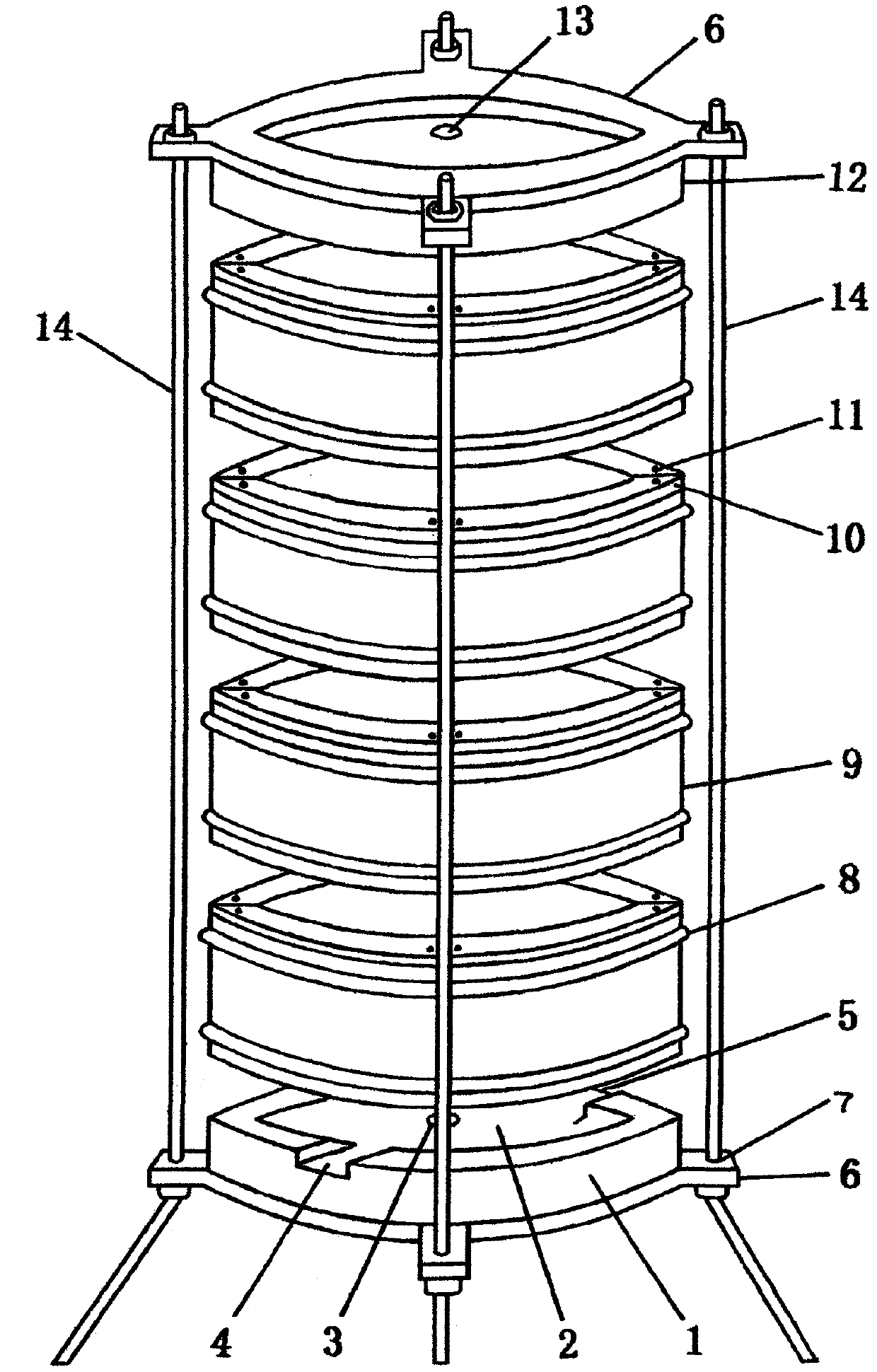

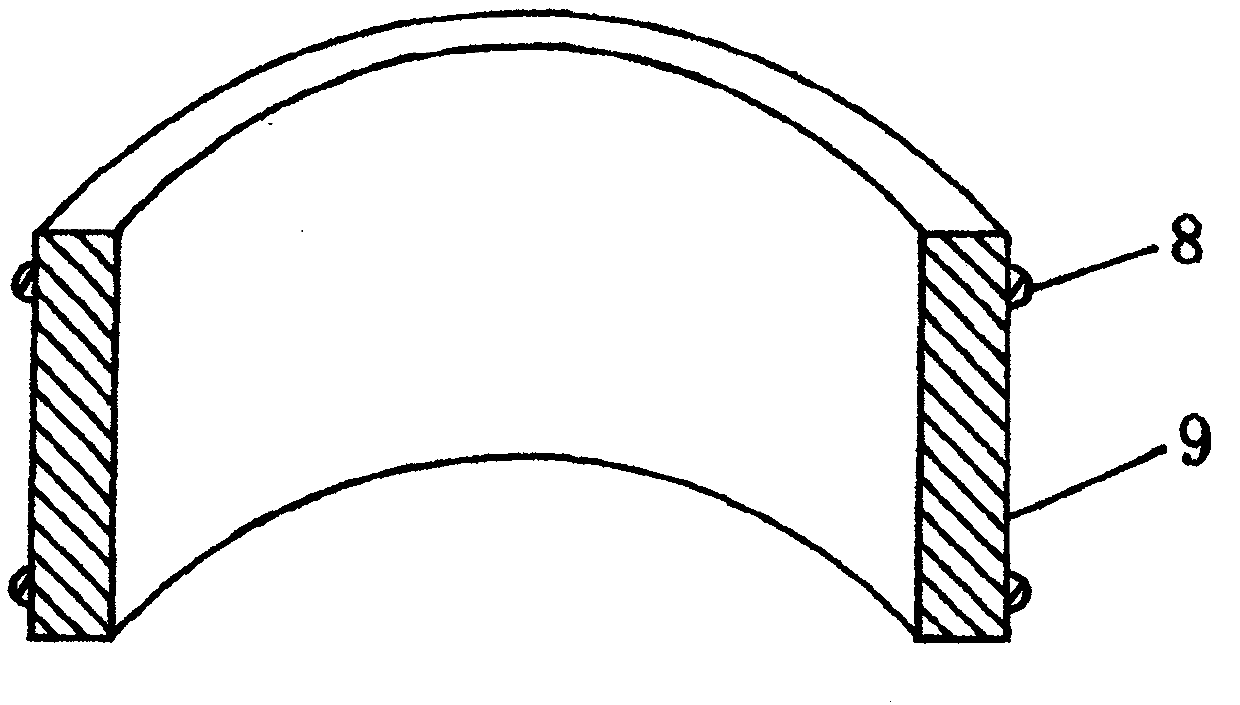

Multi-layer overlaying circular frameless apis cerana cerana beehive

InactiveCN102613110AGather sporadic honey sourcesStrong resistance to bee mitesBeehivesApis ceranaEngineering

A multi-layer overlaying circular frameless apis cerana cerana beehive capable of greatly reducing labor capacity and producing pure primitive ecological apis cerana cerana honey is an integral beehive formed by overlaying a plurality of circular following beehives on a circular base plate machined with a concave natural deslagging slope surface, a deslagging hole, a nest entrance and a feeding hole, placing four metal pads of the following beehives on each following beehive, covering the top following beehive with a circular beehive cover with a vent hole, and vertically penetrating and connecting the base plate and connection holes of a four-corner connection clamp on the box cover through four L-shaped reinforcing bars. Therefore, the apis cerana cerana group can naturally form a sphere apis cerana cerana bulk in the beehives, and nests from the top down; and if the stored honey at the uppermost layer is mature, sealed and covered, the four L-shaped reinforcing bars and the corresponding metal pads are detached, the following beehive at the uppermost layer is transversely cut to take out the honey, and then is additionally arranged on the base plate at the bottom layer; and the survival and propagation of the apis cerana cerana after the honey is taken out are not influenced, the output and quality of apis cerana cerana honey are improved, and the multi-layer overlaying circular frameless apis cerana cerana beehive has a vital significance for apis cerana cerana protection.

Owner:张诚

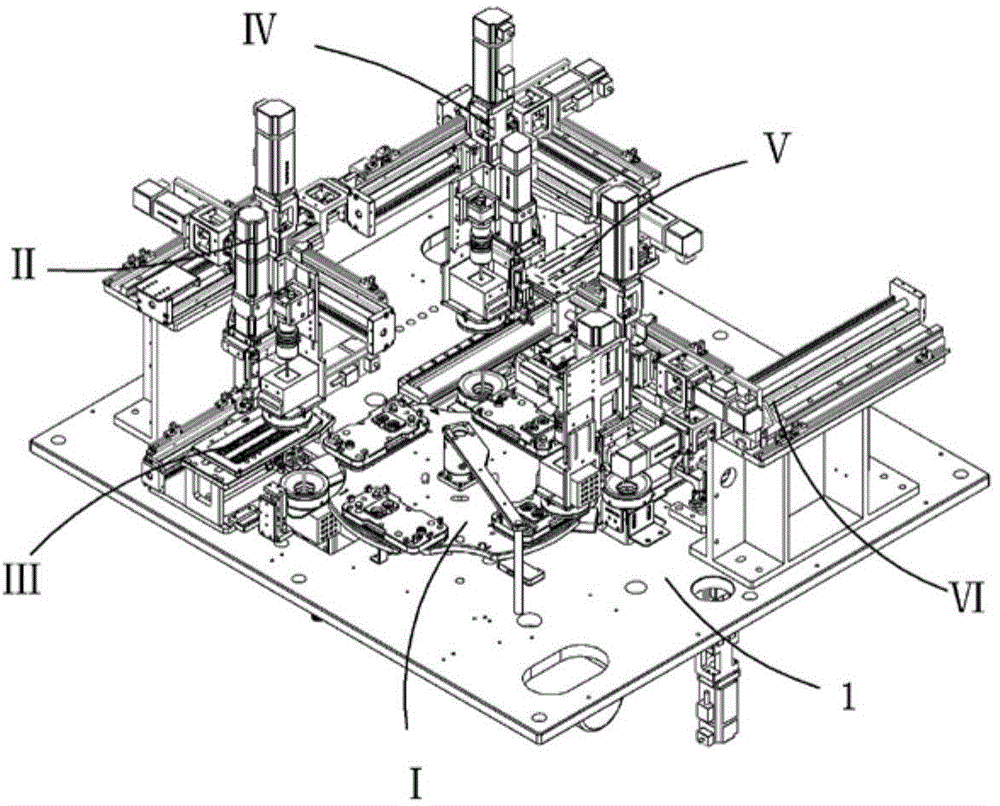

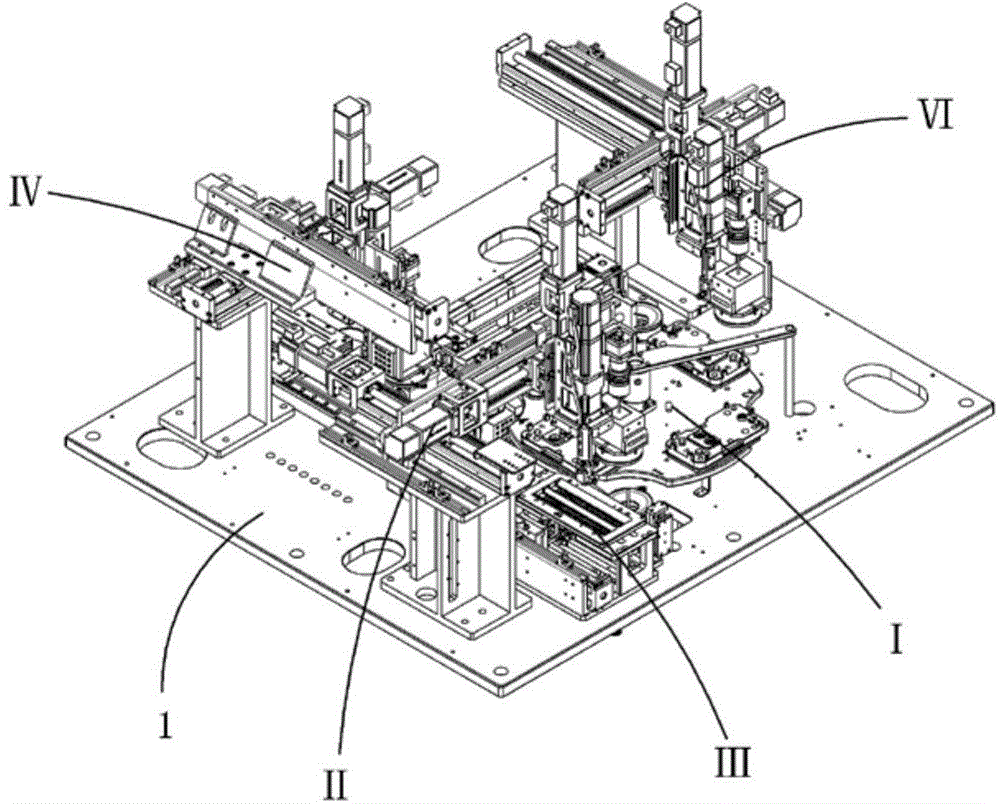

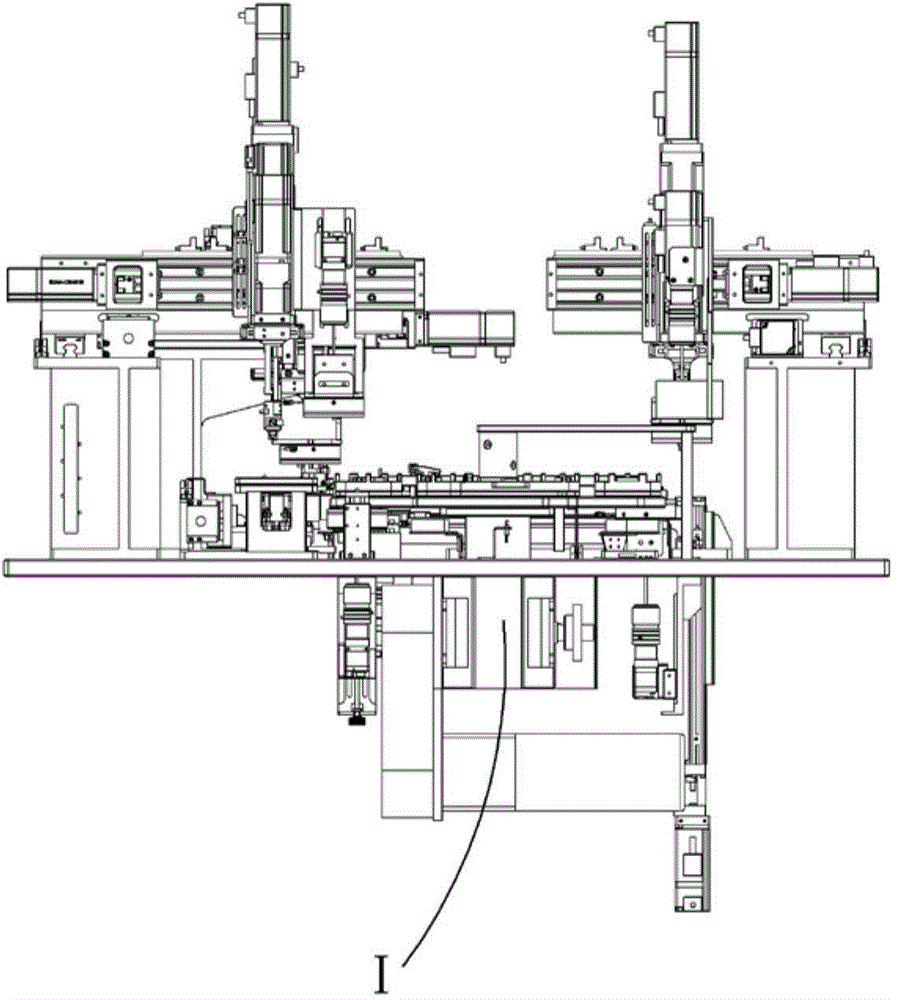

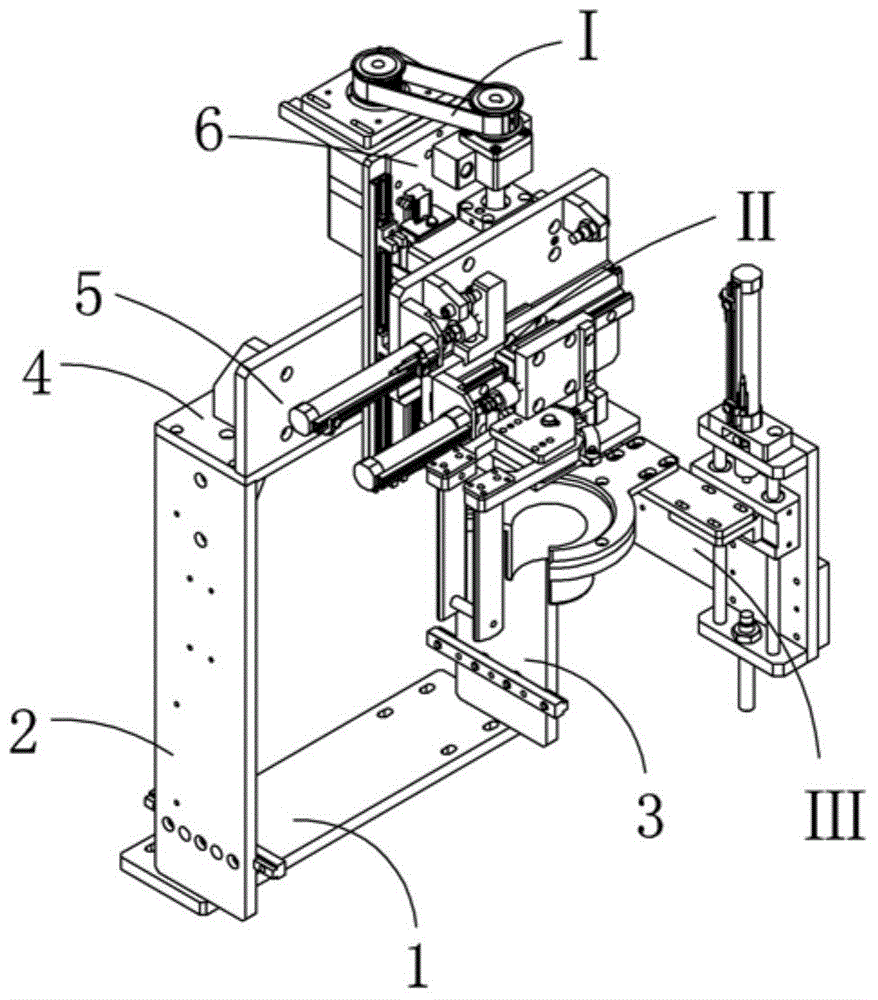

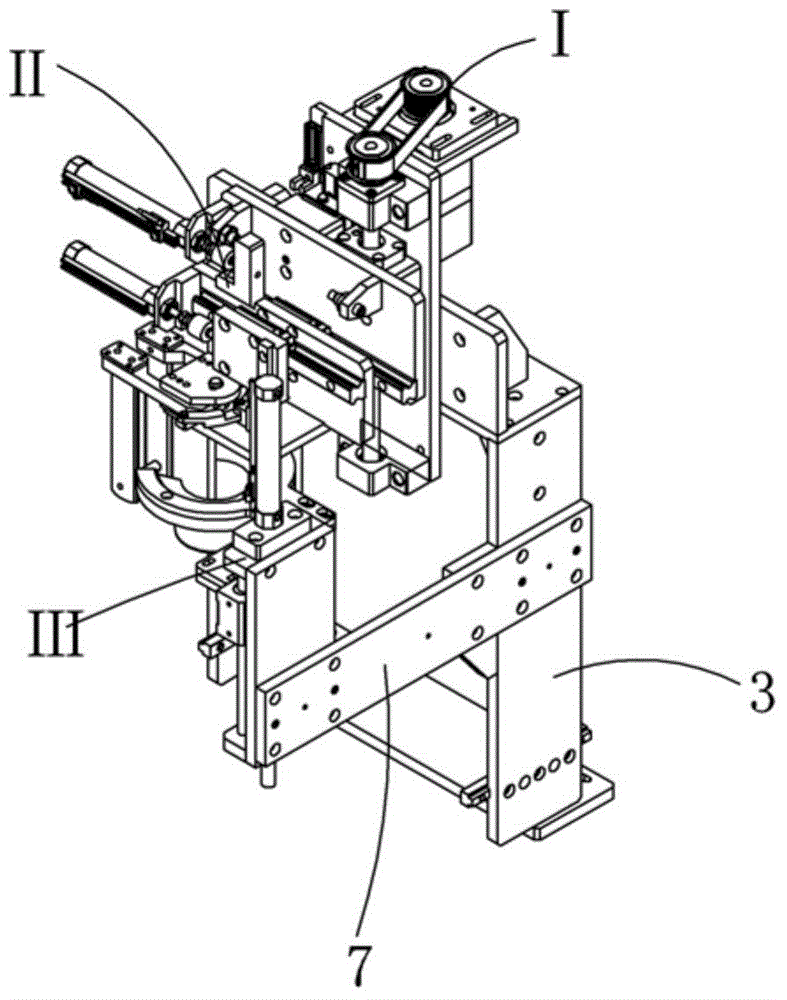

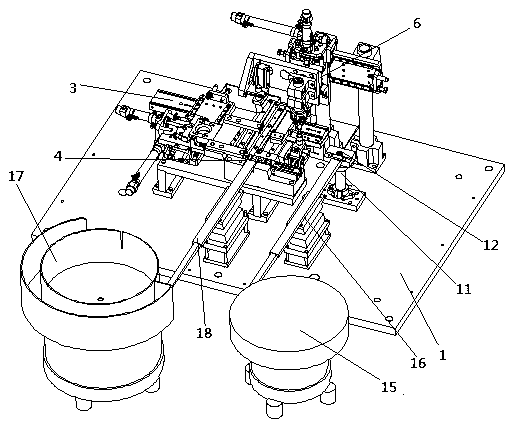

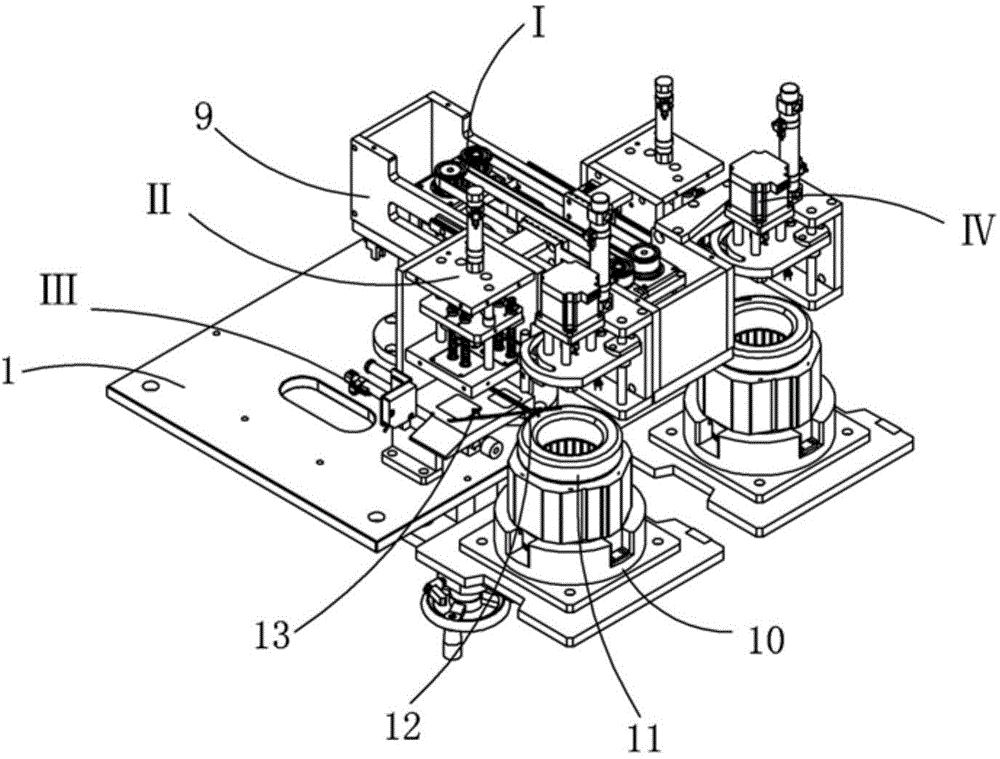

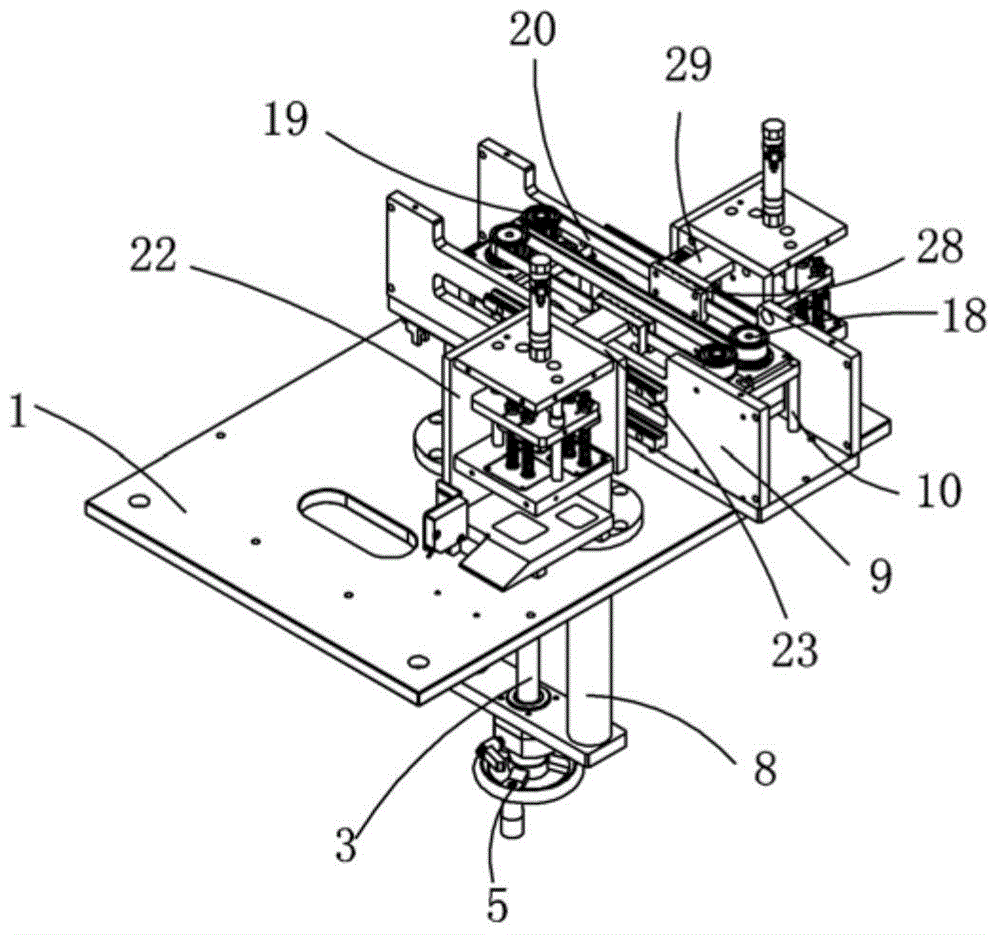

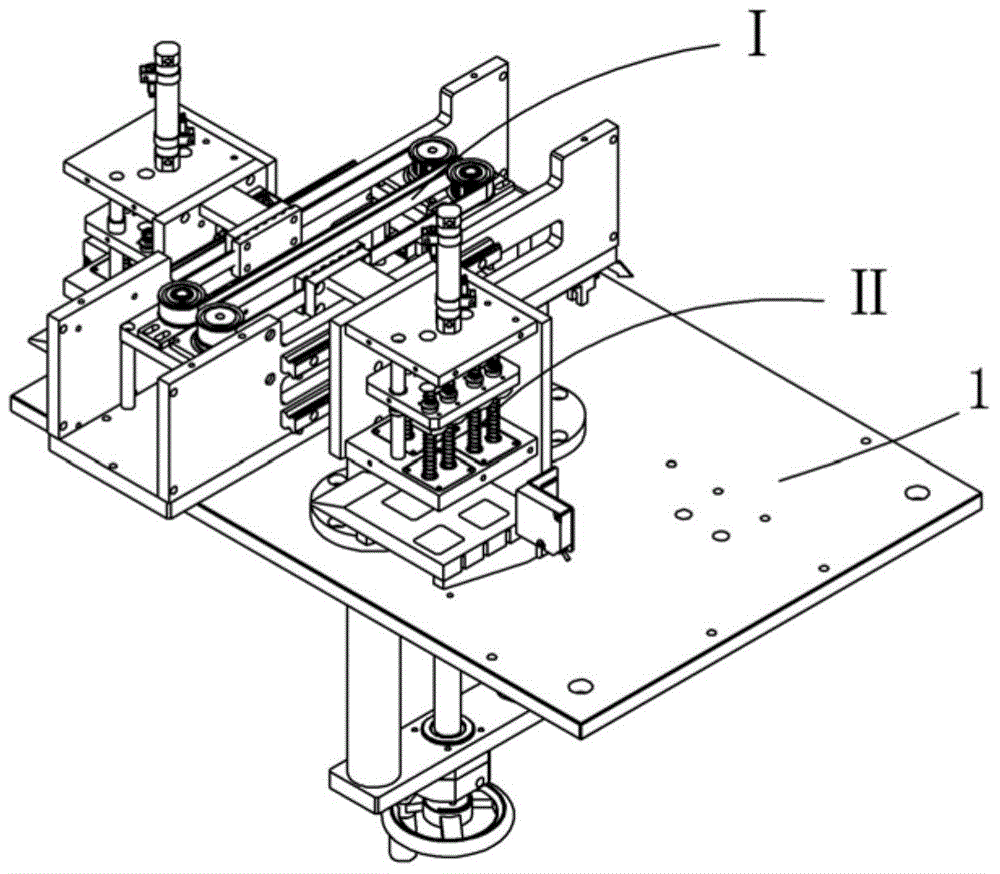

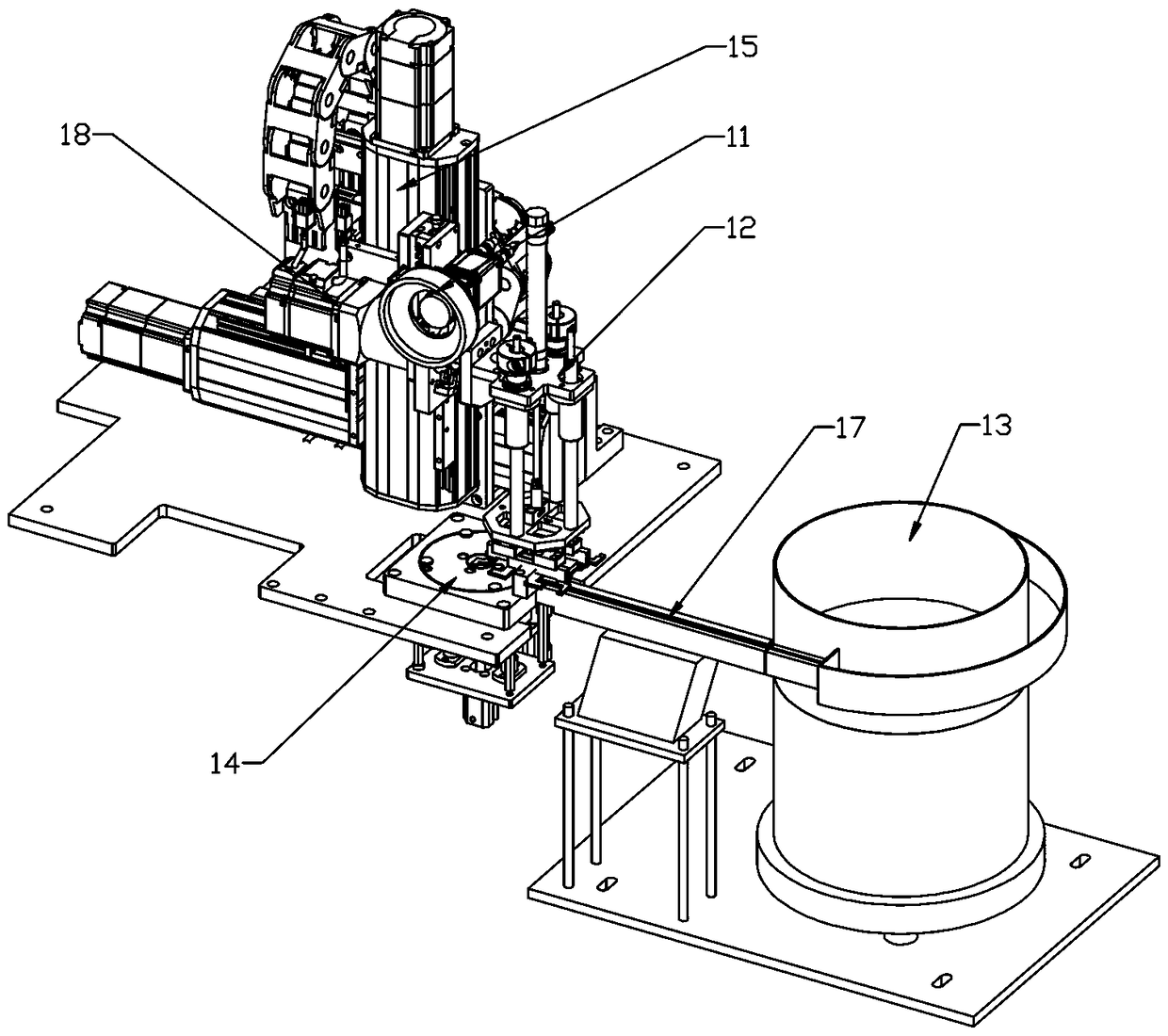

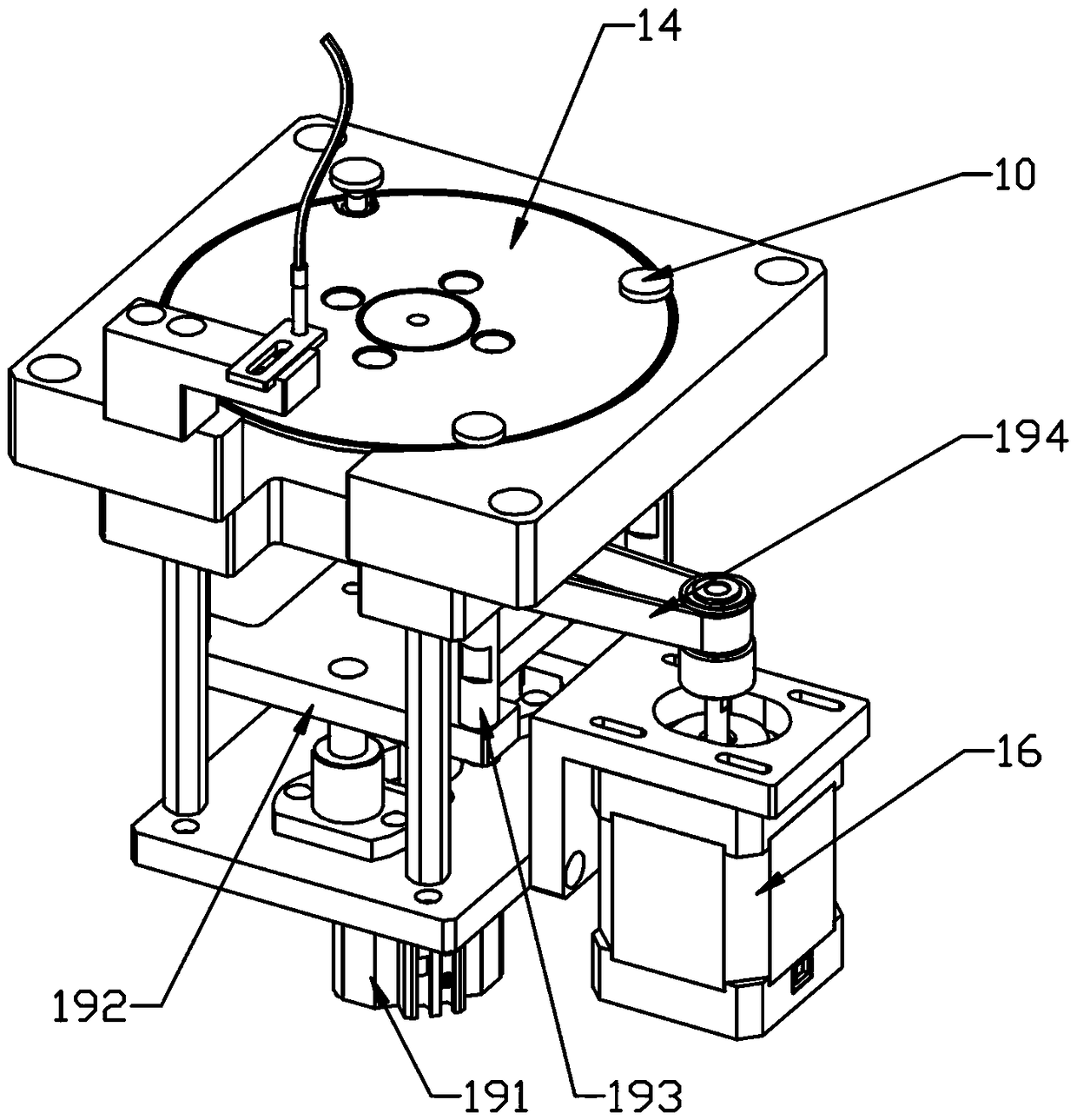

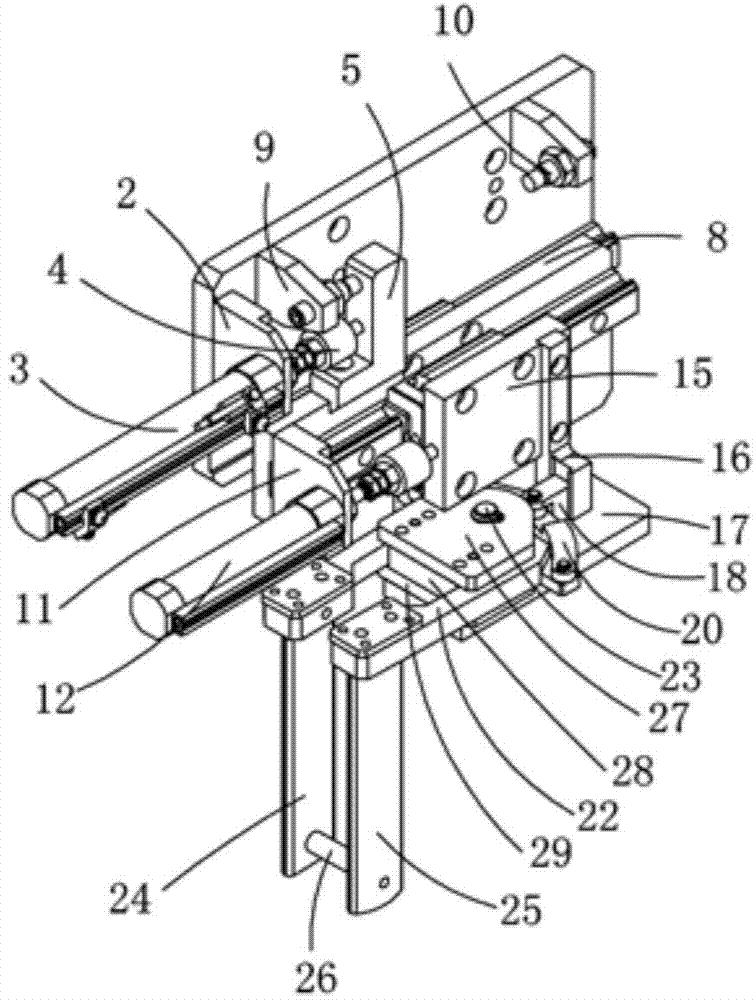

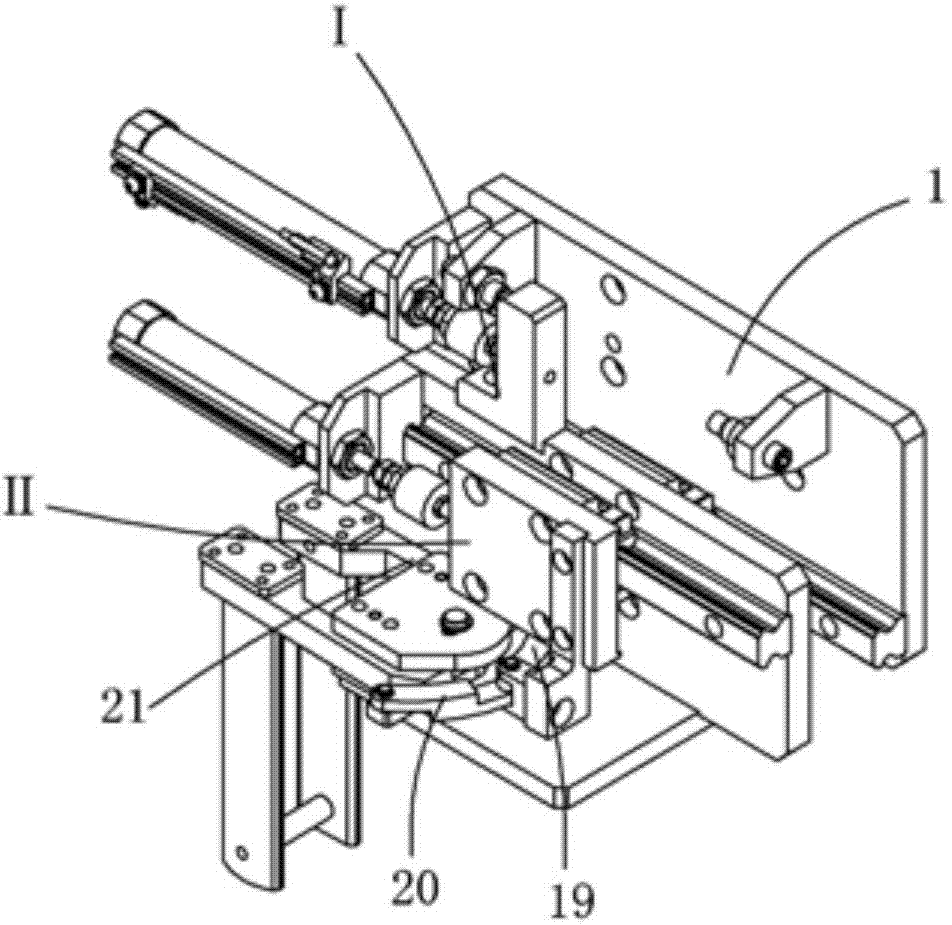

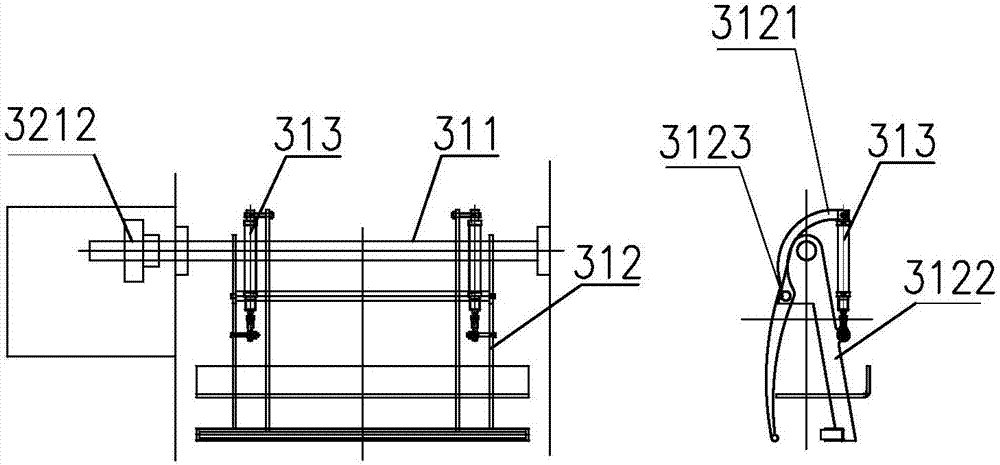

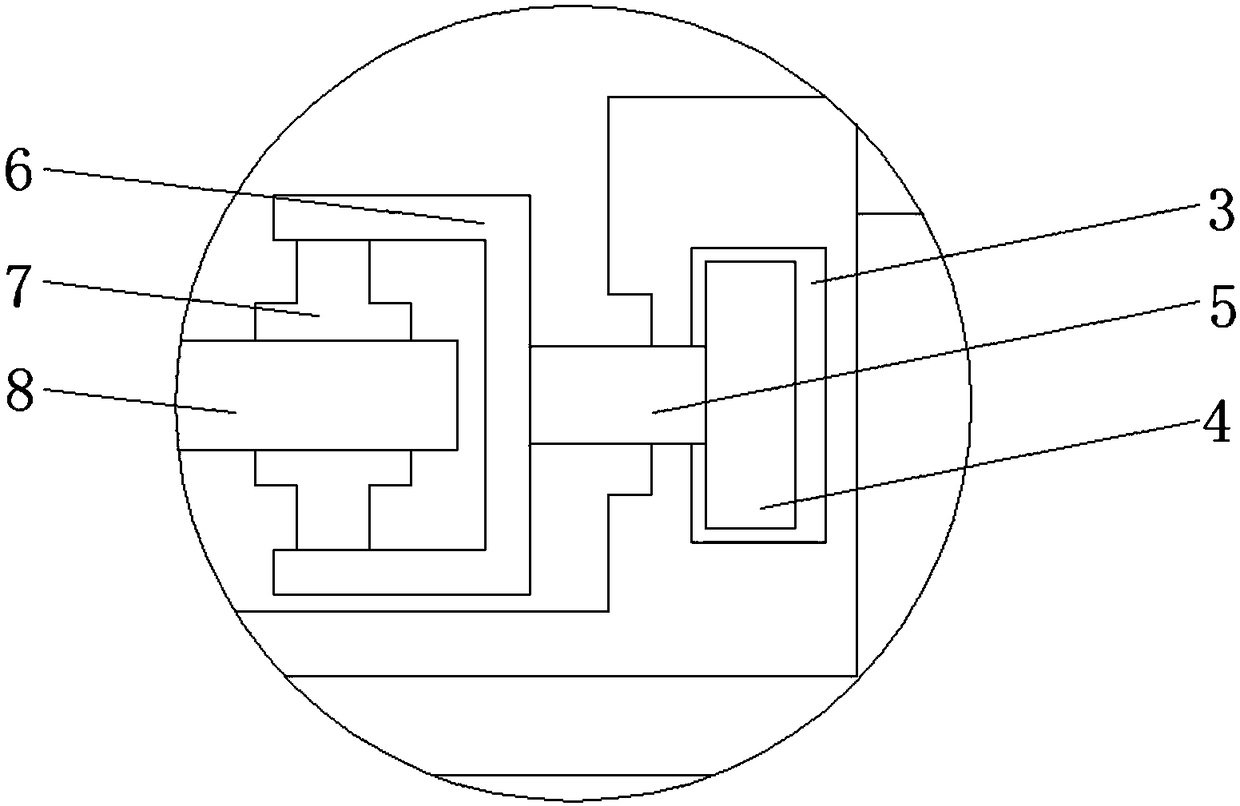

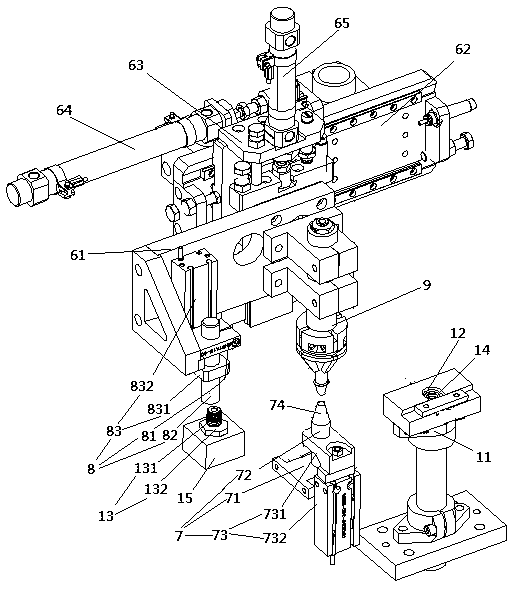

Auto-align multi-station parts mounter

ActiveCN104625731AQuick and accurate assemblyImprove protectionAssembly machinesMetal working apparatusEngineeringProviding material

The invention relates to an auto-align multi-station parts mounter comprising a turnplate mechanism mounted at the center of a bottom plate. The auto-align multi-station parts mounter further comprises a first parts mounting station, a first station stripping mechanism, a second parts mounting station, a second station feeding mechanism, a third parts mounting station and a third station stripping mechanism. The first, second and third parts mounting stations are mounted in the left front, left rear and right rear of a bottom plate, respectively. The first station stripping mechanism is capable of stripping multiple workpieces from workpiece sheets at a time. The second station feeding mechanism is powered by a rodless cylinder and providing material for sheet products. The third stripping mechanism is capable of stripping the workpieces from the workpiece sheets. The auto-align multi-station parts mounter is used for mounting different parts onto electronic products, is simple to operate and allows multiple parts to be accurately and quickly mounted to products, manpower is further saved, production efficiency is improved, and production cost is lowered for companies.

Owner:BOZHON PRECISION IND TECH CO LTD

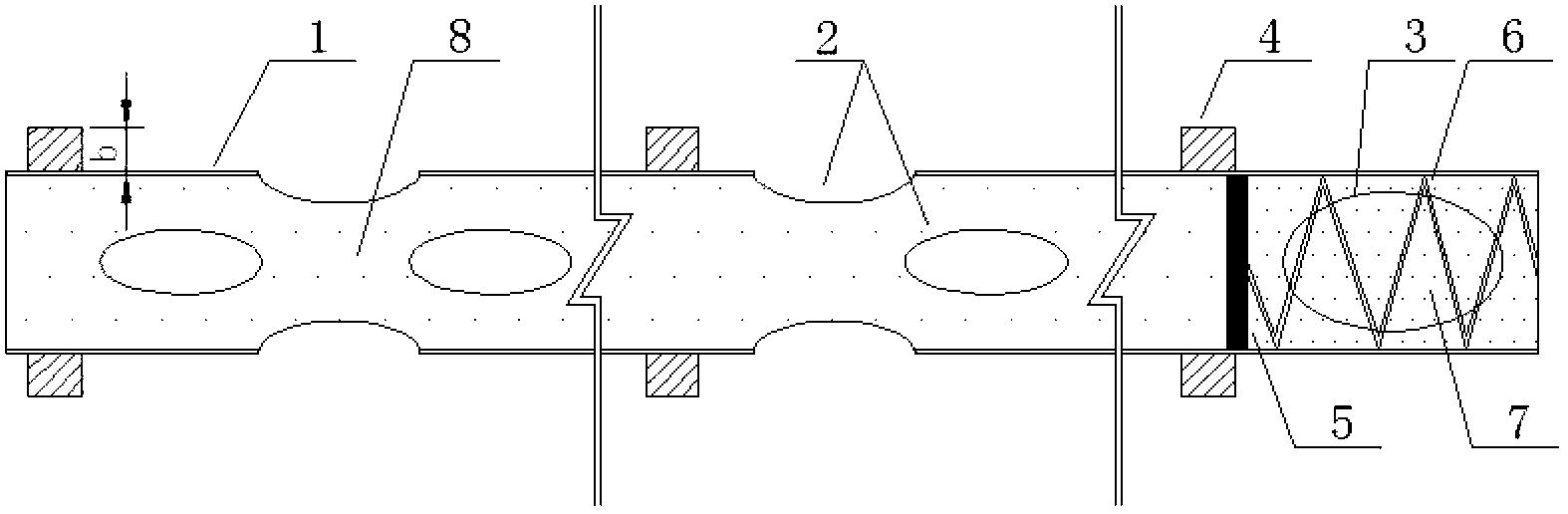

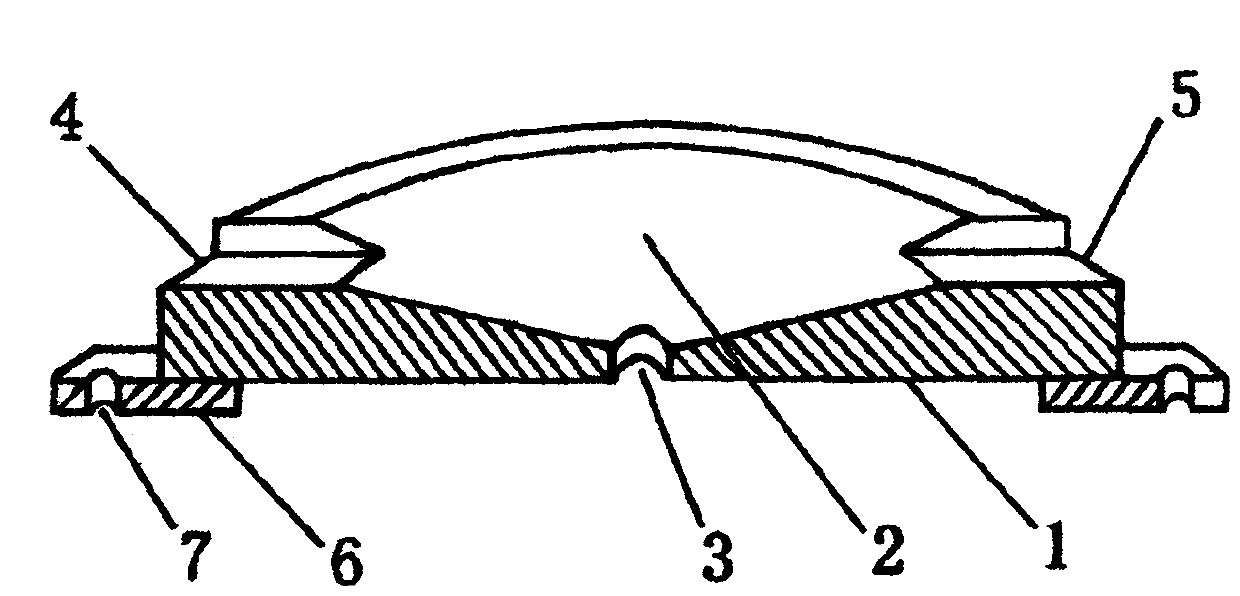

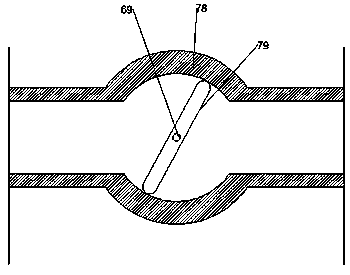

Prestressed full-anchor squeezed anchoring device and method thereof

ActiveCN103061790ASolve the difficulty of overlappingSolve Thickness ProblemsAnchoring boltsPre stressEngineering

The invention discloses a prestressed full-anchor squeezed anchoring device and method thereof. The device comprises a casing with the inner diameter larger than the diameter of an anchor bolt, and a plurality of first holes are distributed in a cross shape on the wall of the casing. A plurality of pulp-divided annular stoppers are sleeved on the casing at intervals, second holes which are a bit larger than the first holes are symmetrically reserved on the front side of the casing, a spring is fixed at the top of the plug which is arranged in the upper portion of the casing, and the casing is coated with polyethylene plastic film outside. Two resin anchoring agents with different solidified time are injected into the casing, then the casing filled with the anchoring agents is inserted into the borehole so that the pulp-divided annular stoppers sleeved on the casing are distributed at intervals and stop the drill holes separately ; when the anchor bolt is inserted into the casing, the two anchoring agents in the casing are squeezed through the holes successively, and then fill the gap between the wall of the tube and the walls of the holes; by the action of intermediate-speed anchoring agents, the top of the anchor bolt is anchored within a short time. The prestressed full-anchor squeezed anchoring device and method thereof have the advantages that the structure is simple and the operation is convenient, the stability is strong, the positioning is accurate and usage is easy.

Owner:CHINA UNIV OF MINING & TECH

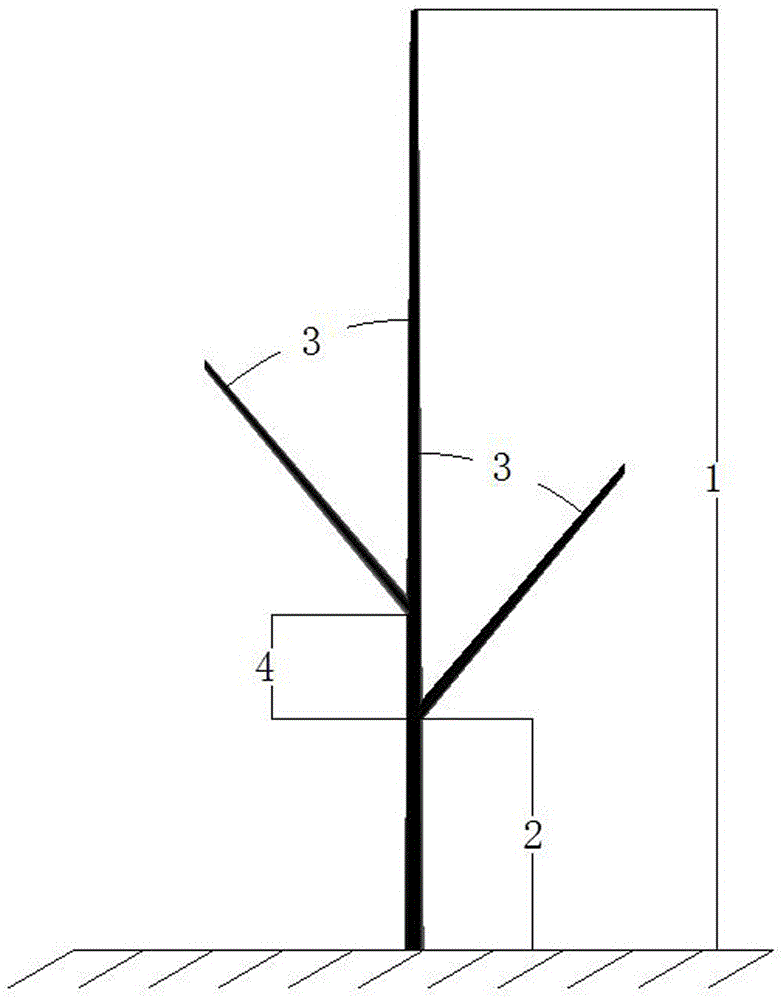

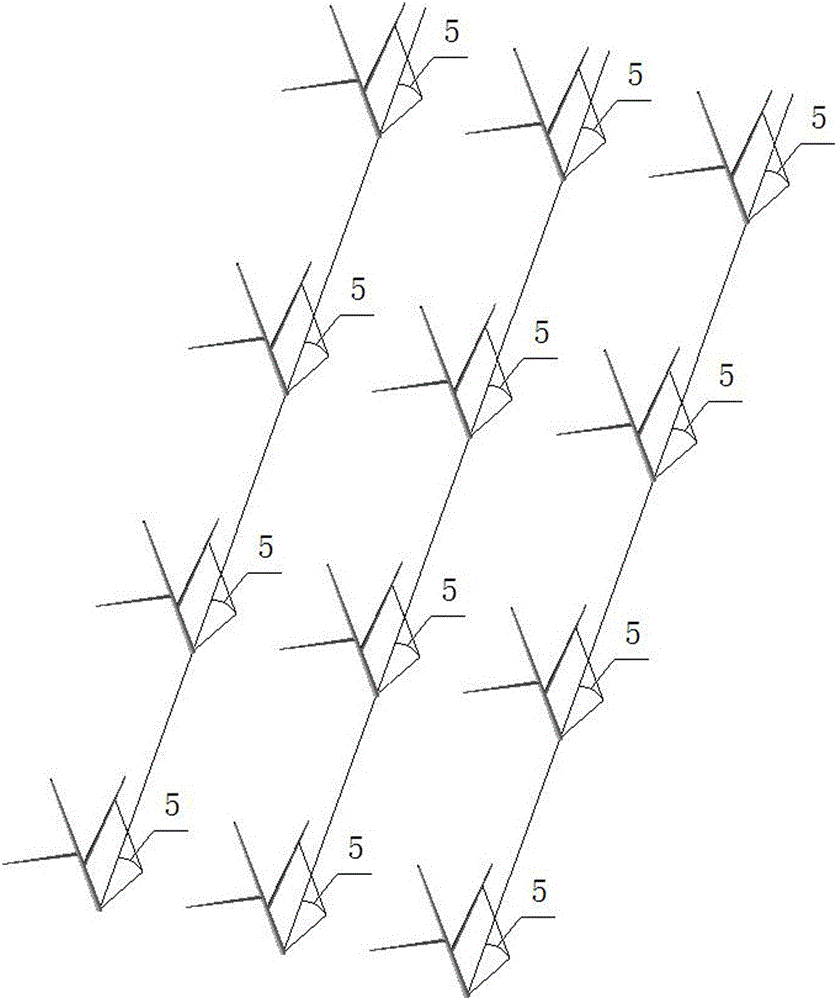

Inverted-umbrella-shaped cultivation technology for peach trees

InactiveCN105746290AExpand line spacingReduce pests and diseasesCultivating equipmentsHorticulture methodsTruckThinning

The invention discloses an inverted-umbrella-shaped cultivation technology for peach trees.The technology comprises the steps of defining the plantation density; conducting shaping and trimming in a quantitive mode, wherein the central trunk of a tree is robust, erect, free of principal branches or lateral branches, two adjusting branch sets grow out of the basal part of the central trunk, small bearing branch sets directly grow out of the remaining parts of the central truck, the small bearing branch sets are distributed at an interval of 10-15 cm and uniformly arranged upward in the helical form, the tree height is 2.5-3 m, the crown diameter is 1.5-2 m, the trunk height is 50-70 cm, the growing points of the two adjusting branch sets are vertically staggered with the spacing being 10-15 cm and are distributed at the angle of 180 degrees, the included angle between the growing points of the two adjusting branch sets and the line direction of a plantation line is 30 degrees, meanwhile the included angle between the growing points of the two adjusting branch sets and the central trunk is 40 degrees, attention is paid to control the thickness of branches on the central trunk so that the thickness cannot exceed 1 / 3 or above of the thickness of the central trunk, and thinning is conducted when necessary.By means of the inverted-umbrella-shaped cultivation technology for the peach trees, early fruiting and a high and stable yield are promoted, the full productive age of the peach trees is prolonged, the commodity rate and high quality fruit rate of fruits are raised, meanwhile, work efficiency is improved, and labor intensity is lowered.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

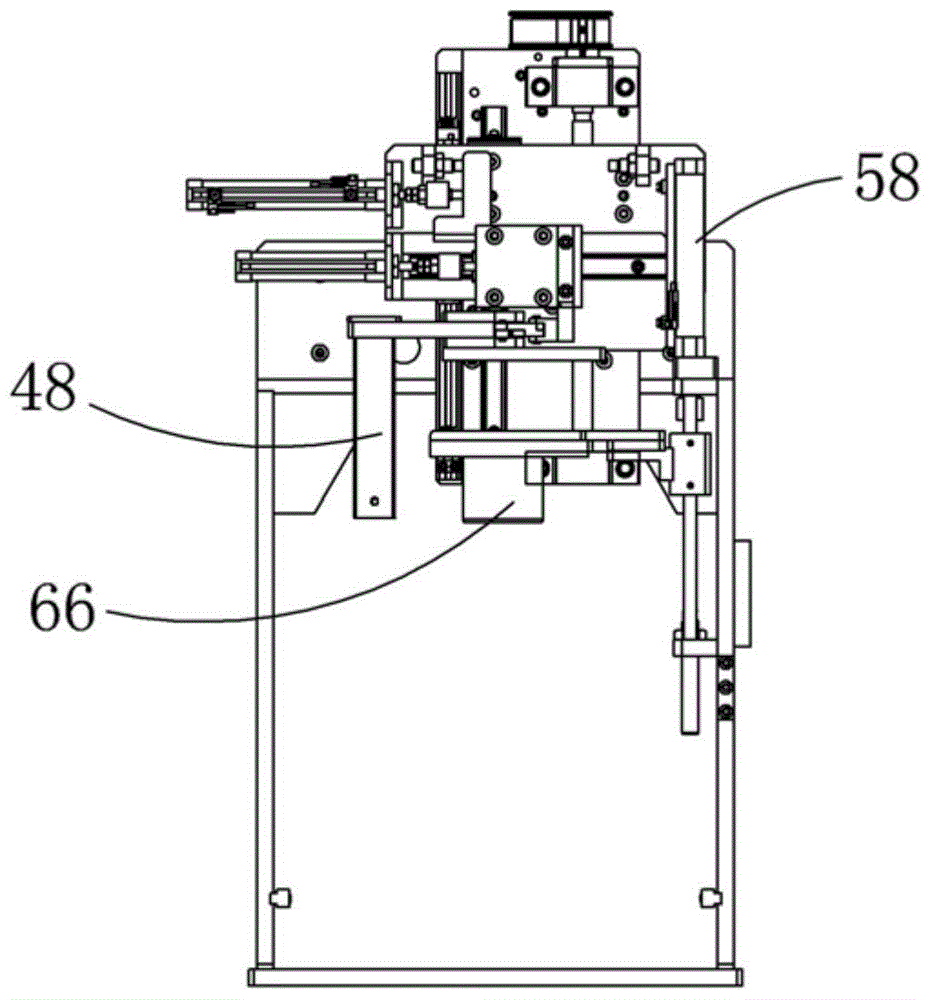

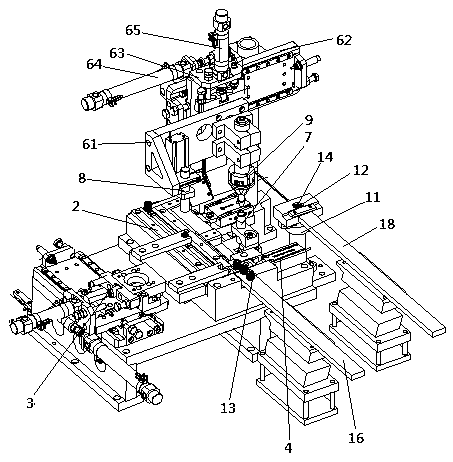

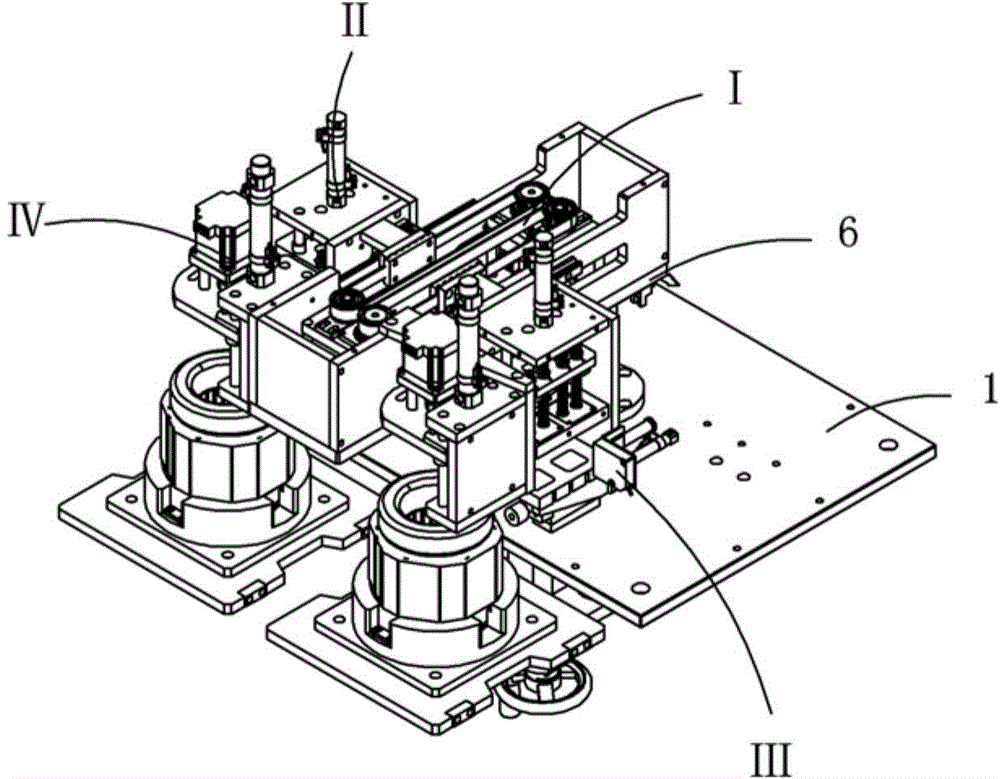

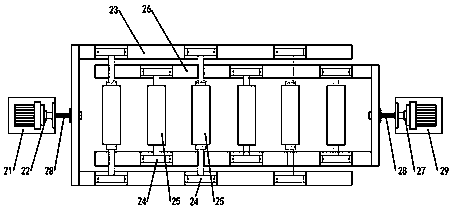

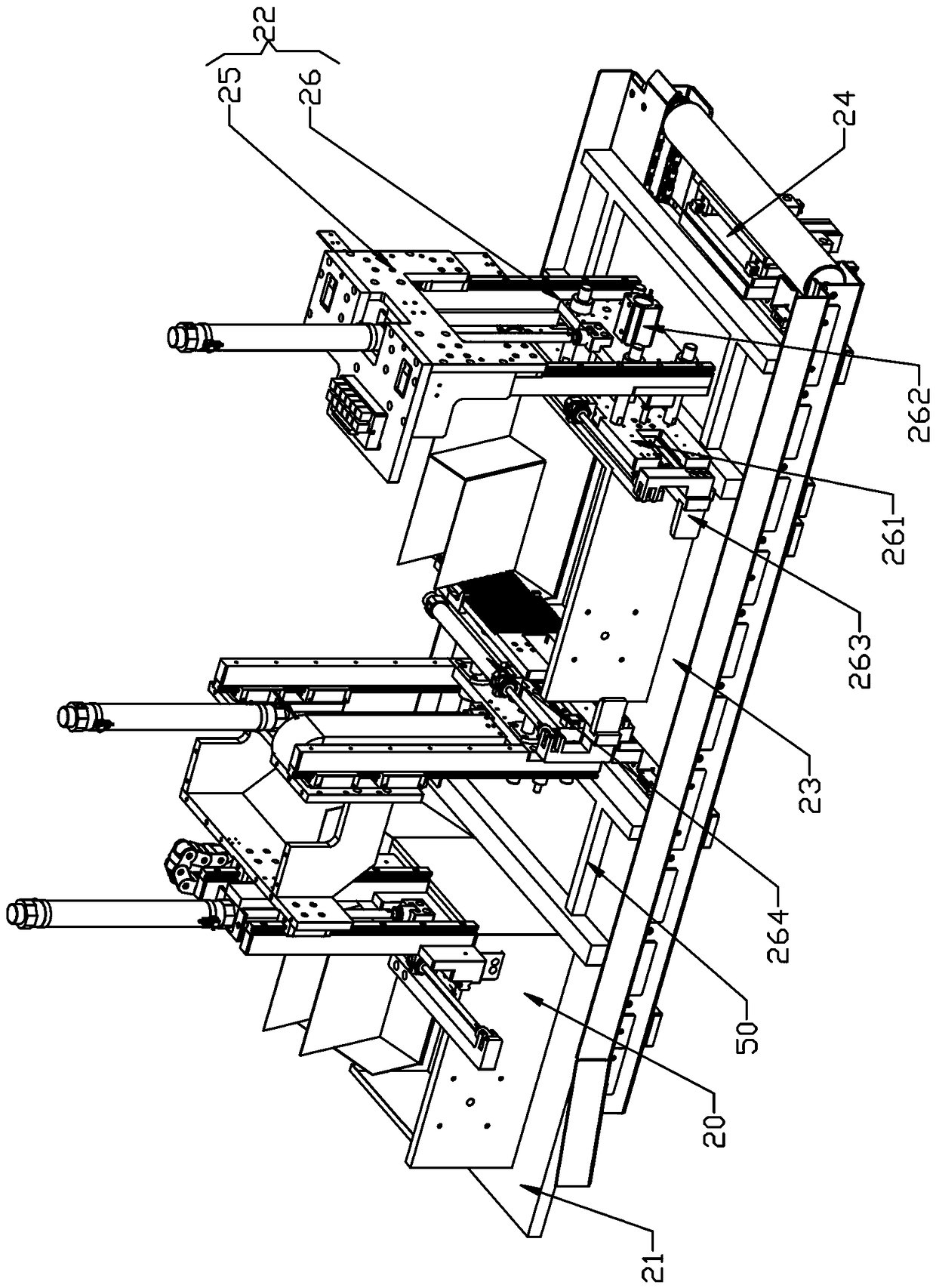

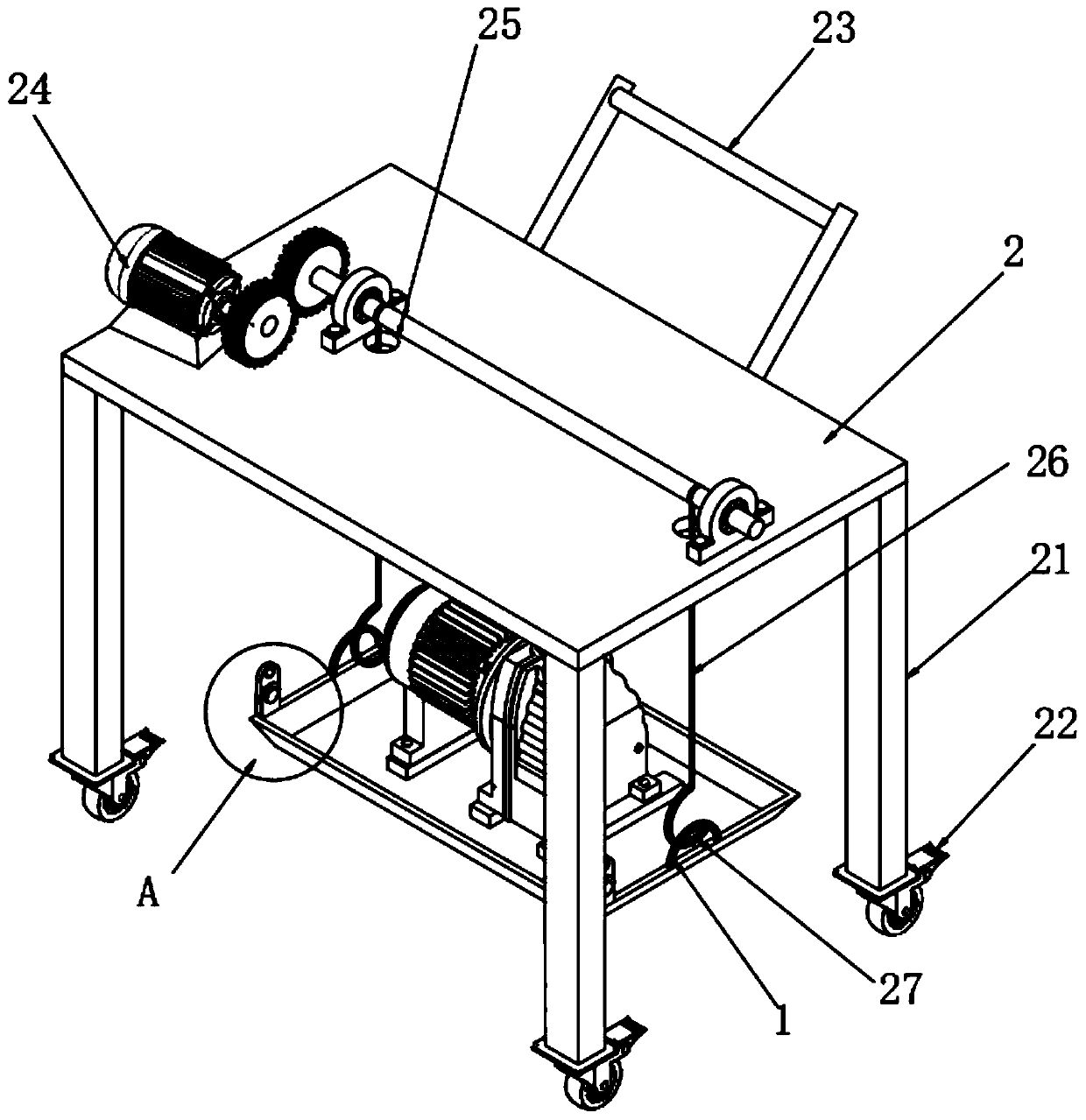

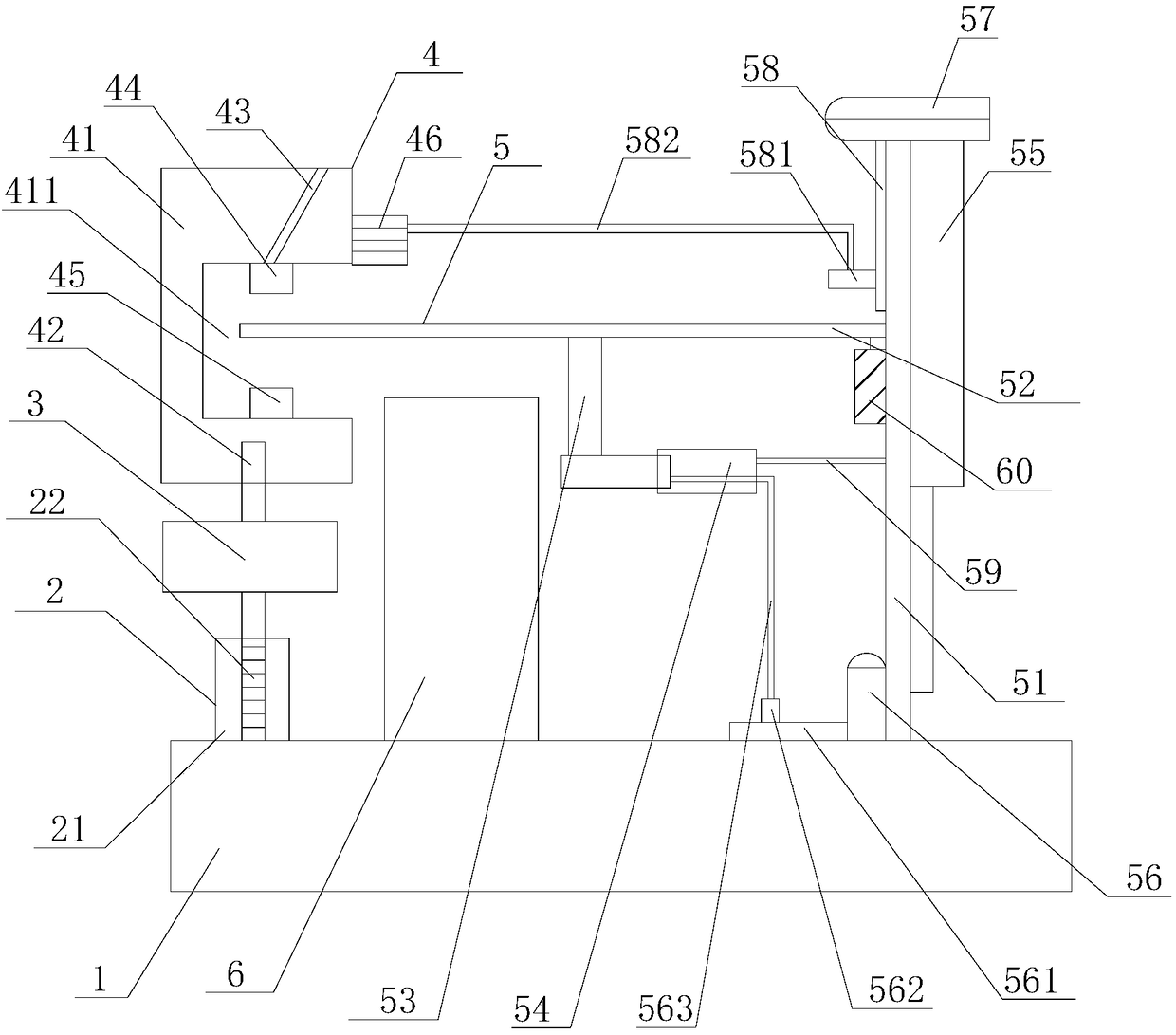

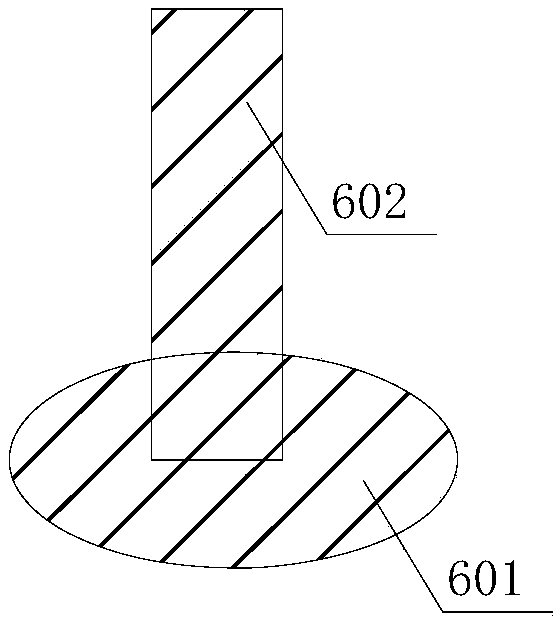

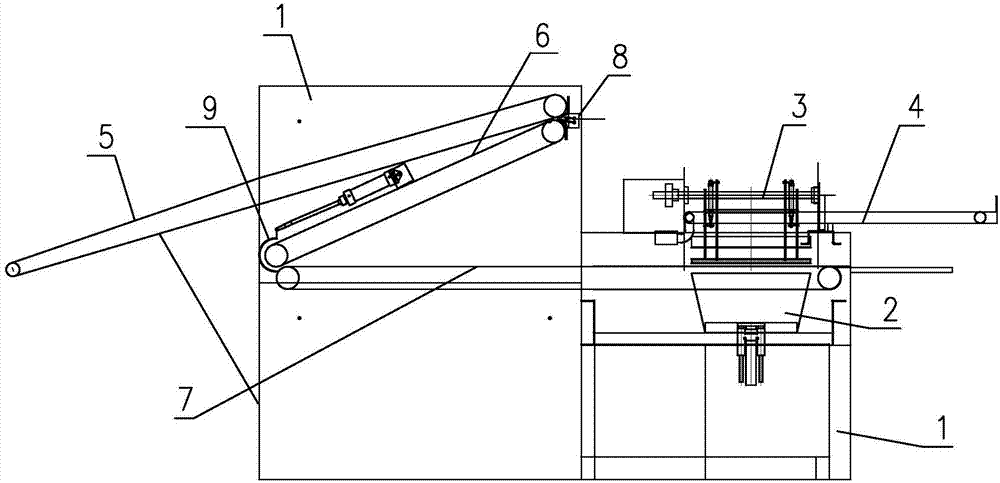

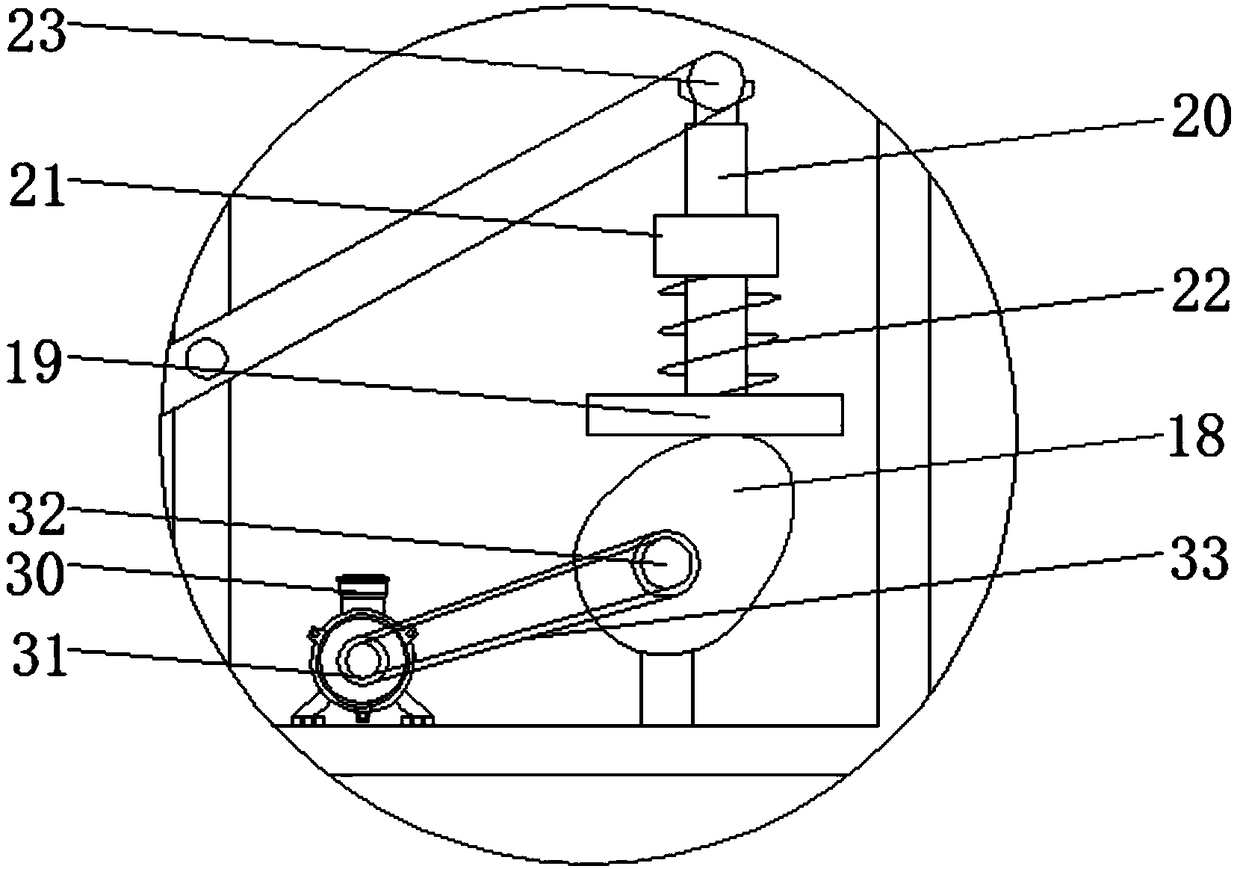

Automatic coiling mechanism for stator winding

ActiveCN104795941AReduce labor forceImprove working environmentManufacturing dynamo-electric machinesProtection mechanismEngineering

The invention relates to an automatic coiling mechanism for a stator winding. A lifting fixing plate is arranged on a bottom plate of the automatic coiling mechanism through a left side plate and a right side plate; a lifting mounting plate is vertically arranged on the front side of the lifting fixing plate; a fixed vertical plate is arranged on the lifting mounting plate; a lifting mechanism is arranged on the fixed vertical plate; a lead guide mechanism is arranged on a lifting side block of the lifting mechanism; a mounting plate is arranged on the right side plate; a stator winding protection mechanism is arranged on the mounting plate, and is used for protecting the stator winding; the lead guide mechanism is used for clamping, guiding and pushing, so that a stator lead is coiled into an inner stator hole; and the lifting mechanism is used for lifting the lead guide mechanism, so that the lead guide mechanism drives the lead to translate above the inner stator hole. The stator winding lead is coiled into the inner stator hole, so that further package is facilitated. Traditional manual coiling is changed into automatic coiling, so that the labor force is reduced; the operation environment is improved; the production efficiency is improved; and the automatic coiling mechanism can be popularized into other automatic coiling mechanisms.

Owner:SUZHOU LINGHOU ROBOT

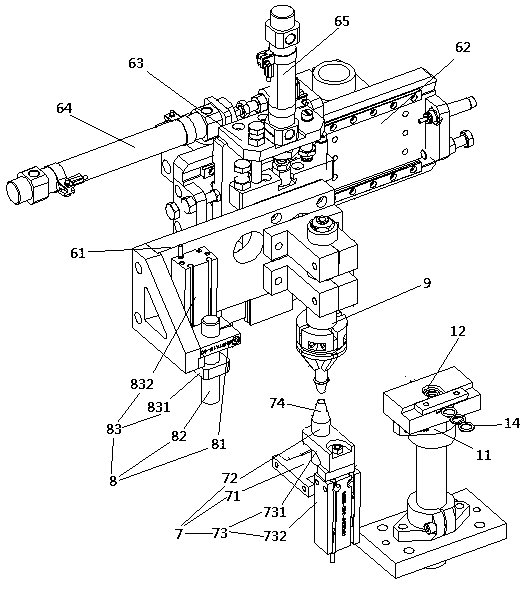

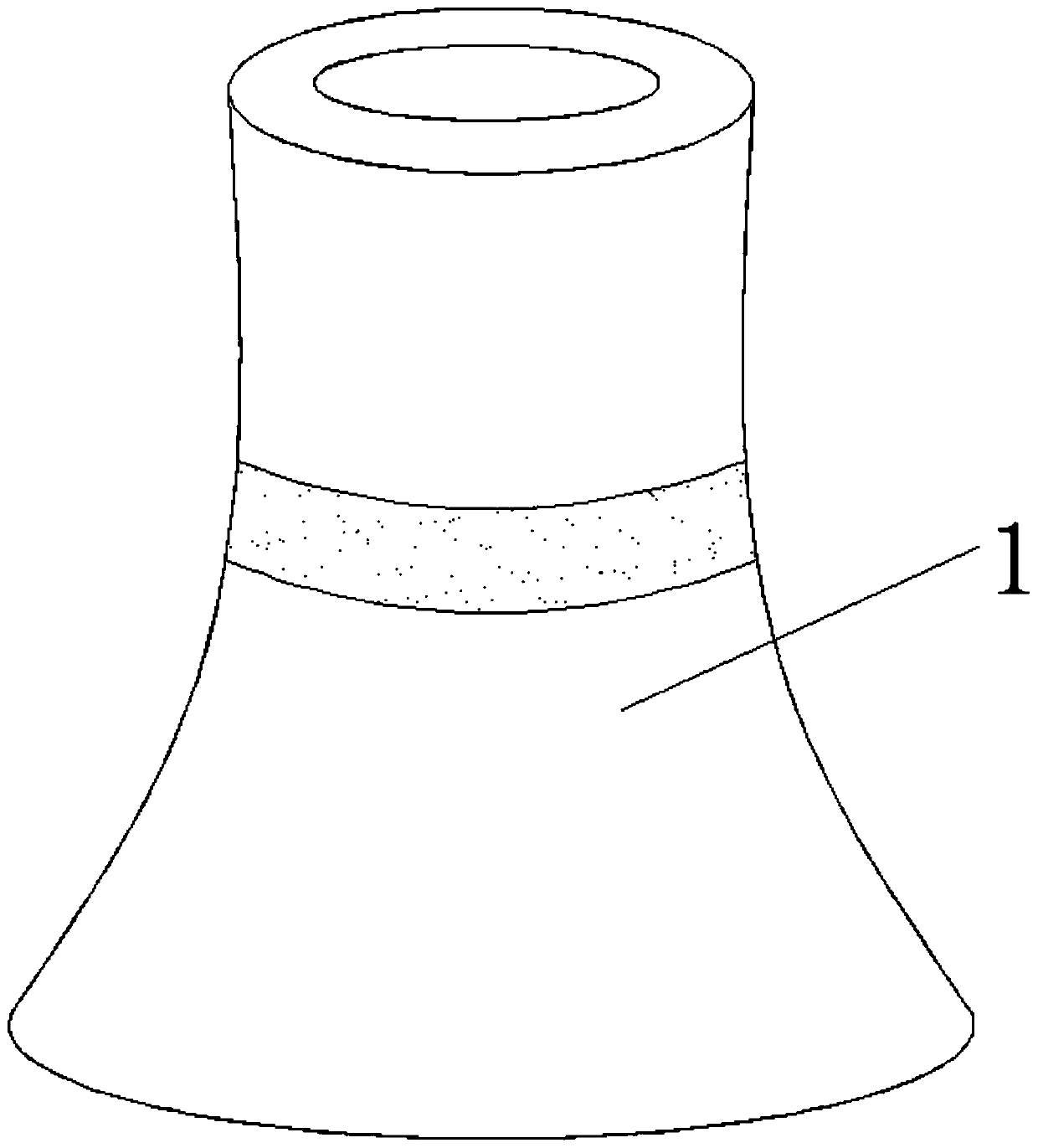

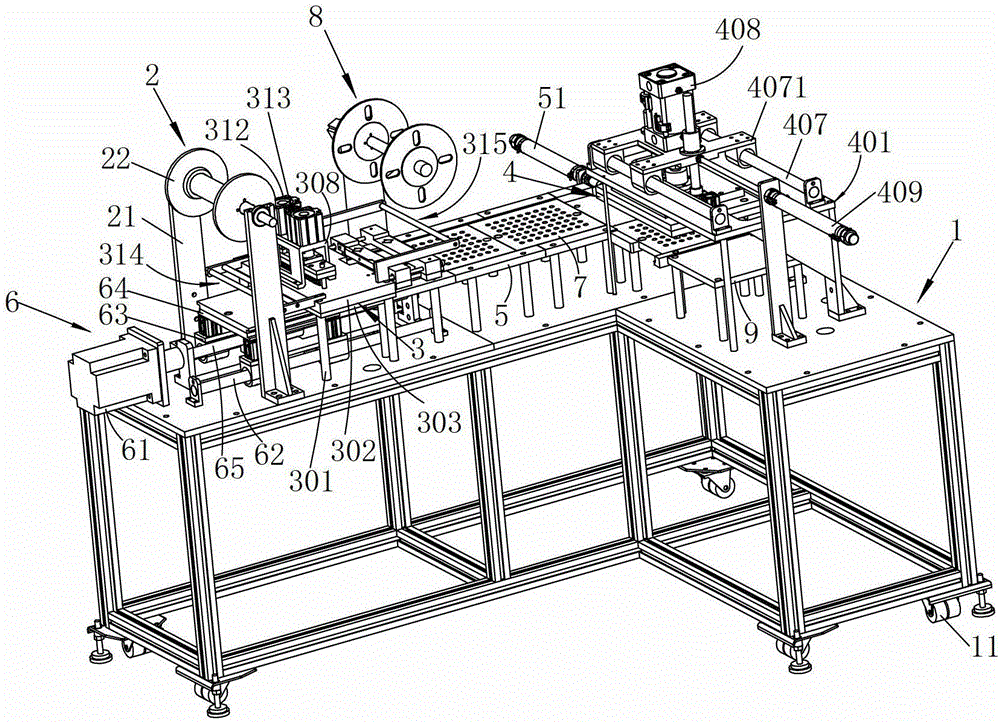

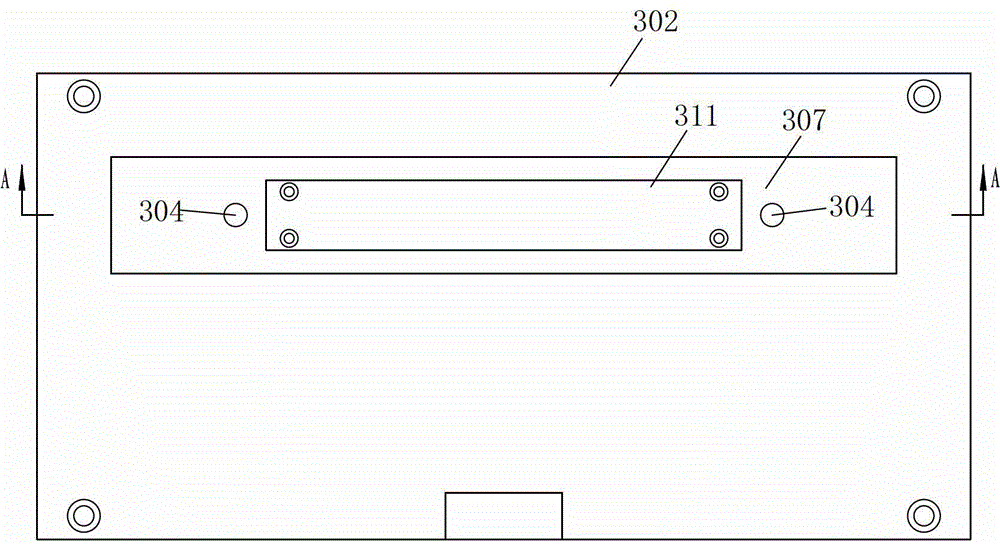

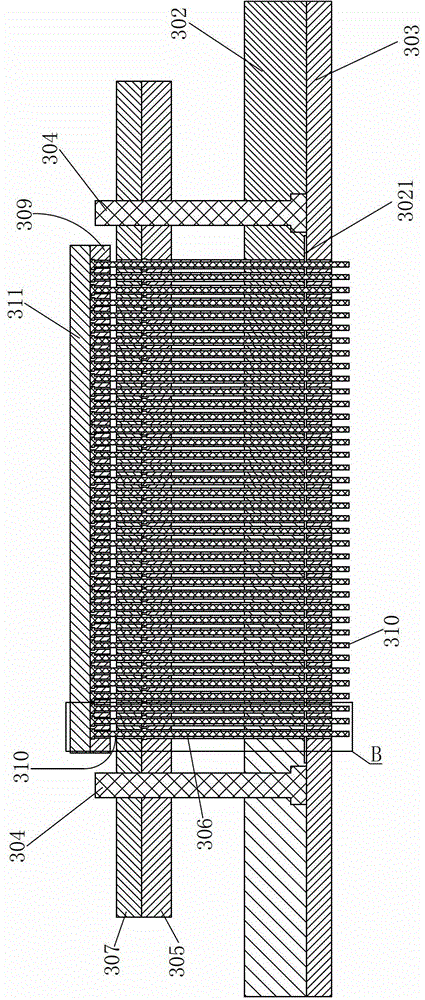

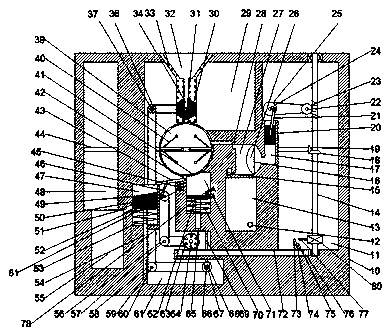

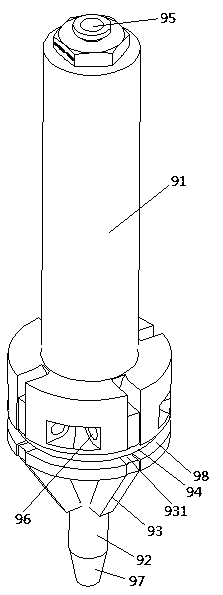

Sealing ring automatic assembling machine and sealing ring assembling method

The invention discloses a sealing ring automatic assembling machine. The sealing ring automatic assembling machine comprises a to-be-assembled sealing ring workpiece moving groove, a sealing ring supporting stand pipe, a sealing ring assembling mechanism and a to-be-assembled sealing ring workpiece transposition mechanism, wherein the to-be-assembled sealing ring workpiece moving groove is provided with a to-be-assembled sealing ring workpiece feeding position, a sealing ring assembling position and a to-be-assembled sealing ring workpiece discharging position; the to-be-assembled sealing ringworkpiece transposition mechanism is used for moving a to-be-assembled sealing ring workpiece from the to-be-assembled sealing ring workpiece feeding position to the sealing ring assembling positionand then to the to-be-assembled sealing ring workpiece discharging position; and the sealing ring assembling mechanism is used for transferring and assembling the sealing ring from the sealing ring supporting stand pipe to the to-be-assembled sealing ring workpiece which is positioned on the sealing ring assembling position. The sealing ring automatic assembling machine is used for assembling thesealing ring on the to-be-assembled sealing ring workpiece so as to replace manual assembling of the sealing ring.

Owner:SHENTONG TECH GRP CO LTD

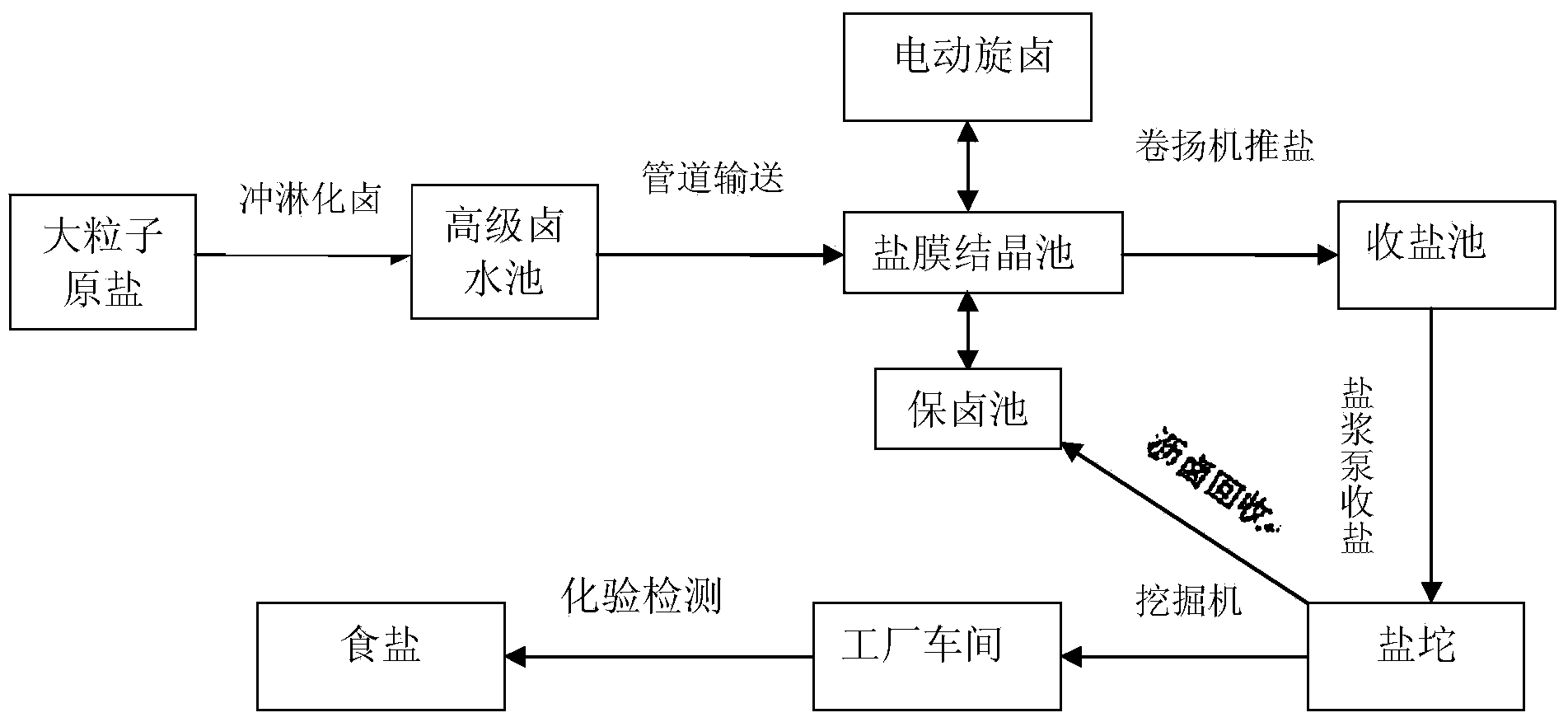

Solarization recrystallization salt-manufacturing technology

ActiveCN104016377AReduce areaReduce energy consumptionAlkali metal chloridesHigh concentrationManufacturing technology

A solarization recrystallization salt-manufacturing technology is characterized by comprising the following steps: (1) utilizing seawater or brine to flush large-particle crude salt, so as to obtain brine with relatively high concentration; (2) sending the high-grade brine subjected to centralized preparation to crystallization ponds; (3) utilizing a mechanical brine-stirring machine to stirring brine and salt; (4) after crystallization is finished in the step (3), centralizing bittern to a salt collection pond and removing superfluous brine; (5) utilizing a salt-slurry pump to transport and stack salt-bittern mixture; (6) returning brine in the step (4) to a brine storage clearing pond for reutilization and crystallization; and (7) performing transportation. Compared with the prior art, the technology has the advantages that seawater or mixed brine is utilized for flushing crude salt, mechanical equipment is not for stirring, and high-grade brine is obtained in a short time; a pipeline system, the mechanical brine-stirring machine, a salt reeling machine, the salt-slurry pump, an excavator and the like are utilized for collecting and stacking salt, the crude-salt output in an unit area is improved, and labor is saved; and the product is pure white and fine, and can be used as a good processing raw material of various edible-salt products.

Owner:浙江绿海制盐有限责任公司

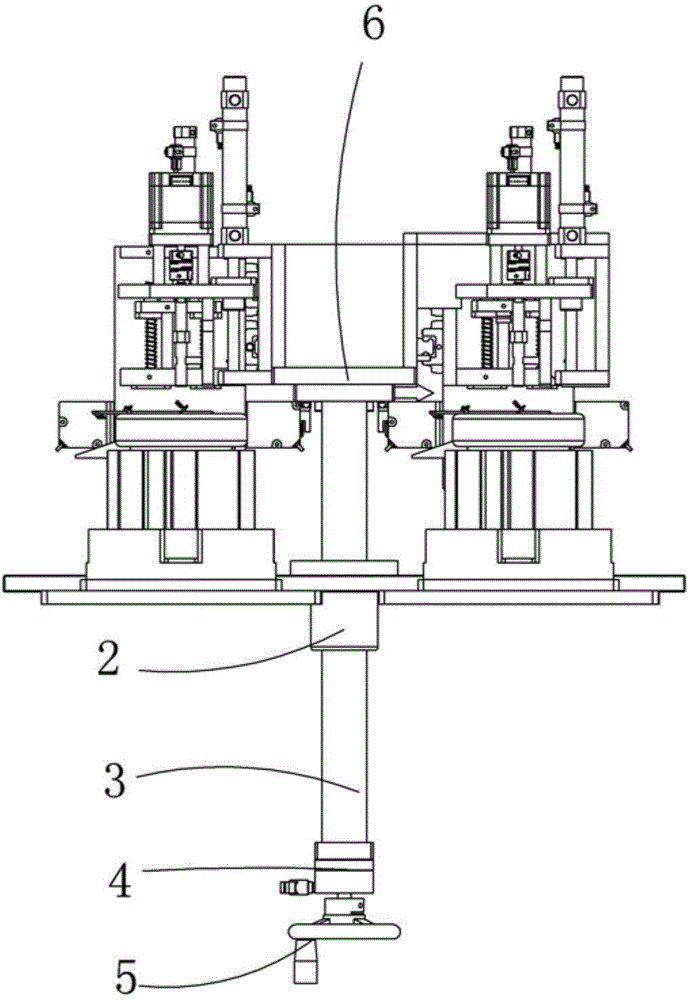

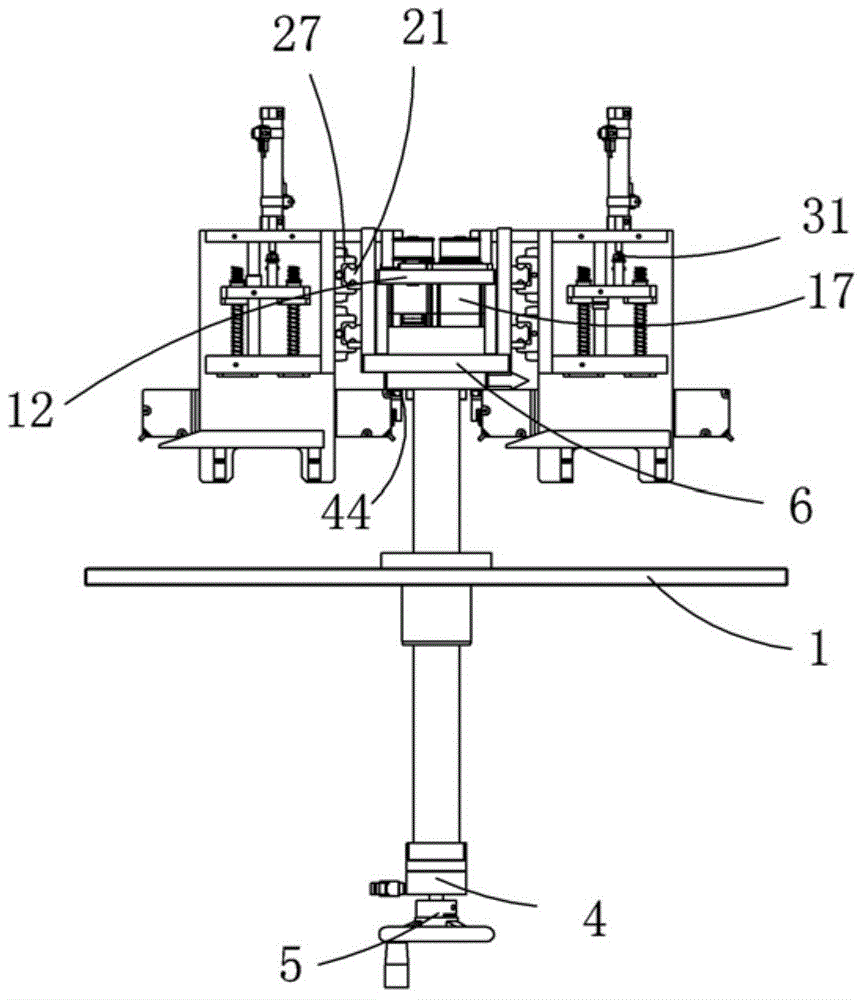

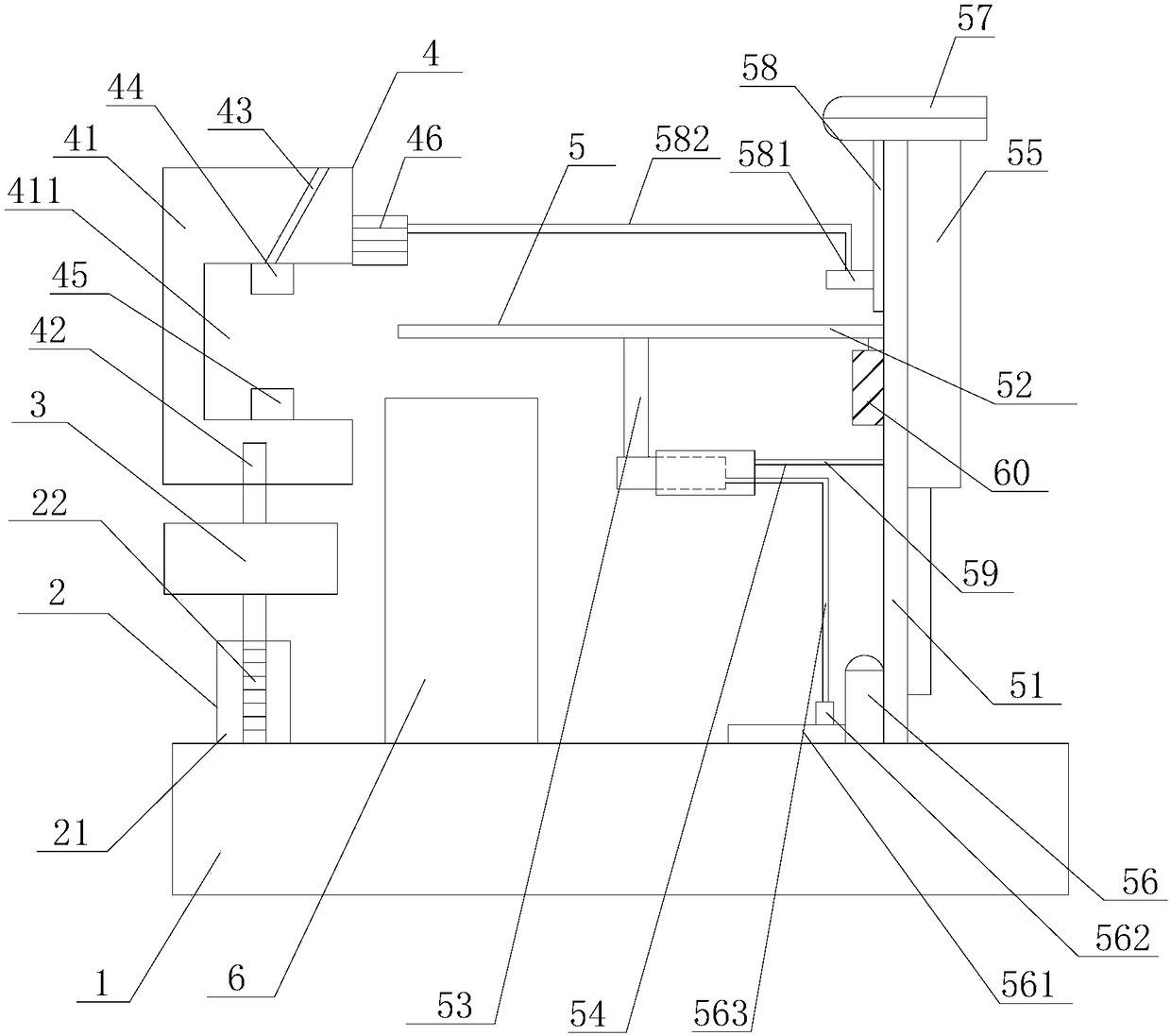

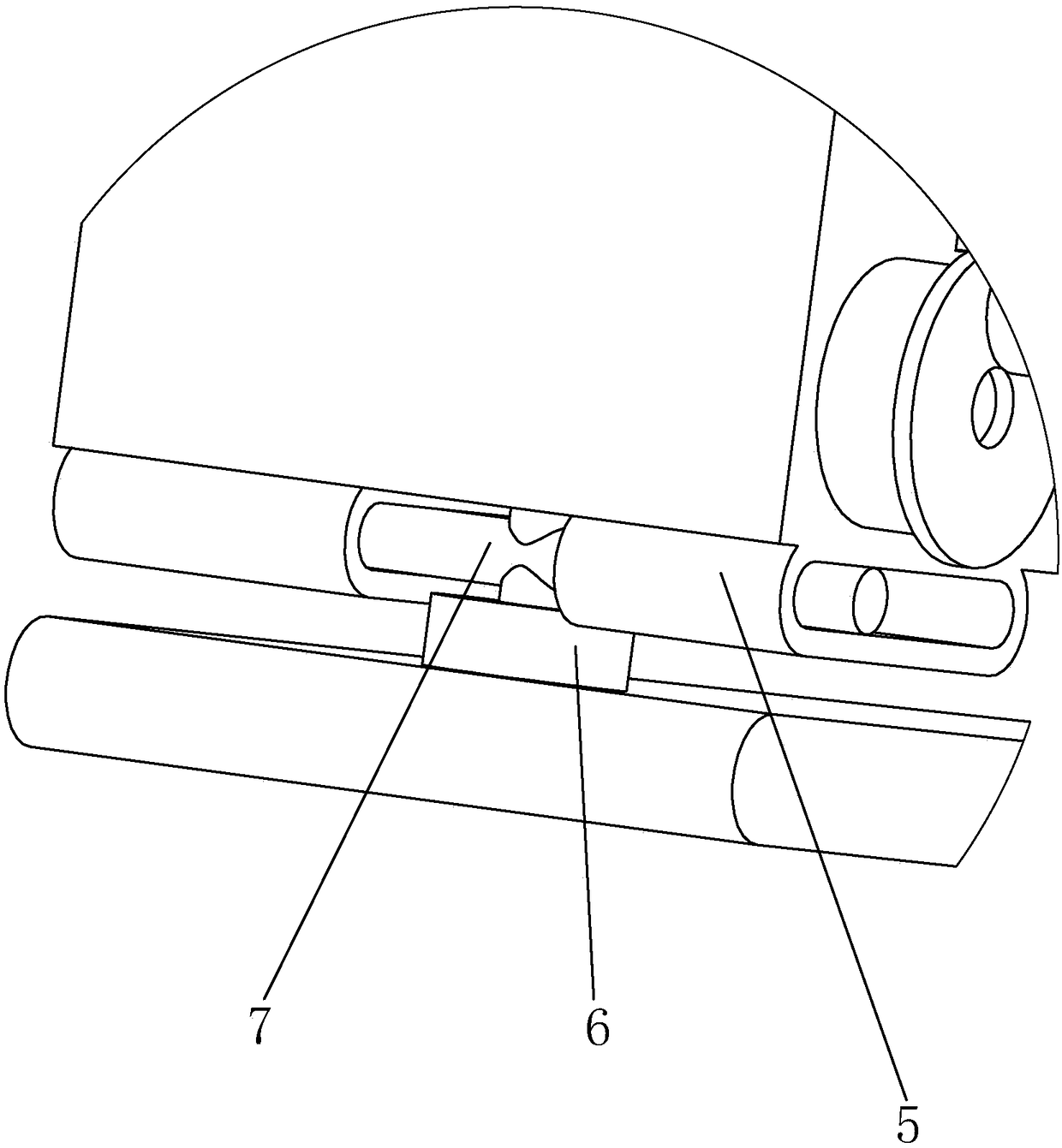

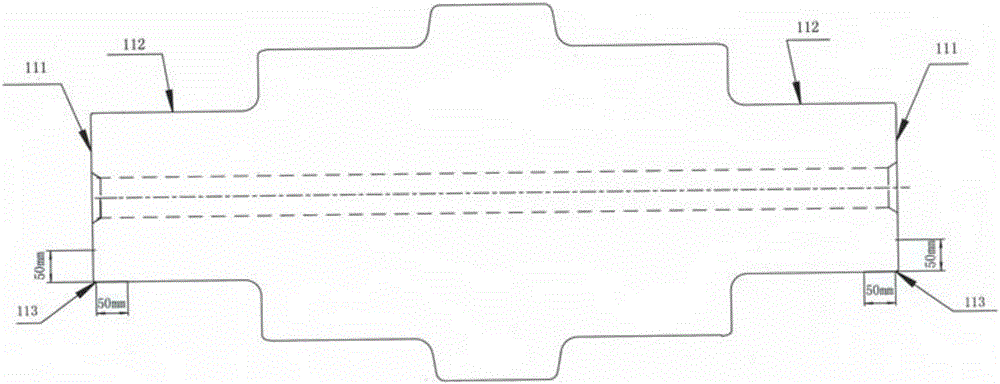

Lead access mechanism for stator winding

ActiveCN104795712AEasy to placeEasy to guide in placeLine/current collector detailsElectrical testingElectric machineEngineering

The invention relates to a lead access mechanism for a stator winding. A screw rod is arranged on a bottom plate through a feed screw nut; a hand wheel is connected with the lower end of the screw rod; the upper end of the screw rod is connected with a transport motor fixing plate; transport modules are arranged on the left side and the right side of the transport motor fixing plate through side fixing plates; a pressing module and a wire-drawing module are arranged on the outer sides of each group of transport modules; conduction modules are arranged on the outer sides of each group of pressing modules; a group of stator tools are arranged below each group of wire-drawing modules; a stator with a stator winding is arranged on each stator tool; a lead terminal is connected with a stator winding lead; the wire-drawing modules are used for drawing the stator winding lead to horizontally bend around the root part of the lead in an XY-axis plane; telescopic cylinders of the conduction modules extend outside and drive a contact to contact the stator surface. According to the lead terminal, through mechanism guide, position confirmation, rectification and pressing, the stator lead terminal and a conductive platform of a stator pulse testing machine are in reliable contact conduction; and the electric properties of the stator winding are automatically tested.

Owner:BOZHON PRECISION IND TECH CO LTD

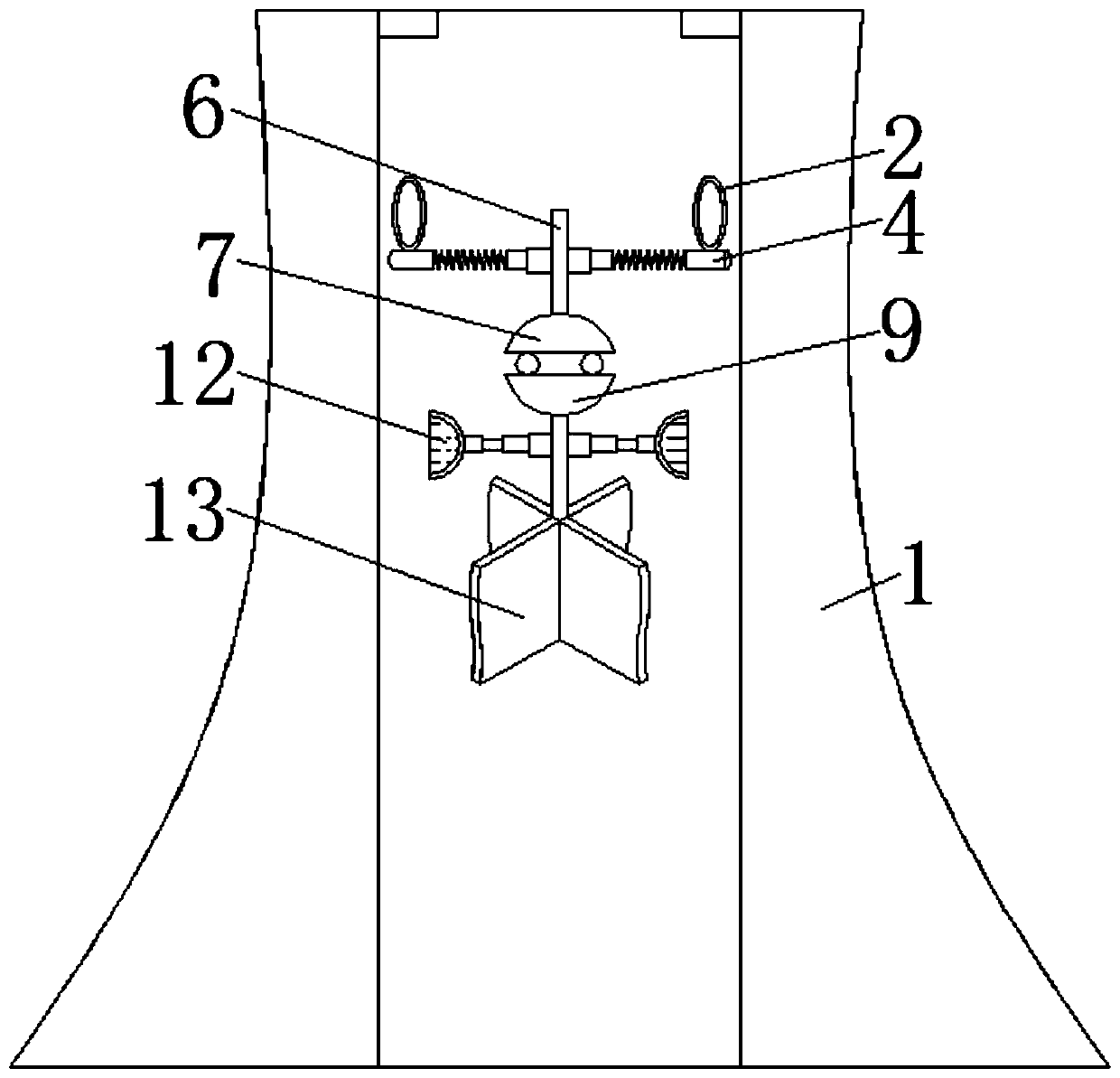

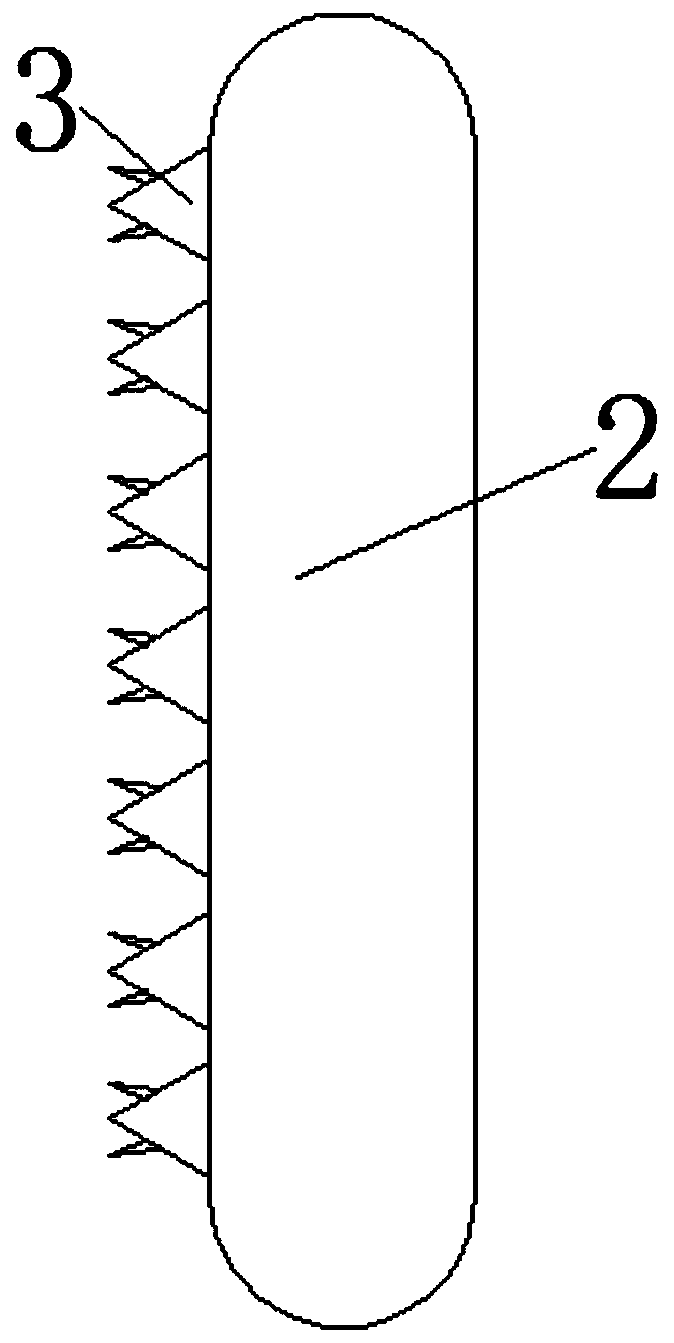

Device for preventing dust agglomeration in chimney based on airflow transformation

InactiveCN110375322AEffective rotationKeep healthyHollow article cleaningSolid removalFlue gasEngineering

The invention discloses a device for preventing dust agglomeration in a chimney based on airflow transformation. The device comprises a chimney body, wherein two symmetrical dust removal rings are inoverlap joint to the inner wall of the chimney body; dust removal blocks are fixed on the side, close to the chimney body, of the dust removal rings; fixed rods are fixed at the lower ends of the dustremoval rings, and tension springs are elastically connected to the middle of the fixed rods. By cooperative utilization of the dust removal rings, the dust removal blocks, telescopic rods, dust removal brushes and airflow plates, the principle that airflow in a furnace moves upwards from the inside of the chimney body can be effectively utilized, and the airflow plates can be effectively drivento rotate, so that the dust removal rings and the dust removal blocks scrape off dust blocks agglomerated in the chimney body; the device has the advantage of automatically removing dust on the innerwall of the chimney body in the process of flue gas emission, the working process is simplified, manual removal is not needed, labor is saved, body health of workers is guaranteed, and the device is convenient to use.

Owner:邓海军

Heat-melting rhinestone automatic assembling machine

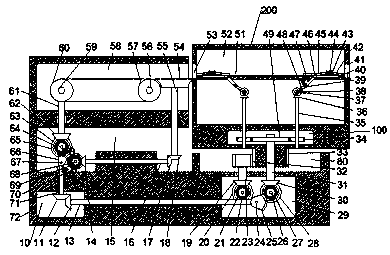

InactiveCN103332054AImprove work efficiencyReduce labor forceOrnamental structuresTextile decorationWorking environmentEngineering

The invention belongs to the technical field of electric automatization equipment, and particularly relates to a heat-melting rhinestone automatic assembling machine. The heat-melting rhinestone automatic assembling machine comprises a main frame, a loading device arranged on one end part of the main frame, a driving device and an ornament recombination device, as well as a transporter, wherein the main frame is provided with a cutting ornament device which can cut a material belt, a material receiving plate of a material receiving groove is arranged below the cutting ornament device; the driving device drives the material receiving plate to step and translate in a batch-type manner; the ornament recombination device is arranged on the other end part of the main frame and can combine an ornament and a transparent heat-melting rhinestone substrate into a whole, the transporter is connected with a material plate driving plate and the ornament recombination device, and passes through the lower part of the cutting ornament device; the loading device is used for supplying the material belt in use, an ornament cut by a trimming die falls on the material receiving plate and is conveyed to the ornament recombination device along the transporter; the ornament recombination device absorbs the ornament and carries and composite the ornament on the back of the transparent heat-melting rhinestone substrate, and the problems that the efficiency of splicing the ornament on the back of the heat-melting rhinestone by adopting a handcraft manner is low, the work environment is worse, and a large number of labor force is wasted are solved.

Owner:WEIFANG HUARUI ELECTRONICS TECH

Production method for continuously formed onion rings

ActiveCN103393031ASkip the quick freezing stepReduce production energy consumptionFood preparationQuick FreezeChloride

The invention discloses a production method for continuously formed onion rings. The production method comprises the following main process steps: selecting fresh white onions; peeling and cleaning the white onions; dicing the white onions by using a dicer; subjecting onion dices to water controlling or mechanical dehydration to realize raw material preprocessing; uniformly mixing the preprocessed onion dices and a binder in proportion in a mixer with stirring; carrying out forming by using a ram-type forming machine so as to obtain onion rings, each weighing 6 to 7 g; spraying a calcium chloride solution and allowing the calcium chloride solution and bonding substances in the accessory material--the binder to undergo hardening and shaping; allowing the shaped onion rings to enter into a powdering machine through a transmission network belt for automatic powdering, then into a starching machine through the transmission network belt for starching, then into a powder wrapping machine for powder wrapping and finally into a tunnel-like frying machine through the transmission network belt for pre-frying; subjecting obtained finished products to oil controlling, cooling and quick-freezing in an individual quick-freezing machine; conveying the quick-frozen onion rings to an automatic packaging machine through the transmission network belt; manually picking out defective onion rings on the transmission network belt; packaging qualified onion rings by using the packaging machine; and carrying out detection and delivery.

Owner:麦康食品(青岛)有限公司

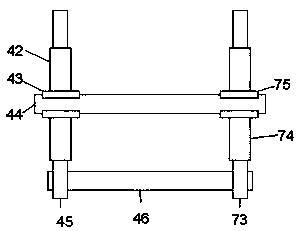

Transport mechanism capable of rising and falling

ActiveCN104808026AImprove detection efficiencyIncrease productivityMeasurement instrument housingElectrical performanceConductor Coil

The invention relates to a transport mechanism capable of rising and falling. A bottom plate is provided with a feed screw nut; the feed screw nut is provided with a feed screw in a matching manner; the upper part and the lower part of the feed screw are respectively supported by a feed screw support; the lower end of the feed screw is connected with a hand wheel; the upper end of the feed screw is connected with a transport motor fixing plate. The transport mechanism is characterized in that the left side and the right side of the transport motor fixing plate are respectively provided with a side fixing plate; each set of the side fixing plates is provided with a transport module; the outer sides of each set of the transport modules are respectively provided with a set of pressing modules; the rise and fall of the transport modules can be adjusted by the hand wheel; the pressing modules can be driven by the transport modules to move in a Y-axis direction, so a lead terminal of a stator winding can be conveniently guided in place. According to the transport mechanism disclosed by the invention, the lead terminal of the motor stator winding is guided, confirmed in position, rectified and pressed through the mechanism, so that the lead terminal of the motor stator winding and an electric conduction platform of a stator impulse testing machine are reliably contacted and conducted to automatically test the electrical performance of the stator winding.

Owner:BOZHON PRECISION IND TECH CO LTD

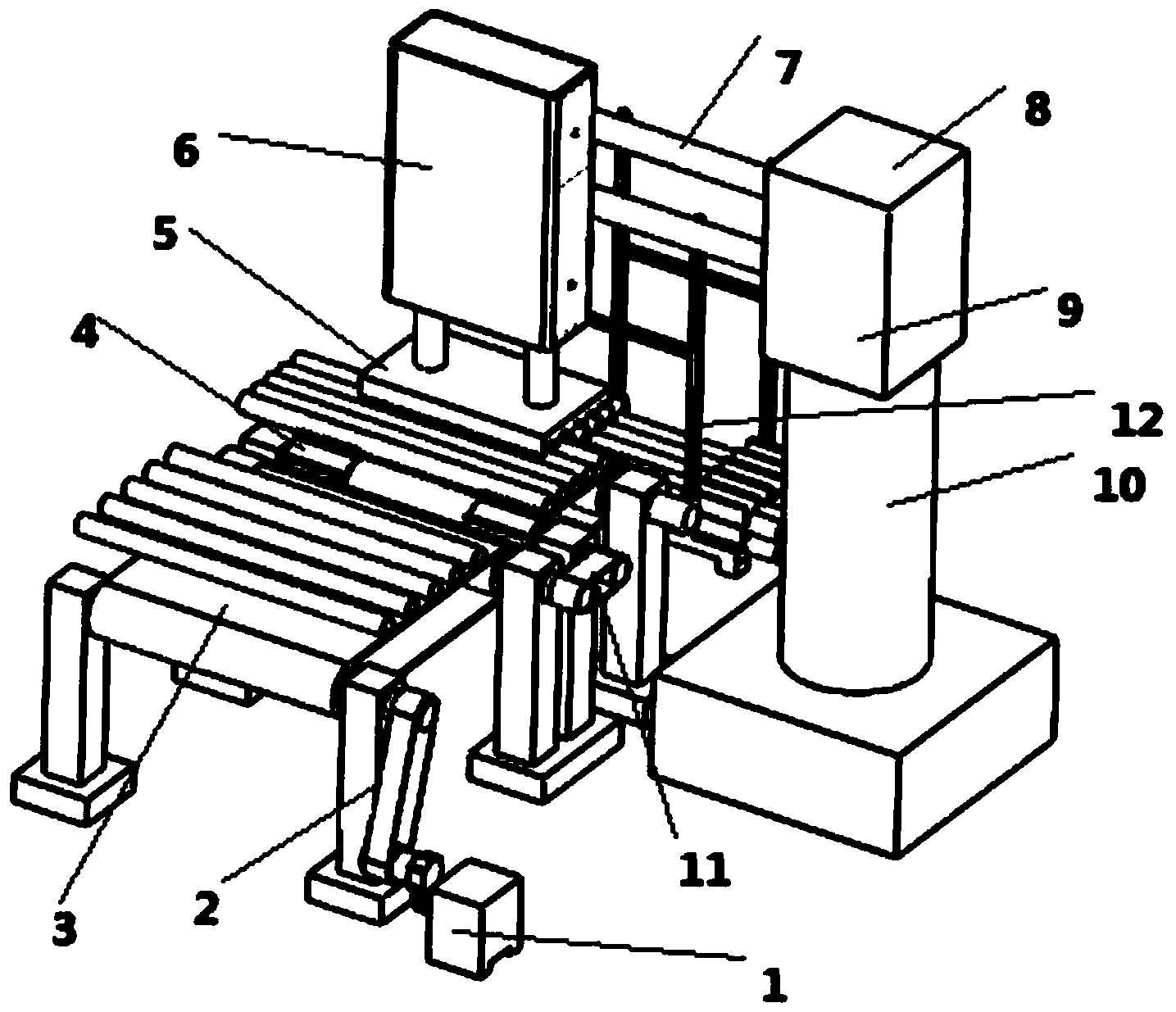

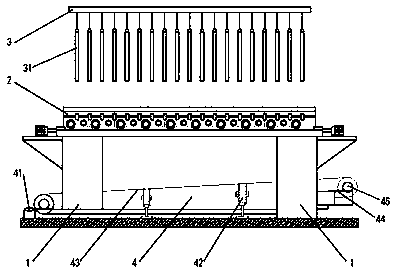

Solar pipe hacking machine

The invention discloses a solar pipe hacking machine, and belongs to the field of an electromechanical device. The solar pipe hacking machine is composed of a main motor, a conveyor belt, a belt pulley, a conveyor chain, a sucker, a connecting rod, a cylinder, an auxiliary rotating motor, a rotating block, a placing frame, a motor support and a connecting belt. The solar pipe hacking machine is characterized in that the belt wheel which drives the conveyor belt is connected with the main motor, the driving belt is connected with a connecting belt arranged on the conveyor chain, the rotating block is arranged on the motor support, and the auxiliary rotating motor is arranged in the rotating block connected with the connecting rod; the connecting rod is connected with the cylinder connected with the sucker, and the solar pipe is placed on the placing frame. The solar pipe hacking machine has the beneficial effects of being capable of automatically hacking solar glass pipes and effectively preventing the solar pipes from being broken.

Owner:崔学礼

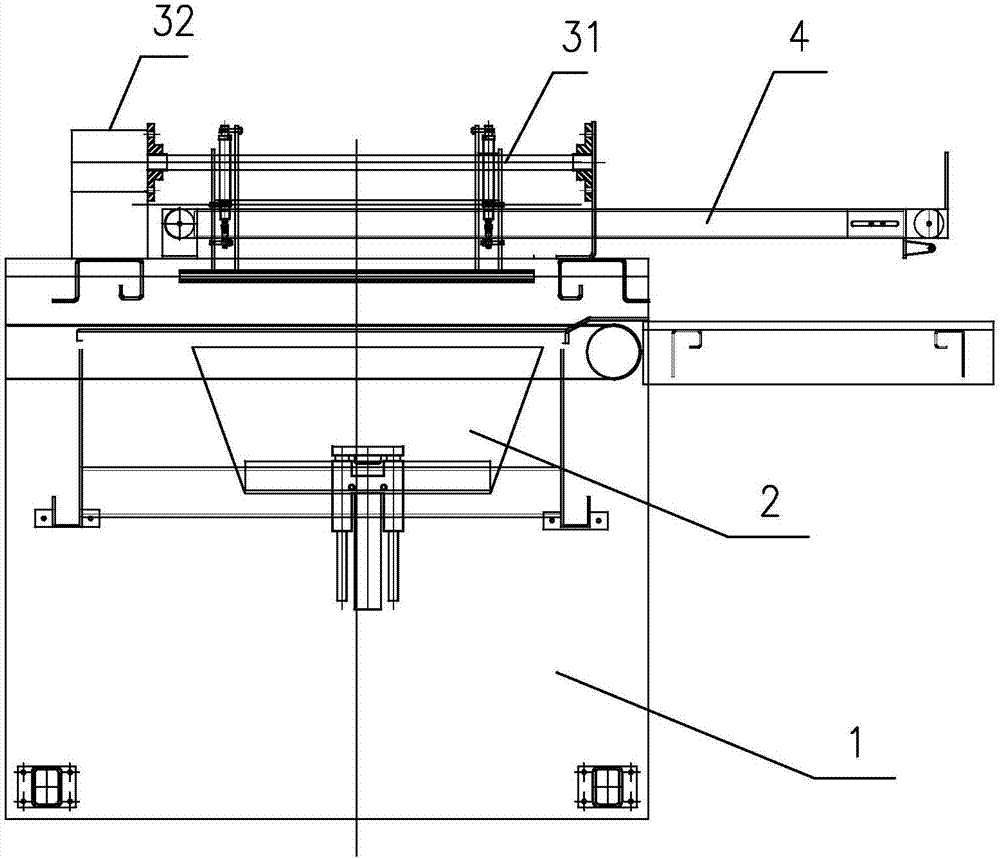

Nickel anode plate cleaning machine

PendingCN108754547AEasy to cleanShorten the timePhotography auxillary processesElectrolysis componentsEngineeringMetallic Nickel

The invention discloses a nickel anode plate cleaning machine. The nickel anode plate cleaning machine comprises a foundation platform, a cleaning mechanism, a crane mechanism and an anode slime recovery mechanism. The foundation platform is fixedly connected with the cleaning mechanism. The anode slime recovery mechanism is arranged below the cleaning mechanism directly. The crane mechanism hoists nickel anode plates from a workshop electrolytic platform to the upper portion of the cleaning mechanism. The nickel anode plate cleaning machine disclosed by the invention has the characteristics of being simple in structure, high in efficiency and easy to operate and has broad market prospects.

Owner:李文斌

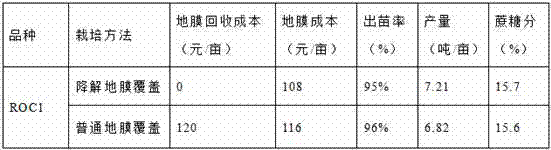

Cultivation method of biodegradation mulching film covering sugarcane

InactiveCN106962000ASmooth germinationYield is not affectedPlant cultivationCultivating equipmentsEcological environmentCultivated sugarcanes

The invention relates to a cultivation method of biodegradation mulching film covering sugarcane, and belongs to the technical field of crop ecological environmental protection cultivation. The method comprises the steps that when the sugarcane is planted in winter or spring, the sugarcane is covered with the biodegradation mulching film, wherein the width is 1-6 m, the thickness is greater than 0.008 mm, the transmittance is greater than 80%, and the biodegradation time is 120 days, 60 days and 45 days; before the film covering, a planting ditch is irrigated with water of 5-8 tons per acre, to ensure the smooth emergence of sugarcane; after irrigation, full film covering is adopted; after the film covering, the film is biodegraded after a specific time period without recycling the mulching film; the labor cost of recycling the mulching film is saved 120 yuan per acre. According to a plurality of experiments on the sugarcane variety, the method has the advantages that the yield of the cultivated sugarcane is not affected by using the method; the net income of sugarcane planting farmers can be increased; and the soil ecological environment is effectively protected.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI +1

Automatic assembling machine for plastic nails of fan of machine box

The invention discloses and provides an automatic assembling machine for plastic nails of a fan of a machine box and with simple structure, reasonable design, high automation degree and high efficiency. According to the technical scheme adopted, the automatic assembling machine comprises a plastic nail feeding module, a machine box feeding module, a fan feeding module and a plastic nail assemblingmodule, wherein the plastic nail feeding module comprises a CCD camera and a plastic nail taking manipulator, and the plastic nail taking manipulator is used for clamping the plastic nails; the machine box feeding module comprises a box feeding track and a material blocking positioning assembly arranged on the box feeding track, wherein the box feeding track is used for conveying the machine box;the fan feeding module comprises a fan discharging positioning assembly, wherein the fan waits for discharging at the fan discharging positioning assembly; and the plastic nail assembling module comprises a fan taking manipulator, the fan taking manipulator takes the fan from the fan feeding module and transports the fan to the machine box on the box feeding track, the plastic nail taking manipulator transports the plastic nails to the machine box, and the CCD camera captures plastic nail holes in the machine box, plastic nail holes in the fan and the positions of the plastic nails. The automatic assembling machine can be used in the technical field of assembling of the plastic nails of the fan of the machine box.

Owner:深圳市运泰利自动化设备有限公司

Workpiece feeding device for seam welder and using method thereof

InactiveCN109093296AReduce the risk factorSimple organizationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

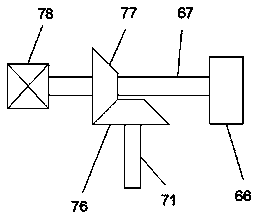

The invention discloses a workpiece feeding device for a seam welder and a using method thereof. The workpiece feeding device for the seam welder comprises a workpiece transmitting device and a workpiece conveying mechanism which is arranged in the workpiece transmitting device; a first rotating cavity is formed in the workpiece transmitting device; a second rotating cavity which is positioned inthe right side of the first rotating cavity is formed in the workpiece transmitting device; a third rotating cavity which is positioned in the upper side of the second rotating cavity is formed in theworkpiece transmitting device; a fourth rotating cavity is arranged in the upper side of the first rotating cavity; a fifth rotating cavity is arranged in the upper side of the fourth rotating cavity; a motor is fixedly arranged on the rear wall of the fourth rotating cavity; the front end of the motor is in power connection with a power shaft; a first bevel gear which is positioned on the frontside of the motor is fixedly arranged on the power shaft; a first fan-shaped bevel gear which is positioned on the front side of the first bevel gear is fixedly arranged on the power shaft; and a first rotating shaft which is positioned on the upper side of the motor is rotatably arranged on the rear wall of the fourth rotating cavity.

Owner:杭州西非电子信息技术有限公司

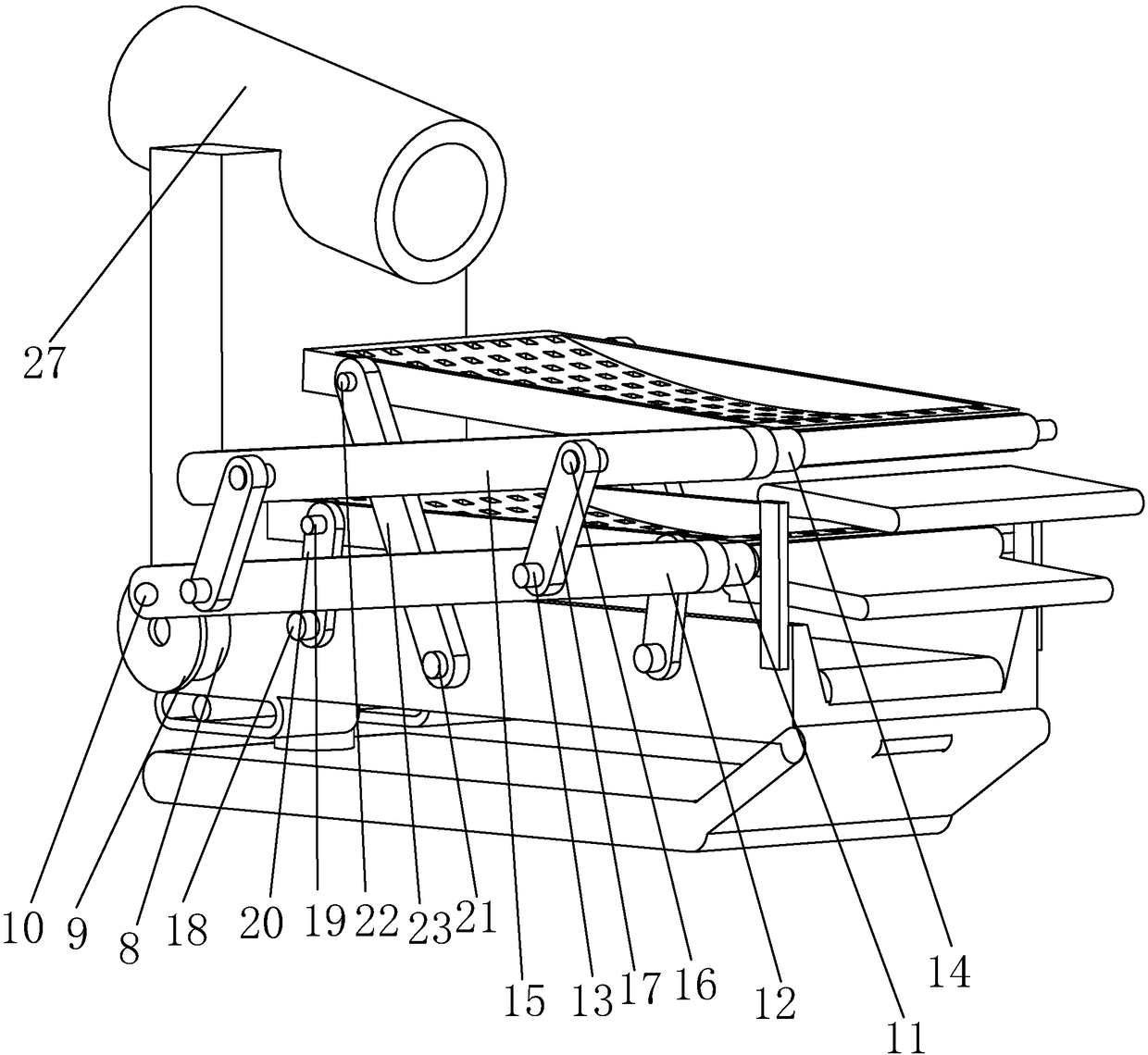

Hand stubble-cleaning return-to-field operation machine

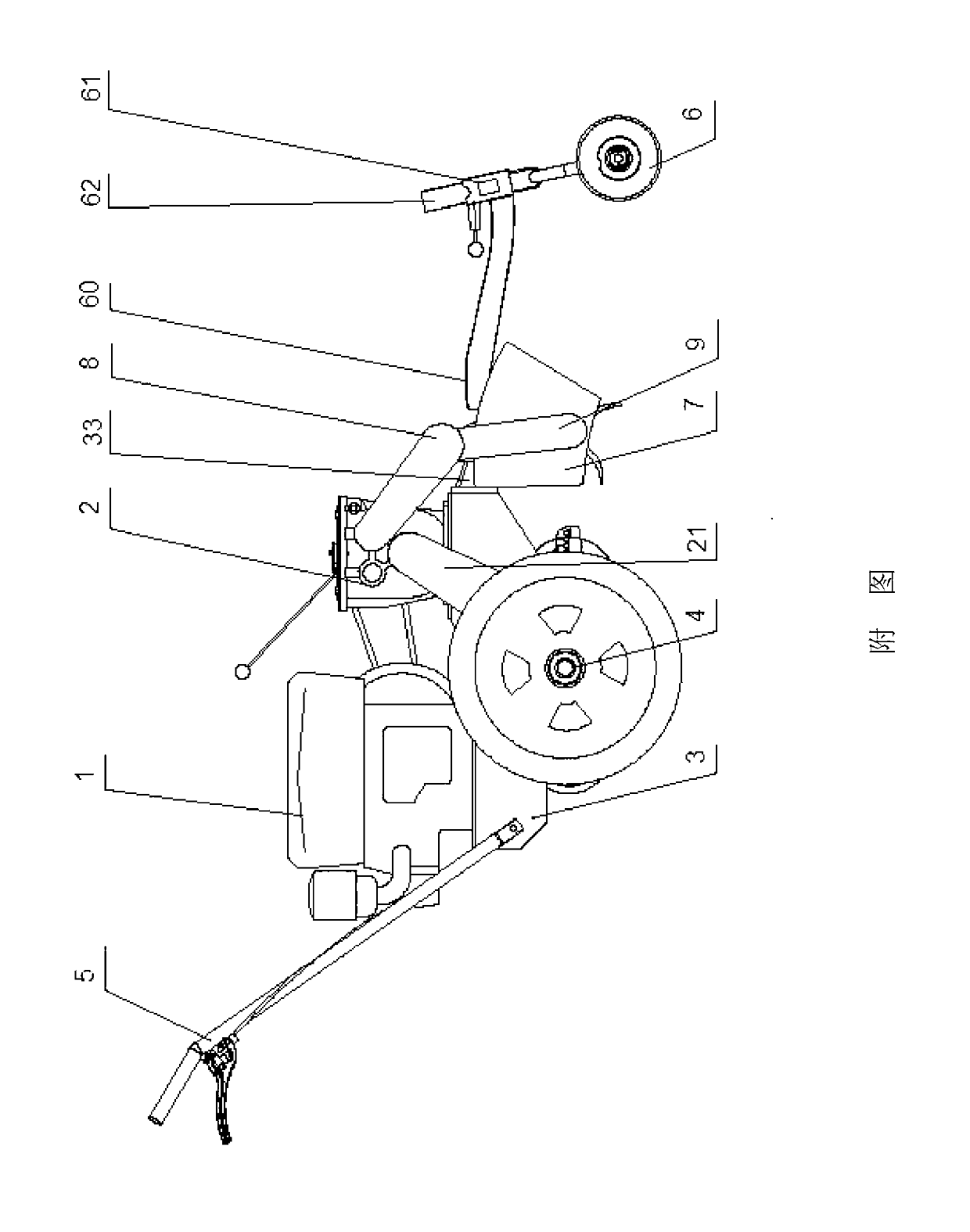

InactiveCN102726173ASolve technical problems with potential safety hazardsStable center of gravityCrop conditionersMowersAgricultural engineeringRidge

The invention provides a hand stubble-cleaning return-to-field operation machine. The operation machine comprises a power walking main machine and a stubble-cleaning assembly, wherein a transmission case in the power walking main machine is arranged on the front part of a machine frame; an engine is arranged on the rear part of the machine frame relative to the transmission case; a walking wheel axle is arranged on the lower part of the machine frame and is in transmission connection with a first output shaft of the transmission case; a ridge guide wheel and a bracket of the ridge guide wheel are arranged at the front end of the machine frame; and the stubble-cleaning assembly is arranged on an installation base, in front of the walking wheel axle, of the machine frame, and a second speed transmission output shaft of the transmission case is in reduction transmission connection with a stubble-cleaning hob shaft arranged in front of the walking wheel axle. The hand stubble-cleaning return-to-field operation machine has the technical advantages of low energy consumption, labor conservation, capability of cleaning stubbles on sloping fields and high safety.

Owner:张凤武

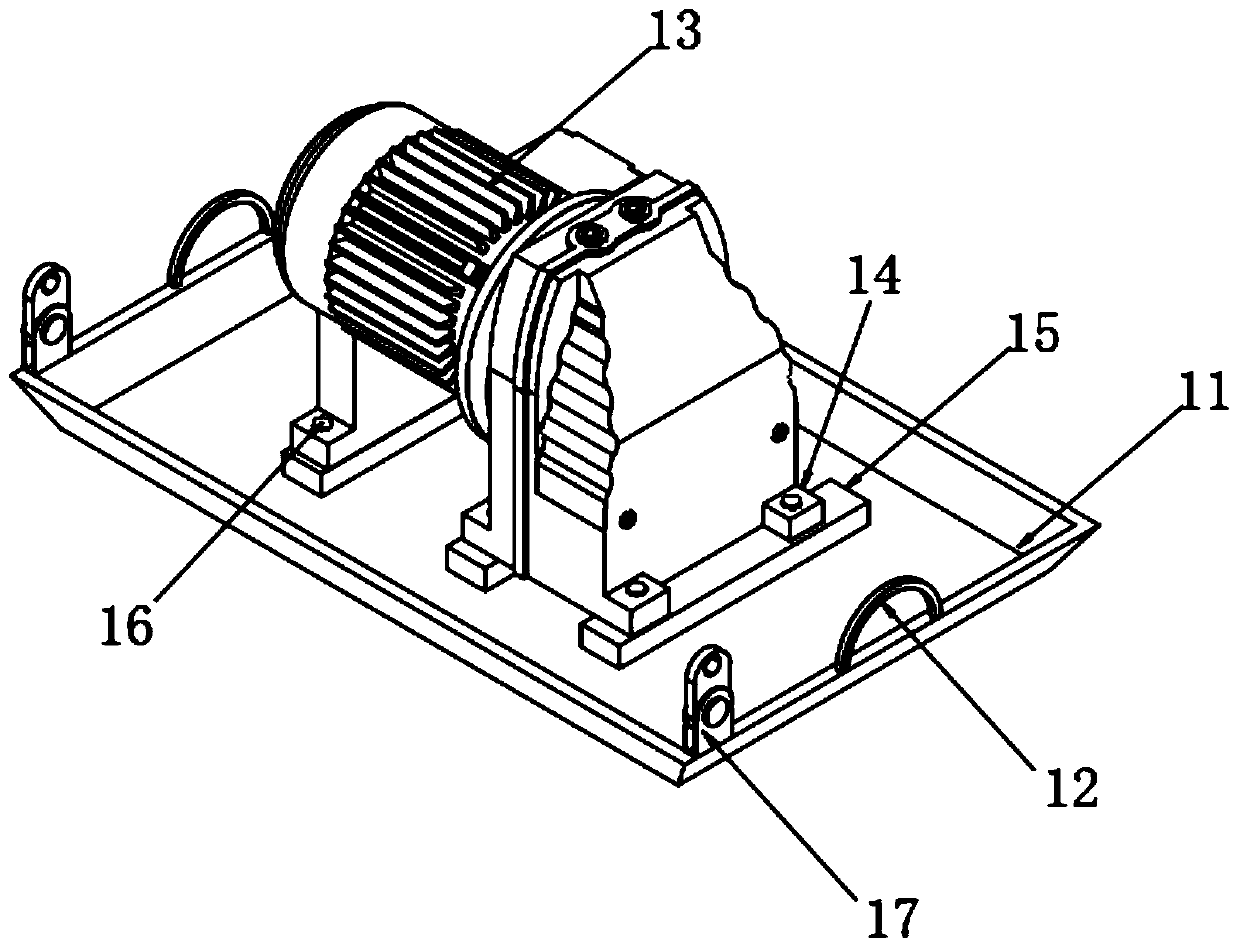

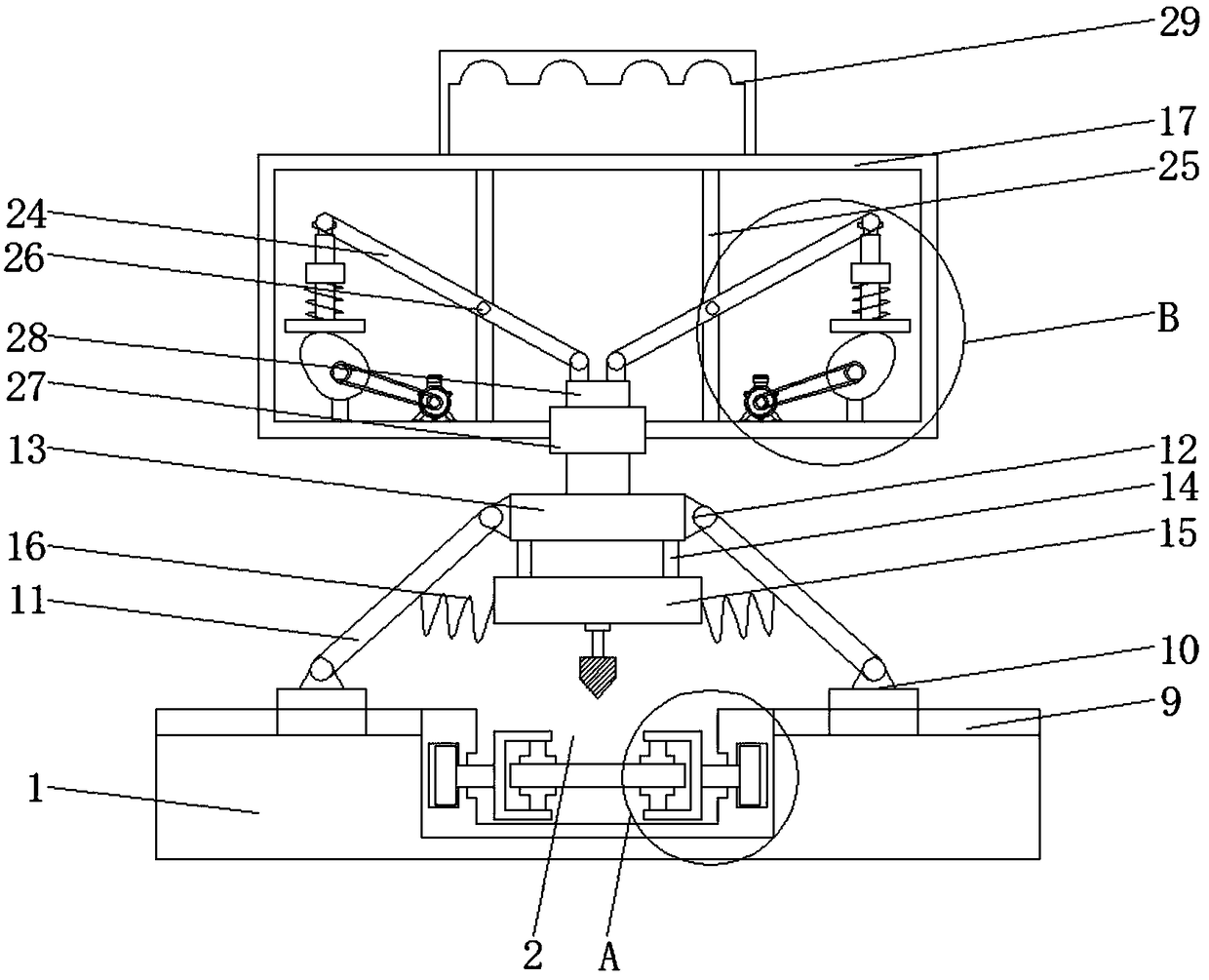

Magnetic attachment type building engineering vibrator

InactiveCN110847613AReduce labor forceEasy to installBuilding material handlingGear wheelConstruction engineering

The invention relates to the technical field of construction equipment, and specifically relates to a magnetic attachment type building engineering vibrator. The vibrator comprises vibrating equipmentand a conveying mechanism for conveying the vibrating device, the vibrating equipment comprises a vibrating plate and a vibrating device mounted at the center of the top of the vibrating plate, lifting rings are symmetrically arranged on the two sides of the vibrating plate correspondingly, the conveying mechanism comprises a supporting frame and a lifting power mechanism arranged at the top of the supporting frame, universal wheels are arranged at the bottom of the supporting frame, the lifting power mechanism comprises a forward and reverse rotating motor and a retracting and releasing rotating shaft, an output shaft of the forward and reverse rotating motor is connected with a driving gear, and the bottom of each rope is connected with a hook. According to the vibrator, the vibrating equipment is moved integrally through the arranged conveying mechanism, manual carrying is replaced by conveying equipment, the labor intensity of an operator is relieved, the retracting and releasingof the ropes are controlled by the forward and reverse rotating motor, the driving gear, a driven gear and the retracting and releasing rotating shaft, the whole vibrating equipment can be lifted, andtime and labor are saved.

Owner:QINGJIAN GRP CO LTD

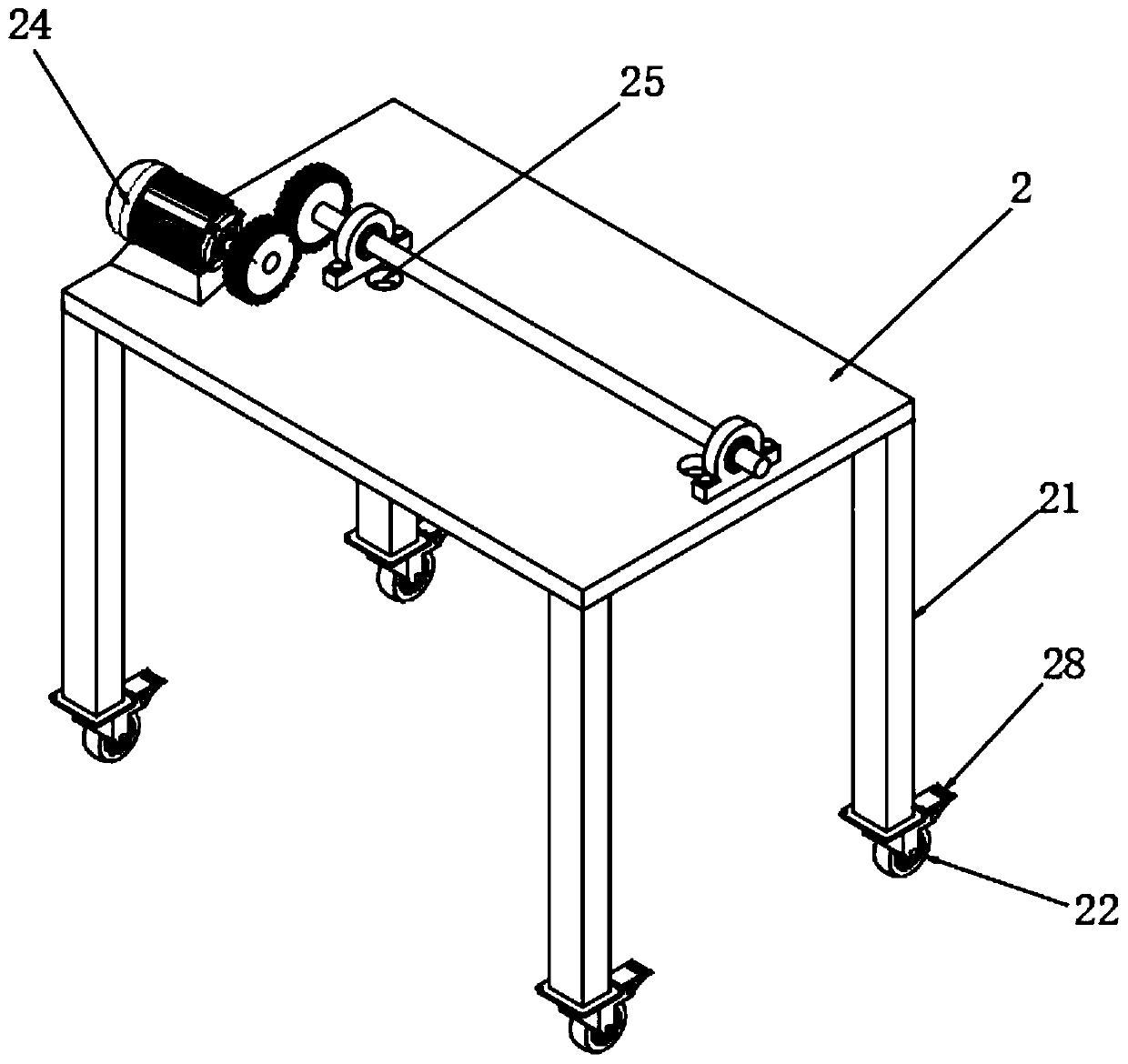

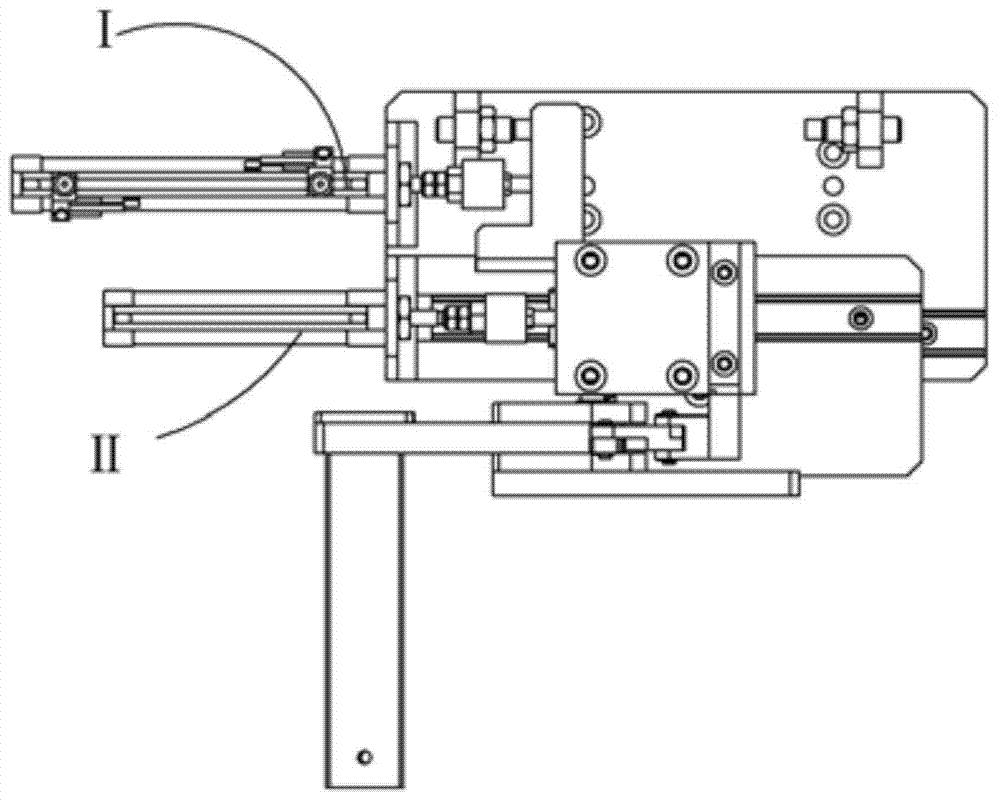

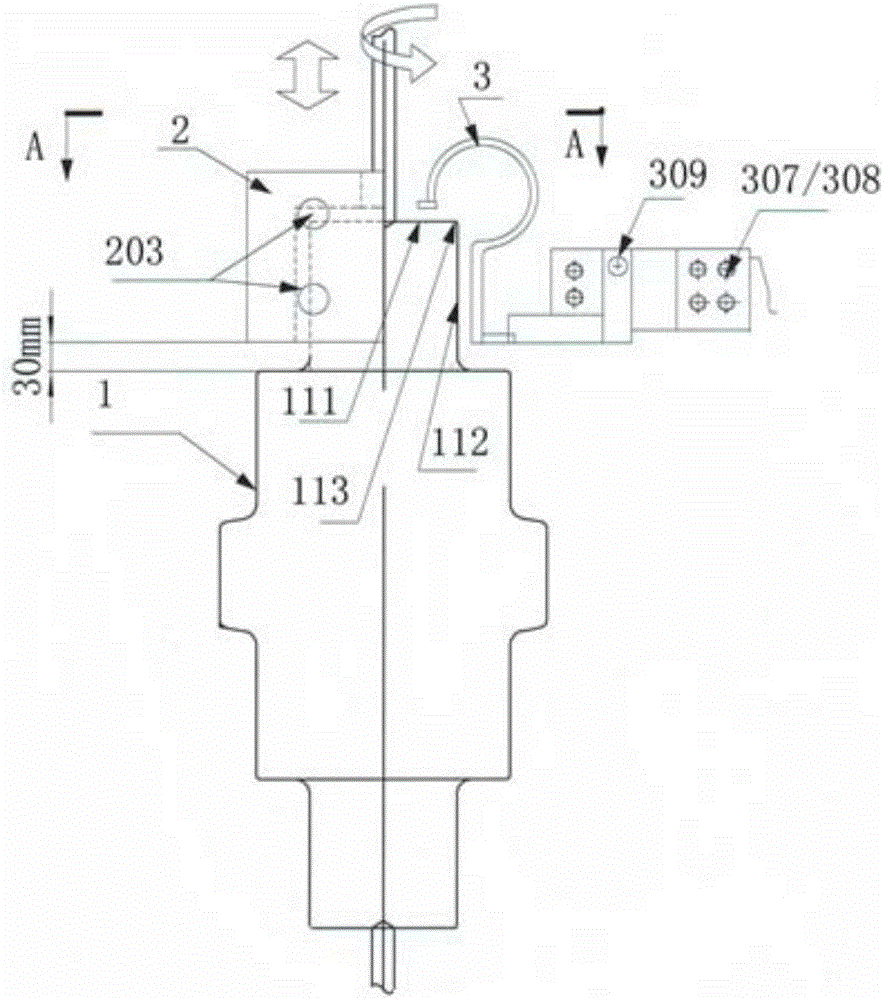

Translatable lead guide mechanism

ActiveCN104852530AReduce labor forceImprove working environmentManufacturing dynamo-electric machinesSlide plateGuide wires

Owner:BOZHON PRECISION IND TECH CO LTD

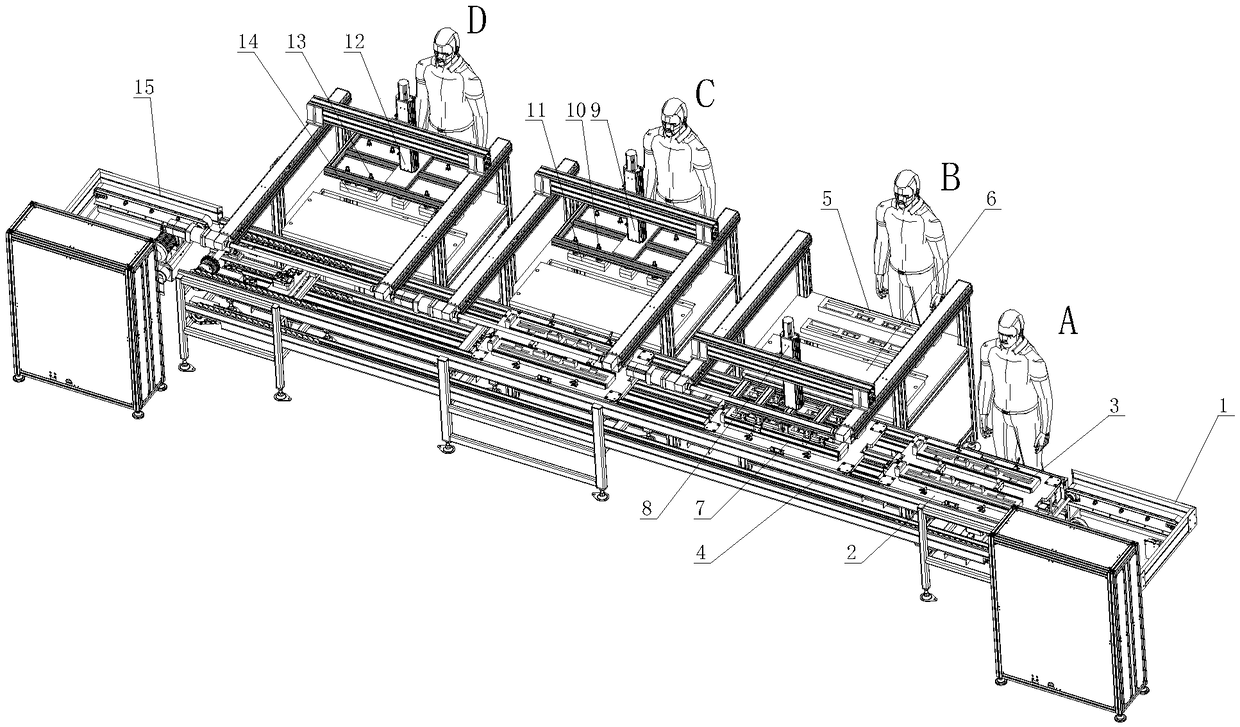

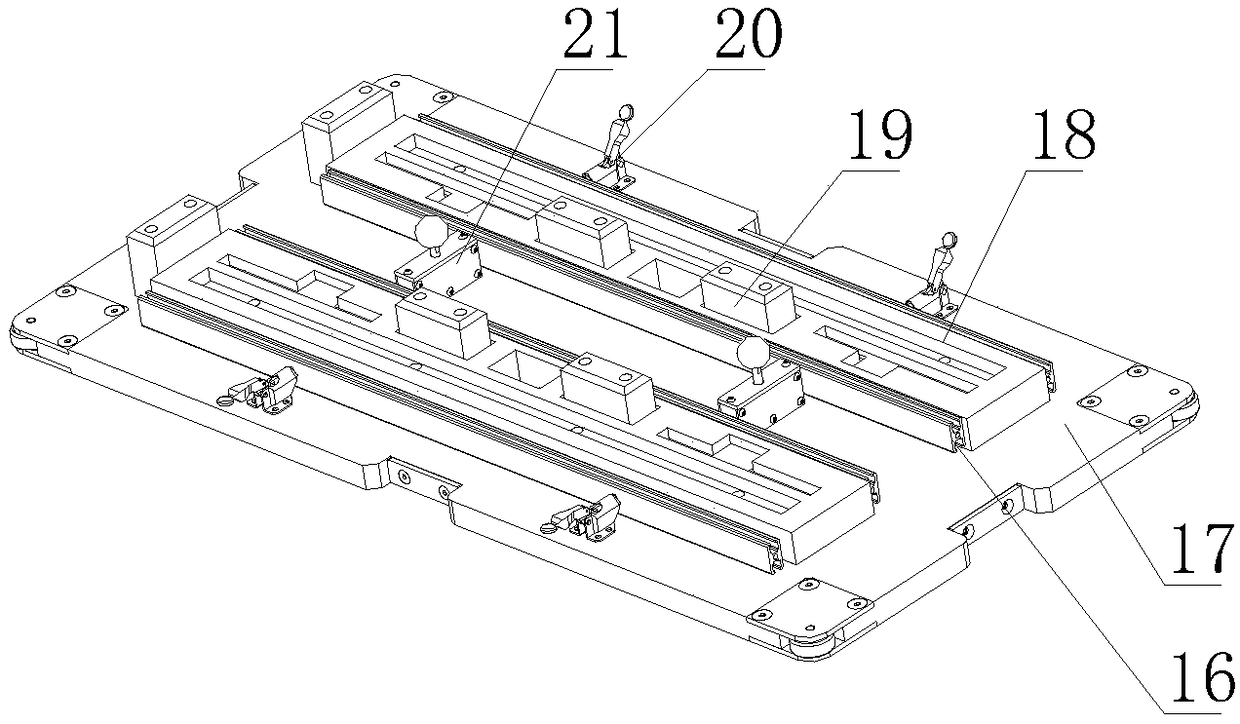

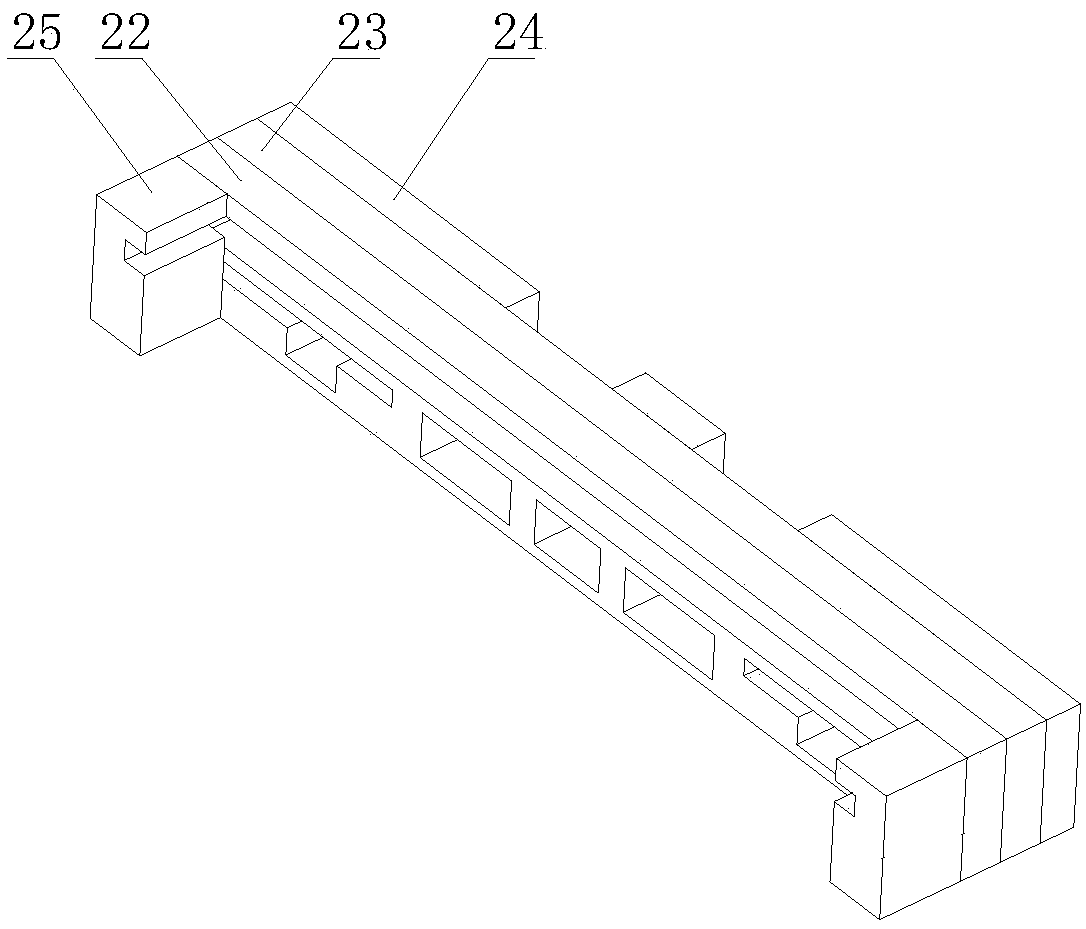

Automatic EPE pasting production system

PendingCN108820875AAvoid deformationReduce wire drawingLamination ancillary operationsLaminationEngineeringUltimate tensile strength

The invention discloses an automatic EPE pasting production system. An elevator a and an elevator b are separately arranged at the two ends of a double chain conveyor. A tool plate is placed on the double chain conveyor through the elevator a or the elevator b. Grabbing stations are arranged on the same side of the double chain conveyor and are spaced from one another by a certain distance. Workpiece sets at the grabbing stations are placed on the tool plate or a positioning plate. Grippers are arranged at the bottoms of three-axis robots and are used for grabbing the workpiece sets. The top ends of the three-axis robots are mounted on a supporting sliding rail. The three-axis robots can be controlled through the supporting sliding rail to move between the tool plate, a smokeless ironing plate and the positioning plate. The workpiece sets on the upper layer are pasted to the workpiece sets on the lower layer. The rigid mechanical grippers are used for fixed-point grabbing, so that fixed-point pasting and mounting are achieved, the precision can be controlled within + / -0.5 mm, the qualification rate and consistency of products are greatly improved, and deformation caused by softnessof raw materials is avoided. By adoption of the automatic EPE pasting production system, the production efficiency is greatly improved, labor consumption is reduced, and the labor intensity is relieved.

Owner:QINGDAO HONGMING MACHINERY

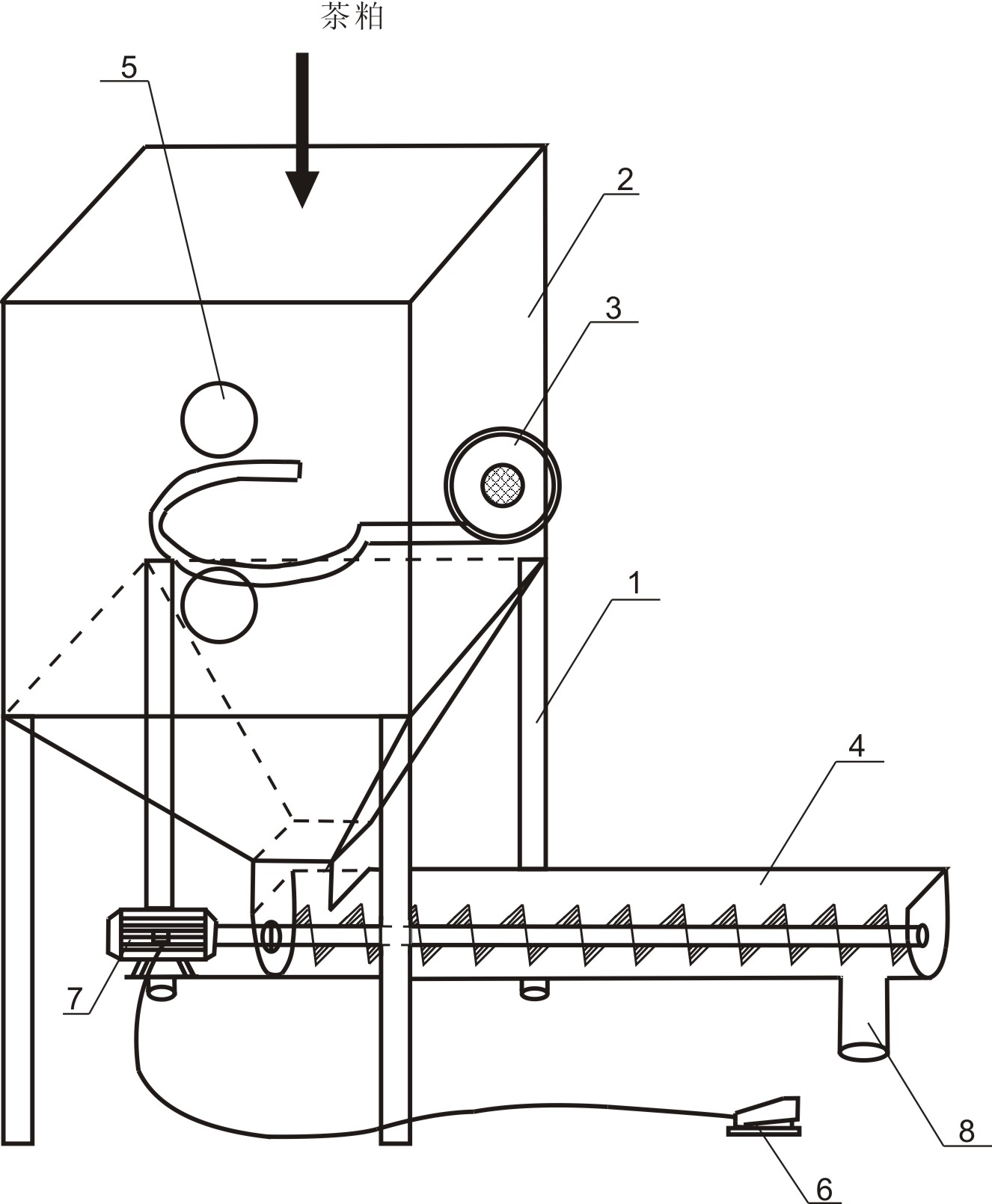

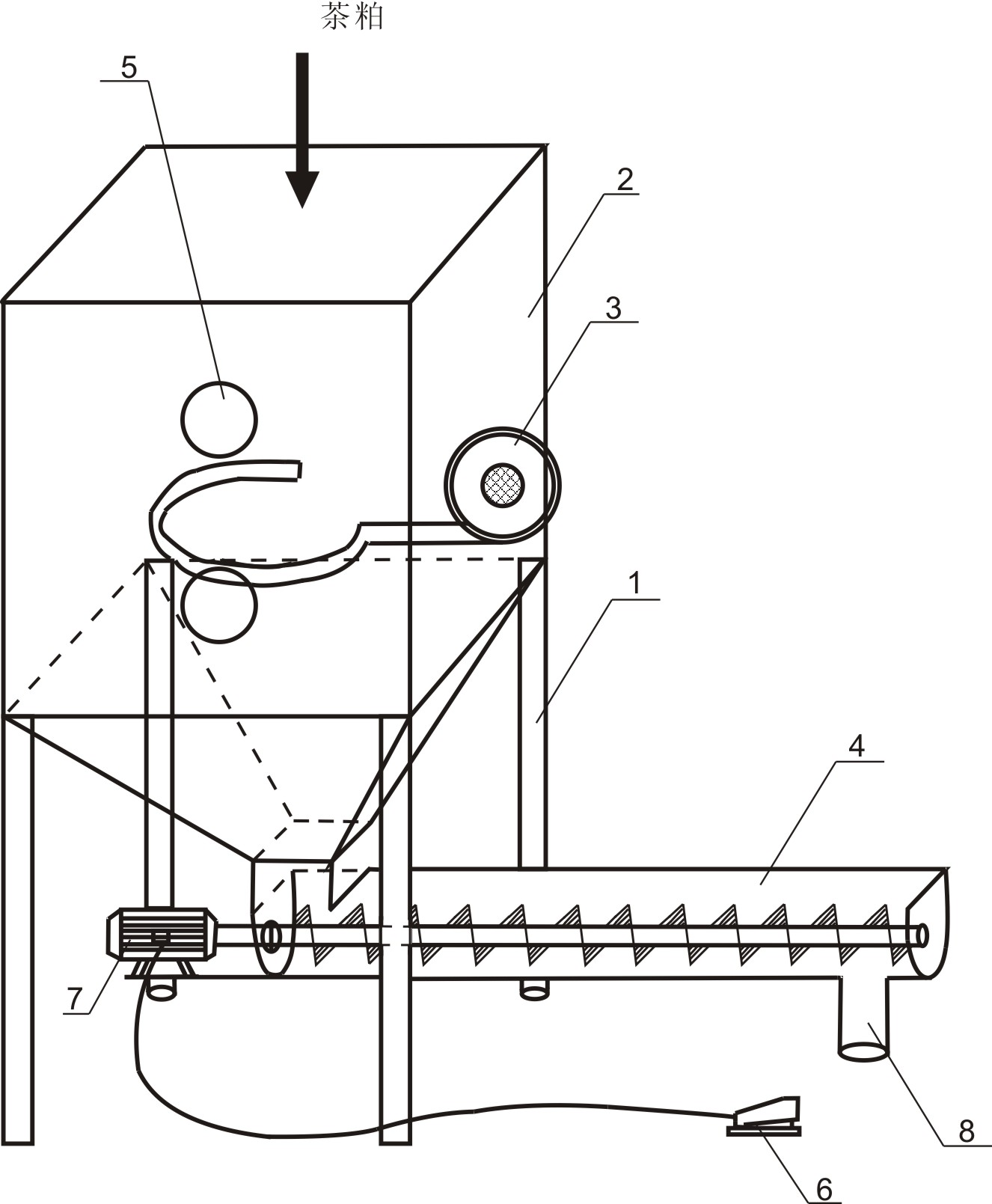

Tea seed cake filler device

InactiveCN102092500AAvoid clumpingGuaranteed qualitySolid materialPackaging automatic controlAgricultural engineeringUltimate tensile strength

The invention discloses a tea seed cake filler device, which comprises a seed cake storage tank, wherein the seed cake storage tank is arranged on a bracket and has an upper opening; the lower part of the seed cake storage tank forms a cone; an air duct of a fan is communicated with the seed cake storage tank; the lower end of the seed cake storage tank is communicated with a material inlet of a screw conveyor; the fan is an intermediate pressure fan; two observation windows are formed on the seed cake storage tank, and are vertically arranged on the front surface of the seed cake storage tank; a switch of a motor of the screw conveyor is a foot switch; and an electronic weigher is arranged below a material outlet of the screw conveyor. The tea seed cake filler device provided by the invention can cool tea seed cakes discharged by a leaching process and automatically bag the cooled tea seed cakes, overcomes the shortcomings of conventional manual bagging, reduces the labor intensity of workers, reduces labor forces and ensures the quality of the tea seed cakes.

Owner:HUBEI HOIL WOODY OIL

Full-automatic punch press facilitating feed collecting and unloading

InactiveCN108127013AFully automatedNo manual operationMetal-working feeding devicesStripping-off devicesPunch pressLeveling mechanism

The invention provides a full-automatic punch press facilitating feed collecting and unloading. The full-automatic punch press comprises a base, a feeding mechanism, a leveling mechanism, a punching mechanism, a feed collecting mechanism and a feed collecting box, the feeding mechanism comprises a feeding frame and a feeding guide groove located in the middle of the feeding frame, the punching mechanism comprises a punch press body, a feed guide plate, a knockout plate, an upper mold, a lower mold and a punch press slide block, the feed collecting mechanism comprises a feed collecting support,a feed collecting disc, a connecting rod and a telescopic rod, a first air cylinder is arranged at the lower end of the feed collecting support, a first slide rail is arranged at the left side of thefirst air cylinder and is connected with a telescopic rod, a second air cylinder is arranged at the upper end of the feed collecting support, and a second slide rail is arranged below the second aircylinder and is connected with the punch press slide block. By means of the full-automatic punch press facilitating feed collecting and unloading, full-automation of feed collecting and unloading is achieved, manual operation is not needed, the labor intensity is lowered, the production safety and the machining efficiency are improved, and the machining production quality is effectively guaranteed.

Owner:XINCHANG GENERAL MACHINERY

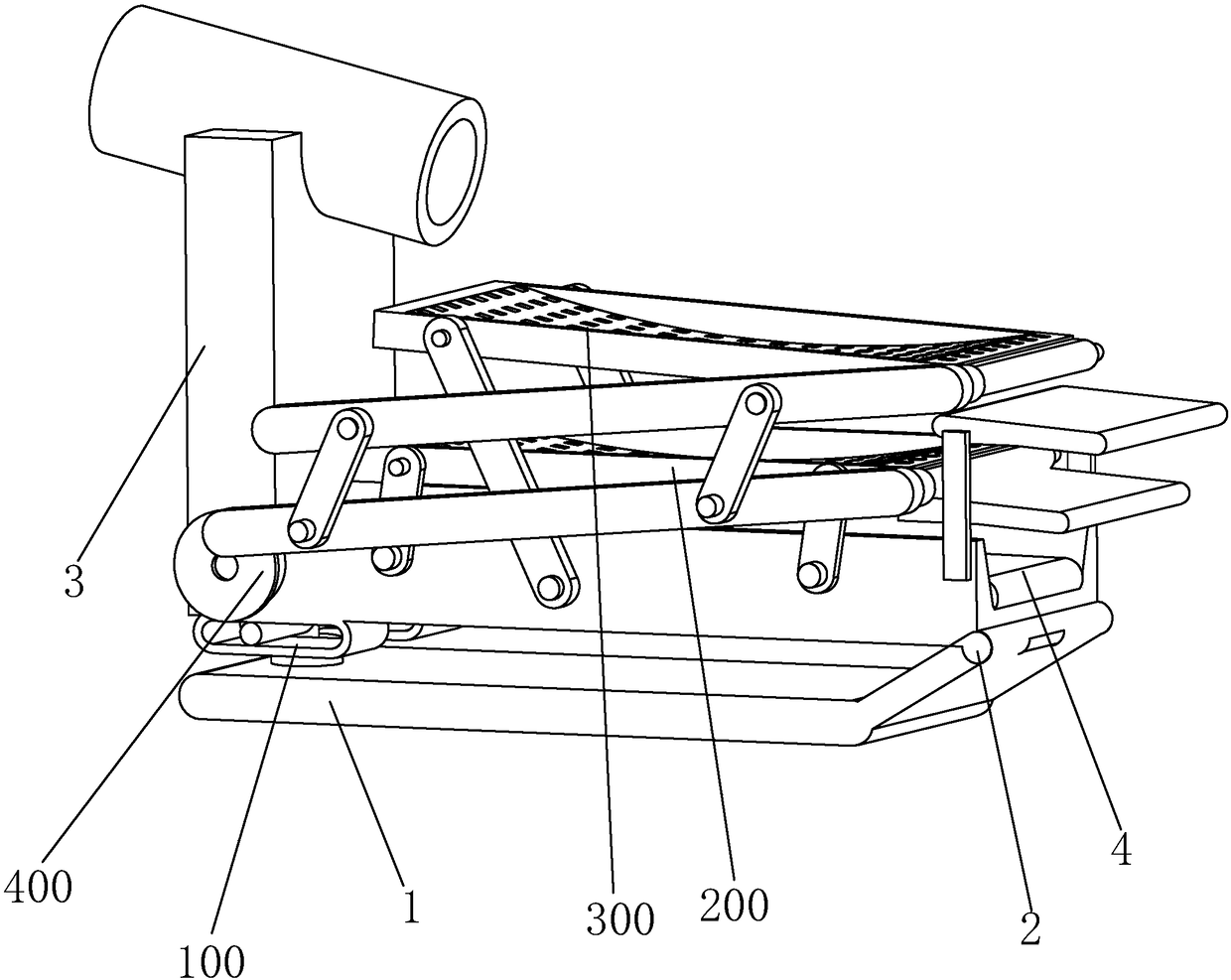

Linen folding and stacking machine

PendingCN107187928AGood folding effectImprove work efficiencyFolding thin materialsProduction lineStructural engineering

The invention discloses a linen folding and stacking machine. The machine comprises a rack, a folding, stacking and inputting belt, a stacking and folding device, a linen clamping, rotating and stacking device and a stacking and conveying platform. With the machine, the linen clamping and overturning technology is combined in the folding process, folding and stacking procedures are combined, the technological process of the machine is simplified, the work production line is shortened, the machine is simple in structure, and the push broach folding manner is adopted in the following folding procedure, so that the linen folding effect can be optimized, and the work efficiency for folding and linen clamping can be improved. With the machine, the linen stacking effect is ideal, and the labor is greatly reduced. The linen folding and stacking machine further has four passages working independently, work of the passages does not affect one another, more folding and stacking work can be completed at the same time, and thus the work efficiency of the machine is further improved.

Owner:广州百胜洗涤设备有限公司

Handheld drilling device for construction

InactiveCN108213517AImprove drilling efficiencyReduce labor forceFeeding apparatusDriving apparatusFixed frameCam

The invention discloses a handheld drilling device for construction, and relates to construction equipment. The handheld drilling device comprises a base fixing plate. The upper side and the lower side of a fixed frame are fixedly connected with spring compressing devices, and a drilling plate is fixedly connected between the spring compressing devices. The bottom end of an auxiliary supporting rod is fixedly connected with a drilling power device, and the two sides of the bottom end in a fixed frame are fixedly connected with cams. The top ends of the cams are in rolling connection with a jacking plate, and the middle of the jacking plate is fixedly connected with an ejector rod. A spring blocking block is fixedly connected in the fixed frame, and the position, located at the bottom end of the spring blocking block, of the surface of the ejector rod is sleeved with a reset spring. The top end of the ejector rod is fixedly connected with a transmission fixed shaft, and the transmissionfixed shaft is rotationally connected with a transmission rod. The handheld drilling device for construction achieves the aims of adjusting the drilling position at any time, improving drilling efficiency, promoting drilling through mechanical assistance, reducing the labor intensity of workers, stabilizing a machine without shaking during drilling and improving the drilling quality.

Owner:湖州蓝云建材股份有限公司

Cleaning blender

InactiveCN109226055ASimple organizationEasy to useCleaning using liquidsGear wheelElectric machinery

The invention discloses a cleaning blender. The cleaning blender comprises a working box and a cleaning device arranged in the working box, a first rotary cavity is formed in the working box, a secondrotary cavity is formed in the portion, located at the left side of the first rotary cavity, of the working box, a third rotary cavity is formed in the portion, located at the lower side of the second rotary cavity, of the working box, and a fourth rotary cavity is formed in the portion, located at the left side of the second rotary cavity, of the working box; a motor is arranged in the first rotary cavity, an electric receiver is fixedly arranged at the left end of the motor, a first rotary shaft of which the upper end is rotatably matched with the top wall of the first rotary cavity is in power connection with the upper end face of the motor, a first bevel gear is fixedly arranged on the first rotary shaft, and a first slide groove is formed in the portion, located in the lower wall ofthe first rotary cavity, in the working box, and communicated with the first rotary cavity and the third rotary cavity.

Owner:兰溪新宽环保科技有限公司

Sealing ring assembly mechanism and sealing ring assembly method

The invention relates to a sealing ring assembly mechanism. The sealing ring assembly mechanism comprises a sealing ring to-be-assembled workpiece moving groove, a sealing ring supporting and holdingvertical pipe, a sealing ring assembly mechanism part and a sealing ring to-be-assembled workpiece inversion mechanism; the sealing ring to-be-assembled workpiece moving groove is provided with a sealing ring to-be-assembled workpiece loading station, a sealing ring to-be-assembled workpiece supporting station and a sealing ring to-be-assembled workpiece unloading station; the sealing ring to-be-assembled workpiece inversion mechanism is used for moving a sealing ring to-be-assembled workpiece from the sealing ring to-be-assembled workpiece loading station to the sealing ring to-be-assembled workpiece supporting station and then to the sealing ring to-be-assembled workpiece unloading station; and the sealing ring assembly mechanism part is used for transferring a sealing ring from the sealing ring supporting and holding vertical pipe to the sealing ring to-be-assembled workpiece assembled on the sealing ring to-be-assembled workpiece supporting station. The sealing ring assembly mechanism is used for assembling the sealing ring to the sealing ring to-be-assembled workpiece so as to replace manual assembly of the sealing ring.

Owner:SHENTONG TECH GRP CO LTD

Sediment sieving machine

InactiveCN108607801AReduce labor forceFast and effective sand screeningSievingScreeningEngineeringSediment

The invention discloses a sediment sieving machine. The sediment sieving machine comprises a supporting plate and is characterized in that the end of the supporting plate is hinged to an L-shaped plate through a tenth rotary shaft. A first conveyor belt is arranged inside the L-shaped plate. An adjusting mechanism capable of adjusting the angle of the L-shaped plate is arranged between the L-shaped plate and the supporting plate. A first sand sieving plate and a second sand sieving plate are arranged inside the L-shaped plate. A driving mechanism capable of driving the first sand sieving plateand the second sand sieving plate is arranged on one side of the L-shaped plate. The driving mechanism is connected with the first sand sieving plate and the second sand sieving plate. The sediment sieving machine is provided with the adjusting mechanism and the driving mechanism, labor force is reduced, the sediment sieving machine can rapidly and effectively conduct sand sieving. The working time is greatly reduced.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

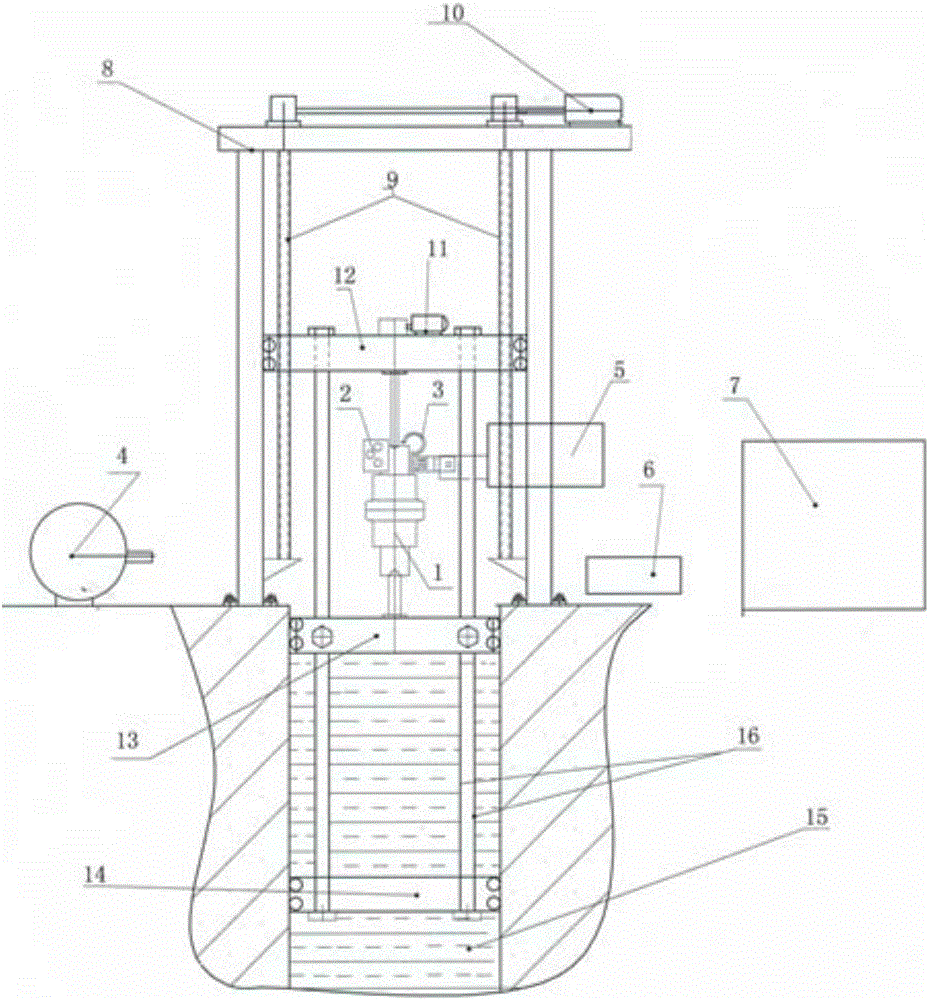

Quenching apparatus used for excavator supporting wheel shaft head and shaft neck portion

ActiveCN106244784AReduce heating timesReduce labor forceIncreasing energy efficiencyFurnace typesIntermediate frequencyQuenching

The invention relates to a quenching apparatus used for an excavator supporting wheel shaft head and shaft neck portion, and belongs to the technical field of metal quenching. The apparatus comprises an intermediate-frequency induction quenching machine tool, a supporting wheel shaft portion and end quenching water spraying quenching mechanism, a supporting wheel shaft portion and end induction quenching heater, a water cooler, a water storage tank and a control bench. A workpiece is put in the intermediate-frequency induction quenching machine tool, is well fixed, and is heated at 300-600 Hz by using the supporting wheel shaft portion and end induction quenching heater, and the heated supporting wheel shaft neck and end portion of the workpiece undergoes water spraying quenching by the supporting wheel shaft portion and end quenching water spraying quenching mechanism with clear water as a cooling medium.

Owner:石家庄新莱特机械轧辊有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com