Linen folding and stacking machine

A stacking machine and stacking technology, applied in the field of linen folding and stacking machines, can solve the problems of long folding and stacking process, high labor intensity, waste of labor, etc., achieve simple equipment structure, improve work efficiency, and simplify equipment The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

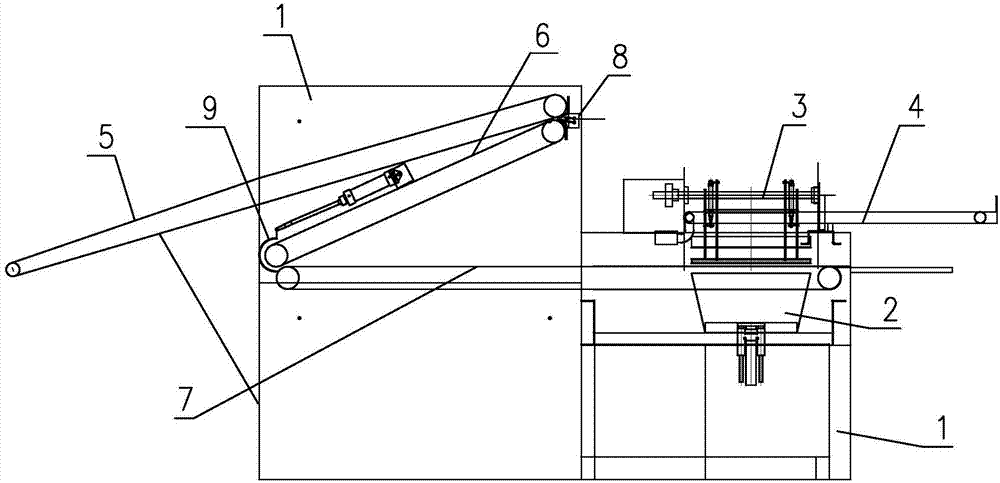

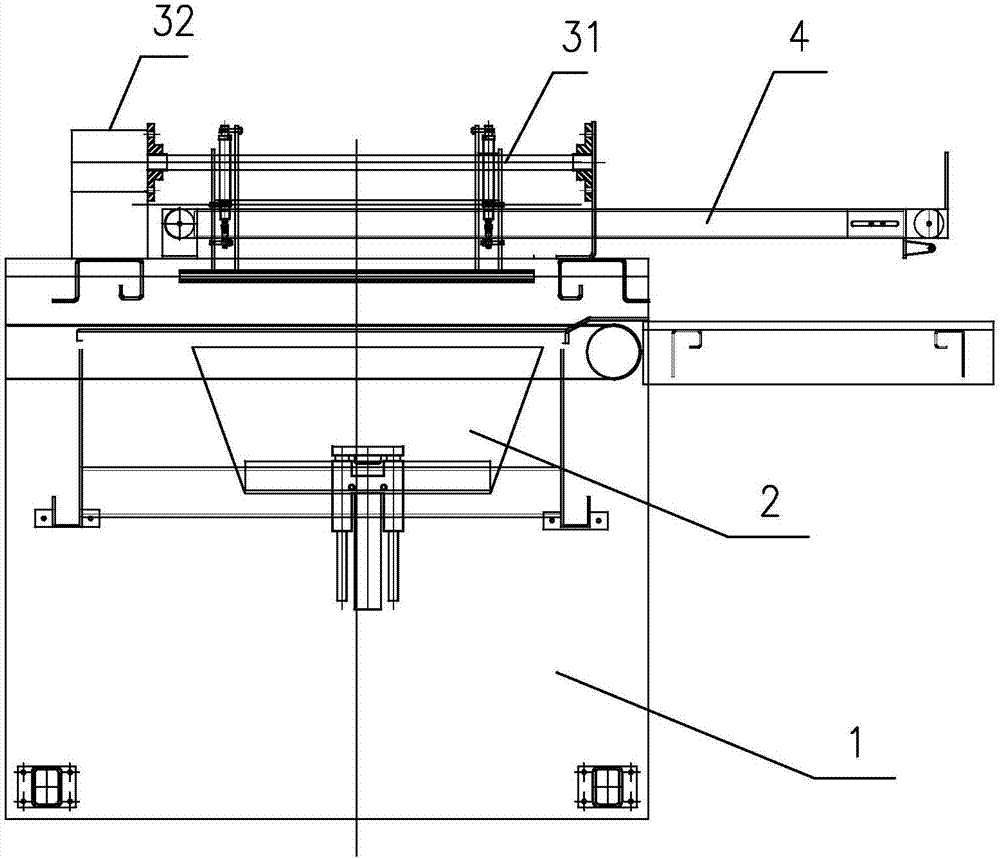

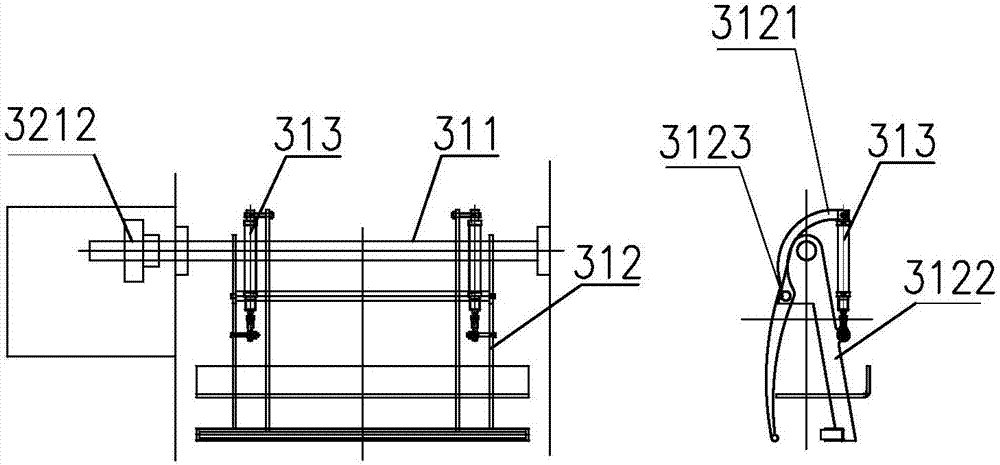

[0028] An embodiment of the present invention provides a linen folding and stacking machine, which combines Figure 1 to Figure 8 As shown, it includes a frame 1 , a folding and stacking input belt 7 , a stacking and folding device 2 , a cloth clamping rotary stacking device 3 and a stacking and conveying platform 4 . The folding and stacking input belt 7 transports the linen that needs to be folded and stacked to the stacking and folding device 2; the stacking and folding device 2 is arranged on the frame 1, and is used to fold the transported linen; The rotary stacking device 3 is arranged corresponding to the stacking and folding device 2, and is used to clamp and rotate the linen passing through the stacking and folding device 2 on the stacking and conveying platform; The stacking device 3 is provided correspondingly, and is used to place and transport folded and stacked linen. The stacking delivery platform 4 of this embodiment is arranged on one side of the cloth clampin...

Embodiment 2

[0035] For some linen with smaller specifications or a small number of folds, the linen folding and stacking machine in the above-mentioned embodiment 1 is sufficient to meet its folding and stacking requirements; Folded linen, the embodiment of the present invention provides a linen folding and stacking machine, the difference from embodiment 1 is that before its folding and stacking input belt 7, it can be used to implement one, two or multiple times of linen folding Folding front-folding device, combined with figure 1 As shown, the front folding device includes a conveyor belt one 5, a conveyor belt two 6, an air blowing folding device 8, a guide bracket 9 and an electronic control system. The linen folding and stacking machine of this embodiment is mainly used for folding pillowcases and towels. Since the pillowcases and towels are relatively small in size, the number of times of folding is relatively small, and generally only two folds are required. The folding process s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com